#stepper servo drive

Explore tagged Tumblr posts

Text

Schneider Electric Bangladesh Supplier

Schneider Electric Bangladesh Supplier in Bangladesh to empower everyone to make the most of your strengths and resources, bridging progress and creating sustainability for all. They call it “Life is On”. They aim to be your digital partner for sustainability and efficiency. They drive digital transformation by integrating world-leading process and energy technologies, cloud-connected products,…

View On WordPress

#AC Conductor#DC Conductor#Electrical Conductor#Life is On#Power Conductor#Schneider AC Conductor#Schneider DC Conductor#Schneider Electric#Schneider Electric Bangladesh#Schneider Electric Product Supplier#Schneider Electrical Conductor#Schneider Power Conductor#Schneider Servo Drive#Schneider Servo Motor#Schneider Stepper Motor#Servo Drive#Servo Motor#Stepper Motor

0 notes

Text

Floppy-Bot by Dan Mathias (1997), FutureBots, West Palm Beach, Florida. A “Robot made from an IBM tandon floppy disk drive” – that’s a 360K full-height 5.25-inch drive. All the functional components are salvaged from the drive, including the servo motor for the rear drive, the unipolar stepper motor for the forward steering wheel, and optical sensors. The construction of the robot is described in an article in the premier issue of ‘Robotics Digest’, Jan-Mar 1997.

26 notes

·

View notes

Text

Understanding Electric Motors: Types, Applications, and Benefits

Electric motors are integral to modern technology, powering everything from household appliances to industrial machinery and electric vehicles. These versatile devices convert electrical energy into mechanical energy, enabling motion and functionality in countless applications. Understanding the types, applications, and benefits of electric motors is essential for both professionals and consumers looking to make informed decisions about their use.

What is an Electric Motor?

An electric motor is a machine that converts electrical energy into mechanical energy through electromagnetic interactions. The basic principle of operation involves generating rotational motion when an electric current passes through coils within a magnetic field. This mechanical energy is then used to drive various devices and systems.

Types of Electric Motors

Electric Motors are categorized based on their design, power source, and intended application. Here are the primary types:

1. AC Motors

AC (Alternating Current) motors are powered by alternating current and are commonly used in applications requiring consistent speed and efficiency.

Induction Motors: These are widely used due to their durability and low maintenance. They are ideal for industrial and domestic applications, such as fans, pumps, and conveyors.

Synchronous Motors: Operate at a constant speed and are suitable for precision tasks like robotics and clock mechanisms.

2. DC Motors

DC (Direct Current) motors run on direct current and offer precise control over speed and torque.

Brushed Motors: Known for their simplicity and affordability, these motors are often used in small appliances and toys.

Brushless Motors: Offer higher efficiency and longevity due to the absence of brushes, making them popular in electric vehicles and drones.

3. Stepper Motors

Stepper motors are designed for precise positioning and control, often used in printers, 3D printers, and CNC machines. They operate in discrete steps, making them ideal for applications requiring accuracy.

4. Servo Motors

Servo motors are compact, high-performance motors used in robotics, cameras, and industrial automation. They provide accurate control of angular position, speed, and torque.

5. Special-Purpose Motors

These include motors designed for unique applications, such as linear motors, which produce linear motion, and universal motors, which can run on both AC and DC power.

Applications of Electric Motors

Electric motors are ubiquitous, serving a wide range of industries and purposes:

Industrial Machinery: Powering conveyors, compressors, and pumps for manufacturing and production processes.

Transportation: Driving electric vehicles, trains, and airplanes, contributing to the shift towards greener transportation.

Home Appliances: Found in washing machines, refrigerators, air conditioners, and vacuum cleaners.

Healthcare Equipment: Used in medical devices such as MRI machines, ventilators, and electric wheelchairs.

Automation and Robotics: Enabling precise movements in robotic arms, drones, and automated systems.

Benefits of Electric Motors

Electric motors offer numerous advantages, making them indispensable in modern technology:

1. Energy Efficiency

Electric motors are highly efficient in converting electrical energy into mechanical energy. Advances in motor design have further enhanced their energy-saving capabilities.

2. Eco-Friendly Operation

Compared to combustion engines, electric motors produce zero emissions during operation, making them a sustainable choice for reducing carbon footprints.

3. Versatility

Available in a wide range of sizes and specifications, electric motors can be tailored to meet specific requirements in diverse applications.

4. Durability and Reliability

With fewer moving parts and robust construction, electric motors are known for their longevity and dependability.

5. Low Maintenance

Many electric motors, especially brushless and induction types, require minimal maintenance, reducing long-term operational costs.

Challenges and Innovations

While electric motors are efficient and versatile, they face challenges such as energy losses and heat generation. However, ongoing innovations are addressing these issues:

Smart Motors: Equipped with sensors and IoT capabilities for real-time monitoring and optimization.

High-Efficiency Designs: Using advanced materials and designs to reduce energy losses and improve performance.

Integration with Renewable Energy: Electric motors are being adapted to work seamlessly with renewable energy sources like wind and solar power.

Conclusion

Electric motors are a cornerstone of modern technology, driving progress across industries and improving everyday life. Understanding the different types, applications, and benefits of electric motors helps individuals and businesses make informed decisions about their use. As innovations continue to enhance efficiency and sustainability, electric motors will remain at the forefront of technological advancement, shaping a greener and more efficient future.

0 notes

Text

Understanding PLC Stepper Motor Control By A Complete Guide

In the industrial automation realm, the combination of programmable logic controllers (PLCs) with stepper motors has revolutionized precision control. This will enable businesses to reach high standards of accuracy, repeatability, and efficiency of motion control systems. If you have just started with PLC Stepper Motor Control, this blog will guide you through its basics, benefits, applications, and setup process.

What is PLC Stepper Motor Control?

A stepper motor is a motor that steps along in steps, thereby making it useful for position and speed control. PLC stands for programmable logic controller, and this is the digital controller applied to machines and processes to automate. Combining these two elements, a PLC stepper motor control makes use of a PLC to send electric pulses to the stepper motor and control the movement and operations.

This system provides an efficient means of controlling motion in applications that require precise positioning, such as robotics, conveyor systems, and CNC machines.

Why Use PLC Stepper Motor Control?

The synergy between PLCs and stepper motors offers several advantages:

Precision and Accuracy

Stepper motors are excellent for exact movements, which makes them great for applications that require high-positioning details.

Flexibility

PLCs can be programmed to suit many tasks, making it very versatile in changing automation needs.

Scalability

Adding more motors or increasing the system complexity is easy with PLCs, ensuring growth without a significant overhaul.

Energy Efficiency

Stepper motors consume power only when needed, minimizing energy waste in operations.

Cost-Effectiveness

For most industrial applications, PLC stepper motor control is more cost-effective compared to servo systems.

Key Components of PLC Stepper Motor Control

PLC Unit

This is the brain of the system, which sends control signals based on programmed logic.

Stepper Motor

It converts electrical pulses into mechanical motion with precise step increments.

Motor Driver

It acts as an interface between the PLC and the motor, amplifying signals to drive the motor.

Power Supply

It provides the necessary power to the motor and driver.

Feedback Systems (Optional)

Encoders or sensors can be added for enhanced control and error correction.

How PLC Stepper Motor Control Works

Programming the PLC

The PLC is programmed with ladder logic or other languages to control the actions of a motor, such as a start, stop, direction, and speed.

Signal Transmission

The pulse signals are sent from the PLC to the motor driver. Each pulse corresponds to a step taken by the motor.

Motor Movement

The motor driver interprets the signals and turns on the stepper motor to perform precise movements.

