#transformers manufacturer

Explore tagged Tumblr posts

Text

Excellent Quality Step Down and Step Up Transformers At Best Price - Shakti Electronics

Buy from Shakti Electronics, leading manufacturer and supplier of Step Down and Step Up Transformer at affordable rates. These products are made from thick insulated copper wire that ensures durability and ease of functionality. We are focused on delivering high quality products made from excellent quality materials.

Contact Us: +91 9829059997

Visit our Website: https://www.shaktiecorp.com/booster-transformers.php

1 note

·

View note

Text

I realized something...

#lambros#somebody please get the reference#we're all brothers in primus#do i get the fourth lamborghini#slippery slope#transformers#transformers breakdown#transformets gen 1#transformers generation one#g1#tf masterpiece#transformers masterpiece#third party manufacturing#breakdown#stunticons#sideswipe#sunstreaker#hoistsautobody

228 notes

·

View notes

Text

So about that funny keychain idea (<- TF ONE spoilers)... I'm making it real :]!!

You can find this little guy in my shop on the 12th of October!

It would be sooner, but I've got to get my spreadsheets into shape before I can reopen my shop...

#i figured out how to make the preview not spoilery but also still have my art in it :]#sentinel prime#macaddams#transformers one#tf one#transformers one spoilers#kinda!#its hinted at.#if you know you know.#transformers#my other preorder stuff just closed. yes. but consider. my little guy?#i just. want him to be real and danglign about.#i am waiting So patiently for manufacturing.#*wiggles around excitedly*#also after i finish this i can make More Art. YAY#i wanna draw more tf stuff........ im bapping my little hands all over my screen with impatient vigour#I FORGOT TO TAG HIM.

65 notes

·

View notes

Text

The more I develop this the funnier it gets

The Seekers didn't fucking exist in Baby Fever Shockwave AU until Starscream went "draw me like one of your French girls" and Shockwave said "Aight, bet" XDXDXDXDXD

Starscream, Skywarp, and Thundercracker are nearly identical bc they're fucking dopplegangers

You know that thing where people say there's someone out there in the world who looks exactly like you? Yeah, that's them

And then Starscream went and made it more complicated bc Shockwave is profoundly uncreative in the visual appeal department and Starscream has an ego the size of the moon

#Pov you need a face for your manufactured army but Soundwave says “FUCK no”#There will be more context soon I swear (it's too funny not to draw)#Transformers#maccadams#transformers au#baby fever shockwave#robits

9 notes

·

View notes

Text

Norway's reTyre claims to be the world’s first carbon-neutral rubber-free all circular materials tyre

The tyre is crafted from 100% reclaimed materials to neutralise the product’s environmental impact, restore ecosystems, and reduce greenhouse gas emissions to zero.

By using algae, recycled para-aramid fibre, post-consumer recyclate and recycled fish nets, reTyre has reduced the product’s greenhouse gas emissions by 100% compared with conventional tyres.

“While we’re not the first to use recycled fishnets in the tyre industry, I have never known of algae, post-consumer recyclate and recycled para-aramid to be used before,” reTyre Brand Designer Friedemann Ohse, who is leading the Carbon-Neutral Project, told Zag Daily.

“We have learned a lot during this production phase and will use this when we move to mass production.”

Algae, which is incorporated in the tread, is sourced from algae blooms to restore aquatic ecosystems, prevent methane release and prevent eutrophication, which is when harmful algal blooms and dead zones develop after the environment becomes enriched with nutrients. According to reTyre, algae’s negative CO2 equivalent offsets the company’s remaining carbon emissions and contributes to a net-zero impact.

Recycled para-aramid is extracted from used body armour to protect the tyre against puncture, while post-consumer recyclate is sourced from local waste streams which have low levels of carbon dioxide.

“Post-consumer waste is not easy to use but it has an amazing impact. It also reduces the price of the tyre because it’s a waste which nobody wants to use.”

Friedemann anticipates wider use of para-aramid in the near future, and the company is currently implementing the material into many of its own products as well as the carbon-neutral tyre.

The fourth sustainable material – recycled fish nets – is used for tyre casing. Fish nets are collected from oceans and reduce emissions by 49% and energy use by 15%.

reTyre says the carbon footprint of this tyre is based on a third-party Life Cycle Assessment verification, which includes almost zero emissions from production and transportation processes, and nearly zero end-of-life carbon emissions due to recycling of the tyres.

