#thermal management solutions

Explore tagged Tumblr posts

Text

Automotive Electronic Components & Thermal Management Solutions - Techni3

For more than two decades, Laird, a DuPont business, has capitalized on its materials science expertise to help Tier 1 automotive suppliers resolve complex electronics design challenges where the structure of the module causes EMI suppression and heat channeling issues. We are designers helping designers avoid wasted effort – and costs – and speeding the time-to-market for key automotive components.

Review our portfolio of automotive component protection solutions. Then contact us today.

Superior Protection From a Global Innovator in Material Science

EV Powertrain Electronics

Our team of engineers applies extensive industry knowledge about sub-assembly design to help safeguard automotive powertrain electronics from heat and EMI issues while resolving complex structural issues.

Examples include PFC chokes and transformers, which by their nature are not perfectly efficient and generate heat. Each must be housed individually – and thermally potted.

We get behind the wheel to help with thermal management solutions issues facing electric vehicles and offer two key differentiators. First, we are vertically integrated down to the magnetic ceramic powder. Second, as a significant thermal compounds supplier we are again vertically integrated down to the resins and fillers.

These differentiators help give us the green light to assume responsibility for automotive powertrain electronics performance and quality assurance across a much larger swath of the supply chain than our competitors.

LED Component Systems

Our team of engineers applies extensive industry knowledge about sub-assembly design to help suppress EMI crosstalk from LED automotive component systems. And to improve thermal management for electric vehicles, for example.

Modern lighting systems are comprised of a power supply, a digital control board, and a light source – all ideally physically separated from each other. The pressure to reduce size frequently results in placing the analog, digital, and optical functions close together and not electrically isolated. This can create electrical crosstalk and can expose the optics to processing chemicals needed for the analog and digital circuits.

Laird has a complete line of non-silicone and low outgassing silicone-based pads, greases and dispensable products. Most importantly, we have the experience to advise you about deploying a variety of strategies. Our multi-functional solutions help cool components and suppress EMI simultaneously – using a single space-saving product.

EV Powertrain ElectronicsADAS / Autonomous Driving Systems

Our team of engineers applies extensive industry knowledge about sub-assembly design to help safeguard ADAS electronic components from EMI and excessive heat while resolving complex structural issues.

Progressive ADAS sensor designs consume more power and emit more heat. To remain competitive, manufacturers must ensure optimum sensor efficiency or face the risk of throttled power, in turn sacrificing sensitivity, range and performance.

electromagnetic interference solutions is a barrier to function and compliance. Increasing transistor switching speeds cause various device fundamentals and harmonics to interact with each other, and the outside world, in unanticipated ways.

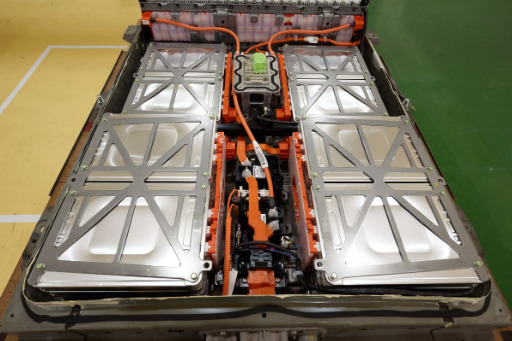

EV/PHEV Battery Packs

Our team of engineers applies extensive industry knowledge about sub-assembly design to help safeguard EV/PHEV battery packs from the consequences of excessive heat.

With increased charging speeds, battery packs emit ever increasing amounts of heat. Are packs actively or passively cooled? Must the thermal material act as a dielectric barrier? Is the pack silicone- or non-silicone mandated? Are the thermal materials themselves relied upon for mechanical support or for high compliance?

Ultimately, the appropriate choice of thermal interface materials satisfies the design constraints while simultaneously satisfying the economics. It comes after extensive evaluation of the total cost of ownership and true cost of implementation in a serial production setting. Huge material volumes are required. The importance of fast placement of preferred materials cannot be overstated.

Infotainment/Cluster Systems

Our team of engineers applies extensive industry knowledge of mechanical, thermal and electronic design to help safeguard infotainment/cluster systems from heat and EMI issues while resolving complex structural issues.

Infotainment electronics are employing greater functionality and higher speeds, causing more pronounced EMI and thermal challenges. A passive cooling strategy is imperative to eliminate the fan without relinquishing any gains in the power budget.

