#ss316 bolt specifications

Explore tagged Tumblr posts

Text

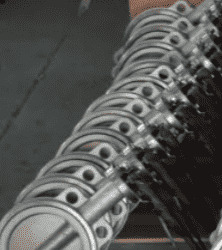

High-Performance Stud Bolts Manufacturer & Exporter – BigBoltNut

At BigBoltNut, we specialize in manufacturing and exporting a comprehensive range of premium-quality stud bolts engineered for critical industrial environments. Crafted from high-grade stainless steel, carbon steel, and alloy steel, our stud bolts deliver exceptional durability, tensile strength, and corrosion resistance across diverse applications.

Types of Stud Bolts We Offer

Stud bolts are not one-size-fits-all. Each type is engineered for specific needs:

Fully Threaded Stud Bolts: Ideal for tension-based applications. These are threaded from end to end, offering ease of installation and uniform grip.

Tap-End Stud Bolts: Designed with a shorter thread on one end for insertion into a tapped hole, while the longer end is used with a nut for secure fastening.

Material Grades Available

We offer stud bolts in a wide variety of material grades, tailored for performance:

Carbon & Alloy Steel Grades: 8.8, 10.9, 12.9

ASTM Grades: B7, L7, 8M

Stainless Steel Grades: SS304, SS316, SS316L, SS316 S31, B8

Applications of Stud Bolts

Our stud bolts are trusted across industries for their performance and reliability. Major applications include:

Wind Energy Installations

Agricultural Equipment

Automotive and Transport Systems

Oil & Gas Refining Units

Plumbing and Pipeline Infrastructure

Water Supply and Treatment Plants

Chemical Manufacturing Facilities

Building and Civil Construction

Marine and Offshore Engineering

Choosing the Right Stud Bolt Grade

Each stud bolt material grade is designed for specific operational demands:

B7 Stud Bolts: Made from heat-treated chromium-molybdenum steel, these are ideal for high-strength and high-temperature applications.

B8 (SS304) Stud Bolts: Provide general corrosion resistance and are suitable for most moderate environments.

B8M (SS316) Stud Bolts: Contain molybdenum for superior resistance to chloride-rich and harsh marine environments.

B16 Stud Bolts: While not stainless, these offer excellent mechanical strength and heat resistance, perfect for high-temperature industrial use.

A193 B8 vs. B8M vs. B16 – What’s the Difference?

A193 B8: Standard stainless option with reliable corrosion protection.

A193 B8M: Enhanced with molybdenum for aggressive chemical and saltwater environments. Optimized for high-heat applications where strength is critical and corrosion is a secondary concern. Source url:

0 notes

Text

Swing Check Valve Manufacturers in india

Speciality Valve is celebrated as the esteemed Swing Check Valve Manufacturers in India. Our advanced manufacturing capabilities enable us to customize valves to your exact specifications, ensuring optimal performance and reliability and type of valve that is designed to prevent backflow in pipelines. It operates automatically without requiring external control.

Working Principle of Swing Check Valve

The Swing Check Valve works through a hinged disc or flap that swings open when the flow direction is correct, allowing fluid to pass through. When the fluid flow reverses or stops, the disc swings back to its closed position, effectively sealing the valve and preventing backflow.

Main Components of Swing Check Valve

Body: The body of the valve is typically made of durable materials like cast iron, stainless steel, or brass to withstand high pressures and resist corrosion.

Hinge and Disc: The disc is attached to a hinge mechanism that allows it to swing open or closed based on the direction of flow.

Seat: The seat provides a surface for the disc to seal against when the valve is closed, preventing leakage.

Bolt: The bolt holds the valve body components together and ensures structural integrity.

Spring (optional): Some designs may include a spring to assist in closing the disc when the flow is stopped.

Benefits of Swing Check Valve

Prevents Backflow: The primary benefit of a Swing Check Valve is its ability to prevent backflow,

Automatic Operation: Swing Check Valves operate automatically, eliminating the need for external control mechanisms.

Low Maintenance: These valves have fewer moving parts and are relatively easy to maintain, reducing downtime.

Durability: High-quality materials used in construction ensure the valve's long service life.

Cost-Effective: it offers affordable solutions for industries, making them a cost-effective choice for preventing backflow.

Speciality valve is the largest Swing Check Valve Manufacturers in India provide guarantees high-quality, durable.

Industries Uses

1.Oil and Gas Industry

2.Chemical and Petrochemical Plants

3.Water Treatment Facilities

4.Power Generation

5.Natural Gas Distribution

its Description

Body Material: Cast Steel (A216 WCB, WCC, LCB, LCC, WC6, WC9), WCB, SS304, 316L, Duplex Steel, 904L, Aluminium bronze, Stainless Steel [ SS316 , SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3,F55, F91 ] Class: 150LB – 2500LB Size: ½” – 40” Ends: butt weld, socket weld, threaded, flanged

Visit now - https://www.specialityvalve.com/product-category/swing-check-valve/

ADDRESS - Satra Plaza, Unit no-126, 1st Floor, 19D, Palm Beach Rd, Phase 2, Sector 14, Vashi , Navi Mumbai, Maharashtra 400703

0 notes

Text

Stainless Steel Ball Valve – Top Manufacturers, Suppliers & Latest Prices

A stainless steel ball valve is a durable and high-performance valve used in industrial, commercial, and domestic applications. It provides excellent flow control, corrosion resistance, and high pressure handling, making it ideal for oil & gas, water treatment, and chemical industries.

Udhhyog, one of the top ball valve manufacturers and suppliers in Delhi, offers a wide range of SS ball valves, ensuring superior quality, competitive pricing, and reliable delivery.

This guide covers ball valve types, working principles, selection criteria, manufacturers, suppliers, and the latest price list to help you choose the best SS ball valve.

What is a Stainless Steel Ball Valve?

A stainless steel ball valve is a quarter-turn valve that controls fluid flow using a rotating ball with a hole inside. When aligned with the pipeline, the fluid flows through; when turned 90 degrees, the flow stops.

Advantages of SS Ball Valves:

✔ Corrosion-resistant – Ideal for harsh environments. ✔ High pressure & temperature tolerance – Suitable for industrial applications. ✔ Low maintenance – Long-lasting and durable. ✔ Leak-proof design – Provides tight sealing. ✔ Easy operation – Quick open and close function.

Stainless Steel Ball Valve Diagram & Symbol

A ball valve diagram illustrates its internal structure, while the ball valve symbol is widely used in engineering schematics.

