#Phase Change Material Market Size

Explore tagged Tumblr posts

Text

Phase Change Material Market Analysis: Key Players and Competitive Landscape

Growing Demand for Energy Efficiency and Thermal Management Solutions Fuels Expansion in the Phase Change Material Market.

The Phase Change Material Market Size was valued at USD 536.3 Million in 2023 and is expected to reach USD 2,721.7 Million by 2032, growing at a CAGR of 19.8% over the forecast period of 2024-2032.

The Phase Change Material (PCM) Market is driven by the increasing demand for energy-efficient thermal management solutions across various industries. PCMs are materials that absorb, store, and release thermal energy during phase transitions (solid to liquid and vice versa), making them ideal for applications in building & construction, HVAC, cold chain logistics, textiles, and electronics. With rising global energy consumption and strict regulations on energy efficiency, industries are rapidly adopting PCM-based solutions to enhance thermal performance and reduce energy costs.

Key Players

AI Technology Inc. (Thermoelectric materials, Thermal Interface Materials)

Appvion Inc. (PCM-based papers, Thermoregulated packaging solutions)

Boyd Corporation (Thermal management materials, Heat exchangers)

Celgard LLC (Battery separator films, Lithium-ion battery separators)

Climator Sweden AB (Climator PCM modules, PCM-based thermal storage systems)

Cold Chain Technologies Inc. (Thermal packaging, Phase change material packs)

Cryopak (Thermal insulation products, PCM-based shipping solutions)

DuPont de Nemours, Inc. (Thermally conductive materials, PCM-based solutions)

Entropy Solutions (PURETemp PCM, Thermal energy storage systems)

Henkel AG & Company KGAA (Thermal interface materials, Thermal management adhesives)

Future Scope

The PCM market is expected to experience strong growth due to advancements in material science, increasing investment in renewable energy, and growing adoption in smart buildings. The construction industry is leveraging PCM-based insulation to enhance energy efficiency in residential and commercial buildings. The cold chain logistics sector is witnessing a surge in PCM usage for temperature-controlled transportation of pharmaceuticals, vaccines, and perishable goods. Additionally, emerging applications in electric vehicles (EVs), aerospace, and wearable technology are expanding market potential. The integration of bio-based and sustainable PCMs is further enhancing their appeal in green energy solutions.

Emerging Trends

The market is shifting towards bio-based and encapsulated PCMs, ensuring higher thermal stability and environmental sustainability. Innovations in nano-enhanced PCMs are improving heat transfer efficiency, making them more effective for electronics cooling and smart textiles. The demand for thermal energy storage (TES) systems in solar power plants and industrial heating applications is also accelerating PCM adoption. Additionally, PCM-infused packaging materials are gaining popularity in the e-commerce and food delivery sectors to maintain product freshness.

Key Points

Growing demand for energy-efficient thermal management solutions in construction, HVAC, and cold chain logistics.

Rising adoption of PCM-based insulation to meet energy efficiency regulations.

Increasing use of PCMs in electric vehicles, smart textiles, and aerospace applications.

Development of bio-based and nano-enhanced PCMs for improved sustainability and performance.

Expanding role of PCMs in thermal energy storage (TES) for renewable energy applications.

Conclusion

The Phase Change Material Market is set for robust expansion as industries prioritize sustainability, energy efficiency, and thermal management innovations. With growing applications across construction, transportation, electronics, and renewable energy, PCM technology is playing a crucial role in reducing energy consumption and carbon footprints worldwide. As research continues to drive new material advancements, PCMs are expected to become a key enabler of next-generation energy-saving solutions.

Read Full Report: https://www.snsinsider.com/reports/phase-change-material-market-1812

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Phase Change Material Market#Phase Change Material Market Size#Phase Change Material Market Share#Phase Change Material Market Report#Phase Change Material Market Forecast

0 notes

Text

Transforming Industries: Phase Change Materials Market Insights

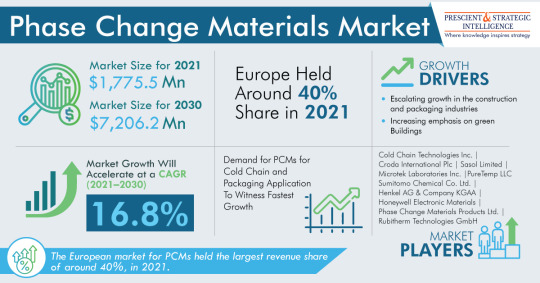

As stated by P&S Intelligence, the total revenue generated by the phase change materials market was USD 1,775.5 million in 2021, which will power at a rate of 16.8% by the end of this decade, to reach USD 7,206.2 million by 2030.

This has a lot to do with the increasing growth in the construction and packaging sectors and increasing importance on green buildings.

Cold chain and packaging category will grow at the highest rate, of above 17%, in the years to come. This can be mostly because of the surge in PCM requirement to sustain precise temperatures through the supply chain while lowering the emissions of carbon dioxide. Using ACs and electric fans to stay cool contributes to approximately 20% of the total electricity employed in buildings globally. The increasing requirement for space cooling is straining quite a few countries' power infrastructure, along with bringing about increased emissions.

With the enormous increase in the requirement for energy-efficient ACs, the requirement for PCMs will soar, as the electrical consumption of modified ACs with PCMs could be brought down by 3.09 kWh every day.

Europe dominated the industry with a share, of about 40%, in the recent past. The predisposition toward the acceptance of eco-friendly materials will power the PCM industry in the region. European regulatory associations, such as the SCANVAC, took more than a few initiatives for developing and promoting and effective building mechanical solutions and increase awareness pertaining to PCM applications.

The convenience of paraffin at a wide range of temperatures is a major reason for its appropriateness as an energy storage medium. Likewise, paraffin-based PCM is called a waxy solid paraffin, safe, dependable, noncorrosive, and economical material.

HVAC systems had the second-largest share, of about 30%, in phase change materials market in the recent past. This has a lot to do with the fact that PCM installation decreases fluctuations of temperature. HVAC with PCM supports in maintaining a steadier temperature and eliminating thermal uneasiness caused by alterations in temperature. It is because of the emphasis on green buildings, the demand for phase change materials will continue to rise considerably in the years to come.

#Phase Change Material Market#Phase Change Material Market Size#Phase Change Material Market Share#Phase Change Material Market Growth#Phase change materials (PCMs)#Thermal energy storage#Energy efficiency solutions#Heat management technology#Sustainable materials#Building insulation#HVAC systems#Thermal regulation#Cold chain logistics#Renewable energy storage#Temperature-sensitive packaging

0 notes

Text

Strategies for Reducing Food Waste in Restaurants

Food waste reduction is a real pressing issue that affects our planet and leads to substantial financial loss for companies, especially the restaurant sector. Around one-third of the food meant for human consumption produced globally every year goes to waste — approximately 1.3 billion tons, according to the Food and Agriculture Organization (FAO). For restaurants, this is both a challenge and an opportunity. Palate cleanser: It is possible for restaurants to save money while boosting their sustainability and appealing to eco-conscious consumers by implementing waste reduction strategies.

Understanding the Scope of Food Waste in Restaurants

Before we get into strategies, it’s crucial to understand where restaurants waste food and its impact. Food waste can be categorized into various stages in a restaurant’s operations:

Purchasing and Inventory Management:

Over-ordering of ingredients, imprecise forecasting, and poor storage practices are some of the main reasons behind spoilage and waste.

Food Preparation:

This phase encompasses waste generated during cutting, peeling and preparing food. Not every food scrap is usable, but most can serve a second life in stocks, sauces or composting.

Serving and Portioning:

Large portion sizes, failure to communicate menu items with customers, or simply not customizing portions to the customer’s taste can leave food on plates untouched.

