#LinearMotionStages

Explore tagged Tumblr posts

Text

Linear Motion Solutions

Linear motion solutions refer to the various technologies and systems designed to provide controlled, precise linear movement. These solutions are used across a wide range of industries and applications, including industrial automation, robotics, machinery, and more.

Here are some key aspects of linear motion solutions:

Types of Linear Motion Systems: Ball screw systems,Lead screw systems,Linear motor systems,Belt-driven systems,Air/fluid bearing systems,Rack and pinion systems,Linear slide systems Key Components:, Linear actuators (e.g. ball screws, lead screws, linear motors),Linear guides (e.g. linear bearings, rails, slides),Drive mechanisms (e.g. stepper motors, servo motors),Control systems (e.g. motion controllers, drivers),Feedback sensors (e.g. encoders, limit switches) Design Considerations: Application requirements (e.g. load, speed, precision),Environmental factors (e.g. temperature, humidity, contaminants),Space constraints and mounting configurations,Integration with other systems and equipment,Maintenance and lubrication needs Common Applications: Industrial automation and robotics,CNC machines and machine tools,Semiconductor manufacturing equipment,Packaging and material handling systems,Medical devices and instrumentation,Test and measurement equipment,3D printing and additive manufacturing Trends and Advancements:,Increased use of linear motors for high-speed, high-accuracy applications,Integration of smart sensors and Industry 4.0 connectivity,Advancements in control algorithms and software,Developments in materials and lubrication for improved performance and reliability

You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#Linearbearingsandshafts#LinearGuides#LinearMotionBearings#LinearMotionComponents#Linearmotionsolutionsandapplications#LinearMotionStages#Linearmotionsystems#linearslidesandpositioningsystems#LinearXYStages#MotionControlSystem#Top-QualityLinearMotionSupplies

0 notes

Text

Single Axis Guide Arms are Under Test for Clients from Germany

Single Axis Guide Arms for Clients from Germany are under test, and will be delivered. Single axis guide arms are mechanical components used in various applications, such as industrial automation and robotics, to provide linear guidance and support for moving parts. They are typically used when a single degree of freedom or linear motion is required.

These guide arms consist of a rigid structure or frame that houses a linear guide system. The linear guide system usually consists of a rail and a carriage, where the rail provides a smooth and precise path for the carriage to move along. The carriage is attached to the moving component or load, allowing it to travel along the rail in a linear direction. Single axis guide arms are often used in applications where there is a need for controlled and accurate linear motion. They can be found in assembly lines, pick-and-place systems, packaging machinery, CNC machines, and other automated systems. These guide arms help to ensure precise positioning, smooth movement, and reduced friction between moving parts. The design of single axis guide arms can vary depending on the specific application and load requirements. They may incorporate different types of linear guides, such as ball bearing guides or roller guides, to accommodate different load capacities and operating conditions. The guide arms may also include additional features like adjustable stops, damping mechanisms, or lubrication systems to enhance performance and longevity. Overall, single axis guide arms play a crucial role in providing linear guidance and support in various industrial and robotic applications, enabling precise and controlled movement of components or loads along a single axis. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#LinearCarriagesAndSlides#LinearGuideSystems#LinearMotionGuide#LinearMotionGuideActuators#LinearMotionStages#LinearMotionSystems#LinearSlideSystem#SingleAxislinearmotion

0 notes

Text

Linear Translation Stages are Finished for Germany Clients.

Linear Translation Stages have been Finished and will be delivered to Germany Clients.You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects.

