#worm geared motors

Explore tagged Tumblr posts

Text

Inline Geared Motors vs Worm Geared Motors

Not sure which gear motor is ideal for your business operations? Read this article on inline and worm geared motors to make an informed purchase decision.

Read More: https://www.santramengineers.com/inline-geared-motors-vs-worm-geared-motors-know-the-difference/

0 notes

Text

Worm Geared Motors for industrial use

https://alienskart.com/snpc_motors

Alienskart web private limited is an online shopping site that provides different electric appliances according to consumer requirements. Motors, swichgears, gearboxes, ac drives, wires, leds, lubricants are our special products. Alienskart prefer branded electronics only as Havells, snpc power solutions, bonfiglioli, crompton. Snpc Power solutions is one of the most trustful brand by Alienskart. Different types of motors like ie2, ie3 motors, Foot or flange mounted motors are available according to industrial requirements. Snpc electric motors with best features and affordable prices are available exclusively on Alieksart Web. Industrial motors, ie2 & ie3 motors, permium-quality motors any many more types of snpc motors are available for industrial and home requirements.

#Alienskart#shopping services#branded motors#electronics#worm geared motors#heavy duty motors#motors with warranty#Havells#Snpc motors#Hindustan motors#Bonfiglioli motors#digital shpping#B2B services

0 notes

Text

Alienskart.com is an online shopping site that enables you to explore different industrial & household electronics such as motors, ac drives, gearboxes, wires, leds, lubricants and many more. Our main brands consist of Havells, Hindustan, ABB, Castrol, Polycabs which are most trustful names in industries. Please visit us to get trustful and quality products. Thankyou for considering our site. For more queries: 8818081001

#Alienskart#high quality motors#Inline helical motors#hindustan motors#worm geared motors#abb motors#online electronics store

0 notes

Text

FHP Geared Motor Suppliers near me

Are you searching for reliable FHP Geared Motor Suppliers near me? Univario is a trusted name in the industry, offering premium-quality fractional horsepower (FHP) geared motors tailored to meet a variety of industrial and commercial needs. With years of expertise and a commitment to delivering exceptional products, Univario ensures that you receive the best solutions for your specific requirements.

#wpo worm gearbox supplier in india#wpa worm gearbox supplier in india#worm reduction gearbox suppliers near me#speed variator gearbox supplier in india#premium worm gearbox suppliers in india#FHP geared motor suppliers near me

0 notes

Text

Worm Gearbox in Chennai | Worm Gear Motor and Reduction

Worm Gearboxes in Chennai are a highly efficient solution for transmitting torque and reducing speed in various industrial applications. Known for its compact design and ability to handle high loads, they are ideal for mining, material handling, and conveyor systems. The worm gearboxes operate smoothly with minimal noise, offering excellent performance in tight spaces where other gearboxes may not fit.

0 notes

Text

Understanding Heavy Duty Stirrer Units: A Guide by Popular Engineering

Heavy duty stirrer units are essential in various industrial processes where robust mixing is required. At Popular Engineering, we offer insights into the workings and applications of these powerful units. Our comprehensive guide covers everything from selection criteria to maintenance tips, ensuring you get the most out of your equipment. We highlight the benefits of using heavy duty stirrers, such as improved mixing efficiency and durability. Popular Engineering's expertise ensures you have the knowledge to choose and maintain the right stirrer unit for your needs.

#siemens motors#motor efficiency#heavy duty stirrer unit#working of fluid coupling#fluid coupling#double reduction worm gearbox#siemens motor supplier#elecon gear coupling

0 notes

Text

Vibratory motors in Delhi

Vibratory motors in Delhi, As a trusted supplier, we offer a diverse range of motors designed to elevate your industrial processes with seamless vibrational precision. Discover the pinnacle of vibrational technology with our Vibratory Motors. Crafted for precision and durability, our motors guarantee optimal performance, delivering consistent vibrations tailored to meet the unique demands of your industrial applications.

