#sodium benzoate

Explore tagged Tumblr posts

Text

What has replaced parabens and is this replacement harmful or not as well-studied as parabens? Are they as effective at preventing microbial growth and extending the shelf life of products?

In recent years, many companies have moved away from using parabens in their products and have turned to alternative preservatives. Some common alternatives to parabens include phenoxyethanol, benzyl alcohol, potassium sorbate, sodium benzoate, and ethylhexylglycerin, among others.

Like parabens, these alternative preservatives are intended to prevent microbial growth and extend the shelf life of cosmetics and personal care products. However, like all chemicals, they have the potential to cause skin irritation or allergic reactions in some individuals, and there may be some concern about their safety over the long term.

Phenoxyethanol, for example, has been the subject of some controversy due to concerns about its potential toxicity and its potential to cause skin irritation. Similarly, benzyl alcohol has been associated with allergic reactions in some people.

At present, there is not enough research to determine the long-term safety of these alternative preservatives. However, regulatory agencies such as the US FDA and the European Union's SCCS have evaluated these ingredients and deemed them safe for use at the concentrations typically used in cosmetics and personal care products.

Ultimately, the choice of preservative is up to individual companies and consumers, who may choose to avoid certain ingredients for personal or environmental reasons. However, it is important to note that preservatives are a necessary component of many cosmetic and personal care products, as they help to prevent microbial growth and ensure product safety and efficacy.

#parabens#preservatives#phenoxyethanol#benzyl alcohol#potassium sorbate#sodium benzoate#ethylhexylglycerin#microbial growth#shelf life#science#chemistry#toxicity#skin irritation#allergy#US FDA#European Union SCCS

2 notes

·

View notes

Text

Sodium Benzoate Prices, News, Trend, Graph, Chart, Forecast and Historical

Sodium Benzoate is a widely used preservative in various industries, including food, beverages, pharmaceuticals, and cosmetics, which makes its market dynamics crucial for multiple sectors globally. The prices of sodium benzoate are influenced by several factors, including raw material costs, manufacturing processes, regional supply-demand dynamics, regulatory policies, and broader economic conditions. As a derivative of benzoic acid, the cost of production is heavily tied to the availability and pricing of toluene, a key feedstock derived from crude oil. Any fluctuations in crude oil prices inevitably cascade down to impact the cost structure of sodium benzoate, often leading to price volatility.

Global demand plays a pivotal role in shaping the sodium benzoate market. The food and beverage industry, as the largest consumer, requires sodium benzoate for its effectiveness as a preservative, especially in acidic products like soft drinks, salad dressings, and fruit juices. This sector's growth is fueled by urbanization, changing consumer lifestyles, and the increasing preference for convenience foods, which in turn exerts upward pressure on sodium benzoate prices. Additionally, the pharmaceutical industry’s use of sodium benzoate in medicines and syrups, along with its application in cosmetics and personal care products, further bolsters demand. Rising consumer awareness about product safety and shelf life ensures that the demand for this preservative remains steady, contributing to stable or increasing price trends.

Get Real time Prices for Sodium Benzoate: https://www.chemanalyst.com/Pricing-data/sodium-benzoate-1185

Regional dynamics also significantly impact sodium benzoate pricing. Asia-Pacific, being a major manufacturing hub for sodium benzoate, benefits from lower production costs due to the availability of inexpensive raw materials and labor. This region often exports to North America and Europe, where stricter environmental regulations and higher labor costs can drive up the local production costs, making imported sodium benzoate a more economical option. However, geopolitical factors, trade policies, and tariffs can disrupt this balance, causing price fluctuations across regions. For instance, any trade restrictions or import duties on raw materials or finished goods can lead to localized supply shortages and subsequent price surges.

Sustainability concerns and regulatory frameworks are increasingly influencing sodium benzoate prices. With growing environmental awareness, regulatory bodies across the globe are tightening rules on chemical production and usage. Compliance with these regulations often necessitates investment in cleaner production technologies, which can elevate manufacturing costs and thereby increase market prices. Moreover, stringent food safety standards in developed regions like North America and Europe require manufacturers to ensure high-quality sodium benzoate, further influencing pricing trends.

Technological advancements in production methods are also shaping the sodium benzoate market. Innovations aimed at enhancing production efficiency and reducing environmental impact have the potential to stabilize costs in the long term. For example, the adoption of bio-based processes to produce sodium benzoate could mitigate dependence on petrochemical-derived feedstocks, offering a sustainable and potentially cost-effective alternative. However, these technologies require substantial initial investments, which could lead to short-term price hikes before economies of scale are achieved.

Market competition is another critical factor influencing sodium benzoate prices. The market is fragmented, with numerous players ranging from large multinational corporations to smaller regional manufacturers. Intense competition often leads to price wars, especially in regions with high production capacities like Asia-Pacific. On the other hand, consolidation in the industry through mergers and acquisitions can reduce competition and lead to price stabilization or even increases. Additionally, the branding and quality differentiation strategies adopted by manufacturers can create price variability, with premium products commanding higher prices.

Environmental and health concerns associated with sodium benzoate are also shaping consumer preferences and regulatory policies, indirectly impacting market prices. While sodium benzoate is generally recognized as safe by regulatory bodies like the FDA, concerns about its potential health effects, especially in large quantities or when combined with ascorbic acid, have prompted some manufacturers to seek alternative preservatives. This shift in consumer and industry preference can affect demand patterns, influencing pricing trends over time.

Looking ahead, the sodium benzoate market is expected to grow steadily, driven by its indispensable role in key industries. Emerging economies in Asia, Africa, and South America present significant growth opportunities due to increasing urbanization, rising disposable incomes, and expanding food and beverage sectors. However, the market is not without challenges, as factors such as rising energy costs, raw material price volatility, and stringent environmental regulations pose potential risks to price stability. To remain competitive, manufacturers must invest in sustainable production practices, explore cost-efficient technologies, and adapt to evolving consumer preferences.

In conclusion, the sodium benzoate market is shaped by a complex interplay of factors, including raw material costs, regulatory pressures, technological advancements, and global demand dynamics. While the market is poised for growth, manufacturers and stakeholders must navigate challenges related to cost pressures and sustainability to ensure long-term price stability and market competitiveness. With its critical role in extending shelf life and ensuring product safety, sodium benzoate will continue to be a key ingredient across industries, driving its relevance and impact on global markets.

