#SCADA

Explore tagged Tumblr posts

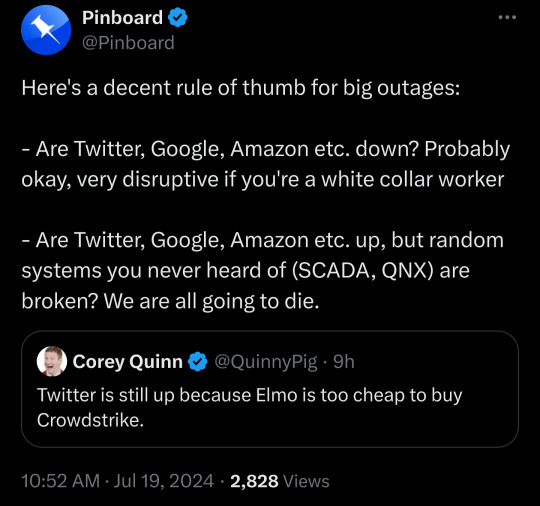

Text

4K notes

·

View notes

Text

Hi guys!! This was a wild impulse series of drawings that I had no intention of finishing and yet here we are- uhhh. I'm also finally moving so to my mutuals: I am VERY sorry if I am m.i.a most of this week 🫡

Quick oc Ramble before I finish up with my plans for today!

Favorite Oc: Ichor! I've posted about him before, but he's *technically* also my very first utmv oc. (I decided there were no repeats-) Ichor has been here since the start of my obsession and still haunts me today. He's a Diety of Punishment after death, but was chained in shackles that restrict his powers, so instead of a God of Punishment, he's the self-proclaimed God or Puns!

First OC: I'm almost 90% sure his name isn't actually Scada but we're rolling with it. This was my 2nd-ish oc for utmv! In his universe, instead of Dusting monsters turn into a weird soul-goop. He's always had weak HP so when he almost died to something stupid one day as a kid, he expended a lot of magic to keep himself alive. His father, Gaster, wasn't very happy that his son was now half-dead so Scada was heavily separated from busy places like the capital and the whole family picked up and moved to Snowdin!

Latest OC: Phishbone. Phishbone was a Papyrus from a universe where Gaster (his father) took both him and Sans to the lab. Gaster trained Sans in the soul studies, but taught Papyrus how to weird concentrated human souls. Because Paps loved puzzles, Gaster constructed a rubix-cuve to contain soul essence for Paps to use in emergencies. When the universe corrupted, Core Frisk was only able to salvage Phishbone. He saw turmoil in the multiverse and decided that he'd set some things right! He has a pocket dimension where he can control anything about it, and usually pulls fueding people into it to force them to play games and use teamwork to overcome their frustration and escape!

Easiest to Draw OC: B.G. Sans (Bubble Gum Sans). She was a skeleton monster who just barely survived the war on the surface. Having been blinded by humans, Gaster took her in and helped her to live underground. She was the "Royal Seer", and was only able to see visions of the future (ex. The freedom of monsterkind). Her brother Gaster had two sons, Sans (who was named after her) and Papyrus. One day a human cornered BG and her nephews in the lab, and she was killed protecting them. Her soul was taken to The Void, and everyone but her family forgot her. Now she and Gaster control the void together, and 1 by 1 all the monsters underground escape the resets and join the Void!

Hardest to Draw OC: Ec-4o.Verse Ink. This guy is a menace. I designed him to have several robotic body parts to resemble a chimera, but I forget where they are at all times. + I always hate his outfit design??? He's on my list to fix his outfit.

#utmv#utmv sans#oc#utmv oc#my art#spot!drawn#ichor#ichor sans#punishment sans#catacombtale#scada#scada sans#phishbone#b.g. sans#b.g.#bg sans#betweentale#ec-4o!ink#ec-4o.verse#N#<- I really really didn't want to draw her smh

30 notes

·

View notes

Text

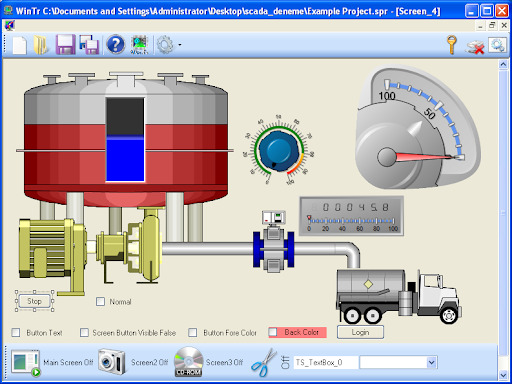

#SCADA#Supervisory Control And Data Acquisition#SCADA software#software#WinTr#industrial#industrial engineering#webcore#old web#techcore#cybercore

