#ac drives

Explore tagged Tumblr posts

Text

Programming and Configuration of PowerFlex 40 AC Drive

Programming and configuring the PowerFlex 40 AC Drive involves several steps and considerations :-

➡️Physical Setup

➡️Parameter Configuration

➡️Motor Configuration

➡️Control Mode Configuration

➡️Input/Output Configuration

➡️Programming Logic

#allen bradley#tumblr trends#rockwell automation#viralpost#automation#bestdeals#trending#viral#trendingnow#trend#top trends#powerflex 40#ac drives

1 note

·

View note

Text

A Comprehensive Guide to Understanding DCS in Chemical Plants

Efficiency, safety, and precision are key competencies in the midst of the complex nature of chemical processing. Some of these technologies are motivated by DCS. The uses of DCS in Chemical Plants will determine management/optimization of different processes, ensuring smooth operation and minimizing risks. What DCS is, why it is important, which parts make up DCS, and how these parts keep developing the broad functionality of the chemical plant will be addressed in this blog.

What is DCS in Chemical Plants?

A Distributed Control System, or DCS, is an automated control system used in chemical plants to manage and control manufacturing processes. Unlike centralized control systems, the DCS distributes control functions across multiple controllers located throughout the plant. This decentralized approach allows for more efficient and reliable process management, as each controller can independently handle specific tasks while communicating with the central system.

The Importance of DCS in Chemical Plants

DCS in chemical plants is crucial for several reasons:

Enhanced Operational Efficiency: DCS facilitates the real-time monitoring and control of different processes so that decisions are made with ease and quick speed. This makes the process operation more efficient with less time out.

Improved Safety: Chemical plants ensure utmost safety. Monitoring critical parameters, DCS facilitates alarms in case of deviation. So, potential hazards can be tackled well in advance.

Consistent Product Quality: DCS ensures consistent product quality by maintaining precise control over process variables. This is important for meeting industry standards and customer expectations.

Cost Savings: DCS helps in optimizing resource usage, reducing waste, and minimizing energy consumption. This results in significant cost savings for the plant.

Components of DCS in Chemical Plants

A typical DCS in chemical plants consists of several key components:

Engineering Workstations: These are the central hubs where engineers and operators can configure, monitor, and control the whole system. Engineering workstations provide a user-friendly interface for managing the DCS.

Operator Workstations: Operator workstations are used by plant personnel to monitor and control the processes in real-time. These workstations display critical data and allow operators to make adjustments as needed.

Controllers: Controllers are the backbones of the DCS. They are spread all over the plant and execute control strategies, collect data from sensors, and send commands to actuators.

Field Devices: Field devices include sensors, actuators, and transmitters that interact directly with the process. These devices collect data and perform actions based on commands from the controllers.

Communication Network: All components of the DCS are connected through the communication network, ensuring seamless data exchange and coordination. Information is passed through accurately and in real-time.

Benefits of DCS in Chemical Plants

Real-Time Monitoring and Control: DCS can monitor and control processes in real time, meaning that operators respond quickly to any change or problem in the process, thus ensuring that the operations run smoothly and efficiently.

Scalability and Flexibility: DCS is highly scalable and flexible; it is easy to expand or modify the system based on the change in needs in the plant. This adaptability is crucial in growing and evolving chemical plants.

Redundancy and Reliability: DCS of a chemical plant is designed redundancy in mind and so that one failure will not shut down the entire system; therefore, a continuous production schedule with minimal downtimes is highly desirable.

Data Integration: A DCS assimilates all kinds of information, giving the view of complete plant operations at any given point in time and enabling better and timely decisions toward the optimization process.

Automated Reporting: DCS is able to provide automated reports on almost any aspect of the operations of the plant, such as production rates, energy consumption, and safety incidents. These are of benefit for analysis and further improvement.

Applications of DCS in Chemical Plants

DCS in chemical plants is used in a wide range of applications, including:

Process Control: DCS is the control of any process, such as mixing, heating, cooling, and reacting, in which strict control is maintained and ensures consistent quality of the final product and improved efficiency in operating the plant.