Get Real time Prices for Sodium Benzoate: https://www.chemanalyst.com/Pricing-data/sodium-benzoate-1185

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Sodium Benzoate#Sodium Benzoate Price#Sodium Benzoate Prices#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Importance of Food Preservatives: Ensuring Quality and Safety

Food preservatives, including antimicrobial agents like sodium benzoate and potassium sorbate, natural preservatives such as sorbic acid, and chemical preservatives like butylated hydroxytoluene (BHT), are essential additives added to food to inhibit the growth of bacteria and fungi, thereby enhancing food safety and extending shelf life. These food preservatives prevent the growth of microorganisms, reducing the risk of food poisoning and ensuring the safety of food products. By maintaining physical and chemical stability, preservatives also contribute to reducing food waste and enabling the widespread availability of preserved foods throughout the year. By maintaining the quality and freshness of food items these preservatives can directly reduce food waste. This reduction occurs because preservatives help to uphold the physical and chemical stability of food, thereby minimizing spoilage and ensuring that consumers can access preserved foods consistently throughout the year.By effectively inhibiting bacterial growth and preventing foods from spoiling prematurely, these preservatives ensure that the food supply remains safe, reliable, and accessible, contributing to a more sustainable food system overall.

To read more please visit:

Reachemical chemicals

16479857177

600 Matheson Blvd W Unit 5, Mississauga, Ontario ,ON L5R 4C1.

#reduce food waste#food products#added to food#bacteria and fungi#butylated hydroxytoluene#growth of bacteria#bacterial growth#prevent foods#food safety#sodium benzoate#antimicrobial preservatives#inhibit the growth#shelf life#natural preservatives#sorbic acid#chemical preservation#physical and chemical#prevents the growth of microorganisms#food preservatives#food poisoning

0 notes

Text

Sodium Benzoate Market Share, Gross Margin, Production and Consumption Analysis, Brands Statistics and Overview by Top Manufacturers 2031

The “Sodium Benzoate Market Share, Size, and Trends | 2031” is market research by The Insight Partners. The Sodium Benzoate market has perceived tides of change in the recent past. This study offers precise projections after detailed scrutiny of a range of factors impacting the business. Considering the present market scenario, this report brings forward correct predictions on revenue, market size, and CAGR of the Sodium Benzoate market. The novel market research which is based on a fact-based foundation is now accessible for purchase. This report can make a variance in wide decision-making and drive business forward in the right direction.

Business is no longer a game of instincts when it comes to capitalizing on new production lines. In a highly competitive Sodium Benzoate market, companies may face several challenges. Having trusted market research is always endorsed for both veteran and new entrants. Sodium Benzoate Market report presents a thorough analysis of local, regional, and global market scenarios through the following details.

Report Attributes

Details

Segmental Coverage

Application

Food and Beverages

Pharmaceuticals

Cosmetics

Agriculture

and Others)

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

Eastman Chemical Company

Foodchem International Corporation

A.M FOOD CHEMICAL CO., LIMITED

Jarchem Innovative Ingredients LLC

MERCK KGaA

LANXESS

Akema S.r.l.

Zancheng Life Sciences Ltd.

FBC Industries

Reagents?

Other key companies

Competitive Landscape

Knowing the state of rivals is a strategically right move to outperform them. This report is the right place to explore key strategies, developments, and recent launches by key Sodium Benzoate market players. This report emphasizes an analysis of business strategies and expected growth opportunities for brands.

Key Coverings:

Current and Future Market Estimates- Sodium Benzoate Market Share, CAGR, and Forecast | 2031

Market Dynamics – Drivers, Challenges, Regional Trends, and Market Opportunities

Market Segmentation – Product, Application, End-use Industries, and Regional Growth Prospects.

Competition Matrix – Key Market Players and Strategies

Recent Developments and Innovation Contributing Market Growth

Need a Customized Market Research Report?

You can always share any specific requirements that you have, and our team will adjust the scope of research offerings as per your needs.

The following are some customizations our clients frequently ask for:

The Sodium Benzoate market report can be customized based on specific regions/countries as per the intention of the business

The report production was facilitated as per the need and following the expected time frame

Insights and chapters tailored as per your requirements.

Depending on the preferences we may also accommodate changes in the current scope.

Key Questions Addressed in the Sodium Benzoate Market Research Include:

What are present Sodium Benzoate market values, and what can be expected in the upcoming decade?

What are the key segments in the Sodium Benzoate market?

What is the regional distribution of the Sodium Benzoate market report?

What are the key players and their recent strategies?

What are the key factors driving Sodium Benzoate market growth?

What are regulatory concerns and requirements businesses have to compel?

Author’s Bio:

Shashikant Ligade

Senior Analyst The Insight Partners

0 notes

Photo

🚨 Uncover the Hidden Danger: Sodium Benzoate in Your Food! 🚨 Are you aware of the potential health risks lurking in your favorite snacks and beverages? Discover the truth about sodium benzoate, a commonly used food additive with possible harmful effects. #FoodAdditives #SodiumBenzoate #HiddenDangers #FoodSafety #StayInformed https://www.smarteatinghabits.com/sodium-benzoate-e211-decoding-its-risks-and-exploring-clean-food-alternatives/

0 notes

Text

IM BEING BETRAYED BY CHOCOLATE

#cookie talks#THINGS STOP HAVING SODIUM BENZOATE IN THEM IMPOSSIBLE CHALLENGE#it's NATURALLY IN IT WHYYYYYYY

2 notes

·

View notes

Text

Global Sodium Benzoate Market: Key Drivers, Challenges, and Opportunities

Increasing Use as a Preservative in Food, Beverages, and Pharmaceuticals Fuels Growth in the Sodium Benzoate Market.

The Sodium Benzoate Market size was valued at USD 1.3 Billion in 2023. It is expected to grow to USD 2.3 Billion by 2032 and grow at a CAGR of 6.4% over the forecast period of 2024-2032.

