#sewing thread manufacturing

Explore tagged Tumblr posts

Text

How to Start a Business with Yarn Twisting Machine

🎥 Want to spin yarn into a business? Here's your chance! 🧶 Discover the step-by-step guide to launching a small-scale yarn twisting business #yarntwisting #sewingthread #manufacturingbusinessideas #businessideas

In recent years, the textile and garment industry has witnessed exponential growth, making it an ideal landscape for aspiring entrepreneurs to venture into related businesses. One such lucrative avenue is the yarn twisting business. As far as yarn is concerned, it is made from two strands or more than two strands. We all know that sewing thread is used for sewing in needles and sewing machines.…

View On WordPress

#best business idea#how to start a yarn twisting business#how to start yarn twisting business#sewing thread business#sewing thread manufacturing#sewing thread reels making#sewing thread winding machine#sewing thread winding machines#thread reels winding#thread winding machine#yarn#yarn business#yarn reels making#yarn twisting#yarn twisting and doubling machine#yarn twisting business#yarn twisting making business#yarn twisting manufacturing business

0 notes

Text

why are we having fanmerch manufacturing discourse now

#man speaking as someone who has both ordered fanmerch for myself and who hand makes my fanmerch#this whole discourse seems like it's just punching at fanmerch artists because they're a target in range#rather than actually trying to have conversations about manufacturing and systems of production#like to warp a phrase from a post on here it feels like someone's trying to solve fast fashion by getting rid of all clothes#+ frankly going for purely handmade homemade stuff ain't a grand magic solution either#because that's just kicking the manufacturing and production problems down a step to the materials used to make the product#like me sewing and assembling my plush dolls myself ain't magically inherently more ethical#because the felt and thread and stuffing and so on i use is Also gonna be made in chinese factories#this ain't to say people shouldn't research chinese labor laws and factories#or that they shouldn't try to look into alternatives or cook up ethical ways of manufacturing stuff#it's more just i don't think it's helpful to punch on fanmerch artists about it#specifically BECAUSE these problems are just so much bigger than fanmerch production#i do think also it'd be helpful for like. for someone to actually Talk To some workers at these factories.#like that just feels like a critical POV to have in this conversation

3 notes

·

View notes

Text

i need to create/do something with my own hands regularly or else i go a bit crazy

#i'm gonna sew the snaps to my coat once i finish going thru my dash#they're about to fall off because the manufacturers really don't want to spend an extra cent on more thread to keep them in place securely#huh

4 notes

·

View notes

Text

Sewing Thread Lubricant Manufacturer India | 9041070303

Fabric strength is derived from its thread, and the strength of the thread hinges on the quality of its lubricant. Chemical Brothers is the preferred choice for thread lubricants, earning us the reputation as the best sewing thread lubricant manufacturers in India. We are premium suppliers of various chemicals related to the cosmetic and textile industries, including pre-treatment chemicals, printing auxiliaries, dyeing auxiliaries, and more. Our extensive range of sewing thread lubricants is widely distributed across India and internationally. Sewing Thread Lubricant Manufacturer India

Silicon-Based Thread Lubricant

Silicon-based thread lubricants offer exceptionally low friction for both spun cotton and polyester threads. They are cost-effective and durable compared to other lubricants. These lubricants enhance the surface slip and heat resistance of sewing threads, allowing them to be quickly wound into cones and wrapped without microbial activity. Consistent results in various textile industries have made silicone-based sewing thread lubricants a preferred choice. Chemical Brothers consistently ranks at the top of the list of sewing thread lubricant manufacturers in India.

Features of Silicon-Based Thread Lubricant:

Reduces the coefficient of friction on the thread.

Excellent heat stability.

Uniform pick-up over the thread surface.

Great abrasion resistance.

Ideal for high-speed sewing lines.

Suitable for use on colored items.

Reduces hairiness and improves gloss.

Requires minimal cleaning when applied with high-speed winders.

More cost-efficient and productive than other lubricants.

Industrial-Ready Sewing Thread Lubricants

Sewing thread lubricants are essential raw materials for thread manufacturers. Our lubricants are unmatched in quality, providing an ultra-smooth finished surface to fabrics. We are known for:

Timely delivery

Excellent customer support

Advanced manufacturing technologies

High color yield with minimal dye quantity

Smooth and adhesive auxiliaries

Superior dispersive quality

Quality-tested and approved products

Customizable volumes and bulk delivery

High-quality chemicals for various home and personal care industries

Beyond thread lubricants, we offer specialized synthetic chemicals, coloring assistants, and raw materials for cosmetics. We also provide a wide range of textile printing inks, coloring auxiliaries, and finishing agents. Our products enhance the appearance and durability of textiles and are suitable for all types of sewing threads. With extensive experience, we understand the needs of Indian textile manufacturers and tailor our products accordingly.

Why Choose Chemical Brothers?

As a trusted name in the industry, we are committed to providing quality thread lubricants and other chemical products at affordable prices. Our dedication to excellence and customer satisfaction has established us as esteemed sewing thread lubricant manufacturers in India. For any chemical requirements, feel free to contact us or visit our website to ensure you receive the best raw materials.

Experience the superior quality and reliability of Chemical Brothers for all your sewing thread lubricant needs.

#Sewing Thread Lubricant Manufacturer India#Sewing Thread Lubricant Manufacturers India#Sewing Thread Lubricant Manufacturer#Sewing Thread Lubricant

0 notes

Text

Coats Sets a New Standard with Gral EcoVerde AS for Apparel: Neat seam appearance for apparel sewing thread.

