#Ammonia Compressor

Explore tagged Tumblr posts

Text

The Best Corken Compressors for Your Needs

In industrial settings, compressors are vital components that drive various processes forward. They are essential for tasks like air compression, gas handling, and refrigeration, playing a role in improving efficiency and productivity. This article will discuss the kinds of compressors, their uses, and important factors to consider when choosing the right compressor for your specific requirements. We'll cover topics such as unloading compressors, ammonia compressors, LPG compressors, and CORKEN compressors to give you an understanding of how they work and where they can be applied.

#Ammonia Compressor#CORKEN Compressor#LPG Compressor#LPG Transfer#unloading compressor#Vane Pump#Pump and Valves#IDEX India

0 notes

Text

Colt: Your Trusted Source for High-Quality Pressure Vessels, Heat Exchangers, and More.

Explore Colt's renowned range of durable pressure vessels, heat exchangers, compressors, and refrigeration equipment. Trusted for reliability and longevity, our products cater to diverse industrial needs.

#ammonia refrigeration equipment#reciprocating air compressors#gas compressors#compressors#heat exchangers#pressure vessels

0 notes

Text

Exploring the Best Refrigeration Compressor and Screw Compressors for Sale.

When it comes to industrial refrigeration, finding the right compressor is essential for ensuring efficiency, reliability, and long-term performance. Whether you're looking for a refrigeration compressor for sale or screw compressors for sale, it’s important to consider various factors such as energy consumption, capacity, and the type of cooling system you're using. In this article, we will explore the benefits of these compressors and what to look for when purchasing them.

What is a Refrigeration Compressor?

A refrigeration compressor is a vital component of a refrigeration or air conditioning system. Its primary role is to compress refrigerant gas, which is then circulated through the system to remove heat from the air or other substances. By using mechanical energy to pressurize the refrigerant, the compressor helps lower temperatures and maintain the desired cooling levels.

Whether for commercial, industrial, or residential use, a refrigeration compressor for sale should provide high efficiency and reliability to ensure your cooling systems operate optimally. With numerous options available on the market, it's essential to choose a compressor that matches your specific needs in terms of capacity and energy consumption.

The Advantages of Screw Compressors

Screw compressors are commonly used in refrigeration systems due to their efficiency and ability to handle large volumes of refrigerant. They use two interlocking screws to compress the gas, resulting in smooth, continuous compression. This makes screw compressors quieter and more reliable than traditional piston-based compressors.

For those seeking screw compressors for sale, the advantages are clear:

Higher Efficiency: Screw compressors are known for their ability to run continuously without overheating, making them ideal for large-scale refrigeration systems.

Low Maintenance: Thanks to their design, screw compressors experience less wear and tear, which reduces maintenance costs over time.

Flexibility: They are suitable for a wide range of applications, including air conditioning, refrigeration, and even some industrial processes.

How to Choose the Right Compressor for Your Needs

When looking for refrigeration compressors for sale or screw compressors for sale, there are several factors to keep in mind:

Capacity Requirements: Make sure to select a compressor that matches the cooling capacity of your refrigeration system. Consider the size of the space or the volume of goods being cooled.

Energy Efficiency: Choose compressors that provide high efficiency while consuming less energy. This not only lowers operational costs but also helps reduce your carbon footprint.

Durability and Warranty: Look for compressors made from high-quality materials, and always check the warranty period to ensure long-term reliability.

Application Type: If you are looking to cool a large industrial facility, screw compressors are often the best option due to their high capacity and continuous operation.

Where to Buy Refrigeration Compressors and Screw Compressors

If you’re in the market for a refrigeration compressor for sale or a screw compressor for sale, it’s essential to choose a trusted supplier that offers high-quality products with excellent customer support. At Coldforce, we provide an extensive range of compressors designed for both commercial and industrial applications.

Our compressors are sourced from leading brands in the industry, ensuring you get the most efficient and durable options available. Whether you’re looking for a single unit or need to purchase in bulk, we can help you find the right solution at the best price.