#Vibratory motor in delhi#Vibratory motor in delhi ncr#top crompton motor dealer#top bbl motor dealer#top monoblock pump dealers#top bbl motor dealer in delhi#worm and helical gear box dealer in delhi ncr#top abb motor dealer in delhi#brakes#electric motors#top abb motor dealers in delhi ncr#drives

0 notes

Text

Revolutionizing Industries: Worm Gear Motors in India by Suraj Machine Tools

Unveiling Worm Gear Motors: The Powerhouse of Precision

Worm gear motors stand as a testament to the marriage of simplicity and efficiency in mechanical engineering. These specialized motors utilize a unique arrangement of gears, with a worm screw driving a worm wheel. This design imparts exceptional torque and ensures smooth, controlled motion, making them indispensable in numerous industrial applications.

Tailored Solutions for Diverse Industries

Manufacturing and Automation

In the bustling manufacturing sector of India, efficiency is paramount. Worm gear motors, with their high torque capabilities and precise control, find extensive use in conveyor systems, packaging machinery, and assembly lines. Suraj Machine Tools, with their state-of-the-art manufacturing facilities, delivers motors that are tailored to meet the specific demands of this sector.

Automotive and Transportation

The automotive industry, a cornerstone of India’s economy, relies heavily on precision engineering for seamless operations. Worm gear motors in India play a pivotal role in various automotive applications, from power windows and seat adjustments to steering systems. Suraj Machine Tools ensures that their motors meet stringent quality standards, contributing to the reliability of vehicles on Indian roads.

Renewable Energy and Sustainability

As India charts a sustainable future, the demand for efficient and reliable power generation systems grows. Worm gear motors find applications in solar tracking systems and wind turbines, where their precision and durability are crucial. Suraj Machine Tools aligns with this vision by providing motors that enhance the efficiency of renewable energy installations.

Read : Gearbox manufacturers in India

The Suraj Machine Tools Advantage

Cutting-Edge Technology

Suraj Machine Tools leverages the latest advancements in engineering and manufacturing technology to produce worm gear motors that surpass industry benchmarks. Their commitment to research and development ensures that each motor is a testament to precision and performance.

Customization for Every Need

Recognizing that each industry has its unique requirements, Suraj Machine Tools offers a range of customizable options for their worm gear motors. From different gear ratios to specialized coatings for enhanced durability, they ensure that every customer’s needs are met with precision.

Unrivaled Quality Assurance

Quality is the cornerstone of Suraj Machine Tools’ ethos. Each worm gear motor undergoes rigorous testing to ensure it meets the highest standards of performance, reliability, and durability. This unwavering commitment to quality has earned them the trust of industries across India.

Conclusion: Powering India’s Industries with Precision

In conclusion, Suraj Machine Tools’ worm gear motors in india have become synonymous with precision and reliability in India’s industrial landscape. Through their unwavering dedication to excellence, they have propelled industries across sectors to new heights of efficiency and productivity. As India continues its march towards technological advancement, Suraj Machine Tools stands as a steadfast partner, powering the nation’s progress.

0 notes

Text

Worm gear motors work by using a worm gear attached to a motor to move the main gear. This set up is ideal for a machine requiring a massive reduction ratio, meaning more torque for less speed. Secondly, the simplicity of the set up avoids the need for unnecessary gears in its operation. They are used in packaging equipment, small machinery, and conveyors. They are ideal for these types of equipment because they have fewer gear sets which achieve high gear ratios. They require smaller gearboxes for these gear sets, making them a great space saver Worm gearboxes are available in various speeds, i.e. from 2 to 600 rev/min (revolutions per minute). Like all gear reducers, worm gears are used to increase torque while slowing output speed. However, worm gears are unique in that they include a worm—a cylindrical screw that reduces the gear ratio—that is set at a ninety-degree angle to the worm wheel. Overall, worm gears require less space than spur gears

