#vertical foam cutting machines

Explore tagged Tumblr posts

Text

youtube

Cutting Precision | Discover ASE's Vertical Foam Cutting Machines

0 notes

Text

How to Choose the Best Foam Cutting Machine for Your Business in India

In today's era of sustainability and innovation, businesses across various industries in India are increasingly turning towards foam cutting machines to streamline their operations. Whether you're in the packaging, furniture manufacturing, or construction industry, investing in the right foam cutting machine can significantly enhance productivity and efficiency while reducing costs. However, with a plethora of options available in the market, choosing the best foam cutting machine for your business can be a daunting task. To help you navigate through this decision-making process, we've compiled a comprehensive guide outlining key factors to consider when selecting a foam cutting machine tailored to your specific business needs.

Understand Your Business Requirements: Before diving into the selection process, it's crucial to assess your business requirements thoroughly. Determine the type and volume of foam materials you'll be working with, the desired cutting precision, production capacity, and budget constraints. Understanding these factors will provide clarity on the type of foam cutting machine that best suits your business operations.

Types of Foam Cutting Machines: Foam cutting machines come in various types, each designed for specific cutting applications. The commonly used types include:

Hot Wire Foam Cutters: Ideal for cutting through expanded polystyrene (EPS) foam with precision and smooth edges. Suitable for intricate shapes and designs.

CNC Foam Cutting Machines: Computer Numerical Control (CNC) machines offer unparalleled precision and versatility in cutting foam materials. They are programmable and can produce complex shapes with high accuracy.

Vertical Foam Cutting Machines: Suited for cutting large foam blocks into sheets or custom sizes. They are efficient for bulk production and are commonly used in the furniture and mattress manufacturing industries.

Horizontal Foam Cutting Machines: Designed for cutting foam blocks horizontally into uniform sheets. They are suitable for applications requiring consistent thickness, such as packaging and insulation materials.

Cutting Capacity and Efficiency: Consider the cutting capacity and efficiency of the foam cutting machine in relation to your business requirements. Assess factors such as cutting speed, throughput, and the ability to handle different foam densities and thicknesses. Opt for a machine that offers optimal performance and can meet your production demands without compromising on quality.

Precision and Cutting Quality: The precision and cutting quality of the foam cutting machine are paramount, especially for industries requiring intricate designs or high-quality finished products. Look for machines equipped with advanced cutting technologies, such as servo motors and precision guides, to ensure accurate and consistent cuts.

Ease of Operation and Maintenance: Choose a foam cutting machine that is user-friendly and easy to operate, minimizing training time and operational complexities. Additionally, consider the maintenance requirements of the machine, including access to spare parts and technical support. A reliable after-sales service network is essential to ensure smooth operation and timely troubleshooting.

Safety Features: Prioritize safety features when selecting a foam cutting machine to protect your workers and maintain a safe working environment. Look for features such as emergency stop buttons, safety guards, and automatic shutdown mechanisms to mitigate the risk of accidents and injuries.

Cost and Return on Investment (ROI): While cost is a significant factor, it's essential to evaluate the overall return on investment (ROI) of the foam cutting machine. Consider factors such as long-term operational costs, energy efficiency, and potential savings in material wastage. Investing in a quality foam cutting machine may entail a higher initial cost but can yield substantial returns through improved productivity and product quality over time.

Reputation and Customer Reviews: Research the reputation of the foam cutting machine manufacturer or supplier in the industry. Look for reviews and testimonials from other businesses who have used their products. A reputable manufacturer with positive customer feedback is more likely to deliver reliable and high-quality machines that meet your expectations.

Customization and Additional Features: Evaluate whether the foam cutting machine offers customization options or additional features that align with your business requirements. Some machines may come with optional accessories or software upgrades that enhance functionality and expand cutting capabilities.

Future Expansion and Scalability: Anticipate your future business growth and consider whether the chosen foam cutting machine can accommodate expansion or scalability. Selecting a machine with modular design or upgradeable features allows you to adapt to changing market demands and increase production capacity as needed.

In conclusion, choosing the best foam cutting machine for your business in India requires careful consideration of various factors, including your specific requirements, cutting applications, efficiency, precision, safety, and overall cost-effectiveness. By thoroughly evaluating these factors and conducting thorough research, you can select a foam cutting machine that maximizes productivity, enhances product quality, and drives long-term success for your business.

#Foam Cutting#Foam Cutting Machines#Santech Foam Machines#Vertical Foam Cutting Machines#Horizontal Foam Cutting Machines#Best Foam Cutting Machines in India

0 notes

Text

Vertical Foam Cutting Machine

The JK-FC04 vertical foam cutting machine stands out for its remarkable efficiency in foam cutting operations, revolutionizing the workflow by eliminating the cumbersome task of removing foam slices from the working table after each cut. This fully automatic machine sets a new standard in foam processing, seamlessly combining cutting and stacking functions for polyurethane (PU) foam with unparalleled ease. Equipped with a conveyor surface, the JK-FC04 enables smooth lateral movement for the band knife, effortlessly slicing through materials with precision. Complementing its cutting prowess is a high-power suction system that firmly secures the foam in place, guaranteeing stability throughout the cutting process. Operators can expect a hassle-free experience and enhanced productivity, making the JK-FC04 an indispensable asset in foam manufacturing operations.

#cutting machine#foam cutting machine#foam cutter#vertical#vertical foam cutting#vertical foam cutting machine#vertical foam cutter#foam#foam block

0 notes

Text

Building Dango: Part 5

While that Thang was drying I wasn't idling around. I got the ears sized out and cut out a pattern for the foam. Theyre just about over a foot in length.

I also decided to tryyyy and do the paws. Now I considered drawing a turkey on a page (tracing my hand) and just doing that.

HOWEVER!

Dango's claws are quite specific. They have serrated ends and the cutline is vertical, as opposed to the horizontally cut palm. Which means this is going to cause problems for that pattern. Therefore, I decided to chance it and tape up my fuckin hand for the pattern.

Now here's something you may overlook with taping: it's accurate to the shape. So when you cut up your pattern how you want it, trace it onto your fabric, and sew it together. It is going to be. Tight. Because the pattern is MADE to be right up against your skin!

Now here's something you may not know about making gloves:

Gloves fucking suck.

This isn't my first time making gloves, you guys watched me struggle with the Kenku gloves too (it took 5 versions.) This time going into it I knew what was up.