How to adjust the preload of ball screw nut. Ball screw nut pair is a high-precision transmission device. It uses rolling friction screw instead of sliding friction screw, which has the advantages of small wear, high transmission efficiency, stable transmission, long service life, high accuracy and low temperature rise. Select high-quality screw to identify titanium Hao. Because the ball screw nut pair has the outstanding advantages of small motion friction and easy to eliminate transmission clearance, it brings great benefits to the performance improvement of electromechanical integration system. Pre tightening is to prevent the ball from slipping. The self-locking property of the ball screw nut pair is poor, which can be said to be absent. It is easy to fall off without pre tightening. https://youtube.com/shorts/ctaMxDnmOC8?feature=share There are four common methods for ball screw preloading: - Double nut gasket type pre tightening The mechanism of this method is simple and reliable. Good rigidity and most widely used. The form of adding gasket between the double nuts can be adjusted in advance by a professional manufacturer according to the user's requirements. It is very convenient to unload when using. - Double nut threaded pre tightening Use the external thread on one nut to adjust the relative axial position of the two nuts through the round nut to achieve pre tightening. - Double nut tooth difference pre tightening On the flanges of the two nuts, cut out the gears with a tooth number difference of 1. The two gears mesh with the corresponding internal gear rings at both ends. The internal gear rings are fastened on the nut seat with screws. By rotating one of the nuts, the mutual positions of the two nuts are changed to adjust the clearance and apply the preload. - Single nut variable lead self preloading The internal thread raceway of the nut will produce a lead sudden change on the middle circle, so that the balls at the left and right ends will be axially displaced after assembly to realize pre tightening. The purpose of eliminating the axial clearance of the ball screw nut pair is to increase the preload and reduce the empty stroke in the reverse direction, so that there is no reverse dead zone, and improve the transmission rigidity and transmission accuracy. Not all ball screws(in Linear Translation Stages) are pre tightened, mainly according to the accuracy requirements. Generally, the pre tightening accuracy is high and the load capacity is large. The pre tightening is graded. The selection is based on the use requirements. You can check the samples of different brands for details. Read the full article

#HighPrecisionPositioning#High-PrecisionLinearStages#LinearMotionStages#LinearRotaryStages#LinearTranslationStages#MiniatureLinearStages#MotorizedLinearStages#MotorizedXYLinearStage#PrecisionLinearStages#X-YStages

0 notes

Text

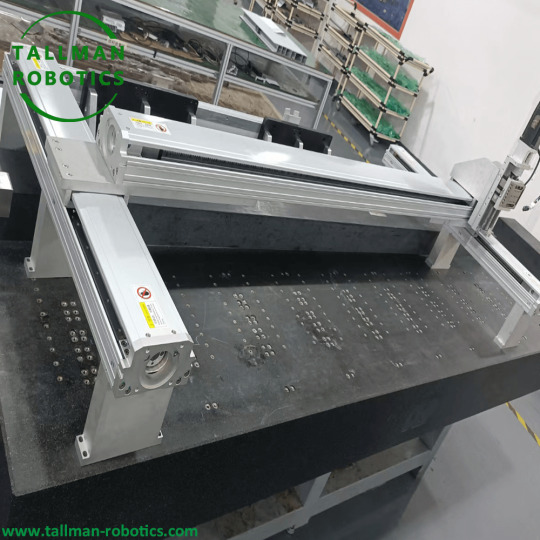

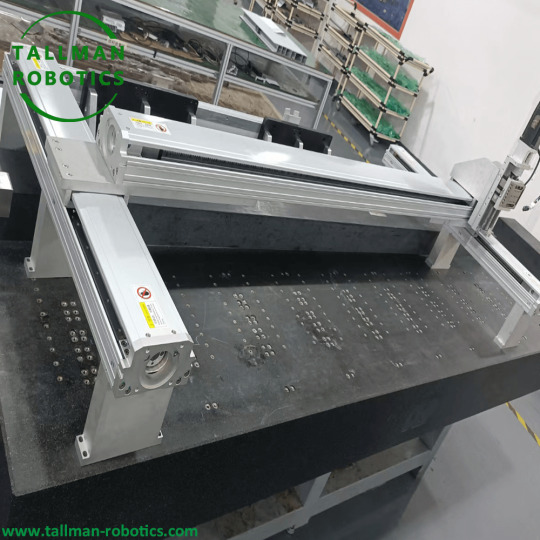

Multi-axis Linear Robot Actuators are Ready for Delivery to Australia.

Multi-axis Electric Linear Robot Actuators have been finished to client from Australia. You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects.