#avoidplastics#FollowTrafficRules#ourbestqualityproduct#ontimematerialdispatch#bestproducts#goodwillenginnering#DrugFreeSociety#wormgearedmotor#Worm gear motors work by using a worm gear attached to a motor to move the main gear. This set up is ideal for a machine requiring a massiv#meaning more torque for less speed. Secondly#the simplicity of the set up avoids the need for unnecessary gears in its operation.#They are used in packaging equipment#small machinery#and conveyors. They are ideal for these types of equipment because they have fewer gear sets which achieve high gear ratios. They require s#making them a great space saver#Worm gearboxes are available in various speeds#i.e. from 2 to 600 rev/min (revolutions per minute).#Like all gear reducers#worm gears are used to increase torque while slowing output speed. However#worm gears are unique in that they include a worm—a cylindrical screw that reduces the gear ratio—that is set at a ninety-degree angle to t#worm gears require less space than spur gears

0 notes

Text

Icarus (1962) by A.B. Orr, in Newnes Practical Mechanics (1962). A simple light-following robot, based on the same 360 degree scanning principles as Grey Walter's tortoises.

"The vehicle comprises a scanning unit mounted on the same axis as the front steering wheel, a simple transistor amplifier, two relays and the necessary batteries. A small electric motor (Mighty Midget or similar) is used as a scanning motor and drives the scanner, and the steering wheel, through 360 deg. A second motor drives the rear wheels through a worm reduction gear. This is how the machine operates. When switched on the vehicle remains stationary and the front wheel with its scanner unit revolves slowly, looking for a light to home on. The photo-cells are fitted with a cowl that makes them directional by cutting out incidental light. A light-source, such as a powerful hand torch, is then switched on and focused on the revolving scanner. On picking up the light beam the photo-cells click the relay (A) and the scanner motor circuit is opened, causing the scanner head to fix on the light-source. At the same time relay (B) is clicked and switches on the drive motor to the rear wheels, causing the vehicle to move forward in whichever direction the scanner, and therefore the front wheel, is facing." – Icarus, Newnes Practical Mechanics, July 1962.

The second photo shows a build of Icarus by David Buckley, that won a Gold medal at the Robot Olympics in Glasgow 1990. "Icarus is really a poorly thought out design especially as Grey Walter had already shown how it should be done. If the light is behind Icarus then Icarus moves away from the light and if off to the side then it can be that the front wheel is then at right angles to the drive direction and the front wheel skids sideways and doesn’t steer." – David Buckley.

20 notes

·

View notes

Text

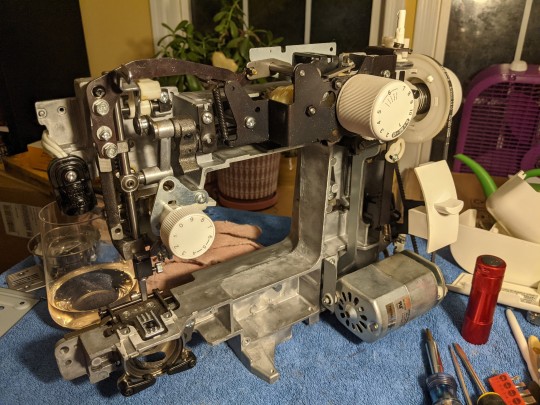

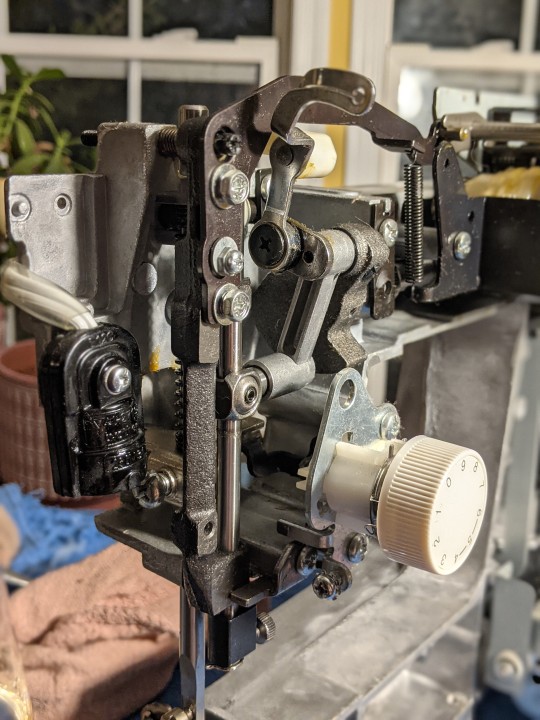

While I wait for the parts I ordered for the older sewing machines, I'm working on my "trusty" Brother (stock photo bc I didn't think to get a pic of her with her clothes still on). The one that wasn't worth paying to have it serviced, because it cost, when it was new, about the same as the service fee would've been, and that was 15 years ago.