Safety Systems: DCS plays a vital role in safety systems also, as in case of anomalies in critical parameters, it shows alarms, so accidents are minimized, and protection of personnel and equipment is safeguarded.

Energy Management: DCS optimizes energy usage by monitoring and controlling energy-consuming processes. This leads to substantial cost savings and reduced environmental impact.

Quality Control: DCS ensures consistent product quality by maintaining precise control over process variables. This is important for meeting industry standards and customer expectations.

Maintenance Management: DCS can be integrated with maintenance management systems to schedule and track maintenance activities. This helps in minimizing downtime and ensuring the longevity of equipment.

Challenges and Considerations

While DCS in chemical plants offers numerous benefits, there are also challenges and considerations to keep in mind:

Complexity: DCS is a very complex system, requiring specific knowledge and skills for design, implementation, and maintenance. This makes it difficult for some plants to use DCS.

Cost: Installation of DCS can be very expensive as it demands considerable investment in hardware, software, and training. However, the long-term benefits often compensate for the initial investment.

Cybersecurity: As DCS is communication network-based, it is a vulnerable target to cyber threats. Therefore, proper security of DCS is mandatory to protect plant operations and data.

Integration: Integration with existing systems and equipment is complex. Compatibility problems along with data-synchronization issues may crop up while making integration seamless.

The Future of DCS in Chemical Plants

The future of DCS in chemical plants looks promising, with several emerging trends and technologies:

Industrial Internet of Things (IIoT): The integration of IIoT with DCS will allow real-time data collection and analysis, which improves operational efficiency and predicts maintenance.

Artificial Intelligence (AI) and Machine Learning (ML): Use AI and ML to make an insightful analysis of the data generated by DCS, hence providing recommendations for process optimization and predictive maintenance.

Cloud Computing: The cloud-based DCS solution offers scalability flexibility and remote access, allowing plants to manage and monitor from any where.

Augmented Reality (AR) and Virtual Reality (VR): The cloud-based DCS solution offers scalability flexibility and remote access, allowing plants to manage and monitor from any where.

Conclusion

A basic form of DCS in Chemical Plants is a kind of technology crucial for improving working efficiency, plant and personnel safety, and product quality. Real time monitoring and control, scalability and reliability are three significant aspects to manage and optimize processes. This notwithstanding, several drawbacks notwithstanding, the benefits gained by DCS far outweigh it.

Originally Published Here:-

#nma group#india#chandigarh#hmi display#variable frequency drive#ac drives#plc motor control#ac dc drives

0 notes

Text

AC drives dealers in Delhi

We are one of the reputed AC Drives Dealers in Delhi, engaged in providing superior quality DELTA A.C. Drives. Our A. C. Drives control motor speed, further develop machine automation and save energy. These A.C. Drive smoothly handle an increased burden and control speed and force. AC Driver are in market demand due to the high quality, high performance and durability. These AC Drives are available in market at very affordable and competitive rates.

ANG Industries is one of the best AC Drives Dealers in Delhi, provide best quality AC Drives to our valuable clients at competitive price.

ANG Industries offers an extensive range of AC Drives, Motors & Geared Motors, & Eddy current Drives power that are obtained from ABB Motors according to the latest technical development. In addition, these products such as AC Drives, Motors & Geared Motors, are also available at very affordable prices. Our Range of these Motors & Geared Motors covers the power spectrum from 0.25KW - 355KW.

ANG Industries - AC Drives Dealers in Delhi. Being a dominant distributor of Automation Products, the company organization has been highly active in offering AC Drives. The drive comes into various use in Automation Industry. These drives come into a broad variety of specification in order to cater the wide range of industry experts AC Drives need. This product assortment is accessible in different specification hence comes in different model numbers.

0 notes

Text

Top-Rated African Industrial Automation Company Products at Low Price in Tanzania

Finding reputable, high-quality electrical supplies and services may be difficult. Customers may feel overwhelmed by the abundance of alternatives available to them, as well as the possibility of receiving inferior products or services. But don't worry, since at JS Electromec LTD, we endeavor to make your search for electrical solutions in Tanzania simple and hassle-free.