Following 20+ years of experience in infotainment electronics, Laird has a first-hand perspective on strategies that have succeeded and failed. We consult with our customers comprehensively on ridding systems of unwanted EMI and growing thermal loads, and on helping design teams succeed as they go-to-market.

0 notes

Text

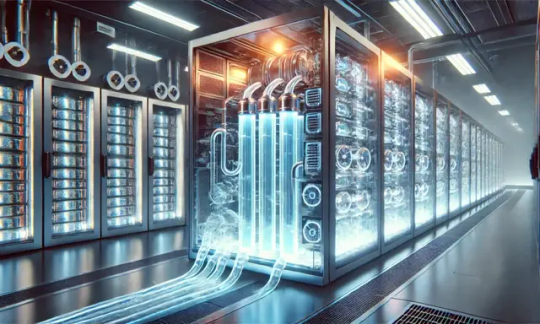

Thermal Management Solutions

Ensure optimal performance and longevity with reliable thermal management solutions, designed to control heat and protect your critical systems. Have a look at the image to enhance efficiency and reliability across all applications.

0 notes

Text

TitanX is a global partner to commercial vehicles manufacturers for heat transfer and engaged in developing thermal management solutions for a cleaner transport.

0 notes

Text

Custom Engineered Cooling Solutions

#Automotive cooling solutions#Engine temperature Sweden#Thermal management solutions#automotive cooling industry

0 notes

Text

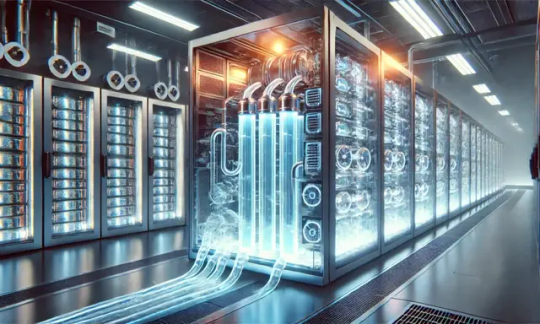

Exploring the Growing $21.3 Billion Data Center Liquid Cooling Market: Trends and Opportunities

In an era marked by rapid digital expansion, data centers have become essential infrastructures supporting the growing demands for data processing and storage. However, these facilities face a significant challenge: maintaining optimal operating temperatures for their equipment. Traditional air-cooling methods are becoming increasingly inadequate as server densities rise and heat generation intensifies. Liquid cooling is emerging as a transformative solution that addresses these challenges and is set to redefine the cooling landscape for data centers.

What is Liquid Cooling?

Liquid cooling systems utilize liquids to transfer heat away from critical components within data centers. Unlike conventional air cooling, which relies on air to dissipate heat, liquid cooling is much more efficient. By circulating a cooling fluid—commonly water or specialized refrigerants—through heat exchangers and directly to the heat sources, data centers can maintain lower temperatures, improving overall performance.

Market Growth and Trends

The data centre liquid cooling market is on an impressive growth trajectory. According to industry analysis, this market is projected to grow USD 21.3 billion by 2030, achieving a remarkable compound annual growth rate (CAGR) of 27.6%. This upward trend is fueled by several key factors, including the increasing demand for high-performance computing (HPC), advancements in artificial intelligence (AI), and a growing emphasis on energy-efficient operations.

Key Factors Driving Adoption

1. Rising Heat Density

The trend toward higher power density in server configurations poses a significant challenge for cooling systems. With modern servers generating more heat than ever, traditional air cooling methods are struggling to keep pace. Liquid cooling effectively addresses this issue, enabling higher density server deployments without sacrificing efficiency.

2. Energy Efficiency Improvements

A standout advantage of liquid cooling systems is their energy efficiency. Studies indicate that these systems can reduce energy consumption by up to 50% compared to air cooling. This not only lowers operational costs for data center operators but also supports sustainability initiatives aimed at reducing energy consumption and carbon emissions.

3. Space Efficiency

Data center operators often grapple with limited space, making it crucial to optimize cooling solutions. Liquid cooling systems typically require less physical space than air-cooled alternatives. This efficiency allows operators to enhance server capacity and performance without the need for additional physical expansion.

4. Technological Innovations

The development of advanced cooling technologies, such as direct-to-chip cooling and immersion cooling, is further propelling the effectiveness of liquid cooling solutions. Direct-to-chip cooling channels coolant directly to the components generating heat, while immersion cooling involves submerging entire server racks in non-conductive liquids, both of which push thermal management to new heights.