“This carbon-neutral tyre is at a concept stage and it is a result of continuous innovation that shows what our unique manufacturing is capable of.”

Source

#solarpunk#solarpunk business#solarpunk business models#solar punk#startup#reculture#transforming the entire business from materials to manufacturing#norway#tires#no more rubber#recycled material#distributed manufacturing

16 notes

·

View notes

Text

"I think Breakdown was a construction worker before the war" I think he'd use a jackhammer to try and kill someone and not be allowed within a 4 mile radius of any construction site

#i dont even have any idea of what he'd have as a job#maybe something to do with weapon designing or manufacturing#i love seeing HCs of his jobs tho#ive seen so many different ones#breakdown#transformers#tfp breakdown#maccadams

43 notes

·

View notes

Text

Low tension insulator for metros manufacturers in India | radiantenterprises

Radiant Enterprises is a trusted manufacturer of low tension insulators for metros in India, delivering reliable solutions to support urban transit systems. Our specialized low tension insulators for metros are designed to ensure safe and efficient operation with conductor rails, enhancing performance and durability in demanding metro environments. With a commitment to quality, we are a preferred choice for advanced low tension insulators across the rail industry.

Choose quality, choose reliability – partner with us for low tension insulator for metros projects.

#Low tension insulator for metros manufacturers in India#India#Australia#Low tension insulators#Brazil#Russia#Germany#Low tension insulators for metros#Conductor rails#Epoxy Insulators#Epoxy Bushings#Railway insulator#Railway Bushings#Business#Pantographs#Transformer#Electricals#Electricity

4 notes

·

View notes

Text

Radiant Enterprises is a trusted name among transformer bushings connectors manufacturers in India, delivering top-tier solutions for power systems. As leading transformer bushing manufacturers in India, we specialize in producing durable and efficient transformer bushings that ensure optimal performance. With a strong focus on quality, we also handle transformer bushing exports and distribution in India, catering to global and domestic markets.

Additionally, we facilitate transformer bushing imports to meet diverse industry needs, offering comprehensive solutions for the energy sector.

#Transformer bushings connectors manufacturers in India#Transformer bushing manufacturers in India#Transformer bushing#Transformer bushing exports and distribution in India#Transformer bushing imports

4 notes

·

View notes

Text

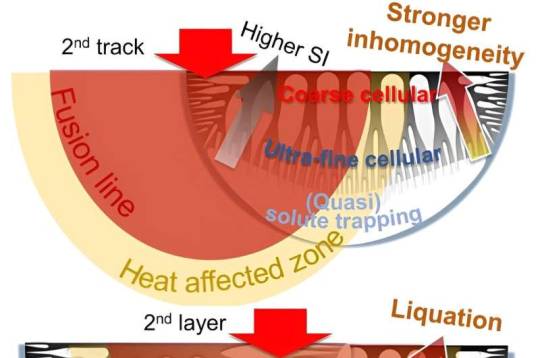

New study into solute transport and solidification mechanisms in additive manufacturing

Additive manufacturing (AM), or 3D printing, is a rapidly growing technology with the potential to revolutionize many industries. However, AM parts can be susceptible to defects, such as porosities and cracks, which can limit their performance and reliability. Researchers at Queen Mary University of London, in collaboration with Shanghai Jiao Tong University, Center of Excellence for Advanced Materials, and University of Leicester, have developed a computational model to reveal how solute trapping occurs during the rapid solidification process in additive manufacturing (AM). The study, published in Nature Communications, provides new insights into the solute transport and solidification mechanisms in AM, which could lead to the development of new materials and processes for 3D printing.

Read more.

#Materials Science#Science#Additive manufacturing#3D printing#Solidification#Phase transformations#Solute#Queen Mary University of London

9 notes

·

View notes

Text

The Global Impact of High-Quality Current Transformer Bases

In the ever-evolving landscape of energy distribution and management, current transformers play a pivotal role in ensuring accurate measurement and monitoring of electrical currents in power systems. A critical component within these transformers is the current transformer base, which serves as the foundation for the safe and efficient operation of transformers. As global demand for energy continues to surge, the significance of high-quality current transformer bases in modern power infrastructures cannot be overstated.