7 notes

·

View notes

Text

Other communication options are available in PowerFlex 525 AC Drives

The PowerFlex 525 AC Drives provide a variety of connection options in addition to typical EtherNet/IP connectivity to guarantee smooth integration with different industrial networks. These drives provide various networking setups by supporting optional dual-port EtherNet/IP, DeviceNet, and Modbus RTU protocols. Communication adapter modules allow them to interact with protocols including ControlNet, BACnet, and Profibus DP. Because of its adaptability, users may connect to various control systems without requiring significant hardware modifications, making the PowerFlex 525 perfect for a variety of automation scenarios. Easy configuration and connectivity are further improved by embedded Ethernet and built-in USB programming.

#automation#technology#tech#technical#AVEVA#PLC#HMI#SCADA#scada systems#industrial#industries#Allen Bradley#Rockwell Automation#Tech#Automotive

2 notes

·

View notes

Text

🌍 Join Trinity Touch at Intersolar Europe 2025 – Munich, Germany 🌍

We are excited to present Trinity Touch’s latest innovations designed to power the future of solar power plants and clean energy infrastructure.

🚀 Explore our advanced range of solutions, including: ☀️ String Monitoring Systems 📊 Next-Gen SCADA Systems 🌦 Weather Monitoring Units 🛡 Integrated Cybersecurity Solutions

With 75+ GW of solar systems delivered, we’re proud to support the global transition to renewable energy.

🔧 Dive into our in-house manufacturing capabilities featuring: Enclosures | Wiring Ducts | Cable Glands | DIN Rails | String Monitoring Boards

Let’s shape a sustainable future—together.

📍 Meet us at: Hall B4 | Stall 670 📅 May 7–9, 2025 📌 Messe München, Germany

💬 Connect with us: 📞 +91 11 71200900 📱 WhatsApp: +91 9911717900 ✉️ [email protected] 🌐 www.trinitytouch.com

#Intersolar2025#TrinityTouch#SolarInnovation#SmartEnergy#CleanEnergy#EVCharging#SCADA#SustainableFuture#MadeInIndia#Renewables#EnergyTech#GlobalExhibitions

0 notes

Text

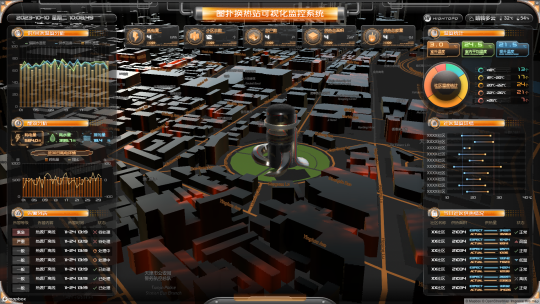

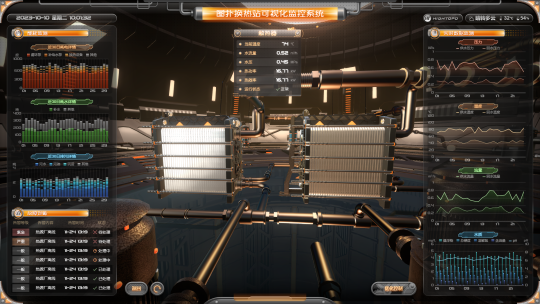

Heat Exchange Station Management System Web Page Design

0 notes

Text

The Importance of PLC in Industrial Automation

Introduction

By enhancing productivity, optimizing the process, and lowering operational costs, industrial automation has transformed the way industries operate. The Programmable Logic Controller (PLC), a dedicated computer used for the automation of industrial equipment and processes, is an important part of this transition. With their flexibility, reliability, and real-time control capabilities, PLC have become a cornerstone of contemporary automation systems.

PLC in Industrial Automation once seemed like machines manufactured only for the automation of various industrial machinery, but little did we know that they are a rugged and reliable computing system that can run efficiently in industrial circumstances that seem impossible.

What is Automation?

Automation is the application of technology to produce and deliver goods and services with minimal human intervention. It is commonly used in parallel fields to improve efficiency and minimize mistakes. Automation can consist of mechanical systems or software applications used in conjunction with specialized automation and/or artificial intelligence technologies in order to provide functionality in operations.

Advantages of Automation:

Speed up processes: work does not get tired like men, machines run continuously.

Cutting of cost: Automation requires less human power which leads to reduction of cost.

Reduction in Errors: Automation reduces the margin of error and improves the reliability of data and consistency of processes.