First up: You can't use non-stretch fabric for gloves. Because your thumb is much thicker than your wrist, and that is the stress point for a glove. If it can't stretch out to let your thumb in, you're fucked.

For Dango, I don't need these to be tight. Actually I want them to be very easy to slip in and out of on the fly.

So moving forward the pattern will be adjusted at the thumb, the wrist, and the fingers, which are just too tight right now as well. Also I machine sewed the thumb and completely fucked up the placement lmfao.

The fabrics I will be using are: - Minky (top of palm) - Rabbit fur (palm + knuckles) - PVC vinyl (claws) - Lycra (inner lining)

The vinyl is 4 way stretch- I am not worried about the vinyl. I am worried about the minky and rabbit fur, which are non stretch. The lycra I have is 2 way stretch, which I'll have to chance my luck with.

*(If you don't know the difference between 2 way and 4 way stretch, it is basically if you grab your fabric on either side and stretch it. If it can stretch west and east but not north and south, that's 2 way. If it stretches every way, that's 4 way. If it doesn't stretch at all. Well. Call that one a stiffy.)

10 notes

·

View notes

Text

DIY Utility Bucket Ottoman

Project by Commonwealth Vintage Rentals and Revive Upholstery & Design:

I love a clever DIY project, especially when it uses an unexpected or overlooked material. This project uses a humble orange utility bucket as the base of an amazing upholstered ottoman. The product of a collaboration between Liz and Rachel of Commonwealth Vintage Rentals and Leland of Revive Upholstery & Design, this utility bucket ottoman was inspired by a trip to Home Depot. Looking for materials to build their own furniture, Liz and Rachel stumbled upon this bucket and explained that they were “hesitant and a little embarrassed to even think of using a plastic bucket,” but they were swayed by the (low) price and decided to pick up a few and team up with Leland to create something custom. Using Pendleton fabric, Leland upholstered the bucket (I never thought I’d write that sentence) and created a project that proves, without a doubt, that even the simplest and least expensive materials can be turned into something beautiful with a little hard work. Thanks so much to Liz, Rachel and Leland for sharing this how-to with us! xo, grace

Materials

yardage for fabric

chalk

scissors

spray Glue

stapler

5-gallon utility bucket

ruler

turkey carver

sewing machine

tape measurer

piping foot (The cord we used is 5/32 and is sold by the yard.)

foam (20′ square of 3” high-density foam and 60” x 1” of foam)

Dacron

square ruler

Instructions

1. Take off the bucket handle and measure the top of the bucket (38″) — the bucket tapers at the bottom, so you need to measure the top and bottom — measure the bottom (33”) and measure the height (17 1/2”). You can also wrap the foam around the bucket and cut accordingly.

2. Mark out the foam with your ruler. Draw out 38”, mark the middle of it and split from the center 33”. Measure 17 1/2” for the vertical foam with the height of the top layer of foam. Cut foam.

3. Spray glue on the bucket and foam, and wait a few seconds for the glue to set and get tacky.

4. Take the lid and trace the top of it onto 3” high-density foam. Spray glue the lid to the foam. Take your turkey carver and cut around the edges of the lid. Snap the lid back onto the bucket. Bring the 1” foam around the lip of the 3” foam.

5. Trim any extra pieces.

6. Take Dacron and spray it with glue to the top of the bucket. Cut off the remaining pieces. Continue to wrap and spray glue the bucket with Dacron. Trim the top but leave extra Dacron on the bottom for finishing.

7. Measure and draw out the longest side of your pattern and mark the center. Take your square and line it up with the edge of your fabric and the center mark. Draw out the height of your pattern on your square. (Note: It is always smart to add 1–2” of extra fabric to your height for fitting; it can always be trimmed down later.) Once the height has been drawn, use your square again to mark the length of the opposite side (remember your height line is at the center, so measure half the length on each side of your center mark). When the two lengths have been drawn out, use your ruler to connect the ends, giving you a nice straight taper.

8. Cut the piping fabric 1 1/2” wide and the same length as the top 46”. Cut the top piece in a 16” circle (allows seam allowance) either by tracing the top or using a string and pencil.

9. Fold the fabric in half and clip the middle top corner. Do the same with the circle piece.

10. Sew in the piping with welt foot. Extend the fabric a small amount past the piping. Sew a 1/2” from the needle. When you start to sew piping on the circular piece, start just in from the cut edge. Cut relief cuts around the perimeter so that the fabric doesn’t pucker when sewn into the side panel. Note: Sew fabric on the piping first, then line up the edge of the piping and the edge of the circle fabric and begin sewing. Make small relief cuts in your piping so it is easier to sew.

11. With side panel folded, sew from the top down with at least 2” at the bottom open, so that it fits over the top of the ottoman.

12. With the seam of the side panel laid flat and the seam of the top panel, start to sew the two pieces together.

13. Test-fit the fabric to make sure it fits smoothly over the ottoman. This requires a little finessing of the fabric to get a snug fit.

14. If fit is smooth, remove the fabric and cut the extra fabric around the edges so the end product has a flush, smooth surface.

15. Pull the fabric over the ottoman again. Rotate it, pulling downward on each side. After the fabric is smooth and in place, staple the fabric to the bottom of the bucket. Start stapling in sections around the circle and then go back and staple in between. If you just went fully around the first time, you would end up with extra fabric at the end and the pattern could be crooked.