Customer Waste:

Customers may waste food at the point of consumption. This is true, for example, in buffet- or family-style servings in which customers tend to get more than is actually necessary.

Post-consumption:

When food is left after consumption and is not given away or recycled, it is often thrown away.

The problem for the restaurants is how to deal with food waste minimization and at the same time accomplish the desired food quality and the satisfaction of the customers. It follows that devising and using sound approaches to food waste minimization is not only ecologically sound but makes business sense.

1. Improve Inventory Management

Efficient management of items in include Field Normalized Items Helped Level(s) – Include Level(s)/An Item Management for Efficient Use Minimization of Spaces (Etalons Inventory) – Allocate Appropriate Time Together with all Frequently Added by Users Items Ordered As The Components Eg Groceries Such Plus Da Foods or Beverages Such or Canned Soup

Best Practices for Inventory Management:

Use Data and Predictive Tools:

Identify historical surveys on targets in terms of demand Guess at the future need of a particular item with the support of the mandated technology. Consumption Pattern for A Particular Item And Its Successive Application to Estimate Future Requirement Minimum Order Quantity for Presales To Minimize Holding Cost of Revision Points of Sale POS Forecasts Data Driven Needs Analysis And Application.

First İn First Out (FIFO) System:

Ensure all older stocks are consumed before newer stock in circulation to achieve his or her aim of improving customer satisfaction that is through minimizing stock tremendous losses. Protect storage and telling peri with raw materials's less risk of spoilage such as.

Regular Stock Checks:

Undertake inventory management to avoid overordering of stock and establish how soon certain items can become obsolete and should be consumed. Maintaining ideal conditions of storage as well can help improve shelf life.

Optimize Supplier Relationships

Collaborate with suppliers to ensure that stock inventories are not rigid and changes can be made to meet market needs. Even some suppliers would also be willing to accept back some excess stock for the future use.

Designing the Menu with Portion and Food Control

In relation to food preparation and consumption, menu design is crucial as it creates an impact in food wastage minimization.

Designing a restaurant menu in particular should include the following strategies:

Flexible Portions:

Incentivise clients to self-determine the size of their portions, for instance the option to have a smaller portion, opt for a ‘half-plate’ and such. That effectively reduces the chances of food being returned to the kitchen uneaten by customers.

Prepare Leftovers:

Create a menu containing ingredients that are useful in the preparation of more than one dish. This way all the excess stock will not go to waste since it will be put to use in preparing other meals, thereby reducing wastage.

Create Specials Out of Wasted Ingredients:

Whenever you are in possession of perishable ingredients which are close to expiry, create specials featuring the ingredients instead. That way there is a reduction in wastage and at the same time there is possible use of the ingredients in making appealing dishes that are out of the ordinary.

Creative Use of Leftover Scraps:

With regards to carrot tops and beet, these can be used in salads or pestos, while bread ends can be made into croutons. There are also other ways to make use of food scraps by incorporating them into other food items for example, using vegetable peels.

Portion Control Techniques:

Use Standardized Recipes:

By setting a group of standardized recipes on how things should be done or sizes of food, more food wastes are controlled since food quality and portion control are ensured.

Train Staff in Proper Portioning:

Explain what are the reasons behind these measurements to the cooks and order them to implement such measures. When a portion is too big, it wastage occurs, even on a customer’s plate and inside the kitchen.

Offer Takeaway Options:

Retrieve food that could have been wasted. Rather than using an excuse of having no containers for takeout, truly make them offer. Tell your workers to explain the option of take out whenever people leave food on the table, which should not be the case at all.

3. Reduce Food Waste Through Repurposing and Recycling

This can easily be accomplished by using leftover food for example. If you have roast chicken from last night, there is absolutely no need to throw it out as it can be used to bake stocks. There are many ways to do this.

Repurposing Strategies:

Make Stocks and Sauces:

These are edibles which are deemed nay useless by quite a number of restaurants. Instead of discarding, leftovers should be combined with vegetable scraps and created behind to be used in gravies, sauces, which will reduce the amount of food waste by a considerable amount.

Composting:

Organic waste is often abused and thrown in the garbage, which shouldn’t be practiced. There is unused food which includes coffee grounds or fruit cores which can be composted, increasing its usage.

Food Donation:

Finding a local shelter, food bank or charity can be relied on which one can serve food beyond what one has to eat themselves, which is a positive way to nourish oneself while decreasing food waste.

Repurpose Day-Old Bread:

One of the most ideal ways to ensure food being wasted decreases is repurpose day old bread. Croutons, breadcrumbs, or even desserts like bread pudding can be made, which is a perfect way to ensure food which would have otherwise been thrown away.

5. Educate and Train Staff

Proper training and education are essential for any strategy to be effective in reducing food waste. Staff members should understand the importance of minimizing waste and be equipped with the knowledge to make changes in their daily routines.

Staff Training Tips:

Training Programs on Waste Reduction:

Organize regular training sessions focused on food waste awareness. Train staff on portion sizes, how to properly store food, and the importance of using food scraps creatively.

Encourage Communication:

Foster a culture where staff members feel comfortable discussing food waste with management. Encourage them to share ideas for reducing waste, as they often have valuable insights from the ground level.

Incentivize Waste Reduction:

Consider creating an incentive program that rewards staff for coming up with waste-reduction ideas or achieving certain waste-reduction goals.

6. Engage Customers in the Effort

Customers also play an integral role in reducing food waste. Engaging them in the process can not only help minimize waste but can also enhance their dining experience.

Customer Engagement Strategies:

Educate Customers on Food Waste:

Use your menu or signage in the restaurant to educate diners on the importance of food waste reduction. This could include messages about sourcing, composting efforts, or the benefits of ordering the right portion sizes.

Offer Leftover Boxes:

Encourage customers to take home leftovers by offering them the option of takeaway containers, particularly for large portions that may not be finished in one sitting.

Promote Sustainable Practices:

Offer discounts or incentives for customers who choose sustainable options, such as smaller portion sizes or plant-based meals, which generally have a lower environmental impact.

Showcase Waste-Reducing Practices:

Make your waste-reduction efforts a part of your brand identity. Let customers know about your sustainability initiatives, such as food donations or composting, which can enhance your restaurant’s appeal to eco-conscious diners.

Conclusion

Reducing food waste in restaurants requires a comprehensive and multi-disciplinary approach. This includes effective inventory management. Creating a thoughtful menu Creative use of ingredients use of technology Engaging employees and customers in waste reduction efforts To apply these strategies Restaurants not only have an impact on the environment... It also reduces, but the ability to make profits grows. Increase operational efficiency and strengthen your brand's reputation... The financial savings and sustainability benefits of reducing food waste are undeniable. And as consumers increasingly value environmental responsibility. Implementing these strategies can help restaurants stay competitive in an ever-evolving market. Ultimately, reducing food waste isn't just good for business, it's good for the planet.

3 notes

·

View notes

Text

Decorated Apparel Market Size, Share, Growth, Trends and Forecast 2023-2030

The decorated apparel market is witnessing a transformative phase, with several new trends taking center stage and reshaping the industry landscape. In 2023, a confluence of factors, including technological advancements, changing consumer preferences, and a renewed focus on sustainability, has given rise to innovative trends that are capturing the attention of both manufacturers and consumers. This article explores the key emerging trends in the decorated apparel market and highlights notable developments in 2023.

Sustainable Fashion:

In response to the growing global awareness of environmental issues, the decorated apparel market is experiencing a surge in sustainable fashion trends. Companies are increasingly adopting eco-friendly materials, such as organic cotton and recycled fabrics, and incorporating sustainable production practices. This shift is not only meeting the demand for environmentally conscious products but also reflecting a broader commitment to responsible manufacturing in the apparel industry.