Types of Stainless Steel Ball Valves

At Udhhyog, we manufacture and supply various stainless steel ball valves for different industries.

1. One-Piece Ball Valve

Simple & compact design.

Ideal for low-pressure applications.

Cost-effective and durable.

2. Two-Piece Ball Valve

Separate body & ball mechanism.

Easy to dismantle and clean.

Suitable for water and oil pipelines.

3. Three-Piece Ball Valve

Bolted construction for easy maintenance.

Used in chemical and pharmaceutical industries.

Handles high-pressure applications.

4. Full Bore vs. Reduced Bore Ball Valves

Full bore ball valve: No flow restriction, used in high-flow systems.

Reduced bore ball valve: Slight flow restriction, cost-effective for general applications.

5. L&T Ball Valves

High-quality L&T stainless steel ball valves for industrial use.

Provides excellent sealing and durability.

Where are Stainless Steel Ball Valves Used?

1. Oil & Gas Industry

Regulates fuel, gas, and crude oil pipelines.

Ensures high-pressure performance.

2. Water Treatment Plants

Used in municipal and industrial water systems.

Provides corrosion-resistant flow control.

3. Chemical & Pharmaceutical Industries

Handles aggressive chemicals & high-temperature liquids.

Prevents contamination.

4. Food & Beverage Processing

Used for hygienic flow control in food manufacturing.

Stainless steel ensures safe, non-toxic operation.

5. HVAC & Fire Protection Systems

Controls water flow in cooling & heating systems.

Essential for fire sprinkler networks.

Stainless Steel Ball Valve Price List

Latest Prices for Different SS Ball Valves

Valve TypeSizePrice Range (INR)One-Piece Ball Valve1/2 to 2 Inch₹500 - ₹2,500Two-Piece Ball Valve1/2 to 4 Inch₹1,200 - ₹6,000Three-Piece Ball Valve1 to 6 Inch₹3,000 - ₹15,000Full Bore SS Ball Valve1 to 6 Inch₹2,500 - ₹12,000L&T Ball Valve1/2 to 6 Inch₹5,000 - ₹25,000

📌 Note: Prices vary based on size, material, and technical specifications. Contact Udhhyog for bulk orders and customized pricing.

How to Select the Right Stainless Steel Ball Valve?

1. Application Type

For industrial pipelines – Choose a full bore ball valve.

For chemical & pharmaceutical use – Opt for a three-piece SS ball valve.

For general plumbing – Select a one-piece or two-piece SS ball valve.

2. Pressure & Temperature Rating

Ensure the valve can handle your system’s pressure range.

Choose a heat-resistant SS ball valve for high-temperature applications.

3. Material Selection

SS304 & SS316 ball valves for corrosion resistance.

L&T ball valves for high-quality industrial performance.

4. Valve Size & Flow Rate

Small sizes (1/2 to 2 inches) for household and low-pressure systems.

Large sizes (3 inches & above) for high-flow industrial pipelines.

5. Trusted Manufacturer & Supplier

Buy from reliable suppliers like Udhhyog for quality assurance.

Why Choose Udhhyog – Best SS Ball Valve Supplier & Manufacturer in Delhi?

At Udhhyog, we are recognized as Delhi’s leading manufacturer and supplier of stainless steel ball valves due to our commitment to quality, performance, and affordability.

✅ Premium Quality Manufacturing

We use top-grade stainless steel to produce high-performance ball valves.

✅ Affordable Pricing

Our SS ball valves are competitively priced for all industries.

✅ Wide Range of Valves

We supply one-piece, two-piece, three-piece, full bore, and L&T ball valves.

✅ Reliable & Quick Delivery

We ensure on-time delivery across Delhi, Haryana, Uttar Pradesh, and Jammu & Kashmir.

✅ Technical Support & Consultation

Our team helps customers choose the best ball valve for their needs.

Contact Udhhyog for the Best Stainless Steel Ball Valves

If you are looking for high-quality stainless steel ball valves in Delhi, Udhhyog is your trusted supplier. We provide top-grade SS ball valves at competitive prices, ensuring efficiency and durability for all applications.

📞 Call Us Today or Visit Udhhyog to explore our extensive range of ball valves.

✨ Choose Udhhyog – Your Reliable Ball Valve Supplier

#BallValve#SSBallValve#StainlessSteelValve#IndustrialValves#L&TBallValve#ValveSupplier#DelhiManufacturer#Udhhyog#PlumbingSolutions#EngineeringSolutions

0 notes

Text

Stainless Steel Ball Valve – Top Manufacturers, Suppliers & Latest Prices

A stainless steel ball valve is a durable and high-performance valve used in industrial, commercial, and domestic applications. It provides excellent flow control, corrosion resistance, and high pressure handling, making it ideal for oil & gas, water treatment, and chemical industries.

Udhhyog, one of the top ball valve manufacturers and suppliers in Delhi, offers a wide range of SS ball valves, ensuring superior quality, competitive pricing, and reliable delivery.

This guide covers ball valve types, working principles, selection criteria, manufacturers, suppliers, and the latest price list to help you choose the best SS ball valve.

What is a Stainless Steel Ball Valve?

A stainless steel ball valve is a quarter-turn valve that controls fluid flow using a rotating ball with a hole inside. When aligned with the pipeline, the fluid flows through; when turned 90 degrees, the flow stops.

Advantages of SS Ball Valves:

✔ Corrosion-resistant – Ideal for harsh environments. ✔ High pressure & temperature tolerance – Suitable for industrial applications. ✔ Low maintenance – Long-lasting and durable. ✔ Leak-proof design – Provides tight sealing. ✔ Easy operation – Quick open and close function.

Stainless Steel Ball Valve Diagram & Symbol

A ball valve diagram illustrates its internal structure, while the ball valve symbol is widely used in engineering schematics.

Types of Stainless Steel Ball Valves

At Udhhyog, we manufacture and supply various stainless steel ball valves for different industries.

1. One-Piece Ball Valve

Simple & compact design.

Ideal for low-pressure applications.

Cost-effective and durable.

2. Two-Piece Ball Valve

Separate body & ball mechanism.

Easy to dismantle and clean.

Suitable for water and oil pipelines.

3. Three-Piece Ball Valve

Bolted construction for easy maintenance.

Used in chemical and pharmaceutical industries.

Handles high-pressure applications.

4. Full Bore vs. Reduced Bore Ball Valves

Full bore ball valve: No flow restriction, used in high-flow systems.

Reduced bore ball valve: Slight flow restriction, cost-effective for general applications.