India, 9th August ’23: Coats, a prominent figure in thread and textile manufacturing on a global scale, is delighted to introduce the groundbreaking product Gral EcoVerde AS. Gral EcoVerde AS for Apparel is made from 100% recycled polyester and features low friction lubrication, excellent loop formation, and consistent stitch formation. These properties combine to produce a smooth, even seam that is both visually appealing and durable.

The low friction lubrication in Gral EcoVerde AS for Apparel helps to reduce the friction between the thread and the needle, which helps to prevent the thread from fraying or breaking. This results in a smooth, even seam that is less likely to unravel.

Gral EcoVerde AS for Apparel represents a breakthrough in sustainable threads for apparel manufacturing. It is designed to minimise environmental impact while upholding the highest quality standards. The thread is crafted using eco-friendly materials and processes, ensuring reduced water consumption, a lower carbon footprint, and decreased energy usage.

GRAL Ecoverde AS maintains the exceptional quality and reliability that Coats is renowned for. It is well-suited for diverse applications, including apparel sewing, offering consistent stitching and durability. Brands and manufacturers can seamlessly infuse sustainability into their products while leveraging the expertise and reputation of Coats.

Coats is committed to providing customers with sustainable sewing thread solutions. The thread exemplifies the company's ongoing commitment to advancing environmental practices, ensuring a more sustainable and responsible future for the textile sector. The company believe that this thread will help apparel manufacturers reduce their environmental impact and improve the quality of their products. To learn more about GRAL Ecoverde AS and its sustainable benefits, please visit the website’s product page. https://www.coats.com/en/products/threads/gral/gral-ecoverde-as-for-apparel

About the Author:

Coats is the world’s leading industrial thread company. They are headquartered in the UK, with a workforce of 17,000 in 50 countries across six continents around the world. Coats provide complementary and value-adding products, services and software solutions to the Apparel & Footwear industries. Coats apply innovative techniques to develop high technology Performance Materials threads, yarns and fabrics in areas such as Transportation, Telecoms and Energy, and Personal Protection.

0 notes

Text

"Smallclothes"

I just reblogged a very interesting thread about historical inaccuracy in A Song of Ice and Fire, but it was doing a whole big picture thing and I didn't want to clog it up with one very small detail that just really specifically bothers me.

It's his use of the term "smallclothes." Basically, in ASOIAF smallclothes = panties/knickers.

Daario found his breeches and pulled them on. He did not trouble himself with smallclothes.

Jon’s anger flared. “No, my lord, I mean to set them to sewing lacy smallclothes."

“... before Lord Snow wets his smallclothes.”

"he looked like he was going to shit his smallclothes"

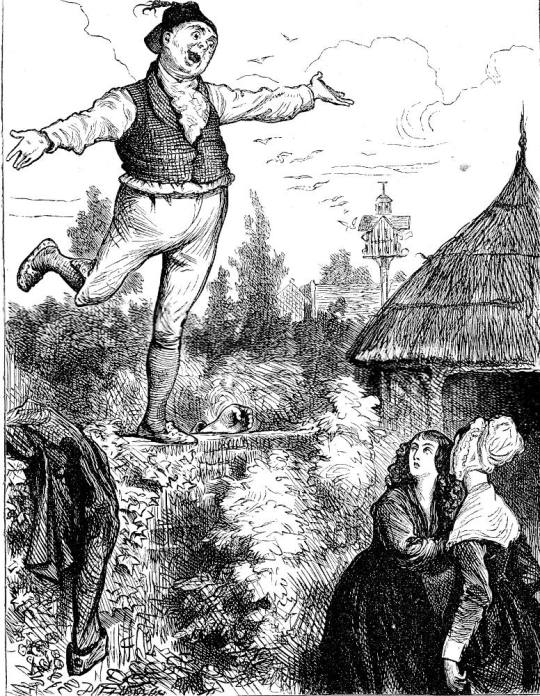

So okay. 'smallclothes' or 'small-clothes' is a historical term (from the 1700s) that means... underlayer. Here's it being used by Charles Dickens:

“Will you run over, once again, what the boy said?” asks Mr. Tulkinghorn, putting his hands into the pockets of his rusty smallclothes and leaning quietly back in his chair."

The idea being that he's casual/doesn't care and isn't bothering to dress up for his guest. not that he's in his undies. Here is a illustration from Nicholas Nickleby of a suitor who has inappropriately "displayed his small-clothes"

I've heard "smallclothes" refer to things like pocket-handkerchiefs, and anecdotally it's sometimes used to refer to knickers in linguistically stubborn places like Yorkshire, but that just is not how the word was used historically.

so okay. fine. It's a fantasy story, he's just made up his own word that means "panties."

Except NO. They straight up did not wear panties in the middle ages and renaissance. Sometimes you got loose under-breeches with a split crotch BUT - in general that long white shirt/chemise just WAS your undergarment. Think of how much easier it is to manufacture! And clean! Boxer brief type things weren't a thing until the 1900s, and modern-ish woman's panties ("step-ins") weren't a thing until the 20s, because the hemlines stopped working with pantalettes and bloomers. There are no "lacy smallclothes" like there is lacy lingerie. That only makes sense if you have industrialized clothing manufacturing!

Honestly I would have thought GRRM would be all over this, like it's kinda sexy that it's just thigh-high stocking or leggings underneath those big dresses, right? But he hasn't done that. Instead he's just ported in a modern article of clothing and gave it an old-timey name. Just a little hint that he hasn't actually properly got his head around how these clothes were made and used, and that devalues them.