https://youtube.com/shorts/zEjllNfwtMk?feature=share Electric sliding table moving platform is an electric driving device that converts the rotary motion of the motor into the linear reciprocating motion of the sliding table. The linear reciprocating action of the sliding table is completed by controlling the forward and reverse rotation of the motor. For example, complex actions such as rotation and swing can be completed through various levers, rocker or connecting rod mechanisms. The electric slide can be used as an actuator in various mechanical equipment and automatic production lines. It can replace the cylinder and hydraulic cylinder to achieve the same working effect, so as to realize remote control, centralized control or automatic control. Precision electric slide incudling Multi-axis Electric Linear Robot Actuators has the following advantages: ◆ low cost and small volume: oil pump, oil tank, air compressor and many complex pipelines and other auxiliary equipment are omitted. ◆ low energy consumption, direct drive by motor saves the intermediate energy conversion link, and the whole machine has high efficiency, thus reducing energy consumption. ◆ low failure rate, no oil pollution: because the use of oil or gas transmission is avoided, there is no oil leakage and other fault phenomena, so that the pollution problem has been fundamentally solved. ◆ maintenance free for a long time during normal use. ◆ adopt high-precision straight slider guide rail, with stable movement; ◆ compact structure, direct motor drive, small overall size; ◆ high bearing, high precision and high efficiency; ◆ stepper motor or servo motor and corresponding driver can be selected; ◆ standard computer communication interface; ◆ zero and limit switches are set at both ends to facilitate accurate positioning and protection of products; ◆ products without motor and driver can be selected; ◆ aluminum alloy body material, light product weight; ◆ the product length can be customized according to the actual requirements of customers; Read the full article

#LinearActuatorandRotaryActuatorMulti-AxisPickandPlace#Linearactuatorsforgantryandmulti-axissystems#LinearMotionDriveSystems#LinearMotionStages#Multi-AxisGantrySystemsforLinearMotionApplications#Multi-axisLinearRobotActuators#Multi-sliderTypeCartesianrobots

0 notes

Text

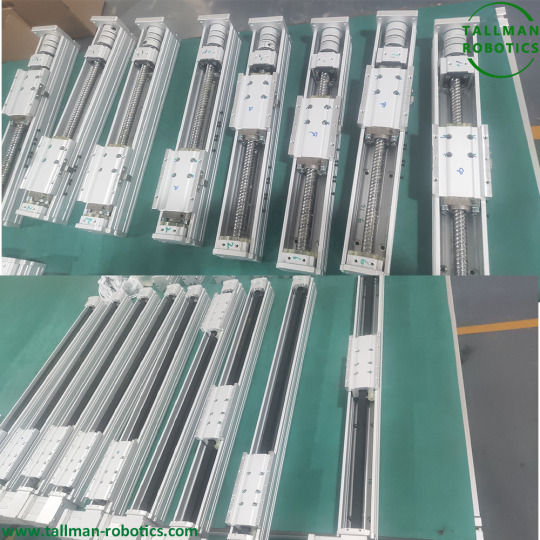

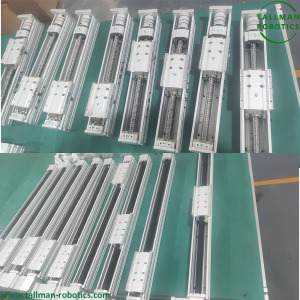

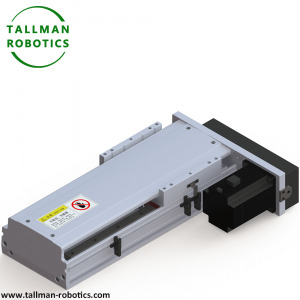

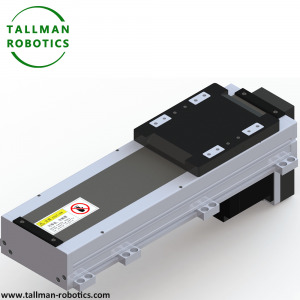

Ball Screw Driven Linear Modules

Ball Screw Driven Linear Modules You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects. The transmission method of Ball Screw Driven Linear Modules is characterized by high repeatability, up to ±0.005mm, high accuracy and high load. Usually used in the production process with a certain precision in industrial production. In the selection process of the ball screw drive, attention should be paid to the selection of the screw, which is usually determined according to factors such as load, speed, and torque. Pay attention to the maintenance of the screw when using the linear module of the ball screw. After cleaning a long distance, clean dirt and grease should be replaced in time, usually every half a month. Ball screw is an ideal product that converts rotary motion into linear motion, or converts linear motion into rotary motion. The ball screw is composed of a screw, a nut and a ball. Its function is to convert rotary motion into linear motion, which is a further extension and development of ball screws. The important significance of this development is to change the bearing from rolling motion to sliding motion. Due to its small frictional resistance, ball screws are widely used in various industrial equipment and precision instruments.

