#syringes manufacturer

Explore tagged Tumblr posts

Text

The role and importance of the use of syringes for medical purposes

Syringes might be small, but they are a big deal in healthcare. From giving patients the right dose of medication to collecting blood for tests, syringes play a number of crucial roles within the healthcare environment. This is why doctors and nurses prefer using them for a wide range of tasks and functions. Keep reading to explore the different types of syringes and tips for choosing the best…

View On WordPress

#medical equipment distributors#medical equipment manuafcturer#medical equipment wholesaler#syringes manuafcturer#syringes manufacturer#wholesale clothing manufacturer#wholesale medical equipment

0 notes

Text

Disposable Syringe Manufacturing Plant Suppliers!

Allied Way (India) offers state-of-the-art Disposable Syringe Manufacturing Plants, ensuring high production speed, low maintenance, and minimal manpower requirements. Our turnkey solutions are designed to provide a complete return on investment for our clients.

0 notes

Text

Business Templates Marketplace | Get Ready-to-Use Solutions with Icrest Models

Looking for high-quality business templates to streamline your project planning? Icrest Models is your one-stop Business Templates Marketplace, offering expertly crafted project reports for various industries. Whether you need a solar energy project report, potato chips manufacturing project report, ethanol project report, tissue paper manufacturing project report, or spinning mill project report, we provide ready-to-use, investor-friendly reports to help you secure funding and make informed decisions. Our professionally designed templates save time, reduce risks, and ensure business success.

#business template marketplace#solar energy project report#potato chips manufacturing project report#cryptocurrency model template#milk dairy farm project report#hotel budget planning template#paint manufacturing project report#sanitary pad project report#detailed project report of solar power plant#syringe manufacturing project report

0 notes

Link

#market research future#fill finish manufacturing#fill finish#fill finish manufacturing size#prefilled syringes market

0 notes

Text

Veterinary Hypodermic Syringes: Easing Animal Pain & Stress

In veterinary care, keeping animals comfortable and healthy is very important. Giving injections is something veterinarians do often, but it can cause pain and stress for animals. Choosing the right veterinary hypodermic syringes can make a big difference in how animals feel during these procedures. In this blog post, we’ll talk about how the right syringe can reduce pain and stress, and we’ll compare different products to help you make the best choice for your pets or veterinary practice.

The Role of Veterinary Hypodermic Syringes in Reducing Pain and Stress

Just like people, animals feel pain and stress when they get shots. The sensation of a needle going into the skin can be uncomfortable and scary for them. Several things can affect how much pain and stress an animal feels during an injection, such as the thickness of the needle, its length, and how the syringe is designed. By understanding these factors and picking the right tools, veterinarians and pet owners can make injections less painful and less stressful for animals.

Comparing Different Veterinary Hypodermic Syringes

1. Needle Gauge Options

The gauge of a needle is how thick or thin it is. This is important because a thinner needle usually hurts less. For example, a 27-gauge needle is very thin and might be best for small animals or injections that need to be very precise, like giving insulin to a cat. A thicker needle, like a 22-gauge, might be better for larger animals or injections that go into the muscle.

Pros of Thinner Needles (Higher Gauge):

Less pain when the needle goes in.

Good for small or delicate animals.

Cons:

Can bend more easily.

Not great for thick fluids or big animals.

Pros of Thicker Needles (Lower Gauge):

Better for large animals.

Can handle thicker medications.

Cons:

Might cause more discomfort.

Not ideal for sensitive areas.

2. Needle Length and Its Impact

The length of the needle also matters. Shorter needles are often used for injections just under the skin, while longer needles are needed for shots that go into the muscle. Choosing the right needle length ensures that the medicine goes where it’s supposed to, without causing extra pain.

Pros of Shorter Needles:

Less invasive and less painful for shallow injections.

Great for small or thin animals.

Cons:

Not good for injections that need to go deeper.

Pros of Longer Needles:

Necessary for deeper injections, like in the muscle.

Better for larger animals with more muscle.