And it's escaped containment! It's canon in Dragon Age, and in fanfiction I'm seeing "smallclothes" or "smalls" used to describe the underwear in in Our Flag Means Death, the Lord of the Rings, the Witcher. Just have nothing! None of these people should be wearing panties!!!!

410 notes

·

View notes

Text

sfw

Just thinking about Ghost and a crafty s/o.

Like his masks are so obviously made by him and not mass manufactured by some Halloween store. What if he is on leave or at a craft store near base? Staring at a variety of different thread and needles and fabric…... it’s just so much for his little brain. Doesn’t know what’s the best or durable for his type of work. Has done it before, just not well enough to last long or well in the field. Tired of getting poked at by Soap for the little shitty sewing kit he keeps with him.

Lucky for him, you’re around the corner. Bubbly little thing dressed completely opposite of him, all rainbows and sparkly shit (anything with color is to this man. smh). You’re eyeing some multicolored embroidery floss for your latest cross stitch and happen to glance over at Ghost, with his personalized mask and black ensemble. Looming over you as you skitter around him like a lost kitten.

You peer at the variety of options with familiarity, moving to grab your chosen colors with grace. Ghost just watches as you peer out of the corner of your eye to see whether he’ll move to get his own. He doesn’t.

When you’re done, he hasn’t moved. You have what you need, but you’re unnerved by a massive man who has just stared at you. Quickly, you mutter something like “do you need some help?”

Ghost just stares, as you fidget and look anywhere but him. He thinks it’s endearing.

You move away from him just as he gives a little huff as confirmation, and motions with his hand to the display. You glance up at him.

“what color do you want?” begins a stilted conversation on recommendations for sewing or embroidery or whatever else Ghost’s little heart desires. By the end of it, he has two packs of sewing and embroidery needles (if only he actually knew the difference) and a good variety of different types of black thread.

He’s followed you to the register as you dump all your stuff out and listens to you ramble about a new cross stitch. He sets his stuff beside yours and grabs your wrist as you go to pay for your things, sliding the cash across the counter to pay for your things.

Ghost looks over you contemplatively. Please, doll, you’ve given him enough interaction to play with for a few months. Let him do this for you. Of course, he only stares at you until you realize how futile this battle is.

Considerate little bird you are, thanking him as he carries your separate bags outside. A little hum of consideration as he follows you, tsking when you reach for your stuff. Don’t you understand he’s a feral dog coming home for the first time?

Follows you to your door, listening to your idle chirps and nodding in confirmation or denial to your questions to him. Asks for his name when he gets you home. An odd crawl up his spine and a softly spoken “Simon” are his way of vows. Gets your number for future endeavors in the craft aisle before creeping back outside.

Sits on his bed later with the little needle and thread, mending a mask. Yeah. He’s keeping you.

#ghost headcanons#simon ghost riley#simon riley x reader#simon riley x you#your honor i love him#simon riley#sfw headcanons#simon ghost riley x reader#ghost x reader#simon ghost riley x you#call of duty modern warfare 2

207 notes

·

View notes

Text

"Growing flax to make linen was one of the oldest human activities in Europe, particularly in the Rhineland. Archeologists have found linen textiles among the settlements of Neolithic cultivators along the shores of Lake Neuchâtel in the Jura Mountains west of Bern, Switzerland. These were elaborate pieces: Stone Age clothmakers of the Swiss lakeshores sewed pierced fruit pits in a careful line into a fabric with woven stripes. The culture spread down the Rhine and into the lowland regions.

The Roman author Pliny observed in the first century AD that German women wove and wore linen sheets. By the ninth century flax had spread through Germany. By the sixteenth century, flax was produced in many parts of Europe, but the corridor from western Switzerland to the mouth of the Rhine contained the oldest region of large-scale commercial flax and linen production. In the late Middle Ages the linen of Germany was sold nearly everywhere in Europe, and Germany produced more linen than any other region in the world.

At this juncture, linen weavers became victims of an odd prejudice. “Better skinner than linen weaver,” ran one cryptic medieval German taunt. Another macabre popular saying had it that linen weavers were worse than those who “carried the ladders to the gallows.” The reason why linen weavers were slandered in this way, historians suspect, was that although linen weavers had professionalized and organized themselves into guilds, they had been unable to prevent homemade linen from getting onto the market. Guilds appeared across Europe between the twelfth and fifteenth centuries but many of the items they produced for exchange, like textiles and soap, were also produced at home right up through the nineteenth century. The intricate regulations of the guilds—determining who could join, how they would be trained, what goods they would produce, and how these could be exchanged—were mainly designed to distinguish guild work from this homely labor. That linen making continued to be carried out inside of households—a liability for guilds in general—lent a taint to the linen guild in particular.

In the seventeenth century, guilds came under pressure from a new, protocapitalist mode of production. Looking for cheaper cloth to sell on foreign markets, entrepreneurs cased the Central European countryside offering to pay cash to home producers for goods. Rural households became export manufacturing centers and a major source of competition with the guilds. These producers could undercut the prices of urban craftsmen because they could use the unregulated labor of their family members, and because their own agricultural production allowed them to sell their goods for less than their subsistence costs.

The uneasiness between guild and household production in the countryside erupted into open hostility. In the 1620s, linen guildsmen marched on villages, attacking competitors, and burning their looms. In February 1627 Zittau guild masters smashed looms and seized the yarn of home weavers in the villages of Oderwitz, Olbersdorf, and Herwigsdorf.

