#ultrasonic level

Explore tagged Tumblr posts

Text

youtube

Liquid Level Indicator Using ULN2003

A water level indicator detects and indicates the level of water in an overhead tank and relays the information back to a control panel to indicate whether the tank has a high or low water level. In this tutorial, I am going to use the ULN2003 IC to create a simple, inexpensive water level indicator. Using this circuit you can easily control the wastage of water and electricity. Watch this video, for detailed step by step instructions on how to build this circuit and to know how this circuit works. Towards the end of the video I will also discuss whether its really worth building this circuit.

3 notes

·

View notes

Text

How to Choose the Right Tank Level Gauge for Your Water Storage System

A tank level gauge and water tank gauge are essential tools for monitoring water levels in storage systems. Whether for residential, agricultural, or industrial use, choosing the right gauge ensures efficient water management, prevents overflows, and avoids shortages. With various options available, selecting the ideal gauge requires careful consideration of several factors. This guide will help you understand how to choose the best tank level gauge and water tank gauge for your needs.

Understanding Tank Level Gauges

A tank level gauge is a device used to measure and display the water level inside a storage tank. These gauges help users track water levels in real-time, ensuring proper water usage and refilling schedules. Water tank gauges come in different types, including mechanical, electronic, and ultrasonic models.

Types of Tank Level Gauges

Mechanical Tank Level Gauges

Use float systems to indicate water levels.

Reliable, durable, and require minimal maintenance.

Ideal for large water storage tanks in rural and industrial settings.

Electronic Tank Level Gauges

Use sensors and digital displays to show precise water levels.

Some models offer wireless connectivity for remote monitoring.

Best suited for high-tech applications and smart water management.

Ultrasonic Tank Level Gauges

Utilize ultrasonic waves to measure water levels without physical contact.

Highly accurate and suitable for hazardous or hard-to-reach tanks.

Recommended for industrial applications and automated water systems.

Key Factors to Consider When Choosing a Tank Level Gauge

1. Tank Size and Capacity

Larger tanks require gauges with higher measurement ranges.

Ensure the gauge is compatible with your tank’s height and volume.

2. Type of Water Storage System

For underground tanks, electronic or ultrasonic gauges provide better readings.

Overhead tanks can utilize mechanical or float-type gauges.

3. Accuracy and Precision

Digital and ultrasonic gauges offer precise readings.

Mechanical gauges provide approximate water levels but are cost-effective.

4. Ease of Installation and Maintenance

Choose a gauge that is easy to install and does not require frequent calibration.

Wireless and digital gauges may require periodic battery replacements or software updates.

5. Durability and Environmental Resistance

Consider materials resistant to corrosion, rust, and extreme weather conditions.

For outdoor tanks, ensure the gauge can withstand UV exposure and temperature fluctuations.

6. Budget and Cost Considerations

Mechanical gauges are more affordable with lower maintenance costs.

Digital and ultrasonic models may have higher upfront costs but offer long-term efficiency.

7. Remote Monitoring and Smart Features

Some modern gauges come with smartphone apps and IoT integration.

Ideal for industries and remote locations where regular manual checks are impractical.

Why Choose Nikeson’s Tank Level Gauges?

Nikeson offers a range of high-quality tank level gauge and water tank gauge solutions tailored for various applications. Their mechanical and digital tank indicators ensure accuracy, durability, and ease of use, making them a top choice for water storage monitoring.

Conclusion

Choosing the right tank level gauge and water tank gauge depends on factors like tank size, accuracy needs, durability, and budget. Whether opting for a mechanical, digital, or ultrasonic model, selecting a reliable gauge enhances water management efficiency. Explore Nikeson’s solutions for the best tank level monitoring devices to suit your specific needs.

For more information, visit Nikeson’s product page and find the perfect gauge for your water storage system today!

#tank level gauge#water tank gauge#level indicators for water tanks#rainwater level indicator#water level indicators for water tanks#level indicator water tank#water level indicator for water tank#Float & Board Level Indicator#Tank Level Indicator#ultrasonic level sensor#Ultrasonic Level Transmitter#water level gauge#water level staff gauge

0 notes

Text

Scotsman 11-0579-01 Ice Machine Ultrasonic Bin Level | HnKParts

The Scotsman 11-0579-01 Ice Machine Ultrasonic Bin Level is an advanced sensor designed to monitor the ice level in the bin of Scotsman ice machines. Utilizing ultrasonic technology, this sensor accurately measures the amount of ice in the bin without physical contact, ensuring precise readings and preventing overfilling. The 11-0579-01 sensor helps optimize the operation of the ice machine by providing real-time feedback to maintain proper ice levels, which in turn improves efficiency and reduces the risk of ice shortages or wastage.