We are one of the most recognized Siemens Electrical Distributors in Tanzania, specializing in high-quality Siemens Automation Systems in Tanzania, Industrial Automation and Control, AC Drives, AC Motors, and Siemens Automation Systems at competitive prices to meet our clients' needs. We are authorized distribution channel partners for well-known global providers of electrical goods and systems, specializing in industrial automation, control, drives, electrical installations, power supply, and backup solutions. We offer a comprehensive array of electrical and industrial technology products to customers in utilities, mining, manufacturing, processing, transportation, and infrastructure.

We are a top-rated African Industrial Automation Company committed to offering low pricing on Tanzania's most effective, high-tech, inventive, and unique Electrical Control Panel Builder in Tanzania. We are Tanzania's top provider of electrical supplies and services. Our company has been in business for more than a decade and has a solid reputation for offering high-quality products and services to our consumers. We take pleasure in being a one-stop shop for all of your electrical needs, providing a diverse choice of goods and services to suit your needs.

We are one of Tanzania's best ABB Automation Distributors, providing a vast selection of top-quality industrial automation, power backup, and electrical installation solutions at low prices. We only stock high-quality items from respected companies. We have everything, including electrical wiring and lighting fixtures, generators, and solar panels. Our team of professionals is always researching and sourcing the latest and most innovative items to guarantee that our clients have access to the finest on the market. We also give customized solutions to meet our clients' demands and expectations.

Visit our website https://www.jselectromec.co.tz/ or contact us today at +255 788 499111 to learn moreabout our products and services.

#ups systems tanzania#control panel fabrication tanzania#ac drives#ac motors tanzania#Electrical Distributors Tanzania

0 notes

Text

High-Quality INVT Drives by Leading Manufacturers

Ac Drive is specialized in delivering high quality INVT drives by leading manufacturer in India. Our design are compete the strict demand of various industries. Our INVT drives are designed to providing reliable performance that’s improve efficiency and precise control for all types of machinery and applications. We are focusing on durability and advance technology that every built to optimize energy use and streamline operation those making it smarter investment for business aiming to improve productivity.

Ac Drive as one of trusted provider in the field. We are committed to providing INVT drives that compete to specific needs of our clients. In our range we have variety of models to accommodate different power requirement that’s all are backed by our experience expert support team. If you want to upgrading equipment or setting up new system the Ac Drives are providing the quality and service that you needs for seamless and efficient industrial solutions.

Ac Drives high quality INVT drives from leading manufacturer for their efficiency and reliability. We are tacked optimal performance across industrial application. Visit Our Website today acdriveindia.in to explore our range and find the perfect drive solution to improve your operation and energy efficiency.

#ac drive manufacturers#ac drive suppliers#solar pump controller#ac drive india#ac drives#solar pump controller suppliers#solar pump controller manufacturers#invt inverters#solar pump controller in india#solar pump controller in ahmedabad

0 notes

Text

1 note

·

View note

Text

oh to be a rookie attorney in France in love with the bitchy prosecutor next door

#the drama potential with the european costume#imagine storming in a tribunal with the sleeves flopping dramatically behind#edgeworth would live for it#he would never take it off#phoenix would never get the hang of it and it would drive edgeworth mad from across the courtroom#dounart#aa#ace attorney#ace attorney fanart#gyakuten saiban#narumitsu#wrightworth#phoenix wright#phoenix wright fanart#miles edgeworth#miles edgeworth fanart#mia fey#art#fanart#phoenix abesolutely almost strangled himself to death with his cravat at least twice

11K notes

·

View notes

Text

AC Drives Market Analysis, Key Trends, Growth Opportunities, Challenges and Key Players by 2032

The global AC Drives Market size was valued at USD 24.22 Billion in 2023 and is projected to reach USD 49.23 Billion by 2032, growing at a CAGR of 8.2% from 2024 to 2032

An AC drive is a tool that improves process control by regulating the speed of an electrical motor. Cut back on energy use and produce energy effectively. Reduce the mechanical strain in applications involving motor control. Streamline the performance of several applications that use electric motors.