Overcoming Challenges

While the benefits of liquid cooling are compelling, the transition to this technology presents certain challenges. Initial installation costs can be significant, and some operators may be hesitant due to concerns regarding complexity and ongoing maintenance. However, as liquid cooling technology advances and adoption rates increase, it is expected that costs will decrease, making it a more accessible option for a wider range of data center operators.

The Competitive Landscape

The data center liquid cooling market is home to several key players, including established companies like Schneider Electric, Vertiv, and Asetek, as well as innovative startups committed to developing cutting-edge thermal management solutions. These organizations are actively investing in research and development to refine the performance and reliability of liquid cooling systems, ensuring they meet the evolving needs of data center operators.

Download PDF Brochure :

The outlook for the data center liquid cooling market is promising. As organizations prioritize energy efficiency and sustainability in their operations, liquid cooling is likely to become a standard practice. The integration of AI and machine learning into cooling systems will further enhance performance, enabling dynamic adjustments based on real-time thermal demands.

The evolution of liquid cooling in data centers represents a crucial shift toward more efficient, sustainable, and high-performing computing environments. As the demand for advanced cooling solutions rises in response to technological advancements, liquid cooling is not merely an option—it is an essential element of the future data center landscape. By embracing this innovative approach, organizations can gain a significant competitive advantage in an increasingly digital world.

#Data Center#Liquid Cooling#Energy Efficiency#High-Performance Computing#Sustainability#Thermal Management#AI#Market Growth#Technology Innovation#Server Cooling#Data Center Infrastructure#Immersion Cooling#Direct-to-Chip Cooling#IT Solutions#Digital Transformation

2 notes

·

View notes

Text

The Evolution of PCB Manufacturing: From Basics to High-Performance Boards

PCB manufacturing has evolved from single-layer boards to high-performance, multi-layered designs, enabling innovation in automotive, healthcare, telecommunications, and aerospace. Learn how cutting-edge PCB technologies support modern electronics and drive UK industries forward. Explore advanced PCB solutions for your business today.

#PCB manufacturing evolution#high-performance PCBs#multi-layer PCB design#PCB for 5G networks#advanced PCB technology#UK PCB industry#flexible PCBs#PCB signal integrity#automotive PCB solutions#medical device PCBs#aerospace PCB manufacturing#PCB miniaturisation#HDI PCBs#thermal management in PCBs#next-gen PCB solutions#A-Gas Electronic Materials

0 notes

Text

Model-Based System Engineering (MBSE) for Efficient Systems Design

Leverage Model-Based System Engineering (MBSE) to enhance efficiency in system simulations, design, and development for optimal performance. To know more about Model based system engineering visit https://eqmsol.com/1D-simulation.php#breadcrumb Model-Based System Engineering, 1D system simulation, engineering consultancy, thermal management solutions.

#Model-Based System Engineering#1D system simulation#engineering consultancy#thermal management solutions.

0 notes

Text

The Evolution of Battery Energy Storage Systems: Shaping the Future of Electric Vehicles

As the global push for sustainable transportation grows, electric vehicles (EVs) have emerged as a key player in reducing carbon emissions and advancing cleaner energy alternatives. At the heart of every electric vehicle is the battery energy storage system (BESS), a technology that stores energy for the electric motor and powers the vehicle. As EV adoption increases, ensuring that these batteries perform at their best becomes paramount. One of the most important factors influencing battery performance and longevity is managing the heat generated by the battery during charging and discharging cycles. This is where battery thermal management systems and effective vehicle cooling solutions come into play.

What is a Battery Energy Storage System (BESS)?

A battery energy storage system (BESS) is designed to store electrical energy in a vehicle's battery for later use. The most commonly used battery in EVs is the lithium-ion battery, known for its efficiency and energy density. However, like all energy storage systems, BESSs are sensitive to temperature. Excessive heat or cold can significantly impact their performance, range, and lifespan.

Battery thermal management systems (BTMS) are implemented to regulate the temperature of the battery and ensure that the BESS operates within optimal conditions. When the temperature of the battery pack is managed efficiently, it helps to:

Maintain optimal energy efficiency.

Extend the lifespan of the battery.

Reduce the risk of thermal runaway, a dangerous scenario where the battery becomes unstable and potentially ignites.

The Importance of Battery Thermal Management Systems in EVs

With battery energy storage systems being central to electric vehicle performance, it is essential to ensure that these systems remain within a safe temperature range. Batteries tend to overheat during charging or high power demand, which can reduce their energy output and degrade the cells over time. By maintaining the correct temperature, battery thermal management systems can:

Enhance Performance: Keeping the battery cool prevents energy loss that can occur when batteries overheat, ensuring the vehicle performs optimally under various driving conditions.