The Sodium Benzoate Market is driven by its widespread use as a preservative in the food & beverage, pharmaceutical, and personal care industries. Sodium benzoate, a widely recognized antimicrobial agent, extends the shelf life of processed foods, carbonated drinks, and cosmetics by inhibiting the growth of bacteria, yeast, and fungi. Additionally, its applications in industrial sectors, such as plastics, paints, and lubricants, are further propelling market demand. With growing consumer awareness about food safety and increasing regulatory approvals for preservatives, the market is set for steady expansion.

Key Players:

DuPont de Nemours Inc.

Lanxess AG

PENTA CHEMICALS

Merck KGaA

Avantor Inc.

Foodchem International Corporation

Tulstar Products Inc.

Wuhan Youji Industries Co. Ltd.

Spectrum Chemicals

FBC Industries Inc.

Future Scope & Emerging Trends:

The future of the sodium benzoate market is shaped by rising consumer demand for packaged and processed foods, coupled with increasing regulatory scrutiny over food preservatives. With the clean-label trend gaining momentum, manufacturers are exploring alternative formulations and lower concentrations of sodium benzoate to maintain consumer trust while ensuring product safety. Additionally, the pharmaceutical industry is expanding its use of sodium benzoate in medications to enhance shelf stability. The growing adoption of eco-friendly and biodegradable preservatives is also influencing market dynamics. Asia-Pacific remains a key growth region due to the rising consumption of convenience foods, expanding pharmaceutical manufacturing, and increased regulatory approvals for sodium benzoate in food applications.

Key Points:

Increasing demand for sodium benzoate as a food and beverage preservative.

Expanding applications in pharmaceuticals, personal care, and industrial products.

Rising consumer preference for clean-label and natural preservatives.

Regulatory scrutiny driving innovation in formulation and application.

Asia-Pacific leading market growth due to urbanization and industrial expansion.

Conclusion:

With the global demand for food preservation, pharmaceuticals, and personal care products on the rise, the sodium benzoate market is set for continued growth. Companies focusing on regulatory compliance, innovative formulations, and sustainable alternatives will maintain a competitive edge in the evolving market landscape. As consumer awareness and industry regulations evolve, sodium benzoate will remain a key ingredient in ensuring product longevity and safety across multiple sectors.

Read Full Report: https://www.snsinsider.com/reports/sodium-benzoate-market-3705

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Sodium Benzoate Market#Sodium Benzoate Market Size#Sodium Benzoate Market Share#Sodium Benzoate Market Report#Sodium Benzoate Market Forecast

0 notes

Video

youtube

sodium benzoate, how it does work badly...

#youtube#Sodium benzoate common food preservative prevent growth bacteria yeast molds acidic foods beverages soft drinks salad dressings processed co

0 notes

Text

Sodium Benzoate: A Popular and Effective Food Additive

Sodium benzoate is a widely used food additive in the food industry due to its preservative and antimicrobial properties. This white crystalline powder is soluble in water and is commonly used to preserve acidic foods such as jams, juices, and soft drinks. In this article, we will explore the uses of sodium benzoate in the food additive industry and its potential health effects.

Uses in the Food Additive Industry

Sodium benzoate is used as a food preservative to prevent the growth of bacteria, yeasts, and fungi in acidic foods. It works by preventing the growth of microorganisms by interfering with their metabolic pathways. Sodium benzoate is particularly effective in acidic foods because it exists in its ionized form (benzoate ion) in acidic environments.

The benzoate ion can penetrate the cell walls of microorganisms and disrupt their internal pH balance, leading to their death. One of the primary uses of sodium benzoate in the food additive industry is in the preservation of fruit juices and soft drinks. These acidic beverages are prone to microbial spoilage and can quickly develop off-flavours and odours.

Sodium benzoate is added to these beverages to inhibit the growth of microorganisms and extend their shelf life. It is also commonly used in the preservation of jams, jellies, and other fruit products. These products have a high sugar content, which can act as a preservative on its own. However, the addition of sodium benzoate can enhance their shelf life and avoid the growth of bacteria and fungi.

In addition, sodium benzoate food preservative is also used as a flavour enhancer in certain foods. It can improve the taste of certain acidic foods, such as pickles and salad dressings, by reducing their sourness and bitterness. Sodium benzoate can also be used to mask unpleasant flavours in certain foods.

Why Finar Chemicals For Food Additives?

Finar Chemicals is a leading food additives manufacturer in India. With over three decades of industry experience, the company has emerged as a reliable source of high-quality additives for the food industry.

One of the reasons why Finar Chemicals is perfect for food additive manufacturing is its commitment to quality. The company has a state-of-the-art manufacturing facility that is equipped with modern technology and equipment. Additionally, they have a team of experienced professionals who ensure that all their products meet the highest standards of quality and safety.

Another reason why Finar Chemicals is perfect for food additive manufacturing is its focus on innovation. The company invests hugely in research and development to emerge with new and better ways of enhancing food products. They work in close proximity with their customers to understand their needs and develop customized solutions to meet those needs. This focus on innovation has helped them to stay ahead of the competition and remain significant in the ever-changing food industry.

If you want to lay your hands on a reliable supplier of high-quality food additives, look no further than Finar Chemicals!

0 notes

Text

correction from twitter, this would have been june 2009 as per NA console release.

blazblue calamity trigger x mana energy potion, aksys.

“not recommended for mortals under 12”

a collaboration between aksys and mana energy potion for the release of blazblue calamity trigger on american consoles. if purchased at retailer gamecrazy, you would receive this 50ml bottle in blazblue packaging as a purchase bonus.

most sources say mana energy potion contains 160mg of caffeine, which is almost 5x as much as monster energy. the ingredients are as follows:

- glucuronolactone, malic acid, DL-phenylalanine, L-taurine, N-acetyl-L-tyrosine, caffeine, amylase, lactase, cellulase, lipase, protease, purified water, glycerin, natural flavors, citric acid, xanthan gum, potassium sorbate (preservative), sodium benzoate (preservative), sucralose, ethyl malitol, FD&C blue 1

these are still floating around on ebay occasionally. please do not attempt to drink one.

16 notes

·

View notes

Text

FDA a criminal organization

In the late 1800s, food producers were selling adulterated products, and pharmaceutical companies peddled medicines with secret ingredients like opium and alcohol. Public outrage grew, especially after exposés like Upton Sinclair’s The Jungle,3 which helped spark the 1906 Pure Food and Drug Act.4 This law gave the Bureau of Chemistry the power to ensure accurate labeling and prevent harmful additives in food.