For more information about our refrigeration compressors for sale and screw compressors for sale, don’t hesitate to get in touch with us at (03) 9318 0903 or email [email protected]. Let us help you choose the best compressor to suit your needs!

Conclusion

Both refrigeration compressors and screw compressors play an integral role in maintaining the efficiency of cooling systems. When purchasing compressors, it's important to ensure you're choosing the right one based on your system's requirements. By investing in reliable compressors, you can achieve better energy efficiency, lower operational costs, and a longer lifespan for your equipment. Contact Coldforce today to explore our range of compressors and find the best solutions for your refrigeration needs.

0 notes

Text

Industrial Screw Chillers, Industrial Screw Chiller Manufacturer India

Industrial Screw Chillers, Industrial Screw Chiller Supplier, Industrial Screw Chiller Exporter, Industrial Screw Chiller Manufacturers Mumbai, India.

Cooling Towers, Frp Cooling Towers, Pultruded Cooling Towers, Timber Cooling Towers, Rcc Cooling Towers, Ice Plant, Block Ice Plant, Ammonia Block Ice Plant, Freon Ice Plant, Flake Ice Plant, Tube Ice Plant, Chilling Plants, Air Cooled Chilling Plants, Water Cooled Chilling Plants, Brine Chilling Plants, Oil Chillers, Air Blast Coolers, Industrial Screw Chillers, Multi Compressor Chillers, Brine Process Cooling System, Water Process Cooling System, Water Cooled Screw Chillers, Atmospheric Type Condenser, Ammonia Cooling Coil, Trunk Coil, Ammonia Receiver, Ammonia Refrigerant Liquid Storing Tank, Ice Can, Cooling Tower Film Fills, Frp Fan Stack, Water Distribution System Frp Fan Stack, Drift Eliminators, Cooling Tower Services, Mumbai, India.

#Cooling Towers#Frp Cooling Towers#Pultruded Cooling Towers#Timber Cooling Towers#Rcc Cooling Towers#Ice Plant#Block Ice Plant#Ammonia Block Ice Plant#Freon Ice Plant#Flake Ice Plant#Tube Ice Plant#Chilling Plants#Air Cooled Chilling Plants#Water Cooled Chilling Plants#Brine Chilling Plants#Oil Chillers#Air Blast Coolers#Industrial Screw Chillers#Multi Compressor Chillers#Brine Process Cooling System#Water Process Cooling System#Water Cooled Screw Chillers#Atmospheric Type Condenser#Ammonia Cooling Coil#Trunk Coil#Ammonia Receiver#Ammonia Refrigerant Liquid Storing Tank#Ice Can#Cooling Tower Film Fills#Frp Fan Stack

0 notes

Text

Ammonia compressor spare parts| Ammonia compressor spare parts supplier, Manufacturer in Pune, Mumbai, India

Asha Enterprises is best Ammonia compressor spare parts supplier, Manufacturer Company in Pune, Mumbai, Thane, Navi Mumbai, Kolhapur, Ratnagiri, Raigad, Nashik, Solapur, Latur, Aurangabad, Sindhudurg, Sangli, Solapur, Ahmednagar, Satara and Maharashtra.

#Asha Enterprises#Asha Enterprises in Pune#Asha Enterprises in India#Ammonia compressor spare parts#Ammonia compressor spare parts supplier#Ammonia compressor spare parts manufacturer#Ammonia compressor spare parts in Pune#Ammonia compressor spare parts in Mumbai#Ammonia compressor spare parts in Thane#Ammonia compressor spare parts in Navi Mumbai#Ammonia compressor spare parts in Kolhapur#Ammonia compressor spare parts in Ratnagiri#Ammonia compressor spare parts in Raigad#Ammonia compressor spare parts in Nashik#Ammonia compressor spare parts in Solapur#Ammonia compressor spare parts in Latur#Ammonia compressor spare parts in Aurangabad#Ammonia compressor spare parts in Sindhudurg#Ammonia compressor spare parts in Sangli#Ammonia compressor spare parts in Ahmednagar#Ammonia compressor spare parts in Satara#Ammonia compressor spare parts in Maharashtra#Ammonia compressor spare parts supplier in Pune#Ammonia compressor spare parts supplier in Mumbai#Ammonia compressor spare parts supplier in Thane#Ammonia compressor spare parts supplier in Navi Mumbai#Ammonia compressor spare parts supplier in Kolhapur#Ammonia compressor spare parts supplier in Ratnagiri#Ammonia compressor spare parts supplier in Raigad#Ammonia compressor spare parts supplier in Nashik