Feedback and Adjustments

Advanced setups have sensors that give feedback to the PLC to ensure accurate execution.

Applications of PLC Stepper Motor Control

CNC Machines

Used for precise cutting, drilling, and engraving works.

Robotics

Ensures smooth, accurate movement in robotic arms and automated systems.

Conveyor Belts

Manages speed and positioning of material handling.

Printing Machines

It keeps paper or other materials at accuracy levels in printing.

Medical Devices

Accurate movements in infusion pumps and in imaging devices are also provided.

Benefits of Combining PLCs and Stepper Motors

Improved Process Control

The combination provides smooth control over intricate operations.

Enhanced Reliability

The system is reliable since stepper motors are simple, and PLCs are robust in nature.

Customizable Solutions

Programming options allow tailored solutions for specific needs.

Ease of Integration

PLCs and stepper motors are easily added to existing systems.

Setting Up PLC Stepper Motor Control

Choose the Right Components

Select a PLC, stepper motor, and driver compatible with your application.

Develop the Program

Write a PLC program to control the motor based on operational requirements.

Connect Components

Wire the PLC, driver, motor, and power supply correctly, following the manufacturer’s guidelines.

Test the System

Run tests to ensure the system operates as intended, making adjustments as needed.

Optimize Performance

Fine-tune settings for speed, acceleration, and torque to maximize efficiency.

Common Challenges and Solutions

Motor Overheating

Solution: Ensure adequate cooling and proper current settings.

Loss of Steps

Solution: Use a feedback system or adjust the step frequency.

Electrical Noise

Solution: Use shielded cables and proper grounding.

Programming Errors

Solution: Debug the PLC program thoroughly before deployment.

Tips for Choosing the Right PLC Stepper Motor Control System

Understand Your Requirements

Determine the load, speed, and precision required for your application.

Check Compatibility

Ensure all components are compatible and meet your operational needs.

Consider Expandability

Plan for future growth by choosing a system that allows scalability.

Prioritize Quality

Invest in high-quality components to reduce downtime and maintenance costs.

Seek Expert Advice

Consult professionals or suppliers to choose the best system for your application.

Future of PLC Stepper Motor Control

Interconnection of IoT and AI-Advancements in PLC stepper motor control have led to smart control systems that provide predictive maintenance, real-time monitoring, and adjustment operations with minimal downtime and high efficiency.

As such, industries continue embracing automation, and all forms of motion control systems will be needed to drive the modern operation.

Conclusion

PLC stepper motor control is an industrial automation game-changer. It can provide precision, flexibility, and cost savings in applications ranging from manufacturing plants to robotics and HVAC management.

By mastering the basics, choosing the right components, and working with reliable suppliers, you can unlock the full potential of PLC stepper motor control in your operations.

Originally Published Here:-

0 notes

Text

Eco-Friendly and Energy-Efficient: The Low-Energy Design of the Double-Sided Labeling Machine

Introduction

In today’s manufacturing landscape, environmental protection and energy efficiency have become critical components of a company’s competitiveness. With rising energy costs and increasingly stringent environmental regulations, businesses need to enhance production efficiency while reducing energy consumption and environmental impact. The double-sided labeling machine, with its advanced low-energy design, offers an efficient and eco-friendly labeling solution for companies. This article will detail the energy-saving design of the double-sided labeling machine and its real-world application effects, providing businesses with insights into achieving green production.

1. Core Elements of Low-Energy Design

High-Efficiency Electric System

The double-sided labeling machine adopts a high-efficiency electric system, with core components such as servo motors and stepper motors being highly efficient and low-energy. Compared to traditional mechanical drive systems, these motors reduce energy consumption by approximately 20%-30% while providing the same level of power. The servo motor’s high precision and fast response capabilities enhance labeling accuracy and reduce operational costs caused by energy waste.

Intelligent Energy Management Module

The intelligent energy management module is key to achieving energy savings. By monitoring and intelligently adjusting current, voltage, and power in real-time, the machine automatically adjusts energy consumption based on load conditions. When the equipment is in standby mode or running under low load, the system automatically switches to energy-saving mode, minimizing unnecessary power usage. This intelligent energy management ensures the machine operates efficiently while keeping energy consumption to a minimum.

Optimized Pneumatic System

The pneumatic system of the double-sided labeling machine is carefully designed with advanced air pressure regulation devices, minimizing the use of compressed air while maintaining labeling speed and precision. The optimized pneumatic system not only reduces gas consumption but also stabilizes pressure control during the labeling process by reducing air pressure fluctuations, enhancing the overall stability and consistency of labeling.

Eco-Friendly Materials and Design

The double-sided labeling machine is made from environmentally friendly materials, such as recyclable metals and low-VOC (volatile organic compounds) coatings, which lower the environmental burden during production. These materials also increase the machine’s durability and safety. Additionally, the machine’s compact design reduces space requirements, improving the utilization of production areas in manufacturing facilities.

2. Practical Benefits of Energy-Saving Design

Reduced Operating Costs

The low-energy design directly reduces equipment operating costs. For example, a battery manufacturing company that adopted the double-sided labeling machine reported annual savings of more than 200,000 yuan in electricity costs. Moreover, the efficient drive system lowers the frequency of maintenance, further reducing daily operational and maintenance expenses.

Lower Carbon Emissions

Environmental regulations impose increasingly stringent requirements on businesses’ carbon emissions. The energy-saving design of the double-sided labeling machine helps companies significantly reduce their carbon footprint. Calculations show that businesses using the double-sided labeling machine can cut carbon dioxide emissions by about 15% annually. This not only helps companies meet environmental standards but also enhances their green image in the eyes of customers and the market.

Extended Equipment Lifespan

With optimized energy management and stable operation mechanisms, the lifespan of key components such as motors, sensors, and pneumatic elements is significantly extended in the double-sided labeling machine. Lower operating temperatures and slower wear rates result in over 20% longer equipment lifespan, further reducing replacement and repair costs for companies.

Compliance with Environmental Regulations

As global environmental regulations become stricter, businesses must comply with higher standards. The double-sided labeling machine meets international environmental standards, such as ISO 14001, ensuring that it easily passes environmental inspections and reduces compliance costs for businesses.

3. How to Further Optimize Energy Efficiency with the Double-Sided Labeling Machine

Regular Maintenance and Inspection

To ensure the machine's energy-saving performance, companies should perform regular maintenance and inspections. Monitoring the condition of motors and pneumatic systems can help identify and address potential energy inefficiencies. Regular cleaning of the equipment, lubricating moving parts, and checking the sealing of airways will all contribute to maintaining high-performance, energy-efficient operations.

Optimizing Production Schedules

Scheduling equipment run times efficiently and avoiding long idle periods can further reduce energy consumption. For example, businesses can run the machine during peak production times and schedule maintenance and adjustments during low-demand periods, optimizing energy utilization.

Employee Training on Energy Conservation

Raising operators’ awareness of energy conservation is an important factor in optimizing the machine’s energy-saving performance. By providing energy-saving training to operators, they will understand how to reduce unnecessary energy waste through proper operation and how to effectively use the machine's energy-saving features. This will help businesses achieve even better energy efficiency.

4. Frequently Asked Questions (FAQ)

How do you enable the energy-saving mode of the double-sided labeling machine? The energy-saving mode of the double-sided labeling machine can be enabled through the settings menu on the user interface. Users can select an appropriate energy-saving mode based on production needs, such as low-speed operation mode or standby energy-saving mode. The equipment will automatically adjust power output and air pressure usage according to the selected mode to achieve energy savings.

