#worm gear manufacturer

Explore tagged Tumblr posts

Text

Understanding Worm Gearbox Ratios and Their Role in Optimizing Operations

Worm gearboxes are considered an important part of any industrial applications that require large amounts of torsion and accurate control. The ratio in case of a worm gearbox is a most critical specification that bears major influence over speed control, torque magnification, and gearbox effectiveness. This blog will help you understand worm gearbox ratios, how these units work and how they could benefit or affect your operations.

What Are Worm Gearbox Ratios?

The worm gearbox ratio defines how much the input speed is slowed down and vice versa how much the torque is increased. For instance, a 10:1 ratio means that for the [output gear] to make a round the input gear has to make 10 rounds. This results in:

A tenfold reduction in speed.

A tenfold increase in torque.

Such ratios are useful in applications where low-speed high torque operations are desired.

How Gear Ratios Affect Torque

Torque Multiplication

A decrease in speed results in a corresponding increase in torque. For instance:

The compound can adopt a one ratio or one to ten, transforming the input torque to deal with the extensive load.

This makes the worm gearbox well suited in hoists that require high torque, in winches and other mechanical systems.

Why Gear Ratio Matters for Your Operations

A. Efficiency and Power Optimization

Choosing the correct gear ratio means that the motor runs at the right speed to be efficient. Higher LG and TM ratios generate more torque than lower ratios, The Battleship OHP achieves a certain power speed/torque balance that is important for energy efficiency.

B. Precision and Control

Therefore in some areas such as robots, and auto systems, the right gear ratio provides improved control. Higher ratios provide slow and continuous motion required in many applications to offer great precision and product quality.

Choosing the Right Gear Ratio for Your Application

Several factors influence the choice of a worm gearbox ratio:

Load Requirements: Systems handling heavy loads, such as cranes, benefit from higher ratios to ensure smooth operation.

Precision Needs: Applications like conveyor belts or robotic arms require lower ratios (e.g., 3:1 to 5:1) for precise motion control.

Real-World Applications of Worm Gearbox Ratios

A. Material Handling

Conveyor systems often use gear ratios of 5:1 to 20:1, enabling controlled material movement with minimal wear on the system.

B. Precision Machinery

Lower ratios are used in robotic systems and automated lines to ensure smooth, precise operations.

Conclusion

Understanding the appropriate worm gearbox ratio is critical to enhancing the performance and safety of your machinery. The right ratio can improve operational consistency and reduce energy costs by optimising speed reduction and torque multiplication.

Contact us today to find the perfect worm gearbox for your operations!

#worm gearbox repairs#double reduction gear box#decades of gearbox experience#worm gear manufacturer#worm reduction gearbox#reduction gearbox manufacturers#gearbox application in industries#gearbox manufacturer in ahmedabad#worm screw gearbox factory#gearbox repair Ahmedabad#double reduction gearbox ahmedabad#gear box manufacturing ahmedabad#reduction gear manufacturers#gearbox repair cost ahmedabad#gearbox manufacturer#gearbox vertical ahmedabad#gearbox repair services ahmedabad#buy worm reduction gearbox#worm gearbox manufacturer Ahmedabad#worm reduction gearboxes Ahmedabad#worm gearbox manufacturer gujarat#gearbox manufacturer in gujarat#gearbox manufacturer rajasthan#gearbox repair rajasthan#worm gearbox manufacturer Rajasthan#reduction gearbox manufacturer Rajasthan#reduction gearbox manufacturer maharashtra

0 notes

Text

Poly V pulley Manufacturers -Muratech Engineering

Muratech Engineering is a top manufacturer of Poly V pulleys, known for their precision and reliability. Our pulleys offer superior power transmission and smooth operation for various industrial applications, ensuring enhanced efficiency and performance.

#Timing Pulley#Timing Pulley Manufacturers#Timing Pulley Manufacturers in India#Industrial pulley#Industrial pulley Manufacturers#Industrial pulley Manufacturers in India#Industrial Spur Gear#Industrial Spur Gear Manufacturers#Industrial Spur Gear in India#Industrial Sprocket#Industrial Sprocket Manufacturers#Industrial Sprocket Manufacturers in India#Helical Gearbox#Helical Gearbox Manufacturers#Helical Gearbox Manufacturers in India#Spiral Bevel Gears#Spiral Bevel Gears Manufacturer#Spiral Bevel Gears Manufacturer in India#Poly V pulley#Poly V pulley Manufacturers#Poly V pulley Manufacturers in India#Worm Reduction Gearbox#Worm Reduction Gearbox Manufacturers#Worm Reduction Gearbox Manufacturers in India#Industrial V Pulley#Industrial V Pulley Manufacturers#Industrial V Pulley Manufacturers in India#Taper Lock Bush & QD Bush#Taper Lock Bush & QD Bush Manufacturers#Taper Lock Bush & QD Bush Manufacturers in India

0 notes

Text

Winter and Claus

Chapter 9

first, previous, next

After wishing Claus goodnight, Winter began his long trek through the walls back to his home. When he arrived back, the borrower peeked his head through the curtain separating his and his brother's rooms. Ryan was fast asleep in his cloth corner. Winter didn't really get why his older brother always opted for the pile of scrap fabric over their sponge beds, but he supposed it was understandable. At their size, the sponge beds were more scrappy and scratchy, and they were far too small for it to actually be plush against their bodies. But still, borrowers weren't akin to waiting supplies. Winter had manufactured a way to carve out portions of the sponge to fit his sleeping habits and positions.

Winter shrugged it off and went to the water room. The dripping wire that funneled dew out of the drains for filtering was a great idea. Winter had come up with it after seeing one of the humans books about the mechanism. This way they didn't have to venture out into the sink to get water every week. Winter stepped over the small pile of threads he assumed Ryan had brought back from their parents house. The borrower grabbed his micro tip paintbrush and dipped it into the massive bottle of toothpaste he and Ryan had managed to sneak out of the human toiletry bag one time. He brushed his teeth with the coarse fibers of the brush then rinsed with some already boiled water.

He shuffled into his night clothes and went to his room, nestling himself in bed. For one reason, he found himself missing the comforting warmth of Claus's hand, his neck, the way the human's pulse thrummed so melodically, like a lullaby. Winter shot up, sitting in his bed trying to process what it was he was thinking. Sure, Claus wasn't as scary as he had first thought, but was winter really fantasizing about sleeping on Claus instead of his safe...spongy bed? What was wrong with him? Claus was supposed to be scary, winter was small, a borrower, Claus had proven different ways in which he posed a threat to the borrower. So why did winter crave to feel the humans touch? Why did he want to be embraced like they had earlier? What the hell was wrong with him!?

