#vulcanized natural rubber

Explore tagged Tumblr posts

Text

Patented Innovation: The Driving Force Behind Kajay Remedies' Success

In the constantly changing scenario of specialty chemicals and industrial solutions, Kajay Remedies has surfaced as a leader. Being built on innovation, research, and customer-centric solutions, the brand continues to bloom by offering cutting-edge products that meet the demands of modern industries. Patented innovations have been the base of success for Kajay Remedies, revolutionizing multiple sectors. Formiphen is one such innovation which is a breakthrough product in industrial processes, setting new benchmarks.

In this blog, we will delve into the kind of patented solutions similar to Formiphen which revolutionize the industries, its precise applications of Formiphen, and the role played by the major constituents in industries, like Formic Acid and Para Nitrophenol. We will then review how the innovations created at Kajay Remedies are beneficial for the industries relating to natural rubber as well as vulcanized natural rubber.

Kajay Remedies: An Epitome of Innovation by Patents

Innovation is the backbone of Kajay Remedies. It has made itself a brand that is recognized as a specialist in delivering specialized chemicals that solve critical industrial challenges. Kajay Remedies has always been committed to R&D to be at the top of its game. Patents on its products have ensured that the brand provides quality and exclusivity to its customers with reliable and efficient solutions.

What is Formiphen?

Formiphen��is a specialty product patented by Kajay Remedies, which has proven very useful in the chemical process and industrial manufacturing business. This chemical is being widely recognized for its specific features that help improve the production process.

The product's formulation was a result of massive research and development, hence promising it to give performance each and every time and the utmost care in safety standards. It applies itself to various industries as such, which explains how its adaptability works best for it.

Applications of Formiphen: Industry Revolutionary

Formiphen, manufactured by Kajay Remedies, has applications in so many aspects that it can be termed an industrial revolutionary. Some of its major applications are the following:

Rubber processing and vulcanization:

Formiphen plays a very crucial role in the vulcanization process involved in the production of natural rubber and vulcanized natural rubber. It actually enhances the elasticity, strength, and durability of the final product, making rubber an applicable material for industrial usage, such as in tires, belts, hoses, etc. Hence, Kajay Remedies' Formiphen promotes a smoother vulcanization process with consistent results that may improve the quality of products made from rubber in general.

Chemical Synthesis and Industrial Applications

Its role in chemical synthesis allows manufacturers to create intermediate compounds with precision and stability. By using Formiphen, industries can improve yields, reduce waste, and enhance cost-efficiency.

Catalyst for Specialty Chemicals:

Formiphen is used as a catalyst in the synthesis of Formic Acid and Para Nitrophenol. These chemicals are widely used in the manufacture of dyes, pharmaceuticals, and agricultural products. The presence of Formiphen in the synthesis process accelerates reactions, improves product quality, and ensures compliance with industrial standards.

Environmental Solutions:

Apart from the industrial uses, Formiphen ensures a 'green' manufacturing process.

Formic acid role in industrial processes

Formic Acid is a critical chemical that has diverse uses in different industries. As a major reagent in industrial processes, Formic Acid is both a preservative and an intermediate in various chemical reactions. Together with Formiphen, this compound is used to boost efficiency in such applications as:

Textile and Leather Processing: Formic Acid has many uses in tanning leather and processing textiles for finished products' durability and quality.

Rubber Production: Its use in coagulant systems makes it an essential component in natural rubber processing.

Agriculture: Formic Acid is used as a preservative in animal feed, contributing to better shelf life and nutrition quality.

Kajay Remedies' innovations, including Formiphen, complement the use of Formic Acid, making industrial processes more efficient and sustainable.

Para Nitrophenol: A Key Intermediate in Specialty Chemicals

Para Nitrophenol is another essential chemical that acts as a collaborator of Formiphen. This intermediate is very vital in the synthesis of the following compounds:

Dyes and Pigments: Para Nitrophenol is used in making bright, color-intensive, and durable dyes and pigments for textile applications as well as coatings.

Pharmaceuticals: It participates in the synthesis of several pharmaceutical intermediates, thus contributing to the production of necessary drugs.

Agrochemicals: Para Nitrophenol is used in the formulation of pesticides and herbicides, supporting agriculture.

With Formiphen as a catalyst or auxiliary chemical, Kajay Remedies makes sure that the industries employing Para Nitrophenol enjoy enhanced synthesis processes, higher yield, and lower environmental footprint.

Vulcanized Natural Rubber: Industrial Strength

Natural rubber is undoubtedly one of the most versatile products for industrial use. A process referred to as vulcanization converts natural rubber to vulcanized natural rubber with improvements in terms of strength and elasticity together with an important attribute towards resistance against frictional wearing.

Automobile: The vulcanized rubber of tires, seals, and gaskets contributes to strength and durability.

Construction: In roofing, flooring, and insulation systems, vulcanized rubber is the main component.

Manufacturing: Hoses, industrial gloves, and conveyor belts make use of the vulcanized natural rubber for the better strength and flexibility it possesses.