The director of the Bureau of Chemistry (and thus the first head of the FDA), Harvey Wiley5 conducted tests on food additives, proving they made healthy volunteers sick. While the public and many scientists supported his findings, the food industry fought back with powerful lobbyists and legal tactics.

Note: The additives Wiley scrutinized were boric acid and borax, salicylic acid (aspirin) and salicylates, benzoic acid and benzoates, sulfur dioxide and sulfites, formaldehyde, sulfate of copper (used to green produce), and saltpeter (nitrates).

Gradually, the food industry hijacked the presidency, and in 1912, Wiley resigned, realizing he could achieve more for America’s health as a private citizen than within the government.

Wiley’s book "The History of a Crime Against the Food Law"6 details much of the same abhorrent industry tactics we see happening now. For example, a series of investigative reports7 have recently shown that the processed food industry’s lobbyists are now working fervently behind the scenes to block RFK’s nomination and ability to Make America Healthy Again.

Those tactics also highlight a key point Wiley made — the only way to create change in this industry is to coax the public at large to demand it, as the moment you rely upon the members of the government to fix it, lobbyists will crush those efforts.

Generally Recognized as "Safe"

Many food additives are "generally recognized as safe" (GRAS), meaning they’re widely used without regulation. Wiley faced two major issues: food industry counterfeiting and harmful additives. The industry often faked products to cut costs, like selling grain alcohol as whiskey or using polluted waters to enlarge oysters.

Despite evidence of harm, the food industry claimed these additives were essential for production, even though competitors showed higher-quality products could be made without them. Wiley also warned that chronic exposure to additives could cause long-term health issues, such as organ damage and aging.

Sadly, his concerns were ignored as industry influence grew and he was unable to ban them. As a result, these "safe" additives have contributed to widespread chronic illness in society.

Note: Those additives included sodium benzoate,8 sulfur dioxide, alum (potassium aluminum sulfate), sulfur dioxide, saccharin, modified corn sugars, saccharin, and nitrogen bleached flour — many of which were linked to cancer.9 Sadly, since 2000, nearly 99% of new food chemicals added to the food supply chain have exploited the GRAS loophole.10

I believe the widespread use of aluminum in processed foods is particularly detrimental (due to it greatly impairing the physiologic zeta potential and causing micro-clotting throughout the body), and provides a key explanation for why you often see certain rapid improvements in individuals once they stop eating processed foods.

15 notes

·

View notes

Text

Sodium Benzoate Prices Trend | Pricing | Database | Index | News| Chart

Sodium Benzoate Prices have shown notable fluctuations in recent years, driven by various factors within the global chemical market. This compound, primarily used as a preservative in food and beverage industries, has experienced price shifts influenced by supply chain dynamics, regulatory changes, and market demand. In the past decade, the prices of sodium benzoate have demonstrated resilience amidst economic uncertainties, reflecting its integral role in food safety and preservation.

Market forces such as raw material costs, particularly the price of benzoic acid, a key precursor in sodium benzoate production, significantly impact its pricing. Fluctuations in benzoic acid prices, driven by factors like crude oil costs, availability of feedstocks, and geopolitical tensions, directly influence sodium benzoate's market value. Manufacturers and suppliers closely monitor these inputs to adjust production and pricing strategies accordingly.

Furthermore, regulatory developments play a crucial role in shaping sodium benzoate prices. Regulatory changes related to food safety standards and permissible limits of preservatives in consumer products can affect demand patterns and production costs. Compliance with evolving regulations often entails additional investments in technology and processes, influencing pricing dynamics across the supply chain.

Get Real Time Prices of Sodium Benzoate: https://www.chemanalyst.com/Pricing-data/sodium-benzoate-1185

Global market demand for processed and convenience foods has also been a pivotal factor in sodium benzoate pricing trends. As consumer preferences shift towards longer shelf-life products and convenience-driven consumption habits, the demand for preservatives like sodium benzoate has risen. This increased demand exerts upward pressure on prices, especially during periods of supply constraints or production disruptions.

Moreover, the geographical distribution of sodium benzoate production facilities contributes to pricing differentials. Regions with concentrated manufacturing hubs may experience localized price variations due to transportation costs, tariffs, and regional economic conditions. Supply chain resilience and logistical efficiencies play a critical role in mitigating these price differentials across global markets.

In recent years, environmental and sustainability considerations have also begun to influence sodium benzoate pricing. As industries strive to meet environmental regulations and consumer expectations for eco-friendly products, investments in sustainable production practices and raw material sourcing can impact production costs and, consequently, pricing strategies.

The competitive landscape among sodium benzoate manufacturers further shapes market dynamics. Pricing strategies vary based on production capacities, technological advancements, and differentiation in product offerings. Intense competition may drive manufacturers to optimize production efficiencies or explore new market segments to maintain competitive pricing while ensuring product quality and compliance with regulatory standards.

Looking ahead, the outlook for sodium benzoate prices remains subject to ongoing macroeconomic trends, regulatory developments, and shifts in consumer preferences. Market participants will continue to monitor global supply chains, raw material costs, and regulatory landscapes to anticipate and respond to pricing fluctuations effectively.

In conclusion, sodium benzoate prices are influenced by a complex interplay of factors including raw material costs, regulatory dynamics, market demand, geographical considerations, sustainability pressures, competitive forces, and global economic conditions. Understanding these dynamics is crucial for stakeholders across the supply chain to formulate resilient pricing strategies and navigate the evolving landscape of the sodium benzoate market.

Get Real Time Prices of Sodium Benzoate: https://www.chemanalyst.com/Pricing-data/sodium-benzoate-1185

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Sodium Benzoate#Sodium Benzoate Price#Sodium Benzoate Prices#Sodium Benzoate Pricing#Sodium Benzoate News#Sodium Benzoate Price Monitor

0 notes

Text

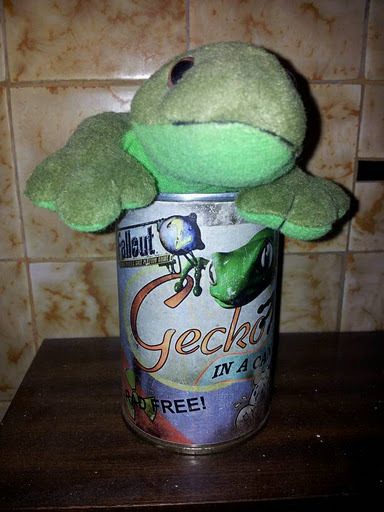

Pictured: A Gecko in a Can. This was a promotional item given away during the launch party for Fallout 2. Nutritional info printed on the can says there are 3.5 servings per can at 2 oz each. It can be served hot or cold, and for breakfast, lunch or dinner.