Recent Developments (2023): Several leading companies, including Adidas and H&M, made significant strides in sustainable decorated apparel. These brands introduced eco-friendly collections, featuring garments made from recycled materials and utilizing innovative printing methods with reduced environmental impact.

Access sample report (including graphs, charts, and figures): https://univdatos.com/reports/decorated-apparel-market?popup=report-enquiry

Tech-Driven Customization:

The demand for personalized and unique apparel experiences is driving the trend of tech-driven customization. Companies are leveraging advanced technologies, such as augmented reality (AR) and artificial intelligence (AI), to offer consumers interactive and personalized design options. Virtual try-on features and design tools are becoming commonplace, allowing customers to visualize and customize their apparel before making a purchase.

Recent Developments (2023): Nike and Puma, two industry giants, embraced tech-driven customization. They launched online platforms with immersive AR experiences, enabling customers to personalize their apparel by choosing colors and patterns and even adding personalized graphics.

Rise of Niche Markets:

As consumer preferences become more diverse, niche markets within the decorated apparel industry are flourishing. Brands are catering to specific interests, subcultures, and communities, producing limited-edition collections that resonate with niche audiences. This trend not only fosters brand loyalty but also allows consumers to express their individuality through apparel that aligns with their unique interests.

Recent Developments (2023): Streetwear brands like Supreme and Off-White continued to dominate niche markets, collaborating with artists, musicians, and influencers to create exclusive, limited-edition collections. These collaborations generated considerable buzz and drove demand for unique, collectible apparel.

Digital-First Retail Strategies:

The accelerated shift towards online shopping has prompted companies to adopt digital-first retail strategies. Enhanced e-commerce platforms, coupled with seamless mobile experiences, are becoming essential for engaging consumers. The integration of virtual showrooms, 3D product displays, and interactive content is creating immersive online shopping environments, enhancing the overall customer experience.

Recent Developments (2023): Zara and ASOS, major players in the fashion retail sector, invested heavily in digital-first strategies. Zara introduced virtual fitting rooms, allowing customers to virtually try on apparel using AR technology, while ASOS focused on optimizing its mobile app for a more intuitive and personalized shopping experience.

Click here to view the Report Description & TOC: https://univdatos.com/reports/decorated-apparel-market

Conclusion:

The decorated apparel market is in the midst of a fascinating transformation, driven by a convergence of sustainability, technology, and niche market dynamics. The trends discussed, including sustainable fashion, tech-driven customization, the rise of niche markets, and digital-first retail strategies, are reshaping the industry's landscape and influencing how consumers engage with and purchase apparel. The developments in 2021, marked by the efforts of industry leaders like Adidas, H&M, Nike, Puma, Supreme, Off-White, Zara, and ASOS, highlight a collective commitment to innovation and meeting the evolving demands of a dynamic market. As these trends continue to unfold, the future of the decorated apparel market appears poised for continued growth, fueled by creativity, sustainability, and a deep understanding of consumer preferences.

According to the UnivDatos Analysis, Emerging Trends in the Decorated Apparel will drive the global scenario of the Decorated Apparel market and as per their “Decorated Apparel Market” report, the global market was valued at USD 22.27 billion in 2022, growing at a CAGR of 12% during the forecast period from 2023 - 2030 to reach USD 34 billion by 2030.

Contact Us:

UnivDatos

Email: [email protected]

Contact no: +1 978 733 0253

Website: www.univdatos.com

1 note

·

View note

Text

USA and Canada Cold Chain Packaging Market Size, Share, Demand, Growth and Future Outlook 2033: SPER Market Research

Cold chain packaging, referred to as temperature-controlled packaging, is intended to preserve the integrity of products that are sensitive to temperature changes throughout storage and transit. This method is widely utilized in the pharmaceutical, biotechnology, and food sectors to ensure that items such as vaccines, biologics, perishable foods, and chemicals remain within specified temperature limits. Typically, these systems incorporate insulated containers, gel packs, dry ice, or phase change materials, often paired with temperature-monitoring devices. Cold chain packaging is crucial in preventing spoilage, degradation, and loss of efficacy due to exposure to unsuitable temperatures. In order to guarantee product safety and regulatory compliance, cold chain packaging is becoming more and more important.

According to SPER market research “USA and Canada Cold Chain Packaging Market Size- By Product Type, By Packaging, By Material Type, By End User- Regional Outlook, Competitive Strategies and Segment Forecast to 2033” states that the USA and Canada Cold Chain Packaging Market is estimated to reach USD 22.23 billion by 2033 with a CAGR of 12.41%.

Drivers:

The cold chain packaging industry in the United States and Canada is witnessing substantial expansion, fueled by the rising demand for temperature-sensitive goods in the food and pharmaceutical sectors. In the U.S., important elements such as the growth of e-commerce, the increased consumption of processed foods, and improvements in pharmaceutical logistics are playing a significant role in this development. Similarly, Canada is witnessing an expansion in its market, with a heightened emphasis on preserving product integrity over extensive distances. Given the escalating requirement for dependable cold chain infrastructure, particularly in the aftermath of the pandemic, the market is projected to maintain its upward trend in the forthcoming years across both countries.

Request a Free Sample Report: https://www.sperresearch.com/report-store/usa-and-canada-cold-chain-packaging-market.aspx?sample=1

Restraints:

The cold chain packaging industry in the US and Canada faces a number of difficulties despite tremendous expansion. The substantial initial investment and operational expenses associated with advanced cold chain infrastructure may discourage smaller enterprises. Compliance with regulations, particularly concerning pharmaceuticals and perishable items, introduces additional complexity and financial burden. The scarcity of skilled labor to oversee cold chain logistics and technical systems presents another obstacle. Furthermore, the environmental ramifications of non-biodegradable packaging materials raise concerns, compelling companies to seek sustainable alternatives, which can be costly. Additionally, fluctuating energy prices and temperature variations during transportation jeopardize the reliability and cost-effectiveness of cold chain packaging solutions.

North America dominates the cold chain packaging market due to proximity to major pharmaceutical hubs and strong transportation networks. Some of the key players in this market are American Thermal Instruments, Cold Chain Technologies, Cryopak Industries Inc., CSafe Global, LLC, DGP Intelsius LLC, Insulated Products Corporation.

For More Information, refer to below link: –

USA and Canada Cold Chain Packaging Size

Related Reports:

Japan Food Cling Film Market Growth, Size, Trends Analysis- By Material, By Product, By Thickness, By Sales Channel, By End User- Regional Outlook, Competitive Strategies and Segment Forecast to 2033

Germany Plastic Caps and Closures Market Growth, Size, Trends Analysis- By Resin, By Product Type, By End User Industry- Regional Outlook, Competitive Strategies and Segment Forecast to 2033

Follow Us –

LinkedIn | Instagram | Facebook | Twitter

Contact Us:

Sara Lopes, Business Consultant — USA

SPER Market Research

+1–347–460–2899

#USA Cold Chain Packaging Market Growth#Canada Cold Chain Packaging Market Size#USA Cold Chain Packaging Market Share#Canada Cold Chain Packaging Market Trends#USA Cold Chain Packaging Market Revenue#Canada Cold Chain Packaging Market Demand#USA Cold Chain Packaging Market Challenges#Canada Cold Chain Packaging Market Competition#USA Cold Chain Packaging Market Report#Canada Cold Chain Packaging Market Revenue

0 notes

Text

The Evolution of Excellence. Understanding Business Maturity

In the lifecycle of any organization, there comes a point when survival gives way to sophistication — when reactive decision-making transforms into strategic foresight. This transition marks the arrival at business maturity, a stage where companies demonstrate consistent performance, organizational resilience, and the ability to create value sustainably.