What are the Basic Specification of Ball Screw Driven Linear Modules from Tallman Robotics Limited Model No Max Payload(kgs) Max Stroke (mm) Repeatability (mm) Drive Solution Motor Power (W) TMS30 4 400 ±0.01/±0.005 screw 30 TMS45 10 800 ±0.01/±0.005 screw 50/100 TMB45 4 800 ±0.04 belt 50/100 TMS62 20 1050 ±0.01/±0.005 screw 100/200/400 TMB62 16 2000 ±0.04 belt 100/200/400 TMS65 30 800 ±0.01/±0.005 screw 50/100 TMB65 4 800 ±0.04 belt 50/100 TMS85 50 1050 ±0.01/±0.005 screw 100/200/400 TMB85 16 2000 ±0.04 belt 100/200/400 TMS100 65 1050 ±0.01/±0.005 screw 100/200/400 TMB100 40 3500 ±0.04 belt 100/200/400 TMS135 110 1250 ±0.01/±0.005 screw 200/400/750 TMB135 42 3500 ±0.04 belt 200/400 TMS150 120 1500 ±0.01/±0.005 screw 400/750 TMB150 75 3500 ±0.04 belt 400/750 TMS170 130 1500 ±0.01/±0.005 screw 400/750 TMB170 75 3500 ±0.04 belt 400/750 TMS220 150 1500 ±0.01/±0.005 screw 750 TMB220 75 3500 ±0.04 belt 750 Ball Screw Driven Linear Modules are composed of multiple single-axis robots to realize multi-axis combination through different combination styles, to achieve applications such as Cartesian actuators, XYZ multi-axis actuators (XY table), and so on. It is widely used in the positioning, transfer, handling, inspection, dispensing, welding, cutting, etc. of LCD panels, semiconductors, home appliances, daily chemicals, automobiles, batteries and other fields. Related Knowledge: The main features of the application of the ball screw in the module. The ball screw is the most commonly used transmission element in machine tools and precision machinery. Its main function is to convert rotary motion into linear motion, or convert torque into axial repetitive force, and it has both high precision, reversibility and high Features of efficiency. Ball screw is also called ball screw and ball screw. 1) High positioning accuracy The ball screw pair realizes rolling friction between the nut and the screw by ball rolling. The motion of the rolling linear guide is realized by rolling of the steel ball. The friction resistance of the guide pair is small, the difference between dynamic and static friction resistance is small, and no crawling occurs at low speeds. . High repeat positioning accuracy, suitable for moving parts that frequently start or change directions. 2) Less wear Due to the low frictional energy consumption of rolling contact, the friction loss of the rolling surface is also reduced correspondingly, so the rolling linear guide system can be in a high-precision state for a long time. At the same time, the use of lubricating oil is also very small, which makes it very easy to design and use and maintain the lubrication system of the machine tool. 3) Long life For the nut of the ball screw pair, the screw hardness reaches HRC58-62, and the ball hardness reaches HRC62-66, and there is rolling friction between them, so higher fatigue life and accuracy life can be achieved. 4) Adapt to high-speed movement Due to the low friction resistance of the rolling linear guide module, the required power source and power transmission mechanism can be miniaturized, and the driving torque can be greatly reduced. It can realize high-speed linear motion and improve the working efficiency of the machine tool. 5) Strong carrying capacity Rolling linear guides have good load-bearing performance and can withstand forces and moment loads in different directions, such as up, down, left, and right directions, as well as bump moments, rocking moments and swing moments. Therefore, it has good load adaptability. 6) Easy to assemble and interchangeable The ball screw and rolling guide are interchangeable. As long as the slider or the guide rail or the entire rolling guide pair is replaced, the module can regain high precision. 7) Micro and high-speed feed can be realized The ball screw pair will not produce such as sliding phenomenon, can realize the micro-feed; as long as the feed pulse is small enough, the ball screw pair can realize the micron-level feed. Because of the low heat generation of the ball screw pair and the ability to manufacture a large lead screw, high-speed feed can be achieved. Read the full article

#BallScrewDrivenLinearModules#BallScrewLinearModule-BallScrewLinearStage#LinearModuleswithballscrewdrive#LinearMotionStages#Miniaturesizedlinearmotion#PrecisionLinearStages#ScrewDrivenActuators#ScrewDrivenModularLinearActuators#X-YStages

0 notes