5. L&T Ball Valves

High-quality L&T stainless steel ball valves for industrial use.

Provides excellent sealing and durability.

Where are Stainless Steel Ball Valves Used?

1. Oil & Gas Industry

Regulates fuel, gas, and crude oil pipelines.

Ensures high-pressure performance.

2. Water Treatment Plants

Used in municipal and industrial water systems.

Provides corrosion-resistant flow control.

3. Chemical & Pharmaceutical Industries

Handles aggressive chemicals & high-temperature liquids.

Prevents contamination.

4. Food & Beverage Processing

Used for hygienic flow control in food manufacturing.

Stainless steel ensures safe, non-toxic operation.

5. HVAC & Fire Protection Systems

Controls water flow in cooling & heating systems.

Essential for fire sprinkler networks.

Stainless Steel Ball Valve Price List

Latest Prices for Different SS Ball Valves

Valve TypeSizePrice Range (INR)One-Piece Ball Valve1/2 to 2 Inch₹500 - ₹2,500Two-Piece Ball Valve1/2 to 4 Inch₹1,200 - ₹6,000Three-Piece Ball Valve1 to 6 Inch₹3,000 - ₹15,000Full Bore SS Ball Valve1 to 6 Inch₹2,500 - ₹12,000L&T Ball Valve1/2 to 6 Inch₹5,000 - ₹25,000

📌 Note: Prices vary based on size, material, and technical specifications. Contact Udhhyog for bulk orders and customized pricing.

How to Select the Right Stainless Steel Ball Valve?

1. Application Type

For industrial pipelines – Choose a full bore ball valve.

For chemical & pharmaceutical use – Opt for a three-piece SS ball valve.

For general plumbing – Select a one-piece or two-piece SS ball valve.

2. Pressure & Temperature Rating

Ensure the valve can handle your system’s pressure range.

Choose a heat-resistant SS ball valve for high-temperature applications.

3. Material Selection

SS304 & SS316 ball valves for corrosion resistance.

L&T ball valves for high-quality industrial performance.

4. Valve Size & Flow Rate

Small sizes (1/2 to 2 inches) for household and low-pressure systems.

Large sizes (3 inches & above) for high-flow industrial pipelines.

5. Trusted Manufacturer & Supplier

Buy from reliable suppliers like Udhhyog for quality assurance.

Why Choose Udhhyog – Best SS Ball Valve Supplier & Manufacturer in Delhi?

At Udhhyog, we are recognized as Delhi’s leading manufacturer and supplier of stainless steel ball valves due to our commitment to quality, performance, and affordability.

✅ Premium Quality Manufacturing

We use top-grade stainless steel to produce high-performance ball valves.

✅ Affordable Pricing

Our SS ball valves are competitively priced for all industries.

✅ Wide Range of Valves

We supply one-piece, two-piece, three-piece, full bore, and L&T ball valves.

✅ Reliable & Quick Delivery

We ensure on-time delivery across Delhi, Haryana, Uttar Pradesh, and Jammu & Kashmir.

✅ Technical Support & Consultation

Our team helps customers choose the best ball valve for their needs.

Contact Udhhyog for the Best Stainless Steel Ball Valves

If you are looking for high-quality stainless steel ball valves in Delhi, Udhhyog is your trusted supplier. We provide top-grade SS ball valves at competitive prices, ensuring efficiency and durability for all applications.

📞 Call Us Today or Visit Udhhyog to explore our extensive range of ball valves.

✨ Choose Udhhyog – Your Reliable Ball Valve Supplier

#BallValve#SSBallValve#StainlessSteelValve#IndustrialValves#L&TBallValve#ValveSupplier#DelhiManufacturer#Udhhyog#PlumbingSolutions#EngineeringSolutions

1 note

·

View note

Text

The Guide to Small Ball Valves: Types, Applications, Tips.

When it comes to fluid control in compact systems, small ball valves, mini ball valves, and miniature ball valves are indispensable components. These valves are designed for precision, durability, and space efficiency, making them ideal for industries ranging from plumbing and HVAC to chemical processing and manufacturing. In this comprehensive guide, we’ll explore the key features, types, materials, and applications of small ball valves, along with tips for selecting the right valve for your needs.

—

What is a Small Ball Valve

A small ball valve is a quarter-turn valve that uses a hollow, perforated ball to control fluid flow. When the valve handle is turned 90 degrees, the ball rotates to align its bore with the pipeline (open position) or block it completely (closed position). These valves are characterized by their compact size, lightweight design, and ease of operation, making them perfect for tight spaces or applications requiring frequent adjustments.

Key advantages of small ball valves include:

- Leak-proof sealing for reliable performance. - Quick shutoff with minimal torque. - Versatility in handling liquids, gases, and corrosive media. - Low maintenance due to simple construction.

—

Types of Small Ball Valves

Small ball valves are available in various designs to suit specific applications. Below are the most common types:

1. Thread Ball Valve

A thread ball valve features threaded ends (NPT, BSPP, or BSPT) for easy installation in pipelines without welding. These valves are widely used in residential plumbing, compressed air systems, and low-pressure industrial setups.

2. Flange Ball Valve

Flange ball valves have flanged ends for bolted connections, ideal for high-pressure or large-diameter systems. They are common in oil and gas, water treatment, and chemical industries.

3. 2 PC Ball Valve vs. 3 PC Ball Valve

- 2 PC ball valves consist of two main body pieces, offering a balance between cost and serviceability. - 3 PC ball valves feature three separable body sections, enabling easy disassembly for cleaning or repair without removing the valve from the pipeline.

4. Floating Ball Valve

In a floating ball valve, the ball is held in place by compression from the valve seats. This design is cost-effective and suitable for low-to-medium pressure applications.

—

Material Choices for Small Ball Valves

The valve material impacts its durability, corrosion resistance, and compatibility with fluids. Popular options include:

1. Stainless Steel Ball Valve

Stainless steel ball valves (e.g., SS304, SS316) excel in corrosive environments, such as chemical processing, marine applications, or food-grade systems.

2. Carbon Steel Ball Valve

Carbon steel ball valves are robust and economical, ideal for high-temperature and high-pressure systems in oil refineries or power plants.

3. Forged Steel Ball Valve

Forged steel ball valves are manufactured through forging, resulting in superior strength and resistance to extreme conditions. They are commonly used in heavy-duty industrial applications.