Eric Hannelius, an expert who has guided numerous companies through growth phases, observes: “Maturity isn’t about size or age — it’s about how an organization thinks. The most mature businesses operate with a quiet confidence, making deliberate choices rather than frantic reactions. They’ve moved from proving they can exist to determining how they’ll excel.”

The Dimensions of Organizational Maturity

Business maturity manifests across multiple interconnected aspects of operations. Financially, mature organizations maintain stability through economic cycles, with diversified revenue streams and managed risk exposure. Operationally, they develop standardized processes that ensure consistency while allowing for necessary flexibility. Culturally, they foster environments where accountability and innovation coexist productively.

What distinguishes truly mature businesses is their holistic development across these areas. A company might boast impressive financials but remain operationally immature if it relies on heroic individual efforts rather than sustainable systems. Another might have polished processes but lack the cultural maturity to adapt when market conditions shift.

The Hallmarks of Mature Organizations

Seasoned companies share recognizable characteristics in how they approach challenges and opportunities. They demonstrate strategic patience, willing to forgo short-term gains when they conflict with long-term objectives. They institutionalize knowledge rather than relying on tribal wisdom, ensuring continuity as personnel changes occur.

Mature businesses also exhibit emotional resilience during setbacks. Where younger organizations might panic in crises, established companies draw on experience and systems to navigate turbulence. This steadiness often gives them competitive advantages during industry disruptions, as they can make clear-headed decisions while competitors react emotionally.

“Maturity shows most clearly in how a company handles adversity,” notes Eric Hannelius. “The businesses that endure view challenges as inevitable phases to work through rather than existential threats. This perspective alone often determines who thrives when conditions toughen.”

The Path to Maturity

Reaching maturity requires intentional evolution across several fronts. Leadership styles must shift from hands-on problem-solving to empowering teams with clear direction. Decision-making processes grow more data-informed yet retain space for intuition and experience. Companies develop the confidence to say no to opportunities that don’t align with core strengths, recognizing that strategic focus beats chasing every possibility.

This journey inevitably involves difficult transitions. Founders often need to adapt their roles as organizations outgrow startup modes. Systems that worked for a 50-person company frequently require reimagining at 500 employees. What begins as informal communication must evolve into structured collaboration without losing the original culture’s vitality.

The Pitfalls of Pseudo-Maturity

Some organizations mistake surface appearances for genuine maturity. Impressive office spaces, polished marketing materials, or even strong financials can mask underlying fragility if not supported by robust systems and culture. Other companies confuse bureaucracy with maturity, implementing excessive controls that stifle rather than support growth.

True maturity balances structure with adaptability. It creates guidelines without rigidity, fosters specialization without silos, and pursues efficiency without sacrificing resilience. Perhaps most importantly, mature organizations maintain learning mindsets even as they accumulate experience — avoiding the complacency that often accompanies success.

The Competitive Advantages of Maturity

Companies that achieve genuine maturity enjoy distinct marketplace benefits. They typically command premium valuations due to predictable performance. They attract and retain top talent seeking stable yet dynamic environments. During industry disruptions, they often capitalize on competitors’ missteps.

Perhaps less obviously, mature businesses become preferred partners for other established organizations. Their reliability makes them safer choices for long-term contracts and strategic collaborations. This network effect creates compounding advantages as their reputations grow.

“In investment terms, mature companies trade at premium multiples for good reason,” explains Eric Hannelius. “They’ve demonstrated the ability to generate returns through cycles, not just during favorable conditions. That consistency is extraordinarily valuable.”

Continuous Evolution

Business maturity shouldn’t be confused with a final destination. The most successful mature organizations view themselves as perpetually evolving — refining practices, updating assumptions, and reinventing aspects of their operations while maintaining core strengths.

This balanced approach allows them to avoid the stagnation that sometimes accompanies aging companies. They retain enough consistency to provide stability while embracing enough change to stay relevant. In an era of rapid technological and social transformation, this duality has become essential for sustained success.

As Eric Hannelius concludes: “The hallmark of true maturity is knowing what to preserve and what to change. Companies that master this discernment don’t just survive the passage of time — they become more valuable with it.”

For business leaders, the pursuit of maturity represents both challenge and opportunity. By focusing on building resilient systems, cultivating adaptive cultures, and maintaining strategic clarity, organizations can position themselves to thrive across decades rather than just quarters. In an economic environment that rewards longevity and consistency, this maturation process may represent the ultimate competitive edge.

0 notes

Text

Biodegradable Lids Market Analysis: Trends, Growth, and Future Outlook

The global shift toward sustainable and eco-friendly packaging solutions has fueled the growth of the biodegradable lids market. As environmental concerns rise and regulatory bodies impose stricter rules on single-use plastics, industries are transitioning toward biodegradable alternatives. Among these, biodegradable lids—used primarily in foodservice and beverage packaging—are gaining significant attention for their environmental benefits and potential to reduce plastic waste.

Market Overview

The biodegradable lids market has experienced steady growth in recent years and is projected to continue expanding at a robust pace. The market size, valued at approximately USD 450 million in 2024, is anticipated to grow at a compound annual growth rate (CAGR) of 6.5% from 2025 to 2030. The food and beverage industry's increasing demand for sustainable packaging solutions is the primary driver of this growth. Additionally, consumer awareness and government initiatives are fostering an environment conducive to innovation and adoption of biodegradable materials.

Key Market Drivers

Environmental Concerns and Legislation: With climate change and ocean pollution dominating the global agenda, there is mounting pressure to phase out plastic products. Countries across Europe, North America, and parts of Asia have implemented bans or heavy restrictions on plastic items, including lids. These regulations are encouraging manufacturers to invest in biodegradable materials like polylactic acid (PLA), bagasse, and other plant-based fibers.

Consumer Preferences: Modern consumers are increasingly aligning their purchasing decisions with sustainability values. This shift in consumer behavior is compelling foodservice businesses—such as cafés, restaurants, and fast-food chains—to adopt biodegradable packaging to retain environmentally conscious customers.

Corporate Sustainability Goals: Multinational corporations are setting ambitious sustainability targets. For instance, major beverage brands and fast-food giants have committed to eliminating non-recyclable and non-compostable packaging by the end of this decade. Biodegradable lids are part of the larger portfolio of solutions helping businesses achieve these goals.

Market Segmentation

The biodegradable lids market can be segmented based on material type, end-use industry, and geography.

By Material Type:

Polylactic Acid (PLA): PLA lids are derived from fermented plant starch and are widely used due to their compostability and performance similar to traditional plastic.

Bagasse: A byproduct of sugarcane processing, bagasse-based lids are heat-resistant and suitable for hot beverages and food items.

Paperboard: Coated and uncoated paperboard lids are biodegradable and often used for cold beverages and dry foods.

By End-Use Industry:

Foodservice: Cafés, fast-food chains, and restaurants dominate the demand for biodegradable lids.

Retail Packaging: Supermarkets and convenience stores are also adopting biodegradable solutions for ready-to-eat products and beverages.

By Geography:

North America: The U.S. and Canada are leading markets, driven by strong regulatory frameworks and high consumer awareness.

Europe: European nations are pioneers in banning plastic lids, creating fertile ground for biodegradable alternatives.

Asia-Pacific: Rapid urbanization and a growing middle class are expanding demand in countries like China, India, and Japan.

Competitive Landscape

The biodegradable lids market is moderately fragmented with the presence of both global and regional players. Key companies include:

Huhtamaki Oyj

Eco-Products, Inc.

GreenGood USA

Biopak Pty Ltd.