AC drives, sometimes referred to as inverters or variable frequency drives (VFDs), are electronic devices that regulate the torque and speed of an AC electric motor. They achieve this by changing the voltage and frequency that are applied to the motor. In many different sectors and applications where exact control over motor speed is necessary, AC drives are indispensable.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/16545

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Leading players involved in the AC Drives Market include:

Rockwell Automation, Inc. (USA), Emerson Electric Co. (USA), Parker Hannifin Corporation (USA), TMEIC Corporation (USA), ABB (Switzerland), Siemens AG (Germany), Invertek Drives Ltd. (United Kingdom)

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

If You Have Any Query AC Drives Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/16545

Segmentation of AC Drives Market:

By Voltage

Low Voltage

Medium Voltage

High Voltage

By Power Voltage

Low Power

Medium Power

High Power

By Application

Pump

Fan

Conveyor

Compressor

Extruders

By End User

Oil & Gas

Power Generation

Food and Beverages

Building Automation

Mining & Metals

Other Industries

Market Segment by Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

Highlights from the report:

Market Study: It includes key market segments, key manufacturers covered, product range offered in the years considered, Global AC Drives Market, and research objectives. It also covers segmentation study provided in the report based on product type and application.

Market Executive Summary: This section highlights key studies, market growth rates, competitive landscape, market drivers, trends, and issues in addition to macro indicators.

Market Production by Region: The report provides data related to imports and exports, revenue, production and key players of all the studied regional markets are covered in this section.

AC Drives Market Profiles of Top Key Competitors: Analysis of each profiled Roll Hardness Tester market player is detailed in this section. This segment also provides SWOT analysis of individual players, products, production, value, capacity, and other important factors.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=16545

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to helping our clients grow and successfully impact the marketplace. Our team at IMR is ready to help our clients grow their businesses by offering strategies to achieve success and monopoly in their respective fields. We are a global market research company, specializing in the use of big data and advanced analytics to gain a broader picture of market trends. We help our customers to think differently and build a better tomorrow for all of us. As a technology-driven research company, we consider extremely large data sets to uncover deeper insights and provide conclusive consulting. We don't just provide intelligence solutions, we help our clients achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1049

Email: [email protected]

#AC Drives#AC Drives Market#AC Drives Market Size#AC Drives Market Share#AC Drives Market Growth#AC Drives Market Trend#AC Drives Market segment#AC Drives Market Opportunity#AC Drives Market Analysis 2024

0 notes

Text

Elevate Industry Efficiency with Industry Automation Products

Industrial Automation products include diverse technology and equipment meant to streamline manufacturing processes, increase efficiency, and boost productivity in industrial settings. Here's a summary of significant points about industrial automation products:

PLCs (Programmable Logic Controllers): PLCs are the brains behind industrial automation systems, operating machines and processes using programmed logic. They provide for accurate management, monitoring, and coordination of numerous equipment and operations on the production floor.

Sensors and Instrumentation: Sensors are essential in industrial automation because they detect and measure temperature, pressure, flow, and location. This data is subsequently used for monitoring and control, resulting in optimal performance and safety.

AC drives and VFDs (Variable Frequency Drives): AC drives and VFDs manage the speed and torque of electric motors, enabling energy-efficient operation and precise control of machines in industrial applications.

Robotics and Automated Guided Vehicles (AGVs): These technologies automate repetitive activities and material handling processes, improving efficiency, accuracy, and safety while lowering labour costs and cycle times.

HMI (Human-Machine Interface): HMIs are user-friendly interfaces that allow operators to engage with and monitor industrial automation systems. They display real-time statistics, alerts, and diagnostic information, allowing for more informed decision-making and troubleshooting.

Industrial Networking and Connectivity Solutions: Industrial networking technologies such as Ethernet/IP, PROFINET, and Modbus provide seamless communication and data exchange between devices, machines, and systems, serving as the foundation of interconnected industrial automation ecosystems.