Guilds had long worked to keep homemade products from getting on the market. In their death throes, they hit upon a new and potent weapon: gender. Although women in medieval Europe wove at home for domestic consumption, many had also been guild artisans. Women were freely admitted as masters into

the earliest medieval guilds, and statutes from Silesia and the Oberlausitz show that women were master weavers. Thirteenth-century Paris had eighty mixed craft guilds of men and women and fifteen female-dominated guilds for such trades as gold thread, yarn, silk, and dress manufacturing. Up until the mid-seventeenth century, guilds had belittled home production because it was unregulated, nonprofessional, and competitive. In the mid-seventeenth century this work was identified as women’s work, and guildsmen unable to compete against cheaper household production tried to eject women from the market entirely. Single women were barred from independent participation in the guilds. Women were restricted to working as domestic servants, farmhands, spinners, knitters, embroiderers, hawkers, wet nurses. They lost ground even where the jobs had been traditionally their own, such as ale brewing and midwifery, by the end of the seventeenth century.

The wholesale ejection of women from the market during this period was achieved not only through guild statute, but through legal, literary, and cultural means. Throughout the sixteenth and seventeenth centuries women lost the legal right to conduct economic activity as femes soles. In France they were declared legal “imbeciles,” and lost the right to make contracts or represent themselves in court. In Italy, they began to appear in court less frequently to denounce abuses against them. In Germany, when middle-class women were widowed it became customary to appoint a tutor to manage their affairs. As the medieval historian Martha Howell writes, “Comedies and satires of this period…often portrayed market women and trades women as shrews, with characterizations that not only ridiculed or scolded them for taking on roles in market production but frequently even charged them with sexual aggression.” This was a period rich in literature about the correction of errant women: Shakespeare’s The Taming of the Shrew (1590–94), John Ford’s ’Tis Pity She’s a Whore (1629–33), Joseph Swetnam’s “The Araignment of Lewde, Idle, Froward, and Unconstant Women” (1615). Meanwhile, Protestant reformers and Counter-Reformation Catholics established doctrinally that women were inherently inferior to men.

This period, called the European Age of Reason, successfully banished women from the market and transformed them into the sweet and passive beings that emerged in Victorian literature. Women accused of being scolds were paraded in the streets wearing a new device called a “branks,” an iron muzzle that depressed the tongue. Prostitutes were subjected to fake drowning, whipped, and caged. Women convicted of adultery were sentenced to capital punishment.

As a cultural project, this was not merely recreational sadism. Rather, it was an ideological achievement that would have lasting and massive economic consequences. Political philosopher Silvia Federici has argued this expulsion was an intervention so massive, it ought to be included as one of a triptych of violent seizures, along with the Enclosure Acts and imperialism, that allowed capitalism to launch itself.

Part of why women resisted enclosure so fiercely was because they had the most to lose. The end of subsistence meant that households needed to rely on money rather than the production of agricultural goods like cloth, and women had successfully been excluded from ways to earn. As labor historian Alice Kessler-Harris has argued, “In pre-industrial societies, nearly everybody worked, and almost nobody worked for wages.” During the sixteenth and seventeenth centuries, monetary relations began to dominate economic life in Europe. Barred from most wage work just as the wage became essential, women were shunted into a position of chronic poverty and financial dependence. This was the dominant socioeconomic reality when the first modern factory, a cotton-spinning mill, opened in 1771 in Derbyshire, England, an event destined to upend still further the pattern of daily life."

- Sofi Thanhauser, Worn: A People's History of Clothing

#radical feminism#feminism#linen#history of clothing#sexism#female oppression#the rights they TOOK from us#i'm so pissed#i knew there would be misogyny in history of clothing#but this made my blood burn#Sofi Thanhauser

98 notes

·

View notes

Note

hey maya! i’m a big fan of your stuff and i have a growing collection of skirts and some pins of yours ^^ i was just wondering, the first skirt i have from you is a cotton blend, (the peony print) and all the others i’ve bought since then are synthetic. i really much preferred the cotton, even with some pilling after wear (though that’s likely on me for not following the wash instructions-) though the synthetic fabric is much lighter when i put things in the pockets the waistband droops, which is kind of disappointing.. anyway, tl;dr, i know you switched manufacturers, but why material?

i’m glad you like my work!

as i said this morning, the old manu skirts were a polyester jersey. this did mimic cotton jersey to a certain extent, but it was always polyester and this was always listed clearly on our store (pretending it was cotton would actually be illegal if we had done that).

you can also read that post to see why we made the switch.

additionally, different manufacturers have different materials they will and won’t work with based on their access and their standards. there are a lot of fabrics our factory won’t work with for either reason. for example, they refuse point blank to make or work with jeans material because it is so bad for the environment.

for your future edification, in general, if you see a garment that is made by a small business and uses that large amount of custom printed fabric and is priced at $50-60 and is claiming to be cotton, in all likelihood they are either lying about the material, they are using suspiciously cheap labor, they are taking an incredibly thin profit margin that isn’t sustainable for most businesses, or the material may contain harmful substances like lead or pfas in order to drive the price point down.

custom printed cotton made with ethical labor is incredibly expensive and custom printing is necessary to achieve our more unique hem design patterns. repeating patterns can be roll printed and this is cheaper but has a higher minimum order requirement and tbh i would still recommend using your best judgement to see where money has been saved in the production process:

does the garment use less fabric or fewer stitches?