0 notes

Text

Ammonia vs. Freon Compressors: Making the Right Choice for Refrigeration

Ammonia and Freon compressors are two key players in the realm of industrial refrigeration, each with its own unique characteristics and applications. When it comes to choosing between them, it's crucial to understand the differences and select the right option for your specific needs. In this article, we'll explore the features, benefits, and applications of ammonia and Freon compressors to help you make an informed decision.

Ammonia Compressors

Ammonia compressors are known for their efficiency and low operating costs, making them a preferred choice for industrial refrigeration. Here are some key points to consider:

Efficiency: Ammonia is a highly efficient refrigerant with excellent heat transfer properties, which translates into lower energy consumption and reduced operating costs.

Eco-Friendly: Ammonia is considered an environmentally friendly refrigerant because it has zero ozone depletion potential (ODP) and a negligible global warming potential (GWP).

Industrial Use: Ammonia compressors are commonly used in large-scale industrial applications, such as cold storage warehouses, food processing plants, and ice production facilities.

Safety: While ammonia is safe when handled properly, it can be hazardous if released into the air. Adequate safety measures and training are essential when using ammonia compressors.

Freon Compressors

Freon compressors, on the other hand, have been widely used in commercial and residential air conditioning and refrigeration systems. Here are some key considerations:

Versatility: Freon refrigerants, such as R-134a or R-410a, are versatile and suitable for various applications, including air conditioning, refrigeration, and heat pumps.

Safety: Freon refrigerants are generally considered safe for use and do not pose significant risks to human health. However, some older Freon types have been phased out due to environmental concerns.

Environmental Impact: Some Freon refrigerants have high GWP and have been linked to ozone depletion. In response to environmental concerns, many countries have phased out or restricted the use of certain Freon types.

Energy Efficiency: While Freon compressors are energy-efficient, they may not be as efficient as ammonia compressors in large-scale industrial applications.

Choosing the Right Compressor

The choice between ammonia and Freon compressors largely depends on your specific refrigeration needs, system size, and environmental considerations. When making this decision, consider the following:

Application: Assess the application of the refrigeration system. If you need a large-scale industrial refrigeration system, ammonia may be the better choice. For smaller commercial or residential systems, Freon may suffice.

Environmental Impact: Take into account the environmental impact of the refrigerant. If sustainability and environmental regulations are a concern, choose refrigerants with lower GWP.

Safety: Ensure that your staff is trained in the safe handling of the chosen refrigerant. Proper safety measures are essential to prevent accidents.

In conclusion, the choice between ammonia and Freon compressors is significant and should be made after careful consideration of your specific refrigeration requirements and environmental concerns. It's essential to work with experts in the field who can guide you in selecting the most suitable compressor for your needs while ensuring safety and efficiency in your refrigeration system.

0 notes

Text

updates from the second time my friend plays! very slow progress

vomited even with the ammonia so he's internalizing Volumetric Shit Compressor. he thinks Kim is good at his job and very kind because he lets human disaster "I really don't remember anything, I'm afraid it's a serious medical condition" Harry open his car like nothing. he also finds the motorcarriages very weird, said out loud "how the hell are cars made in this game?!" (hehehe it's true that deathtrap is fucking weird)

he opened Cuno's shack with a very low percentage?! "wait, does that mean I stole that kid's money?" "you *can* pick up stuff, nobody's *forcing* you to do it :)"

but he could not make the jump to get his coat back, Immense disappointment. he still doesn't know about the white rectangles and wonders how people know they're cops