#11-0579-01#Scotsman#Ice Machine Ultrasonic Bin Level#HnKParts#homeappliances#HnKBuzz#KitchenApplianceParts#appliancepartsonline

0 notes

Text

How Do Air Quality Meters Help in Ensuring a Healthier Living Environment?

In our modern, increasingly industrialized and urbanized society, the quality of the air we inhale is more important than it has ever been. Unhealthy air quality can significantly impact health, comfort, and productivity levels. From residences and workplaces to educational institutions and medical facilities, ensuring clean air is vital for general health. This is where air quality meters become relevant—sophisticated instruments created to track and evaluate air contaminants, enabling individuals and organizations to implement the required actions to foster healthier environments.

Air quality meters are advanced devices that feature sophisticated sensors capable of identifying a variety of pollutants. These contaminants consist of particulate matter (PM2.5 and PM10), volatile organic compounds (VOCs), carbon monoxide (CO), nitrogen dioxide (NO₂), sulfur dioxide (SO₂), and various other harmful gases. Through the ongoing observation of these elements, air quality meters deliver immediate data, allowing users to efficiently control and enhance their air quality.

One of the key advantages of air quality meters is their capacity to provide instant information about the level of air pollution. Through real-time monitoring, both individuals and businesses can implement effective measures to improve their surroundings. For example, homeowners can track air quality in different parts of their homes, enhancing ventilation and utilizing air purifiers to remove harmful contaminants. In work environments, maintaining clean air boosts employee well-being, decreases absenteeism, and enhances overall performance.

Moreover, air quality monitors are essential in detecting concealed contaminants that might be overlooked without adequate surveillance. Indoor air frequently gathers contaminants from routine activities, including cooking, cleaning, and the application of synthetic materials. VOCs, for instance, are often present in paints, glues, and domestic cleaning supplies, leading to diminished air quality. Air quality monitors assist in identifying these contaminants, enabling individuals to implement steps to reduce exposure and foster healthier environments.

In professional settings like schools and healthcare facilities, ensuring excellent air quality is crucial for safety and adherence to health regulations. For educational institutions, fresh air creates a favorable learning atmosphere, devoid of allergens and contaminants that might affect student achievement. In hospitals, monitoring air quality is essential to minimize infection risks and ensure a safe environment for both patients and staff.

Additionally, companies are progressively acknowledging the significance of air quality meters to meet industry standards and ensure a safe work environment. Through the use of these devices, organizations can track air quality and make required changes to foster a safer, more pleasant atmosphere for workers and guests.

Intelligent air quality meters provide a more sophisticated option for managing air quality. These devices effortlessly connect with home automation systems, providing automated regulation of air purifiers, ventilation systems, and various environmental elements. By means of wireless connections and immediate data assessment, smart meters offer users easy management and enhanced insights into their air quality.

AAM Trading is recognized as a reliable source of premium air quality monitoring solutions. AAM Trading, dedicated to innovation and dependability, provides an extensive selection of sophisticated air quality meters designed to meet diverse requirements. For residential, commercial, or industrial applications, their products guarantee precise, high-quality air monitoring. AAM Trading’s commitment to providing solutions that focus on customer satisfaction has established their reputation for excellence.

Alongside offering advanced air quality meters, AAM Trading delivers professional consultation and assistance to aid clients in enhancing their air quality management systems. Their group of experts collaborates closely with clients to grasp particular requirements and provide solutions that address their individual needs. AAM Trading prioritizes precision and performance, guaranteeing that each solution is crafted to provide accurate, real-time insights on air quality.

AAM Trading is more than a source of advanced technology; they are collaborators in fostering healthier, safer surroundings. Their all-encompassing strategy guarantees that clients obtain solutions that are customized, dependable, and supported by outstanding service. With ongoing innovation and a focus on customer needs, AAM Trading continues to be a reliable name in air quality monitoring solutions.