Safety Products: Safety relays, light curtains, and emergency stop devices are critical for protecting persons and equipment in industrial settings. They identify and reduce potential hazards, guaranteeing safety legislation and standards adherence.

Energy management systems: Energy management systems optimise energy usage and save costs by monitoring and controlling power, water, and other resources in industrial facilities.

Industrial automation products transform industrial processes by increasing efficiency, lowering downtime, increasing product quality, and increasing worker safety. In today's dynamic market context, industries may increase their competitiveness, flexibility, and sustainability by embracing these technologies. Visit - www.visheshgroup.in.

1 note

·

View note

Text

Emotron AC Drives provided by Market leaders

Alienskart Web, online shopping portal

An AC drive is a device used to control the speed of an electrical motor in order to: enhance process control. reduce energy usage and generate energy efficiently. decrease mechanical stress on motor control applications. Alienskart Web provides you the best quality AC drives with brands like Emotron in afforadable prices. So pick your phone and start shopping online with Alienskart Web.

#online shopping portal#shopping kart#emotron ac drives#shopping services#heavy duty motors#commercial equipment#ac drives#Alienskart Web#Alienskart#mobile shopping#shop anywhere and anytime#online shopping

1 note

·

View note

Text

Phoenix as soon as maya mentioned Edgeworth in Justice For All

#ace attorney#gyakuten saiban#phoenix wright#maya fey#doodle#yes i drew in class again ok#sketch#stupid#im aware that Phoenix doesnt know how to drive#dont look at the hands

2K notes

·

View notes

Text

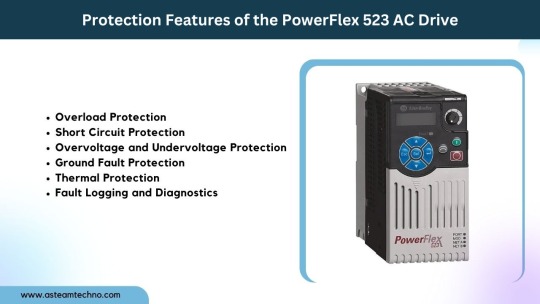

Protection Features of the Allen Bradley PowerFlex 523 AC Drive

The Allen Bradley PowerFlex 523 AC Drive incorporates several protection features to ensure safe and reliable operation of the drive and connected motor.

1.Overload Protection

2.Short Circuit Protection

3.Overvoltage and Undervoltage Protection

4.Ground Fault Protection

5.Thermal Protection

6.Fault Logging and Diagnostics

#allen bradley#rockwell automation#tumblr trends#viralpost#automation#bestdeals#trending#viral#trendingnow#plc#AC Drives#VFD#Global#globalbusiness

1 note

·

View note

Text

What to Do When Your HMI Screen Won’t Respond

In the world of industrial automation and manufacturing, Human Machine Interface (HMI) plays an important role in process monitoring and control. They provide operators with an intuitive interface for interacting with machines and systems. But like all other electronic devices, sometimes the HMI Screen can cause problems such as not responding. When your HMI screen is not responding. It may interfere with work and cause the machine to stop working. This can be expensive.

If you stare at an unresponsive HMI screen Don’t be alarmed. There are several troubleshooting steps you can take to identify and fix the problem. In this blog, we will walk you through the steps. To help the HMI screen work again

1. Check for Physical Damage

The first step in detecting the failure of an unresponsive HMI screen is to examine the screen for physical damage. Look for splatters, tears, or other signs of wear. visible on the screen Damage to the shock absorber may affect its ability to respond to shock data. If you experience physical damage It may require professional repair or replacement.

Also check the connectors and cables that secure the HMI screen. Loose or damaged cables can cause the screen to become disconnected from the system and make it unresponsive. Make sure all cables are properly connected and in good condition.

2. Reboot the HMI System

Sometimes an HMI screen that is unresponsive may require a reboot to restore normal functionality. Turn off the HMI and wait a few minutes before turning it back on. This may help you clear any temporary errors or programming issues that might be causing the screen to freeze or stop responding.