looks like the Kim Kitsuragi effect is working, he did not even think about snorting that speed (but I should probably mention the drugs mechanic, I'm not sure he got that)

he hates Cuno and Cunoesse lol, asked them about the crime scene but got nothing

I got the impression the long intercom's button list intimidated him because it would take too much time, so I pushed him to see his reaction to the non-answers. he "talked" to the woman in the intercom. he's confused but thinks it's an important piece of the story (I told him that even if I can't say anything about it, I do think everything is important in this game)

he keeps running around without talking to people! like full in the middle of the strike protest, no questions. picturing Harry doing it is very funny. and he keeps trying white checks without clicking the other options before! I scream internally every time (dude the modifiers!!! he also missed the crane convo with Kim and likely will miss it again :/). but has shifted from "what would I do" to "what do I want my character to do?" ("well, I am an alcoholic, it makes sense if I say some childish stuff *clicks I don't want to get better*")

he thinks the music fits the game very nicely, and likes the art style, but sometimes finds the map confusing, like that crumbling building's floor near Cuno's shack, it's not clear it's a building floor and not on the ground (tbf I was also confused by that)

he got a very improbable history lesson from the statue (the Sensitive type has 1 in Intellect!?). sounds like what a King would do! he doesn't know how the political stuff works, I'm sure he'll be baffled by the fascist point he got by saying that lol

he found the Frittte bag! "what do I even do with money in this game" "uhm. you have a debt with Garte" "ah you're right. how much was it again?" "130 real" "*looks at his 2,00 real* oh 😬"

now he's picking up bottles. he runs around but still hasn't found Roy, he knows he can sell stuff but now wonders how he'll manage to repay Garte (unfortunately I had spoiled him that Kim can sell something he likes to help him, but I also told him it's only one of the ways you can solve the problem)

I pointed out that he hasn't checked what points the clothes he's already wearing give him, so he did. and removed his pants and shoes because they put his Savoir Fare at 0. he doesn't have another pair yet

I asked what he thinks about the skills talking to him, and he said it's weird. I answered that yeah it's supposed to be weird. he's not sure of what to say (he hasn't read their description at the beginning either)

"*looks at Renè* how the hell is that man dressed?" "see if you can ask him if you want" "oh ok *ignores him*" "(screaming internally Why Aren't You Detecting Or Dying but not saying anything because player choice is important)"

the Kim building's door bug pierced our ears but I warned him about it. talked to the smoker, got the key, aaand we stopped here because his eyes were killing him

2 notes

·

View notes

Text

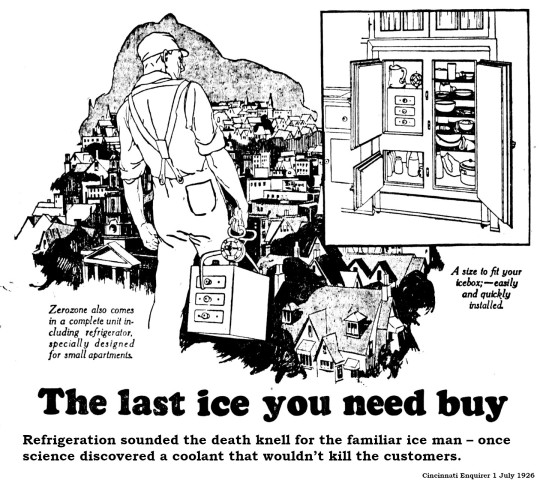

Refrigeration Was A Wonderful Invention When It Wasn’t Trying To Kill You

Over the years, Cincinnatians have discovered myriad methods to kill themselves. Breweries alone offered boiling vats, open shafts, toppling equipment and exploding barrels. At home, poisonous wallpaper, flammable nightgowns and yawning cesspools claimed many lives. As if we needed any additional hazards to jeopardize our safety, the Twentieth Century introduced yet another deadly contraption – the refrigerator.

The Cincinnati Post [22 June 1920] related one incident that nearly ended in tragedy:

“Firemen carried several tenants from upper floors of a four-story building at Eighteenth and Main streets Tuesday when ammonia fumes, escaping from an ice machine in the cellar, entered corridors and apartments. A valve in a machine that supplies refrigeration in the butcher shop of John Stegner, first floor of the building, blew off shortly before 10 a.m., causing the fumes to escape.”