Cons:

More invasive and might hurt more if not used carefully.

Risk of hitting bones or nerves if not handled properly.

3. Syringe Design and Ergonomics

The design of the syringe itself can also affect how comfortable the injection is. Some syringes are made to be easy to use, with smooth plungers, clear barrels to see the dose, and secure needle attachments. These features can make the injection process less stressful for both the animal and the person giving the shot.

Pros of Ergonomic Syringes:

Easier to handle, making injections more accurate.

Reduces hand strain for the person giving the injection.

Smooth plunger action means the needle is less likely to move suddenly, which can reduce pain.

Cons:

Might be more expensive than regular syringes.

May not be available everywhere or for all uses.

Innovations in Veterinary Hypodermic Syringes

Advancements in Needle Technology

New needle technologies are making injections less painful and more comfortable for animals. Ultra-sharp needles made from better materials can pierce the skin more easily, causing less pain. Some needles also have special coatings that help them slide into the skin more smoothly.

Smart Syringes

Smart syringes are a new idea that could make injections even better. These syringes might have features like digital tracking of doses, automatic needle retraction, and sensors that help control the pressure of the injection. Though still in development, these smart syringes could change how injections are given in the future.

Eco-friendly Options

With more people caring about the environment, some companies are making eco-friendly syringes that can be recycled or are biodegradable. These syringes not only help the planet but can also reduce stress for animals. For example, some eco-friendly syringes are made for single use, which ensures they are always clean and safe to use.

Services and Support for Selecting the Right Syringe

Veterinary Supplier Recommendations

When choosing the right veterinary hypodermic syringes, it’s important to think about the services offered by different suppliers. KDL is top manufacturer of veterinary hypodermic syringe that are design with diffrent needle gauge so you choose custom needle options, so you can get the exact gauge and length you need. Others offer bulk ordering, which can save money for bigger practices. Many suppliers also provide helpful resources and support to guide your decisions.

Training and Support

Proper training is key for anyone giving injections, whether it’s a veterinarian, a technician, or a pet owner. Some brands and suppliers offer training programs to make sure injections are done right and with minimal stress to the animal. This training can include tips on picking the right syringe, handling it correctly, and keeping the animal calm during the injection.

Tips for Minimizing Pain and Stress During Injections

Besides choosing the right syringe, there are other ways to make injections less painful and stressful for animals:

Creating a Calming Environment: Reducing noise and making the area comfortable can help animals feel more relaxed.

Gentle Handling: Handling the animal gently and confidently can prevent them from getting anxious or scared.

Distraction Techniques: Using treats, toys, or soothing words can distract the animal during the injection, making them less aware of what’s happening.

Proper Restraint: Making sure the animal is held securely but not too tightly can prevent sudden movements that could cause pain.

Conclusion

Choosing the right veterinary hypodermic syringe is key to reducing pain and stress for animals. By considering factors like needle gauge, length, and syringe design, veterinarians and pet owners can make injections as comfortable as possible. Staying informed about the latest products and best practices can also improve the care we provide to animals. By making careful choices and using a gentle approach, we can make injections less uncomfortable and help animals feel better during these necessary procedures.

Source :Veterinary Hypodermic Syringes: Easing Animal Pain & Stress

#Veterinary Hypodermic Syringes#veterinary care#Hypodermic Syringes#Syringe Manufacturer#Syringe Supplier#healthcare#Veterinary Medicine

0 notes

Text

Fill Finish Manufacturing Market is Estimated to Witness High Growth Owing to Increasing Demand

The fill finish manufacturing market involves various downstream processing methods in the production of pharmaceutical products and medical devices which includes pre-filling inspection and labeling. The fill finish processes encompass liquid filling as well as lyophilization, assembly, labeling and packaging of vials, syringes, and cartridges. It ensures optimal product quality, safety and integrity for final use. The fill finish manufacturing plays a crucial role in bringing biologics and vaccines to patients requiring strict adherence to regulations. The need for personalized medicine and shortage of vaccines during the COVID-19 pandemic has also propelled the demand in recent times. The fill finish manufacturing market is estimated to be valued at USD 16.41 Bn in 2024 and is expected to reach USD 30.36 Bn by 2031, exhibiting a compound annual growth rate (CAGR) of 9.2% from 2024 to 2031.