The process of vulcanization with the use of Formiphen enhances consistency, durability, and reliability in the end product. Patented innovations are the pillar of Kajay Remedies' success, promoting the company's growth and solidifying its position in the specialty chemicals sector. Formiphen, due to its myriad applications and synergy with Formic Acid and Para Nitrophenol, reflects the excellence of the brand. Kajay Remedies enhances the process in natural rubber and vulcanized natural rubber industries so that manufacturers achieve superior quality, durability, and efficiency. The company continues to innovate as it remains a trusted partner for industries worldwide in delivering solutions that drive success. Patented products of Kajay Remedies are not just chemicals, they are innovations that transform industries, support sustainability, and pave the way for a better future.

0 notes

Text

Building with Bounce: Unleashing the Power of Rubber in Construction

Discover the innovative uses of rubber in building construction. Learn why rubber is revolutionizing the industry—uses of Rubber in Building Construction. Rubber in building construction isn't just about tires anymore. It's a game-changer, offering unparalleled versatility and durability for all your construction needs.

#Rubber in Building Construction#Types of Rubbers#Natural Rubber#Synthetic Rubber#Vulcanization of Rubber

0 notes

Note

Do you know anything about pre-colonization chemistry

I only know about a few examples. The most common one is the use of morning glory sap to chemically vulcanize rubber to make it more bouncy and more cohesive. Timothy Knab has a short chapter in "Moctezuma's Table" (2010) in which he used his culinary knowledge to point out the kinds of foods served to Cortes and his men would have caused them intense gastrointestinal distress if they had eaten the foods in the proper cultural order. The last example I can think of is that Mesoamericans would have needed chemistry/metallurgy to produce liquid mercury from cinnabar since mercury is not naturally in liquid form.

46 notes

·

View notes

Text

Before Gear 5th was revealed, theorists tried to predict its abilities based on the themes of the previous Gears

Gear 2nd used the cardiovascular system

Gear 3rd used the skeletal system

Gear 4th used the muscular system

So naturally fans assumed that Gear 5th would use another aspect of the body

Some thought it would be the nervous system and increase Luffy's intelligence or reflexes, possibly giving him a big head

Some thought it would be the integumentary system, affecting either his skin by vulcanizing his rubber body or his hair by letting him produce static electricity by sprouting hairs along his limbs (I came up with that one and am still fond of it)

They were more niche, but I even occasionally saw some ideas for the respiratory system, digestive system, or, most surprisingly, the endocrine system (and least surprisingly the urinary system...)

Obviously, none of these came to pass, and the most popular theory, that Gear 5th would just be Luffy's Awakening, was ultimately correct, but that doesn't mean it abandoned the overall theme of the Gears

While Luffy isn't using his new abilities to stretch his nerves, hair, lungs, stomach or bladder, he did find one new thing to stretch: his imagination!

In the end, one might argue that Gear 5th is related to the nervous system, at least tangentially, since now Luffy's powers are only limited by his mind, not his body

19 notes

·

View notes

Text

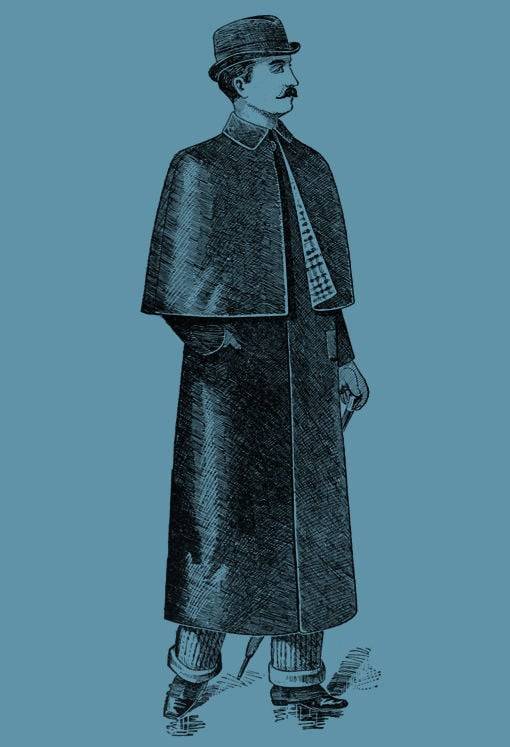

On June 17th 1823 Charles Macintosh patented the waterproof cloth he was using to make raincoats.

Mackintosh rubberized coats were not immediately successful. Although they were waterproof, they had a strong smell which most wearers found unpleasant. It was not until a fellow chemist, Thomas Hancock, invented a process involving vulcanized rubber that the problem was solved. Hancock became a partner in Macintosh’s business in 1834. This marked the real start of the iconic Mackintosh brand.

In 1824 an Arctic exploration team trialled rubber coated waterproof canvas bags, air-beds and pillows made by the Macintosh patented process. In 1841 the British army ordered waterproof clothing for all its troops. The rubberized coats and capes were functional and hard wearing and they soon became standard army issue.

After the death of Charles Macintosh in 1843, the company had a period of decline. But in 1851 the Mackintosh coat was shown at The Grand Exhibition at Crystal Palace, London. And the rest is history.

Of course just because you patent something it does not mean you actually were the first to invent it, controversy has followed the invention of the telephone since Alexander Graham Bell patented it, other inventions were questioned, the tyre, the television and the bicycle, all connected to Scotland and all have earlier versions that were thought of, or made beforehand, the “Mac” is no different.