The circumstances involved here were fairly typical for Cincinnati in the early 1920s and 1930s. Refrigeration was just beginning to enter the domestic market and most electric refrigerators were installed by businesses. In the early days, the noisy refrigeration machinery was usually relegated to the basement. The coolant of choice for most commercial systems was ammonia. Some of these installations were ponderous, as reported in the Post [10 March 1930]:

“Attempting to shut off ammonia pipes after a compressor head broke in the 15-ton refrigeration plant at Hamilton County Tuberculosis Sanitarium Monday at 8 a.m., Gus Leistner, 65, of 914 Findlay-st, engineer, partially was overcome by fumes.”

Later that same year, the University Club at Fourth and Broadway had to be evacuated because of ammonia leaking from its refrigeration system. The Strietmann Baking Company at Central Parkway and Plum Street suffered a massive ammonia spill in 1924. Firemen needed gas masks to enter the Hilberg Packing Company at 516 Polar Street in 1928 when ammonia seeping from the refrigerator filled the building.

Despite such catastrophes, ammonia was the most common coolant for the first thirty years of the 1900s. A Cincinnati firm, the F.W. Niebling & Son Co., of 406 Elm Street, boasted in an advertisement [20 February 1927] that the first ammonia-infused refrigeration plant installed by the company was 31 years old and still “in excellent condition.”

Still, ammonia was connected to so many mishaps that advertisers touted any system that did not involve ammonia. In 1926, the Tudor Court Apartments in Clifton installed a building-wide refrigeration system, with each of the 86 apartments equipped with a Frigidaire unit serviced by a massive compressor in the basement. The owners hastened to advertise that “no brine or ammonia” was used in that system.

Ammonia wasn’t the only chemical employed in refrigeration equipment. Responding to a reader’s inquiry, the Post [22 July 1921] inventoried a veritable witch’s cauldron of compounds used in various systems:

“What is the formula for the solution which is used in the cooling coils of an electric refrigerator? Substances are: Ammonia, carbon dioxide, ethyl chloride, methyl chloride and sulphur dioxide.”

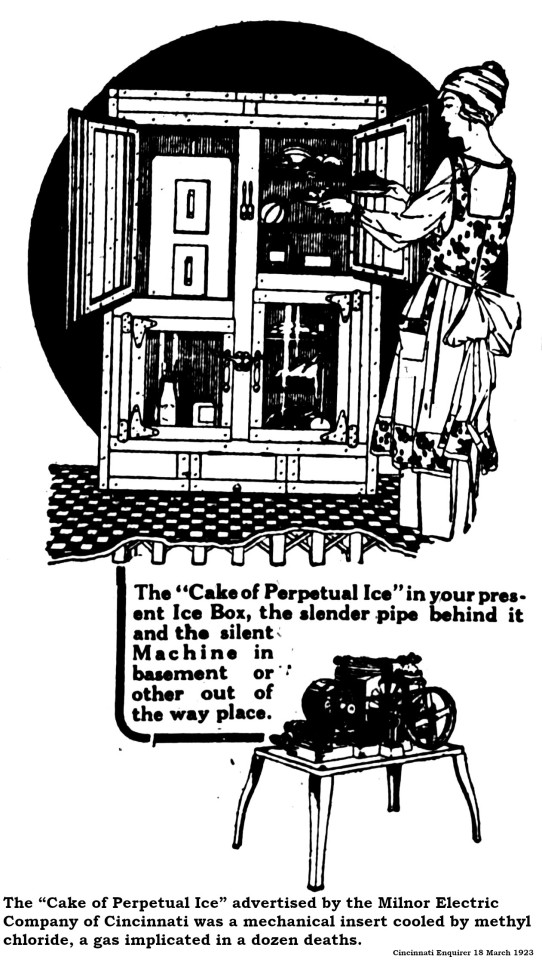

Of that formulary, ammonia’s biggest competitor was methyl chloride, a colorless, odorless, flammable gas. Methyl chloride was more efficient than ammonia and better suited to the small coolant devices required for a single house, as opposed to the big industrial machines cooled by ammonia. Units incorporating methyl chloride were so small they were retrofitted as mechanical ice blocks. Customers kept their old ice boxes, canceled ice delivery and turned on a methyl chloride unit in the same compartment where they would formerly have loaded a block of ice.