Key Takeaways Key players operating in the fill finish manufacturing market are Asymchem Inc., Syntegon Technology GmbH, I.M.A. INDUSTRIA MACCHINE AUTOMATICHE S.P.A, West Pharmaceutical Services, Inc., Gerresheimer AG, AptarGroup, Inc., Dätwyler Holding Inc., Stevanato Group, OPTIMA, SGD Pharma, Nipro Corporation, Bausch Advanced Technology Group, and Berry Global Inc. The key opportunities in the market include increased outsourcing activities by pharmaceutical companies and advanced technologies providing flexibility, connectivity and efficiency. Emerging economies in Asia Pacific and Latin America present lucrative growth prospects owing to rising healthcare expenditures and increasing biologics production. The Fill Finish Manufacturing Market Share is witnessing increased global expansion strategies by key market players through mergers, acquisitions and partnerships. This allows companies to broaden their service offerings and geographic footprints to tap high growth markets. Market drivers The major market driver is the rising demand for biologics and vaccines. Biologics have revolutionized the treatment of complex diseases but require specialized fill finish facilities owing to their sensitivity. Furthermore, inadequate vaccine supplies during the pandemic underscored the need to boost local manufacturing capacities through technology transfers. This is expected to drive greater outsourcing of fill finish activities to specialized contract service providers globally.

PEST Analysis Political: Regulations regarding pharmaceutical packaging have become increasingly stringent over the years, requiring compliance. This drives demand for technologically advanced fill and finish manufacturing solutions. Economic: With the economy recovering post-COVID and healthcare expenditure rising worldwide, the Fill Finish Manufacturing Market Challenges And Opportunities inindustry is benefitting from higher outsourcing and greater uptake of advanced machinery. Social: An aging global population is driving higher demand for medicines and therapeutics. Further, greater health awareness is boosting pharmacy visits and medication consumption. Technological: Advanced technologies like automation, Internet of Things connectivity, and digital manufacturing are being integrated to enhance production efficiency, throughput, quality control, and regulatory compliance documentation in fill and finish plants. Geographical regions of concentration The North American and European fill and finish manufacturing markets currently account for the largest share of the global market value, driven by strong domestic pharmaceutical industries and stringent quality and regulatory standards in countries like the US, Germany, France, and UK. Proximity to key pharmaceutical markets and customers provides an inherent advantage to manufacturers located in these regions. Fastest growing region The Asia Pacific region, led by China and India, is poised to witness the fastest growth in the fill and finish manufacturing market over the forecast period. This can be attributed to rising generic and biologics manufacturing in the region coupled with increasing localization requirements. Additionally, lower operating costs and a rapidly expanding local pharmaceutical customer base are encouraging global players to set up or expand operations in Asia Pacific.

PEST Analysis Political: Regulations regarding pharmaceutical packaging have become increasingly stringent over the years, requiring compliance. This drives demand for technologically advanced fill and finish manufacturing solutions. Economic: With the economy recovering post-COVID and healthcare expenditure rising worldwide, the fill and finish manufacturing industry is benefitting from higher outsourcing and greater uptake of advanced machinery. Social: An aging global population is driving higher demand for medicines and therapeutics. Further, greater health awareness is boosting pharmacy visits and medication consumption. Technological: Advanced technologies like automation, Internet of Things connectivity, and digital manufacturing are being integrated to enhance production efficiency, throughput, quality control, and regulatory compliance documentation in fill and finish plants. The North American and European fill and finish manufacturing markets currently account for the largest share of the global market value, driven by strong domestic pharmaceutical industries and stringent quality and regulatory standards in countries like the US, Germany, France, and UK. Proximity to key pharmaceutical markets and customers provides an inherent advantage to manufacturers located in these regions. The Asia Pacific region, led by China and India, is poised to witness the fastest growth in the fill and finish manufacturing market over the forecast period. This can be attributed to rising generic and biologics manufacturing in the region coupled with increasing localization requirements. Additionally, lower operating costs and a rapidly expanding local pharmaceutical customer base are encouraging global players to set up or expand operations in Asia Pacific.