—

Applications of Small Ball Valves

- Plumbing and HVAC: Regulating water flow in residential or commercial systems. - Chemical Processing: Handling aggressive fluids with stainless steel or PTFE-lined valves. - Automotive: Fuel and coolant control in compact engine systems. - Pharmaceuticals: Ensuring sterile fluid transfer with sanitary ball valves. - Agriculture: Irrigation and fertilizer distribution.

—

How to Choose the Right Small Ball Valve

1. Pressure and Temperature Ratings: Ensure the valve meets your system’s operational limits. 2. Connection Type: Select threaded, flanged, or welded ends based on installation requirements. 3. Material Compatibility: Match the valve body and seal materials to the fluid type (e.g., PTFE seals for chemicals). 4. Valve Size: Confirm the port size (e.g., ¼” to 2”) matches your pipeline dimensions. 5. Certifications: Look for industry standards like API, ANSI, or ISO for quality assurance.

—

FAQs About Small Ball Valves

Q: What’s the difference between a mini ball valve and a standard ball valve

A: Mini ball valves are smaller in size (typically under 1” diameter) and designed for low-flow or precision applications, whereas standard ball valves cater to larger systems.

Q: Can a stainless steel ball valve handle seawater

A: Yes, SS316 stainless steel valves offer excellent corrosion resistance in marine environments.

Q: When should I choose a 3 PC ball valve over a 2 PC design

A: Opt for a 3 PC ball valve if frequent maintenance or cleaning is required, as it allows easy access to internal components.

—

Conclusion

From thread ball valves in household plumbing to flange ball valves in industrial pipelines, small ball valves play a critical role in modern fluid control systems. By understanding the differences between floating ball valves, stainless steel ball valves, and forged steel ball valves, you can make informed decisions to optimize performance and longevity. Whether you need a miniature ball valve for a lab setup or a heavy-duty carbon steel ball valve for a refinery, prioritize quality materials, proper sizing, and compliance with industry standards.

Need a reliable small ball valve supplier, Contact Chinese NSW valve manufacturer experts today to find the perfect valve for your application.

#ball valve manufacturers in india#ball valve suppliers#ball valve#small ball valve#mini ball valve#china ball valve manufacturer#ball valve manufacturer#ball valve factory#ball valve supplier

0 notes

Text

Reliable Industrial Parts Supplier - Rajal Industries

Rajal Industries stands out as a premier supplier of high-quality Industrial Parts Supplier, specializing in precision-engineered components. Located in Surendranagar, Gujarat, we offer an extensive range of products, including hex nuts, bolts, and custom fasteners, designed to meet the demanding needs of various industrial applications. Our commitment to quality and precision ensures that every part meets the highest standards, providing durability and reliability for your projects.

With a robust manufacturing facility equipped with advanced technology, Rajal Industries is dedicated to delivering products that cater to diverse specifications, including grades MS, SS202, SS304, and SS316. Our expert team is focused on offering tailored solutions, from standard components to customized fasteners, ensuring that your requirements are met with accuracy and efficiency. Whether you need threaded studs, high-tensile nuts, or stainless steel components, we provide comprehensive solutions to support your industrial operations. Trust Rajal Industries for exceptional quality, reliability, and service in every part we supply.

0 notes

Text

Washers Manufacturers, Stockist, Supplier, and Exporter – Ananka Group

When it comes to industrial fasteners, washers play a crucial role in ensuring that bolts and nuts remain securely fastened. They distribute the load, prevent damage to the surface, and ensure a tight and stable connection. At Ananka Group, we specialize in providing high-quality washers that meet a diverse range of industrial needs.

Who Are We?

Ananka Group, based in Mumbai, India, is a leading manufacturer, stockist, supplier, and exporter of high-quality washers. With years of expertise in the fasteners industry, we have built a reputation for delivering reliable and durable products that meet international standards. Our commitment to quality and customer satisfaction has made us a preferred choice in the global market.

Range of Washers

At Ananka Group, we offer an extensive range of washers designed to cater to various applications across different industries. Our product range includes:

1. Flat Washers: These are the most common type of washers and are used to spread the load of a bolt or screw over a larger area, reducing stress on the material.

2. Spring Washers: Designed to provide a compensating spring force and sustain a load or absorb shock, spring washers are commonly used in applications subject to vibration and dynamic loads.

3. Tab Washers: These washers are used to prevent a nut or bolt head from loosening. Our Tab Washers made from SS316 are perfect for applications where resistance to corrosion and strength are critical.

4. Lock Washers: Available in different shapes, such as split or tooth, lock washers are used to prevent nuts and bolts from turning, slipping, or coming loose due to vibration and torque.

5. Specialty Washers: We also manufacture custom washers based on specific requirements, ensuring that our products meet unique operational needs.

Types of Washers and Our Expertise

At Ananka Group, we specialize in a comprehensive range of washers tailored to meet various industrial needs. Here's a look at the types of washers we manufacture and supply:

1. Wedge Lock Washers

Wedge lock washers are designed to prevent loosening of nuts and bolts due to vibration or torque. They provide a secure grip and enhance the stability of fastened joints.

2. Square Washers

Square washers offer a larger surface area for load distribution compared to round washers, making them ideal for applications where extra support is needed.

3. Spring Lock Washers

Spring lock washers are used to maintain tension and absorb shock, preventing fasteners from loosening under dynamic loads.

4. Self-Locking Washers

Self-locking washers are designed to prevent nuts and bolts from loosening by creating friction and a secure fit.

5. Sealing Washers

Sealing washers provide a tight seal around fasteners to prevent leakage of fluids and gases in various applications.

6. Plain Flat Washers

Plain flat washers are the most common type, used to distribute the load of a fastener and reduce stress on the material being fastened.

7. Hex Washers

Hex washers have a hexagonal shape and are used to provide additional support and load distribution, particularly in applications with hexagonal bolts.

8. Finishing Washers

Finishing washers are used to provide a neat and finished appearance while distributing the load evenly, often used in visible applications.

9. Conical Washers

Conical washers are designed with a tapered shape to fit into conical recesses, providing a stable and secure fit.

10. Countersunk Washers

Countersunk washers have a beveled edge that fits into countersunk holes, giving a smooth, flush finish and helping to keep the fastener low-profile.

11. Square Beveled Washers

Square beveled washers are used in applications where a square washer with a beveled edge is needed for a precise fit.

12. Curved Wave Washers

Curved wave washers are designed to provide a spring-like effect, absorbing shock and maintaining tension in fastened assemblies.

13. External Tooth Lock Washers

External tooth lock washers feature teeth that grip the surface of the material, preventing loosening due to vibration.

