#steel warehouse

Explore tagged Tumblr posts

Text

Smart Storage Solutions: TSSC Group's Steel Warehouse Building Expertise

Elevate your storage capabilities with TSSC Group's expertise in steel warehouse building. Our advanced designs combine strength and flexibility, providing a seamless solution for your storage requirements. Choose TSSC for innovative steel warehouse buildings that stand the test of time.

#steel warehouse buildings#warehouse buildings#steel warehouse#TSSC Group#manufacturer#manufacturing

0 notes

Text

About Qingdao Omiga Construction Engineering steel structure building

Later harshly, China's steel structure sports ground will put off subsidiary titivation manner and worries. On the a person hand, by now the continuous advancement of engineering, tally steel structure resources, structure methods and manufacturing systems will go concerning to emerge, bringing new amassing opportunities to the steel structure marketplace.

Brief Construction: Prefabrication methods in steel construction offer leave to enter sudden assembly. This minimizes construction epoch, minimizes disruptions to operations, and brings approximately speedier ROI for warehouse in flames owners.

Share your perception by taking the survey and commenting! #culturematters #employeeengagement #bestpractices #workplaceculture

Steel Warehouse continues to be a major armor supplier into the US and guidance forces overseas for armored troop carriers and armored truck cabs.

steel warehouse

0 notes

Text

Steel Warehouse Foundations: The Key to a Solid Structure

The foundation of any building is its most critical component, and steel warehouses are no exception. The success of a steel warehouse project depends on a solid and well-constructed foundation. In this article, we'll explore the importance of steel warehouse foundations and the key considerations in ensuring a stable and reliable base for your structure.

Foundation Types

Several foundation types can be used for steel warehouses, including concrete slabs, piers, and deep foundations. The choice of foundation depends on factors such as soil conditions, site location, and the specific needs of the warehouse.

Soil Testing

Conduct thorough soil testing to assess the soil conditions at the construction site. Soil tests determine factors such as load-bearing capacity, settlement potential, and soil stability, which influence the foundation design.

Load-Bearing Capacity

Determine the load-bearing capacity required for the warehouse. This includes considering the weight of the steel structure, equipment, inventory, and any additional loads the foundation must support.

Frost and Moisture Considerations

In regions prone to frost or high moisture levels, the foundation design must account for these factors. Frost heave can damage a foundation, so appropriate measures must be taken to prevent it.

Engineering and Design

Work with structural engineers and architects to design the foundation. The design should consider the size and weight of the steel warehouse, soil conditions, and any specific requirements for the project.

Foundation Preparation

Proper site preparation is essential to ensure the foundation's stability. This may involve excavation, grading, and the removal of unsuitable soil.

Compaction and Grading

Compaction of the soil is crucial to ensure stability. Proper grading and compaction help prevent uneven settling, which can lead to structural issues.

Reinforcement and Anchoring

Steel warehouse foundations are often reinforced with steel rebar or mesh to enhance strength and stability. Anchoring the foundation to the steel structure provides additional security.

Drainage Solutions

Effective drainage systems around the foundation are necessary to prevent water accumulation and potential damage. Proper drainage keeps the soil stable and minimizes erosion.

Inspection and Quality Control

Throughout the foundation construction process, regular inspections and quality control checks are essential to ensure that the foundation meets design specifications and industry standards.

Soil Settling and Post-Construction Monitoring

After construction, monitor the foundation for any signs of settling or issues related to soil conditions. Promptly address any concerns to prevent structural problems.

Adherence to Local Codes and Regulations

Ensure that the foundation construction complies with local building codes and regulations. Non-compliance can result in delays and costly corrections.

Conclusion

The foundation of a steel warehouse is the bedrock of its structural integrity. A well-designed, carefully constructed foundation ensures the stability and longevity of the entire structure. By considering factors such as foundation types, soil conditions, load-bearing capacity, and engineering expertise, you can create a solid foundation that provides a reliable base for your steel warehouse.

I hope you find this blog post on the importance of steel warehouse foundations informative. If you have any specific details or additional information you'd like to include, please let me know.

