#HMI

Explore tagged Tumblr posts

Text

Daniel Lepik

#Daniel Lepik#cgi#product#digital art#electronics#hmi#orange#lighting#light#diffuse#gradient#purple#pastel

10 notes

·

View notes

Text

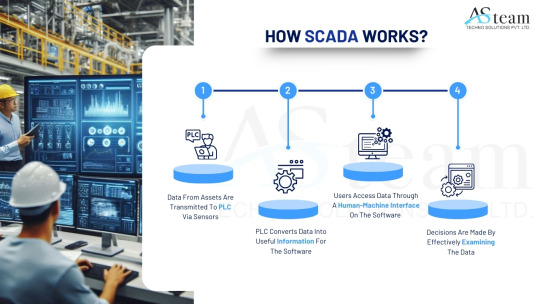

How SCADA Works?

Supervisory Control and Data Acquisition (SCADA) systems are critical in managing and monitoring industrial processes across various industries, including manufacturing, utilities, transportation, and energy.

Field Devices

At the process level, field devices like sensors, meters, and actuators are used to monitor variables like voltage, flow, temperature, and pressure. These gadgets collect information and carry out system-directed operations.

Remote Terminal Units (RTUs) and Programmable Logic Controllers (PLCs)

The SCADA software and the field devices are connected by RTUs and PLCs. After gathering information from the sensors, they transmit it to the control center. Additionally, the SCADA system may send them orders to modify settings or control actuators.

Communication Infrastructure

Strong communication networks are necessary for SCADA to transmit data between the control center and field equipment. This infrastructure can be wireless (such as satellite, radio, and cellular networks) or wired (such as Ethernet and fiber optics).

Centralized Control Station

SCADA software, which analyzes data, creates visualizations, and gives operators tools to monitor and manage operations, is housed in the control station.

Human-Machine Interface (HMI)

The SCADA system's user interface is called the HMI. Operators can engage with the system and make well-informed decisions because to its graphical depictions of processes, warnings, and trends.

#automation#SCADA#PLC#HMI#Automation#Technology#business and industry sectors#business#industrial automation#soft starter#software#software engineering

3 notes

·

View notes

Text

Unlock the Power of Employee Automation Control Training

At BIN95, we understand the importance of equipping your team with the skills they need to excel in today's fast-paced world. That's why we offer an unbeatable deal - half off of our comprehensive training program and unlimited user and installation licenses.

Imagine the possibilities when every member of your organization (company or School) has access to cutting-edge training materials and resources. Our program covers everything from basic concepts to advanced techniques, ensuring that your team is well-equipped to handle any automation challenge that comes their way.

But time is running out! Don't let this opportunity slip through your fingers. Visit https://bin95.com/educational-site-licenses/ for more details and secure your purchase order today.

Invest in the future of your business or institution with Automation Control Training. Together, let's unlock a world of endless possibilities!

#automation control software#automation training#plc training#training solutions#tech school#STEM education#corporate training#community colleges#vocational training#plc#Motor Controls#hmi#vfd

2 notes

·

View notes

Text

Anggota DPRD Kota Tegal dari Fraksi Amanat Persatuan, Serap Aspirasi Melalui Reses

Beritalidik.com ( Tegal ) Anggota Dewan Perwakilan Rakyat Daerah (DPRD) Kota Tegal dari Fraksi Amanat Persatuan, Tengku Rayhan Makarim, B.A, M.IKom melakukan Reses masa sidang II pada tanggal 16 Maret 2025. Kegiatan reses bertempat di salah satu warga Kelurahan Debong Kulon Kecamatan Tegal Selatan. Momentum tersebut dimanfaatkan oleh mas Rayhan kembali ke daerah pemilihannya (Dapil) yaitu…

#ANggaran#Anggota DPRD#APBD#Balapulang#Camat#Debong kulon#DPR#DPRD#DPRD Kota Tegal#F-PAN#HMI#Indonesia#Karangjambu#Kecamatan#Kota Tegal#Masyarakat#Pekerja#Pemerintah#Pengawas#peraturan#Rakyat#Reses#RTLH#Rumah#Tegal

0 notes

Text

Ketua Bidang Politik dan Demokrasi HMI Cabang Bandar Lampung Soroti Minimnya Variasi Makanan MBG

Presiden Prabowo melalui Badan Gizi Nasional (BGN) telah mengalokasikan miliaran rupiah untuk Program Makan Bergizi Gratis (MBG) bagi siswa SD hingga SMA selama bulan Ramadan. Dengan anggaran Rp10.000 per porsi dan total lebih dari Rp2 miliar untuk 30 hari, program ini diharapkan dapat meningkatkan asupan gizi anak-anak sekolah. Namun, apakah program ini benar-benar memberikan manfaat nyata bagi…

0 notes

Text

RD Automation – Your Trusted Partner in Smart Industrial Automation!