14. Internal Tooth Lock Washers

Internal tooth lock washers have teeth on the inside diameter that grip the fastener, providing secure locking and resistance to loosening.

15. Internal Tab Washers

Internal tab washers have a tab that locks into a notch in the material, preventing rotation and ensuring a secure fit.

16. Tab Washers

Tab washers are designed to lock nuts and bolts in place by using a tab to prevent loosening under vibration.

17. Structural Washers

Structural washers are used in heavy-duty applications, providing additional strength and load distribution for structural components.

Why Choose Ananka Group?

Quality Assurance: We manufacture our washers using high-grade raw materials and adhere to strict quality control processes. This ensures that every washer produced meets industry standards and performs reliably in various applications.

Wide Stock Availability: As a prominent stockist, we maintain a comprehensive inventory of washers in various sizes and materials, ensuring that we can meet your immediate and bulk requirements promptly.

Global Supplier Network: Our extensive distribution network allows us to supply washers across the globe efficiently. Whether you're in Asia, Europe, North America, or elsewhere, we ensure timely delivery of your orders.

Customization: We understand that different applications require different specifications. That's why we provide custom washer solutions tailored to meet the unique needs of each client.

Competitive Pricing: We believe in providing high-quality products at competitive prices, ensuring value for money for our clients.

Our Commitment to Sustainability

At Ananka Group, we are committed to sustainable manufacturing practices. We prioritize using eco-friendly materials and processes to minimize our environmental footprint while delivering high-performance washers. Our dedication to sustainability not only benefits the environment but also enhances the quality and longevity of our products.

Conclusion

Choosing the right washer is crucial for ensuring the durability and reliability of your fastening applications. At Ananka Group, we are dedicated to providing high-quality washers that meet diverse industrial requirements. With our extensive range, global supply capabilities, and commitment to quality, we have established ourselves as a trusted partner for businesses worldwide. Whether you need standard washers or custom solutions, we are here to meet your needs with excellence and precision. Trust Ananka Group for all your washer requirements, and experience the difference of working with a leading manufacturer, stockist, supplier, and exporter.

FAQs

1. What types of washers do you manufacture?

At Ananka Group, we manufacture a wide range of washers, including flat washers, spring washers, tab washers, lock washers, and specialty washers. We also provide custom washer solutions based on specific client requirements.

2. What materials are your washers made from?

Our washers are made from high-quality materials such as stainless steel (including SS316), carbon steel, and other alloys to ensure durability, corrosion resistance, and high performance in various environments.

3. What are the benefits of using tab washers?

Tab washers are specifically designed to keep nuts and bolts from loosening in situations where vibrations are frequent. They provide additional security by locking the fastener in place, making them ideal for dynamic or high-stress environments.

4. How do you ensure the quality of your washers?

We adhere to strict quality control processes and use high-grade raw materials in our manufacturing process. Each washer undergoes rigorous testing to ensure it meets industry standards and performs reliably.

5. Can you supply washers globally?

Yes, Ananka Group has a robust global supply network, allowing us to deliver washers to clients worldwide promptly. We ensure efficient logistics to meet the demands of our international customers.

6. What makes Ananka Group different from other washer manufacturers?

Our commitment to quality, wide range of products, customization options, and global supply capabilities set us apart from other manufacturers. We strive to provide exceptional customer service and value for money, making us a preferred choice in the industry.

0 notes

Text

Knife Gate Valve Manufacturers in India

Speciality Valve proudly leads as the foremost Knife Gate Valve Manufacturers in India, with our products reaching global destinations including Canada, France, Australia, and Mexico.

What are Knife Gate Valves?

A knife gate valve, designed specifically for on-off and isolation applications, is meticulously engineered to provide precise control over fluid or slurry flow. Its design enables it to efficiently facilitate complete shut-off or minimal-resistance flow control, making it ideal for managing various fluids or slurries in industrial settings.

Features:

We, the Knife Gate Valve Manufacturers in India, meticulously engineer our valves to excel in handling abrasive, viscous, and highly contaminated media such as wastewater, pulp, mining slurries, and bulk solids. Their unique design incorporates a sharp-edged, flat gate or blade that moves laterally across the flow path, efficiently obstructing or permitting the passage of fluids as required. These valves serve as indispensable flow control devices, engineered for precise regulation of fluid or slurry flow in industrial processes and systems.

Recognizable by their distinctive construction, they feature a flat and sharpened gate or blade housed within the valve body. Positioned perpendicular to the flow path, the gate is controlled by an external mechanism such as a handwheel, pneumatic actuator, or electric actuator. This external mechanism facilitates smooth movement of the gate into or out of the flow path, enabling precise control over the passage of fluids.

Parts:

Valve Body: Main housing of the valve that contains and directs the flow of fluids. Gate or Blade: Sharp-edged component that moves laterally across the flow path to control fluid passage. Stem: Connects the actuation mechanism to the gate, facilitating its movement. Actuation Mechanism: External mechanism such as a handwheel, pneumatic actuator, or electric actuator used to control the gate's movement. Seat: Provides a sealing surface for the gate to prevent leakage when the valve is closed. Bonnet or Packing Gland: Encloses and secures the stem, preventing fluid leakage. Port: Opening through which fluid flows when the valve is open. Yoke and Stem Nut: Components that support and guide the stem's movement. Gland Follower: Helps maintain the packing gland's compression, ensuring a tight seal. Bolting and Fasteners: Secure various components of the valve together.

Types:

Through Conduit Knife Gate Valve Uni Directional Knife Gate Valve Bi Directional Knife Gate Valve Slurry Knife Gate Valve

Advantages:

Unobstructed Flow Isolation Handling Slurries and Solids Low Maintenance Compact Design Quick Operation Versatility Corrosion Resistance Long Service Life Cost-Effective Bi-Directional Flow Zero Leakage

Industries:

Wastewater Treatment Pulp and Paper Industry Mining and Minerals Processing Chemical Processing Bulk Material Handling Power Generation Oil and Gas Industry Marine and Offshore Applications Construction and Dredging Textile Industry Petrochemical Industry

Description:

Available Materials: SS306, SS904, SS316, Aluminium Bronze, Monel, Bronze, Brass, Duplex steel, Inconel, Titanium, WCB, CF8, CF8M, CF3, CF3M, WC1, WC6, WC9, Cast iron

Size: 1/2″- 64”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Operation: Hand Wheel, Gear operated, Electric and Pneumatic Actuated

Ends: Flanged, Wafer, Lug

Standards: ASME, API6D, API607, DIN, BS, ANSI, AWWA

Explore our range of Valves on our website: https://www.specialityvalve.com/product-category/knife-gate-valve