The borrower sighed, shaking his head to rid himself of these thoughts. Not now, it was too soon. He didn't even know claus. So what if he had the humans schedule fully memorized, including holidays. So what if winter knew the different breathing patterns that Claus had depending on how deep his sleep was? That was irrelevant. Just normal borrower stuff. It didn't mean that winter....*liked* claus or anything. He was just overthinking again. After all, what borrower wouldn't like being surrounded by a gentle safe warmth? It was instinct, in his nature. He was just doing what he was supposed to. With these thoughts out of the way, winter laid back down to sleep, though not without tossing and turning a few times.

The next morning winter was awoken by an annoying amount of poking to the face by none other than his older brother.

"Ngh....RYAN!!" Winter swatted at the other borrower's hand as he groggily sat up and glared drowsily.

Ryan laughed, a deep, warming sound that echoed through the creaky hollowed out part in the wall where they lived. "Common lil whinny~ its time to get up. The red currant ain't gonna pick themselves!" Ryan grabbed Winter's hand and dragged the stubborn borrower out of bed.

Winter groaned and complied, rubbing the tiredness from his eyes as his brother dragged him out "didn't we harvest some before you left last week?" Winter yawned as Ryan finally let go of his hand.

"Well yeah, but I gave that stock to mom and dad, remember?" Ryan said chipperly. The mention of their parents made winter's face sour.

"Ugh. Fine we can go, but at least let me gear up man. I swear don't you know the first thing about borrowing? The early worm gets caught remember" winter grumbled as he pulled his shirt over his head. The walls were drafty today, which meant they'd need to prepare for cold weather and wind.

Once winter had finally gotten dressed and eared up, his overly energetic brother wasted no time in pulling winter through the walls and vents until they reached the small garden. The mistress of the house often busied herself and the little girl here during her husband and stepson's 'little spats' as she so underwhelmingly called them. Nevertheless, the garden is a welcome and appreciated resource for the borrowers residing in the area. Fresh fruit and vegetables were hard to come by for most borrowers so of course, winter's neighbor's often used the garden themselves.

By borrower courtesy, winter and the other borrowers in the area also helped grow the garden, doing menial tasks that took groups such as pulling weeds and planting extra seeds that weren't fully buried. Winter had realized quickly that if the humans thought they were good at gardening, they would plant more, which meant more supplies and resources for the borrowers in the area.

As they reached the current bush, which was Ryan's obvious favorite, the borrowers set out their fruit bag. It was an old jewelry bag that was the size of winter himself, but the mesh pattern was breathable and the perfect size for holding berries.

Ryan scrambled up the bush as winter set out the bag and prepared to catch the falling berries. One by one, Ryan used his blade to chop the berries off the stem. Each one was the size of winter's head. current was a spherical red berry mainly used to make jams. It was the easiest berry for borrowers to use because the skin was very thin and the seeds were easy to spot.

Winter hummed contentedly as they filled up the bag half way. Ryan clambered down the tall plant and hopped down to winter. The two made quiet conversation as they lugged the bag of berries back home.

"so...uh...how was the trip?" Winter asked awkwardly.

Ryan raised an eyebrow "surprised you asked at all, seeing as how they treated you." The other borrower pushed his lips in thought as he walked backwards "i guess it was alright, the usual. Mom's doing well. Apparently the humans started fostering yet another kid. I kinda forgot how loud that place was honestly, glad im back here anyways."

Winter nodded as he led both of them into the drainage pipe, hopping down and gently lowering the bag through the grates "did...did anyone ask about me?" Winter asked, a look of faint hope sparking in his eyes.

Ryan sighed, knowing the question would come up "I mean, you know how it is, i don't want you to hurt your feelings but if I'm telling you honestly, they're so caught up in their own little world that they don't care man. Although~" Ryan smirked as if remembering something.

Winter perked up momentarily "although...what?" He said as they both stepped into the hollow interior of the wall, their footfalls echoing quietly as they walked.

"Well, Pat asked how you are, you know how she is" Ryan smiled coyly, as if his words held deeper meaning.

Winter sighed and deadpanned "common Ryan, she can't still have those feelings, you and I both know how it ended last time" he looked down blush ringing his cheeks "plus even if she did, it wouldn't work anyway. Not with me living two days' journey out. Just leave it as is, "Winter said in a more stern tone as the two borrowers finally reached the interior wall, pulling away the old soda can in place to hide their entrance.

Ryan just shrugged "whatever you say bro" he said as he let go of the bag. Winter stepped into the other room and removed his gear as Ryan started the pot. Winter checked the mini wristwatch hanging next to Ryan's bed. The borrower silently cheered, because Claus would be getting home soon.

"Ah-" Winter caught himself, looking at his brother through the curtain door, he chewed on his knuckle's anxiously. He would have to inevitably tell Ryan about claus, it would be for the both of their safety, and if he didn't aren't Ryan about the human then that could end terribly for the both of them later.

#winter#Claus#winter and Claus#oc winter#oc Claus#gt#giant tiny#giant tiny angst#gt fluff#gt writing#writing#fluff writing

5 notes

·

View notes

Text

EIFCO Gear Hobbing Machine: A Reliable Solution for Precision Gear Manufacturing

In today’s competitive manufacturing industry, precision and efficiency are crucial for producing high-quality gears. One of the most reliable and advanced machines used for gear cutting is the EIFCO Gear Hobbing Machine. With its robust design, high efficiency, and superior precision, the EIFCO Gear Hobbing Machine is widely used in various industries such as automotive, aerospace, industrial machinery, and robotics. In this guide, we will explore everything about the EIFCO Gear Hobbing Machine and why it is the best choice for manufacturers looking for reliability and accuracy in gear production.

What is an EIFCO Gear Hobbing Machine?

An EIFCO Gear Hobbing Machine is a high-precision machine used for manufacturing different types of gears, including spur gears, helical gears, worm gears, and splines. The machine operates using a rotating cutting tool known as a hob, which gradually cuts gear teeth into a workpiece. EIFCO is a trusted brand known for producing durable and efficient gear hobbing machines that enhance production quality and reduce manufacturing time.

How Does an EIFCO Gear Hobbing Machine Work?

The gear hobbing process with an EIFCO Gear Hobbing Machine consists of the following steps:

Mounting the Workpiece: The gear blank is securely fixed onto the spindle of the machine.

Tool Setup: The hob is positioned according to the required gear specifications.

Synchronization: The hob and the workpiece rotate in a synchronized manner to ensure accurate cutting.

Gear Cutting: The hob gradually cuts into the gear blank, forming the precise gear teeth.

Final Inspection: The finished gear is inspected for accuracy and quality assurance.

Advantages of Using an EIFCO Gear Hobbing Machine

EIFCO Gear Hobbing Machines offer numerous benefits that make them a preferred choice for gear manufacturers:

1. High Precision and Accuracy

EIFCO machines are designed with advanced technology that ensures every gear is manufactured with extreme precision, meeting strict industry standards.