16. Take a razor blade and cut off the extra fabric.

17. The last step is a dust cover for the bottom. Voila!

7 notes

·

View notes

Text

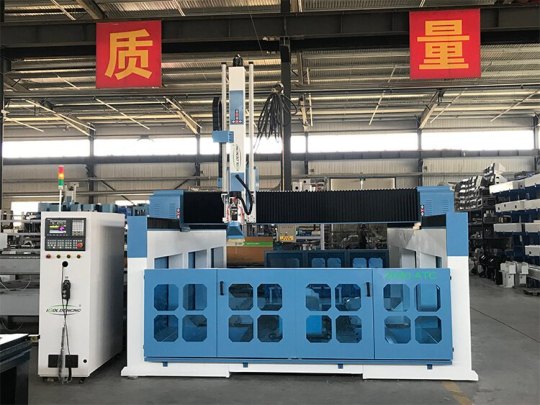

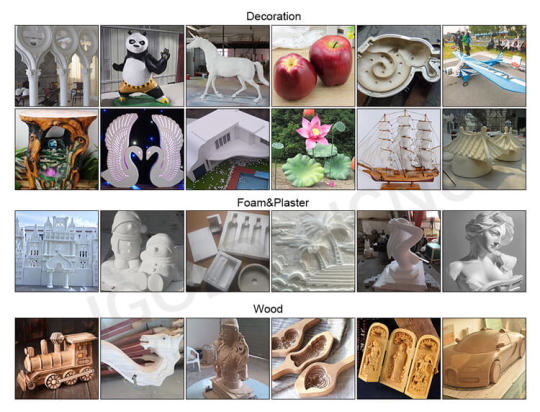

Automatic Tool Change Foam Router EPS CNC Carving Machine

CNC Router Foam Cutting Machine

Automatic Tool Change Foam Router, also known as an EPS CNC Carving Machine with Automatic Tool Change, is a specialized computer-controlled machine designed for cutting, carving, and shaping Expanded Polystyrene (EPS) foam materials. These machines are equipped with an automatic tool change system that allows for the seamless swapping of cutting tools during the CNC routing process.The 3d CNC router milling machine can be seamlessly spliced, suitable for various shapes.This CNC router foam machine also can be used in embossing, lettering, hollowing, cutting, vertical carving, round carving, etc.

This 4 axis cnc foam router is a little special when compared with the ordinary four axis machine. The conventional 4-axis construction has two types: one is that the spindle can swing ±90 degrees; the other refers to the rotary axis. Either of the two can be called the ordinary 4-axis cnc machine. What makes this machine special is that it is actually a 2 in 1 cnc foam router as it has the two types 4 axis construction stated above. Based on this design, there is no doubt that it has more possibilities than a normal 4-axis machine. The 4 axis cnc foam router here is perfect for 3D polystyrene shapes making.

4 Axis 3d CNC Router Milling Machine

EPS/foam CNC router usually comes with a big working dimension for carving and cutting large-size workpieces of wood, aluminum, and styrofoam. It can also be equipped with an ATC spindle and a rotary device for complex, heavy-duty, and long-term work. It is widely used to process and carve wood and styrofoam automotive, ship or other molds, and GRG or GRC decorations, and architecture models.

Automatic Tool Change Foam Routers are specifically designed to work with EPS foam materials. EPS foam is commonly used in various industries for insulation, packaging, and creative applications due to its lightweight and easy-to-cut properties.Like other CNC machines, EPS CNC carving machines with automatic tool change offer high precision and accuracy. The CNC technology ensures that complex designs, intricate patterns, and 3D shapes can be executed with precision.

Foam Router EPS CNC Carving Machine

Packaging: Creating custom foam inserts for protecting fragile items during shipping.

Sculpture and Art: Carving intricate sculptures and art pieces from EPS foam.

Architectural Design: Crafting decorative elements and architectural details.

Set Design: Producing props and scenery for theater, film, and events.

Sign Making: Crafting 3D signs, logos, and lettering.

This cnc router foam cutter is designed especially for custom EPS expanded polystyrene foam moldings. The molded foam is usually used for casting & founding. Three-axis construction with 1500x3000mm machining size (5×10 in English); (need 4th rotary? please check out foam milling machine with rotary axis) Dirt guard is designed on X Y Z axes particular for cnc foam machining, which keeps the precise transmission parts away from the machining debris. The table is made of aluminum profiles. It is ideal for EPS EVA foam machining as well as wood machining. CNC router foam cutter for custom EPS EVA molding for sale at a reasonable price now!

Application Scope

How Many Kinds of CNC Foam Router Are There?

Well, this need to see from which perspective. From a motion axis quantity perspective, there are 3 axis, 4 axis and 5 axis cnc foam router; from application point of view, there are cnc foam router for polystyrene, for woods and for aluminum.

0 notes

Text

From Kitchen to Bathroom: Understanding the Household Cleaners Market Landscape

Household Cleaners: Essential Products for a Clean Home They come in a wide variety of forms to fulfill different cleaning needs around the home. Whether it's all-purpose cleaners for general surfaces, bleach for disinfecting, or glass cleaners for shiny windows, there are effective product options available. All-Purpose Cleaners A staple in many households is the trusty all-purpose cleaner. These multi-use formulas can be applied to surfaces throughout the home like countertops, appliances, floors, and more. All-purpose cleaners are generally designed to cut through grease, food particles, and everyday dirt and grime. They often contain surfactants that allow the cleaner to cling to vertical surfaces for optimal cleaning results. When choosing an all-purpose cleaner, consider if you need one with disinfecting abilities or just basic cleaning power. Fragrance is also a personal preference. Specialty Cleaners While all-purpose cleaners can handle a variety of tasks, there are also focused cleaners formulated for specific applications. For example, glass cleaners contain strong streak-free formulas that dry clear, leaving windows and mirrors sparkling. Bathroom cleaners are typically more acidic to break down soap scum, hard water stains, and mildew. Appliance cleaners are gentle enough for sensitive surfaces like refrigerator doors yet effective on food spills. Other specialty cleaners target jobs like cleaning wooden furniture, removing stains, disinfecting surfaces, cleaning grout, stripping floors, and more. Greener Cleaning Products In recent years, many household manufacturers have responded to consumer demand for eco-friendly alternatives. Multiple "green" cleaner lines now exist made of plant-based, biodegradable, and non-toxic ingredients. These safer options may contain ingredients like citrus, vinegar, baking soda, essential oils, and natural surfactants. Common green products include multipurpose cleaners, dishwasher detergents, laundry detergents, and personal care items like hand soaps. Look for third party certifications on green cleaners guaranteeing their sustainability claims. While these earth-friendlier products perform well, some users report they may not clean as heavily soiled surfaces as aggressively as conventional cleaners. However, they provide a healthier choice for families focused on reducing toxic chemical exposure. Proper Use and Storage of Cleaners To get the best results from household cleaners and protect family health, it's important to follow some basic safety guidelines. Only use cleaners as directed on product labels, which recommend specific quantities, test areas, protective equipment if needed, ventilation during use, and more. Never mix cleaners together as dangerous chemical reactions could occur. Store all cleaners, especially those under sink and ones containing bleach, out of reach of children and pets in their original containers. Be sure to replace caps tightly after use. Dispose of cleaning wipes in the trash instead of flushing. Proper use and storage helps cleaners last longer and perform as intended without posing safety risks. Soft Surfaces and Upholstery Cleaning Keeping soft surfaces like upholstery, carpet, and curtains looking fresh requires dedicated cleaners. For routine maintenance between deep cleanings, use an upholstery spray or foam to quickly lift dirt, dust, and stains. Look for plant-based or enzyme-based formulas that are colorfast and won't saturate fabrics. For more stubborn issues or a deeper clean, rent or purchase an upholstery cleaner for professionally cleaning furniture and flooring. These machines use hot water extraction to thoroughly rinse away embedded grime. Test cleaning solutions in hidden areas first to avoid damaging delicate fibers or intricate patterns on furnishings. Let all fabrics dry completely before use to prevent mold growth. Periodically cover furniture to protect against accumulations of airborne dirt and allergens too.