Improve Battery Life: Consistent and controlled temperatures prevent thermal stress on battery cells, prolonging their lifespan and maintaining their storage capacity over time.

Boost Safety: Lithium-ion batteries can overheat and potentially cause dangerous situations like thermal runaway. A good EV thermal management system prevents these issues by keeping the battery within a safe operating range.

Types of Battery Thermal Management Systems

Battery thermal management is typically achieved through one of several methods, depending on the design requirements of the vehicle and the capacity of the battery.

Air-Cooled Systems Air cooling systems circulate air around the battery to absorb heat and dissipate it into the surrounding environment. While air cooling is the simplest and most cost-effective option, it may not be suitable for high-performance vehicles or for regions with extreme temperatures.

Liquid-Cooled Systems Liquid cooling is a more advanced and efficient method used in most modern EVs. These systems circulate a coolant (often a mixture of water and glycol) around the battery, absorbing heat and expelling it through a radiator or other heat-exchanging components. Liquid-cooled systems are more effective at managing heat and are ideal for vehicles with larger battery packs.

Phase Change Materials (PCM) Some innovative systems use phase change materials (PCM), which absorb heat when they melt and release it when they solidify. This passive system helps to regulate temperature without requiring active cooling mechanisms, though it is still a developing technology in the field of battery energy storage systems.

Heat Pipe Systems Heat pipes use a combination of liquid and gas to transport heat away from critical components of the vehicle. These systems are known for their efficient heat transfer capabilities and are used in high-performance EVs to manage both battery and motor temperatures.

How Vehicle Cooling Solutions Integrate with Battery Thermal Management

The success of a battery thermal management system does not rely solely on the battery itself. The overall vehicle cooling solution plays a critical role in ensuring that the battery, as well as other components like the motor and electronics, remain at safe operating temperatures.

An integrated vehicle cooling solution typically includes:

Efficient battery pack placement: Optimizing the location of the battery pack within the vehicle can enhance airflow and cooling efficiency.

Radiators and heat exchangers: The cooling system will often include a dedicated radiator to help dissipate heat from the coolant circulating around the battery.

Active cooling systems: Using fans or pumps to ensure that the coolant is moving efficiently around the system, removing excess heat. In this way, the vehicle cooling solution ensures that the battery energy storage system is not only safe but also performs efficiently across a range of driving conditions, from extreme heat to cold environments.

Advancements in EV Battery Thermal Management

As the demand for electric vehicles grows, so does the need for more efficient battery thermal management systems. New materials, smarter systems, and more efficient technologies are being developed to meet these needs:

Graphene for Enhanced Heat Dissipation Graphene is a cutting-edge material that is incredibly efficient at dissipating heat. By incorporating graphene into battery thermal management systems, manufacturers can enhance the cooling capacity without increasing weight or complexity. This material is becoming more prevalent in next-generation battery energy storage systems.

AI and Smart Cooling Artificial intelligence (AI) is being integrated into battery thermal management systems to optimize cooling. AI algorithms can adjust the cooling process in real time based on driving conditions and battery temperature, ensuring that the vehicle always operates within the optimal temperature range, improving efficiency and safety.

Nanofluids Nanofluids, which are liquids infused with nanoparticles, can dramatically improve the thermal conductivity of coolants used in liquid-cooled systems. By improving heat transfer, nanofluids can help manage the high thermal loads that come with larger, more powerful battery packs.

Solid-State Batteries Solid-state batteries represent the future of EV battery technology. Unlike traditional batteries that use liquid electrolytes, these batteries employ a solid electrolyte, offering the potential for enhanced energy density, improved safety, and greater overall efficiency. As solid-state technology evolves, it may require new thermal management techniques, pushing the industry to innovate even further in EV battery cooling solutions.

Challenges in Battery Thermal Management

Despite these advancements, there are challenges that manufacturers must overcome to ensure the success of battery energy storage systems in electric vehicles:

Cost and Complexity: Advanced thermal management systems can increase the cost and complexity of EVs, which may deter some consumers. Balancing performance and affordability is key. Energy Efficiency: Cooling systems require energy, and ensuring that they do not drain the battery is a critical concern. More energy-efficient cooling methods must be developed to minimize this impact. Environmental Factors: EV batteries can experience significant temperature fluctuations based on geographical location. Thermal management solutions must be versatile enough to perform efficiently in both extreme heat and cold.