0 notes

Text

#non destructive testing#Magnetic Particle Inspection Services#non destructive testing solutions#non destructive testing equipment manufacturers#penetrant inspection near me#non destructive hardness testing#non destructive testing companies near me#non destructive thickness measurement#magnetic particle inspection near me#ndt labs near me#hardness test non destructive#ultrasonic testing gauge#ultrasonic metal thickness tester#ultrasonic gauge thickness tester#material thickness tester#metal thickness testing#ultrasonic level detection#non destructive testing systems#ndt radiography#non destructive testing radiography

0 notes

Text

HARNESSING THE POWER OF PRECISION WITH ULTRASONIC LEVEL TRANSMITTER

Nagaman Flow Level Systems And Solutions takes pride in being one of the leading providers of advanced level measurement solutions, renowned for its high-quality ultrasonic level transmitters. These devices have become our most popular product due to their precision, reliability, and versatility. Ideal for applications requiring chemical compatibility, and minimal maintenance, our ultrasonic level transmitters stand out in the market for their superior performance and innovative design.

Principles of Working

Ultrasonic level transmitters operate on the transient time principle, which involves the emission and reception of acoustic vibrations. The device emits an ultrasonic pulse from a sensor mounted on top of a pipe or container. This pulse travels through the medium and reflects off the surface back to the sensor. By measuring the time taken for the pulse to return, the transmitter calculates the distance or height of the medium in the container. This method leverages the conductivity of sound to provide accurate and reliable measurements.

Technical Aspects

Our ultrasonic level transmitters are engineered and designed with cutting-edge technology that caters to the diverse needs of various industries keeping their best interests at heart. Here are some key technical specifications:

-Level Range: Available in multiple ranges including 4m, 6m, 8m, 10m, 12m, 15m and 20m

-Accuracy: Up to ±0.25% full range

-Resolution: 3mm or 1%

-Power Supply: 24VDC, 2 Wire

-Display: 128*64 lattice LCD display for clear and precise readings

-Analog Output: 4-20mA

-Environmental Temperature:

- Transmitter: -20°C to 60°C

- Sensor: -20°C to 80°C

-Communication: RS485, HART for seamless data integration

Advantages

High level Accuracy

Our ultrasonic level transmitters deliver exceptional accuracy, up to 0.50% of the entire range, ensuring reliable data crucial for various applications.

Non-Contact Measurement

These devices feature non-contact sensors, preventing corrosion and wear, especially useful in hazardous mediums. They can be easily installed on top of a pipe without the need for cutting or making any changes to the existing setup.

Versatility

Our transmitters display an exceptional level of versatility in terms of liquid measurement and can be used to measure various types of liquids including liquids of thicker consistency like slurry, making them suitable and useful for a wide range of applications, including urban sewage, paper pulp industry, urban water supply systems, sewage treatment plants, river level monitoring, and water conservancy projects.

Smart Data Filtering

Equipped with intelligent digital circuitry and smart data filtering, these devices minimize noise and enhance measurement reliability, ensuring accurate and consistent results.

Concerns

While ultrasonic level transmitters offer numerous benefits, there are a few limitations to consider before you consider investing in a Ultrasonic level transmitter.

Compatibility with Distilled Water

Even though one of the major advantages of an Ultrasonic level transmitter is its ability to be versatile in measuring any kind of liquid, they are ineffective with distilled water due to its lack of conductivity, it can’t be detected by ultrasonic transmitters due to the lack of ions present in distilled water. In such cases, alternative measurement transmitters may be required.

Installation Considerations

Proper alignment and positioning are crucial for accurate measurements. Careful installation is necessary to avoid errors and ensure optimal performance.

Conclusion

Nagaman Flow Metre Company's ultrasonic level transmitters are a superior choice for accurate and reliable level measurement. Their high accuracy, non-contact measurement capability, and versatile applications make them a valuable necessity for accurate liquid measurement in various industries. Despite some limitations, such as compatibility with distilled water and the need for precise installation, the benefits they offer far outweigh these concerns. Experience the precision and reliability of Nagaman’s ultrasonic level transmitters and elevate your measurement capabilities to new heights.

0 notes

Text

#𝗡𝗼𝗻 𝗗𝗲𝘀𝘁𝗿𝘂𝗰𝘁𝗶𝘃𝗲 𝗧𝗲𝘀𝘁𝗶𝗻𝗴 [𝗡𝗗𝗧] 𝐂𝐨𝐮𝐫𝐬𝐞𝐬#Level II#1. Visual Testing (VT)#2. Liquid Penetrant Testing (PT)#3. Magnetic Particle Testing (MT)#4. Ultrasonic Testing (UT)#5. Radiography Testing (RT)#6. Thermal/Infrared Testing (IR)#7. Acoustic Emission Testing (AET)#8. Eddy Current Testing (ECT)#9. Magnetic Flux leakage (MFL)#Contact Us:#Mob:#+919787872866#Email:#[email protected]#Web:#www.cosmostrg.com#WhatsApp Channel :#https://whatsapp.com/channel/0029VaHMYayGufJ45OH4Xo1n#WhatsApp Group :#https://chat.whatsapp.com/IunhDueyuLsEPc9SkB7dlK#NDT#ndtinspection#ndttraining#visualtesting#liquid#penetranttesting#Magnetic#magneticparticletesting