0 notes

Text

CNC Router Machine

What is the CNC Router Machine?

A CNC router (Computer Numerical Control router) is a computer-controlled cutting machine used for cutting various materials, such as wood, plastics, composites, foam, and non-ferrous metals.

Key components of a CNC router machine include:

Controller: The CNC router is controlled by a computer that interprets the design file and generates the toolpaths. The controller translates these toolpaths into specific movements for the machine.

Motors: Motors drive the movement of the router along the X, Y, and Z axes. They precisely control the position and speed of the cutting tool.

Cutting Bed: The cutting bed is the surface on which the material being cut is placed. It is usually a flat table, and the material is secured to it during the cutting process.

Spindle or Router: The spindle or router is the cutting tool that spins at high speeds. It can be equipped with various types of cutting tools, such as end mills, to perform different cutting operations.

Guideways/Rails: These are the linear guides that allow smooth and precise movement of the router along the X, Y, and Z axes

Specification of CNC Router Machine:

A CNC router machines are widely used in industries such as woodworking, sign making, prototyping, and manufacturing. They offer several advantages, including high precision, repeatability, and the ability to produce complex shapes with accuracy. Additionally, CNC routers are known for their efficiency in mass production and the ability to automate the cutting process, reducing human error and increasing productivity.

A CNC router machine with the size specification "2000 x 2500 x 450 mm" can cut or carve materials within a rectangular workspace with a length of 2000 mm, a width of 2500 mm, and a depth of 450 mm. These specifications are crucial for determining the size and scale of projects that the CNC router can handle.

Let's break down what each dimension represents:

2000 mm (X-axis): This is the maximum distance the CNC router can travel along the horizontal axis (from left to right).

2500 mm (Y-axis): This is the maximum distance the CNC router can travel along the vertical axis (from front to back).

450 mm (Z-axis): This is the maximum distance the CNC router can travel along the vertical axis (up and down), representing the depth of the cutting or milling capacity.

Jalpadevi Engineering Private Limited (JDEPL) Specifications:

Jalpadevi Engineering Private Limited (JDEPL) stands at the forefront of engineering excellence with a robust set of specifications that underscore its commitment to innovation and precision.

The company boasts proficiency in CNC programming, utilizing Autodesk PowerMill software tailored for CNC router machine, guaranteeing efficiency and accuracy in manufacturing operations.

What Jalpa Devi engineering pvtltd offers?

At the core of JDEPL's capabilities is its well-equipped in-house pattern manufacturing facility, featuring a CNC router machine with a substantial capacity of 2000 x 2500 x 450 mm. This facility specializes in the production of diverse patterns, including wooden, metallic, and shell patterns, tailored to meet the unique requirements of a broad spectrum of engineering projects.

0 notes

Text

During the mid semester break, my partner and I met up at the workshop to work on the physical elements of our assignment. She would start working on our aluminium bird, while I started making a foam bird. It was at this point that we discussed incorporating a 3D element, specifically in the wings. We thought the foam bird would be a good place to start, so what I did was cut out templates of the wings from the base bird. Then I just scaled them down twice. I'll be honest, I don't remember what the machine I used was called, but I was able to cut out the shape of the foam bird with heat from this little blade-thing.

The result turned out pretty well - albeit a little wonky because of how unfamiliar I was with working the machinery (and the material, honestly). I don't have the steadiest of hands, so in some spots where I went slow or even stopped for a moment, my hands shook and I ruined the outline a bit. But it didn't really matter in the end, because my partner and I both agreed that it worked for the purpose we needed it for - and it was a module, not an actual artwork. The wings haven't been put on as of the time of writing this post, however, my partner and I were discussing how they would be attached. A couple of things that were suggested were, PVA glue, hot glue (on a low setting of course) or toothpicks. My partner was going to come back into the workshop soon, and so we both agreed to leave it to her to experiment with.

My project partner later in this week had then turned both the foam bird and the wooden bird into 3D models. For the wooden bird, she also carved out the wings and tail. She explained to me that we could add dirt and plants, adding another element to the project that she had an idea for in the beginning.

Dale Rodgers is an award winning metal sculptor and artist, and he created these pieces called the Flight collection. They're a series of metal birds suspended in vertical rectangle frames. They're supposed to mimic migrating birds, and the Madison Area Arts Alliance said they're there to 'nest' for the exhibition they were featured in, before migrating elsewhere. Rodgers himself calls them "gulls", and says they're a travelling exhibition, adding to the 'migrating birds' feel of them.

I love the fact that you can stand under these birds and have the feeling of watching them soar past you overhead. It gives them a sense of life, despite their mostly 2D nature. In which I mean that standing under them makes them seem 2D, while stepping back and really taking in the detail makes them 3D. This shift, both in perspective and dimension, is what makes this piece really interesting to me. While I don't really have the materials and time to make something of this scale, I think this aspect would have been incredibly interesting to explore.

Located in Fort Worth, Texas, this scissor-tailer flycatcher bird was created by studioOutside and is located in Bluestem Park in Alliance Town Centre. The large sculpture acts as a playground, able to be climbed on and played with, as seen in the above picture.

I really love the semi-realistic elements of the composition of the bird. The interactive elements are what I'm drawn to the most and I find the abstract nature awesome. Similar to what I discussed in my last post with Fiona Foley's work, the sculpture invites the audience, though mainly kids, to interact with it and encourages imaginative play. I really like this more childish rendition of the contemporary sculpture. I think that creating something in this style would be fun. While my own is, again, vastly different in visual terms, we come back to the similarities with the context behind it. The wish that the general public interact with it and invite some elements onf imaginative play.