Get more insights on Fill Finish Manufacturing Market

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#Coherent Market Insights#Fill Finish Manufacturing Market#Fill Finish Manufacturing#Pharmaceutical Manufacturing#Biopharmaceuticals#Drug Production#Sterile Filling#Aseptic Processing#Vial Filling#Syringe Filling

0 notes

Text

Prefilled injection manufacturer in India.

Syringes are widely utilized worldwide on a daily basis; this is the reason pharmaceutical company came up with the idea of manufacturing prefilled syringes (PFS) to make it safer and more hygienic to patients. Everyday doctors use fresh syringes, unlike the old times doctors used them to boil the syringe and use them again, but recently due to Covid nowadays doctor and patients as well take precautions. Prefilled syringes revolutionized the way medications were administered before, offering with numerous advantages over traditional vial and syringe systems.

Sanjar Pharma is renowned name for its wide range of pharmaceutical products, including Pre-filled Syringes (PFS), we are knowns for our high-quality pharmaceutical products with competitive pricing accessible to every common individual worldwide. Our company manufacture, supply and export prefilled syringe under strict hygienic conditions and suitable temperatures, with following all strict international guidelines.

Here’s a brief detail on prefilled syringes and their uses:

What are pre-filled syringes.

Pre-filled syringe (PFS), is a disposable syringe that is already loaded with premeasured medication or vaccine for direct administration. Prefilled Syringes have four key components; a plunger, stopper, barrel and a needle. This provides convenience, safety and accuracy for injecting into the body manufactured by pharmaceutical company. A pre-filled syringe which comes for a single dose of medication with a fixed needle, this ensures accurate dosing by reducing errors, contamination and needlestick injuries. Some medications, such as biologics and specialty drugs, require precise dosing amounts and careful handling, this is why nursing homes and long-term care facilities often rely on prefilled syringes for administering medications to residents.

Pre-filled syringes are highly useful in pediatric care due to its precise dosing and ease of use. Making them more efficient for administering medication to children. By reducing discomfort, and enhancing the overall patient experience. Pre-filled syringes play a crucial role in pediatric healthcare.

Healthcare institutions utilize prefilled syringes for a variety of purposes, here’s a list:

Convenience: Due to its measured preloaded dosage of medication, healthcare professionals find it way more convenient to use.

Safety: Pre-filled syringes come with built-in safety features such as needle guards or retractable needles. Thus, preventing needlestick injuries and by reducing contamination, ensuring overall safety for healthcare workers and patients.

Accuracy: Due to its preloaded precise dosing, it ensures patients that patients receive the correct amount of medication each time.

Reduce Waste: This pre-filled syringe is particularly beneficial for expensive medications or those with limited doses. They help in minimizing costs, shelf lives and medication waste by eliminating the need of overfill of doses.

Standardization: Prefilled syringes promote standardization by providing a consistent and reliable method for delivering medications. They help maintain quality and safety standards across facilities.

Business Opportunities with Sanjar Pharma:

We at Sanjar Pharma, welcomes pharmaceutical companies interested in third-party manufacturing, pharma dealer, distributorship, or loan license manufacturing to join hands with us. Partnering with Sanjar Pharma offers several advantages because:

Save on heavy investments in capital-intensive by utilizing our infrastructure.

Get uninterrupted manufacturing processes that boost your earnings and cash flow.

Rely on us for consistent supply of validated and approved products.

Focus on your strength, such as marketing, while we manage the manufacturing process for you.

Be assured and confident with our strict quality control measures.

Rest assured for product quality, timely delivery and complete customer satisfaction.

Let’s unite, collaborate and work together for mutual success and growth.