Does the energy-saving design affect labeling efficiency and accuracy? No, the energy-saving design is implemented while maintaining labeling efficiency and accuracy. The high-efficiency electric system and intelligent energy management module ensure that the machine continues to deliver high labeling performance while reducing energy consumption. The energy-saving mode primarily activates during non-peak operation, so it does not impact normal production runs.

What should you do if the equipment’s energy efficiency performance declines? If the machine’s energy efficiency drops, it is recommended to first check its maintenance status, including whether the sensors are clean and whether the motors and pneumatic systems are functioning properly. If the problem persists, contacting the manufacturer’s technical support team for remote diagnostics or on-site service can help restore the machine to optimal energy efficiency.

Does using a double-sided labeling machine help with environmental certifications? Yes, the eco-friendly and energy-efficient design of the double-sided labeling machine meets international environmental standards such as ISO 14001. Using this machine can help businesses reduce energy consumption and carbon emissions, making it easier to obtain environmental certifications, which enhances market competitiveness and customer trust.

Conclusion

The double-sided labeling machine achieves exceptional energy-saving results through its high-efficiency electric system, intelligent energy management, and optimized pneumatic design. Its environmentally friendly features help businesses reduce operating costs and minimize environmental impact, making it an ideal choice for achieving green production. In modern manufacturing, the double-sided labeling machine is undoubtedly a powerful tool for businesses seeking to meet environmental goals and enhance economic benefits.

0 notes

Text

How to Select the Right Servo Drive for Your Application: A Comprehensive Guide

Servo drives are crucial components in modern automation systems, providing precise control of electric motors in various industrial applications. Selecting the right servo drive for your specific needs can significantly impact your system's efficiency, accuracy, and overall performance. With numerous options on the market, it's essential to understand the key factors involved in choosing the best servo drive for your application. In this guide, we'll walk you through the critical considerations and steps to help you make an informed decision.

1. Understand Your Application Requirements

The first step in selecting the right servo drive is to thoroughly understand your application’s specific requirements. Servo drives are used in a wide range of applications, from robotics and CNC machines to packaging equipment and automated conveyor systems. Each application has unique demands in terms of speed, torque, and precision.

Speed requirements: Determine the required speed range of your motor. Applications like conveyor systems may require constant speed, while robotics and CNC machines often need dynamic speed control for precise positioning.

Torque requirements: Torque is the force that the motor produces. Some applications, such as heavy-duty industrial machinery, require high torque, while others, like small assembly line robots, may need lower torque. Make sure the servo drive can handle the maximum torque required by your motor.

Precision and accuracy: For applications that require precise positioning or tight control over motor movements, such as pick-and-place machines or medical devices, you’ll need a servo drive that offers high resolution and accuracy.

By understanding these core requirements, you can narrow down your servo drive options to those that meet the specific needs of your application.

2. Match the Servo Drive to the Motor

Once you’ve identified your application’s needs, the next step is to ensure that the servo drive is compatible with your motor. Servo drives are designed to work with specific types of motors, such as brushed or brushless DC motors, stepper motors, or AC motors. Matching the drive to the motor is crucial for optimal performance.

Motor type: Verify that the servo drive you’re considering is compatible with the motor you plan to use. For instance, if you’re using a brushless DC motor, you’ll need a drive that supports this type of motor.

Power ratings: Check the voltage and current ratings of both the motor and the servo drive. The servo drive must provide enough power to drive the motor effectively. Using a drive with insufficient power can lead to underperformance, while overpowered drives may result in inefficiency and unnecessary costs.

Feedback mechanism: Many servo systems rely on feedback mechanisms, such as encoders or resolvers, to ensure accurate positioning and control. Ensure that your servo drive is compatible with the feedback devices used in your system, as this will directly impact the precision of motor control.

3. Consider Control Options and Communication Protocols

Servo drives offer various control options and communication protocols that allow them to integrate seamlessly into different automation systems. Depending on your application’s complexity and requirements, you may need advanced control features or specific communication interfaces.

Control modes: Servo drives typically offer different control modes, such as torque control, velocity control, and position control. Choose a drive that provides the control mode that best suits your application’s needs. For example, CNC machines often require precise position control, while conveyor systems might prioritize velocity control.

Communication protocols: Modern servo drives support a variety of communication protocols, including EtherCAT, CANopen, Modbus, and others. Ensure that the drive you select is compatible with your existing automation system’s communication infrastructure. If you’re integrating the drive into an advanced control system, selecting a drive with flexible communication options can simplify system integration and future scalability.

4. Evaluate Environmental Conditions

Environmental conditions can significantly impact the performance and longevity of your servo drive. Consider the following factors when selecting a servo drive for your application:

Temperature range: Some servo drives are designed to operate in extreme temperature conditions, while others are better suited for standard industrial environments. Make sure to choose a drive that can withstand the temperature range of your operating environment.

Ingress protection (IP) rating: The IP rating indicates the drive’s resistance to dust and moisture. For applications in harsh or outdoor environments, selecting a drive with a higher IP rating (e.g., IP65 or higher) can help protect the drive from damage caused by exposure to water or dust.

Vibration and shock: In applications with high levels of vibration or shock, such as automotive manufacturing or heavy machinery, choose a servo drive that is built to withstand these conditions. Drives designed for rugged environments often feature reinforced components and housings to ensure durability.

5. Plan for Scalability and Future Needs

When selecting a servo drive, it's essential to consider not only your current application but also future needs. Investing in a drive that can scale with your operations or accommodate potential upgrades can save you time and money down the line.

Expandability: If you anticipate needing additional axes of control or increased system complexity in the future, choose a servo drive that can be easily expanded or integrated into a more advanced system.

Software and firmware updates: Some servo drives offer upgradable firmware or software, allowing you to add new features or improve performance over time. Drives with strong manufacturer support and regular updates can provide greater longevity and adaptability.

Conclusion

Choosing the right servo drive for your application involves careful consideration of your specific requirements, motor compatibility, control options, environmental factors, and future scalability. By following this comprehensive guide, you can ensure that you select a servo drive that enhances the performance, efficiency, and reliability of your automation system. Whether you’re working with robotics, CNC machinery, or any other precision-driven application, the right servo drive can make all the difference in achieving your operational goals.

0 notes

Text

Rajlaxmi Machine Tools offers HMP | Ramato | Roent Make All Type Of Industrial Automation Products As Worm Reduction Gear Box, Stepper Motor, Stepper Drive, Gear Motor, Gear Drive, Servo Motor, Servo Drive, AC motor, AC Gear Motor, AC Drive, AC Gear Drive, VFD Drive, Proximity Sensors, PLC, HMI, Scada, Panels, Drives and All Type Of Machinery Related Automatic Automation Products Exporter From Rajkot Gujarat Bharat (INDIA).

#HMPIndustrialAutomation#RamatoIndustrialAutomation#RoentIndustrialAutomation#WormReductionGearBox#StepperMotor#StepperDrive#GearMotor#GearDrive#ServoMotor#ServoDrive#ACMotor#ACGearMotor#ACDrive#ACGearDrive#VFDDrive#ProximitySensors#PLC#HMI#SCADA#Panels#Drives#AutomationProducts#MachineryAutomation#RajkotAutomation#GujaratAutomation#IndiaAutomation#IndustrialAutomationExporters#GearBoxExporters#StepperMotorExporters#ServoMotorExporters

0 notes

Text

youtube

Small Ampoule Filling Machine R&D Lab Model

Small Ampoule Filling Machine R&D Lab Model is designed to fill pilot-scale R&D batches in volumes ranging from 1 to 30 milliliters. Devices are made with filling and sealing components on a single platform, making it a preferred option. Equipment contact areas constructed in accordance with cGMP standards using FDA-approved materials or stainless steel 316L.