2. Efficient and Fast Gear Production

Compared to traditional gear-cutting methods, EIFCO Gear Hobbing Machines provide faster production speeds while maintaining consistent quality.

3. Versatility in Gear Manufacturing

These machines can manufacture a wide range of gears, including:

Spur gears

Helical gears

Worm gears

Splines

Sprockets

4. Cost-Effective Manufacturing

EIFCO Gear Hobbing Machines reduce material waste and labor costs, making them a highly economical solution for manufacturers.

5. Robust and Durable Construction

Built with high-quality materials, EIFCO machines are designed to last, reducing maintenance costs and ensuring long-term reliability.

Applications of EIFCO Gear Hobbing Machines

EIFCO Gear Hobbing Machines are used in various industries, including:

Automotive Industry: Manufacturing transmission gears, differentials, and other critical automotive components.

Aerospace Industry: Producing high-precision gears for aircraft engines and navigation systems.

Industrial Machinery: Creating gears for heavy-duty machinery, compressors, and pumps.

Robotics: Manufacturing small, intricate gears for robotic systems and automation.

Renewable Energy: Producing durable gears for wind turbines and solar tracking systems.

Features of an EIFCO Gear Hobbing Machine

Modern EIFCO Gear Hobbing Machines come equipped with advanced features to enhance efficiency and precision:

High-Speed Spindles: Ensures faster cutting without compromising accuracy.

Automatic Tool Change System: Reduces downtime and increases productivity.

CNC Integration: Enables automated and highly accurate gear production.

User-Friendly Interface: Simplifies machine operation and programming.

Integrated Cooling Systems: Prevents overheating and extends the lifespan of cutting tools.

Why Choose EIFCO Gear Hobbing Machines Over Other Brands?

EIFCO Gear Hobbing Machines stand out from other gear-cutting machines due to their superior build quality, precision, and efficiency. Here’s why manufacturers prefer EIFCO:

Trusted Brand: EIFCO has a strong reputation for delivering reliable and high-performance manufacturing equipment.

Advanced Technology: The machines incorporate the latest innovations in gear manufacturing.

Custom Solutions: EIFCO provides machines tailored to specific industry needs.

Comprehensive Customer Support: From installation to maintenance, EIFCO ensures customers receive full technical support.

Competitive Pricing: High-quality machines at cost-effective prices provide excellent value for money.

Choosing the Right EIFCO Gear Hobbing Machine

When selecting an EIFCO Gear Hobbing Machine, consider the following factors:

Production Requirements: Determine the type and volume of gears you need to produce.

Gear Specifications: Ensure the machine can accommodate the desired gear size and type.

Automation Level: CNC-enabled machines offer greater efficiency and precision.

Budget Considerations: Balance cost with the required features and capabilities.

After-Sales Support: Choose a supplier that provides excellent technical support and spare parts availability.

The Future of EIFCO Gear Hobbing Machines

The gear manufacturing industry is evolving, and EIFCO Gear Hobbing Machines continue to lead the way with advancements in:

Artificial Intelligence (AI) Integration: Enhancing predictive maintenance and optimizing production.

IoT-Enabled Machines: Enabling real-time monitoring and remote operation.

Sustainable Manufacturing: Reducing energy consumption and material waste through eco-friendly designs.

With continuous technological advancements, EIFCO Gear Hobbing Machines will remain at the forefront of precision gear manufacturing.

Conclusion

The EIFCO Gear Hobbing Machine is a game-changer in the gear manufacturing industry, offering unmatched precision, efficiency, and versatility. Whether you need gears for automotive, aerospace, industrial, or renewable energy applications, investing in an EIFCO machine can significantly improve your production capabilities.

At Gear Hobbing Solutions, we are dedicated to providing the best EIFCO Gear Hobbing Machines to meet your manufacturing needs. Contact us today to discover how our machines can help you achieve greater precision, efficiency, and cost savings in your gear production process.

0 notes

Text

Dhara Agro Products

Dhara Agro Products :

Dhara Agro Products is a leading manufacturer, supplier, and exporter of high-quality mechanical transmission and engineering products in Gujarat, India, with 25 years of experience. We specialize in a wide range of products that meet ISO standards to ensure top-quality performance. Our product lineup includes:

Pulleys: Taper Lock Pulleys, QD Bush Pulleys, V-Belt Pulleys, V-Groove Pulleys, Solid Pulleys, Plate Type Pulleys, Split Type Pulleys, Patta Pulleys, and Timing Belt Pulleys.

Couplings: Full Gear Couplings, Half Gear Couplings, Rigid Couplings, BC Couplings, RB Couplings, Pin Bush Couplings, Chain Couplings, Jaw Couplings, Star Couplings, RRL Couplings, RRS Couplings, HRC Couplings, SW Couplings, Resilient Couplings, Muff Couplings, and Encoder Couplings.

Gears: Worm Gears, Bevel and Spiral Bevel Gears, Spur Gears, and Helical Gears.

Chain Sprockets: Simplex, Duplex, Triplex Chain Sprockets, Two-Stand, Three-Stand, Four-Flex or Quadruple Sprockets, and Taper Lock Sprockets.

We take pride in delivering top-notch mechanical products designed for durability and efficiency, serving a diverse range of industries.

0 notes

Text

Leading conveyor Gear Box Manufacturer in India

When it comes to high-quality conveyor gearboxes, Nisuka Industries stands out as a leading conveyor gearboxes manufacturer in India. With years of expertise and a commitment to innovation, Nisuka Industries delivers durable, efficient, and precision-engineered conveyor gearboxes that cater to various industrial needs.

Why Choose Nisuka Industries for Conveyor Gearboxes?

Superior Quality Nisuka Industries uses premium-grade materials and advanced manufacturing techniques to ensure high-performance gearboxes that can withstand demanding operational conditions.

Innovative Designs The company specializes in designing customized gearbox solutions that enhance conveyor system efficiency, reduce downtime, and improve productivity.

Wide Range of Products Nisuka Industries offers an extensive range of conveyor gearboxes, including:

Helical Gearboxes

Worm Gearboxes

Bevel Gearboxes

Planetary Gearboxes

Industry Applications Their gearboxes are widely used in cement plants, mining, steel industries, food processing, pharmaceuticals, and material handling systems.

Energy Efficiency & Reliability Nisuka gearboxes are engineered for low power consumption, high torque transmission, and long service life, making them a cost-effective solution for industrial applications.

Exceptional After-Sales Support The company provides prompt customer service, maintenance support, and technical assistance to ensure smooth operations.