For more information kindly contact us:

Mobile no- 6352986603

Survey No. 622/2/1/4, Dedhrota, Himatnagar-Vijapur Highway, Sabarkantha, Gujarat - INDIA

#prefilled injection#injections#syringes#injection manufacturer#pharmaceutical#pharmaceutical products#hospitals#doctors

1 note

·

View note

Text

It's t-shot Tuesday, y'all! Woo!

#I do wish I could figure out the trick to consistent shot administration#by that I mean every week is a Russian Roulette on the spectrum of “is this gonna hurt like a mfer or am I not gonna feel it at all”#today was closer to the hurt like a mfer but not all the way there#Everything was against me taking the shot this morning#first I ended up with a bit of the vial gasket in my syringe#which meant disposing of the whole thing#T and all#which was hard AF to do but it's not like I could strain and resterilize#and then#After applying the thinner needle to my syringe and uncapping it#I noticed there was some odd fucking white plastic or something attached to the side#some kind of manufacturing issue I guess#so all in all I used twice as many supplies for a single shot today

0 notes

Text

youtube

Disposable Syringe Production Plant

Thank You for watching my Video Laxmi Enterprises is the leading manufacturer, retailer,importer, exporter and service provider of , Egg tray machine, Disposable Syringe Production Plant etc.

#Laxmi Enterprises is the leading manufacturer#retailer#importer#exporter and service provider of#machines & equipment molds syringe assembly machine barrel printing machine blister packing machine needle assembly machine insulin sy#Youtube

0 notes

Text

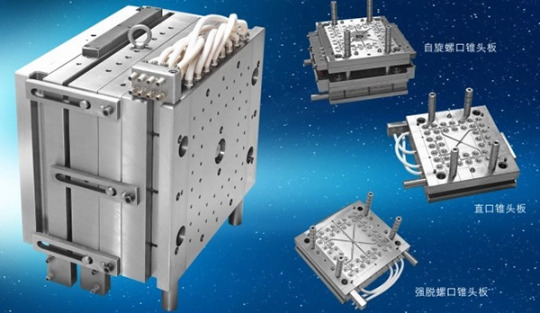

DISPOSABLE SYRINGE MOLD

Welinktech Disposable Syringe Mold is a high quality and precise injection mold that meets the needs of medical and healthcare applications. It has a unique design that is easy to use and allows for accurate and efficient production. The mold is crafted from durable materials and is safe and reliable for use.

ADVANTAGES OF DISPOSABLE SYRINGE MOLD

Disposable syringe molds offer several advantages compared to their reusable counterparts: they are more cost effective, require less maintenance, and are easier to use. Additionally, disposable molds can be quickly cleaned and sterilized, eliminating the need for manual cleaning and reducing the risk of cross-contamination. Finally, due to their single-use nature, the risk of spreading disease or infection through multiple uses is greatly reduced, making them a much safer option for medical and healthcare settings.

HOW TO STORE DISPOSABLE SYRINGE MOLD?

1

Disposable Syringe Mold should be stored in a clean, dry and well-ventilated environment.

2

Ensure that the temperature and humidity of the storage environment are suitable and it is away from direct sunlight.

3

Place the mold in a flat position and keep it away from sharp objects and corrosive chemicals.

4

Wrap the mold in a protective material such as cloth or plastic to prevent dust or other contaminants from affecting the mold.

0 notes

Text

#wholesale insulin syringe manufacturer#insulin syringe manufacturer and supplier#wholesale insulin syringe supplier#insulin syringe manufacturer in usa

0 notes

Text

Disposable Syringe Manufacturing Plant Suppliers in India!

Starting a Disposable Syringe Manufacturing Plant open the door to a lucrative and essential healthcare business. At Allied Way India, we provide cutting-edge machinery and expertise for seamless syringe production. Our solutions ensure precision, hygiene, and cost-efficiency, enabling businesses to meet global medical standards while achieving maximum profitability. Explore our website today!