0 notes

Text

Installation of a drain pipe for a washing machine and dryer

The drain pipe that you install for your washing machine and dryer is, of course, only to supply the washing machine. The dryer is not connected to the plumbing because it does not use water. However, it does need a vent, and that is just as important as the drain for your washing machine. The washing machine drain is part of the plumbing system, and you must follow the plumbing codes when installing it.

Washing machine drain

Find a drain pipe to which you can connect the washing machine drain. A nearby sink, bathtub, shower or toilet drain is suitable. You may need to remove some wall paneling to access the pipe.

Cut the pipe with a hacksaw and install an elbow or plumbing tee, depending on the orientation of the pipe. Glue the fitting to the drain pipe with plastic pipe cement. Make sure the fitting has a 5 cm outlet pointing toward the washing machine.

Install a 5 cm ABS pipe on the wall behind the washing machine. At a distance of about one meter from the washing machine, install a 5 cm sanitary tee with its outlet pointing upwards. This tee is for the vent pipe.

Install the pipe about 5 cm from the wall and 90 to 105 cm above the floor. Glue on an ABS siphon. Glue a 25 cm long pipe to the siphon inlet. Connect the washing machine's drain hose to this vertical piece of pipe, which is called a standpipe.

Run the vent up from the plumbing tee you glued into the drain line. Connect it to the main vent duct in the attic.

Venting the dryer

Using a drill and hole saw, cut a hole in the trim large enough to accommodate a vent cap. Screw the cap to the siding and insulate the opening with sealant or foam insulation.

Connect a rigid galvanized steel vent pipe to the dryer exhaust outlet. Secure it with a pipe clamp. Route the pipe to the cap you placed on the siding. Cut the pipe with a hacksaw if necessary. Connect the pipes with tape on the back of the liner.

Hang the vent pipe from ceiling joists with pipe straps if you need to run it through a crawl space. Keep a distance of 30 cm from the floor and 30 cm from obstacles.

Call the Emergency Plumber in Southend-on-Sea. We are 24 hours available. Call us whenever you want, 01702668129.

0 notes

Text

Precision Vertical Saw Machine for Block Trimming

Flexible polyurethane foam serves as a versatile cushioning material, indispensable in various applications such as mattresses, furniture, automotive interiors, packaging, and carpet underlays. To shape this foam effectively, the right equipment is paramount.

With over 30 years of experience in the PU foam industry, ASE stands as a premier manufacturer of PU foam cutting equipment, offering comprehensive solutions for your cutting tool needs.

Our vertical foam cutting machines provide a reliable and adaptable method for precision foam cutting, ideal for transforming large foam blocks into precise shapes, slices, or blocks. These machines come in various models, guaranteeing cutting accuracy within +/-2 mm.

When it comes to vertical foam cutting, we cater to both large-scale and small-scale operations. Large-scale applications involve slab stock cutting, with one type of machine featuring a floor-to-ceiling blade for transverse cuts, and the other featuring a horizontal blade for longitudinal cuts.

In small-scale scenarios, our vertical cutting machines can be converted into angle-cutting devices, allowing for angular cuts, be it triangles, trapezoids, or other shapes. With ASE's expertise and equipment, you have the perfect solution for all your PU foam cutting requirements.

Know More....

0 notes

Text

Discover top-quality foam cutting machines in India, tailored to meet your manufacturing needs. From precision cutting to intricate designs, find the perfect machine to streamline your production process. Explore reliable options and enhance efficiency in foam fabrication today. To know more in details, visit our website today: https://santechfoammachines.com

#vertical cutting machine#horizontal foam cutting machine#foam cutting machine manufacturers and suppliers#circular cutting machine#foam cutting machine in india#foam cutting machine#edge cutting machine#Carousel Cutting Machine#Rotary Foam Cutting Machine#Horizontal Cutting Machine

0 notes

Video

PE/EVA Foam Cutting Machine,Slitting Machine,Bandsaw,EPE Foam Auto. Vertical Cutter(Custom Design)

EVA/EPE Foam Vertical Cutting Machine can clamp, cut, and feed planks. This is ideal t cut PE, EPE, PP, PU, XLPE etc. foam materials. It's designed to increase the production rates and provide operator safety.

#eva foam cutting machine#eva cutter#pe foam cutter#foam slitting machine#epe foam vertical cutting#veinas machine#zhuhai huasu#guangdong huasu

1 note

·

View note

Note

Are you taking prompts with the Florence + The Machine prompt list? ;v; If yes, can I request "She’s just like the weather, can’t hold her together" for Hawke x Isabela? Thank you!

This made me so happy and was such a gorgeous prompt for them, I really really hope you like it!

(If you’d like me to write you a dragon age fic, send me a prompt from here!)

@dadrunkwriting

Pairing: F!HawkeBela

Characters: Marian Hawke, Isabela

Tags: brief reference to infanticide and making children tranquil, fuck the chantry, mage hawke, hurt/comfort, established relationship, I just really like writing boats in storms, do you like character’s eyes glowing whilst they lose control of their powers because they’re overwhelmed by emotion and Only Their Loved One can get through to them?, this fic is for you

Rating: Mature

Isabela had joked once to her first mate that if she ever fell in love with anyone it would be with a strong gale blowing in a south-westerly direction. She had never thought she would mean it literally. But now, struggling to stand on her ship as it kicks and bucks harder than any deep road Bronto, boots slipping against the deck wet with lashing rain, Isabela can’t even find the good sense to regret it. Around them, waves roar as living mountains, crashing down in blue-grey cliffs of granite that howl as they fall and send The Harpy tossing on the water like an unhappy Orlesian princess on a mattress full of peas.

Isabela ignores this, and the shouts of her crew as they swing over the side of the deck, barely held onto the ship in the storm by the lifelines they’ve tethered to the mast. Templar bodies go swinging over the sides of the boat like shooting stars or diving bells, crushing what crew Isabela has left against the rigging before flying off into the night like so much crumpled silver ribbon. Isabela opens her mouth, trying to shout over the storm. “HAWKE!”