Getting the plastic covers off was a bitch and a half, and that's with the service manual I downloaded. I took several wrong things off trying to find what was still holding it together, and eventually found a poorly-lit yt video of somebody doing this. Turns out there's plastic tabs that are fully absent from the technical drawings & service instructions, and you have to use a lot more force on those suckers than I'd've thought prudent.

But once you get in there...

Oh, it's a sewing machine! This is recognizable & comprehensible now.

(That statement would've been wild to me a couple months ago, before I took apart & cleaned two older machines.)

See, there's a standard presser bar, and the needle bar's a little different but that's so it can zigzag. And there's a plastic cam stack & a worm gear - simpler, actually, than on the 1960s Singer!

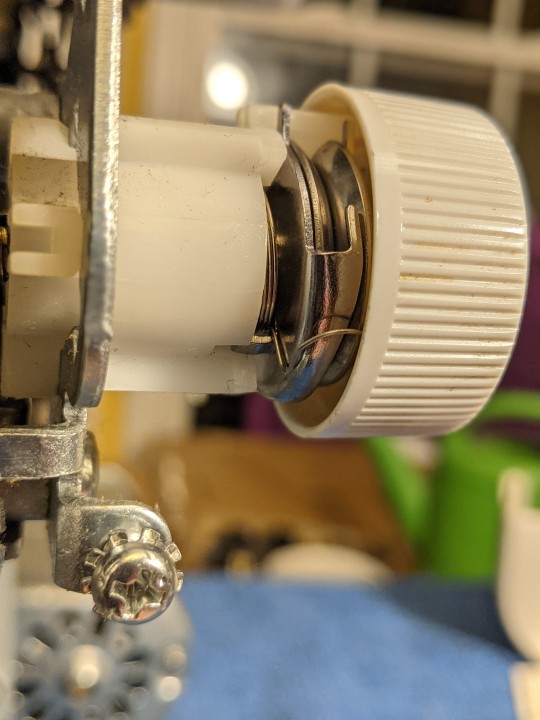

Even the tension assembly is, really, the same technology as on the 60 & 70 year old machines. It's hidden behind a tidy plastic knob, but with the covers off, there are the same opposed, convex tension discs, even the spring with the U-shaped guide on the end (this is apparently the "upper thread tension take up check spring").

The bit that surprised me the most (by being exactly the same tech) was the bobbin winder. Idk how I thought it worked - maybe I never thought about it, you just put the bobbin on the thingy, pop it over, & go until it's full enough - but here inside the machine is a little rubber tire that moves to contact the inside of the handwheel, which spins it to fill your bobbins. The only real difference is that on the older ones you have to disengage the needle bar manually, so it doesn't move while you wind, whereas on the Brother the action of moving the bobbin winder into position does it automatically.

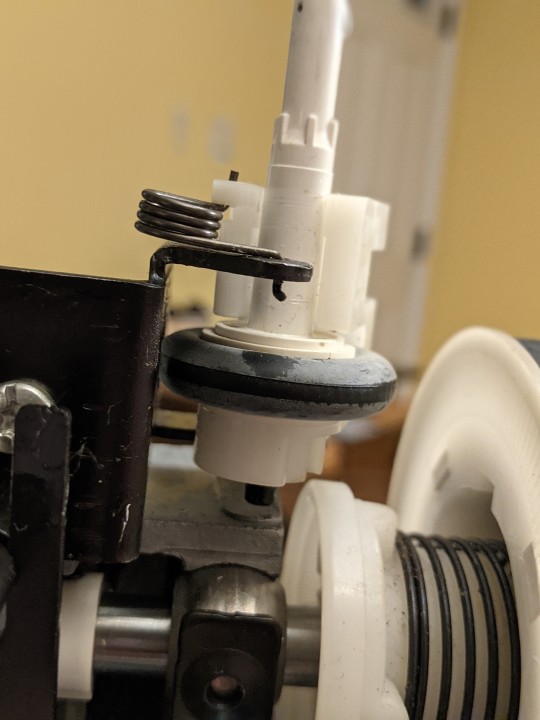

Here's the same thing on a 100 year old machine (not mine, alas):