#conveyor Gear Box#Shaft Mounted Gearboxes#manufacturer#conveyor Gear Box Manufacturer#conveyor Gear Box supplier#conveyor Gear Box exporter#conveyor Gear Box Manufacturer in India

1 note

·

View note

Text

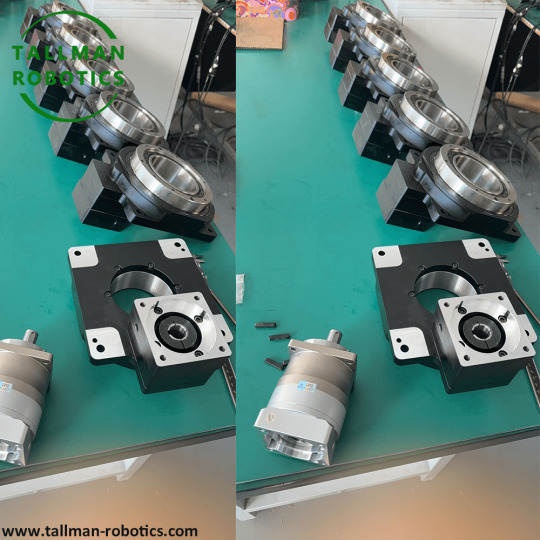

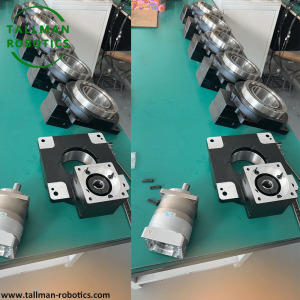

Precise Positioning Hollow Rotary Tables Will Be Delivered to Pakistan

Precise Positioning Hollow Rotary Tables are specialized rotational devices featuring a central hollow shaft, designed for high-accuracy angular positioning. The hollow core allows cables, pneumatic lines, or shafts to pass through, eliminating cable tangling and reducing system complexity.

https://youtu.be/ZP31od3m6Xc?si=KSzfpuXjjSW-2xnV Key Components and Features 1. Drive Mechanisms: Harmonic Drives: Preferred for near-zero backlash and high torque density. Direct Drive Motors: Offer smooth operation and precise control without mechanical reduction. Alternative systems like worm gears may be used but are less common in ultra-high-precision settings. 2. Bearings: Crossed Roller Bearings: Provide high rigidity and accuracy, handling both radial and axial loads efficiently. 3. Feedback Systems: High-resolution absolute encoders ensure accurate position tracking, even after power interruptions. 4. Materials and Construction: Made from rigid materials like aluminum or steel alloys to minimize deflection under load. Standardized mounting interfaces (e.g., ISO/SAE flanges) for easy integration with machinery. Applications of Large hollow shaft rotary tables CNC Machining: Enables multi-axis machining by rotating workpieces precisely. Semiconductor Manufacturing: Used in wafer handling and inspection systems. Optics and Medical Devices: Positions lenses or surgical tools with high accuracy. Robotics: Facilitates precise joint movements in automation and articulated robots. Advantages Over Standard Rotary Tables Hollow Design: Central pass-through avoids cable management issues, enhancing reliability. High Precision: Sub-arc-minute accuracy achievable with advanced feedback and drive systems. Versatility: Suitable for diverse industries due to customizable sizes and load capacities. Conclusion Precise Positioning Hollow Rotary Tables/Large hollow shaft rotary tables are critical in applications demanding exact angular positioning with central component pass-through. Their design combines mechanical precision with intelligent feedback systems, making them indispensable in advanced manufacturing and automation. You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#CNCHollowRotaryActuator#HeavyDutyHollowRotaryTables#HighPrecisionHollowRotaryTablesforCNCMachines#High-precisionrotarytable#HollowAxes#HollowRotaryPlatform#HollowRotaryTableRightAngleManufacturer#LargeApertureHollowRotaryTables#Largehollowshaftrotarytables#PlanetaryGearboxes#PrecisePositioningHollowRotaryTables#PrecisionHollowRotaryTable#PrecisionRightAngleRotaryTables#RotaryActuators

0 notes

Text

MRVMRV Worm Gearbox Suppliers in New Delhi

NMRV worm gearbox is a vital component in industrial automation, power transmission and motion control systems. Known for its compact design, high efficiency and durability, this gearbox is widely used in conveyors, packaging machines, manufacturing equipment and heavy machinery. If you are looking for a reliable NMRV Worm Gearbox supplier, this guide will help you find the best manufacturers and distributors in New Delhi and other areas.

What is NMRV Worm Gearbox?

An NMRV worm gearbox is a worm gear reducer designed for efficient torque transmission and speed reduction. It consists of a worm (screw-shaped shaft) and a worm wheel, which work together to reduce speed while increasing output torque. These gearboxes are widely used due to their smooth operation and long service life,

Main advantages of NMRV worm gear reducers:

✔ High efficiency: Reduces energy losses and ensures optimal power transmission. ✔ Compact and light: ideal for space applications without prejudice to performance. ✔ Low noise and vibration: offers smooth and silent operation for various types of industrial use. ✔ Durable and Corrosion Resistant: Designed to withstand harsh environments and requires minimal maintenance. ✔ Versatile Applications: Used in automation, conveyor belts, textile machinery and food processing equipment.

Best supplier of NMRV gearboxes in New Delhi

If you are looking for a reliable supplier of NMRV worms in New Deli, consider these best manufacturers and distributors.

1. Univario Transmission

📍Location: New Delhi, India.

Web: https://www.univario.in/

About Univario Transmission:

Univario Transmission is a leading manufacturer and supplier of NMRV worm gearboxes in India.

They specialize in:

* Precision-engineered worm gear reducers with advanced technology.

* Durable, corrosion-resistant materials suitable for harsh industrial environments.

* Custom gear solutions to meet your specific industrial needs.

*Complete quality tests to ensure optimal performance and lifespan.

*Technical support and after-sales services are the trusted names of power transmission

solutions. Whether you need a standard worm gear reducer or a custom design, Univario Transmission offers customized solutions for the heavy industry and automation sectors.

#NMRV gearboxes in New Delhi#Best supplier NMRV gearboxes in New Delhi

0 notes

Text

Maximizing Efficiency in Stone Cutting: How Worm Reduction Gearboxes Make a Difference

The nature of the stone-cutting business requires accuracy, dependability, and speed for the value to be added to products. Reduction gearboxes are reportedly worm reductions gear, a pacesetter in stone-cutting across equipment manufacture to help boost performance and control costs. As for this gearbox, this blog seeks to discuss how it assists in operations in the stone cutting industry.

Superior Torque Output for Heavy-Duty Applications

Stone cutting machines deal with hard and massive materials that need high power for operation. Worm reduction gearboxes excel in:

Delivering High Torque: They effectively translate motor speed into the high level of torque essential for carving and other applications on rock like materials.

Managing Heavy Loads: Its construction allows for their stable operation under a significant level of loading.

Compact Design with Multi-Purpose Applications

Industrial applications especially need to get the space optimized to the fullest. Worm gearboxes stand out due to:

Streamlined Design: Originally, they do not occupy a lot of space making it easier to install them on various equipment that possibly can be available.

Flexible Mounting Options: It is available in machine positioning methods including horizontal, vertical and square mounting to suit a host of layouts.