0 notes

Text

#engineering services#ultrasonic level transmitter#best level measurement devices#level measurement devices#engineering#water technology#technology

1 note

·

View note

Text

Ultrasonic Sensors: A Comprehensive Guide

Ultrasonic sensors are devices that use ultrasonic waves, which are sound waves with frequencies higher than the audible range for humans (typically above 20,000 hertz), for various applications.

These sensors operate on the principle of sending out ultrasonic waves and measuring the time it takes for the waves to bounce back after hitting an object. This information can then be used to determine the distance or presence of the object.

Ultrasonic Sensors Working Principle

The working principle of ultrasonic sensors is based on the transmission and reception of ultrasonic waves. Here’s a step-by-step explanation of how these sensors operate:

Generation of Ultrasonic Waves:

Ultrasonic sensors consist of a transducer, typically a piezoelectric crystal, that can convert electrical energy into ultrasonic waves. When an electrical voltage is applied to the crystal, it vibrates and generates ultrasonic waves in the frequency range beyond human hearing (typically above 20,000 hertz).

Wave Emission:

The ultrasonic sensor emits a short burst of ultrasonic waves into the surrounding environment. This burst of waves travels outward from the sensor.

Wave Propagation:

The ultrasonic waves move through the air until they encounter an object in their path. The waves continue to propagate until they hit a surface.

Reflection of Ultrasonic Waves:

When the ultrasonic waves strike an object, they are reflected back towards the sensor. The reflection occurs because the ultrasonic waves encounter a change in the medium (from air to the object’s surface), causing the waves to bounce back.

Reception of Reflected Waves:

The same transducer that emitted the ultrasonic waves now acts as a receiver. It detects the reflected waves returning from the object.

Time Measurement:

The sensor measures the time it takes for the ultrasonic waves to travel from the sensor to the object and back. This time measurement is crucial for determining the distance to the object.

Distance Calculation:

Using the known speed of sound in the air, which is approximately 343 meters per second (at room temperature), the sensor calculates the distance to the object. The formula for distance (D) is given by D = (Speed of Sound × Time) / 2.

Output Signal:

The calculated distance information is then processed by the sensor’s electronics, and the output is provided in a suitable format, often as an analog voltage, digital signal, or distance reading.

These sensors work by emitting ultrasonic waves, detecting their reflections from objects, measuring the time taken for the round trip, and using this time information to calculate the distance to the objects in their detection range. This working principle is fundamental to various applications, including distance measurement, object detection, and obstacle avoidance.

Ultrasonic Sensors Pins Configurations

The pin configurations of ultrasonic sensors may vary depending on the specific model and manufacturer. However, We will discuss general overview of the typical pin configuration for a commonly used ultrasonic sensor module, like the HC-SR04. This module is widely used in hobbyist and educational projects.

The HC-SR04 ultrasonic sensor typically has four pins:

VCC (Voltage Supply):

This pin is used to provide power to the sensor. It typically requires a voltage in the range of 5V.

Trig (Trigger):

The Trig pin is used to trigger the start of the ultrasonic pulse. When a pulse of at least 10 microseconds is applied to this pin, the sensor emits an ultrasonic wave.

Echo:

The Echo pin is used to receive the ultrasonic waves that are reflected back from an object. The duration of the pulse received on this pin is proportional to the time it takes for the ultrasonic waves to travel to the object and back.

GND (Ground):

This pin is connected to the ground (0V) of the power supply.