Scalability: A business can grow and not have to pay a bank to become big.

In most of the fields, we have automation like in manufacturing, IT, marketing, customer service, etc., where it is used to reduce the effort in repetitive tasks, to optimize the utilization of resources, and improve overall efficiencies.

What is Industrial Automation?

Industrial automation involves the use of control systems, such as computers or robots for handling different processes and machinery for the industry to operate with minimal or reduced human intervention. It finds application across a range of industries including manufacturing, energy, pharmaceuticals, automotive, and food processing.

Key Advantages of Industrial Automation

More Efficiency: Machines do operating continuously which increases the output.

Enhanced Quality: Automation results in maintaining consistency and thus helps with minimizing defects.

Cost Reduction: Decreases labor costs and increases energy efficiency.

Improved safety: Removes humans from dangerous situations.

Industrial automation has been transformed based on the concept of smart factories powered by AI, IoT and robotics driven state-of-the-art decision making and production optimized through complex networked devices and systems, ushering forth Industry 4.0.

Understanding PLC in Industrial Automation

Programmable Logic Controller, a programmable computer used for process automation, to control machinery, to monitor production processes, and to maintain efficiency. PLC differ from traditional computers, as they need to operate in harsh industrial environments that can include extreme temperatures, a large amount of dust, and vibrations.

Key Features of PLC:

Immediate Control: PLC analyze sensor data in real-time, maintaining operational stability.

Adaptability: Should be quickly re-programmable for new tasks and changes.

Reliability: Runs smoothly in extreme conditions.

Communication: Connects to supervisory systems for monitoring and decision making.

PLC are at the heart of all of this, running assembly lines, monitoring environmental conditions, controlling energy in our buildings, and maintaining product quality. These serve as the core of industrial automation, enabling the industries to bring forth tasks with higher productivity, while minimizing the downtime, along with the cost.

Conclusion

PLC play a key role in industrial automation by providing accuracy, efficiency, and safety for industrial processes. The PLC in Industrial 4.0 Whether it is the smart manufacturing adopted decisions across industries, the role of PLC will further blossom, resulting in smart manufacturing, sustainable, and productive production environments. PLC are cost-effective automation solutions for today, for industries to remain competitive in the future global market.

0 notes

Text

🤖 Need Industrial Automation Solutions? Let’s Talk!

Running an industrial operation? Then you know how important automation is for efficiency and reliability! ⚙️ At Fast Cal Industrial Corp, we provide expert automation solutions, from PLC programming and SCADA systems to power quality analysis and electrical installations.

Need expert consultation or troubleshooting? 🛠️ Our team is here to assist you with customized industrial solutions to ensure seamless operations. Whether you’re looking for automation system upgrades or preventive maintenance, we’ve got you covered!

📩 Reach out to us today for expert industrial automation support!

#IndustrialAutomation#AutomationExperts#ManufacturingSolutions#SmartIndustry#ProcessControl#IndustrialSolutions#AutomationSolutions#MechanicalSolutions#ElectricalSolutions#FastCal#PLC#SCADA#ControlPanelDesign

0 notes

Text

#ICONICS#Electric#SCADA#automation#digitalization#empowering#cutting_edge#sustainable#DigitalSolutions#Innovation#powerelectronics#powermanagement#powersemiconductor

0 notes

Text

Siemens SCADA: The Backbone of Smart Industrial Operations

Success in present times of rapid industrial developments depends on efficiency, accuracy, and real-time control. This is where SCADA (Supervisory Control and Data Acquisition) systems come in. One of the leading providers of SCADA solutions, Siemens, has a selection of advanced Siemens SCADA systems. The Siemens SCADA is designed to work in tandem with PLC SCADA with the utmost control, monitoring, and data analysis functions. This article talks about why Siemens SCADA is a big game changer for industries everywhere in the world.

What is Siemens SCADA?

Siemens SCADA is a cutting-edge SCADA system that allows industries to perform monitoring, control, and optimizing in real-time. It serves as the CNS of industrial automation by gathering information from sensors, equipment, and PLCs (Programmable Logic Controllers) for presentation in a user-friendly manner.

The seamless integration of Siemens SCADA with the PLC SCADA systems will allow the operators to act on the information in an informed manner and in practically real-time. Whether it is for the management of the manufacturing plant or controlling the grid, Siemens SCADA gives you the tools to keep things running.

Siemens SCADA Key Features

1. Monitoring Real-Time Data

It is using Siemens SCADA that gives real time views of industrial processes and helps operators step forward for detecting and resolving problem areas before escalating them.