0 notes

Text

Best Industrial plant and steel structure building

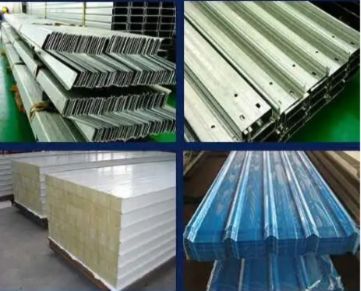

Qingdao Omiga Construction Engineering Co., Ltd., as a leading supplier and manufacturer in the field of steel structure construction, specializes in the export of steel structure building materials and related products. The company Located in the beautiful coastal city of Qingdao, with over 20 years of experience in steel structure projects and are a key incubation enterprise in the Qingdao Park of China Science and Technology Development Institute. Omiga is committed to providing high-quality steel structure building solutions for global customers. Our products cover various fields, including industrial plants, commercial buildings, sports arenas, residential buildings, bridges, etc. We have a first-class design team and advanced production equipment, enabling us to provide customized solutions based on customer requirements.

We offer one-stop procurement services, including product design, raw material procurement, production processing, quality control, logistics distribution, and installation guidance. In the field of steel structure building exports, we have established long-term partnerships with well-known domestic steel structure manufacturers. This enables us to meet customer requirements with competitive prices and high-quality products, ensuring the quality and delivery time of our products. We introduce and apply international advanced steel structure building technologies and equipment, strictly implementing quality management systems to ensure that our product quality meets international standards.

Advantages of Steel Structure Buildings:

Exceptional Strength: Steel is renowned for its high strength-to-weight ratio. Steel structure buildings can withstand heavy loads, making them ideal for tall skyscrapers, industrial facilities, and bridges. This strength provides long-lasting durability and structural integrity.

Speedy Construction: Steel structures can be fabricated off-site, allowing for faster construction compared to traditional methods. This reduces construction time, labor costs, and disruptions to nearby areas.

Design Flexibility: Steel allows for creative and flexible architectural designs. The material's ability to span large distances without the need for numerous columns or supports enables open, spacious interiors and innovative aesthetics.

Sustainability: Steel is a recyclable material, making it environmentally friendly. The recycling process does not compromise its structural integrity, making steel structures an eco-conscious choice. Additionally, steel can be repurposed for other construction projects.

Cost-Effective: Despite initial higher material costs steel structure buildings often provide long-term cost savings due to their durability, minimal maintenance, and shorter construction times.

Innovations in Steel Structure Buildings:

Advanced Coatings:Innovations in coatings have enhanced the corrosion resistance of steel structures, increasing their lifespan and reducing maintenance requirements. These coatings also offer aesthetic options and energy-efficient features.

Prefabrication and Modular Construction:

Prefabrication techniques have improved efficiency in steel construction. Components can be manufactured off-site with precision and then assembled on-site, reducing construction time and waste.

High-Strength Steel Alloys: The development of high-strength steel alloys allows for lighter and stronger structural elements, reducing material usage and enabling more sustainable construction.

Building Information Modeling (BIM):

industrial plant BIM technology enables precise planning and coordination of steel structure projects. It helps optimize designs, reduce errors, and improve project management, resulting in cost savings and better project outcomes.

Sustainable Practices: Innovations in steel production have led to more sustainable practices, such as energy-efficient manufacturing processes, reduced emissions, and responsible sourcing of raw materials.

Steel structure buildings continue to be a fundamental part of the construction industry, offering numerous advantages and benefiting from ongoing innovations. Their strength, versatility, sustainability, and cost-effectiveness make them an attractive choice for a wide range of construction projects, from residential buildings to large-scale industrial complexes. As technology and materials continue to evolve, steel structures will likely play an increasingly vital role in shaping the future of modern construction.

Steel warehouses are essential components of the supply chain and industrial infrastructure. These structures provide storage solutions that are durable, cost-effective, and versatile, making them integral to various industries.