0 notes

Text

Icrest Model: Empowering Businesses with Cutting-Edge Growth Solutions

ICrest Model provides businesses with cutting-edge solutions designed to drive growth and enhance efficiency. Our tailored strategies empower organizations to optimize operations, increase profitability, and unlock new opportunities. With a focus on innovation and long-term success, ICrest offers expert guidance to navigate complex business challenges. Whether you're looking to scale, streamline processes, or expand your market presence, ICrest equips you with the tools and insights needed for sustainable growth. Visit icrestmodels.com to learn how we can transform your business strategy and future success.

#cryptocurrency model template#hotel budget planning template#milk dairy farm project report#paint manufacturing project report#sanitary pad project report#detailed project report of solar power plant#project report for dairy#syringe manufacturing project report#toughened glass project report#financial model of cryptocurrency

0 notes

Text

Safe and Sustainable: Exploring the Advantages of Disposable Vaccine Syringes

Disposable vaccine syringes offer several advantages in terms of safety and sustainability, especially in the context of administering vaccines on a large scale. Let's explore some of the key advantages of using disposable vaccine syringes:

Prevention of Infections: Disposable vaccine syringes are designed for single use, ensuring that each patient receives a sterile and uncontaminated dose. This significantly reduces the risk of infections and cross-contamination, making them a safer option for healthcare professionals and patients alike.

Precise Dosage Delivery: The design of disposable vaccine syringes allows for accurate and consistent dosage delivery, ensuring that patients receive the correct amount of the vaccine. This is crucial for the effectiveness of vaccinations and to avoid under or over-dosing.

Convenience and Speed: Disposable vaccine syringes are pre-filled and ready to use, simplifying the vaccination process and saving time during mass vaccination campaigns or in emergency situations.

No Needle Reuse: With disposable vaccine syringes, there is no risk of needle reuse, which can lead to infections and bloodborne diseases. Once the syringe is used, it is safely discarded, eliminating the possibility of accidental needlestick injuries.

Waste Management: While disposable vaccine syringes contribute to medical waste, they are typically designed to be compact and easy to dispose of properly. Proper waste management practices can mitigate their environmental impact.

Cost-Effective: Disposable vaccine syringes can be produced at a relatively low cost, making them an affordable option, especially for vaccination programs in resource-constrained areas.

Supply Chain Efficiency: Disposable vaccine syringes simplify the logistics of vaccine distribution and storage. They can be pre-filled, reducing the need for separate vials, and facilitating the delivery and administration of vaccines in remote or hard-to-reach locations.

Safety for Healthcare Workers: By eliminating the need for needle recapping and reducing the risk of needlestick injuries, disposable vaccine syringes enhance the safety of healthcare workers during vaccination campaigns.

Sustainability Considerations:

While disposable vaccine syringes offer many advantages, there are sustainability considerations related to medical waste. Proper disposal and recycling of medical waste are essential to mitigate the environmental impact. Some efforts to address these concerns include:

Recycling Programs: Implementing recycling programs for medical waste, including syringes and other plastic materials, can help reduce the amount of waste going to landfills.

Biodegradable Materials: Researchers are exploring the use of biodegradable materials for disposable vaccine syringes, which would break down naturally over time and reduce long-term environmental impact.

Waste Reduction Strategies: Healthcare facilities can implement waste reduction strategies to minimize overall waste production and promote more sustainable practices.

In summary, disposable vaccine syringe manufacturers play a crucial role in ensuring safe and efficient vaccination campaigns. While they do generate medical waste, proper waste management and efforts toward sustainable materials can help minimize their environmental impact.

0 notes

Text

Syringe Pump Manufacturers

We are providing a huge list of syringe pump manufacturers, syringe pump suppliers, & syringe pump dealers from India. The Hospital product directory is India based directory that gives you healthcare-related product vendor details. let's talk now. Hospital Product Directory is a business directory featuring listing Medical Equipment's Indian manufacturers and suppliers of India with their product profiles and contact details.