The ingredients listed on the can are: Water, Reconstituted, chopped, diced, minced, cooked Eublepharis Macularius (Gecko), including but not limited to; Gecko flanks, briskets, kidneys, hearts, livers, and brains; MSG, Propylene glycol, Sugar, Sodium benzoate, Potassium benzoate, Methyl4-hydroxybenzoate, Salt, Thiabendazole, Onion, Potassium nitrate, tert-Butylhydroquinone, Garlic, Tri-ammonium citrate, Sulfuric acid, Talc, FD&C Red no. 8, Potassium Bromate, artificial essences and flavorings.

You can read a transcript of the text on the can and see more pictures of it here: https://fallout.wiki/wiki/Fallout_2_marketing/Gecko_in_a_Can

139 notes

·

View notes

Text

Study on the storage stability of phycocyanin from Spirulina obtusususiae

Abstract: The effects of temperature, sunlight and different additives on the stability of aqueous solutions of phycocyanin were studied. It was concluded that phycocyanin should be stored at 40 ℃ and protected from light, and should be stored under neutral conditions; glucose, sodium chloride and sorbitol could effectively improve the stability of phycocyanin, and the pigment preservation rate of phycocyanin increased from 50.90% to 78.10%, 67.02% and 69.08% after 72 h at room temperature, respectively; the stabilizers of phycocyanin were compounded with glucose, sodium chloride and sorbitol in the mass ratio of 1 : 1 : 0.3 and left at 4 ℃ for 14 days. After adding glucose, sodium chloride and sorbitol as stabilizers in the mass ratio of 1:1:0.3, the pigment retention rate of the alginate was increased by 54.4% compared with that of the unadded alginate after being placed at 4 ℃ for 14 d. The pigment retention rate of the alginate added with the additive was increased by 16.1% compared with that of the unadded one after being placed at 25 ℃.

Spirulina (English name spirulina), also known as "spirulina", belongs to the family of Cyanobacteria, Chlamydomonas; at present, there are three types of large-scale cultivation at home and abroad, namely, Spirulina major, Spirulina obtususus and Spirulina indica. Spirulina obtususus is a blue-green seaweed (cyanobacteria) belonging to the Candida family.

It is a non-branched, multicellular spiral mycelium with a length of about 200 μm~300 μm and a width of about 5 μm~10 μm [1]. The amino acid composition of the proteins contained in Spirulina obtusususiformis is very uniform and reasonable, which suggests that it can be used as a potential health food for human beings [2].

Phycocyanin is one of the photosynthesizing proteins in the phycobilins, which are chromophore polypeptides consisting of α and β subunits with a molecular weight of about 20,000 daltons [3]. The phycobilisome in the cyanobacterium Spirulina obtususus is composed of an alpha and beta subunit in the center and a phycocyanin in the periphery. Phycocyanin is the most important bile protein in Spirulina, accounting for about 20 % of the dry weight [4-6]. It has a blue color in aqueous solution and fluoresces in purple. The UV-Vis spectra of phycocyanin in Spirulina obtusususiformis show characteristic absorption peaks at 278, 360 and 620 nm [7]. It has also been shown that the maximum absorption peak of L. obtususus is at 620 nm and its fluorescence emission peak at room temperature is at 645 nm [8].

Natural pigments are very rich in variety and are classified according to a variety of bases. According to solubility can be divided into fat-soluble pigments, water-soluble pigments; according to the source can be divided into animal pigments, microbial pigments and phytochromes; in order to classify the different chemical structures for anthocyanins, carotenoids and other five categories [9-10].

Alginin is a natural blue pigment with high application value. It has been shown to be anticancer[11-12] and can be used as a health food for patients with enteritis[13] . It is highly water-soluble and can be easily extracted from Spirulina. In the process of extraction and purification, the control of pH value and ionic strength is very crucial for the stability of algal blue protein. The discoloration and denaturation of phycocyanin is determined by the grade of protein polymers, and its polymer form is mainly affected by light intensity, light time, temperature, pH value, irradiation and protein concentration [14-17].

It has been studied that the higher concentration of sodium chloride can protect the stability of alginate, and the appropriate amount of sodium benzoate can protect the color and preservation of alginate to a certain extent [18-19], but the stability of alginate is still low. Therefore, on the basis of previous studies, this experiment was carried out to investigate the effects of different food-grade additives as well as glucose, sodium chloride and sorbitol additives on the stability of alginate.

1 Materials and Methods

1.1 Materials and Main Instruments

Spirulina obtususifolia powder: Inner Mongolia Wuxingzhao Ecological Industry Development Co.

FD-10 Freeze Dryer: Beijing DTY Technology Development Co., Ltd; 756PC UV Spectrophotometer: Tianjin Prius Instrument Co., Ltd; DK-98-II Electric Thermostatic Water Bath: Tianjin Taiste Instruments Co.

1.2 Extraction and purification of algal blue protein

1.2.1 Extraction of algal blue proteins[19]

Appropriate amount of spirulina powder was dissolved in distilled water according to the material-liquid ratio of 1:40 (mass ratio), and then stirred with a stirring rotor at a speed of 1,000 r/min for 1.5 h. It was frozen at -18 ℃, and then thawed rapidly in a 37 ℃ water bath for 24 h. After repeating this procedure for four times, it was centrifuged at a high speed for 10 min at 10,000 r/min, and the absorbance at 620 and 280 nm was measured after taking the supernatant and diluting it with appropriate multiplicity.