Hawke doesn’t respond. Her always-blue eyes are blinding now, washed bright with light and magic. Her body is crackling with electricity and the tempest spirals around her, exploding outward in a strange suspension of rain and wind before crescendoing into the maelstrom above them. Around her feet are three dead bodies in apprentice robes. The oldest cannot be fourteen. Their bodies are still on the one patch of dry deck left on the ship.

A wave slams into the Harpy will all the force of an avalanche, and Isabela’s feet go flying, sending her tumbling into the wheelhouse hard enough to bend her ribs close to breaking. She swears, and slips a dagger from her belt, cloth-wrapped hilt damp as bloody bandages. “Sorry, pet.” She mutters to the deck as it rises to meet her almost vertically, like a cliff face, and the Harpy’s keel tries desperately to keep her anchored in the water against the force of the shoving waves like a bird tugged off its perch by a particularly strong wind. With a wordless shout of effort, Isabela slams her dagger into the deck, and uses it to help her start scaling her ship as she moves back toward her lover. Hawke herself is blind and raging, lost to her magic, the dead apprentices and their injured bodies as still around her as lambs in a dream.

Thunder cracks the sky open and lets lightning through, and where it spears into the ocean the water flashes from ink black to teal, illuminating like a witch’s cauldron and skittering with sparks that dance over the frothing waves. Isabela thinks she can hear someone screaming. Cannons come rolling toward her with a sound like groaning millstones, and Isabela kicks away from the deck in time to swing her body over the iron, cursing as she watches them hit and splinter the far railing before sinking into the belly of the sea.

Water is running down Isabela’s back and chest, icy fingers digging into every wrinkle and crease of her body that she’d almost forgotten she had. Her hair is heavy and damp as wet kelp on her shoulders, and her knuckles are aching. The Harpy crashes back down into the waves with an explosion of white foam like shattered glass, and above them the mainsail swells with the wind, wrenching the Harpy forward and up the next blue mountain of water that dwarfs her the way a giant would a child. Isabela gets onto her feet and sprints, chest aching with the effort.

Hawke is surrounded by a vortex of magic, and as Isabela breaks through it the lightning skitters across her arms, singeing her clothes and hair. She pushes through, fighting the water and the howling gale until, abruptly, she is in the eye of the storm. It’s silent.

Isabela stumbles to a stop and hesitates, transfixed as she stares at her lover, black hair lifting on a wind Isabela cannot feel here, so close to the centre of the tempest. Light jumps across her skin and down her body. Her clothes are dry but there is water on her nose and cheeks and chin. She is frozen like some strange Tevene statue, reduced to nothing but spitting magic. Around them on the deck, which is pale as sand next to the rain-dark wood beyond them, the apprentices lie as quiet as the sleeping children they should have been. Their hair is shaved roughly, and their foreheads are blistered with burns. Their bodies are littered with bruises.

Isabela holds her breath as she steps over them, and lifts a hand over Marian’s cheek. When she speaks, it’s in a whisper. “Hawke.”

Marian doesn’t move. Isabela catches her breath, and looks up at the whirling vortex of black clouds above them. She clenches her teeth, and touches her lover’s skin. The effect is like getting hit by lightning, a burning punch up the inside of her arm that she can feel in her bones. Isabela grits her teeth, and brings her other hand up to clasp Marian’s face in her hands, pressing forward to push their foreheads together as she kisses her cold, still lips.

Ignoring the pain of the magic racing through her skin, Isabela steps closer, winding her arms around Marian’s chest and pressing her face into her shoulder. The ship and the storm and her screaming crew may as well have been an ocean away. Here it is dry, and quiet, and still.

Isabela holds Hawke as tightly as she can, and shuts her eyes. “It’s alright. I’m here. I’m so sorry, love. I’m so sorry. I’m here.”

Isabela doesn’t know when the storm stops, or how they make it out alive. She keeps her eyes shut, and her arms around the stiff, tense line of Marian’s chest until her lover slumps like a puppet with its strings cut, and collapses around her, weeping. Isabela doesn’t move away, she just holds her tighter, running her hand through the unruly mess of Marian’s black hair as she presses kisses to every part of her she can reach. “It’s alright. It’s alright, I’m here.”

Eventually, Marian’s weight is too much for Isabela to hold standing, but she still doesn’t pull away. Instead she folds, taking Marian with her. The crew don’t come closer, and their voices are quiet - though whether that’s only the echo of the storm in her ears Isabela doesn’t know. She waits until Marian opens her eyes to look up at her, once again fully human, face red with sunburn and wet with tears. She says, “I didn’t, I’m sorry, I -”

Isabela says nothing. She just presses her closer, and rubs slow circles in her back, hushing her. Marian weeps until she cannot cry any more, and then lies there, quiet and shivering, face hidden in Isabela’s shoulder. Isabela holds her with shaking arms, and kisses her again and again. Around them, the ocean sways and kicks gently under a suddenly clear sky. Marian sniffs, and wipes her nose with the back of her hand. “Sorry, again, Guessing this really wasn’t what you signed up for, was it?”

Isabela purses her lips, and catches her face in her hands, forcing her to meet her eyes. “I always know exactly what I’m getting myself into, harpy.” Marian’s mouth twitches in the direction of a smile, and Isabela leans forward and kisses her, deeply, despite the snot and tears and ozone sting of magic on her tongue.

Marian pays for the cannons, later. But first, they give the children a proper burial. Afterwards, they share a drink on deck together, sweating and dusty from the beginning of extensive repairs. The crew give Marian a wide berth. She drinks deeply from her cup, and looks at the horizon when she says, “it’s bad luck, you know.” She cuts a glance at Isabela, eyes blue as magic in the twilight. “Mages, on ships.”

Isabela shrugs, and steps closer, resting her hand over Marian’s on the railing and winding their fingers together, tightly. “Bad luck for templars, maybe. But something tells me we’re going to be just fine.” The corner of Marian’s eyes tighten, and she looks away from her, toward the leaping horizon.

“You have a lot of faith in me.” The words are pulled thin, like too little thread across an open wound. Isabela squeezes her hand against the still damp railing of her ship. The sea breeze pulls her salt-thick hair whipping against her cheeks and chest. She’s looking at the sunset when she replies, gazing at where the sun burns the sky as it dips into the sea.

“I know. But I have to have faith in something.”

24 notes

·

View notes

Text

What happens when... I get an MRI?