There are various filling choices available for the little ampoule filling machine. A mechanical filling syringe is included with the standard machine. A machine with a stepper motor that drives valveless pistons under servo or stepper motor control. machine with a peristaltic pump unit for filling operations, based on peristatic pumps. The same sealing process is used in all machines with a mix of flammable and oxygen gas.

0 notes

Text

The Power of Rotation: A Comprehensive Look at Rotary Actuators

Transform Pneumatic, Hydraulic, or Electric Energy to Mechanical Rotation

In the realm of industrial automation, precise control over movement is paramount. Rotary actuators play a vital role in achieving this control, converting various forms of energy into rotary motion to power a wide range of applications. From the delicate movements of robotic arms to the powerful operation of valves and gates, rotary actuators offer a versatile and efficient solution for driving rotational tasks. This article delves into the world of rotary actuators, exploring their types, working principles, functionalities, and their diverse applications across various industries.

Understanding Rotary Actuators:

At their core, rotary actuators are mechanical devices that translate energy into rotary motion, or torque, around a specific axis. This energy source can be electric, pneumatic, hydraulic, or even manual. By converting this energy, rotary actuators enable precise control of angular displacement and rotational force, making them ideal for applications requiring positioning, opening, closing, or rotating various mechanisms.

Types of Rotary Actuators:

The diverse world of rotary actuators encompasses various types, each catering to specific needs and applications:

Electric Rotary Actuators: Powered by electric motors, these actuators offer precise control and are well-suited for automated applications. They come in various configurations, including stepper motors, servo motors, and DC gear motors, each offering distinct torque and speed characteristics.

Pneumatic Rotary Actuators: Utilizing compressed air as the energy source, these actuators are known for their speed and force output. They are commonly used in applications requiring high-speed actuation or limited space availability. Rack and pinion and vane types are two common configurations of pneumatic rotary actuators.

Hydraulic Rotary Actuators: These actuators rely on hydraulic fluid for power, offering exceptional force and torque capabilities. They are ideal for heavy-duty applications requiring high power output, such as operating large valves or manipulating massive machinery components.

Working Principles of Rotary Actuators:

The specific working principle of a rotary actuator depends on its type. Here's a simplified breakdown of the primary types:

Electric Rotary Actuators: An electric motor converts electrical energy into rotational motion of the motor shaft. This rotation can be geared down or up to achieve the desired output speed and torque. In stepper motors, the rotation occurs in discrete steps, offering precise positioning control. Servo motors provide continuous rotation with precise control over speed and position based on feedback signals.

Pneumatic Rotary Actuators: Compressed air enters the actuator body, pushing against a piston or vane, causing it to rotate. The direction of rotation is controlled by valves that direct the compressed air flow. Rack and pinion actuators convert the linear motion of the piston or vane into rotary motion using a gear rack and pinion gear. Vane actuators utilize the direct rotation of the vane within the actuator body.

Hydraulic Rotary Actuators: Hydraulic fluid, pressurized by a pump, enters the actuator body and exerts force on a piston or vane. The resulting linear motion is converted into rotary motion through a gear mechanism similar to pneumatic rotary actuators.

Functionalities of Rotary Actuators:

Rotary actuators perform a wide range of functions in various applications. Some key functionalities include:

Positioning: Rotary actuators can precisely position mechanical components or robotic arms to specific angles.

Opening and Closing: They can be used to open and close valves, gates, dampers, and other mechanisms requiring rotational movement.

Mixing and Stirring: Rotary actuators can power mixing blades or stirrers in various industrial processes.

Indexing and Material Handling: They can be used for precise indexing of materials in automated production lines or material handling equipment.

Clamping and Gripping: Rotary actuators can be used to clamp or grip objects in robotic applications or assembly lines.

Selection Considerations for Rotary Actuators:

Choosing the right rotary actuator for your application requires careful consideration of several factors:

Torque and Speed Requirements: The actuator's torque output and speed capabilities need to match the application's specific demands.

Power Source: Electric, pneumatic, or hydraulic power sources should be chosen based on available resources and desired control characteristics.

Duty Cycle: The frequency and duration of operation for the actuator must be considered to ensure proper sizing and prevent overheating.

Accuracy and Repeatability: The level of precision required for positioning or control should be factored in when selecting the actuator type.

Environmental Conditions: The operating environment, including temperature, humidity, and potential exposure to dust or liquids, should be considered to ensure proper material selection and protection for the actuator.

Applications of Rotary Actuators (Continued):

Building upon the previous section, here's a detailed look at some key industry applications of rotary actuators:

Oil & Gas: Rotary actuators are crucial in the oil & gas industry for:

Valve operation: Opening and closing valves for flow control in pipelines, refining processes, and wellheads.

Actuating blowout preventers (BOPs): Ensuring safety by closing wellbores in case of emergencies.

Positioning drilling equipment: Providing precise control over drilling heads and other downhole tools.

Power Generation: Rotary actuators are used in power plants for:

Valve actuation: Regulating fluid flow in cooling systems, boiler operations, and steam turbines.

Damper control: Adjusting air intake and exhaust dampers for combustion efficiency.

Positioning solar tracker systems: Optimizing the angle of solar panels to maximize sun exposure.

Food & Beverage: Rotary actuators contribute to automation in food processing by:

Operating valves for ingredient mixing, filling lines, and sterilization processes.

Positioning robotic arms for food handling, packaging, and palletizing.

Controlling conveyor belts for product movement within the production line.

Automotive Industry: Rotary actuators play a role in:

Robotic welding and painting applications: Precise movement of robotic arms for welding and painting car bodies.

Assembly line automation: Positioning and manipulation of components during vehicle assembly.

Climate control systems: Adjusting air flow dampers for heating, ventilation, and air conditioning within vehicles.

Aerospace & Defense: Rotary actuators find application in:

Aircraft control surfaces: Moving rudders, ailerons, and flaps for aircraft maneuverability.

Landing gear deployment and retraction: Precise actuation of landing gear mechanisms.

Radar positioning: Controlling the movement of radar antennae for target detection and tracking.

Construction: Rotary actuators contribute to automation in construction by:

Operating valves in concrete mixing trucks and other heavy machinery.

Positioning robotic arms for automated welding and material handling.

Controlling the movement of construction equipment attachments like excavator buckets and bulldozer blades.

Beyond these specific examples, rotary actuators are present in countless other applications across diverse industries. Their versatility, reliability, and ability to convert various energy sources into precise rotational motion make them a cornerstone of industrial automation.

Freture Techno: Your Partner in Rotary Actuator Solutions

Freture Techno Pvt. Ltd., a leading manufacturer of rotary actuators in Mumbai, India, offers a comprehensive range of high-quality electric, pneumatic, and hydraulic rotary actuators. With a commitment to innovation and engineering excellence, Freture Techno caters to diverse industry needs. Their team of experts can assist you in selecting the optimal rotary actuator for your specific application, ensuring optimal performance, reliability, and efficiency. Visit their website today to explore their product portfolio and discover how Freture Techno can be your trusted partner in rotary actuator solutions.