James Syme, a surgeon and chemist based in Edinburgh, had discovered a derivative of coal tar (naphtha) could dissolve rubber and published his findings in Thomson's Annals of Philosophy five years before Macintosh came up with his idea.

It was the same process used by Macintosh following his own chemistry experiments with waste from Glasgow’s coal-gas works, and it has been claimed that the inventor had read Syme’s work before developing it for his own uses.

While Syme, uninterested in commercial matters, failed to patent his valuable discovery and continued to build a noteworthy career in surgery, Macintosh stamped his name on the idea in 1823, had Syme done so you might be calling the coats Symes.....it doesn’t have the same ring does it? Syme’s paper had not detailed the crucial sandwich-type construction employed by Macintosh, although this too was not completely new.

Spanish scientists previously used the method to make leak-proof containers for mercury, and renowned British balloonist Charles Green made a balloon envelope that applied the same principle in 1821.

French scientists also made balloons gas-tight and impermeable by impregnating fabric with rubber dissolved in turpentine and the use of rubber to waterproof fabric dates back to the Aztecs, who used natural latex.

But what made Macintosh’s invention revolutionary was its ease of manufacture and wear, seeing him swiftly launching into the production of cloth to be converted into coats and other garments by tailors in Glasgow.

Some of you might have picked up on the different spelling of the names in the first two paragraphs? Others will now be scrolling back to see what I mean! Well when As news of his invention spread, the repeated misspelling of the inventor’s name is thought to have popularised the description of the resulting coat as a “Mackintosh” – a name that has stuck to the present day.

Macintosh was elected as a fellow of the Royal Society for his contributions to chemistry and enjoyed considerable success before his death in 1843, aged 76.

First sold in 1824, his coat remains on the market in numerous forms across the world, it is now primarily a luxury brand still bearing its inventor’s name, even though it is spelled wrong!

11 notes

·

View notes

Text

Charles Goodyear (December 29, 1800 – July 1, 1860)

An American chemist and engineer, Charles Goodyear is most well known for his development of vulcanized rubber. Natural rubber is a soft material, and vulcanization stabilized and hardened the material, allowing it to be adopted for a variety of applications. However, although he patented the process in the 1840s, Goodyear never truly profited from his work. He died in debt in 1860, and it was only after his death that his family began to receive significant royalties. Notably, the Goodyear Tire & Rubber Company has no association with Charles Goodyear or his family beyond being named in his honor when it was founded nearly 40 years later.

Sources/Further Reading: (Image source - Wikipedia) (PBS) (MIT) (Goodyear)

#Materials Science#Science#Rubber#Materials processing#Science history#Scientists#ScientistSaturday#2024Daily

12 notes

·

View notes

Text

"the goodyear blimp" is such a dense phrase. in order to truly understand it, it's almost too much to ask, the nature and mechanics of a blimp, and yet this is only the beginning. you have to also understand that the goodyear tire and rubber company is named after -- well, charles goodyear, who invented the process of vulcanization (named by some other guy), although the company was formed 40 years after his death -- i mean, so, vulcan, the roman god of volcanoes, right -- and so, when you form crosslinks in a polymer chain, it... well, in any case, the field of public relations, or "PR," uh... and the process involves sulphur, which is why it smells like a volcano. and it was all to sell car tires. to carry a combustion engine across great distances -- curiously, not named after the god of fire -- because of the free market economy. and there are four of them left. because blimp advertising has fallen in popularity

39 notes

·

View notes

Text

Viewers turning in for the track and field events at the Summer Games in Paris next week might just do a double-take: Instead of the usual rust-colored reddish hue, the track is purple.

The new, eye-catching color will serve as the backdrop for runners competing at the Stade de France, the country’s largest stadium, located in the northern Paris suburb of Saint-Denis. The track is made by Mondo, a company based in Alba, Italy, that has made every track used at the Olympics since 1976.

The color was mainly an aesthetic choice, as purple, blue and green make up the palette for the competition venues at this year’s games. The design actually incorporates three separate colors: lavender for the track itself, darker purple for the service areas and gray for the exterior curves at each end.

Even the glue used to adhere the track to its asphalt base—2,800 pots in total—is purple, just in case any becomes visible.

“The big part of the job was to come up with a track that was different from what we had seen … to go a little bit outside the box,” says Alain Blondel, an Olympic decathlete who now serves as the sports manager for the Paris games, to Olympics.com’s Nicolas Kohlhuber.

This is the first time an Olympic track has been purple. But it’s not uncommon for athletics venues around the world to play around with color. For example, since 1986, Boise State University has famously eschewed the traditional green-colored turf for its football field, opting instead for a shocking shade of bright blue.

Color aside, the Paris track is unique for several other reasons. For one, it incorporates the shells of bivalve mollusks, like mussels and clams. Ahead of the games, track-maker Mondo began partnering with a mussel farming and fishing company called Nieddittas to give used shells a second life.