1.2.2 Purification of algal blue proteins[17]

Take the crude extract of algal blue protein with the concentration of 5 mg/mL, slowly add ammonium sulfate solid to the saturation degree of 40%, and at the same time, carry out magnetic stirring until complete dissolution, stand at 4 ℃ for 2 h, then centrifuged at 10 000 r/min for 15 min, collect the precipitate, dissolve it in an appropriate amount of distilled water, and then freeze-dried after dialysis and set aside.

1.3 Research on storage stability of algal blue protein

1.3.1 Effect of temperature on the stability of phycocyanin[19]

30 mg of alginate was dissolved in 30 mL of citrate phosphate buffer at pH 5.0, 6.0 and 7.0, and incubated in 6 temperature gradients (20, 30, 40, 50, 60 and 70 ℃) for 30 min. The absorbance was measured at 620 nm after appropriate dilution, and the pigment retention rate was calculated. The pigment retention rate was calculated according to equation (1):

Pigment retention rate/% = ×100 Equation (1)

1.3.2 Effect of daylight illumination on the stability of phycocyanin [19]

Two groups of 1 mg/mL aqueous phycocyanin solution were taken, one group was irradiated under a single light source (sunlight) and the other group was stored away from light, and then diluted appropriately after 12, 24, 36, 48, 60, and 72 hours, respectively, and the absorbance value was measured at 620 nm to compare the changes in the retention rate of phycocyanin pigments.

1.3.3 Effect of pH on the stability of algal blue protein

Take 0.1 g of alginate powder and dissolve it in 100 mL of citrate phosphate buffer with pH value of 5.0, 5.5, 6.0, 6.5 and 7.0 respectively, there are 5 groups in total, and take samples at 30 min intervals to dilute appropriately, and measure the absorbance value at the wavelength of 620 nm, and then compare the changes of the preservation rate of the alginate pigment.

1.3.4 Effect of food additives on the stability of algal cyanoproteins [20-21]

Take 100 mL of algal blue protein solution with a concentration of 1 mg/mL, and add the following additives in order according to the maximum additive amount of food additives stipulated in GB 2760-2011 Standard for the Use of Food Additives: glucose (5 g), sucrose (5 g), sodium chloride (5 g), sorbitol (0.003 g), sodium benzoate (0.000 2 g), ascorbic acid (0.002 g), and sodium benzoate (0.000 2 g), and the following additives are added to the solution. 0.002 g). After 24, 48 and 72 hours of exposure to sunlight at room temperature and appropriate dilution, the absorbance value at 620 nm was measured to compare the changes in the retention rate of phycocyanin pigments. The effects of different concentrations of glucose and sodium chloride on the stability of algal blue protein were measured according to the above method. Select appropriate concentrations of glucose, sodium chloride and sorbitol and add them into the aqueous solution of phaeocyanin, and carry out the test according to the above method to observe the change of pigment retention rate.

2 Results and analysis

2.1 Effect of temperature on the stability of phycocyanin

The effect of temperature on the stability of phycocyanin is shown in Fig. 1.

As can be seen from Fig. 1, the pigment retention rate of algal blue protein decreased with the increase of temperature when it was placed at different temperatures for 30 min. When the temperature was 20 ℃

The pigment retention rate of alginate stored at 40 ℃ was almost unchanged; the pigment retention rate of alginate stored at 50 ℃ and 60 ℃ decreased by 11.68% and 20.71%, respectively, compared with that of the initial one after 30 min, and the pigment retention rate of alginate stored at 70 ℃ showed the greatest decrease, which was 58.58% lower than that of the initial one.

High temperature will destroy the structure of algal blue protein and cause its denaturation, resulting in a decrease in the pigment retention rate of algal blue protein. It can be seen from the results that phycocyanin has the highest and most stable pigment retention rate between 20 ℃ and 40 ℃. Therefore, high temperature storage should be avoided below 40 ℃.

2.2 The effect of light on the stability of phycocyanin

The effect of sunlight illumination on the stability of phycocyanin is shown in Fig. 2.

As can be seen from Fig. 2, under the irradiation of room temperature and single sunlight source, the pigment retention rate of the algal blue protein solution decreased greatly from 48 h. At the same time, the color fading was obvious, and the color gradually changed from sapphire blue to light blue from 48 h, and became almost colorless and transparent at 60 h. The pigment retention rate decreased by 59.31% compared with that at 0 h, and the rate of the pigment retention rate was only 29.26% of the initial one at 72 h. The color retention rate of the solution decreased from 0 h to 60 h, and the color retention rate of the solution was only 29.26% of the original one at 72 h. After 72 h, the pigment retention rate was only 29.26%. The pigment retention rate of phycocyanin stored at room temperature under the condition of light protection was higher than that of sunlight, but the effect was not great, and the pigment retention rate of phycocyanin at 72 h was 13.51% higher than that of sunlight. It can be concluded that the sensitivity of phycocyanin to heat is greater than that to light, but light also has a certain effect on the pigment stability of phycocyanin. Therefore, phycocyanin should be stored under light-proof conditions.

2.3 Effect of pH value on the stability of algal blue protein

The effect of pH on the stability of phycocyanin is shown in Fig. 3.

Figure 3 shows that the pigment retention rate of phycocyanin solution at pH 5.0, 5.5, 6.0, 6.5 was small, and the pigment retention rate was kept in the range of 95.49%~102.19%; and it can be seen that the phycocyanin was the most stable and the highest pigment retention rate was found at pH 6.0. At pH 7.0, the pigment retention rate decreased greatly, from 100 % to 87.46 % gradually. This may be due to the fact that the alkaline condition damaged the structure of phycocyanin, so it should be preserved in neutral condition instead of alkaline condition.

2.4 Effect of additives on the stability of algal blue proteins

The effect of food additives on the stability of algal blue proteins is shown in Fig. 4.

Additive type

Fig. 4 Effect of food additives on the stability of algal blue proteins

Fig.4 The influence of food additives on stability of phycocyanin

Figure 4 shows that the retention rate of phycocyanin pigments in phycocyanin solutions with different additives increased and then decreased during 72 h of storage at room temperature under sunlight. This may be due to the incomplete dissolution of phycocyanin at the beginning. The highest pigment retention was observed in the alginate with glucose, sorbitol and ascorbic acid, which decreased from the initial 100 % to 78.10 %, 69.08 % and 67.24 %, respectively, which was significantly higher than that of the blank group (50.90 %). This may be attributed to the fact that the additives can protect the color of the algal blue protein and increase its pigment retention rate. However, the solution of phycocyanin with ascorbic acid produced a large amount of precipitation. Therefore, glucose, sodium chloride and sorbitol were selected for further study.