If the HMI screen is part of a larger control system You may be able to restart the entire system. Be sure to follow the proper shutdown and restart procedures recommended by the manufacturer. To avoid data loss or damage to the system.

3. Calibrate the Touchscreen

If the HMI screen responds inconsistently or incorrectly to navigation information It may need to be recalibrated. Calibration ensures that the bearing display instantly detects the bearing position. Most HMI systems have a built-in calibration tool that can be installed through the settings menu.

To calibrate the touchscreen, follow these steps:

Access the calibration tool from the HMI settings.

Follow the on-screen instructions to touch specific points on the screen.

Save the calibration settings and test the touchscreen for responsiveness.

If the calibration process doesn’t resolve the issue, it may indicate a deeper problem with the touchscreen hardware.

4. Check for Software Issues

Application problems can cause the HMI screen to become unresponsive. outdated hardware Software errors Or corrupted files may interfere with the normal operation of the HMI. Check whether there are any pending software updates for the HMI system and install those if available. Updates often contain bug fixes and improvements that can improve the performance and stability of the HMI.

If you suspect a software problem You can try to restore the HMI system to its factory default settings. This will delete any customized settings or configuration options. Therefore, you need to backup important data before proceeding. Restoring to factory settings may help unlock application-related issues that may be affecting the HMI screen.

5. Inspect the Power Supply

An unstable or inaccessible power supply can cause the HMI screen to fail. Ensure that the power source is stable. and provide the speed and power required for the HMI system. If the HMI screen is flickering, slow, or not fully powered on, This may be caused by a power supply problem.

Check any wires, switches, and power adapters. used with HMI systems if you suspect that the power supply is defective. You should consider replacing the power supply with a compatible, reliable one to see if that resolves the problem.

6. Look for Environmental Factors

Environmental conditions also affect the productivity of an HMI screen. Dust, dirt, humidity, or extreme temperatures can cause the screen to respond or malfunction. Ensure that the HMI system is installed in a clean, dry, temperature-controlled environment.

If the HMI screen is exposed to harsh conditions Consider using a protective board or enclosure to protect against environmental factors. Clean the screen and surroundings regularly to prevent debris and rust from accumulating which could interfere with driving comfort.

7. Test with Another HMI Screen

If you have tried the steps above and the HMI screen still does not respond, Try testing with a different HMI screen, if available. Replace the mismatched screen with a working screen to determine whether the problem is with the screen itself or with the connected system.

If the replacement screen works as it should This indicates that the original HMI screen may be damaged and difficult to repair or replace. If the replacement screen is unresponsive The problem may be related to the system hardware or software components. and further investigation is required.

8. Consult the Manufacturer or Support

If all else fails and your HMI screen remains unresponsive It’s time to consult the manufacturer or technical support. Provide detailed information about the problem. Including error messages Steps that you have taken to resolve the issue HMI system model and serial number

The manufacturer and support team have the expertise and resources to diagnose complex issues and offer appropriate solutions. They may recommend that you send the HMI screen in for repair. Replaced under warranty or provide a software update to resolve the issue.

Conclusion

An unresponsive HMI Screen can be a major drawback. But with the correct troubleshooting steps You can often identify and fix problems. Start by searching for physical damage, restarting the system, and calibrating the navigation screen. Look for programming problems. consumes power supply and evaluate environmental factors that may affect the screen’s output.

If the problem persists Testing with a different HMI screen or consulting with the manufacturer may help you find a solution. By following these steps You can reduce downtime and get your HMI screen back up and running smoothly. This ensures that your industrial processes can continue uninterrupted.