Staff at Nieddittas harvest, clean and prepare the shells—which are made primarily of calcium carbonate—so they can be ground into a powder that can be incorporated into the track material. The shells would have otherwise been headed to a landfill, so the process transforms waste into something useful. It also reduces the need for mining, which is how manufacturers usually obtain calcium carbonate.

All told, 50 percent of the Paris track comes from recycled materials, reports BBC’s Padraig Belton.

This innovative use of recycled natural materials aligns with the goals of the International Olympic Committee, which vowed to make the Summer Games in Paris the most sustainable Olympics yet. Other sustainability efforts include bike parking at many venues, more plant-based food options for spectators, 100 percent locally sourced renewable energy, a geothermal cooling system at the Olympic Village and aquatic center seats made from recycled plastic bottle caps, among many others.

The track’s design and materials may also help athletes perform their best. The Paris track has the same base as the one used at the 2020 Summer Games in Tokyo, with some minor modifications, per reporting by Reuters’ Manuel Ausloos and Vincent Daheron. At those games, athletes set three world records and 12 Olympic records—and officials expect even more records to fall next week in Paris.

“The first indications are that it will be a very, very good track,” Blondel told the Associated Press’ (AP) Jerome Pugmire in April. “If we see athletes with personal bests on the scoreboard, it means we did a good job.”

For this iteration of the track, Mondo researchers improved upon the new polymeric material first introduced in Tokyo. They also used computer algorithms to further refine the optimal shape and size of the air bubbles within the lower layer of the track, which help absorb and then rebound the energy from the runner’s foot striking the ground.

The vulcanized rubber provides good grip and resistance for Paralympic athletes who use wheelchairs and prosthetics. The track has also been specially designed to complement the latest generation of running shoes.

“For the track, we only see the aesthetics, but there is great work that goes into the underlayer,” says Alessandro Piceli, a research and development manager at Mondo, to the Guardian’s Sean Ingle.

Mondo leaders say the Paris track will be 2 percent faster than the one used in Tokyo, per the BBC. But, in 2020, runners also got a boost from hot temperatures and new shoe spike technology, per the Guardian. It remains to be seen how the track will affect athletes’ times, but its creators are confident we will see records fall in Paris.

“The athletes will find this track to be more reactive and better suited for their competition,” said Maurizio Stroppiana, vice president of Mondo’s sport division, to the AP’s Andrew Dampf and Luca Bruno in March.

#current events#olympics#sports#athletics#environmentalism#technology#2024 olympics#france#paris#shells

3 notes

·

View notes

Text

Spirktober 2023, day 2: Running

I'm doing these all out of order, I know, but I'm having a grand old time. Wahoo!!

Also, if anyone is seeing these and wants to request stuff alongside the Spirktober prompts, just let me know :)

Also posted on AO3 here.

☆ ☆ ☆

As a general rule, Spock knew many things. He knew the planet they were on (Aldux II), the language of the intelligent lifeforms that had lived on the planet since the beginning of their history (called D’xian, with a case system suspiciously similar to Russian), and how long they had been on the planet for (16.8 hours). He knew that his stride length was 62.25 inches. He knew that he was fond of this number, as it was also Lieutenant Uhura’s height. He knew that he had been running for 2.4 hours.

He knew that his last two security officers had fallen away 528 strides ago, and that one of them --- Ensign Karros, who smiled at him illogically at least twice an hour and was a vicious student of Suus Mahna --- had gasped, “Keep going,” at him even as she staggered to her knees, clutching her chest. He knew that his footfalls were the only ones he could hear, that his heartbeat was thrumming uncomfortably in his side, and that the small package of antibiotics in a pouch slung across his chest was the most valuable material on the planet at this moment. He knew that it there was a one in ten chance that the ion storm swirling in the atmosphere over his head would create conditions nonconducive to life, specifically his, at some point during this trek, but he also knew that he was the only member of the crew who could conceivably cover the significant distance between hospitals faster than the storm would dissipate naturally.

He did not know how the other hospital was faring. He did not know if his captain was still alive. He did not know if Dr. McCoy was still with him, or if he would be available to synthesize the antibiotic quickly enough to distribute to the crew of the Enterprise and what remained of the D’xian population.

Sometimes he thought that continually running into the boundary of his knowledge about the universe would eventually kill him. His mind would revolt at the illogical things he had to do to survive, or he would learn something on some planet that would destabilize the foundations of his life, and he would lay down and curl up and go to sleep forever. He knew, however, that today would not be that day. He was not content to give up when he, stronger and faster and more durable than his human crewmates, was the last man standing, to borrow a human phrase. If McCoy was not available, he would synthesize the antibiotic himself. He knew that, although he was not a doctor, he knew enough about chemistry to do it. He knew that he would rather run until his heart stopped than die without knowing what had happened to the captain.

So he ran.

☆ ☆ ☆

Spock knew, by the time the hospital building appeared in his vision, that he had destroyed the soles of his feet. Starfleet standard-issue boots were many valuable things: they were waterproof, rubber-soled, useful for climbing and standing and walking. He doubted that the Fabrication and the Material Construction team had ever tested the boots as he had today. He had run for 5.2 hours; his lungs ached, his heart pounded unsteadily, and he had turned off all sensation from his feet after the third hour. He did not want to think about the state of his skin and bones. Even Vulcan skin blistered eventually.