MRI stands for magnetic resonance imaging. It’s a scan that creates very detailed images of the inside of your body, so it’s used for just about any scenario where the doctors want to know what’s going on without cutting you open. I’ve had MRIs done while I was in the emergency room or admitted to the hospital, but also as an outpatient visitor to a hospital or orthopedics clinic- it depends why you’re getting it. So, let’s get into what this actually is!

You might recognize this scan as the one that’s bad if you’re claustrophobic at all. I’m not going to lie, there are some MRI machines that are pretty tight. If you google “MRI machine”, most of the pictures are a version of the standard kind so you can see the variety, but I’ll put a picture and image description below too:

[image description: A white, standard MRI machine in a room with windows. The machine is a large, thick tube with a hole in the middle that is about two feet (60 cm) wide and long enough for an adult to lie in. There is a long, narrow table that extends from about 7 feet (213 cm) out of the machine and all the way through it. A person is lying on the table inside the machine. End image description]

So your average MRI machine is like the one above and has about a 2 foot (60 cm) diameter opening (also called the bore). There are lights inside though, and many of them are open on both ends, so that helps. If that’s too small for you, they also make wide bore machines, which are just like the one above except with an extra 4 inches (10 cm) of space. I’ve also seen machines that look like these, except they’re more of a ring than a long tube. The best kind (in my highly professional opinion, I’ve had 7 MRI’s, okay?) is an open MRI. There are a lot of variations on this one, but generally there’s a big piece over you and a big piece below you, but the sides are open. I’ll put a picture and image description of one kind below:

[Image description: White MRI machine with a big platform that a person is lying on, and another big piece of plastic directly over the person’s torso. There is about 2 feet (60 cm) of vertical space between the pieces. End image description.]

If you’re at all nervous, it’s definitely worth asking the doctor who ordered the MRI if you can get it done somewhere that has a more open MRI machine. Or even somewhere with windows in the room, that made me feel better.

If these pictures are making you super nervous already- take a couple deep breaths. You’re going to be okay. Every form I’ve ever filled out for an MRI asked if I am claustrophobic, and gave the option for an anti-anxiety medication to be prescribed to take before the scan. The MRI techs also do this all day every day and have probably seen it all. They understand that people might be scared and can help you along the way too.

Because an MRI uses giant magnets to take the pictures, nothing made of potentially magnetic metal can be in the room with the scanner. Anything you bring with you will go safely into a locked space while you’re getting scanned. In my experience, if you’re careful about getting dressed that morning and don’t have any metal, they’ll let you wear your own clothes minus shoes. This means check for zippers, buttons, rivets, rings around drawstrings, metal caps on drawstrings, snaps, bra fasteners, adjustable strap sliders, glitter fabric, studs, belt buckles, jewelry, piercings, or glasses. If you show up with metal in your clothes, you’ll probably be given scrubs or a gown to change into instead. Although the facility might also have a standard procedure of making everyone change, so I make no promises. If you have metal somewhere that is part of you and can’t be taken off, that will get flagged on the pre-MRI paperwork, and your doctor will help you decide what to do.

Once you’re metal free, you get positioned on the table that goes into the MRI machine. This is to make you comfortable, but also to make sure the body part getting scanned holds still, or else it will be blurry and you’ll have to do part of the scan again. Body part getting scanned gets held still with some combination of pillows, foam wedges, and/or plastic frames. For example, when I got my foot scanned, they had a plastic u-shape that my foot went in, surrounded by little pillows. When I got my neck scanned, a special plastic frame went over my neck- although it wasn’t even close to actually touching me and was more to align the camera.

Speaking of aligning the camera- if you have a very specific spot that needs to be looked at, you might get a vitamin E pill taped to it! This shows up as a bright spot on the MRI results so they know where to look. If you need an overall more detailed picture, you’ll be given contrast. This means you get an IV placed, and they inject a dye into you. That happens either right before you go in, or they’ll slide you out mid-MRI to do it. It feels weird and cold, but it’s pretty safe.

I’ve always been offered earplugs and/or headphones, and they let me pick what music I want to listen to during the scan, so that’s fun! You’ll also get a button that goes in with you that you can press if you want to stop for any reason, and the tech will come get you right away. Once you’re all lined up, you get slowly slid into position, and the tech will check in with you the whole time to make sure you’re doing okay. To get the right body part in the middle of the machine, it’s always farther in than I expect to go- just so you’re not as surprised as I was!

The MRI itself will take somewhere between 15 minutes to an hour and a half. (I like to play the alphabet categories game in my head to pass the time, or you could even take a nap! Also pro tip- pee before your scan). It consists of a series of pictures, and the techs can explain to you how long each picture and the overall scan will take. During the pictures, the MRI machine is LOUD. It makes these rhythmic banging, clunking, clicking, humming noises and sounds a little like it’s falling apart, but it’s normal. In between pictures, you’ll stay in the machine but probably be allowed to wiggle a little bit. The headphones they give you also connect to the tech, so they talk to you to check in between pictures, and you can talk to them as well. It also tends to get pretty warm inside the machine, so maybe don’t wear a sweatshirt. But by all means press the button if you’re too hot or feeling icky!

Once you’re done, you get slid back out and sit up slowly in case you get dizzy from lying down so long. But then you’re all done and just have to wait for results! Fingers crossed that they show whatever is most helpful for you 🤞🏻

Source for the precise numbers: https://info.blockimaging.com/bid/102182/closed-bore-mri-vs-open-mri-vs-wide-bore-mri

Source for picture 1: https://www.itnonline.com/content/mri-scan-used-heart-disease-could-also-pick-out-aggressive-cancers

Source for picture 2: https://www.tampabay.com/news/health/medicine/more-soothing-mri-option-is-a-tradeoff/1274118/

8 notes

·

View notes

Text

Water Heater

If you are expecting to buy a Geyser or Water hotter to overcome the cool this colder season, you are in the advantage place.In the colder season, It is unfathomably trying in tidying up with the crisp water.Also, we feel apathetic to scour when the water is cold. Essentially present a Geyser or a water radiator in your home and capitalize on your shower.