The Future of EV Battery Thermal Management

Looking ahead, the development of smarter, more efficient battery energy storage systems will be crucial in driving the future of electric vehicles. The goal is to create cooling solutions that are not only effective but also cost-efficient, lightweight, and scalable to suit a wide range of EV models. Whether through graphene-based solutions, nanofluids, or AI-enhanced cooling, the future of EV thermal management systems will likely see innovations that improve both performance and safety.

As the electric vehicle industry continues to grow, the role of battery energy storage systems will remain pivotal. With continued advancements in battery thermal management technologies, we can look forward to a future where EVs are more efficient, more reliable, and safer than ever before.

Conclusion

The advancement of battery energy storage systems and battery thermal management systems is crucial for the future of electric vehicles. Efficient cooling solutions play a vital role in ensuring that EV batteries operate at their best, stay safe, and enjoy prolonged longevity, all of which are key factors in fostering widespread adoption. As innovation propels the development of new technologies, we can expect EV battery cooling to become more advanced, energy-efficient, and accessible, setting the stage for the next generation of electric vehicles. Companies like Liquid Plates are leading the charge in creating cutting-edge solutions to meet these evolving demands.

#battery energy storage system#vehicle cooling solution#ev thermal management system#battery thermal management system#EV Battery Cooling#ev cars#thermal solutions

0 notes

Text

Top 5 Uses of Mica Paper: A Comprehensive Guide for Engineers and Designers | OmkarPaper

Discover the top 5 uses of mica paper in engineering and design with our comprehensive guide. Learn how mica paper enhances electrical insulation, thermal management, and structural applications. Perfect for engineers and designers seeking innovative solutions. Explore OmkarPaper's offerings today!

#Mica Paper Uses#Mica Paper for Engineers#Mica Paper for Designers#Electrical Insulation Mica Paper#Thermal Management Mica Paper#Structural Mica Paper Applications#Fireproof Mica Paper#Decorative Mica Paper Laminates#OmkarPaper Mica Solutions#Mica Paper Provider Service

0 notes

Text

0 notes

Text

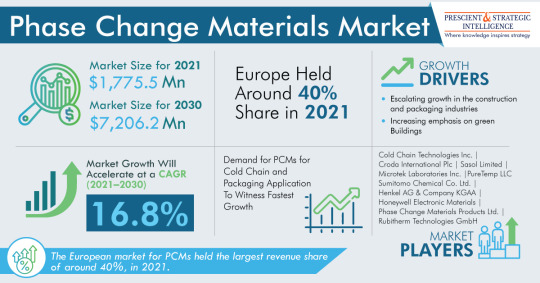

Transforming Industries: Phase Change Materials Market Insights

As stated by P&S Intelligence, the total revenue generated by the phase change materials market was USD 1,775.5 million in 2021, which will power at a rate of 16.8% by the end of this decade, to reach USD 7,206.2 million by 2030.

This has a lot to do with the increasing growth in the construction and packaging sectors and increasing importance on green buildings.

Cold chain and packaging category will grow at the highest rate, of above 17%, in the years to come. This can be mostly because of the surge in PCM requirement to sustain precise temperatures through the supply chain while lowering the emissions of carbon dioxide. Using ACs and electric fans to stay cool contributes to approximately 20% of the total electricity employed in buildings globally. The increasing requirement for space cooling is straining quite a few countries' power infrastructure, along with bringing about increased emissions.

With the enormous increase in the requirement for energy-efficient ACs, the requirement for PCMs will soar, as the electrical consumption of modified ACs with PCMs could be brought down by 3.09 kWh every day.

Europe dominated the industry with a share, of about 40%, in the recent past. The predisposition toward the acceptance of eco-friendly materials will power the PCM industry in the region. European regulatory associations, such as the SCANVAC, took more than a few initiatives for developing and promoting and effective building mechanical solutions and increase awareness pertaining to PCM applications.

The convenience of paraffin at a wide range of temperatures is a major reason for its appropriateness as an energy storage medium. Likewise, paraffin-based PCM is called a waxy solid paraffin, safe, dependable, noncorrosive, and economical material.

HVAC systems had the second-largest share, of about 30%, in phase change materials market in the recent past. This has a lot to do with the fact that PCM installation decreases fluctuations of temperature. HVAC with PCM supports in maintaining a steadier temperature and eliminating thermal uneasiness caused by alterations in temperature. It is because of the emphasis on green buildings, the demand for phase change materials will continue to rise considerably in the years to come.