Structural Integrity and Durability:

Steel is renowned for its strength and resilience. Steel warehouses can withstand extreme weather conditions, seismic activity, and heavy loads, ensuring the safety and security of stored goods over the long term.

Spacious Interiors: Steel's high strength-to-weight ratio allows for large, open interior spaces without the need for numerous columns or support structures. This design flexibility makes steel warehouses ideal for efficiently storing and accessing goods.

Quick Construction: Prefabrication techniques in steel construction enable rapid assembly. This reduces construction time, minimizes disruptions to operations, and leads to faster ROI for warehouse owners.

Customizable Designs: Steel warehouses can be customized to meet specific storage needs. This includes adjustable shelving, racks, and mezzanines, enabling efficient space utilization and organization.

Cost-Efficiency: While initial construction costs may be higher than other materials, steel's longevity, minimal maintenance requirements, and energy-efficient features make it a cost-effective choice over the long term.

Sustainability: Steel is recyclable and environmentally friendly. Many steel warehouse structures incorporate eco-conscious features such as energy-efficient insulation, lighting, and roofing systems.

Innovations in Steel Warehouses:

Automated Storage and Retrieval Systems (AS/RS): AS/RS technology optimizes warehouse operations by automating the retrieval and storage of goods, reducing labor costs, and increasing efficiency.

Energy-Efficient Design: Innovative designs incorporate natural lighting, solar panels, and energy-efficient HVAC systems to reduce energy consumption and environmental impact.

Security and Surveillance Systems: Modern steel warehouses often feature advanced security systems, including surveillance cameras, access control, and fire suppression systems to safeguard valuable inventory.

Inventory Management Software: Integration of warehouse management software streamlines inventory tracking, order fulfillment, and overall warehouse operations, increasing accuracy and efficiency.

Distributed Warehousing Networks:

Companies are increasingly adopting distributed warehousing networks, strategically locating smaller steel warehouses in proximity to customers to reduce shipping times and costs. Steel warehouses are indispensable assets in today's industrial landscape, providing the durability, flexibility, and efficiency required for modern supply chain management. As technology and sustainability practices continue to evolve, steel warehouses will play an even more crucial role in optimizing storage and distribution processes. Their resilience, cost-effectiveness, and adaptability make steel warehouses a cornerstone of the global logistics industry, supporting economic growth and innovation.

0 notes

Text

Warehouse Office in Ageo, Japan - Arii Irie Architects

#Arii Irie Architects#architecture#design#building#modern architecture#interiors#minimal#modern#contemporary#contemporary architecture#design blog#cool architecture#cool design#industrial#chic#light#transparent#polycarbonate sheets#metal cladding#steel#aluminium#urban#city#warehouse#office#office design#timber frame#beautiful architecture#japan#japanese architecture

66 notes

·

View notes

Text

#art#artists on tumblr#my art#artwork#digital art#meme#original art#digital illustration#advertising#fanfic#potato bomb au#portal 2 ats#portal cores#portal caroline#portal 2 art#portal 2 wheatley#portal pals#portal 2 chell#portal game#portal 2#portal chell#portal#portal wheatley#portal au#portal art#portal atlas#portal memes#portal gun#portal human au#portal steel structure warehouse

9 notes

·

View notes

Text

Vipul Infra Systems Pvt. Ltd. is the Best PEB manufacturer In India specializing in pre-engineered buildings and industrial sheds. Known for quality and innovation, they deliver customized, durable, and efficient solutions.

#peb manufacturers#pre engineered building#pre engineered steel buildings#industrial sheds#warehouse construction

2 notes

·

View notes

Text

Warehouse Project (Indonesia) 2018

2 notes

·

View notes

Text

youtube

steel building supplier from China, Qingdao Sincere Steel Structure.

3 notes

·

View notes

Text

once again grappling with the peculiar grief of the almost post-grad student: i like doing this work, and there is no guarantee i will get to continue it after spring. i went into grad school knowing that the odds were not good for academic employment, but i also spent six years studying this thing and building a highly specific body of knowledge, and i might have to let all that go soon.