Tire move up into contact with wheel (treadle or hand crank driven, at that stage) and spins to wind thread onto the bobbin. This one has the addition of the cute little heart-shaped gear on the thread guide, which serves to evenly wind on, because the bobbins were long & narrow, like a small spool of thread, and fit in a device much like a weaving or tatting shuttle, which was moved forward & back under the needle to form the lower stitches. Yes, they hadn't even invented the round bobbin & hook system that every sewing machine uses today, hadn't put motors on these machines, couldn't even go in reverse, but the bobbin winder? Same then, same in my two vintage machines, same today.

#the massive continuity of sewing machines#tbh new fancy machines might be doing this differently now#and idk how the ones that wind the bobbin in place work#vintage sewing machines#sewing machine repair#diy#mending is better than ending

24 notes

·

View notes

Text

Hey everyone, it's time for another game update!

But first I just wanted to say a big thanks to all of you for playing the game and sharing your creations. It's great to see so many new players joining the community, it really helps motivate me to keep trying to make the game better!

OK, on to the update.

Soap Box Challenge

See how fast you can get down the hill under gravity alone, no motors allowed. This new scenario gives you an idea of the kind of "mini games" possible with Lua scripting, but it still barely scratches the surface really, hopefully we can push the boundaries of this more in the future. Anyway, check it out and let me know what you think.

New Parts

Continuous servo motors, more crown, rack, & worm gear sizes, more "hole & plate" connectors, and round ended beams.

Part Behaviours

Separate servo forward & reverse angles, flip pulley belts, link displays to multiple parts, etc.

Here's a quick look at some of these changes:

youtube

Release notes:-

New Soap Box Challenge scenario.

New parts:-

Small and medium continuous servo motors.

24T and 40T Hi & Lo crown gears.

x3 rack gear.

x1 worm gear.

More "1-Hole Plate" and "2-Hole Plate" resizable connectors.

Rounded and half rounded resizable beams.

Part behaviour improvements:-

Servo motor part behaviour now has separately tweakable forward and reverse angles.

Servo and stepper motor part behaviours now have an "angular speed" data channel.

Pulley part behaviour now has an option to flip belt routing.

Displays can now be linked to multiple other parts.

Motor, battery, and rotor parts can now attach to each other, and to other parts in a more consistent way.

Changed plate on "plate axle" connector part to be circular.

Tweaked material strength of all wheels.

Added buttons to UI screens to open containing folder in Windows Explorer.

Added player "free flight movement mode" setting to allow for moving horizontally rather than along the view direction.

Added settings to the controls options screen for disabling each of the manipulators.

Improved crosshair.

Added Hungarian translations to currently localised strings, thanks to BlueGoldFlag.

Bug fixes.

Upgraded to Unity 2021.3.33.

2 notes

·

View notes

Text

Alienskart.com is an online shopping site that enables you to explore different industrial & household electronics such as motors, ac drives, gearboxes, wires, leds, lubricants and many more. Our main brands consist of Havells, Hindustan, ABB, Castrol, Polycabs which are most trustful names in industries. Please visit us to get trustful and quality products. Thankyou for considering our site. For more queries: 8818081001

#Alienskart#high quality motors#ABB motors#havells motors#worm geared motors#ie2 & ie motors#electronics store

0 notes

Text

Understanding Worm Gearbox Ratios and Their Role in Optimizing Operations

Worm gearboxes are considered an important part of any industrial applications that require large amounts of torsion and accurate control. The ratio in case of a worm gearbox is a most critical specification that bears major influence over speed control, torque magnification, and gearbox effectiveness. This blog will help you understand worm gearbox ratios, how these units work and how they could benefit or affect your operations.