Manufacturers also claimed methyl chloride was safer than ammonia. Cincinnati’s Milnor Electric Co. highlighted this benefit in an advertisement [18 March 1923] for their Serv-el Automatic Electric Home Refrigeration products in the Cincinnati Enquirer:

“Important Notice: The gas (methyl-chloride) used in Serv-el is harmless, odorless and non-poisonous. Only Serv-el has this advantage.”

This claim was sorely tested in August 1929 when a rash of deaths blamed on methyl chloride refrigerators was reported from Chicago. The Chicago deaths created a panic among refrigeration companies who appealed to the federal government for assistance. The Cincinnati Enquirer [23 August 1929] reported that three governmental agencies – the Public Health Service, the Bureau of Standards, and the Bureau of Mines – had announced that household refrigeration systems were safe.

“Serious accidents from household refrigeration systems, the statement continued, have been small in comparison to the number in use and added that improvements might be expected that would reduce materially the small hazard that does exist.”

The Chicago deaths gave hope to the consumer ice industry, fighting a losing battle against the march of progress. In an Enquirer advertisement [31 July 1926], the City Ice & Fuel Co. complained that these new-fangled systems required:

“ . . . a complicated, high-cost mechanical-chemical outfit, dependent on a large and continuous supply of electricity to make it ‘run,’ and on some chemical (SULPHUR DIOXIDE OR METHYL CHLORIDE) to create cold – just as ammonia is used in the big ice plants.”

It was, of course, a losing proposition. The old ice boxes were messy, moldy things that really didn’t keep food all that cold and regularly flooded the kitchen with water melted from the huge block of ice delivered by some guy who tracked muddy footprints across your carpet.

All the industry needed was a better coolant, a chemical that cooled your refrigerator but didn’t kill you. The solution came from an inventor named Thomas Midgley Jr., who lived just up the road in Dayton. In 1932, Midgley came up with something called Freon. It checked all the boxes and soon replaced all other coolants for the next 60 years or so.

Problem was, Freon, a chlorofluorocarbon, accumulated in the atmosphere and contributed to the destruction of the ozone layer that protects life on earth from the harmful rays of the sun. So, in essence, to avoid a few disastrous refrigeration accidents, we found a solution that endangered all life on the planet.

Ponder that the next time you pull a brewski from the fridge.

4 notes

·

View notes

Text

Water-Cooled Chillers Market Research, Analysis | Trends 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Water-Cooled Chillers Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Water-Cooled Chillers Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Water-Cooled Chillers?

The global water-cooled chillers market size reached US$ 4.8 billion in 2023. Looking forward, Reports and Insights expects the market to reach US$ 5.6 billion in 2032, exhibiting a growth rate (CAGR) of 3.2% during 2024-2032.

What are Water-Cooled Chillers Market?

Water-cooled chillers are refrigeration systems utilized to extract heat from liquids by employing water as the cooling agent. These chillers find extensive applications in air conditioning, industrial processes, and large-scale facilities where effective cooling is crucial. The process involves circulating water through a condenser to absorb heat from a refrigerant gas. This gas is subsequently compressed and cooled, generating chilled water for various cooling needs. Known for their efficiency and ability to handle substantial cooling demands, water-cooled chillers are ideal for environments requiring precise temperature regulation and energy conservation.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1907

What are the growth prospects and trends in the Water-Cooled Chillers Market industry?