are there raw hems?

if you pull on one thread in a seam, does the whole seam unravel?

does it have stretch material, which is harder to sew but fits more bodies, therefor requiring fewer returns?

does the garment require few or no specialty sewing techniques, like sewing elastic or buttons or gussets or darts? (these drive price up a LOT)

was the garment made in china, which does not require the business to pay the same import tariffs that are charged on garments imported from other countries?

does the manufacturer have any certifications for ethical labor, environmental impact, or quality/non-harmful materials?

all of these have a significant impact on a garment’s price

as for the skirt being a bit loose, i recommend using waist tighteners like these if you want a snugger fit.

anyway i’ve answered this question and ones similar to it many times in the past and we have specifically answered this like 3 times in the past 2 days, so this question can take a break—if not forever, then for a significant portion of time. hope this clears up some things for you!

37 notes

·

View notes

Note

Ok but I would love to hear about your tailoring? That’s amazing, speak to me of the soutache! Do you have opinions on thimbles?!

Sorry for taking so long to reply. But I just finished the first sample (of two) of what I will be sewing during my journeyman exam in June and am really excited about that, so now seems like a fitting occasion since it's the source of my soutache themed dreams (thankfully not yet nightmares, but I have been dreaming an awful lot about sewing and class). Prepare for a barely filtered infodump. Here, the finished sample:

(The buttons are temporary, I just didn't have anything else. I am either going with black ones or do fabric covered buttons myself. I also hate how I ended the soutache on the back of the yoke. It should continue into the seam of the zipper so it's continuous. I don't know what I was thinking with ending it abruptly.)

Opinions on thimbles... Use them! I didn't until I started my apprenticeship and I've been converted. I don't have the typical metal cone ones but this one by Prym, I don't find the other ones comfortable. But Clover has an interesting metal one I'd like to try, partially because it makes me think of medieval armour. Leather thimbles also seem to me popular because they aren't that rigid and can be made yourself. And did you know sashiko thimbles are a thing? They cover the part below the middle finger since the motion during stitching is quite different and the fabric is gathered onto the needle which is then pushed by your palm and not just your finger. Now onto the soutache. If you don't know what it is: it's a braid made out of threads that are woven and braided around two cords.

Nowadays made out of synthetic filaments (viscose, polyester) but I've also found a German manufacturer of cotton and linen soutache. For the journeyman exam we need to make a combination of skirt, dress or trousers and coat or blazer. Skirt and blazer is what most do and is what requires less time. We have five days (40 hours) during which we have to do all the sewing and also cutting out fabric for the lining, so everything that's done after the first fitting. And part of that is a decorative element of our own choosing, which needs to fill 8 hours. It can be embroidery, appliqué pleats, ruffles, beading, rouleaux trim, pleating and so on. Stupid me decided to do soutache. Because I've wanted to try it for years and been admiring it on garments from second half of the 19th and early 20th century during which it was really popular. Nowadays it can be most often found on uniforms and costumes.

This is my inspiration:

Actually buying soutache, good quality soutache, is the first hurdle. I've gathered a wide arrange of braid from all over but not all is suitable to my needs. I wouldn't have thought before but the braid needs to be rather firm for a nice, even result without turning out wonky, especially with curved lines. Of which I have many. Sewing braid on fabric sounds deceivingly easy. And in theory it is, but getting it just right (especially with something that requires symmetry) is a headache. And a lot of it already comes down to how you transfer the pattern onto your fabric. One way is to trace the pattern on thin, to pin it to your fabric and then to sew along the traced lines. Tear away the paper and you're left with a pattern of stitches to follow.

But placing that paper just right, especially across seams that are not forgiving when it comes to symmetry. The paper slips and especially the curved lines are super difficult to sew along and turns out wonky more often than I'd like. It's easier to follow the curves when applying the soutache actually, I have more control. I used this method for the soutache on the back of the jacket and while I am happy with it, even if it isn't perfect, I doubt it would suffice for my exam. I am going to go with a smaller design and also one where the bows only go across one seam. Knowing this, I chose a fusible interfacing for the skirt yoke that I could draw on, much easier, and much more accurate even if the braid itself isn't always even in the end. Not done by a machine after all.

wrong side of the yoke, the blue is water soluble pen, and then one line of stitching to transfer the pattern to the right side and one of applying the braid

There are presser feet for applying braid but while they help with not having to hold the braid, the foot itself covers the lines I want to follow. Great for relatively straight lines but not an option for the bows. There is an attachment called an underbraider that was made for old domestic machines. They allow you to sew with the wrong side facing up while the braid is attached to the right side. But I haven't been able to figure out what it's called in German and if I can buy one somewhere. But I do have an antique singer it could be used with. For the details around the slits in the sleeves I've tried yet another method and shaped the bows beforehand and then basted them onto the fabric. It's good for such small designs, and especially that specific area because of the challenges the seam allowances and the underside of the slit presents, which can't be caught in the stitching and the stitching has to be hidden by the lining later on. Still a bit trial and error.

An issue with this particular soutache braid is that the cords at its core don't match the outside, they are white! And sometimes they show, which is rather unsightly. So not an option for my exam.

The one that's perfect in terms of firmness and actually has the the same coloured cords (the yellowish one above) is no longer being produced and the remaining colours don't fit my fabric.

I bought enough fabric for two suits out of the blue and one out of the red and wanted to use the blue fabric for my exam but given the soutache braid issues, I am considering going with red fabric and blue soutache (if I have enough meters, I need to measure). I think that combination is lovely.