He slowed to a walk as he approached the building and called, as loudly as his chest could manage, “Dr. McCoy!”

Relief. Illogical, irrational, overwhelming relief flooded him as McCoy stuck his head out of a second-story window and looked down at him.

“Spock?” Disbelief dripped from the single syllable. “How the hell did you get here?”

Wrong question, thought Spock. He lifted the pouch that had bounced against his chest for the better part of the day. “I have the antibiotic.”

“How did you get here?” McCoy said again, and then he vanished from the window. Spock finally, finally came to a halt, standing outside what he estimated was the front door.

McCoy cracked it open and stuck his tricorder through. “You’re not infected, are you?”

“I do not believe so, doctor.” But the tricorder whirred and dinged, and when McCoy read the screen he opened the door fully. Spock handed the pouch to McCoy and had to use more mental effort than average to exert enough control to keep his hands from shaking.

McCoy took the pouch and flipped open the top flap, confirming that the three little glass bottles inside were whole. He looked up at Spock with none of his usual animosity. “I thought the ion storm made their transporters and ours useless.”

“It did, doctor. I brought the antibiotic.” The numbness that Spock had intentionally blanketed over his feet was spreading up his calves. This change in sensation was concerning, but likely not life-threatening.

“The other hospital was eighty kilometers from here,” McCoy said suspiciously, but he led Spock deeper into the cool building. The circulating air felt pleasant against his skin, and as they walked his heart rate started to slow.

“I am aware of the distance. Had it been closer, I would have arrived sooner.”

They entered a laboratory. This planet, unlike many of the others they had visited on their exploratory mission, was scientifically advanced. The D’xians were curious by nature, and becoming a scientist was both a professional and a social achievement. Spock found himself unwilling to consider the possibilities of what would have happened if they had been struck by the same virus on a planet without a fully functioning biological laboratory. If there hadn’t been a virus, if there hadn’t been an ion storm that blocked Mr. Scott from simply beaming Spock from one hospital to another, if it had been anyone but the captain who lay gasping on a hospital bed… it was not logical to consider alternative outcomes. This was the future that had happened.

They set to replicating the success of the other hospital’s scientists immediately. Despite their frequent arguments, Spock thought that he and McCoy made reasonably efficient labmates. McCoy talked to himself too much, and talked to Spock more than he preferred, but he knew what he was doing and he was the only other person, besides himself, that Spock trusted to keep the captain safe.

His entire lower body was numb, and his hands shook, but he assisted McCoy until McCoy slapped one of the machines happily and hoisted the first replicated dose of the antibiotic up into the air. “Got it,” he said grimly, and marched immediately from the room. Spock followed.

The room that McCoy led him to had only one occupant. He lay quietly in a narrow hospital bed, the only movement the shallow rise and fall of his chest beneath a threadbare blanket. This hospital’s equipment was different than that of the Enterprise, and Spock found himself discomfited by the difference in noises from this hospital’s machines.

McCoy loaded the antibiotic into a hypo and drove the needle into the captain’s neck. Without the captain’s customary wince and complaint, the action seemed like one-half of a duet: incomplete. They waited in silence for fifteen seconds. Thirty seconds.

Fifty-three seconds after the hypo pierced the captain’s skin, his eyes opened. His eyes---their color muted in the dim light of the room---landed on McCoy. “Hey, Bones,” Captain Kirk said softly. “Why don’t you ever buy me dinner first?”

“Jesus, Jim,” McCoy said, and laughed with relief. “Give a man a break. Didn’t want you to choke to death on a pill you couldn’t swallow.” The captain smiled at the doctor, and then his eyes flicked to Spock.

“Mr. Spock,” he said, voice thick with hushed delight. “I thought you were up north. Is the storm over, then?” He sat up, flexing his hands. His hands were brown, the backs tanned and dusted with freckles. It never ceased to amaze Spock that the captain was covered in freckles despite his infrequent exposure to any sun.

“Spock?” The captain’s voice was concerned. Spock realized that he had been staring at the captain’s hands for approximately nine seconds, that he could not remember what he was supposed to be saying, and that the numbness had spread to his neck. He looked down and assured himself that his body was still connected to his head.

He cleared his throat. “No, captain. The storm continues.”

The captain and Dr. McCoy continued to stare at him, some emotion he couldn’t identify rising on both of their faces. Perhaps they hadn’t heard him. “The storm…” he said again, but he forgot what he was saying.

He felt liquid on his upper lip, and raised a hand to it. His fingers came away green.

“Mr. Spock!” The captain stood abruptly and moved towards him.

“Why don’t you sit, Spock?” Dr. McCoy approached him, hands outstretched.

Sitting seemed like a logical idea. To maximize efficiency, he collapsed instead.

☆ ☆ ☆

The healing trance ended as suddenly as it began. Spock opened his eyes to see both the familiar tiled ceiling of the Enterprise’s own Medbay and the captain and the doctor hovering nearby.

“Captain,” Spock said. His throat was dry. It came out as more of a croak.

“What the hell were you thinking? Eighty kilometers?” Spock’s eyes found the captain’s.