#valves#automation#Pneumatic#Hydraulic#Electric#Rotary Actuators#Freture Techno#Manufacturer#Mumbai#India

0 notes

Text

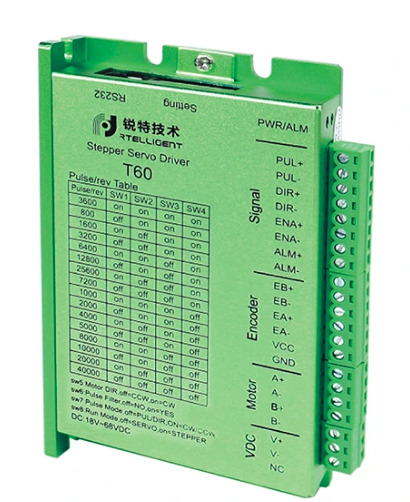

Stepper Servo Drive Suppliers - RB Automation

The precision and efficacy of machines are critical in the field of industrial automation. Stepper servo drives are essential for precise control and smooth functioning of a variety of devices. RB Automation stands itself from other providers in the industry by offering superior solutions that are customized to satisfy the various demands of various industries.

RB Automation has established itself as a leading supplier of stepper servo drives, offering innovative solutions that empower businesses to enhance productivity and streamline processes. With a focus on reliability, performance, and customer satisfaction, RB Automation has earned a reputation for excellence in the automation industry.

Stepper Servo Drives: The Industrial Automation Organization

Industrial automation systems depend substantially on stepper servo drives, which convert electricity into accurate mechanical motion. These drives are essential for guaranteeing precise and smooth operation, whether they are managing the motion of automated arms, CNC machines, or 3D printers.

RB Automation understands the importance of reliable Stepper Servo Drive Suppliers in today's fast-paced manufacturing environments. That's why they offer a comprehensive range of products designed to meet the demands of various applications. Stepper servo drive suppliers in Gujarat, India compact drives for space-constrained setups to high-torque drives for heavy-duty tasks, RB Automation has a solution for every requirement.

General-purpose T series

Matching motor frame below 86mm

PUL&DIR or CW&CCW

Auto-tuning match motor function

Smoothing filter function optional

Debugging software to modify and monitor drive parameters and status

Conclusion

For companies looking for dependable stepper servo drive solutions, supplier of stepper servo drive in India RB Automation is a dependable partner. They continue to lead the automation industry in standards of excellence with a priority on quality, innovation, and customer satisfaction. With the knowledge and tools at RB Automation, you can accomplish your objectives in terms of process optimization, quality improvement, and overall efficiency.

Contact Us: - +91 9662027058, [email protected]

Address: - B-197, GIDC SECTOR 25, ELECTRONICS ESTATE, Gandhinagar-382025, Gujarat, India

Visit for More Information: - https://www.rbautomate.com/

#Stepper Servo Drive Suppliers#stepper servo drive#series steppper servo drive#stepper servo drive suppliers in gujarat#supplier of stepper servo drive#stepper servo drive suppliers in india#supplier of stepper servo drive in india

0 notes

Text

What are the main components of a CNC Vertical Machine? | SBV Engineering Works Coimbatore

Main Components of a CNC Vertical Machine

A CNC Vertical Machine is an advanced manufacturing tool widely used in industries for its precision, efficiency, and versatility. These machines automate complex tasks such as cutting, milling, drilling, and shaping materials, mainly metals and plastics. To understand the functionality and importance of CNC vertical machines, it is crucial to explore their main components.

Machine Frame

The machine frame is the backbone of a CNC vertical machine. Typically made from cast iron or steel, it provides structural integrity and stability to the entire setup. The rigidity of the frame is vital as it minimizes vibrations and ensures precision during machining operations. The frame houses and supports other critical components, such as the spindle, worktable, and guideways.

Spindle

The spindle is one of the most critical components of a CNC vertical machine. It is responsible for holding and rotating the cutting tool at various speeds, depending on the material and operation being performed. Spindles in CNC machines are typically powered by electric motors and can achieve very high rotational speeds, enabling precise and efficient material removal. The quality and performance of the spindle directly impact the machine’s accuracy and surface finish of the workpiece.

Worktable

The worktable, also known as the bed or table, is the platform where the workpiece is securely clamped or fixtured during machining. The worktable moves along the X and Y axes to position the workpiece under the spindle for machining operations. Many CNC vertical machines feature T-slots or grid patterns on the worktable, allowing flexible and secure clamping of various workpieces. The worktable's movement is controlled by precision ball screws and linear guideways, ensuring smooth and accurate positioning.

Control System

The control system is the brain of a CNC vertical machine. It interprets the G-code or machine instructions, which are programmed commands that dictate the movement and operations of the machine. Modern CNC machines utilize advanced computer control systems equipped with user-friendly interfaces, allowing operators to input, modify, and monitor machining parameters easily. The control system coordinates the movement of the spindle, worktable, and other components to execute complex machining tasks with high precision.

Motors and Drives

Motors and drives are essential for the movement of various machine components. Stepper motors or servo motors, coupled with precision ball screws and linear guideways, enable the controlled movement of the spindle, worktable, and other axes. Servo motors, known for their high torque and accuracy, are commonly used in CNC machines. These motors receive signals from the control system and translate them into precise mechanical movements, ensuring accurate positioning and repeatability.

Tool Changer

Many CNC vertical machines are equipped with an automatic tool changer (ATC). The ATC allows the machine to switch between different cutting tools without manual intervention, significantly increasing productivity and reducing downtime. The tool changer typically consists of a carousel or linear magazine that holds multiple tools, and a robotic arm or similar mechanism that exchanges tools as needed during the machining process.

Coolant System

The coolant system plays a crucial role in maintaining the temperature of the cutting tools and workpiece. During machining, cutting tools generate significant heat due to friction. The coolant system delivers a steady flow of coolant, usually a mixture of water and soluble oil, to the cutting zone. This not only reduces heat but also lubricates the cutting process, prolonging tool life and ensuring a better surface finish.

Enclosure

The enclosure, or machine cabinet, serves multiple purposes. It contains the machining area, protecting the operator from flying debris, coolant splash, and noise. The enclosure also helps in containing the coolant within the machine, reducing wastage and maintaining a cleaner work environment. Many CNC machines feature transparent panels in the enclosure, allowing operators to monitor the machining process safely.

Sensors and Feedback Systems

Modern CNC vertical machines are equipped with various sensors and feedback systems that enhance accuracy and reliability. These sensors monitor parameters such as tool position, spindle speed, temperature, and vibration. Feedback systems provide real-time data to the control system, enabling dynamic adjustments to optimize machining performance and prevent errors.

conclusion

CNC vertical machines are sophisticated tools composed of several integral components working in harmony. Each component plays a vital role in ensuring precision, efficiency, and productivity in modern manufacturing processes. Understanding these components provides insight into the complex yet fascinating world of CNC machining.

See more: https://www.sbvengineering.com/

#cncmachine#cncturningmachinejobwork#cnccompany#cncmachinejobwork#cncverticalmachining#cncmachineshop#horizontal milling and boring machine#commercial

0 notes

Text

Electrical Motors in Aviation: Powering Precision and Efficiency

In the dynamic realm of aviation, electrical motors play a foundational role, driving essential systems with precision and efficiency. These motors convert electrical energy into mechanical motion, supporting critical functions from flight controls to auxiliary systems. Let’s delve into the intricacies of electrical motors in aviation, exploring their types, applications, advancements, and future prospects.

Fundamental Principles of Electrical Motors

At the heart of every electrical motor lies electromagnetism—a fundamental principle where the interaction between electric currents and magnetic fields generates rotational force. This principle underpins the operation of all electrical motors, regardless of their size or complexity.

Types of Electrical Motors in Aviation

1. AC Motors:

Synchronous AC Motors: Maintain constant speed regardless of load, suitable for applications requiring precise synchronization such as aircraft auxiliary systems and conveyor belts.