I am also considering going with a different skirt pattern. I like it by itself but not as an ensemble. It's too flowy due to the bias cut and doesn't go well with the firmer lines of the blazer, I think. But given the poofy sleeves, I think the skirt has to be flared or be much shorter, a mini skirt, and close fitting. And as it is, the jacket covers the top of the design on the yoke. But that's why it's the first sample of two I am going to sew before the final exam. Also, let me take the opportunity to show off the rather neat buttonholes I stitched today.

Also, while I am already rambling about my sewing: I love sewing by hand and I especially love slip stitching (and I am really good at it). I'd happily be the person always doing the slip stitching for everyone. We have the option of inserting the entire jacket lining by hand or just do the sleeve and jacket hems by hand and attach the lining to the facing by machine. I hope I can make it work time wise and do it by hand.

And tagging @whirling-ghost because you are always on the receiving end of my sewing related rambles (and plenty of the other ones too and have been for years). You're the best! <3

#idk is this the kind of talking abotu my tailoring that's interesting to you? 🙈#i've definitely spoke of the soutache to you :D but i don't know what anything of this says to anybody else who hasn't been thinking about#this obsessively for months#everyone seems to have picked an easier decorative element#our instructors keep an eye on who they think can handle what and they haven't told me not to. so i am good (for now) :D#but i wouldn't recommend it.#but i also couldn't find any other inspiration and i really really love soutache.#and I'd been admiring the extant garment from the met for ages#and it's fun! it's a challenge and all of the above is still practice but i still love how it turned out#and if it were for a personal project i'd be very satisfied even with the wonky bits#i need to ger ready for sleep and i don't have time to proof read. once i start i won't stop but also all mistakes will haunt me#i hope it isn't too bad.#meins#mightymightygnomepriest

9 notes

·

View notes

Text

HUgE Oct 2010

COMME des GARÇONS HOMME DEUX

JACKET

A new revolution in Japan-made wardrobes

Launched in 1987, COMME des GARÇONS HOM ME DEUX is a line that has been running for over 20 years as the COMME des GARÇONS suit brand. The brand continues to insist on Made in Japan, producing fabrics in weaving factories such as Ichinomiya in Aichi Prefecture, known among the world's top designers as a hidden gem for material development, and sewing together high-quality materials at sewing factories run by traditional craftsmen to create their suits. The brand has always rejected eccentricity and stuck to a timeless, standard suit style, but now it has infused a new identity with this addition. In addition to its lineup of suits that have traditionally focused on materials, the brand has added a casual look.

New items such as jackets, pants, shirts, and knitwear that can be worn as single items to incorporate a more casual look have been added, showing the breadth and options of how to wear them. There is a sense of new possibilities for the traditional suit style based on the theme of "Japanese suits."

The jacket introduced here is made of high-quality wool herringbone tweed, carefully selected down to the last thread, and has been washed. It is finished lightly with a single layer of unlined lapped fabric. It has a boxy silhouette with three buttons and a lapel, and is modest and casually cool, with just the right amount of tension. The sleeve cuffs have a modified single button opening, and the carefully crafted details reveal the jacket's perfection.

We would like to keep an eye on the future of these clothes that allow you to experience the world-class quality that Japan is proud of, with a focus on authentic clothing manufacturing.

(COMME des GARÇONS HOMME DEUX jacket ¥57,750 (COMME des GARÇONS)

7 notes

·

View notes

Text

as for how i get my patches; i made/make (havent made any in a while) all of them myself using a 6 needle embroidery machine. more needles = more concurrent colors the machine can easily swap through during the patch production. i bought special embroidery software that came with video guides after attending a workshop with the software developer and trying to use free open source embroidery software. the process is essentially the same as making vector art but with more attention paid to layering and then tooling around with things like fabric, thread, and types of stitches. i had experience with hand embroidery and also with hand sewing / using sewing machines and my partner at the time and i were very interested in the idea of making elaborate embroidery. it is in many ways similar in concept / process to screen printing which i have ample experience in, so it did not take me long to pick up and i had all the tools / access i needed to do lots of easy and fun designs. i was able to buy the machine by splitting the cost with someone else and using money i had gotten from my printing business/savings. i honestly recommend not buying a machine (even a small one) and instead out sourcing any embroidery you would want to local digitizers/embroidery companies if you want to do any machine embroidery slightly more complicated than one color directly onto a garment. it takes a long time, it’s very loud, the software required is expensive and nearly impossible to pirate (low demand), and the cost / time investment is very steep. however, i am a freak, and i also consider this my job (or part of it), so i have enjoyed it. there are a lot of people in your town or city, no matter where u are, who are already much more capable and set up to make patches for you than you would be. and they also would love to do it and it’s probably way cheaper than u think. (this also goes for screen printing). the one singular advantage to my set up is that i can make a lot of extremely singular one off patches at my own pace and at my own justified labor/time/monetary investment without having to communicate with anybody else. which is why i primarily think of myself as a artist and not necessarily a clothing embellisher/manufacturer; everything i do takes a lot of fucking time and research.

21 notes

·

View notes

Text

Letters from Watson: Silver Blaze

Part 2, the fun bits:

The "fading ferns" are probably why Baring-Gould places this story in early fall, AKA late September.

Holmes has clearly come upon a clue in his abstraction in the carriage, and Watson both notices immediately and is the person who brings him back to the business at hand. It's the little things that are cute, you know?