2.5 Effect of glucose concentration on the stability of algal blue proteins

The effect of glucose concentration on the stability of phycocyanin is shown in Fig. 5.

As shown in Fig. 5, the color retention rate of glucose-added phaeocyanin increased after 24 h, and then decreased with time. This may be due to the color protection effect of glucose on phycocyanin. The pigment retention rate of the alginate without glucose did not change much after 24 h at room temperature. When the concentration of glucose was 10 mg/mL, the absorbance value of phycocyanin increased greatly after 24 h, and the pigment retention rate of phycocyanin increased by 16.15%, which was 12.62% higher than that of phycocyanin without added glucose; the pigment retention rate of phycocyanin with added glucose at 10 mg/mL reached 78.09%, which was 27.19% higher than that of phycocyanin without glucose. After 72 h, the color retention rate of the solution with 10 mg/mL glucose reached 78.09%, which was 27.19% higher than that of the solution without glucose, and then the retention rate of alginate color tended to slow down as the concentration of glucose solution increased. Therefore, for the purpose of cost saving, 10 mg/mL of glucose was chosen for the next study.

2.6 Effect of sodium chloride concentration on the stability of algal blue proteins

The effect of NaCl concentration on the stability of algal blue protein is shown in Fig. 6.

Fig. 6 Effect of sodium chloride concentration on the stability of algal blue protein

As can be seen from Fig. 6, the pigment retention rate of the alginate without NaCl remained almost unchanged after 24 h, while the absorbance values of the alginate with NaCl increased, which was attributed to the protective effect of NaCl on the color of the alginate to inhibit the denaturation of the alginate. The color retention rate of the solution with 10 mg/mL NaCl was significantly higher than that of the blank group after 72 h, reaching 75.90%, and then leveled off. Therefore, in order to save the cost of the experiment, 10 mg/mL NaCl was chosen for the next study.

2.7 Effects of sorbitol, sodium chloride and glucose on the stability of phycocyanin

The effects of sorbitol, NaCl and glucose on the stability of phycocyanin are shown in Figure 7.

Figure 7 shows the complex color protection effect of the three additives on phycocyanin. The pigment retention rate of the alginate solutions increased to different degrees after 24 h at room temperature under sunlight, which was attributed to the color protection effect of the additives. In the blank group, the pigment content of the alginate solution remained almost unchanged after 24 h, and then decreased rapidly; the absorbance value of the alginate solution with the addition of sorbitol, dextrose and sodium chloride increased the most obviously, which was 41.29% higher than that at 0 h, and 38.38% higher than that of the alginate solution without the addition of the additives; and the color preservation was 23.01% higher than that of the blank group at 72 h. The effect of color preservation was very obvious. After 72 h, the color preservation rate was higher than that of the blank control group by 23.01%, and the color preservation effect was obvious. The stability of sorbitol-added phycocyanin was second, and its pigment preservation rate was 19.09% higher than that of the blank control group after 72 h at room temperature under sunlight. This is due to the compound effect of sorbitol, glucose and sodium chloride on alginate to play a good role in color protection and preservation, which is better than several other combinations of additives. Therefore, sorbitol, dextrose and sodium chloride can be added as compound stabilizers in alginate at a mass ratio of 1 : 1 : 0.3.

2.8 Effect of three additives on the stability of algal blue proteins

The initial pictures of phycocyanin (without additive) and phycocyanin (with additive) at (4±5)°C and (25±5)°C are shown in Fig. 8, and the pictures of phycocyanin (without additive) and phycocyanin (with additive) at (4±5)°C and (25±5)°C after 14 d are shown in Fig. 9, and the effects of three additives on the stability of phycocyanin are shown in Fig. 10.

Figures 8, 9 and 10 show the changes in pigment content of phycocyanin after the addition of glucose, sodium chloride and sorbitol as stabilizers for 14 d. The pigment retention rate of phycocyanin solutions decreased with the increase of storage days and varied under different conditions. The pigment retention of phycocyanin solutions decreased with the increase of storage days, and the pigment retention varied under different storage conditions. The most suitable storage condition for phycocyanin solution was 4 ℃ with preservative, and its pigment retention rate only decreased by 30.21% after 14 d of storage, which was 54.5% higher than that of phycocyanin stored at 4 ℃ without additive. However, the pigment retention rate of the unadditive alginate solution was almost zero after 14 d of storage at 25 ℃, with almost total loss of phycocyanin, and the pigment retention rate of the additive solution was 16.1% higher than that of the unadditive one. The pigment retention rate of the additive solution was significantly higher than that of the unadditive one at 25 ℃ and 4 ℃, which was attributed to the excellent color protection and anticorrosive effect of the three additives on the phycocyanin. This is due to the fact that the combination of the three additives has a good effect on the color protection and preservation of phycocyanin. Therefore, alginate is suitable for storage at low temperature with additives.

3 Conclusion

Differences in temperature, sunlight and pH all affect the storage stability of phycocyanin, with temperature having the most pronounced effect on the stability of phycocyanin and sunlight having a lesser effect on the stability of phycocyanin.

Appropriate concentrations of sorbitol, dextrose and sodium chloride can obviously protect the color of alginate and preserve it, and do not affect its properties. In this experiment, the three additives were added into the aqueous solution of phycocyanin, and it was found that they had obvious improvement effects on the storage stability of phycocyanin pigments. The compound additives added to phycocyanin can be widely used in food, cosmetics and other fields, and has high application value.