1 note

·

View note

Photo

Stainless Steel L bolt 304 316 A2-70 L Bolt and ground screw

click here to see more of this product

#threaded l bolt#stainless l bolt#l bolt anchor#stainless steel bolts#foundation bolt#large diameter stainless steel bolts#L bolt 304#304 bolt#ss 304 screw#stainless steel bolt class#ss 304 anchor fasteners#ss nut bolt material grades#ss 304 fasteners standard#stainless steel bolts and nuts#ss 316 nut bolt price list#stainless steel 316s31 fasteners torque value#ss316 bolt mechanical properties#316 stainless steel bolts yield strength#316 stainless steel screw#ss316 bolt specifications#ss 316 bolt grade#ss 316 bolts#ground screw length#ground screw calculator#ground screw machine#where to buy ground screws#ground screws vs concreteground screw length#ground screws drill

0 notes

Text

ANSI/ASME B1.1 Inch Threaded Fasteners – Manufactured by BigBoltNut

At BigBoltNut, we specialize in manufacturing high-performance ASME B1.1 fasteners (also known as ANSI B1.1). This Unified Inch Screw Thread Standard plays a crucial role in ensuring precision, compatibility, and strength across a wide range of industrial applications.

What is ASME B1.1?

ASME B1.1 is a unified screw thread standard based on inch dimensions. It defines thread shapes, series, classes, tolerances, and allowances to ensure seamless compatibility and performance in mechanical assemblies. This standard is essential for industries requiring precision-engineered screw threads.

Key Thread Series Under ASME B1.1

1.UN (Unified National) – Standard internal and external thread profiles.

2.Unified National Rounded Root – Features a rounded root for increased fatigue resistance.

3.UNJ Series – Designed for high-stress environments with an enlarged root radius for improved fatigue strength.

Thread Series Applications

•UNC (Unified National Coarse) – Suitable for general industrial applications and similar to ISO metric threads.

•UNF (Unified National Fine) – Higher thread count, ideal for applications requiring increased tensile stress areas.

ASME Thread Fit Classes

•Class 1A/1B – Loose fit, allows for easy assembly even with minor thread damage.

•Class 2A/2B – Most commonly used; offers a balance between performance and ease of installation.

•Class 3A/3B – Not suitable for applications requiring precision tolerance.

________________________________________

BigBoltNut – ASME B1.1-Compliant Fastener Solutions

We produce a wide range of ASME B1.1 threaded fasteners that meet stringent dimensional and quality standards:

•Stud Bolts – Available in full thread, double-ended, and reduced shank designs. Made from carbon steel, alloy steel (Grades 8.8, 10.9, 12.9), and stainless steel (SS304, SS316, SS316L, B8, B7, L7, 8M, and more).

•Hex Head Bolts & Screws – Conforming to ASME B18.2.1 specifications.

•Nuts and Washers – Manufactured to ensure complete ASME compatibility with our bolt range.

Contact BigBoltNut for bulk export inquiries and reliable ANSI/ASME B1.1 threaded fasteners engineered for high-performance applications across the globe.

Source Url:

0 notes

Text

Jmiks Fastenersss316 Bolt Specificationssupplier and Manufacturers

Jmiks Fasteners is one of the known supplier and manufacturers of Stainless Steel 316/316 H/ 316L/316Ti Bolts, where the prime attributes of these products are corrosion resistance and used for the industries.

Our 316L stainless steel fasteners are of superior quality and are used in various industries such as food processing plants and components, sea and sea water applications, petrochemical industries and also in the aerospace industry. These SS 316L hex bolts are a chromium-nickel alloy with molybdenum. The addition of molybdenum makes the creep resistance of 316L stainless steel studs higher with better anti-corrosion properties. There is also a lower carbon version of the same material. SS 316L nuts and bolts are made from the lower carbon version of the material and are less corrosive and highly weldable. Nutbolt 1.4404 is the specification for grade 316 and 316L bolts, nuts and other fasteners. Our 316L stainless steel threaded rods and studs are stronger and more durable. ASTM A193 316L fasteners are slightly more expensive than SS 304 bolts, but are high performance and tensile strength with additional anti-corrosion properties and high weldability. Therefore, our UNS S31603 bolts and nuts are preferred in high cost applications. You can get a complete list of products and prices by contacting us.

ss316 bolt specifications

316 Stainless Steel Bolts Specification :

Material

316 Stainless Steel Bolts

Size

M02 to M33

Standards

ASTM / ASME - A/ SA 193 / 193

Length

3 mm to 200 mm

Specification

IS, BS, ASTM

Manufacturer

GKW, Unbrako, Kundan, APL, Sundaram Precision, EBY Fastener Etc.

Conclusion:-

Generally, 316 stainless steel nut bolts used in various industries, including pulp and paper, textiles, sugar, rubber, etc., prefer to use coated. The coating used on the surface of these A4 grade 316 threaded rods improves wear resistance while reducing corrosion resistance to some extent. Normally, materials like zinc, phosphate coating, galvanizing, Teflon can be used to coat nuts, bolts, washers, etc. The application of a coating can serve as a pretreatment to paint screws, threaded rods or hex bolts. Buy directly it from Jmiks Fasteners the Stainless Steel 316 Fasteners manufacturer in India for prime quality & best price.

0 notes

Text

Wafer butterfly valve supplier in Dubai

Middleeast valve is a topmost Wafer butterfly valve supplier in Dubai. We supply to cities like Ajman, Hatta, and Kho Fakkan.

What is wafer butterfly valve?

A wafer butterfly valve is a type of industrial valve used for regulating and controlling the flow of fluids in a pipeline. It consists of a flat, disc-shaped closure element (resembling a butterfly) that rotates on a spindle to control the flow of fluid.

Wafer butterfly valve installation:

Verify the valve size: Ensure that the valve size matches the pipe size where it will be installed.

Check the valve for any damage: Inspect the valve body, disc, stem, and seals for any signs of damage or defects. If any defects are found, the valve should be repaired or replaced before installation.

Prepare the pipe: Clean the flange faces on both sides of the pipe and remove any debris or foreign materials. Ensure that the flange faces are smooth and free of burrs or scratches.

Position the valve: Place the valve between the two pipe flanges, making sure that the valve's arrow is pointing in the direction of flow.

Align the valve: Align the bolt holes on the valve flanges with the corresponding holes on the pipe flanges. Use alignment pins to hold the valve in place.