“The needs of the many outweigh the needs of the one, captain,” he said. His captain rubbed one hand over his face in a familiar and exasperated gesture. “I estimated that it would not be significantly more taxing than running through the Forge.”

“And did you estimate your footwear, and the atmosphere, and differences in gravity?”

“Naturally,” Spock said. “I used all data available to me.” He did not add that he had never run for five straight hours through the Forge, and that it was actually easier for him to run in dry heat than in the cool and damp humidity of Aldux II, or what he was considering to mean ‘significant’ in this situation. He had survived. The captain did not need to know.

The captain sat heavily into the chair next to Spock’s bed, placed one hand on Spock’s forearm, and squeezed. Through the contact Spock was deluged with his emotions, as forceful as a hurricane: anger, concern, pride, affection, warmth, and Spock was gratified to learn that his captain was impressed by his display of athleticism.

“I estimated the odds of your survival based on my action or inaction, captain,” Spock said quietly. Across the room, Dr. McCoy began loudly clattering materials on the medical cart by the door. Through his captain’s hand, he felt the other man’s affection and concern pulse up his arm like a heartbeat.

“Yes, Mr. Spock,” Jim said quietly. “I thought you might have. Would it change your behavior at all if I asked you to be more careful in the future?”

“I am careful, captain,” Spock said, affronted. Careful with you, he thought.

Spock knew many things. Despite the illogic of it, despite his best attempts to meditate it away, he knew this: that he would protect his captain, even at his own expense, until his katra was returned to the stars.

#spirktober2023#spirktober#kirk/spock#k/s#spirk#star trek fan fiction#spirk fan fiction#my writing#s'chn t'gai spock#:) i love him#spirktober 2023

8 notes

·

View notes

Text

30 Days of Prodigy, day 24 - Holodeck

Commander Tysess hadn’t realized that the Admiral had a holo recording of the Protostar’s christening ceremony, although he shouldn’t have been surprised. Rumors had been flying since the moment they stepped off of Voyager and despite the fact that Chakotay appeared to be dating that Borg girl, the Janeway/Chakotay star-crossed lovers story had been a favorite of tabloids and Starfleet gossip alike.

Tysess never paid much attention to such frivolous things but now that he was Admiral Janeway’s second in command, it was his duty to understand her weaknesses - especially if Chakotay was one of them. He had never met Captain Chakotay in life and so the opportunity now to observe an interaction between the two was too good to pass up. Which is how the Andorian found himself standing in the holodeck, watching the ceremony playback.

The Admiral was always a very tactile person, especially with her former Voyager crew, so Tysess was unconcerned to see her hug Chakotay in greeting. What was concerning was the awkwardness of the hug and the slight color that rose in her cheeks. Was Admiral Janeway�� blushing?

Furthermore, Tysess noted that while every other officer in the room was standing at ease and conversing casually, Janeway and Chakotay both stood at parade rest: stiff spines and hands clasped behind their backs. On anyone else, this posture might make them appear distant. But somehow, he got the feeling that their hands were behind their back to counteract a natural magnetism between the two. As if, when they relaxed their hands, it would be like releasing a taut rubber band and they would shoot forward into each other’s personal space.

Tysess had seen enough, he decided, turning off the program with a beleaguered sigh. It was clear to him now that emotions could easily get in the way of this mission. He would need to be strong, stoic, and ready to call the Admiral out if her personal feelings started to get in the way.

Tysess envied Voyager’s Vulcan second officer. Surely his unflappable nature would come in handy about now. Tysess reflected that was probably a part of why that mission had been so successful: balance. As he left the holodeck, he wondered if maybe he should give Captain Tuvok a call.

#janeway/chakotay#janeway x chakotay#commander tysess#star trek prodigy#save star trek prodigy#savestartrekprodigy#i wrote this#30daysofprodigy#fanfic#star trek voyager#kathryn janeway#chakotay#holodeck

10 notes

·

View notes

Text

Discover how Kajay Remedies leverages patented innovation to lead the pharmaceutical industry. Learn about their groundbreaking solutions and commitment to excellence.

0 notes

Link

Check out this listing I just added to my Poshmark closet: Hunter Original Tall Rubber Wellington Rain Boots M10.

0 notes

Text

Zinc Oxide Market Adoption Rates: Key Trends Driving Growth Across Electronics, Healthcare, and Cosmetics.

Zinc oxide (ZnO) has been a pivotal material across various sectors due to its versatility and essential properties. From its common usage in pharmaceuticals and cosmetics to its crucial role in manufacturing electronics, the demand for zinc oxide has been rising steadily. The growing adoption of zinc oxide is driven by its broad array of applications, rising health concerns over other materials, and the increasing emphasis on sustainability. This blog aims to explore the key drivers, adoption rates, and trends shaping the zinc oxide market.

The Growing Demand for Zinc Oxide

Zinc oxide is a white powder with a vast range of properties including being non-toxic, highly efficient, and resistant to UV radiation. These unique features have catalyzed its uptake across different industries. It plays an indispensable role as a key ingredient in sunscreens due to its ability to block harmful UV rays. Moreover, its role in the rubber industry, electronics, pharmaceuticals, and paint formulations positions it as one of the most sought-after materials globally.