Current transformer bases are instrumental in energy distribution networks, helping to measure current accurately and protect electrical systems from faults and overloading. This blog will delve into the global impact of high-quality current transformer bases and highlight the importance of reliable manufacturers and exporters in India, the growing role of air-insulated switchgear companies, and the increasing need for advanced power monitoring systems.

The Role of Current Transformer Bases in Power Systems

Current transformers (CTs) are essential in the measurement and control of electrical currents in various applications, from power generation and transmission to industrial automation and energy metering. The current transformer base acts as the structural platform on which the transformer operates, ensuring the stability and insulation of the CT during operation.

High-quality current transformer bases provide enhanced accuracy in current measurement, which is critical for maintaining the efficiency and safety of power systems. These bases also ensure proper insulation and protection of the transformer, preventing short circuits, arcing, and other potential hazards.

For industries where power quality and reliability are paramount, such as manufacturing, utilities, and data centers, the performance of the current transformer base directly impacts the effectiveness of power monitoring and control systems.

India: A Global Hub for Current Transformer Base Manufacturing

India has emerged as a key player in the global energy sector, and its manufacturers are becoming increasingly prominent in the production of critical power components. As a leading current transformer base manufacturer and exporter in India, Radiant Enterprises and other companies have made significant strides in meeting global demand for high-quality products. Indian manufacturers are known for their technical expertise, innovative solutions, and adherence to international standards, making them a trusted source for current transformer bases.

The rise of India as a global manufacturing hub has been driven by several factors:

Cost-Effective Production: Indian manufacturers offer competitive pricing without compromising on quality, making their products attractive to global markets.

Skilled Workforce: India boasts a highly skilled workforce with expertise in the design, production, and testing of electrical components, including current transformer bases.

Adherence to International Standards: Indian manufacturers comply with global quality standards such as ISO, IEC, and other industry certifications, ensuring that their products meet the stringent requirements of international clients.

Growing Export Market: India’s export market for electrical components has seen steady growth, with manufacturers catering to the needs of clients across Europe, North America, Africa, and Asia.

As the global demand for energy continues to rise, the role of Indian manufacturers and exporters in meeting the need for high-quality current transformer bases becomes even more significant.

Impact on Power Monitoring Systems

Power monitoring systems are essential tools in modern electrical infrastructure, providing real-time data on the performance of power distribution networks. These systems help monitor energy usage, detect faults, and optimize the efficiency of electrical systems, thereby ensuring the reliability and safety of power networks.

The accuracy of power monitoring systems depends heavily on the precision of current transformers and, by extension, the quality of the current transformer bases. High-quality current transformer bases ensure that the transformers can operate effectively, delivering accurate data to power monitoring systems.

Some of the key benefits of power monitoring systems include:

Real-Time Data: Power monitoring systems provide instant data on power usage, current levels, and potential faults, allowing for immediate corrective action.

Improved Energy Efficiency: By analyzing data from power monitoring systems, businesses can optimize their energy usage, reduce waste, and lower operational costs.

Enhanced Safety: Power monitoring systems can detect anomalies in current flow, such as overloads or short circuits, and alert operators to potential safety hazards before they escalate.

Preventive Maintenance: With accurate data on system performance, companies can implement preventive maintenance strategies, reducing downtime and preventing costly repairs.

Given the growing emphasis on energy efficiency and sustainability, the demand for high-quality power monitoring systems continues to rise globally. In turn, the importance of reliable current transformer bases in supporting these systems cannot be overstated.

The Role of Air Insulated Switchgear Companies in India

Switchgear is a vital component of power distribution systems, used to control, protect, and isolate electrical equipment. Air-insulated switchgear (AIS) is one of the most widely used types of switchgear in medium- and high-voltage power distribution applications. These systems use air as the primary insulating medium and are designed to protect electrical circuits from faults while ensuring the continuity of power supply.

Air-insulated switchgear companies in India are playing a key role in modernizing electrical infrastructure across the country and globally. India has become a prominent player in manufacturing air-insulated switchgear due to its expertise in power distribution equipment, favorable production costs, and adherence to international quality standards.