#welcome to academia#also if i don't get an academic career or some adjacent career i will be dead to my peers#i don't think i'm ''owed'' a job but.#why can't someone just offer me a job.#i have written 20 variations on the same cover letter#i have applied to 20 different institutions for various positions#i am writing a book that will never see the light of day#i don't regret doing the degree...#i regret that the degree is going to make it harder for me to get a normal job#steeling myself to work in like. a large company warehouse. in four months.

7 notes

·

View notes

Text

Prefabricated Modular Building Structure Company India - Kaizen Steel Building

Kaizen Prefabricated Modular Building Structure Company India is an efficient solution for a wide range of applications. Dry construction process ensures faster project timelines. Built with high-grade steel frames and insulated panels, these modular structures are designed for durability and easy on-site installation. Their construction makes them resistant to earthquakes, adverse weather, and leaks, ensuring long-lasting performance.

Contact Us Today.

#industrial shed manufacturer in india#pre engineered metal building manufacturers#steel building manufacturer#warehouse construction company in india

0 notes

Text

Building Warehouse | Choose Our Steel Structure Company in the Riyadh

Building warehouses ( بناء مستودعات ) is not a job of a naive contractor it requires experience, expertise, quality craftsmanship and access to the right tools and equipment. Every business has its construction needs and expectations but everyone wants robust outcomes. It is important to have a high-quality steel structure when building a warehouse. It plays a major role in creating a robust framework. So, if you want your warehouse not wear off quickly, then make sure to choose the reputed and best steel structure company riyadh. By selecting a reputed steel structure company, you can access the robust steel structure that benefits you, which is also a primary need in building a warehouse.

Benefits of Steel Structure in Warehouse Construction

Strength and Durability: Steel structures are infamous for their robustness. They are an ideal metal option for warehouse construction. Steel does not wear off, and its withstand capability is exceptional. Steel structures can resist harsh weather conditions and other harmful aspects. They are perfect for warehouses as steel can load heavy equipment.

Cost-effectiveness: When you compare the cost of other metals, steel is less costly and economical. So, steel is the ideal choice when searching for a cost-effective metal for warehouse construction that does not compromise strength.

Speed and construction: When you buy a steel structure, it is robust and quicker to construct overall. Pre-engineered parts make the construction process quicker and easier. So, if you are searching for the best quality pre-designed and engineered steel structure, our company is the perfect choice. We are a leading and reputed firm offering the best service.

Design Flexibility: Another reason to select steel metal for warehouse construction is that it is customizable. You can easily modify and expand the structure according to your business needs, and due to its customizable feature, you can create a unique design.

Lightweight and sturdy: Steel is a lightweight metal, so it is easy to handle and quicker to construct. Due to its lightweight ability, it requires less labor to move it from one spot to another.

These are some benefits of steel, so if you are searching for the best steel structure company Riyadh, do not look for here and there. Contact us. We are a leading and reputed company providing the best service. Our experience and knowledge keep us the best of all. Moreover, all our contractors are excellent at their jobs. So, if you are ready to acquire the best team for warehouse construction, our steel structure company riyadh, is the right choice. If you are looking for a Hanger contractor, call us again without any second thought. We are a leading and reputed firm offering the best service.

0 notes

Text

Steel Warehouse Construction: Navigating the Permit and Regulatory Landscape

Embarking on a steel warehouse construction project requires more than just architectural plans and steel beams. Navigating the complex world of permits and regulations is a vital aspect of ensuring your project complies with local laws and standards. In this article, we'll explore the process of obtaining permits and adhering to regulations when constructing a steel warehouse.

Initial Research

Before you begin construction, conduct thorough research to understand the local permitting requirements and regulations that apply to your steel warehouse project. These requirements can vary significantly from one jurisdiction to another.

Permit Applications

Identify the specific permits you need for your project. Common permits for steel warehouse construction may include building permits, zoning permits, environmental permits, and special permits for unique features or uses.

Consult Local Authorities

Consult with local planning and building authorities to get a clear understanding of the permitting process. They can provide guidance on the required documents, application forms, and fees.