1. Bajaj New Shakti Storage 15-Liter Vertical Water Heater'

Bajaj New Shakti amassing water warmers are open with different cutoff points going from 10L to 25L. This model goes with a limit breaking point of 15 liters and is thoroughly fitting for high rise buildings.As you have high rise lofts mushrooming all over , the interest for water radiators fit for withstanding 8-bar pressure. This Bajaj New Shakti amassing 15L water radiator is unquestionably proper for lofts masterminded in the most elevated levels of high rise buildings.This water hotter features Titanium Armor development, an uncommon internal tank covering for thwarting utilization and rusting, thusly achieving a comprehensive tank life. The invigorating piece of this hotter is the rust-confirmation outside body made of a single weld sheet metal.Water radiators consume a huge load of force. Regardless, this Bajaj New Shakti 15L vertical water radiator is an energy-successful one, fit for fulfilling your step by step necessities of hot water.Improper use of water warmers can cause awful setbacks. This Bajaj water hotter goes with an alternate prosperity system for protection against issues like dry warming, overheating, and overpressure. This water hotter features imaginative development, spin stream advancement to ensure 20% speedier warming of water, subsequently saving energy.Some of the other empowering features are powder-shrouded metal body, adaptable indoor controller, and magnesium anode for additional confirmation from disintegration and spillage. The exceptional temperature pointer dial is a useful segment.

2. AO Smith SDS-Green Series 015, Storage 15L Vertical Water Heater

AO Smith is a top-quality worldwide water radiator maker. This model, SDS-Green Series, is available in two sizes, 15L and 25L. A 4-star 25L model is similarly open in this series.When it comes to saving force, AO Smith water radiators are at the most elevated purpose of the heap. This SDS-Green game plan 015 water radiator is the most energy-beneficial of the part. Other than giving you the benefit of low force charges, this spring goes with incredible features. he strong generous check mixture steel tank is 25% more grounded than copper or standard treated steel tanks. The Blue Diamond glass-lining advancement makes the tank disintegration safe, thusly extending the tank's lifespan.The glass-covered cover back warming segment fits perfectly into the tank and ensures uniform warming to ensure consistent availability of hot water.The inventive PUF Injection development ensures uniform and high-thickness foam scattering. The nonappearance of openings between the tank and security gives most extraordinary adequacy and power savings.This water hotter goes with a gainful bay water diffuser to break the moving toward water fly into little streams adjusting the water stream course from vertical to the in any event, heading. The changed grant anode bar works in different water conditions, thusly, protecting the tank and warming segment from disintegration. This wellspring incorporates an indoor controller to help set bubbling water temperature. It moreover makes the warming part non-operational after the water achieves the set temperature.

3. Crompton Amica ASWH-2015 15-Liter Storage Water Heater

Little families will find this 15-liter water radiator sufficient for their necessities. Regardless, this machine comes in different cutoff points like 10L and 25L. Dependent upon the family size, you can pick your Compton Amica accumulating water heater.With a Crompton Amica, you can restore yourself reliably with high temp water. This spring features an earth shattering warming segment worked in extraordinary material that grants it to warm the water snappier than various machines in its esteeming range.This water hotter can withstand 8-bar pressure, thusly showing proper for raised designs. The high-precision indoor controller, reset handle, and warm cut-off features ensure a huge degree of prosperity as it shields this water radiator from power cuts and voltage fluctuations.he metallic body of this wellspring is powder-concealed to keep its strength and keep it functional after a long time of utilization. This water hotter is open in three sizes, 10L, 15L, and 25L to give a steady supply of bubbling water at whatever point of the day.This water radiator incorporates incredible assurance as Insitu-PUF to enable successful warmth support and thusly, decline your force bills. The sharp arrangement of this spring featurin a reinforcement cut-off base of activity exhibits supportive by eating up less power and perform gainfully without choosing quality.This energy-capable water hotter has a 5-star BEE energy rating that underscores its energy-saving attributes. From now on, this Crompton Amica water radiator positions as a champion among other water warmers open.

4. Crompton Arno Neo ASWH-3015 15L 5-star rate amassing water radiator

Crompton is a supposed maker of water warmers. Here is another model that is available in various cutoff points going from 6L to 25L. This 15L breaking point Crompton Arno Neo water radiator has a 5-star energy rating to qualify as an energy-viable appliance.You can for the most part accept a Crompton water hotter torovide your family with their warmed water requirements. Other than giving enough bubbling water, this specific Crompton model is potentially the most energy-profitable springs on the market.hese amassing tank-type water radiators are standard since they can store satisfactory water for use at a later stage. Such water radiators incorporate awesome assurance as PUF to keep the inside water warm for extended periods.The most amazing aspect of the Crompton water hotter is the presence of indoor controller to control the water temperature. It doesn't allow the water to warm over the set temperature by killing the power supply. Thus, it is an extraordinary security measure.The Crompton water radiator incorporates a nano polymer-covered water tank to give better warming efficiency.Generally, water radiators don't work commendably with hard water because of the improvement of a salt film over the warming part. This Crompton Arno Neo wellspring is unmistakable in light of the fact that it is suitable with hard water. In like manner, it is a well known machine in more humble towns in .These water warmers are available on the web and at the near to display areas, as well.

5. Crompton Solarium Qube 15L, 2KW, 5-star evaluated Storage water hotter

This energy-profitable water hotter from Crompton is open in various cutoff points, 15L, and 25L. The model being discussed is a 15L water radiator, undeniably fitting for little families.Crompton Solarium Qube accumulating water warmers are well known for their supervisor presentations, high energy-capability, and go with stimulating features like a splendid LED indicator.These machines incorporate a dominating 1200gm copper warming part for speedier warming. This segment can warm the water to 45 degrees inside ten minutes.Though water radiators are power-chugging contraptions, this Crompton Solarium Qube storing water hotter has a 5-star rating recommending that it is an energy-saving device. The splendid arrangement goes with a reinforcement cut-off component that diminishes power use considerably.Catering to people living in tall designs is an essential issue for basically all water radiators. This water radiator is a splendid contraption since it can withstand water at phenomenal pressure.This Solarium Qube water hotter comes outfitted with Advanced 3-level security features. The pervasive indoor controller and cut-off instruments oversee water temperature and swear off overheating by killing the warming segment as the water goes to the ideal temperature.Another empowering component of the Crompton Solarium Qube is its strong body that offers high warmth resistance considering its extreme exterior. The pervasive polymer covering keeps the tank from utilization and rusting, in this way expanding its as a rule lifespan.The sharp LED pointer is an imaginative game-plan that shows warming levels. The know grants you to change the temperature levels some place in the scope of 25 and 75 degrees Celsius.

1 note

·

View note