2. Scalability

Siemens SCADA systems range from small- to large-scale factories to cater to the needs of the entire operation.

3. PLC SCADA Integration

Siemens SCADA is perfectly compatible with Siemens PLCs and creates a unified automation solution that improves efficiency and reduces downtimes.

4. User Friendly Interface

Thus, Siemens SCADA has an intuitive design of user-friendliness such that it can be manipulated by non-technical users.

5. Advanced Analytics

The tools for heavy analytics incorporated in the application Siemens SCADA, benefit industries in trend analysis, process optimization, and productivity improvements as well.

Siemens SCADA Benefits

Improved Operational Efficiency: By means of automation in repetitive tasks and streamlined processes, maximum productivity can be assured.

Enhanced Decision-Making: The ability to access real-time data makes setting existing processes into action easy.

Reduced Downtime: Predictive maintenance assures a smooth-running operation by preventing equipment failures.

Less Expenses: Better resource utilization naturally brings down operational costs.

Easy Integration: Existing PLC SCADA systems may be easily integrated as part of a seamless automation solution.

Some of the Application of Siemens SCADA can be listed as follows:

Manufacturing: Monitor and control production line quality assurance.

Energy management: Keep track of energy utilization and control power distribution.

Water purification: Efficiently purify and distribute water.

Oil and Gas: Ensure safety and efficiency in operations in hazardous environments.

Transport: Control traffic and manage rail operations.

Siemens SCADA vs. Other SCADA Systems

Reliability, scalability, and advanced features differentiate Siemens SCADA from other SCADA systems. Unlike other SCADA companies, it has an edge in PLC SCADA integration. Innovation at Siemens ensures that SCADA systems remain widely compatible with other platforms.

Approach To Implementing Siemens SCADA in Your Industry

This is how you can implement Siemens SCADA in your industry:

Understand What You Really Need: Identify the specific needs for your operation.

Choose the Right PLC SCADA Setup: It must be capable of working with Siemens PLCs for optimal performance.

Install and Configure: You will need to work with either Siemens or a certified partner for the installation and configuration of the system.

Train Your Staff: Ensure training is provided to staff so that they can effectively use the SCADA system with comprehensive knowledge.

SCADA system future trends

The bright future of SCADA systems dwells on the advancement of IoT(Internet of Things) and AI(Artificial Intelligence). Siemens is leading these developments, integrating smart technologies into SCADA systems for better functionality and security. In addition, going forward, with increased interconnectivity of industries, the relevance of SCADA system cybersecurity cannot be overemphasized.

Conclusion

Siemens SCADA is no doubt an excellent automation tool for industries. Through its advanced features, seamless integration with PLC SCADA systems, and user-friendly interface, Siemens SCADA has the modern solutions for industries. No matter what your business is producing, be it from manufacturing, energy, or transportation, Siemens SCADA can help you in terms of efficiency, productivity, and cost savings.

Want to take your operations up a notch? Get in touch Naksh Technology Solutions LLP with Siemens or a certified partner today to discover custom SCADA system solutions to fit your operations.

0 notes

Text

Arduino: Qué es y Cómo se Usa en la Electrónica y Programación

Baratos, eficientes y extremadamente poderosos. Conoce qué son los Arduinos y en qué se pueden utilizar.

Arduino es mucho más que una simple herramienta para hacer proyectos de “hágalo usted mismo”. Aunque es cierto que ha ganado popularidad en la comunidad DIY (Do It Yourself) debido a su bajo costo y facilidad de uso, su potencial va mucho más allá de simples proyectos de bricolaje. Esta plataforma de hardware libre está diseñada para ser accesible tanto para principiantes como para expertos, lo…

#arduino#Bar di Re Arduino#bootloader#bricolaje#diy#hardware libre#ide#inicios del arduino#ivrae#massimo banzi#mcu#microcontrolador#scada#utilidad de un arduino

0 notes

Text

Como hacer un Backup o Respaldo en Intouch Wonderwore Scada

En el software InTouch Wonderware de AVEVA, existen distintas formas de realizar un respaldo o copia de seguridad, dependiendo del tipo de aplicación que se esté utilizando. Es importante mencionar que para cada tipo de aplicación, ya sea Stand Alone o Moderna, dispone de un método específico para realizar esta tarea. Es importante tener en cuenta que un backup o copia de seguridad mal hecha…

0 notes

Text

How SCADA, HMI & PLC work together

SCADA (Supervisory Control and Data Acquisition), HMI (Human-Machine Interface), and PLC (Programmable Logic Controller) work together as key components in industrial automation and control systems.