Air-insulated switchgear companies in India contribute to the global power industry in several ways:

Innovative Solutions: Indian manufacturers are continually developing advanced air-insulated switchgear solutions to meet the evolving demands of modern power systems. These innovations include more compact designs, improved insulation technologies, and enhanced safety features.

Cost Efficiency: Indian air-insulated switchgear companies offer competitive pricing compared to manufacturers in other parts of the world, making them a cost-effective solution for global clients.

Environmental Considerations: As the world shifts toward greener energy solutions, air-insulated switchgear offers an environmentally friendly alternative to gas-insulated switchgear, which uses greenhouse gases such as SF6 for insulation.

The Global Impact of High-Quality Electrical Components

The global energy landscape is undergoing a profound transformation driven by the increasing demand for electricity, the transition to renewable energy sources, and the need for improved energy efficiency. As a result, the demand for high-quality electrical components, including current transformer bases and air-insulated switchgear, is growing at an unprecedented rate.

High-quality current transformer bases are crucial for ensuring the accuracy and reliability of electrical measurements, which in turn supports the effective operation of power monitoring systems. These systems are essential for optimizing energy usage, improving safety, and ensuring the reliability of electrical infrastructure.

The growing role of current transformer base manufacturers and exporters in India in meeting global demand highlights the country's importance in the global energy sector. Indian manufacturers are supplying high-quality products that meet international standards, helping to improve power distribution networks around the world.

Similarly, air-insulated switchgear companies in India are contributing to the modernization of electrical infrastructure, both domestically and internationally. Their innovations are helping to improve the efficiency and reliability of power systems, while also offering environmentally friendly solutions.

Conclusion: Powering the Future with Quality

As the world moves toward a more connected and energy-efficient future, the importance of high-quality electrical components, such as current transformer bases, air-insulated switchgear, and advanced power monitoring systems, will continue to grow. These components are critical to ensuring the safe, reliable, and efficient operation of power distribution networks, which are essential to the global economy.

Manufacturers and exporters in India, including current transformer base manufacturers, are playing a vital role in meeting global demand for high-quality electrical products. Their commitment to innovation, quality, and sustainability is helping to shape the future of the global energy landscape, ensuring that power systems are equipped to handle the challenges of tomorrow.

With the rise of renewable energy, the expansion of smart grids, and the increasing focus on energy efficiency, the demand for reliable and accurate electrical components will only continue to grow. By investing in high-quality current transformer bases and partnering with reputable air-insulated switchgear companies in India, businesses can ensure that they are prepared for the future of energy.

#Power monitoring system#Current transformer base manufacturer and exporter in India#Air insulated switchgear companies in India

4 notes

·

View notes

Text

I feel like I’ve been posting a ton lately (because there’s a lot goin on!!!!) but FOR THOSE OF YOU WITH TWITTER: Figmin XR just published our AWE competition video!!!

❗ PLEASE like/retweet it if you want to help us with our company mission of using AR (augmented reality) to reduce material waste. ❗

we’re an indie team of 4 people competing against large companies, so we’re relying pretty much entirely on word of mouth to spread the word about what we’re doing. we’re also competing against the AI and web3 (crypto) crowd, which are unfortunately still big in the tech industry

we’re competing in multiple award categories at AWE and will be relying on public votes, so literally any and all visibility helps us immensely right now. 🙏

I’ll be posting the video to @figminxr later, so don’t stress if you’re not on twitter. I’ll be sharing more info about the competition in the post as well!

#auropost#i'm pulling out the exclamation mark emojis so you know i'm serious lol#i am a little bit serious though#there is a non-zero possibility that figmin could singlehandedly transform the way we think about material objects#i don't talk about this much since 1) we're humble indie devs and 2) it breaks my brain to think about#but there is a reason we went on the meta world tour and got into the disney family gallery#and there is a reason every new headset manufacturer recently has reached out to us directly#and also our app is starting to be implemented in classrooms for children AND adults#like a fucking ARCHAEOLOGY team is using figmin as a learning tool#it's international too!!!!#and the reason it's getting so big is that no one else is making anything like this#and if we can prove to the xr industry that the general public WANTS tech like this#that's the next step towards getting companies to make it actually affordable#and once it's affordable.......... you will be able to Download A Frisbee#and just. anything else you want.#MAN!!! what a wild thing to be able to say!!!!