Ensuring Precision and Operational Stability

Precision and stable conditions are important characteristics in operating the stone cutting equipment. Worm gearboxes contribute by:

Providing Controlled Speed Reduction: Due to this, their gear ratio counts allows for blending steady speed and accuracy to make precise cuts all the time.

Dampening Vibrations: The wo mechanism quiets the vibrations ensuring enhanced cut quality as well as smooth functionality.

Energy Efficiency for Cost-Effective Operations

Energy costs are considered one of the main expenses of any organisation and business. Worm reduction gearboxes support:

Minimizing Power Loss: Their design provides maximum conversion of energy, thus minimizing wastage of energy which is not required.

Long-Lasting Performance: Longevity with very little maintenance is usually a plus since it reduces the general cost of operations and reduces on time the machines would be out of service.

Extending Equipment Longevity

Stone-cutting machines remain under great stress continuously. Worm gearboxes protect these machines by:

Reducing Mechanical Stress: They share operational loads evenly hence; they cause little stress or pressure to other parts.

Resisting Harsh Conditions: Made using strong rugged materials, worm gearboxes are able to withstand abrasive operating conditions and usage.

Quieter Operations for a Better Work Environment

Acoustic control is a much neglected area of manufacturing concerns. Worm gearboxes help by:

Smooth Gear Engagement: Its design minimizes backlash hence less operational noise.

Self-Locking Capability: This avoids reversals that are disruptive and damaging to operational stability, thus extending noise reduction measures.

Diverse Applications in Stone Cutting

To cater to the specific needs of the stone-cutting industry, worm gearboxes offer customization options such as:

Bridge Saws: A machine employed in sawing of large stones into various sizes and shapes as may be required.

Block Cutters: Most suitable in breaking huge pieces of stones into smaller chunks.

Conclusion

Worm reduction gearbox plays the most critical role in increasing the performance, reliability and accuracy in stone cutting machines. High quality yet cost effective customized gearboxes will enable enhancement of business operations, low maintenance costs, and high customer satisfaction. These gearboxes are not just parts – they are the soul of today’s stone-cutting industry success.

#worm gearbox repairs#worm gear manufacturer#reduction gearbox manufacturers#worm reduction gearbox#worm reduction gearbox near me#gearbox repair cost ahmedabad#gear box manufacturing ahmedabad#double reduction gearbox ahmedabad#gearbox repair ahmedabad#buy worm reduction gearbox#gearbox repair services ahmedabad#gearbox manufacturer#gearbox vertical ahmedabad#reduction gear manufacturers

0 notes

Text

spur gear manufacturer -Muratech Engineering

Muratech Engineering is a leading manufacturer of high-quality spur gears, offering precision-engineered solutions for various industrial applications. Our gears are designed for durability and optimal performance, ensuring reliable power transmission and efficient operation.

#Timing Pulley#Timing Pulley Manufacturers#Timing Pulley Manufacturers in India#Industrial pulley#Industrial pulley Manufacturers#Industrial pulley Manufacturers in India#Industrial Spur Gear#Industrial Spur Gear Manufacturers#Industrial Spur Gear in India#Industrial Sprocket#Industrial Sprocket Manufacturers#Industrial Sprocket Manufacturers in India#Helical Gearbox#Helical Gearbox Manufacturers#Helical Gearbox Manufacturers in India#Spiral Bevel Gears#Spiral Bevel Gears Manufacturer#Spiral Bevel Gears Manufacturer in India#Poly V pulley#Poly V pulley Manufacturers#Poly V pulley Manufacturers in India#Worm Reduction Gearbox#Worm Reduction Gearbox Manufacturers#Worm Reduction Gearbox Manufacturers in India#Industrial V Pulley#Industrial V Pulley Manufacturers#Industrial V Pulley Manufacturers in India#Taper Lock Bush & QD Bush#Taper Lock Bush & QD Bush Manufacturers#Taper Lock Bush & QD Bush Manufacturers in India

0 notes

Text

Structural features and precautions of Worm Gearbox

1.What is Worm Gearbox Worm Gearbox is a transmission machine with compact structure, large transmission ratio and self-locking function under certain conditions. It is one of the most commonly used reducers. It is mainly composed of a worm wheel and a worm. The speed converter of the gear is used to reduce the number of revolutions of the motor to the required number of revolutions and obtain a larger torque.

2.Working principle of Worm Gearbox Worm Gearbox realizes the function of reducing speed and increasing torque through the meshing of the worm wheel and the worm. The worm usually has a spiral thread, and the worm wheel has a corresponding groove to match it. When the worm rotates, the worm wheel moves along the spiral line, thereby achieving the effect of reducing speed and increasing torque.

3.Structural features of Worm Gearbox 1.Large transmission ratio: The worm gearbox has a large transmission ratio, which can achieve a wide transmission ratio range in a limited space and meet the deceleration needs of various scenarios. 2.Compact structure: The structural design of the worm gearbox is compact, occupies a small space, and is easy to install and maintain. Its compact structure enables a large transmission ratio to be achieved in a limited space, meeting the needs of various complex working conditions. 3.Smooth transmission and low noise: The transmission process of the worm gearbox is extremely smooth and the noise is very low, which helps to improve the operating stability and durability of the equipment. 4.Strong load-bearing capacity: The worm gearbox can withstand significant radial and axial loads, which is very suitable for applications under heavy loads. Its load-bearing capacity is higher than that of the staggered axis helical gear mechanism, and is suitable for occasions requiring high load-bearing capacity. 5.Self-locking function: Under certain conditions, the worm gearbox has a self-locking function, that is, when the lead angle of the worm is less than the equivalent friction angle between the meshing gear teeth, the mechanism has self-locking properties and can achieve reverse self-locking, which is suitable for application scenarios that require safety protection. 6.Materials and manufacturing processes: The worm gearbox usually uses high-quality materials and exquisite design processes to ensure that the produced worm gearbox has long-term wear resistance, high transmission efficiency and long life.

4.Precautions for the use of Worm Gearbox 1.Choose the appropriate reduction ratio and power: Accurately calculate the load according to actual needs, choose the appropriate reduction ratio and power, and avoid overload or frequent start and stop to cause impact damage to the worm gearbox. 2.Temperature and environmental conditions: Ensure that the working environment temperature of the worm gearbox is within the specified range (-40℃ to +40℃). Appropriate measures such as heating the lubricating oil (below the freezing point) and adding cooling equipment should be taken to maintain normal working conditions. At the same time, avoid overheating caused by long-term continuous work. 3.Installation and commissioning: Before installing the worm gearbox, carefully check whether the various components of the reducer are intact. During installation, ensure that the axis between the reducer and the power source is well aligned to avoid vibration and noise that affect the operating efficiency and life. Before starting, a no-load test run should be carried out, and after confirmation, it should be gradually loaded to normal working conditions. 4.Lubrication and maintenance: Regular inspection and replacement of lubricating oil is one of the key steps to keep the reducer working properly. The oil volume must be kept within the specified range to avoid excessive oil leakage or lack of oil to cause increased wear. In addition, the status of wearing parts such as seals and bearings should be checked and updated and maintained in time to ensure the stability of the overall performance. 5.Smooth start and stop operations: During the start or stop process, the operation should be slow to avoid the impact caused by sudden and drastic changes, thereby damaging the structural integrity and stability of the internal components. 6.Environmental requirements: Ensure that there is a good ventilation environment near the motor fan, and avoid exposing the reducer to the sun and harsh environment to avoid affecting the heat dissipation effect.