Induction AC Motors: Known for their robustness and ability to handle varying loads, widely used in pumps, fans, and HVAC systems within aircraft.

2. DC Motors:

Brushed DC Motors: Utilize brushes and a commutator for switching current direction, offering simplicity and reliability in applications such as actuators and instrumentation.

Brushless DC Motors: Provide higher efficiency and lower maintenance due to their brushless design, ideal for propulsion systems, flight controls, and onboard electronics.

3. Specialized Motors:

Servo Motors: Offer precise control and accuracy, essential in flight control surfaces, autopilot systems, and UAVs for maintaining stable flight paths and operational safety.

Stepper Motors: Provide precise angular positioning, crucial in cockpit displays, navigation systems, and automated controls where accuracy and repeatability are paramount.

Applications in Aviation

Electrical motors are integral to numerous aircraft systems:

Flight Controls: Powering ailerons, elevators, and rudders for precise maneuverability and stability during flight.

Landing Gear: Actuating mechanisms for extending and retracting landing gear swiftly and reliably.

Avionics: Driving instrumentation, displays, and communication systems to provide accurate data and operational feedback to pilots.

Advancements and Innovations

Continual advancements in electrical motor technology focus on:

Efficiency: Enhancing energy efficiency to reduce fuel consumption and operational costs.

Reliability: Improving durability and robustness to withstand harsh aviation environments and operational demands.

Integration: Incorporating smart technologies for enhanced performance monitoring, diagnostics, and predictive maintenance.

Future Trends

The future of electrical motors in aviation is shaped by:

Electric Propulsion: Advancing electric propulsion systems for cleaner, quieter, and more sustainable aircraft operations.

Automation: Integrating motors with advanced automation and artificial intelligence to optimize flight performance and safety.

Materials and Design: Innovating lightweight materials and compact designs to reduce overall aircraft weight while maintaining performance and safety standards.

Conclusion

Electrical motors are indispensable in modern aviation, driving efficiency, safety, and innovation across a spectrum of applications. As the industry progresses, advancements in motor technology continue to elevate performance standards, supporting the evolution towards more efficient and sustainable air travel. Whether powering critical flight controls or enhancing onboard systems, electrical motors remain at the forefront of aviation technology, ensuring the reliability and precision necessary for safe and efficient air travel.

0 notes

Text

PLC Motor Control: A Simple Guide for Beginners

In today’s fast-paced industrial world, automation is key to increasing efficiency, productivity, and safety. One essential part of automation is controlling motors, which are the backbone of many machines and processes. The easiest and most efficient way to achieve motor control is through a PLC, or Programmable Logic Controller. This blog will explain everything you need to know about PLC motor control, its importance, and how it works — all in simple terms.

What Is PLC Motor Control?

PLC motor control refers to using a Programmable Logic Controller (PLC) to manage and automate the operation of motors. A PLC is essentially a computer designed to control machinery and processes in industrial settings. It processes inputs from sensors and other devices, then sends signals to control the motors based on programmed instructions.

Motors are crucial in various industries, from manufacturing and packaging to robotics and HVAC systems. Managing these motors efficiently requires precision, reliability, and flexibility, which is where PLC motor control comes into play.

Why Use PLCs for Motor Control?

There are many reasons why PLC motor control is preferred in modern industrial applications:

Flexibility: PLCs can control different types of motors — AC, DC, or servo motors. They can be programmed to run motors at specific speeds, reverse their direction, or make them stop at certain positions.

Automation: One of the main reasons for using a PLC is automation. By programming the PLC to handle motor control tasks, human intervention is minimized, leading to more consistent and error-free operations.

Safety: Motors can be dangerous if not handled properly. A PLC ensures that motors are operated safely by monitoring conditions like overloads, overheating, or blockages, automatically shutting down the motor if needed.

Efficiency: By automating the motor’s operation, the overall process becomes more efficient. Motors are only run when needed, and their speed and direction can be adjusted in real-time.

Scalability: As your operations grow, your PLC motor control system can easily expand to include more motors and processes without needing significant changes to the hardware.

How Does PLC Motor Control Work?

To understand PLC motor control, let’s break it down into simpler components:

Inputs: Sensors or switches send signals to the PLC. These inputs provide real-time information about the motor’s status, like whether it’s on or off, running too hot, or if a safety limit has been reached.

Programming: The PLC is programmed with specific instructions, often using a simple programming language called ladder logic. These instructions tell the PLC how to control the motor based on the inputs it receives.

Outputs: The PLC sends signals to control devices such as motor starters, drives, or relays, which in turn manage the motor’s operation. This might involve starting or stopping the motor, changing its speed, or reversing its direction.

Feedback: Motors often send feedback to the PLC, such as information about their speed, position, or load. This feedback allows the PLC to make real-time adjustments and ensure smooth operation.

Common Types of Motors Controlled by PLCs

In PLC motor control systems, various types of motors can be controlled. Here are a few of the most frequently encountered examples:

AC Motors: These are the most commonly used motors in industrial applications due to their reliability and simplicity. They are often used in conveyor belts, pumps, and fans.

DC Motors: These are used where precise control of speed and torque is required, such as in elevators or printing presses.

Servo Motors: These motors are used for precise positioning applications. They are commonly found in robotics, CNC machines, and automated production lines.

Stepper Motors: Similar to servo motors, these are used in applications where precise movement and control are necessary, such as 3D printers or medical devices.

Steps to Implement PLC Motor Control

Implementing PLC motor control involves a series of steps that ensure the motor is integrated correctly into the system. Here’s a basic outline:

Select the Right PLC: The first step is to choose the right PLC for the job. It should have enough inputs and outputs to control all the motors in your system. Consider the type of motors you are using, as some motors (like servo or stepper motors) may require specialized modules.

Design the Control System: Determine the motor control strategy. This includes deciding what the motor will do (e.g., start, stop, run at different speeds, reverse, etc.) and under what conditions.

Program the PLC: Using ladder logic or another PLC programming language, write the program that will control the motors. The program should account for all the possible scenarios and include safety features such as overload protection and emergency stops.

Connect Sensors and Actuators: Connect all necessary inputs and outputs to the PLC. This includes wiring sensors, switches, motor drives, and relays to the appropriate terminals on the PLC.

Test the System: Before going live, thoroughly test the system to ensure that the PLC is controlling the motor as intended. This involves checking the wiring, verifying the program logic, and running the motors under different conditions to confirm they operate correctly.

Benefits of PLC Motor Control

There are numerous advantages to using PLC motor control in industrial settings:

Reduced Downtime: With automated control and real-time monitoring, potential issues can be detected early, minimizing unplanned downtime.

Cost Savings: By optimizing motor operation, energy consumption is reduced, leading to lower operational costs.

Improved Accuracy: PLCs offer precise control, which is especially important in applications like robotics or precision manufacturing.

Simplified Maintenance: Troubleshooting is easier since the PLC provides detailed information on motor performance and potential faults.

Conclusion

In summary, PLC motor control is a powerful tool that enhances the efficiency, safety, and reliability of industrial operations. By automating motor control, industries can streamline processes, reduce errors, and save on costs. Whether you’re working with AC motors in a factory or precise servo motors in a robotic system, a PLC offers the flexibility and control needed to keep things running smoothly. Originally Published Here:-

0 notes

Text

Linear Motion Solutions

Linear motion solutions refer to the various technologies and systems designed to provide controlled, precise linear movement. These solutions are used across a wide range of industries and applications, including industrial automation, robotics, machinery, and more.