What Are Worm Gearbox Ratios?

The worm gearbox ratio defines how much the input speed is slowed down and vice versa how much the torque is increased. For instance, a 10:1 ratio means that for the [output gear] to make a round the input gear has to make 10 rounds. This results in:

A tenfold reduction in speed.

A tenfold increase in torque.

Such ratios are useful in applications where low-speed high torque operations are desired.

How Gear Ratios Affect Torque

Torque Multiplication

A decrease in speed results in a corresponding increase in torque. For instance:

The compound can adopt a one ratio or one to ten, transforming the input torque to deal with the extensive load.

This makes the worm gearbox well suited in hoists that require high torque, in winches and other mechanical systems.

Why Gear Ratio Matters for Your Operations

A. Efficiency and Power Optimization

Choosing the correct gear ratio means that the motor runs at the right speed to be efficient. Higher LG and TM ratios generate more torque than lower ratios, The Battleship OHP achieves a certain power speed/torque balance that is important for energy efficiency.

B. Precision and Control

Therefore in some areas such as robots, and auto systems, the right gear ratio provides improved control. Higher ratios provide slow and continuous motion required in many applications to offer great precision and product quality.

Choosing the Right Gear Ratio for Your Application

Several factors influence the choice of a worm gearbox ratio:

Load Requirements: Systems handling heavy loads, such as cranes, benefit from higher ratios to ensure smooth operation.

Precision Needs: Applications like conveyor belts or robotic arms require lower ratios (e.g., 3:1 to 5:1) for precise motion control.

Real-World Applications of Worm Gearbox Ratios

A. Material Handling

Conveyor systems often use gear ratios of 5:1 to 20:1, enabling controlled material movement with minimal wear on the system.

B. Precision Machinery

Lower ratios are used in robotic systems and automated lines to ensure smooth, precise operations.

Conclusion

Understanding the appropriate worm gearbox ratio is critical to enhancing the performance and safety of your machinery. The right ratio can improve operational consistency and reduce energy costs by optimising speed reduction and torque multiplication.

Contact us today to find the perfect worm gearbox for your operations!

#worm gearbox repairs#double reduction gear box#decades of gearbox experience#worm gear manufacturer#worm reduction gearbox#reduction gearbox manufacturers#gearbox application in industries#gearbox manufacturer in ahmedabad#worm screw gearbox factory#gearbox repair Ahmedabad#double reduction gearbox ahmedabad#gear box manufacturing ahmedabad#reduction gear manufacturers#gearbox repair cost ahmedabad#gearbox manufacturer#gearbox vertical ahmedabad#gearbox repair services ahmedabad#buy worm reduction gearbox#worm gearbox manufacturer Ahmedabad#worm reduction gearboxes Ahmedabad#worm gearbox manufacturer gujarat#gearbox manufacturer in gujarat#gearbox manufacturer rajasthan#gearbox repair rajasthan#worm gearbox manufacturer Rajasthan#reduction gearbox manufacturer Rajasthan#reduction gearbox manufacturer maharashtra

0 notes

Text

Kitchen Aid 4162897 Worm Gear, K5 Series Mixers - PartsFe

The KitchenAid 4162897 Worm Gear is a crucial replacement part for KitchenAid K5 series stand mixers. This gear is a key component of the mixer's drive system, responsible for transferring power from the motor to the various attachments. It handles the torque and stress involved in mixing everything from light batters to heavy doughs.

To keep your restaurant running smoothly, it's crucial to invest in Kitchen Aid Worm Gear that ensure long-lasting performance

#KitchenAid#KitchenAidParts#4162897#WormGear#partsfe#partsfebuzz#restaurantowner#ovenparts#icemachineparts#dishwasherparts

0 notes

Text

https://github.com/anushka224473/TrendMosaic/blob/main/North America Helical Worm Geared Motors Market Drivers And Trends.md

0 notes