Vegware Ltd.

These players are investing in research and development to create high-performance, affordable biodegradable lids. Partnerships with food chains and government support through grants and subsidies also give a competitive edge.

Challenges and Restraints

Despite its promising outlook, the biodegradable lids market faces several hurdles:

Cost and Production Scalability: Biodegradable lids are generally more expensive to produce than conventional plastic alternatives. For small- and medium-sized businesses, cost can be a barrier to adoption.

Composting Infrastructure: In many regions, the infrastructure for industrial composting is underdeveloped, limiting the actual biodegradability of the products post-consumption.

Product Performance: While advancements have improved durability and heat resistance, biodegradable lids still lag behind plastics in certain use cases, such as sealing carbonated beverages.

Future Outlook

The future of the biodegradable lids market is optimistic. Technological innovations are expected to lower production costs and improve material performance. As circular economy principles gain traction and composting infrastructure expands, the lifecycle benefits of biodegradable products will become more evident. In parallel, consumer advocacy and corporate responsibility will continue driving market penetration.

Governments may also introduce incentives or subsidies to support biodegradable product adoption, further accelerating growth. Emerging economies, particularly in Latin America and Southeast Asia, represent untapped potential, especially as global brands expand into these markets with sustainable product lines.

Conclusion

The biodegradable lids market stands at the intersection of innovation, environmental stewardship, and consumer demand. Although challenges remain, the trajectory is clear: biodegradable packaging, including lids, is set to become a standard rather than a niche. Stakeholders who invest early in sustainable solutions are likely to reap long-term benefits, both financially and reputationally.

0 notes

Text

Streamlining Your Office Move in Northshore: A Comprehensive Guide

Relocating an office can be an exciting step toward growth, but it’s also a complex process that requires strategic planning and execution. If you're planning an office move in Northshore, you're not alone—many businesses are making the shift to this dynamic and economically growing region. Whether you're upsizing, downsizing, or simply moving to a more strategic location, having a clear plan can minimize downtime and ensure a smooth transition.

In this guide, we’ll walk you through every step of a successful office move in Northshore, from preparation to execution, while addressing key considerations such as budgeting, timelines, employee communication, and more.

Why Northshore?

Before diving into the logistics, let’s consider why an office move in Northshore might be an excellent business decision. Northshore has become a popular destination for companies of all sizes thanks to its:

Robust local economy

Proximity to Sydney CBD

Excellent public transport links

Scenic surroundings and modern infrastructure

These factors make it a prime location for businesses looking to elevate their image and attract top talent.

Step 1: Strategic Planning for Your Office Move in Northshore

Success begins with strategy. The earlier you start planning, the smoother the transition will be. At least three to six months before the move, start assembling a relocation team and assign a project manager.

Key tasks to handle during this phase include:

Defining the objectives of your office move in Northshore

Setting a realistic moving date

Allocating a budget with contingencies

Conducting site inspections and space planning

Make sure you also begin assessing how the new space will meet your current and future operational needs.

Step 2: Budgeting for an Office Move in Northshore

Budgeting is more than just accounting for the moving truck. When planning an office move in Northshore, consider these essential cost factors:

Professional moving services

Packing materials and equipment

Temporary storage (if needed)

IT and telecommunications setup

Furniture relocation or new purchases

Cleaning services

Marketing materials updates (business cards, signage, website)

Having a detailed budget helps avoid financial surprises and gives leadership confidence in the move.

Step 3: Communication is Key

The success of your office move in Northshore depends heavily on communication—with your employees, stakeholders, and clients. Keep everyone informed with timely updates:

Announce the move early and explain the benefits

Provide timelines and key dates

Share new address details and logistical changes

Offer support to help employees adapt to the new location

Use email newsletters, internal meetings, and digital noticeboards to maintain clear communication throughout the process.

Step 4: Choosing the Right Moving Partner

When managing an office move in Northshore, choosing the right moving company is crucial. Look for professionals who:

Specialize in commercial relocations

Are familiar with Northshore’s geography and regulations

Offer IT equipment handling and setup services

Can provide packing, labeling, and unpacking assistance

Get multiple quotes and read reviews before selecting a partner. The right mover can mean the difference between a chaotic relocation and a seamless transition.

Step 5: IT Infrastructure and Utilities

One of the most critical components of your office move in Northshore is ensuring your IT and communications systems are up and running without delay. Coordinate with your IT team or provider to:

Back up all important data

Transfer servers and hardware securely

Reconnect internet and phone lines before the move

Test systems before employees arrive

Also, remember to update your address with service providers, and ensure utilities are ready and functional on day one.

Step 6: Furniture and Layout Planning

Your new office layout should enhance productivity and reflect your brand. When coordinating an office move in Northshore, consider:

Whether to move existing furniture or purchase new

Optimizing workflow through strategic desk placements

Creating breakout and meeting spaces

Ensuring accessibility and compliance with local regulations

Work with a designer or space planner to create a functional, welcoming environment for your team.

Step 7: Moving Day Execution

The big day is here! A well-organized office move in Northshore requires clear roles, strong coordination, and contingency planning. On moving day:

Supervise loading and unloading

Check all items off your inventory

Have an emergency contact list handy

Set up signage in your new office for easy navigation

Offer refreshments or snacks for moving staff and early arrivals

Make sure the first impression in the new office is a positive one—for employees and visitors alike.

Step 8: Post-Move Follow-Up

Once your office move in Northshore is complete, the job isn’t over just yet. You’ll need to:

Update business listings online (Google, LinkedIn, directories)

Notify clients and partners of the new address

Conduct a team walkthrough and welcome orientation

Survey employees for feedback on the new workspace

Celebrate with a small opening event to boost morale

Use this opportunity to reinforce your brand and set a positive tone for your next chapter.

Common Mistakes to Avoid

Even a well-planned office move in Northshore can go awry without attention to detail. Watch out for these common pitfalls:

Underestimating timelines

Forgetting to back up data

Failing to involve key departments early

Overlooking building access and elevator restrictions

Not labeling boxes clearly

Avoiding these mistakes can save time, money, and headaches.

Final Thoughts

An office move in Northshore is more than a physical transition—it’s a strategic opportunity to grow, reinvent, and energize your business. With careful planning, transparent communication, and the right partners, your move can go off without a hitch and leave your team feeling empowered in their new space.

Whether you're expanding your workforce, seeking a more accessible location, or modernizing your operations, office move in Northshore could be the catalyst for the next exciting phase of your business journey.

0 notes

Text

The Real-World Magic of Generative AI: 10 Ways It’s Changing 2025

In 2025, Generative AI is no longer a distant tech marvel—it’s a real-world force disrupting industries, transforming workflows, and amplifying human creativity. From streamlining business operations to generating art and improving healthcare, the reach of generative AI has expanded rapidly, touching nearly every aspect of our lives.

If you’re curious about what generative AI actually does in the wild—or wondering why Generative AI courses in Bengaluru are filling up fast—this blog will give you a comprehensive look at how this transformative technology is shaping the present and future.

Let’s explore the top 10 real-world applications of generative AI in 2025 that you absolutely need to know.

1. Content Creation for Marketing and Media

From writing SEO blogs and social media captions to crafting compelling ad copy, generative AI tools like ChatGPT, Jasper, and Copy.ai are supercharging marketing teams.

In 2025, companies are using AI not just to generate content, but also to optimize it for different channels, languages, and audience segments. Creative professionals can now focus more on strategy and storytelling while AI handles the repetitive drafts.

Why it matters: Brands save time and scale content production dramatically without sacrificing quality.