Source:https://plaza.rakuten.co.jp/stovenstepper/diary/202501140000/

0 notes

Text

Industrial Gears Market Forecast: 4.2% CAGR from 2025 to 2033

Astute Analytica, a prominent market research firm, has recently published a comprehensive report that offers an extensive analysis of the Industrial Gears market. This report goes beyond mere statistics, providing deep insights into various critical aspects such as market segmentation, key players, market valuation, and regional overviews. It serves as a valuable resource for businesses and stakeholders seeking to navigate this evolving industry landscape.

Market Valuation

The report includes a thorough evaluation of the market valuation, drawing from historical data, current trends, and future projections. By employing rigorous analytical methods, it effectively captures the growth trajectory of the market. This detailed assessment allows businesses to understand the factors driving growth and make informed decisions regarding investments and strategic initiatives.

Industrial gears market was valued at US$ 229.3 billion in 2024 and is expected to exceed US$ 332.0 billion by 2033, registering a CAGR of 4.2% over the forecast period 2025-2033.

A Request of this Sample PDF File@- https://www.astuteanalytica.com/request-sample/industrial-gears-market

Comprehensive Market Overview

Astute Analytica's report provides a holistic overview of the Industrial Gears market. It encapsulates a wide array of information related to market dynamics, including growth drivers, challenges, and opportunities. Stakeholders can leverage these insights to formulate effective strategies and maintain a competitive edge in the market.

Key Players in the Market

The report identifies and profiles the major players who are influencing the Industrial Gears market. Through meticulous research, it presents a clear view of the competitive landscape, detailing the strategies, market presence, and significant developments of leading companies. This section is vital for stakeholders who wish to understand the positioning and actions of their competitors.

Key Companies:

Aero Gear Incorporated

Precipart Corporation

Itamco

Riley Gear Corporation

Atlas Gear Company

Ashoka Machine Tools Corporation

Hota Industrial Manufacturing Co., Ltd.

Bevel Gears India Pvt. Ltd.

Fiat Chrysler

Ford

General Motors

Honda

Toyota

Caterpillar

Jackson Gear Company

Cleveland Gear Company

David Brown Inc.

Eaton

OKUBO GEAR Co., Ltd.

Elecon Engineering Company Limited

KHK Stock Gear

Martin Sprocket & Gear, Inc.

Overton Chicago Gear Corporation

Philadelphia Gear

Havlik International

Omni G & M Corporation

Commercial Gear & Sprocket Company, Inc.

Gear Motions, Inc.

ZF Friedrichshafen

Other Prominent Players

For Purchase Enquiry: https://www.astuteanalytica.com/industry-report/industrial-gears-market

Segmentation Analysis

A crucial component of the report is the segmentation analysis, which delves into various market segments based on industry verticals, applications, and geographic regions. This detailed examination provides stakeholders with a nuanced understanding of market dynamics, enabling them to identify opportunities for growth and areas for investment.

Market Segmentation:

By Product:

Spur Gear

Planetary Gear

Helical Gear

Rack and Pinion Gear

Worm Gear

Bevel Gear

Others

By Application:

Automotive

Aviation

Agricultural Machinery

Construction Machinery

Material Handling

Mining Equipment

Oilfield Equipment

Power Plants

Pulp and Paper

Steel and Manufacturing

Others

By Distribution Channel:

OEMs

Aftermarket

By Region:

North America

The U.S.

Canada

Mexico

Europe

The UK

Germany

France

Italy

Spain

Poland

Russia

Rest of Europe

Asia Pacific

China

India

Japan

Australia & New Zealand

ASEAN

South Korea

Rest of Asia Pacific

Middle East & Africa (MEA)

UAE

Saudi Arabia

South Africa

Rest of MEA

South America

Argentina

Brazil

Rest of South America

Research Methodology

Astute Analytica is recognized for its rigorous research methodology and dedication to delivering actionable insights. The firm has rapidly established a solid reputation by providing tangible outcomes to clients. The report is built on a foundation of both primary and secondary research, offering a granular perspective on market demand and business environments across various segments.

Beneficiaries of the Report

The insights presented in this report are invaluable for a range of stakeholders, including:

Industry Value Chain Participants: Those directly or indirectly involved in the Industrial Gears market need to stay informed about leading competitors and current market trends.

Analysts and Suppliers: Individuals seeking up-to-date insights into this dynamic market will find the report particularly beneficial.

Competitors: Companies looking to benchmark their performance and assess their market positions can leverage the data and analysis provided in this research.

Astute Analytica's report on the Industrial Gears market is an essential resource that empowers stakeholders with the knowledge needed to navigate and thrive in this competitive landscape.

Download Sample PDF Report@- https://www.astuteanalytica.com/request-sample/industrial-gears-market

About Astute Analytica:

Astute Analytica is a global analytics and advisory company that has built a solid reputation in a short period, thanks to the tangible outcomes we have delivered to our clients. We pride ourselves in generating unparalleled, in-depth, and uncannily accurate estimates and projections for our very demanding clients spread across different verticals. We have a long list of satisfied and repeat clients from a wide spectrum including technology, healthcare, chemicals, semiconductors, FMCG, and many more. These happy customers come to us from all across the globe.

They are able to make well-calibrated decisions and leverage highly lucrative opportunities while surmounting the fierce challenges all because we analyse for them the complex business environment, segment-wise existing and emerging possibilities, technology formations, growth estimates, and even the strategic choices available. In short, a complete package. All this is possible because we have a highly qualified, competent, and experienced team of professionals comprising business analysts, economists, consultants, and technology experts. In our list of priorities, you-our patron-come at the top. You can be sure of the best cost-effective, value-added package from us, should you decide to engage with us.

Get in touch with us

Phone number: +18884296757

Email: [email protected]

Visit our website: https://www.astuteanalytica.com/

LinkedIn | Twitter | YouTube | Facebook | Pinterest

0 notes

Text

CNC Vertical Gear Hobbing: The Future of Precision Gear Manufacturing

In today’s world of advanced engineering, high-precision gears are essential for various industries, including automotive, aerospace, industrial machinery, and robotics. One of the most efficient and reliable methods for producing these gears is CNC vertical gear hobbing. This cutting-edge technology ensures precision, efficiency, and consistency, making it the preferred choice for manufacturers worldwide.