Install the bolts: Insert the bolts into the bolt holes and hand-tighten them in a crisscross pattern. Do not fully tighten the bolts yet.

Tighten the bolts: Using a torque wrench, tighten the bolts in a crisscross pattern according to the manufacturer's specifications. Do not overtighten the bolts, as this can damage the valve or the flanges.

Check for leaks: Test the valve for leaks by filling the pipe with water or another suitable fluid and pressurizing it to the maximum operating pressure. Check for any leaks around the valve body or seals.

Finalize the installation: Once the valve has been successfully tested, finalize the installation by removing the alignment pins and installing any necessary accessories, such as handles or actuators.

Middleeast valve is a topmost Wafer butterfly valve supplier in Dubai and are known for their compact design, ease of installation, and cost-effective operation. However, they are typically used for applications with moderate temperature and pressure conditions and may not be suitable for high-temperature or high-pressure applications without proper design considerations.

Advantages of wafer butterfly valve:

Compact size

Low cost

Ease of installation

Simple design

Quick opening and closing

Good flow control

Low pressure drop

Resistance to corrosion

Industries of wafer butterfly valve:

Water treatment

Chemical

Oil and gas

Petrochemical

Power generation

Plumbing

Description:

Body materials: Cast iron, Carbon steel, Ductile iron, SS304, SS316

Class: 150 to 300, PN6 to PN40.

Size: 2’’-72’’.

End: wafer.

Operation: lever operated, Gear Operated, electric actuated, pneumatic actuated.

Disc: Carbon steel, Cast iron, Ductile iron, SS304, SS316

Visit us: https://www.middleeastvalve.com/product-category/wafer-butterfly-valve/

0 notes

Text

Bronze valve Manufacturer in Australia

Australian valve is the best rated Bronze valve Manufacturer in Australia. We supply to cities like Coffs Harbour, Mildura, Bendigo. A bronze valve is a type of valve that is made from bronze, which is an alloy of copper and tin. The function of a bronze valve is to control the flow of fluids, such as liquids or gases, by opening or closing a passageway through which the fluid flows.

The specific function of a bronze valve depends on its type and design, as there are various types of bronze valves, including ball valves, gate valves, globe valves, check valves, and butterfly valves, among others. Here are some common functions of bronze valves:

On/Off Control: Bronze valves can be used to start or stop the flow of fluid completely. For example, a ball valve, which has a lever handle or a gear-operated handle, can be rotated to either open or close the valve, allowing or stopping the flow of fluid.

Flow Control: Bronze valves can also be used to regulate the flow rate of fluids. For example, a globe valve, which has a disk that moves up and down to control the flow, can be partially opened or closed to adjust the amount of fluid passing through the valve.

Backflow Prevention: Check valves, which are commonly used in plumbing systems, can prevent backflow of fluids by allowing flow in one direction while preventing flow in the opposite direction. This function helps to protect water supplies from contamination.

Pressure Relief: Some bronze valves, such as pressure relief valves, are designed to automatically open and release excess pressure from a system to prevent over-pressurization, which could lead to damage or failure of the system.

Mixing/Diverting: Bronze valves can be used to mix or divert fluids from different sources or to different destinations. For example, a three-way ball valve can be used to switch flow between two different pipes or sources.

6. Temperature Control: Bronze valves can also be used to control the temperature of fluids. For example, thermostatic mixing valves are commonly used in plumbing systems to control the temperature of water for showers or faucets.

Australian valve is the prominent Bronze valve Manufacturer in Australia and these valves can be operated manually or automatically and are designed to withstand high pressures, temperatures, and corrosive environments.

Types of Bronze Valve

Bronze globe valve

Bronze gate valve

Bronze check valve

Bronze butterfly valve

Bronze ball valve

Bronze angle valve

Bronze pressure release valve

Top of Form

Bottom of Form

Bottom of Form

Parts

Body

Bonnet

Seat

Valve Element

Stem

Packing

Actuator

Bolts and Nuts

Advantages of Bronze Valves:

Corrosion Resistance

High Temperature Resistance

Durability

Low Friction

Applications of Bronze Valves:

Plumbing

Marine Industry

Oil and Gas Industry

Fire Protection

Industry

Chemical industry

Petroleum industry

Mining

Water treatment plants

Description:

Body material- Bronze (CAC401, CAC406), B148 C95800, CAC401,CAC406, SS304, SS904, SS904L, SS316, Aluminium Bronze, Monel, Bronze, Brass, Duplex steel, Inconel, Incoloy, Titanium, WCB, CF8, CF8M, CF3, CF3M, WC1, WC6, WC9, Cast iron, super duplex

Class- 150-2500

Ends- Flanged, wafer, lug, Buttweld, threaded

Size-1/2’’- 4’’

Operations- Pneumatic actuated, Electric Actuated, Gear Operated, Lever Operated, Handwheel Operated

Visit our website- https://www.australianvalve.com/product-category/bronze-valve/

0 notes

Text

Spear Bolts and Sockets - Sundream Group

Over 3000 different fastener parts, including pipe clamps, stone cladding clamps, nylon fasteners, stainless steel fasteners, self-drilling screws, and metal fasteners, are among the many Anchor Fasteners we offer.

Should Read!

10000+ Contented Clients Older than 50 years, business enterprise 500+ Cr worth of projects delivered. Exporting to 33+ countries; 72-hour product dispatch guarantee; all Metros and Government projects authorised items. Items made in India available in a variety of grades, including 4.6, 4.8, 5.8, 8.8, EN8, SS202, SS304, and SS316; hot-dip galvanised; white zinc plating; yellow zinc plating; black oxidised; and other specific finishes. providing on-site random sample testing, online order tracking, and 24-hour customer service; flawless product delivery with nine rigorous quality checks; customisation choices; Indian products meeting international standards;

To know more about Sundream Group, visit https://www.sundreamgroup.com/products/tunnel-segment-bolts/

0 notes

Text

What is the importance of Incoloy 825 Pipe Fittings?

With a modest quantity of extra Copper, Titanium, and Molybdenum, Incoloy 825 Pipe Fittings offer superior chemical and mechanical qualities. You should use UNS N08825 Incoloy 825 Pipe reducers that are more resistant to crevice and pitting corrosion and can operate smoothly at moderately elevated temperatures.Incoloy 825 Pipe End Cap is used in acid production units, pickling tanks and equipment, and nuclear waste and handling devices because it is corrosion resistant in both oxidizing and reducing situations.