Originally Published Here:-

0 notes

Text

Ace fuckin' fell off

Oh look, here he is!!! ↓ ↓ ↓

Y’all I did this one in 20 mins no effort have mercy

#twst#twisted wonderland#twisted wonderland fanart#aimagallery101#ace fell off#they be driving#winning#twst epel#twst jack#twst deuce#deuce spade#epel felmier#jack howl#these guys be driving#this took me longer than I wanted it to#idk what I was doing#why did I put so much effort into this#aaaaaaaaaaaaaaaaaaaaaaa

2K notes

·

View notes

Text

Leading Provider Of Reliable Electrical Distribution and enclosure solutions in Tanzania

JS Electromec LTD is a leading provider of electrical and mechanical services, catering to a diverse range of industries with unparalleled expertise and innovation. With a strong commitment to excellence, we offer comprehensive solutions tailored to meet the unique needs of each client.

We understand the importance of quality service, which is why we prioritize efficiency, reliability, and safety in everything we do. Our team of highly skilled technicians and engineers is equipped with the latest tools and technology to deliver exceptional results on every project. Whether it's electrical installations, mechanical repairs, or maintenance services, we have the knowledge and experience to get the job done right, the first time.

We understand the critical role that electrical distribution plays in powering your operations. Whether you're a manufacturing facility, a commercial complex, or a residential development, we offer a comprehensive range of electrical distribution solutions to ensure reliable power supply.

When it comes to protecting your electrical equipment and ensuring operational safety, JS Electromec LTD offers a wide selection of electrical enclosures tailored to your specific needs. From weatherproof enclosures for outdoor installations to NEMA-rated enclosures for hazardous environments, we have the expertise to provide the right solution for any application.

Our team of skilled technicians can design, fabricate, and install electrical enclosures that meet your exact specifications. We use high-quality materials and advanced manufacturing techniques to ensure durability, reliability, and compliance with industry standards. Whether you need standard enclosures or custom-built solutions, we have the capabilities to deliver on time and within budget.

Our team is dedicated to providing top-notch service with a focus on professionalism and integrity. From initial consultation to project completion, we strive to exceed expectations and build lasting relationships with our clients. We understand the importance of minimizing downtime and maximizing productivity. That's why we work quickly and efficiently to complete projects on time and within budget, without compromising on quality.

In a rapidly evolving industry, innovation is key to staying ahead of the curve. We embrace new technologies and methodologies to continuously improve our services and deliver cutting-edge solutions to our clients. Safety is our top priority on every job site. We adhere to the highest safety standards and protocols to ensure the well-being of our team members, clients, and the community.

Our services include the supply and installation of distribution boards, switchgear, circuit breakers, and other essential components. We work closely with you to assess your requirements and provide customized solutions that optimize efficiency, safety, and cost-effectiveness. With our expertise and attention to detail, you can trust us to deliver reliable electrical distribution systems that meet the highest standards of quality and performance.

With JS Electromec LTD, you can count on superior products, expert craftsmanship, and exceptional service every step of the way. Contact us today at +255 788 499111 to learn more about our electrical distribution and enclosure solutions in Tanzania and visit our website at https://www.jselectromec.co.tz/ to discover how we can help power your success.

0 notes

Text

Power Your Projects INVT Inverters Manufacturers in India

AcDrive is a well known name for INVT inverter manufacturers in India. We are providing modern inverter solution designed to power your project efficiently. Our INVT inverters are manufactured for high performance and we could make sure reliable energy conversion for various industrial and commercial application. If you needs inverters for heavy machinery, automation system or renewable energy projects then AcDrive provide best range of INVT inverters that are built to handle demanding environment with precision and durability.

AcDrive are focusing on delivering advance technology that improve energy efficiency and reduce operational costs. Our INVT inverters are known for their long lasting performance, seamless integration with existing systems and user friendly operation. AcDrive is committed to quality and innovation to become leading provider of INVT inverters in India and helping business power their projects with confidence.

Explore our full range of INVT inverters and learn more how AcDrive can support your energy needs then visit our website acdriveindia.com today. We are providing complete inverter solution for wide array of industries. Follow this link to discover more and contact with us by acdriveindia.com. Power your project with AcDrive advance INVT inverters.

#ac drive manufacturers#ac drive suppliers#solar pump controller#ac drive india#ac drives#solar pump controller suppliers#solar pump controller manufacturers#invt inverters#solar pump controller in india#solar pump controller in ahmedabad

0 notes