2. AI-Generated Art and Design

Tools like DALL·E, MidJourney, and Stable Diffusion are redefining what it means to be an artist. Whether it’s graphic design, 3D modeling, or even textile pattern creation, designers are collaborating with AI to generate stunning visuals in seconds.

Even architectural firms and urban planners use generative AI to visualize complex structures, mood boards, and interior layouts during ideation phases.

Why it matters: Design cycles are faster, more experimental, and often more cost-effective.

3. Music and Audio Production

Generative AI is making waves in the music industry by composing melodies, writing lyrics, and producing entire tracks based on mood, style, or even voice cloning.

Musicians, podcasters, and sound designers use tools like Amper Music, Aiva, and Boomy to explore new sonic landscapes—and even customize soundtracks for commercial use.

Why it matters: It democratizes music creation and opens new avenues for artists and content creators.

4. Healthcare: Drug Discovery and Diagnosis

In 2025, generative AI plays a crucial role in bioinformatics and pharmaceuticals. AI models simulate the structure of new molecules, predict drug interactions, and even generate synthetic patient data for faster clinical trials.

Generative models also assist radiologists by generating and enhancing medical images for quicker diagnosis.

Why it matters: Drug development becomes faster and more affordable, with life-saving potential.

5. Finance: Report Generation and Market Analysis

In the financial sector, generative AI is used to automate routine tasks like generating investment reports, summarizing earnings calls, and even simulating economic scenarios.

AI-generated insights and forecasts help analysts make data-driven decisions quickly.

Why it matters: It saves countless hours and minimizes human error in data-heavy environments.

6. Gaming and Virtual Worlds

Video game developers are harnessing generative AI to build levels, design characters, write dialogue, and even adapt gameplay in real time based on user behavior.

In 2025, AI-generated non-playable characters (NPCs) now react more dynamically, making gameplay more immersive.

Why it matters: Developers build richer, more complex worlds with less manual effort.

7. Education: Personalized Learning Content

Generative AI is revolutionizing the classroom by creating customized quizzes, study materials, lesson plans, and even tutoring experiences tailored to each student’s learning style and pace.

Teachers use AI to auto-generate lesson summaries or convert complex topics into bite-sized learning nuggets.

Why it matters: It enhances learning accessibility and supports teachers in content delivery.

8. E-commerce: AI Product Descriptions and Visuals

E-commerce platforms use generative AI to automatically create product descriptions, reviews, and even augmented images for thousands of items.

Some AI systems even generate customer personas and simulate user behavior to A/B test new offerings.

Why it matters: Retailers scale up faster while maintaining consistent branding and personalization.

9. Legal and Compliance Document Drafting

Legal teams are using generative AI to draft contracts, summarize legal cases, and flag potential compliance risks. Tools trained on legal language now generate first drafts of agreements in seconds.

While final reviews still require human expertise, the groundwork is handled by AI.

Why it matters: It drastically reduces time spent on legal documentation and improves accuracy.

10. Film and Scriptwriting

Writers and filmmakers now brainstorm with AI co-writers. Generative AI can create characters, plots, and dialogue based on themes and genres. It can even convert written scripts into animated previews or voiceovers.

Some studios now use AI to test audience reactions to multiple storylines before choosing a direction.

Why it matters: It accelerates creative development and opens storytelling to a broader range of creators.

Why Learn Generative AI Today?

With such widespread use across industries, the demand for skilled professionals who understand generative AI is skyrocketing. And if you’re based in India’s tech capital, you’re in luck.

🌐 Generative AI Courses in Bengaluru: A Gateway to the Future

Bengaluru—India’s innovation hub—is quickly becoming the go-to destination for mastering cutting-edge technologies. Reputed institutes now offer Generative AI courses in Bengaluru that combine theoretical learning with practical, project-based experiences.

Whether you're a content creator, developer, designer, or data analyst, these courses help you:

Understand the fundamentals of generative models like GANs and LLMs

Build real-world applications using tools like ChatGPT, MidJourney, and Runway ML

Learn ethical implications and responsible AI practices

Prepare for careers in tech, media, healthcare, and beyond

The best part? Many of these programs are flexible, with online or hybrid formats tailored for working professionals.

Final Thoughts: AI Is Your New Creative Partner

Generative AI isn’t about replacing humans—it’s about empowering us to do more, think bigger, and innovate faster. From streamlining workflows to opening up new realms of creativity, its real-world impact in 2025 is undeniable.

So, whether you're a student, professional, or entrepreneur, now is the perfect time to explore how generative AI can boost your skillset—and your career.

0 notes

Text

Center Enamel's Ethanol Storage Tanks – Engineered for Safety, Efficiency, and Sustainability

As the world transitions towards sustainable energy solutions, ethanol has emerged as a critical biofuel, driving the shift away from fossil fuels. Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), a global leader in advanced storage solutions, is at the forefront of this revolution with its meticulously engineered Ethanol Storage Tanks. These tanks are designed to provide a safe, efficient, and environmentally responsible solution for the storage of this vital renewable resource.

As a leading storage tanks manufacturer worldwide. Center Enamel can provide Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, galvanized steel tanks and aluminum geodesic dome roofs, Wastewater and Biogas Project Equipments for global customers.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

The Strategic Importance of Ethanol and the Demands of Modern Storage

Ethanol, derived from renewable sources like corn, sugarcane, and cellulosic biomass, plays a pivotal role in:

Reducing Greenhouse Gas Emissions: Contributing to global efforts to combat climate change.

Enhancing Energy Independence: Diversifying energy sources and reducing reliance on fossil fuels.

Supporting Agricultural Economies: Creating new markets for agricultural products and fostering rural development.

However, the properties of ethanol, including its corrosive nature, volatility, and flammability, necessitate specialized storage solutions. Modern ethanol storage tanks must address:

Corrosion Resistance: Preventing degradation and ensuring the integrity of stored ethanol.

Leak Prevention: Safeguarding the environment and minimizing product loss.

Vapor Containment: Reducing evaporative losses and minimizing fire hazards.

Compliance with Safety and Environmental Regulations: Adhering to stringent industry standards.

Operational Efficiency: Optimizing storage capacity and minimizing maintenance requirements.

Center Enamel: Pioneers in Advanced Ethanol Storage Solutions

Center Enamel has established a global reputation for delivering high-performance storage tanks that meet the demanding requirements of the biofuel industry. Our expertise in materials science, engineering, and fabrication techniques, coupled with our unwavering commitment to quality, ensures that our tanks provide exceptional performance and longevity.

Why Center Enamel's Ethanol Storage Tanks Stand Out

Material Versatility: We offer a range of materials, including:

Fusion Bonded Epoxy (FBE) Coated Steel: Providing exceptional corrosion resistance and durability.

Stainless Steel: Ensuring unmatched purity and hygiene, ideal for high-grade ethanol.

Glass-Fused-to-Steel (GFS): Offering robust protection against corrosion and chemical attack.

Customized Engineering and Design: Our experienced engineers provide tailored solutions, offering a wide range of tank sizes, configurations, and accessories to meet specific project requirements.

Precision Fabrication and Welding: Our tanks are fabricated and welded by certified professionals using advanced techniques, ensuring precise dimensions and leak-proof performance.

Rigorous Quality Control: We implement comprehensive quality control measures throughout the manufacturing process, from material inspection to final testing, ensuring consistent product excellence.

Compliance with Industry Standards: Our tanks are designed and manufactured to meet or exceed relevant international standards, including API, ASTM, and others.

Enhanced Safety and Leak Prevention: Our tanks are designed and fabricated to minimize the risk of leaks and structural failures, ensuring the safety of personnel and the environment.

Vapor Containment Systems: We offer advanced vapor containment systems to minimize evaporative losses and reduce emissions.