Upgrade your industry with RD Automation’s advanced automation solutions! We offer high-performance AC drives, PLCs, HMIs, motion control systems, and more to enhance efficiency and reduce downtime.

✔️ Authorized Delta Electronics Dealer ✔️ Reliable & Energy-Efficient Solutions ✔️ Seamless Integration for Maximum Productivity

RD Automation is committed to delivering top-quality automation products for your business needs. Contact us today! 🚀

Visit now : rd automation

0 notes

Text

Essential Components of Industrial Automation & Control Systems

Industrial automation and control systems rely on essential components to enhance efficiency, accuracy, and productivity. Programmable Logic Controllers (PLCs) manage operations with precision, while sensors and transducers collect real-time data. Human-Machine Interfaces (HMIs) enable seamless interaction, and motor drives control speed and movement. SCADA systems ensure remote monitoring, while industrial networking connects devices for smooth communication. Power supplies and circuit breakers safeguard equipment, preventing failures. Together, these components create a reliable automation ecosystem, optimizing production, reducing downtime, and improving safety across industries. Investing in high-quality automation components ensures long-term operational success.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Control systems#Industrial Control systems#Plc#sensor#motor#hmi

0 notes

Text

Life After Programming: Embracing Human-Machine Symbiosis in the Age of AI

As AI continues to evolve, conversations have started questioning the future of traditional programming and computer science education. The rise of prompt engineering—the art of crafting inputs to lead AI models to generating specific outputs—has led many to believe that mastering this new skill could replace the need for deep computational expertise. While this perspective does capture a real…

#abacus#Ada Lovelace#alignement#AR#BCI#ECA#embodied cognition#future of programming#Ghibli#HCI#HMI#LLM#new human interfaces#post-coding#programming#programming: human invention or discovery#prompt engineering#Technology

0 notes

Text

https://electronicsbuzz.in/microchip-expands-maxtouch-m1-for-large-curved-automotive-displays/

#Microchip Technology#maXTouch#AutomotiveDisplays#HMI#Infotainment#DigitalCockpit#TouchControl#CarTech#Innovation#powerelectronics#powermanagement#powersemiconductor

0 notes

Text

peugeot fractal 2015

#transport#auto#car#concept car#black#hmi#full black#detail#technical#grain#technical grain#lines#stripes

11 notes

·

View notes

Text

Micro850 Integration with SCADA and HMI Systems

Integrating a Micro850 PLC with SCADA and HMI systems involves multiple steps, including programming the PLC, setting up communication protocols, and configuring the SCADA/HMI software.

#trending#automation#tumblr trends#viral#viralpost#bestdeals#trendingnow#allen bradley#rockwell automation#plc#HMI#SCADA#micro850plc

2 notes

·

View notes

Text

HMI: 78 Tahun Mengabdi untuk Bangsa

HARI ini, 5 Februari 2025, Himpunan Mahasiswa Islam (HMI) genap berusia 78 tahun! Organisasi mahasiswa tertua di Indonesia ini telah melahirkan banyak tokoh bangsa dan tetap eksis dalam perjuangan di berbagai lini kehidupan. Sejak didirikan oleh Lafran Pane pada 5 Februari 1947 di Yogyakarta, HMI hadir sebagai wadah bagi mahasiswa Islam untuk mengembangkan intelektualitas, membangun karakter…

0 notes

Text

Logo Milad HMI 2025 dan Download Logo

BERITABORNEO.COM– Milad Himpunan Mahasiswa Islam jatuh pada tanggal 5 Februari 2025. Milad yang ke-78 Tahun. Sejarah Singkat HMI HMI sendiri didirikan pada 5 Februari 1947 di Yogyakarta dan bertujuan demi membentuk insan akademis yang berlandaskan nilai-nilai Islam. Organisasi ini juga diharapkan mampu menciptakan generasi muda yang memiliki komitmen dalam menciptakan masyarakat yang adil dan…

0 notes

Text

RD Automation helps industries with the best automation products. We provide AC drives, PLCs, HMIs, servo motors, motion controllers, and control panels. As an authorized Delta Electronics dealer in Coimbatore, we bring quality and trust. Our 14 years of experience ensure the best solutions for every industry. Visit now https://rdautomationindia.com

0 notes

Text

The Domino TS_SL7 Touch Screen Control Panel with Windows CE Core 5.0 is a user-friendly, high-performance interface designed for industrial automation. Featuring a responsive touch screen, it allows seamless control and monitoring of machinery and processes. With Windows CE Core 5.0, the control panel offers enhanced stability and efficient performance. Its compact design makes it ideal for various automation applications, ensuring easy integration into existing systems. Perfect for businesses looking to streamline operations, the Domino TS_SL7 offers intuitive control, real-time monitoring, and reliable performance for optimal productivity in industrial environments.

#marine spare parts#auto2mation#industrial equipment#industrial and marine automation#industrial and marine automation equipment#industrial spare parts#marine automation#industrial automation#industrial automation equipment#domino#hmi#automation

0 notes