The water-cooled chillers market growth is driven by various factors and trends The water-cooled chillers market includes systems that effectively remove heat from liquids using water as a cooling agent. These chillers are vital for applications in air conditioning, industrial processes, and large-scale facilities where efficient cooling is paramount. Growth in the market is fueled by rising demand for energy-efficient cooling solutions, stringent environmental regulations favoring sustainable technologies, and expanding construction and industrial activities. Manufacturers are prioritizing improvements in chiller efficiency, reliability, and environmental sustainability to meet varied customer demands and global regulatory standards. Hence, all these factors contribute to water-cooled chillers market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Type:

Centrifugal Chillers

Screw Chillers

Absorption Chillers

Reciprocating Chillers

Scroll Chillers

Capacity

Small Capacity Chillers

Medium Capacity Chillers

Large Capacity Chillers

End-Use Industry

Manufacturing

Commercial Buildings

Data Centers

Healthcare

Hospitality

Others

Application

Air Conditioning

Process Cooling

Compressor Type

Scroll Compressors

Screw Compressors

Centrifugal Compressors

Reciprocating Compressors

Refrigerant Type

Hydrochlorofluorocarbon (HCFC)

Hydrofluorocarbon (HFC)

Ammonia

Others

Power Source

Electric Chillers

Absorption Chillers

Engine-Driven Chillers

Component

Compressors

Condensers

Evaporators

Control Systems

Others

Sales Channel

Direct Sales

Distributor/Wholesaler

Service Type

Installation and Commissioning

Maintenance and Repair

Consulting and Training

Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

The U.K.

France

Spain

Italy

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

India

Japan

South Korea

Australia

New Zealand

ASEAN

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

United Arab Emirates

South Africa

Egypt

Israel

Rest of MEA.

Who are the key players operating in the industry?

The report covers the major market players including:

Daikin Industries Ltd.

Johnson Controls International plc

Trane Technologies plc

Carrier Global Corporation

Mitsubishi Electric Corporation

York (Johnson Controls)

LG Electronics Inc.

Schneider Electric SE

Climaveneta (Mitsubishi Electric)

Smardt Chiller Group Inc.

McQuay International (Daikin)

Thermax Limited

Multistack International Limited

Frigel Firenze S.p.A.

Broad Air Conditioning Co. Ltd.

Discover more: https://www.reportsandinsights.com/report/Water-Cooled Chillers-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Water-Cooled Chillers Market Size#Water-Cooled Chillers Market Share#Water-Cooled Chillers Market Demand#Water-Cooled Chillers Market Analysis

0 notes

Text

How CORKEN Compressors Are Shaping a Sustainable Energy Landscape in 2024

In today's world, keeping sustainability an integral part of their operational strategy plays an essential role in the success of industries. Keeping the same in mind, industries, known for their contribution to harm, must prioritise practices that lower their carbon footprint and protect natural resources. Embracing sustainable methods not only helps combat climate change but also brings cost savings, market growth, and compliance with regulations. The increasing consumer demand for eco products emphasises the need for industries to focus on sustainability to uphold their reputation and long-term viability. Sustainability is key for industries to safeguard our planet, ensure stability, and secure a future for generations to come.

#Ammonia Compressor#CORKEN Compressor#LPG Compressor#LPG Transfer#unloading compressor#Vane Pump#Pump and Valves#IDEX India

0 notes

Text

#ammonia refrigeration equipment#screw air compressors#industrial equipment#gas compressors#compressors#pressure vessels

0 notes

Text

Water Cooled Chilling Plants, Chiller, Chilling Plant Mfgr

Water Cooled Chilling Plants, Chilling Plant, Water Cooled Chiller, Chiller Supplier, Chilling Plant Exporter, Chilling Plant Manufacturer Mumbai, India.

Cooling Towers, Frp Cooling Towers, Pultruded Cooling Towers, Timber Cooling Towers, Rcc Cooling Towers, Ice Plant, Block Ice Plant, Ammonia Block Ice Plant, Freon Ice Plant, Flake Ice Plant, Tube Ice Plant, Chilling Plants, Air Cooled Chilling Plants, Water Cooled Chilling Plants, Brine Chilling Plants, Oil Chillers, Air Blast Coolers, Industrial Screw Chillers, Multi Compressor Chillers, Brine Process Cooling System, Water Process Cooling System, Water Cooled Screw Chillers, Atmospheric Type Condenser, Ammonia Cooling Coil, Trunk Coil, Ammonia Receiver, Ammonia Refrigerant Liquid Storing Tank, Ice Can, Cooling Tower Film Fills, Frp Fan Stack, Water Distribution System Frp Fan Stack, Drift Eliminators, Cooling Tower Services, Mumbai, India.