0 notes

Text

Medicine Bottle Syringe Adapters: Streamlining Medication Admin

Medication administration is a crucial aspect of healthcare that requires efficiency, accuracy, and safety. However, traditional methods of administering medication, such as using a spoon or cup, can be time-consuming and prone to error. This is where the Medicine Bottle Syringe Adapters comes in – a simple yet innovative solution that can streamline the process of medication administration.

What is a Medicine Bottle Syringe Adapter?

A medicine bottle syringe adapter is a small, practical device that fits onto the opening of a medication bottle. It allows for the easy and accurate extraction of liquid medicine into a syringe, ensuring precise dosing. The adapter typically features a secure, leak-proof fit, preventing spills and making the process of drawing up medication smoother and more efficient.

Advantages of Using a Medicine Bottle Syringe Adapters

1. Saves Time and Reduces Error

One of the primary benefits of using a medicine bottle syringe adapter is the time it saves. By simplifying the process of drawing up medication, the adapter reduces the steps involved, thereby minimizing the risk of errors. This is particularly important for those who need to administer medications frequently or in a fast-paced healthcare setting.

2. Easy to Use

The user-friendly design of the adapter makes it accessible to everyone, regardless of their experience with medical devices. Simply attach the adapter to the bottle, insert the syringe, and draw up the required dose. The straightforward operation ensures that anyone, from patients to caregivers, can use it with confidence.

3. More Accurate Dosing

Accurate dosing is critical to effective treatment. The adapter allows for precise measurement of medication, reducing the risk of underdosing or overdosing. This accuracy ensures that patients receive the correct amount of medicine every time, contributing to better health outcomes.

4. Reduces Waste

By allowing for exact measurement and easy extraction, the adapter helps minimize medication wastage. This is especially beneficial for expensive medications where every drop counts. Reducing waste not only saves money but also ensures that patients have enough medication for their treatment duration.

5. Cost-Effective

Using a medicine bottle syringe adapter can be a cost-effective solution. By reducing medication waste and minimizing errors, it can lead to significant savings over time. Additionally, the adapter itself is typically affordable, making it a worthwhile investment for both individual patients and healthcare facilities.

Who can benefit from using a medicine bottle syringe adapters?

Everyone involved in medication administration. Patients can benefit from accurate dosing and reduced risk of errors. Caregivers can save time and effort while providing the best care for their loved ones. And healthcare professionals can ensure precise dosing and reduce the chances of medication errors.

How to use the bottle syringe adapters correctly

1. Prepare the Bottle: Ensure the medication bottle is clean and dry.

2. Attach the Adapter: Secure the adapter onto the bottle’s opening.

3. Insert the Syringe: Place the syringe tip into the adapter’s opening.

4. Draw the Medication: Pull back the syringe plunger to draw up the required dose.

5. Administer the Dose: Remove the syringe from the adapter and administer the medication as prescribed.

6. Clean the Adapter: After use, clean the adapter thoroughly to maintain hygiene.

Tips for Maintaining and Cleaning the Adapter

Proper maintenance and cleaning of the adapter are essential for ensuring its longevity and effectiveness:

Regular Cleaning: Clean the adapter after each use with warm soapy water and rinse thoroughly.

Disinfecting: Periodically disinfect the adapter using a mild antiseptic solution to prevent contamination.

Drying: Ensure the adapter is completely dry before storing it to prevent mold or bacterial growth.

Storage: Store the adapter in a clean, dry place, preferably in a sealed container to keep it free from dust and germs.

Conclusion

Innovations in healthcare technology, such as the Medicine Bottle Syringe Adapter, are crucial for improving patient care. Not only does the adapter streamline medication administration, but it also promotes safety and accuracy. As more healthcare facilities and individuals adopt this device, we can expect to see a significant improvement in the way medication is administered. Let’s embrace this simple yet effective solution and make medication administration a hassle-free process.

Read More : How Medicine Bottle Syringe Adapters are Streamlining Medication Administration

#Bottle Syringe Adapters#Syringe Adapters#Healthcare#Medicine Bottle#Medication#Syringe Manufacturers#Medical Equipment

0 notes