References:

[1] Hedenskog G, Hofsten A V. The Ultrastructure of Spirulina platensis -A New Source of Microbial Protein[J].Physiologia Plantarum, 1970, 23(1):209- 216

[2] Belay A, Ota Y, Miyakawa K, et al. Current knowledge on potential health benefits of Spirulina[J]. Journal of Applied Phycology, 1993, 5(2):235-241

[3] Serena Benedetti, Sara Rinalducci, Francesca Benvenuti, et al. Pu - rification and characterization of phycocyanin from the blue-green alga Aphanizomenon flos-aquae [J]. Journal of Chromatography B, 2006, 833(1):12-8

[4] Jaouen P, Lépine B, Rossignol N, et al. Clarification and concentra- tion with membrane technology of a phycocyanin solution extracted from Spirulina platensis[J]. Biochemical Society Transactions, 1999, 13(12):877-881

[5] Cohen Z. Spirulina platensis (Arthrospira), Physiology, Cell-Biology and Biotechnology [J]. Quarterly Review of Biology, 1997 (3):353 - 354

[6] Jespersen L, Stromdahl L D, Olsen K, et al. Heat and light stability of three natural blue colorants for use in confectionery and bever- ages[J]. European Food Research & Technology, 2005, 220 (3/4): 261-266

[7] Yin Gang, Li Chen. Separation and purification of algal bile proteins and polysaccharides from Spirulina and product characterization [J]. Fine Chemical Industry, 1999, 16(2):10-13

[8] PENG Weimin, SHANG Shutian, FU Youlan, et al. Studies on the nature of bile protein in Spirulina obtususus[J]. Journal of China Agricultural University, 1999, 4(C00):35-38

[9] Hui Qiusha. Research overview of natural pigments[J]. Northern Pharmacology, 2011, 8(5):3-4

[10] GUO Fenghua,WANG Hui . Research on the extraction and application of natural pigments[J]. Shandong Food Fermentation , 2007, 36(4):36-38

[11] Ch R,González R,Ledón N,et al. C-phycocyanin: a biliprotein with antioxidant, anti-inflammatory and neuroprotective effects[J]. Cur- rent Protein & Peptide Science, 2003, 4(3):207-216

[12] Eriksen N T. Production of phycocyanin--a pigment with applica - tions in biology, biotechnology, foods and medicine[J]. Applied Mi- crobiology & Biotechnology, 2008, 80(1):1-14

[13] Fretland D J, Djuric S W, Gaginella T S. Eicosanoids and inflamma DOI: 10.3969/j.issn.1005-6521.2017.12.008

#phycocyanin #Spirulinaobtusususiae #phycocyaninpowder

9 notes

·

View notes

Text

Drug Dealing Mod Report(Crafting Drugs, Rehab, and Laundering Dirty Money)

Another month has passed. which means I have been rather silent, but I haven't been idle. This month I have been working on features involving Crafting Drugs, Rehab, and introduced a Dirty Money/Laundering System. Which is what this report will go over.

Crafting Drugs

On my report last month, I showcased some harvestable plants. Which some of those ingredients obtained through the harverstable plants will be used to craft drugs. Those being Buds for White Widow, Purple Haze, Skunk, OG Kush, AK47, and Amnesia. As well as Opium and Coca Leaves.

[Producing Weed Baggies]

Everything you will need, 16 of a single weed strain, Empty Jar, and a Baggy.

In order to produce your very own weed baggies. You will first need to grow Cannabis plants and obtain 16 buds of a weed strain.

Upon obtaining 16 buds you will need to obtain a Empty Jar. While having the 16 buds of a strain in your inventory select the Empty Jar and choose a strain to cure.

In this case we chose to cure White Widow. The Empty jar will be removed and the White Widow Jar will appear in your inventory.

It will take any weed strain 24 hours to fully cure. Once it is cured you will be allowed to Collect the Cured Weed. So long as you have a baggy inside your inventory. Once collected you will receive a Weed Baggy. In this case we received a White Widow Baggy.

[Producing Molly/MDMA]

Everything you need to produce MDMA will be Painkillers, Hydrogen Peroxide, and either three Baggies or empty Pill Bottles.

After obtaining the necessary ingredients you will need to ensure that you have a Logic Skill level of 3. In which the option to produce Molly should appear on the Chemistry Table.

Upon selecting the Process Molly option your sim will go ahead and produce either 3 MDMA Baggies or 3 MDMA Pill Bottles.

[Producing Heroin]

The ingredients to produce Heroin will be 15 Opium and 5 Baggies.

After obtaining the necessary ingredients you will need to ensure that your sim has a Logic Skill level of 4. In Which the option to produce Heroin should appear on the Chemistry Table.

Upon Selecting Process Heroin option your sim will go ahead and utilize the Chemistry Table to produce 5 Heroin Baggies.

[Producing Meth Package]

The ingredients to produce a Meth Package will be Sodium Benzoate, Hydrochloric Acid, Hydrogen Peroxide, Toluene, and a Empty Meth Tray.

After obtaining the necessary ingredients you will need to ensure that you have a Logic Skill level of 5. In which the option to produce a Meth Tray should appear on the Chemistry Table.

Upon Selecting Process Meth Tray option, your sim will go ahead and utilize the Chemistry Table to produce a Meth Tray.

After producing the Meth Tray you will need to aquire a Empty Meth Bin. While the Meth Tray is in your inventory, select the empty Meth Bin and choose Pour Meth Tray

After pouring your Meth tray into the Empty Meth Bin, you will receive a Meth Bin. It will take up to two days for the Meth Package to be ready.

Once it is ready you will receive a Meth Package. The Meth package can be cut into 20 Meth Baggies to sell on the street or be kept as a package to be used to smuggle(Smuggling in the works).

[Producing Cocaine Brick]

The ingredients to produce a Cocaine Brick will be 11 Coca Leafs, Baking Soda, Powdered Milk, and a Empty Bowl.

After obtaining the necessary ingredients you will need to ensure that you have a Logic Skill level of 6. In which the option to process Coke Powder should appear on the Chemistry Table.

Upon Selecting Process Cocaine Powder option, your sim will go ahead and utilize the Chemistry Table to produce a Coke Bowl.

After producing the Coke Bowl you will need to aquire a Empty Cocaine Brick Press Container. While the Coke Bowl is in your inventory, select the Empty Cocaine Brick press Container and choose Pour Coke Powder.

After pouring the Coke Powder into the Empty Cocaine Brick Press Container, you will receive a Cocaine Brick press Container with Cocaine in it. It will take up to two days for the Cocaine Brick to be ready.

Once it is ready you will be able to collect. The Cocaine Brick can be cut into 20 Cocaine Baggies to sell on the street or be kept as a Brick to be used to smuggle(Smuggling in the works).

27 notes

·

View notes