Know about Duplex 2205 Round bar

Duplex 2205 Round bar is a type of duplex stainless steel that has had its nitrogen content increased. The alloy grade 2205 Duplex Stainless Steel Round Bar is created to address frequent corrosion issues with austenitic stainless steels in the 300 series.You should know about stainless steel threaded rod manufacturers to get premium quality.

The mixed microstructure of the S32205 Duplex Polished Bar contains around 40% - 50% ferrite in an annealed condition. Because the alloy is the most extensively used grade in the duplex category of stainless steel, the Duplex Steel S32205 Forged Bar is sometimes referred to as the workhorse grade.

The benefit of a dual or duplex microstructure is that the Duplex Steel Uns S31803 Hollow Bar has a set of integrated yet distinct properties.

What is the usage ofstainless steel threaded?

A threaded rod is a sort of fastening bar threaded on both ends and is rather lengthy. The threading on the ss acme threaded rod can be stretched down the rod's length. You can also look for ASTM a193 grade b7 as they are of high strength. Manufacturers of SS threaded rod refer to it as a stud. The ss316 threaded rod is intended for tension application. The Stainless Steel Flanges m12 stainless steel threaded rod is commonly referred to as an all-thread in bar stock form.

Specifications of ASTM a193 grade b7

TheASTM A193 Grade B7 specification includes high-tensile alloys steel. It is a standard specification for bolting used in pressure vessel service, valves, flanges, and fittings that defines the typical chemical composition, hardness requirement, preferential heat treatment, product labeling, mechanical qualities, certification, and other conditions. You should know about Stainless Steel U Bolts as they are used to increase strength.

What are Stainless Steel Flanges used for?

The flange and monel bolts business isa high carbon form of the most often used and incredibly adaptable stainless steel. 304H is an austenitic chromium stainless steel with a carbon content of.04–.10, which aids in heat resistance in high-temperature applications. It also has all of the general characteristics and service features of the standard stainless steel grade 304.

Why is the demand for monel bolts increasing?

Monel bolts are usually nickel-copper alloys with exceptional strength, hardness, and corrosion resistance throughout a wide temperature range. Monel bolts are notable for their extraordinary resistance to hydrofluoric acid. Look for the best stainless steel stud bolt manufacturers.

Monel bolts are possibly the most resistant of all regularly used specialty alloys for hydrofluoric acid applications.In marine applications, Monel alloy 400 and K500 bolts have high corrosion resistance, and under reducing conditions, they have good corrosion resistance to sulfuric and hydrochloric acids.

0 notes

Text

Primary Packaging and Secondary Packaging with Nichrome.

Nichrome developed and manufactured India's first milk pouch packaging machine four decades ago. Since then, it’s been a continuous journey of advancing expertise, indigenous innovation, growing product range and technology tie-ups – all aimed at offering clients a superior experience in packaging solutions.

Today, Nichrome boasts an enviable portfolio of automated packaging machines for primary packaging. Primary packaging is the packaging in direct contact with the product, the material that most closely protects and contains the product. For snacks, it could be the flexible pouch; for beverages, it could be the tin or bottle; for pharma tablets or capsules, it could be the aluminum blister strip or bottle.

NICHROME PRIMARY PACKAGING Nichrome offers a comprehensive range of primary packaging machines in India. These can be broadly divided into 3 categories:

Vertical Form Fill Seal (VFFS) machines VFFS machines are used primarily in the Food packaging industry, for a wide variety of powder, liquid, granular, viscous products. The product to be packed is dispensed vertically. The machine constructs the bag or pouch out of a roll of film, fills the bag and seals it. Even formed, bulk good like nuts, cookies, and even nuts & bolts, can be packed using automated VFFS packaging machines.

VFFS machines require less floor space and cost less than HFFS machines.

Horizontal Form Fill Seal (HFFS) machines HFFS packaging machines operate horizontally, and are suited for larger packs and heavier products that do not flow. HFFS packaging machines are also better suited for packing fragile products that cannot withstand a high drop. Companies prefer these machines when they require a stand up pouch or a pouch with a zipper and/or spout that facilitates ease of opening and comfortable consumption of products.

Bottle/Tin Filling solutions Nichrome offers an efficient integrated system for bottle filling and packaging that covers a turntable, UV sterilisation chamber, automatic liquid filling machine, cap feeding elevator, rotary capping machine, induction sealer, labeling machine, date & batch coding system, and packing table.

SKUs range from 100 ml to 20 ltrs. Applications include a wide range of food & beverage liquids such as flavoured milk, soft drinks, energy drinks, water & buttermilk; non-food liquids such as perfumes, oil, shampoo, handwash; viscous products such as ghee, ketchup, chocolate sauce and more.

Nichrome's Tin Filling Line is a sturdy, low-maintenance system made for accurate and efficient performance. The PLC-controlled line has a digital LCD touch screen displaying settings, and safety enclosures with interlocks for rotary parts.

Machine construction is available in SS3014, SS316 and MS painted material. Various tin sterilisation and cleaning options are available.

NICHROME SECONDARY PACKAGING In any trade transaction, where logistics is involved, secondary packaging forms an important part of a shipment. Secondary packaging is the outer packaging primarily used for collating smaller individual units for storage and transportation of mass quantities of the product to the end user or point of sale.

In the beverage, food & cosmetic sectors, secondary packaging is sometimes used for display and branding on retail shelves.

Good external packaging or secondary packaging offers many benefits. These include:

- Eases handling and transportation of goods

- Reduces chances of pilferage and theft

- Helps preserve and protect the product from weather conditions like rain and heat, and reduces damages due to accidents

- Facilitates timely and correct delivery as secondary packaging usually feature handling instructions, weight & dimensions, deliver address etc.

Nichrome’s secondary packaging offerings include:

- Crating – for milk pouches

- Cartoning – Bag in Box

- Multiple sachets in a Carton

- Collating / Bundling and Over Wrapping

- Labelling

- Automated inline / offline Case Erecting and Case Packaging

- Palletizing

Nichrome also provides complete packaging line integration with fully engineered solutions delivering highly efficient flexible lines to maximise your line's OEE, with real time operator-specific production and diagnostics data.

For the full range of primary and secondary packaging solutions tailored for your individual needs, connect with Nichrome, India’s leading integrated packaging solutions provider, with over four decades of industry expertise and indepth knowledge of diverse application requirements.

#integrated packaging solutions#Packaging#automated packaging systems#Packaging solutions#Horizontal form fill seal machines#vertical form fill seal machines#food packaging machines#PrimaryPackaging#pouch packaging machine

0 notes