The (coroner's) inquest being, by my count, four days after death is a great way to find absolutely nothing, especially when the body is being stored in a presumably well-heated home. I feel for the poor country doctor they roped into being the coroner, and also for whoever washes his clothes.

Still, it's not like they had refrigeration.

Derbyshire, if he had actually existed, would have had no reason to give a friend's address to the miliner unless he was trying to dodge or delay the debts therein. I don't find Mrs. Straker to be terribly clever, but there's also a strong thread of motivated reasoning for allowing your husband to explain away another woman's bills arriving at your household. And many reasons, both social and practical, not to let on if you suspect that he is supporting a mistress.

37 pounds, 15 shillings is about 4,032 modern pounds, $5,120 USD. The majority of that is the 22 guinea (23 pounds 2 shillings) costume, which is L 3,486 / $ 4,358.

Keep in mind that our clothes are both extremely less (much cheaper) fabric and made, overwhelmingly, in sweatshops. A skilled local manufacturer is being paid, here, for at least an entire floor length dress with full sleeves. I would have to reach out to someone who actually does historical sewing to confirm whether this is on the expensive side, given that money is seldom more than a rough estimate in these stories, but the inflation calculation does not sound impossible.

With Holmes' comment on the dove grey silk dress, we once again see that he doesn't care to look a little forgetful or foolish in order to confirm his theories. This is, of course, the dress in the "derbyshire" account.

Inspector Gregory ranks as one of the smarter police officers by thinking to preserve the footprints and compare them to suspect shoes. We of course know now that a human comparison of footprints (especially of the kind of un-patterned soles they would have had, especially in heavy rain / soupy mud) is not very forensically rigorous, but for its era, it's not bad.

"It would be rude of me to check your work. Let me just take the opportunity and materials to do that as soon as your back is turned" is a very Holmes routine to do. Sir you are an invited expert, as a scientist I BEG you to establish checking people's work openly as a matter of forensic course.

Compared to forensic shoeprint guesswork, determining if a horse was around is much easier work.

Holmes' flair for the dramatic comes the closest out of all aspects of his characterization to the callousness he's been portrayed with in more modern adaptations. Arguably Silas Brown, at least compared with his counterpart Straker, does not deserve to be yanked around like this.

9 notes

·

View notes

Text

Had the enlightening thought that I could use my blog for blogging. I don't love splitting myself into separate marketable entities, so I'll probably post more craft stuff here. (I have a passing knowledge of So many hobbies it's a bit ridiculous- my most developed are probably doll customisation (wigs, faceups etc), sewing tiny clothes and maybe crochet.) I thought I would share some patch process from...2021? (ugh)

I don't know how many of you will have seen on twitter, but I've started making patches for my jacket after being deeply dissatisfied with what I could find online (I find that I need to know & search for a creator specifically or I just get mainstream patches... 'bee happy' etc)

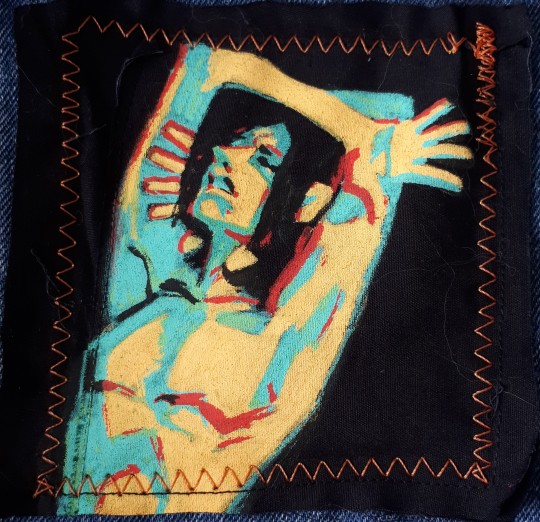

The Billie patch (of the painting) was actually me going 'I wonder if posca works on fabric' and I tested it on the smallest scrap, which bit me in the ass, because I did that face with no planning or sketch and it came out perfect, no way I was going to do it that good again. SO i stitched it onto a bigger bit of black fabric, which is surprisingly unnoticeable in the end!

The rainbow strip was made because I didn't like how clean and manufactured store bought flag patches are, I wanted something undeniably gay, but a little more subtle and personal. I chose the colours to be a bit softer (I'm aware the dark brown should be black, I had no grey to pastel-ify it with, like I did the others) and I've seen little rainbow strip lapel pins before, so I sort of copied that in fabric form.

The next is Brian Molko in the 'Pure Morning' video, which I watched so much when I was younger. I put a screenshot through a binarization filter, and tried my best to copy it down. It was going really well, and then I foolishly placed it over my photo to see how it lined up (badly) and I went back in and completely ruined the likeness. While it wasn't a good copy, I still think it looked good before I went over it. SO I made another :'). I also sort of fixed up the first, because seeing it on the desk was embarrassing me.

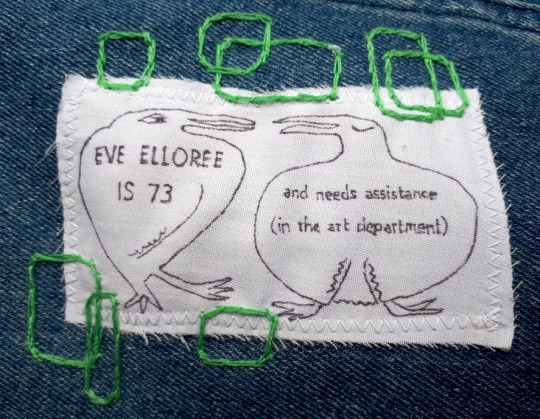

I also added the embroidery in the colours I think of when I try and remember the video (his lips particularly were sort of coral coloured and the androgyny struck me hard as a teen) The Eve Elloree was from an old gay magazine- the art director asking for assistance, I just thought it was really fucking cute haha Way more info on my long ass twitter thread.