What is CNC Vertical Gear Hobbing?

CNC vertical gear hobbing is an advanced gear-cutting process that utilizes Computer Numerical Control (CNC) technology to automate and optimize gear manufacturing. Unlike traditional hobbing machines, CNC vertical gear hobbing machines operate in a vertical orientation, offering greater control, accuracy, and flexibility.

This process involves using a rotating cutting tool, called a hob, which progressively cuts into a gear blank to form precise gear teeth. The CNC system controls the movements of both the hob and the gear blank, ensuring accurate synchronization and high-quality gear production.

How CNC Vertical Gear Hobbing Works

The CNC vertical gear hobbing process consists of the following steps:

Workpiece Setup: The gear blank is securely mounted on the machine’s spindle.

Tool Positioning: A high-precision hob is positioned according to the gear specifications.

CNC Programming: The machine is programmed with precise cutting parameters.

Gear Cutting: The rotating hob cuts gear teeth into the blank with extreme accuracy.

Quality Inspection: The finished gear is inspected to ensure it meets industry standards.

Advantages of CNC Vertical Gear Hobbing

Industries prefer CNC vertical gear hobbing due to its numerous benefits, including:

1. Superior Precision and Accuracy

CNC technology ensures high precision, enabling manufacturers to produce gears with tight tolerances and minimal deviations.

2. Improved Efficiency and Productivity

With automated operations, CNC vertical gear hobbing machines can produce gears at a faster rate while maintaining consistent quality.

3. Versatile Gear Production

These machines can manufacture various types of gears, such as:

Spur gears

Helical gears

Worm gears

Sprockets

Splines

4. Cost-Effective Manufacturing

Automation reduces manual intervention, minimizes material waste, and lowers labor costs, making the process highly economical.

5. Enhanced Machine Longevity

CNC vertical gear hobbing machines are designed for durability and long-term reliability, reducing maintenance and operational costs.

Applications of CNC Vertical Gear Hobbing

CNC vertical gear hobbing is widely used across multiple industries, including:

Automotive: Manufacturing high-precision gears for transmissions, differentials, and powertrains.

Aerospace: Producing lightweight, high-strength gears for aircraft engines and navigation systems.

Industrial Machinery: Creating gears for pumps, compressors, and heavy equipment.

Robotics: Manufacturing small, intricate gears for robotic applications.

Renewable Energy: Producing gears for wind turbines and solar tracking systems.

Features of a Modern CNC Vertical Gear Hobbing Machine

Advanced CNC vertical gear hobbing machines come equipped with state-of-the-art features, including:

Multi-Axis Control: Allows for complex gear designs with high precision.

High-Speed Spindles: Enhances production speed without compromising accuracy.

Automated Tool Changes: Reduces downtime and increases operational efficiency.

Integrated Cooling Systems: Prevents overheating and extends the lifespan of cutting tools.

User-Friendly Interfaces: Simplifies programming and machine operation.

Why Choose CNC Vertical Gear Hobbing Over Traditional Methods?

While traditional gear hobbing methods have been effective for many years, CNC vertical gear hobbing offers several advantages:

Greater Flexibility: CNC machines can easily switch between different gear types and sizes with minimal reconfiguration.

Higher Precision: Advanced CNC technology ensures accurate gear tooth profiles and reduces human error.

Faster Turnaround Times: Automated systems significantly speed up the gear production process.

Better Quality Control: Real-time monitoring and automated inspection improve consistency and quality.

Reduced Production Costs: Less material waste and fewer defects result in cost savings for manufacturers.

Choosing the Right CNC Vertical Gear Hobbing Machine

When selecting a CNC vertical gear hobbing machine, consider the following factors:

Production Requirements: Choose a machine that meets your volume and quality expectations.

Type of Gears: Ensure the machine can produce the specific gears required for your industry.

Automation Level: Higher automation reduces labor dependency and increases productivity.

Machine Durability: Opt for a machine with robust construction and long service life.

Budget Considerations: While CNC machines have higher initial costs, they offer long-term savings through efficiency and precision.

Why Gear Hobbing Solutions is Your Best Choice for CNC Vertical Gear Hobbing

At Gear Hobbing Solutions, we specialize in providing high-quality CNC vertical gear hobbing machines that deliver exceptional precision, efficiency, and durability. Here’s why customers trust us:

Industry Expertise: With years of experience in gear manufacturing, we offer the best solutions for our clients.

State-of-the-Art Technology: Our CNC vertical gear hobbing machines feature the latest advancements for superior performance.

Custom Solutions: We provide tailored machines to meet specific customer requirements.

Strict Quality Standards: Our machines undergo rigorous testing to ensure compliance with international quality standards.

Comprehensive Support: From installation to maintenance, we provide full-service support to our customers.

The Future of CNC Vertical Gear Hobbing

The gear manufacturing industry continues to evolve, with innovations in CNC vertical gear hobbing shaping the future. Some upcoming trends include:

AI and Machine Learning: Enhancing predictive maintenance and optimizing production processes.

IoT Integration: Enabling real-time monitoring and remote machine operation.

Eco-Friendly Manufacturing: Developing sustainable solutions to reduce energy consumption and material waste.

As technology advances, CNC vertical gear hobbing will remain at the forefront of high-precision gear manufacturing, offering unmatched efficiency and reliability.

Conclusion

CNC vertical gear hobbing is revolutionizing the gear manufacturing industry, providing high-precision, cost-effective, and efficient solutions for various applications. Whether you’re in the automotive, aerospace, industrial, or renewable energy sector, investing in CNC vertical gear hobbing technology can significantly enhance your production capabilities.

At Gear Hobbing Solutions, we are committed to delivering the best CNC vertical gear hobbing machines to meet your manufacturing needs. Contact us today to learn how we can help you achieve greater precision and efficiency in your gear production process.

0 notes

Text

Industrial Gear Oils Market

Industrial Gear Oils Market Overview:

Industrial Gear Oils Market Size is forecast to reach $ 5820.0 Million by 2030, at a CAGR of 3.80% during forecast period 2024–2030.

Request PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

According to an IndustryArc report, the Industrial Gear Oils Market in 2030 was valued at $5820.0 million and is expected to grow rapidly considering the large industrialization and manufacturing activities especially in the BRICS (Brazil, Russia, India, China and South Africa) region. Industrial Gear oils are used across various industries namely the mining, construction, energy, oil and gas, chemicals, food and beverage industries as they involve heavy machinery and drive systems which need to be heavily lubricated, well oiled, under heavy pressures and high temperatures. This market is segmented based on its applications, end user industry and gearbox configuration. One application which is witnessing a large demand for Industrial Gear Oils is the renewable energy industry in the construction of wind turbines.