In the cosmetics and personal care industry, ZnO’s adoption rate continues to rise because of the increasing consumer demand for skin protection products. The rise in concerns over the harmful effects of chemical-based sunscreen ingredients has bolstered the market for products that contain zinc oxide. This is particularly true among consumers who prefer natural or mineral-based products, leading to an expanded consumer base. It has also found a significant role in the healthcare industry, particularly as a key ingredient in ointments used for treating skin conditions such as rashes and irritation.

Key Drivers of Zinc Oxide Market Adoption

Increased Demand for Sunscreens and Cosmetics As the global population becomes more aware of the adverse effects of sun exposure, zinc oxide-based sunscreens are becoming more mainstream. As a highly effective mineral sunscreen agent, zinc oxide provides broad-spectrum protection against UV rays. Consumers' desire for cleaner, safer, and more sustainable products fuels the growth of this segment, driving a steady increase in zinc oxide adoption in cosmetic products.

Rising Applications in Rubber and Tires The rubber industry has also been a major source of demand for zinc oxide. It is primarily used as a vulcanization activator in tire manufacturing, contributing to enhanced durability, improved performance, and longer service life of rubber goods. With increasing global vehicle production and growing demand for high-quality tires, the rubber industry remains one of the most consistent drivers of zinc oxide consumption.

Growing Adoption in Electronics The increasing use of zinc oxide in electronics and semiconductors, particularly in applications like varistors, photovoltaic devices, and LED technology, plays a pivotal role in its adoption. As technology continues to advance, the demand for ZnO-based products is surging, further pushing up the material’s usage rates in these cutting-edge sectors. Zinc oxide's role as a semiconductor material is expected to gain more prominence as green technologies and energy-efficient devices become mainstream.

Sustainability and Environmental Impact As environmental concerns become more prevalent in both consumer and industrial settings, the preference for non-toxic and eco-friendly materials is influencing the zinc oxide market. Manufacturers of environmentally-conscious products choose zinc oxide due to its relatively low environmental footprint compared to alternative materials. Zinc oxide’s non-toxic and biodegradable nature places it at the forefront of markets striving for eco-friendly alternatives.

Challenges in the Zinc Oxide Market

Despite the growing adoption of zinc oxide, several challenges hinder its widespread usage. One of the primary obstacles is the high cost of production, particularly when compared to other more widely available materials. This could limit its adoption rate in certain price-sensitive applications, especially in industries where cost-efficiency is a major consideration.

Furthermore, while zinc oxide’s benefits are considerable, its sourcing and production processes can sometimes involve environmental considerations related to mining practices and heavy energy requirements. Thus, industry players must balance the demand for sustainability with the necessity for cost-effective production processes.

Conclusion

In conclusion, zinc oxide adoption rates have been on the rise due to its diverse applications across various industries, from healthcare to electronics and sustainability-driven innovations. The material continues to be a critical component in emerging technologies, driven largely by evolving consumer preferences and industrial needs. As market awareness grows and more industries recognize the benefits of zinc oxide, its role across several sectors is expected to continue expanding. With a steady increase in consumer demand for natural and sustainable products, the zinc oxide market is set for substantial growth.

0 notes

Text

The #Global #Natural #Rubber #Market Size is expected to reach USD 25.2 #Billion by 2032, at a #CAGR of 4.3% during the #forecast #period 2022 to 2032.

Natural rubber is a naturally occurring, elastic hydrocarbon polymer obtained from the latex sap of trees belonging to the Hevea and Ficus genera. This latex is harvested from the tree trunks and processed into various forms, including vulcanized rubber, gum elastic, and caoutchouc. Natural rubber is widely used in manufacturing products such as automobile tires, toys, rug pads, surgical gloves, flotation devices, tubes, adhesives, roll coverings, hoses, and gaskets.

It offers several advantageous properties, including high resiliency, excellent vibration dampening, superior tensile strength, resistance to tearing and water, and the ability to stretch at low temperatures. Unlike synthetic rubber, natural rubber is free from petrochemicals, non-sticky, and environmentally friendly. Read More: https://www.sphericalinsights.com/reports/natural-rubber-market

0 notes

Text

On June 17th 1823 Charles Macintosh patented the waterproof cloth he was using to make raincoats.

While he was trying to find uses for the waste products of gasworks, Charle discovered that coal-tar naphtha dissolved india rubber. He took wool cloth and painted one side with the dissolved rubber preparation and placed another layer of wool cloth on top.

This created the first practical waterproof fabric, but the fabric was not perfect. It was easy to puncture when it was seamed, the natural oil in wool caused the rubber cement to deteriorate. In cold weather the fabric became stiffer and in hot weather the fabric became sticky. When vulcanized rubber was invented in 1839, Macintosh's fabrics improved since the new rubber could withstand temperature changes.

Of course just because you patent something it does not mean you actually were the first to invent it, controversy has followed the invention of the telephone since Alexander Graham Bell patented it, other inventions were questioned, the tyre, the television and the bicycle, all connected to Scotland and all have earlier versions that were thought of, or made beforehand, the “Mac” is no different.