Here are some key aspects of linear motion solutions:

Types of Linear Motion Systems: Ball screw systems,Lead screw systems,Linear motor systems,Belt-driven systems,Air/fluid bearing systems,Rack and pinion systems,Linear slide systems Key Components:, Linear actuators (e.g. ball screws, lead screws, linear motors),Linear guides (e.g. linear bearings, rails, slides),Drive mechanisms (e.g. stepper motors, servo motors),Control systems (e.g. motion controllers, drivers),Feedback sensors (e.g. encoders, limit switches) Design Considerations: Application requirements (e.g. load, speed, precision),Environmental factors (e.g. temperature, humidity, contaminants),Space constraints and mounting configurations,Integration with other systems and equipment,Maintenance and lubrication needs Common Applications: Industrial automation and robotics,CNC machines and machine tools,Semiconductor manufacturing equipment,Packaging and material handling systems,Medical devices and instrumentation,Test and measurement equipment,3D printing and additive manufacturing Trends and Advancements:,Increased use of linear motors for high-speed, high-accuracy applications,Integration of smart sensors and Industry 4.0 connectivity,Advancements in control algorithms and software,Developments in materials and lubrication for improved performance and reliability

You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#Linearbearingsandshafts#LinearGuides#LinearMotionBearings#LinearMotionComponents#Linearmotionsolutionsandapplications#LinearMotionStages#Linearmotionsystems#linearslidesandpositioningsystems#LinearXYStages#MotionControlSystem#Top-QualityLinearMotionSupplies

0 notes

Text

Electric Motor Market - Forecast(2024 - 2030)

Electric Motor Market Overview

Electric Motor Market Size is forecast to reach $169 billion by 2030, at a CAGR of 5.6% during 2024-2030. The increase in global electricity consumption and the use of electrical equipment and machines in different industries and the renewables sector are major factors driving the growth in the electric motor market during the forecast period. An increase in awareness of green vehicles among customers has been a key factor leading the market. Besides this, a rising number of government incentives to encourage sales of green vehicles for safeguarding the environment from carbon emissions is analysed to drive the market. The growing interest in sustainable transportation has driven the demand for electric vehicles. Electric motors play a crucial role in powering EVs, and advancements in motor technology contribute to increased efficiency and range. The industrial sector is witnessing the integration of electric motors with the Internet of Things (IoT) and Industry 4.0 technologies. This integration allows for real-time monitoring, predictive maintenance, and improved efficiency in industrial processes.

Smart motor technologies, incorporating features like connectivity, sensors, and advanced control systems, are becoming more prevalent. These innovations contribute to better performance, remote monitoring, and enhanced automation in various applications. Developments in motor control systems, including advanced algorithms and power electronics, contribute to improved motor performance, reduced energy losses, and enhanced control precision. There is an increasing emphasis on developing more energy-efficient electric motors to meet sustainability goals and reduce energy consumption. Regulations and standards promoting energy efficiency also influence the design and manufacturing of electric motors. Additionally, Electric motors have been observing several advancements in technology over the past few years, owing to which its demand is set to gain higher traction during the forecast period 2024-2030.

Report Coverage

The report: “Electric Motor Market Report– Forecast (2024-2030)”, by IndustryARC covers an in-depth analysis of the following segments of the Electric Motor market

By Product Type: AC Motor (Induction Motor, Synchronous Motor, Servo Motor, Stepper Motor), DC Motor (Brushed DC Motor, Brushless DC Motor, Servo Motor, Series Motor, Stepper motor, Compound Motor).

By Product Category: Permanent Magnet, Non-Permanent Magnet.

By Phase: Single Phase, Three Phase.

By Power Rating: Below 0.5W, 0.5W-1W, 1W to 100W, 100W to 1KW, 1KW to 10KW, 10KW and Above.

By Efficiency: IE1, IE2, IE3, IE4.

By Application: Commercial (Automated Doors, Elevators & Escalators, Blowers, Electric Sweepers, Hand Dryers, Data Center & UPS, Pumps, Power Tools, Water Coolers, Camera PTZ Control, Drones, Others), Consumer Products (Pumps, Hair Dryers, Lawn Mowers, Boilers, Dishwashers, Vacuum Cleaners, washing machine, Blenders & Mixers, Fans & Chimneys, Desktop & Laptops, Smartphones, Refrigerators, Others), Automotive (Body Control motors, EPS Motors, Brake Booster BLDC Motor, Seat Adjustment, Belt Tensioner, Car Window Motor, Door Lock Motors, Wiper Motor, Others), Medical & Healthcare (Diagnostic Equipment (CT Scanners, MRI, Biopsy Systems, Diagnostics Analyzers, Ultrasound Transducers, X-Ray, Others), Medical Centrifuges, Medical Pumps, Blowers and Compressors, Surgical Instruments (Saws, Drills, Surgical Robots, Others), Dental CAD/CAM Milling Machines, Exoskeleton & Prosthetics, Microscopes, Wheelchairs & Scooters, Stair Lifts, Hospital Beds & Exam Tables, Others).

By Geography: North America (U.S, Canada, Mexico), South America(Brazil, Argentina and others), Europe(Germany, UK, France, Italy, Spain, Russia, Netherlands, Poland, Czechia, Belgium, Sweden and Others), APAC(China, Japan India, SK, Aus and Others), and RoW (Middle East and Africa)

Request Sample

Key Takeaways

• The rising demand for efficient energy usage over concerns of environmental impact of energy generation from conventional sources such as coal and natural gas, is expected to help grow the electric motor market in APAC.

• The DC Motor segment is growing at a significant CAGR of 7.6% in the forecast period 2024-2030. A DC motor consists of a stator and a rotor.

• Medical & Healthcare sector is expected to witness a highest CAGR of 8.5% the forecast period 2024-2030, due to its extensive reliance on electrically powered devices and equipment. Diagnostic imaging equipment, such as MRI and CT scanners, demands high-performance electric motors for precise movements and accurate imaging.

• Electric Motor companies are strengthening their position through mergers & acquisitions and continuously investing in research and development (R&D) activities to come up with solutions to cater to the changing requirements of customers.

Electric Motor Market Segment Analysis - By Product Type

The DC Motor segment is expected to grow at a significant CAGR of 7.6% during the forecast period 2024-2030. Owing to the growing penetration of brushless DC motors across various industry verticals substituting brushed dc and even ac induction motors in certain applications such as home appliances. DC motors are used in electric vehicles in the automotive industry for various non-traction applications, contributing to the ongoing shift towards sustainable transportation. As the demand for electric vehicles grows, so does the demand for efficient and dependable DC motors. DC motors are also widely used in industrial automation, powering conveyor systems, robotics, and manufacturing equipment. Owing to the ease of control, they are suitable for accurate and regulated movements in automated processes.

Inquiry Before Buying

Electric Motor Market Segment Analysis - By Application

Medical & Healthcare sector is expected to witness a highest growth of CAGR 8.5% during the forecast period 2024-2030, owing to the increase in investments in healthcare and medical sector, along with growing penetration of advanced medical devices & equipment in the sector such as surgical robots, advanced imaging & diagnostic equipment, prosthetics and so on. Medical advances and technical improvements have resulted in the development of a wide range of medical instruments and gear that significantly rely on the precision and efficiency provided by electric motors. High-performance electric motors are required for precise motions and accurate imaging in diagnostic imaging equipment such as MRI and CT scanners. Electric motors provide stability and consistency to patient care and monitoring systems such as infusion pumps and monitoring equipment. Furthermore, the incorporation of electric motors in mobility aids such as electric wheelchairs and patient lifts improves accessibility for people who have mobility issues. Electric motors are used in laboratory equipment, robotic surgical systems, and a variety of medical tools, all of which contribute to the overall efficiency and improvement of healthcare techniques. The demand for electric motors is on the rise as the healthcare industry evolves and adopts more technologically sophisticated solutions, fueling additional innovation in this critical sector.