Thermal Insulation Options: Upon request our tanks can be insulated to maintain ethanol temperatures.

Comprehensive Installation Support: We provide detailed installation manuals and technical assistance to ensure proper tank assembly and commissioning.

Applications of Center Enamel's Ethanol Storage Tanks

Ethanol Production Facilities: Storage of ethanol at production plants.

Biofuel Blending Terminals: Storage of ethanol for blending with gasoline.

Distribution Depots: Storage of ethanol for transportation and distribution.

Refineries: Storage of ethanol for blending and processing.

Agricultural Cooperatives: Storage of ethanol produced from agricultural feedstocks.

Fuel Retail Outlets: Storage of ethanol blends for dispensing to consumers.

Center Enamel's Commitment to Sustainability and Innovation

At Center Enamel, we are committed to providing sustainable and innovative ethanol storage solutions that contribute to a greener future. We adhere to stringent environmental regulations and continuously invest in research and development to improve our products and processes.

The Future of Ethanol Storage: Advanced Technologies and Sustainable Practices

As the demand for ethanol and other biofuels continues to grow, Center Enamel is dedicated to staying at the forefront of innovation. We are developing cutting-edge technologies that enhance the performance, durability, and sustainability of our ethanol storage tanks.

Center Enamel's Ethanol Storage Tanks represent a superior solution for the safe, efficient, and environmentally responsible storage of this vital biofuel. With our commitment to quality, innovation, and customer satisfaction, we are the trusted partner for industries seeking robust and dependable ethanol storage solutions. By choosing Center Enamel, you can ensure the integrity of your stored ethanol and contribute to a more sustainable energy future.

0 notes

Text

Business Term Loans: Transforming and Driving Growth

Business Term Loans

Over the past decade, Indian businesses across industries and scales have evolved at a remarkable pace. From mid-sized enterprises expanding into global markets to large manufacturers modernising their supply chains, capital remains the single most critical lever for sustainable growth. Therefore, when it comes to structured funding with clarity on tenure and repayment, Business Term Loans have emerged as the preferred financing instrument.

Whether your business is planning capacity expansion, technological upgrades, infrastructure development, or even managing cash flow, term loans offer a dependable and customizable funding option. So, what exactly are Business Term Loans, and how can they power your next phase of growth?

What Is a Business Term Loan?

At its core, a Business Term Loan is a debt facility extended to businesses for a fixed period ranging from a few months to several years with clearly defined repayment schedules. These loans are disbursed as a lump sum and are often used for purposes such as:

Asset acquisition (machinery, intellectual property, equipment)

Business expansion or diversification

Working capital augmentation

Debt consolidation or refinancing

Technology upgrades

Unlike revolving credit facilities, term loans are structured with fixed interest rates or floating rates, along with consistent EMIs, helping businesses plan finances with precision.

The Two Pillars: Short-Term vs Long-Term Business Loans

While both short-term and long-term business loans fall under the term loan umbrella, they serve distinct business needs and life cycles.

Short-Term Business Loans

Tenure Typically 12–24 months.

These loans are ideal for managing seasonal demand spikes, short-term operational costs, or bridging temporary cash flow mismatches. Companies in sectors like retail, logistics, trading, or FMCG often turn to short-term loans to remain agile.

Example Use Case:

A garment exporter receiving a large order may need short-term capital to purchase raw materials and cover wage bills until export proceeds are realized.

Long-Term Business Loans

Tenure Ranges from 3 years to 15+ years.

Designed for capital-intensive goals like factory construction, real estate acquisition, or major equipment installation. Long-term loans offer structured repayment options aligned with the lifecycle of the asset or project.

Example Use Case:

A manufacturing company investing in a new plant setup can avail a long-term loan to finance infrastructure, power supply, and advanced machinery installation.

Why Business Term Loans Are Gaining Traction

Across industries, be it pharmaceuticals, infrastructure, IT services, automotive, or textile manufacturing, the preference for term loans is growing, and rightly so. Key advantages include:

Helps in disciplined cash flow planning

Funds can be tailored to diverse business needs

Unsecured term loans are available for eligible borrowers

Based on the scale and urgency of funding

Most importantly, they help businesses retain ownership while still accessing the funds needed for transformation and scaling.

Industry Demand: Who Needs Business Term Loans?

Capital is the catalyst for operational continuity and strategic acceleration. That’s not just a philosophy, it’s a reality for sectors including:

Hospitals and diagnostic centres are upgrading to cutting-edge tech

Educational institutions are investing in hybrid classrooms and digital tools

Renewable Energy: Solar power firms scaling operations in new geographies

Agri-Tech & Food Processing: Cold storage, logistics, and farm automation

Manufacturing Automation, compliance, and export-readiness initiatives

Each of these sectors requires timely and appropriately structured term loans to stay ahead of competition, adapt to policy changes, and respond to market demand.

The Terkar Capital Advantage

Terkar Capital understands that every business has unique funding requirements. Therefore, with our deep domain expertise and access to a wide network of lenders, we offer end-to-end advisory services, from documentation to disbursal. Additionally, we provide tailored funding solutions structured to align with your specific business model and goals.

Furthermore, we ensure fast turnaround times, recognising that timing can be crucial for business success. Finally, we offer both collateral and non-collateral options, ensuring accessibility for businesses of all sizes. Whether you're a startup, a conglomerate, or a legacy business, Terkar Capital can craft solutions that align your capital with your ambition.

In Conclusion

Business Term Loans are not merely borrowed capital; they are strategic tools that, when structured correctly, can expand a business's capacity, empower innovation, and strengthen its competitiveness.Further, as economic cycles fluctuate and business challenges evolve, having a dependable financial partner like Terkar Capital can be invaluable. From short-term liquidity support to long-term expansion planning, we help businesses secure capital with clarity, confidence, and credibility.

0 notes

Text

Sampling 101: Why First Samples Matter More Than You Think

Introduction

In the world of fashion design and manufacturing, the first sample of a garment isn’t just a rough draft, it’s the blueprint of success. Whether you're an emerging label or an established fashion house, your first sample can make or break your production timeline, design accuracy, and brand reputation. It’s the first tangible version of your vision, and it deserves your full attention.

What Is a First Sample?

A first sample, also known as a prototype or initial sample, is the earliest physical version of your design brought to life by your manufacturer. It’s made based on your fashion design tech pack, which includes all the specifications for the garment: measurements, fabric type, trims, stitch details, and more.

This sample is not meant to be perfect, it’s a test. But it’s an important one. It allows designers and manufacturers to evaluate how the garment looks, fits, and functions in real life. This stage is especially crucial for startups building their first collections or for luxury labels introducing innovative designs.

Why First Samples Are Critical

1. Design Validation

The first sample helps you confirm whether your concept works in real form. It reveals flaws or changes that might be needed in design, fit, proportion, or functionality. A fashion design consultant will often use this phase to refine your garment before approving further production.

2. Fit and Construction Checks

From seam placement to fabric drape, a sample lets you test how your chosen materials behave. You can ensure that the garment is flattering, wearable, and consistent with your brand’s quality standards.

3. Cost Efficiency

Skipping or rushing the first sampling process can lead to costly errors in bulk production. Identifying issues early saves time and money later. It’s always cheaper to correct a sample than to discard hundreds of flawed garments.

4. Clear Communication

A first sample serves as a communication bridge between designer and manufacturer. When paired with a comprehensive fashion tech pack template, it allows manufacturers to interpret your vision accurately.

The Sampling Process: Step-by-Step

Submit Your Tech Pack: The process begins with a clear fashion design starter kit, which includes your sketches, mood boards, fabric choices, and a detailed fashion design tech pack.

Pattern Development: Manufacturers create a pattern based on your provided specs.