#Phase Change Material Market#Phase Change Material Market Size#Phase Change Material Market Share#Phase Change Material Market Growth#Phase change materials (PCMs)#Thermal energy storage#Energy efficiency solutions#Heat management technology#Sustainable materials#Building insulation#HVAC systems#Thermal regulation#Cold chain logistics#Renewable energy storage#Temperature-sensitive packaging

0 notes

Text

How Can Computational Fluid Dynamics (CFD) Be Used For Designing Better EV Battery And Thermal Management Systems (BTMS)

Introduction Electric vehicle batteries are transforming how we move, live, and work. Architects and engineers have a crucial role in shaping the future of EVs and their integration with buildings and infrastructure. By understanding electric vehicle batteries’ challenges and opportunities, they can create innovative and sustainable solutions that benefit both people and the planet. However, EVs…

View On WordPress

#Battery Heat Dissipation#BTMS#BTMS Optimization#CFD#CFD for Battery Design#CFD in BTMS#CFD Simulation for EV Batteries#Computational Fluid Dynamics#Computational Fluid Dynamics for EV Batteries#Computational Fluid Dynamics for Thermal Management#Designing Better EV Battery#EV Battery Cooling#EV Battery Cooling Solutions#EV Battery Design#EV Battery Efficiency#Thermal Management in EV Batteries#Thermal Management Systems

0 notes

Text

Fellow Travelers Fic Recs | Featured WIPs: May/June

Active WIPs with an updated chapter posted in the past two months. Most recent works posted on top. Featuring a Jackson and Tim reunion, not one but two afterlife AU's, a pizza delivery driver AU, some more of everyone's favorite fake dating Disaster, Fire Island, another hospital conversation and even more time travel. Take your pick... There's something for everyone!

Happy reading!

✨ Be sure to show the authors some love and appreciation with kudos and comments on the fics you enjoyed!

right or wrong i can't get along without you by @promise-you-wont-write | masterwords [NR, 3K] Jackson Fuller disappears and everyone fears the worst - until he turns up in San Francisco asking Tim for help.

Almost Paradise by @likerealpeopledo-on-ao3 | Likerealpeopledo [T, 8K] In 1992, Hawk dies and goes...somewhere.

Equal parts apology tour, long-awaited reunions, and reluctant spiritual exploration, Hawk takes a journey through the afterlife and back to Tim.

A Disaster, Beyond Measure by drabbleswabbles💠 [NR, 50K] Hawkins Fuller is a campaign manager with a PR disaster on his hands. The solution involves pretending to date none other than Timothy Laughlin.

Featuring: unrealistic portrayals of the life and job of a campaign manager for the sake of the fake dating trope.

Added Delivery Fees by spiffyyy💠 [E, 12K] Hawk stared at him. Thick black glasses that he adjusted as he turned with a serviced half grin. A goofy red ball cap hat that covered straight brown hair cut in a neat trim. He was cute: in an endearing, somewhat dorky way.

The man laughed. ���I was a little worried I was at the wrong place.” He turned back and shuffled over as he unzipped the thermal bag. “This is like some government office, right?” “Senate affairs,” Hawk evenly supplied. Or, Hawk falls hard for a pizza delivery worker despite his best attempts not to.

Within The Heart of Me by drabbleswabbles💠 [NR, 14K] Lucy goes to the hospital to talk to Tim. When she arrives, Hawk is already there.

Otherwise known as a prompt fill that wanders a bit off the mark, but is close enough in spirit to give credit where credit is due as far as inspiration goes.

I Have You by @beyondxmeasure | Cyantific [NR, 3K] After receiving a cryptic postcard, and hearing from Lucy that Hawk's in trouble, Tim takes a trip back east to find out for himself.

A different version of the events that unfold in Fire Island, told from Tim's perspective.

Part 3 of FT Talk Hub Sunday Drabbles & Snippets

just like romantic verses, just like a joyous end by @startagainbuttercup | startagainbuttercup [T, 1K] One day Hawk spots a new handsome teacher. It's a bad idea to lust after your colleague, but Hawk is only a man.

Sands of Time (Turn Backwards) by @brouill3r | brouiller [NR, 30K] 1987 Hawkins Fuller is full of regrets for the life he's lived, though Tim once told him he regrets nothing. Hawk so wishes he could say the same.