#Cooling Towers#Frp Cooling Towers#Pultruded Cooling Towers#Timber Cooling Towers#Rcc Cooling Towers#Ice Plant#Block Ice Plant#Ammonia Block Ice Plant#Freon Ice Plant#Flake Ice Plant#Tube Ice Plant#Chilling Plants#Air Cooled Chilling Plants#Water Cooled Chilling Plants#Brine Chilling Plants#Oil Chillers#Air Blast Coolers#Industrial Screw Chillers#Multi Compressor Chillers#Brine Process Cooling System#Water Process Cooling System#Water Cooled Screw Chillers#Atmospheric Type Condenser#Ammonia Cooling Coil#Trunk Coil#Ammonia Receiver#Ammonia Refrigerant Liquid Storing Tank#Ice Can#Cooling Tower Film Fills#Frp Fan Stack

0 notes

Text

Ammonia refrigeration compressors| Ammonia refrigeration compressors supplier, Manufacturer in Pune, Mumbai, India

Asha Enterprises, is best Ammonia refrigeration compressors supplier, Manufacturer Company in Pune, Mumbai, Thane, Navi Mumbai, Kolhapur, Ratnagiri, Raigad, Nashik, Solapur, Latur, Aurangabad, Sindhudurg, Sangli, Solapur, Ahmednagar, Satara and Maharashtra.

#Asha Enterprises#Asha Enterprises in Pune#Asha Enterprises in India#Ammonia refrigeration compressors#Ammonia refrigeration compressors supplier#Ammonia refrigeration compressors manufacturer#Ammonia refrigeration compressors in Pune#Ammonia refrigeration compressors in Mumbai#Ammonia refrigeration compressors in Thane#Ammonia refrigeration compressors in Navi Mumbai#Ammonia refrigeration compressors in Kolhapur#Ammonia refrigeration compressors in Ratnagiri#Ammonia refrigeration compressors in Raigad#Ammonia refrigeration compressors in Nashik#Ammonia refrigeration compressors in Solapur#Ammonia refrigeration compressors in Latur#Ammonia refrigeration compressors in Aurangabad#Ammonia refrigeration compressors in Sindhudurg#Ammonia refrigeration compressors in Sangli#Ammonia refrigeration compressors in Ahmednagar#Ammonia refrigeration compressors in Satara#Ammonia refrigeration compressors in Maharashtra#Ammonia refrigeration compressors supplier in Pune

0 notes

Text

Jyoti Engineering Combine, a top manufacturer and supplier of refrigeration compressor parts, offers high-quality rebuilt ammonia and freon compressors. Explore our range of refurbished compressors for exceptional performance.

0 notes

Text

Refrigerators and Freezer Components: 1- Compressor (Power by motor for cooling by sent gas to condenser on warm portion of circuit), 2- Condenser (Changes gas to liquid by substantial copper coils), 3- Evaporator (Keep content chilled), 3- Capillary Tube of Expansion valve (Tiny set of copper tubes reduces temperature and pressure of liquid refrigerant to facilitate cool conditions inside refrigerator and/or freezer), 4- Refrigerant (Change gas to liquid and back again to gas such as Freon or ammonia gas), 5- Evaporator Fan Motor (Distribute cold air across refrigerator or freezer), 6- Condenser Fan Motor (Drive air through condenser coils with compressor to cool), 7- Thermistor (Monitor internal temperature of refrigerator of freezer), 8- Water Inlet Valve (Responsible for generating enough water pressure and dispense water into ice tray to make ice), 9- Water Filter (Prevent water from reaching ice maker) #geneticteacher

0 notes