Industrial Gear Oils Market Outlook:

Industrial Gear oils are made of 2 major ingredients — the base oil and additives — that aim to suppress undesirable properties and enhance desirable ones so as to ease the functioning of automatic transmission. Wind energy, one of the popular renewable energy source has become a favorite worldwide, particularly in the European Union. The efficiency of the wind-turbines clearly depends on the reliability of the gear boxes that are an integral part of these machines. In addition, worm gear drives in industrial applications such as lifts, elevators, conveyor belts and torsen differentials are also witnessing a large demand. Thus, for the effective, reliable and long term running of these gear based machines, gear oils help to fulfill these requirements.

Industrial Gear Oils Market Growth drivers:

As the wind energy is rapidly evolving and a high growth industry, this large growth rate would directly boost the demand for high performance, excellent corrosion and oxidation resistance, enhanced bearing and long life operational performance industrial gear oil. Furthermore, as the developing countries in the APAC region such as India and China invest and build large manufacturing facilities and transportation technologies due to heavy urbanization and population growth, the reliable operation of machines in these sectors would be vital, which are impacted by gear oil performance. In addition, many responsible customers who are environment friendly and prefer sustainable alternatives to synthetic oil gears, would increasingly demand for bio-based alternatives.

Industrial Gear Oils Market Challenges:

The prime challenge faced by the Industrial Gear Oils market is the unstable crude oil market wherein the latter could directly impact the former, as crude oil is the prime raw material needed to manufacture gear oils for industries. Crude oil is the most volatile product in the world, and thus selling price of certain industrial gear oils would be dictated by the fluctuating prices of oil. Moreover, as concerns for environmental impact of industrial gear oils are rising among many industrial customers, key players would be forced to develop and market bio-based lubricants that are derived from vegetable oils that deliver an equivalent performance when compared to synthetic or mineral based gear oils.

For more details on this report — Request for Sample

Industrial Gear Oils Market Research Scope:

The base year of the study is 2023, with forecast done up to 2030. The study presents a thorough analysis of the competitive landscape, taking into account the market shares of the leading companies. It also provides information on unit shipments. These provide the key market participants with the necessary business intelligence and help them understand the future of the Industrial Gear Oils market. The assessment includes the forecast, an overview of the competitive structure, the market shares of the competitors, as well as the market trends, market demands, market drivers, market challenges, and product analysis. The market drivers and restraints have been assessed to fathom their impact over the forecast period. This report further identifies the key opportunities for growth while also detailing the key challenges and possible threats. The key areas of focus include the types of plastics in the Industrial Gear Oils market, and their specific applications in different types of vehicles.

Industrial Gear Oils Market Report: Industry Coverage

Industrial Gear Oils– By Gear Configuration: Worm Gears, Spur Gears, Helical Gears, Bevel Gears, Light Duty Gears and Others

Industrial Gear Oils– By Application: Wind Turbine Gearboxes, Shock loads, Mining Machinery, Extreme loads, Worm drives and others

Industrial Gear Oils– By Make-up: Synthetic, Mineral oil, Additives, Bio-based and others

Industrial Gear Oils– By End-User: Agriculture, Chemicals, Oil and gas, Mining, Energy and Power, Construction, Food and Beverage, Transportation and Fleet, Paper and Pulp and Others

The Industrial Gear Oils market report also analyzes the major geographic regions for the market as well as the major countries for the market in these regions. The regions and countries covered in the study include:

North America: The U.S., Canada, Mexico

South America: Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, Costa Rica

Europe: The U.K., Germany, Italy, France, The Netherlands, Belgium, Spain, Denmark

APAC: China, Japan, Australia, South Korea, India, Taiwan, Malaysia, Hong Kong

Middle East and Africa: Israel, South Africa, Saudi Arabia

Industrial Gear Oils Market Key Players Perspective:

Some of the Key players in this market that have been studied for this report include: Addinol Lube Oil GmbH, Advanced Lubrication Specialitis Inc., Amalie Oil Co., BP P.L.C., Bechem Lubrication Technology LLC, Chevron Corporation, Croda International PLC, ExxonMobil Corporation and others.

Market Research and Market Trends of Industrial Gear Oils Market

Researchers at the Nanotechnology & Catalysis Research Centre (NANOCAT), University of Malaya, Malaysia developed a potential antioxidant for Industrial Gear Oils. Esters of Thiolated Butylated Hydroxytoluene (BHT) derived from vegetable oils were discovered to have profound antioxidant properties, a vital property in industrial gear oils that prevent oxidation, rust and As the gear oils used in heavy duty industries are exposed to high temperatures and heavy pressures, the thermal stability, antioxidant behavior, structural integrity and performance are a cause of concern for many industrial customers. End user industries are aiming for gear oils with longer life cycles and which fulfill the above criteria. Bio-based lubricants available in the market have yet to compete on par with synthetic based gear oils and thus discoveries like this can push the green industrial gear oils to become a viable replacement to environmentally damaging synthetic and mineral based lubricants.

Get this Report on discount of $1000 on purchase of Credit Card

Researchers are actively seeking improvised nanomaterials for functioning as a lubricant additive due to their compact size and large surface area. A novel attempt to create an oil soluble Ni-promoted Molybdenum disulfide (MoS2) nanostructure has been successful by the Centre for NanoScience and Technology based in India. As industries aim to deliver gearboxes that are expected to operate heavy loads at high speeds and harsh conditions, without undergoing major surface failures and frictional damages. Thus, nanotechnology additive solutions as this can prove to improve the performance of traditionally used industrial gear oils thereby driving growth and increased demand for high performance gear oils.

#IndustrialGearOils#LubricantsMarket#IndustrialLubricants#GearOilSolutions#MachineryMaintenance#HeavyMachinery#IndustrialMachinery#EngineeringSolutions#ManufacturingIndustry#IndustrialInnovation#HighPerformanceLubricants#GearOilTechnology#SyntheticLubricants#OilAndLubricants#EcoFriendlyLubricants#SustainableOils#EnergyEfficiency#B2BMarketing#IndustryLeaders#MarketInsights

0 notes

Text

Worm gear box dealer in Delhi

If you are looking for Worm Gear box Dealer in Delhi, then we can confidently tell you that you are at the right place. We are prominent wholesaler, trader and retailer of a wide range of worm and helical gearbox. ANG Industries is one of the best supplier, trader, dealer and retailer of worm Gearbox.

Our highly designed Worm and Helical Gear Boxes are designed with latest innovative techniques. We use good quality primary ingredients to deliver premium quality aforementioned Gear Box. Our products are energy efficient and thus reduce running expense to considerable extent. Our worm and helical gear box is dimensionally interchangeable with other manufacturer. Oil tight gear head empowers motor removal without spillage.

ANG Industries is a leading Worm Gear Box Dealer in Delhi, provide best quality gearboxes to our valuable clients at competitive price.

0 notes