Electric Motor Market Segment Analysis - By Geography

Electric Motor market in Asia-Pacific region held significant market share of 38% in 2023. Increasing compliance for energy efficient motors and rising adoption of motor-driven electric vehicles are the key factors driving market growth. The rising demand for efficient energy usage over concerns of environmental impact of energy generation from conventional sources such as coal and natural gas, is expected to help grow the electric motor market. In addition, advancements in the agriculture sector and enormous investments in industrialization in countries such as China, India, South Korea, and Australia is driving the market growth. Further, the increasing production and sales of electric vehicles in countries including China and Japan is also analyzed to drive the market growth.

Schedule a Call

Electric Motor Market Drivers

Rise in demand for Electric Vehicles

The electric car market has witnessed rapid evolution with the ongoing developments in automotive sector and favorable government policies and support in terms of subsidies and grants, tax rebates. Major manufacturers such as General Motors, Toyota, and BMW plan to release a potential of 400 models and estimated global sales of 25 million by 2025. In 2022, Ford Motor has committed to increase its investments in electric vehicles to $50 billion by 2026, up from a previous spend of $30 billion by 2025. Similarly, in 2020, Volkswagen, Chinese ventures has committed to invest $17.5 billion in electric vehicles by 2025. As electric vehicles use various types of electric motors for traction & auxiliary applications, the rising demand for electric vehicles globally is set to assist the market growth for electric motors used in the same.

Growing R&D activities

Manufacturers are continuously focusing on R&D to develop new and effective electric motors to meet consumer demand. Increasing concerns, such as environmental pollution and regulations, are forcing manufacturers to develop electric motors that reduce vibration and increase efficiency. For instance, a synchronous electric motor is around 80% more efficient than an induction electric motor. Similarly, the development of a new type of steel for electric motors, which reduces the weight of the electric motor and makes it more efficient and powerful. This new type of electric motor will be small in size and cost effective, which will raise demand from residential and commercial applications. Moreover growing developments from various companies is also analysed to drive the market growth. Hence these factors are analysed to drive the market growth in the forecast period 2024-2030.

Electric Motor Market Challenges

Easy availability of low-quality electric motors

The market for electric motors is highly fragmented, with a significant number of domestic and international manufacturers. Product quality is a primary parameter for differentiation in this market. The organized sector in the market mainly targets industrial buyers and maintains excellent product quality, while the unorganized sector offers low-cost alternatives to tap local markets. Local manufacturers of electric motors in most countries target the unorganized sector and compete strongly with the global suppliers in the respective markets. Leading market players are currently exposed to intense competition from such unorganized players supplying inexpensive and low-quality electric motors. This acts as a key challenge for the growth of the market.

Buy Now

Market Landscape

Product launches, acquisitions, Partnerships and R&D activities are key strategies adopted by players in the Electric Motor market. Electric Motor top 10 companies include:

ABB Ltd

Johnson Electric Holdings Limited

Siemens AG

Rockwell Automation

Nidec Corporation

Bosch Electric

Regal Rexnord

Franklin Electric Company Inc.

Teco Electric & Machinery Co. Ltd.

Wolong Electric Group co. ltd.

Acquisitions/Product Launches

• In July 2023, Nidec Corporation announced that it has successfully developed a new electric power steering motor power pack*1 (“EPS-PP”).

• In July 2023, WEG announced new investments for its motor manufacturing plant located in Manaus, Brazil. The Company will invest R$ 48 million, in the next three years, to expand production capacity and adapt the plant to produce a new line of permanent magnet electric motors for split-type air conditioners

• In December 2023, Johnson Electric Launches 48-Volt Cooling Fan Module with High Power and Efficiency. Johnson Electric is pleased to announce the launch of the 48-Volt Cooling Fan Module with power up to 1.5kW to meet the most demanding cooling requirements. The need to reduce emissions and increase the electrification of the vehicle, requires higher cooling performance and efficiency.

#Electric Motor Market#Electric Motor Market size#Electric Motor industry#Electric Motor Market share#Electric Motor top 10 companies#Electric Motor Market report#Electric Motor industry outlook

0 notes

Text

A Human-Machine Interface: What Is It and How Does It Operate?

Human-Machine Interfaces from best Weidmuller power supplies create a usable interface that helps a person establish a communication system with a device. We can explain this more straightforwardly by saying it is simply an input/output device. The information is input here. The person operating the machine inputs it into the machine. The machine outputs the commands based on the data fed into it. On the other hand, the machine may also input the information from its sensors or hardware, which is then outputted on the HMI for the machine operator to decipher and ultimately make out.

Next, combined with programmable logic controllers or PLC, machine sensors record and put forward the information as inputted and received. HMIs are often utilised in industrial settings because of the particular input/output relationship they carry with them. In this sector, an HMI is very frequently used to decipher, see, and control the following information:

Production Time

Production Trends

Visual Data

Temperature Control

Human-Machine Interface and Its Benefits

Human Machine Interfaces, or HMI, from us as one of the best cable assemblies in India, has become part and parcel of machine designs in the industrial sector primarily because of the number of benefits it offers its users. First, the increased visibility of these interfaces makes data centralisation easy to read and ensures that vital notifications or production changes are never missed. This interface's enhanced efficiency results in accurate, real-time data generation that is particularly useful in such a high-paced environment. Here are some other benefits of Human Machine Interface and they are:

Reduction in Cost

Improved Usability

Improved Management of Time

Areas of Application of HMI

We find the maximum utilisation of Human Machine Interface from Hengstler counters supplies in the industrial settings as this sector needs to communicate with and control the machines accurately. This sector requires this kind of control so that industrial processing can be maintained at the optimal level, proper control over the final finished product can be maintained, and the overall safety of the process can be taken care of. To be specific, the industries that use HMIs include:

Manufacturing

Recycling and Waste Management

Oil and Gas

Energy and Power

Food and Beverage

We Give a New Meaning to the Word “Efficiency”

We, SR Indus Electro System, one of the best Weidmuller Distributors in India, are the single source provider equipped with the latest Human-machine Interface technology. It is capable of meeting complex processes of machines and systems. Weidmuller HMI provides efficient integration to your automation systems. They are optimised to meet specific human-machine interfaces. Through our UV66-BAS-4-RES-W easy multi-touch panels, it becomes easier to monitor and control the machines and systems. Moreover, the u-view multi-touch panels from Weidmuller offer perfect image quality and are fit for use in the industrial environment devoid of any restrictions. Additionally, we provide profinet encoders.

Our HMI is very efficient performance-wise, as its image quality is unparalleled. Besides the image quality, its powerful processors make working with u-view multi-touch panels smooth and enjoyable. The compatibility rate of u-view multi-touch panels allows them to be used in various applications. This becomes possible because we use world-class web technology based on HTML5. Hengstler encoders presents robust motor feedback encoders tailored for demanding applications, compatible with both brushless servo and stepper motors. Leveraging Acuro drive technology, dynamic servo drives transition into a fully digital realm for the first time. Even under harsh operating conditions, such as those encountered within motor housings, reliability remains uncompromised. Proudly brought to you by Sr Indus Electro Systems.

#hengstler encoders#weidmuller power supplies#cable assemblies#harting han connectors#electronic components supplier#profinet encoders

0 notes