25 notes

·

View notes

Text

sometimes i see posts where i think That Doesn't Sound Right But I Don't Know Enough About Neurobiology to Dispute It

#my understanding of dopamine and serotonin deficiencies is that they tend to be issues of uptake rather than production#like generally if you eat enough casein rich foods you should be good. your brain will manufacture a pretty sizeable amount#but from what i've gathered#the problem is that it will generally USE and transform those chemicals at a rate that fucks you over#so ssris and stimulants for adhd tell your brain HEY JACKASS WE NEED THESE#or more specifically they bind to the places that would usually be grabbing your dopamine and serotonin and doing shit with em#again. big grain of salt here. i'm not a pharmacist or a neurologist or psych#just a nosy and neurotic creature that reads papers on everything i have ever been prescribed. due to my brain problems.

9 notes

·

View notes

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Text

Whenver I see that post abt a Twitter user completing Keith Haring's unfinished painting with AI and getting replies like 'NO this is BAD ❌🙅♂️🔥 the original meaning of the painting wasssss' I'm always a little baffled that rarely do people reblog a version clarifying that the tweet is like. Satire and/or bait

#like cmon it cant just be me right?#its an incredibly provocative painting to alter with ai even without knowing the background#and the ai version is jumbled and frankly boring#shapes dont make sense. motifs are forgotten. the use of negative space is completely removed from the piece#the tweet that it's in reply to sets up the painting as one that 'always makes you cry' thus increasing the impact of the punchline#if it were a genuine example of ai's capabilities it wouldn't have kneecapped itself by setting itself up like that#even the tweet featuring the ai has a tone which feels stilted and manufactured#the use of emojis and phrasing is aggressively neutral particularly the crying emoji#the tone would maybe fit more on facebook or something else#but twitter's audience skews younger and the tweeter's pfp is anime-esque iirc so it feels stilted#i actually think that the tweet itself is a compelling piece of art#idk my spidey senses were tingling#EDIT ok yeah i looked up the twitter user and pretty much all they post is bait particularly wrt gen ai#we can argue about the morality of this transformation but like. much worse has been done to a piece of art#and this kind of intertextuality is wicked common esp in modern satire

4 notes

·

View notes

Text

The next few posts are going to be from a visit to a vintage toy store near Cincinnati Ohio. So technically not thrift - at all - BUT an amazing store!!! with some cool things to see!

"HASBRO STANDARDS" for Transformers Animated Deluxe Optimus Prime and Bumblebee. I guess these are factory packaged versions that are used in manufacturing to make sure the product turns out okay?

#toy collector#hasbro#factory#toy manufacturing#tfa#transformers animated#tf animated#optimus prime#2007#cartoon network#2000s#toy factory#packaging#toy packaging#off topic#not thrift

14 notes

·

View notes

Text

i think my greatest deviation from canon & real life is that under no circumstances will i ever write/draw rusty as a switcher locomotive. cuz in my aus they don't exist.

it's like, within the context of my aus--in a world where trains are robots who have the power to move freely and transform between humanoid and locomotive/car forms at will--there's no reason to make a train that is weaker, smaller, and functionally tied to a small radius of movement for the sole purpose of assembling trains when trains can just line up in their order and then transform.

instead, to achieve a similair story, rusty is stuck in a yard management job--tackling schedules, yard work, maintenance, loading & unloading, etc

he has the same desire to pull passengers, but the thing holding him back is that he can't pick up a contract with any transit company due to both his rusted condition (with all the ways it affects him), and by being a steam engine when humans increasingly prefer the reliability and lower cost of hiring a diesel engine.

#with trains taking control of their own manufacturing and acting on free will it makes sense that all trains are built roughly equal#obviously not a thing for REAL ACTUAL TRAINS but we're not talking about those. we're talking about people-trains who have desires and live#anyways just random thoughts#this has been in my drafts since like the creation of this account#sketchbles#alsooo for the record too the same goes for coaches/freight (hollow) cars. upform* trains all roughly have the same freedom of movement#the major differences are their transformed forms and the functions of those forms and also like. power capacity#*racing mode/humanoid form. etc etc#stex

3 notes

·

View notes