In the still night air of a hotel room, clutching a cracked paperweight to his chest like it's carved of the finest gold, Hawk gets his wish.

Or, a time-travel fix-it fic that nobody asked for.

look homeward, angel by @earth-3490s | earth3490s [NR, 1K] Hawkins Fuller died on a rainy Sunday in 2001, at a DC hospital with his daughter holding his hand.

AU based on The Five People You Meet in Heaven.

💠Authors: if your tumblr (or other socials) isn’t linked, and you'd like it to be, let me know and I'll be happy to add it! Or, if you’re linked already and would prefer not to be, please contact me to remove it.

#fellow travelers fic recs#ftficrecs#ftfics wips#fellow travelers fics#wips#works in progress#fellow travelers#ftfics jun24

18 notes

·

View notes

Text

Enhancing mechanical and thermoelectric performance of alloy for chip-scale refrigeration

The advancement of information technology necessitates efficient thermal management for chips to ensure stable information transmission. Meanwhile, the thermal management technology must be vibration-free and easily miniaturized to accommodate increasingly integrated chip modules. Peltier coolers (PCs) based on the thermoelectric (TE) effect have emerged as one of the most promising solutions for chip-scale refrigeration, garnering increasing attention in recent years. Currently, bismuth telluride (Bi2Te3) alloy remains the only candidate material available for commercial PCs. Unfortunately, the layer-structured Bi2Te3 is connected by van der Waals forces, and thus exhibits poor mechanical properties, posing great challenges in miniaturization. Therefore, enhancing both the mechanical strength and TE performance of bismuth telluride alloy is crucial in the miniaturization and integration of PCs.

Read more.

#Materials Science#Science#Transistors#Electronics#Thermoelectric#van der Waals#Bismuth telluride#Bismuth#Tellurium#Materials processing

6 notes

·

View notes

Text

The Power Of Polymer: Unfolding The Magic Of Polyurethane Foam Production

INTRODUCTION:

In the dynamic and evolving world of polymer science, one name specifically stands out due to its versatility and vast applicability – Polyurethane. A byproduct of the mind-boggling chemical reaction between two liquid materials, polyurethane is a unique type of polymer that effectively transforms into a foam. This article endeavors to offer you a detailed look into the exciting world of polyurethane foam production

THE DYNAMIC DUO:

Polyurethane foam is produced when two chemically distinct liquid materials – commonly referred to as the “”A”” component and “”B”” component – are combined under specifically controlled conditions.

The “”A”” component, or Polymeric MDI (methylene diphenyl diisocyanate), is a reactive isocyanate that boasts a relatively low viscosity level, enabling it to mix flawlessly with the “”B”” component. It has a brownish coloration and often exudes a slightly sweet smell.

Meanwhile, the “”B”” component, also known as Polyol, is a polyether compound that is generally less reactive than its “”A”” counterpart. It is characterized by a pale, almost transparent color and presents a tasteless, odorless profile.

POLYURETHANE PRODUCTION:

Let’s delve into the fascinating process through which these two distinct liquids join forces to produce the mighty polyurethane foam.

When combined, the polyether polyol and the polymeric MDI kickstart an exothermic chemical reaction that generates a considerable amount of heat. During this process, tiny gas bubbles are formed, which get trapped within the polymer structure, eventually giving rise to what we commonly recognize as foam. This intriguing process is commonly referred to as “”foaming.””

The reaction’s speed and the cell structure’s quality are heavily dependent on the specific quantities and properties of the A and B components. Manipulating these parameters allows for the production of a wide variety of foam types from rigid and semi-rigid to flexible. Additionally, various catalysts and surfactants can be added to control the cell structure’s size and distribution, as well as the reaction speed.

The transformation process from a liquid state to a solid, foamed state is surprisingly quick – often taking less than a few minutes. However, it’s noteworthy to mention that the foam continues to cure and reach its complete strength over the course of a few hours or even days.

APPLICATIONS OF POLYURETHANE FOAM:

The versatility of polyurethane foam is extraordinary. From furniture and bedding to automotive applications, thermal insulation in construction, and even in the footwear industry, polyurethane foam has spread its roots far and wide.

UNDERSTANDING THE SCIENCE:

The combination of a polyether polyol and a polymeric MDI generates not just heat but also a new product – urethane. Urethane forms strong, resilient bonds that contribute to the flexible, durable nature of the resultant foam. This is what makes polyurethane an excellent choice for various applications that require durability, flexibility, and excellent thermal and acoustic insulation properties.