Read More: Ultrasonic Sensors

#ultra sonic#ultrasonic sensors#ultrasonic technology#sensor technology#sensor applications#non-contact measurement#distance measurement#level measurement#flow measurement#object detection#obstacle avoidance#industrial automation#automotive industry#robotics#healthcare#home automation#smart homes#IoT#internet of things#technology#innovation#engineering#science#research#development#education#learning#acoustics#sound waves#frequency

0 notes

Text

A dial bore gauge measures the inner diameter of tiny holes. When counting objects with small holes in them, bore gauges are essential. Keep reading to know the details.

visit: https://tools-suppliers-in-uae-dubai.blogspot.com/2024/01/blog-post.html

#Tools suppliers in uae Dubai uae#ultrasonic thickness gauge Supplier in Dubai Uae#insize measuring instruments Supplier in Dubai uae#rsk precision level in uae dubai

0 notes

Text

Ultrasonic Continuous Level Sensor

SEGMEN SENSOR offers a range of high-quality ultrasonic continuous-level sensors for precise and reliable level measurement in various industrial applications. For more information, please visit https://segmensensor.com/

0 notes

Text

Ultrasonic Level Sensor: Your Precision Measurement Solution

Upgrade industrial operations with the ultrasonic level sensor, offering exceptional precision and durability. Discover how it fits your application needs at Nikeson.

#ultrasonic level sensor#Ultrasonic Level Transmitter#water level gauge#water level staff gauge#water tank level indicator#tank level staff gauge#tank level gauge#water tank gauge#level indicators for water tanks#rainwater level indicator#water level indicators for water tanks#level indicator water tank

0 notes

Text

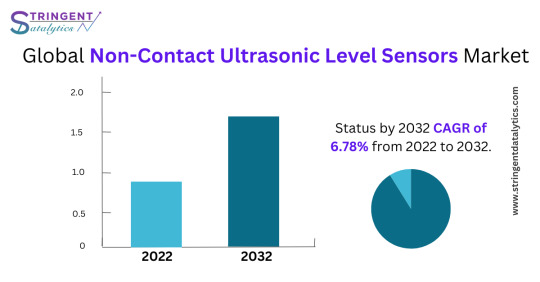

Non-Contact Ultrasonic Level Sensors Market

0 notes

Text

#𝗔𝗩𝗧 𝗔𝗰𝗮𝗱𝗲𝗺𝘆#𝗛𝗶𝗴𝗵𝗳𝗶𝗲𝗹𝗱 - 𝗨𝗞#1. Food Safety (Level 1 to 4)#2. HACCP (Level 2 to 4)#3. Food Allergen (Level 2 to 3)#4. Nutrition & Health (Level 2 to 3)#𝗔𝗺𝗲𝗿𝗶𝗰𝗮𝗻 𝗛𝗦𝗜 - 𝗨𝗦𝗔#MEDIC First Aid Training#MEDIC First Aid Train the Trainer#𝗡𝗗𝗧 𝗟𝗲𝘃𝗲𝗹 𝟮 𝗖𝗼𝘂𝗿𝘀𝗲𝘀#1. Visual Testing#2. Liquid Penetrant Testing#3. Magnetic Particle Testing#4. Ultrasonic Testing#5. Radiographic Testing#6. Thermal/Infrared Testing#Contact Us:#Mob:#+919361165584#+917530075440#+919655111155#Email:#[email protected]#Web:#www.avtacademy.com#nutrition#nutritioncourse#nutritionsafety#nutritiontrainingcourse#nutritioncourses

0 notes

Text

#non destructive testing solutions#hardness test non destructive#ultrasonic testing gauge#ultrasonic metal thickness tester#ultrasonic gauge thickness tester#material thickness tester#metal thickness testing#ultrasonic level detection#non destructive testing systems#ndt radiography#non destructive testing radiography

0 notes

Text

#𝗔𝗩𝗧 𝗔𝗰𝗮𝗱𝗲𝗺𝘆#𝗛𝗶𝗴𝗵𝗳𝗶𝗲𝗹𝗱 - 𝗨𝗞#1. Food Safety (Level 1 to 4)#2. HACCP (Level 2 to 4)#3. Food Allergen (Level 2 to 3)#4. Nutrition & Health (Level 2 to 3)#𝗔𝗺𝗲𝗿𝗶𝗰𝗮𝗻 𝗛𝗦𝗜 - 𝗨𝗦𝗔#MEDIC First Aid Training#MEDIC First Aid Train the Trainer#𝗡𝗗𝗧 𝗟𝗲𝘃𝗲𝗹 𝟮 𝗖𝗼𝘂𝗿𝘀𝗲𝘀#1. Visual Testing#2. Liquid Penetrant Testing#3. Magnetic Particle Testing#4. Ultrasonic Testing#5. Radiographic Testing#6. Thermal/Infrared Testing#Contact Us:#Mob:#+919361165584#+917530075440#+919655111155#+919787637876#Email:#[email protected]#Web:#www.avtacademy.com#foodallergn#foodallergns#foodallergies#foodallergyawareness

1 note

·

View note