Fabric & Trim Sourcing: Based on your material list, the supplier sources or substitutes fabrics.

Sample Cutting & Sewing: A sample garment is cut and constructed following your instructions.

Fit Testing & Review: The garment is evaluated for design accuracy, sizing, and overall quality.

Feedback & Revisions: You provide notes, and the sample is revised until approved for production.

You can find templates and guidelines to streamline this process by using tools like a fashion tech pack template download online, which ensures nothing is missed in your communication.

Common Issues Found in First Samples

Incorrect measurements

Fabric doesn’t behave as expected

Stitching flaws or seam mismatches

Trim or button misplacement

Color mismatches or dye issues

Spotting these in the sample saves you from expensive mistakes in full-scale production.

The Role of a Fashion Design Consultant

A seasoned fashion design consultant can be invaluable at the sampling stage. They help you:

Translate your sketches into production-ready documents

Source appropriate sustainable or luxury materials

Liaise with manufacturers to ensure accurate execution

Troubleshoot sampling issues to maintain your brand’s design integrity

For luxury labels, a luxury fashion consultant offers elevated guidance, aligning your sample with both brand aesthetics and premium market expectations.

Global Perspectives on Sampling

The importance of first samples is universal, whether you're working with:

A luxury fashion consultant in India guiding artisanal production

A tech-driven studio in London assisting startup brands

A boutique manufacturer in Melbourne specializing in organic customwear

Precision-driven fashion factories in Germany

High-end production hubs in Dubai, Riyadh, or Kuwait

Each location brings a unique advantage, but one thing remains constant your first sample sets the tone for everything that follows.

Future of Sampling: Digital Innovations

Tech is redefining the sampling process. Brands are now using:

3D virtual sampling tools to preview designs digitally

AI-driven fit analysis to reduce revisions

Digital tech pack software to manage communication and updates

Although physical samples remain critical, these innovations can shorten timelines and reduce costs.

Conclusion: Don’t Skip the Sample

If you’re serious about your fashion brand, treat your first sample as a strategic milestone. It’s your chance to refine your design, build trust with your manufacturer, and ensure consistency in your production run.

When paired with a professional fashion tech pack, a thoughtful sampling process protects your vision, your budget, and your brand’s reputation. So, whether you’re launching a streetwear label or a high-end collection, remember: first samples matter more than you think.

#fashion design starter kit#fashion tech pack template#fashion design tech pack#fashion design consultant#luxury fashion consultant

0 notes

Text

Unlocking the Power of Event Live Streaming

In a world where digital connectivity reigns supreme, event live streaming has emerged as a game-changing tool for businesses, organizations, and individuals. With the global live-streaming market projected to reach $247 billion by 2027, it’s clear that this technology is no longer optional—it’s essential. Whether you're hosting a corporate conference, product launch, or wedding, live streaming transforms your event into an engaging spectacle accessible to audiences worldwide. Let’s dive into actionable strategies and insights to make your next event live streaming experience unforgettable!

Why Event Live Streaming Matters

Breaking Geographical Barriers

Imagine hosting a keynote speaker in New York while engaging audiences from Tokyo, London, and São Paulo—all in real time. Event live streaming eliminates physical boundaries, enabling global participation. This inclusivity fosters deeper engagement and allows you to connect with audiences who would otherwise miss out due to distance or time constraints.

Boosting Engagement with Interactive Features

Live streaming isn’t just about broadcasting; it’s about creating experiences. Features like live chat, polls, and Q&A sessions turn passive viewers into active participants. For example:

Live Chat: Facilitates real-time interaction between attendees and hosts.

Polls: Gauge audience sentiment or spark debates.

Gamification: Incentivize participation with quizzes or point systems.

These tools foster community and keep viewers invested throughout the event.

How to Execute High-Quality Event Live Streaming

Choose the Right Platform

Selecting a reliable platform is crucial for seamless streaming. Platforms like YouTube Live, Facebook Live, or private services offer tailored solutions depending on your audience size and needs. Ensure your chosen platform supports HD video quality and interactive features.

Invest in Equipment

High-quality gear is non-negotiable for professional streams. Here’s what you need:

Cameras: Opt for HD or 4K cameras for crisp visuals.

Microphones: Use noise-canceling microphones for clear audio.

Encoders: Convert raw footage into streamable formats. Testing your equipment beforehand ensures smooth delivery during the event.

Optimize Internet Speed

A stable upload speed of at least 5 Mbps is essential for HD streaming. Use wired connections whenever possible to minimize interruptions.

Maximizing Audience Reach and Impact

Global Accessibility

Event live streaming services allow you to expand your reach exponentially. From small gatherings to large-scale productions, you can engage audiences across continents without logistical hurdles like venue rentals or travel expenses.

Content Longevity

Live streams can be recorded and repurposed into evergreen content for marketing campaigns or training materials. This extends the life of your event beyond its initial broadcast.

Best Practices for Event Live Streaming

Pre-Stream Testing

Always conduct thorough tests of your equipment, internet connection, and platform settings before going live. Address issues like audio-video sync or lighting during this phase.

Minimize Latency

Use platforms optimized for real-time delivery and adjust settings to balance quality with delay.

Engage Your Audience

Incorporate interactive elements such as polls and Q&A sessions to make viewers feel valued. Encourage social media sharing to amplify your event’s visibility.

Leveraging Data Insights for Future Success

Event live streaming doesn’t end when the broadcast concludes—it opens doors to invaluable analytics:

Viewer Engagement Metrics: Identify which segments resonated most.

Demographics: Understand your audience’s preferences and geographic distribution.

Sentiment Analysis: Use feedback from chats and polls to refine future events.

These insights allow you to fine-tune strategies and create more impactful experiences moving forward.

Building Communities Through Live Streaming

Live streaming is more than technology; it’s a tool for fostering connection:

Shared Experiences: Features like chat boxes create vibrant communities.

Post-Event Interaction: Recorded content sparks discussions long after the event ends.

Speaker-Audience Bonding: Direct interaction through Q&A sessions builds trust and admiration.

By nurturing these connections, you transform viewers into loyal advocates who amplify your message organically.Event live streaming is not just about broadcasting—it’s about creating dynamic experiences that transcend physical barriers, engage audiences deeply, and drive measurable results. By leveraging the right tools, platforms, and strategies, you can turn any event into a global phenomenon. Ready to unlock the potential of event live streaming? Start planning today by exploring Springforest Studio's event live streaming services!

0 notes

Text

2025 Global 4D Printing in Healthcare Market Size: Forecast, Growth Drivers, And Challenges

The global 4D Printing in Healthcare Market was valued at USD 35.41 billion in 2023 and is projected to reach a staggering USD 203.45 billion by 2032, growing at a compound annual growth rate (CAGR) of 21.5% over the forecast period of 2024 to 2032. This exponential growth highlights the transformative potential of 4D printing technology in revolutionizing the future of healthcare delivery, treatment customization, and patient outcomes.

Get Free Sample Report on 4D Printing in Healthcare Market Size

What is 4D Printing in Healthcare?

4D printing refers to the next generation of 3D printing that incorporates the dimension of time—allowing printed materials to change their form, properties, or function over time in response to environmental stimuli such as temperature, moisture, pH, or light. In the context of healthcare, this cutting-edge innovation is paving the way for self-adjusting medical implants, responsive drug delivery systems, and dynamic tissue engineering solutions.

Unlike traditional 3D printing, which creates static structures, 4D printing enables the fabrication of smart, adaptable, and patient-specific devices and biological materials. This unlocks a host of possibilities—from implants that adjust to body movement and healing phases to scaffolds that evolve alongside growing tissues.

Key Drivers Fueling Market Growth