In conclusion, the creation of polyurethane foam from two liquid materials is a mesmerizing example of polymer formation, which encapsulates the dexterity and capability of synthetic chemistry. By manipulating the compounds’ properties and the conditions under which the reaction occurs, scientists and engineers have managed to expand the realms of possibility, thereby furthering the boundaries of modern industrial applications. Thus, polyurethane foam not only offers an excellent material for various purposes but also profoundly echoes the power and potential of polymer science.

Tagged Foundation Solutions, Polymer, Power Of Polymer

#Foundation Solutions#Power Of Polymer#Foundation Repair#Foundation#Polymer#foundation contractor#foundation experts#foundation services#foundation repair near me

6 notes

·

View notes

Text

Protecting Your AI Investment: Why Cooling Strategy Matters More Than Ever

New Post has been published on https://thedigitalinsider.com/protecting-your-ai-investment-why-cooling-strategy-matters-more-than-ever/

Protecting Your AI Investment: Why Cooling Strategy Matters More Than Ever

Data center operators are gambling millions on outdated cooling technology. The conversation around data center cooling isn’t just changing—it’s being completely redefined by the economics of AI. The stakes have never been higher.

The rapid advancement of AI has transformed data center economics in ways few predicted. When a single rack of AI servers costs around $3 million—as much as a luxury home—the risk calculation fundamentally changes. As Andreessen Horowitz co-founder Ben Horowitz recently cautioned, data centers financing these massive hardware investments “could get upside down very fast” if they don’t carefully manage their infrastructure strategy.

This new reality demands a fundamental rethinking of cooling approaches. While traditional metrics like PUE and operating costs are still important, they are secondary to protecting these multi-million-dollar hardware investments. The real question data center operators should be asking is: How do we best protect our AI infrastructure investment?

The Hidden Risks of Traditional Cooling

The industry’s historic reliance on single-phase, water-based cooling solutions carries increasingly unacceptable risks in the AI era. While it has served data centers well for years, the thermal demands of AI workloads have pushed this technology beyond its practical limits. The reason is simple physics: single-phase systems require higher flow rates to manage today’s thermal loads, increasing the risk of leaks and catastrophic failures.

This isn’t a hypothetical risk. A single water leak can instantly destroy millions in AI hardware—hardware that often has months-long replacement lead times in today’s supply-constrained market. The cost of even a single catastrophic failure can exceed a data center’s cooling infrastructure budget for an entire year. Yet many operators continue to rely on these systems, effectively gambling their AI investment on aging technology.

At Data Center World 2024, Dr. Mohammad Tradat, NVIDIA’s Manager of Data Center Mechanical Engineering, asked, “How long will single-phase cooling live? It’ll be phased out very soon…and then the need will be for two-phase, refrigerant-based cooling.” This isn’t just a growing opinion—it’s becoming an industry consensus backed by physics and financial reality.

A New Approach to Investment Protection

Two-phase cooling technology, which uses dielectric refrigerants instead of water, fundamentally changes this risk equation. The cost of implementing a two-phase cooling system—typically around $200,000 per rack—should be viewed as insurance for protecting a $5 million AI hardware investment. To put this in perspective, that’s a 4% premium to protect your asset—considerably lower than insurance rates for other multi-million dollar business investments. The business case becomes even clearer when you factor in the potential costs of AI training disruption and idle infrastructure during unplanned downtime.

For data center operators and financial stakeholders, the decision to invest in two-phase cooling should be evaluated through the lens of risk management and investment protection. The relevant metrics should include not just operating costs or energy efficiency but also the total value of hardware being protected, the cost of potential failure scenarios, the future-proofing value for next-generation hardware and the risk-adjusted return on cooling investment.

As AI continues to drive up the density and value of data center infrastructure, the industry must evolve its approach to cooling strategy. The question isn’t whether to move to two-phase cooling but when and how to transition while minimizing risk to existing operations and investments.

Smart operators are already making this shift, while others risk learning an expensive lesson. In an era where a single rack costs more than many data centers’ annual operating budgets, gambling on outdated cooling technology isn’t just risky – it’s potentially catastrophic. The time to act is now—before that risk becomes a reality.

#000#2024#Accelsius#aging#ai#AI Infrastructure#ai training#approach#budgets#Business#cooling#data#Data Center#Data Centers#disruption#Economics#efficiency#energy#energy efficiency#engineering#factor#financial#Fundamental#Future#gambling#Hardware#how#how to#Industry#Infrastructure

2 notes

·

View notes