Compliance with Building Codes

Ensure that your steel warehouse design complies with local building codes and standards. Your architectural and engineering plans should meet these requirements to facilitate permit approval.

Environmental Considerations

If your project has potential environmental impacts, such as stormwater management or soil erosion control, you may need to obtain environmental permits. Consult with environmental agencies or departments as needed.

Fire Safety and Hazard Regulations

Comply with fire safety regulations and any other hazard-related requirements. These may involve the installation of fire suppression systems, exit plans, or other safety measures.

Accessibility Standards

Ensure that your steel warehouse adheres to accessibility standards, providing access for people with disabilities, as required by the Americans with Disabilities Act (ADA) or similar regulations in other countries.

Special Use Permits

If your steel warehouse will have a special use, such as a chemical storage facility or food processing center, you may need additional permits to meet specific industry standards and safety regulations.

Consistent Communication

Maintain open communication with local authorities during the permit application process. Address any questions or concerns they may have promptly to avoid unnecessary delays.

Project Documentation

Accurately document every step of the permit application process and any interactions with regulatory agencies. This documentation can be invaluable in case of disputes or audits.

Stay Informed

Regulations and building codes may change over time. Stay informed about any updates or revisions to ensure your project remains compliant throughout construction.

Professional Guidance

Consider working with professionals who have experience navigating the permit and regulatory landscape. Architects, engineers, and contractors with local knowledge can be valuable assets in ensuring compliance.

Conclusion

Navigating the permit and regulatory landscape is an essential part of any steel warehouse construction project. By conducting thorough research, applying for the necessary permits, complying with building codes and regulations, and maintaining open communication with local authorities, you can ensure that your steel warehouse is constructed legally and safely. A well-managed approach to permits and regulations is critical for the successful completion of your project.

0 notes

Text

EPACK Prefab offers customized solutions for Industrial Factory Buildings, delivering durable, cost-effective, and efficient structures. Designed with precision using advanced pre-engineered techniques, our factory buildings ensure optimal functionality and space utilization.

✅ Key Features:

Quick construction with PEB technology

High-quality steel ensuring strength and durability

Energy-efficient designs with insulated panels

Custom layouts to suit specific industrial needs

👉 Contact EPACK Prefab today for innovative factory building solutions tailored to your requirements!

#Industrial Factory Building#Factory Building Construction#Pre-Engineered Buildings#PEB Structures#Industrial Construction Solutions#Steel Factory Buildings#Warehouse Construction#Prefabricated Industrial Buildings#Durable Factory Buildings#Custom Industrial Structures#EPACK Prefab#Modern Industrial Construction#Factory Building Design#Turnkey Construction Solutions#Industrial Building Manufacturers#Energy-Efficient Buildings#Steel Structures for Factories#Fast Construction Solutions#Prefab Industrial Structures#Reliable Factory Buildings

0 notes

Text

Expert Steel Warehouse Construction Company - Akmy Buildcon

Akmy Buildcon is a trusted steel warehouse construction company, specializing in designing and building durable, cost-effective steel warehouses. Our structures are engineered for strength, safety, and efficiency. Count on us for customized, high-quality solutions that meet your storage and operational needs.

0 notes

Text

The best Steel fabrication company | AFCO STEEL

AFCO STEEL experience in structural steel design, engineering, drafting, detailing, procurement, fabrication, surface treatment and erection commitment to safety, quality and scheduling allow us to reduce risk for our clients. The result: greater peace of mind for our clients, who can trust us to deliver exactly what they need when they need it. From start to finish, we meticulously organize every project for extreme efficiency. When materials reach their destination, they are properly itemized and sequenced, drastically reducing field labour time. We are passionate about giving our clients the best products possible with delivery and service they can trust.

#steel silo manufacturers#steel storage tank#steel tank manufacturers#Steel fabrication services#steel structure company in saudi arabia#industrial steel fabrication#steel structure manufacturers#Steel product manufacturing#Steel fabrication company#Industrial steel structures#Bulk storage silos#Warehouse construction

0 notes