James Syme, a surgeon and chemist based in Edinburgh, had discovered a derivative of coal tar (naphtha) could dissolve rubber and published his findings in Thomson's Annals of Philosophy five years before Macintosh came up with his idea.

It was the same process used by Macintosh following his own chemistry experiments with waste from Glasgow’s coal-gas works, and it has been claimed that the inventor had read Syme’s work before developing it for his own uses.

While Syme, uninterested in commercial matters, failed to patent his valuable discovery and continued to build a noteworthy career in surgery, Macintosh stamped his name on the idea in 1823, had Syme done so you might be calling the coats Symes.....it doesn’t have the same ring does it? Syme’s paper had not detailed the crucial sandwich-type construction employed by Macintosh, although this too was not completely new.

Spanish scientists previously used the method to make leak-proof containers for mercury, and renowned British balloonist Charles Green made a balloon envelope that applied the same principle in 1821.

French scientists also made balloons gas-tight and impermeable by impregnating fabric with rubber dissolved in turpentine and the use of rubber to waterproof fabric dates back to the Aztecs, who used natural latex.

But what made Macintosh’s invention revolutionary was its ease of manufacture and wear, seeing him swiftly launching into the production of cloth to be converted into coats and other garments by tailors in Glasgow.

Some of you might have picked up on the different spelling of the names in the first two paragraphs? Others will now be scrolling back to see what I mean! Well when As news of his invention spread, the repeated misspelling of the inventor’s name is thought to have popularised the description of the resulting coat as a “Mackintosh” – a name that has stuck to the present day.

Macintosh was elected as a fellow of the Royal Society for his contributions to chemistry and enjoyed considerable success before his death in 1843, aged 76.

First sold in 1824, his coat remains on the market in numerous forms across the world, it is now primarily a luxury brand still bearing its inventor’s name, even though it is spelled wrong!

6 notes

·

View notes

Text

A trip to the Rubber Museum,

A trip to the Rubber Museum,

Located in the heart of rubber production, the Rubber Museum offers a fascinating journey into the world of rubber and its significant impact on our daily lives. Whether you're an enthusiast of industrial history or simply curious about how a simple tree sap has shaped technology and commerce, a trip to the Rubber Museum is sure to leave you enlightened.

The Museum's Origins

The Rubber Museum was established to preserve the legacy of rubber, a material that has revolutionized industries across the globe. It was born out of a desire to honor the centuries-old traditions of rubber tapping and its vast influence on everything from medical devices to vehicle tires. The museum showcases the evolution of rubber from its natural form, tapped from rubber trees, to its modern-day uses in countless applications.

Exhibits and Collections

Visitors to the Rubber Museum will encounter a wide range of exhibits that span the history of rubber. The museum’s collections are divided into thematic sections, allowing guests to explore the history, science, and technology of rubber.

The History of Rubber: This exhibit traces the discovery and use of rubber, from indigenous cultures in the Amazon rainforest who first discovered its properties, to its spread across the world during the colonial period. Early rubber products, such as waterproof shoes and raincoats, are on display alongside artifacts illustrating the development of rubber into a global commodity.

Industrial Rubber Production: In this section, the museum delves into the evolution of rubber manufacturing. From the first rubber plantations to modern synthetic rubbers, the exhibit demonstrates how the production process has become more efficient and diverse. It also highlights key innovations such as vulcanization, a process that transformed rubber into a more durable material.

Rubber in Everyday Life: Perhaps the most striking section of the museum is its exploration of how rubber touches our everyday lives. It highlights rubber’s vital role in everything from tires and medical equipment to clothing and household items. Interactive displays allow visitors to engage with the many forms of rubber products, offering a hands-on experience with everything from latex balloons to high-tech rubber seals in machinery.

Rubber in Technology and Medicine: This area focuses on the critical role of rubber in technological advancements and medicine. It illustrates how rubber has enabled the development of crucial medical devices, from surgical gloves and catheters to prosthetics and vaccines.

Interactive Learning Experiences

One of the museum’s standout features is its commitment to interactive education. The Rubber Museum is designed to be engaging for visitors of all ages, with hands-on activities and educational programs. There are live demonstrations on how rubber is harvested from rubber trees, as well as interactive exhibits explaining the chemical properties of rubber and its many applications.

For those interested in a deeper understanding, the museum also offers workshops and lectures by industry experts who share insights into the future of rubber production, sustainable practices, and innovations in rubber technology.

The Importance of Preservation

The museum emphasizes the importance of preserving the rubber tree and its role in the global economy. With increasing concerns about deforestation and environmental sustainability, the museum educates visitors about efforts to protect rubber-producing regions and the need for eco-friendly practices in rubber production.

Planning Your Visit

The Rubber Museum is an ideal destination for families, students, and industry professionals. Whether you're looking for an educational outing or simply a fun way to learn about this indispensable material, the museum offers something for everyone. Conveniently located near major transportation routes, it is easily accessible and provides an enriching experience for visitors from around the world.

A visit to the Rubber Museum promises an eye-opening adventure into the fascinating history and future of one of the world’s most versatile materials. Whether you're exploring its origins in the Amazon or its latest technological breakthroughs, you'll leave with a greater appreciation for rubber's far-reaching impact.

4o mini

0 notes