#automation#trending#tumblr trends#viral#viralpost#trendingnow#bestdeals#rockwell automation#allen bradley#plc#hmi#scadatraining#scada

2 notes

·

View notes

Text

Unlock Your Future in Smart Industries with IIoT!

The rapid advancement of technology has transformed industries across the globe, and the Industrial Internet of Things (IIoT) is at the forefront of this revolution. As industries move towards automation, smart factories, and real-time data-driven decision-making, IIoT is becoming an essential skill set for professionals.

Sharadha Skill Academy proudly presents an exclusive Industrial Internet of Things (IIoT) course designed to equip learners with hands-on experience, real-world applications, and industry-relevant knowledge. This comprehensive program will empower professionals and students alike to excel in the field of industrial automation and smart manufacturing.

Why Choose the IIoT Course at Sharadha Skill Academy?

✅ Practical Learning – Gain hands-on experience with IoT devices and industrial automation. ✅ Expert Guidance – Learn from industry professionals with years of experience. ✅ Career Advancement – Enhance your job prospects in the rapidly growing IoT sector. ✅ Affordable Fees – High-quality education at a reasonable cost. ✅ Limited Seats – Ensuring personalized attention and better learning outcomes.

Course Details

📅 Start Date: 3rd February 2025 ⏳ Duration: 5 Weeks 💰 Course Fee: ₹12,500

This course is meticulously designed to cover key aspects of IIoT, including:

Introduction to IIoT and Industry 4.0 – Understanding the evolution of industrial automation.

IoT Device Integration and Communication Protocols – Learning about MQTT, OPC UA, and Modbus.

Cloud Computing and Data Analytics in IIoT – Harnessing the power of cloud platforms.

Cybersecurity and Risk Management in Industrial Environments – Safeguarding industrial networks.

Who Should Enroll?

This course is perfect for:

Engineering students and graduates – Looking to build a strong foundation in IIoT.

Working professionals in manufacturing, IT, and automation sectors – Aiming for career growth and upskilling.

Entrepreneurs and business owners – Seeking to integrate IoT solutions in their operations.

What You Will Gain?

A deep understanding of IIoT concepts and their applications.

The ability to design and implement IIoT solutions for industries.

Hands-on experience with industry-grade IoT hardware and software.

Exposure to real-time industrial challenges and their solutions.

A certification that enhances your professional credentials.

The confidence to work in IIoT-related job roles and projects.

Enroll Now – Limited Seats Available!

Don’t miss out on this chance to upskill and future-proof your career in smart industries. With industries increasingly adopting IIoT for efficiency, sustainability, and automation, now is the perfect time to gain expertise in this transformative technology. Secure your seat today!

🌐 Website: sharadhaskillacademy.org 📞 Contact Us: +91 73977 88918 / 917 / 915 📍 Location: Sharadha Skill Academy, KG Garden City, Commercial Building 3rd Floor, Vedapatti, Via Nagarajapuram to Perur Road, Coimbatore – 641007, TN

Invest in your future – learn IIoT and take your career to the next level with Sharadha Skill Academy!

#IIoT#IndustrialAutomation#SmartIndustries#IoT#Industry40#Automation#Technology#SkillDevelopment#CareerGrowth#SharadhaSkillAcademy#TechTraining#CyberSecurity#CloudComputing#PredictiveMaintenance#SCADA#PLC#EdgeComputing#AI#MachineLearning#DataAnalytics#SmartManufacturing#TechInnovation#FutureSkills#HandsOnTraining#ProfessionalCertification#IndustrialRevolution#IoTSolutions#Engineering#Entrepreneurship#IndustrialEngineers

0 notes

Text

Smart Street Light Digital Twin System | Virtual City | Web UI Design | Web Development

Hightopo - YouTube

1 note

·

View note

Text

Is your industrial system running at its full potential? ⚙️🚀

Let’s talk about efficiency! 🔍 Whether it’s real-time data monitoring or seamless automation, the right tech makes all the difference. A monitoring controller ensures that industrial processes stay on track, while a gateway controller enables smooth communication between systems. 💡

With programmable logic controllers (PLC), automation gets even better—less downtime, more accuracy, and improved workflow. 🏭 No more costly breakdowns or inefficient processes! Optimize your industrial automation today with advanced control systems that boost efficiency and reliability.

#Automation#SmartIndustry#IndustrialTech#ProcessControl#Efficiency#MonitoringController#GatewayController#IndustrialSolutions#AutomationSolutions#MechanicalSolutions#ElectricalSolutions#FastCal#PLC#SCADA#ControlPanelDesign

0 notes