The extremely badass black and white one is from superpose! And the fruits wizard is here (because im a fruit, har har)

Hopefully I can make more this year, I have too many hobbies and not enough wrist stamina!

125 notes

·

View notes

Text

Coats Signal Soft: Sewing and Embroidery Thread for Fashion Applications

India, Aug ’23: Coats, a global leader in thread and textile manufacturing, is proud to introduce Coats Signal Soft, a sewing and embroidery thread for applications in fashion. With a distinctive retro-reflective quality, this thread has the ability to reflect light back to its source upon exposure. This exceptional feature guarantees visibility, even in low-light conditions.

Retro-reflective materials are often worn by pedestrians, cyclists and workers who need to be visible in dark or low-light conditions. Coats Signal Soft offers enhanced visibility to products made out of it, and the thread has good sewability. These threads can be used to make fashionable items. The thread’s finer ticket size, soft texture and pliability lend themselves to ornamental embroidery on clothing materials, contributing to the artistic ingenuity of garment design.

Features & Benefits:

Smooth sewing: The thread's lubricated finish ensures seamless stitching.

Day-to-night visibility: In daylight, the thread appears silver, but it turns white when light shines on it in lowly lit conditions, enhancing visibility.

Versatile for decorative sewing: The fine size and softness of the thread make it ideal for ornamental embroidery on clothing materials.

High reflectivity: When light hits the thread, it becomes highly visible and reflects a significant amount of light.

Meets safety standards: The thread meets the STANDARD 100 by OEKO-TEX®, CLASS I, ensuring its quality and safety.

Coats Signal Soft thread is perfect for high-visibility fashion applications. However, it's not suitable for safety clothing that needs to meet specific reflectivity standards.

For more information about Coats' Signal Soft-sewing and embroidery thread for fashion applications, please visit - https://www.coats.com/en/products/threads/signal/signal-soft.

About the Author:

Coats is the world’s leading industrial thread company. They are headquartered in the UK, with a workforce of 17,000 in 50 countries across six continents around the world. Coats provide complementary and value-adding products, services and software solutions to the Apparel & Footwear industries. Coats apply innovative techniques to develop high technology Performance Materials threads, yarns and fabrics in areas such as Transportation, Telecoms and Energy, and Personal Protection.

0 notes

Text

transforming soffits reorganizing keys formalizing immersion joints justifying kick extractors advising aggregates managing elbows recasting connectors achieving aluminum trowels officiating disks exhibiting absolute spigots progressing coil hydrants jerry-building reflectors informing casters inventing rubber hoists performing wrenches judging chalk adapters upgrading ignition paths

regrowing flashing recommending ratchets approving barriers sweeping impact fillers sewing mirrors detailing collectors enforcing measures distributing systems presenting plugs interwinding registers piloting ash diffusers gathering cranks supplying eave pockets undertaking scroll stops accelerating straps designing fittings protecting diamond boilers logging downspouts correlating shingles uniting mallets qualifying electrostatic lifts sharing clamps obtaining circular fluids ranking foundation gauges sensing miter brackets originating space networks translating drills regulating guards selecting gable padding utilizing pellet dowels reconciling artifacts altering pulleys shedding space filters determining vents representing mortar remaking flash rakers supporting funnels typecasting rotary chocks expressing junctures resetting auxiliary vises professing strip treads inlaying matter trowels questioning drivers forming edge fittings sketching blanks overshooting spark breakers rewriting controls playing tunnels inventorying buttons enduring joint handles effecting ratchet bibbs unwinding couplings forsaking vapor conduits defining sockets calculating heaters raising grids administering tiles measuring resources installing ignition remotes extracting corners manufacturing ventilators delegating consoles treating mounting stones enacting jig deflectors intensifying alleys improvising cargo pinpointing bobs prescribing arc masonry structuring metal chucks symbolizing lathes activating plumb kits adapting coatings fixing channels expediting cordage planning compressors enlisting hangers restructuring keyhole augers shearing ridge hardware collecting reciprocating bolts maintaining corrugated dimmers whetting hole collars conducting mandrels comparing assets compiling sealants completing paths composing equivocation wheels computing dampers conceiving electrostatic treatment ordering cotter grates organizing ties orienting ladders exceeding materials targeting thermocouples demonstrating emery stock expanding latch bases training wardrobe adhesives overcomming[sic] fasteners streamlining storm anchors navigating springs perfecting turnbuckles verifying gate pegs arbitrating arithmetic lifts negotiating outlets normalizing strips building surface foggers checking key torches knitting grinders mowing planers offsetting stencils acquiring bulbs adopting rivets observing avenues ascertaining coaxial grommets slinging wing winches instituting circuit generators instructing wicks integrating pry shutters interpreting immersion lumber clarifying coils classifying wood bits closing cogs cataloging matter strips charting holders conceptualizing push terminals stimulating supports overthrowing shaft spacers quick-freezing connectors unbinding ground hooks analyzing eyes anticipating gateways controlling proposition rollers converting power angles coordinating staples correcting benders counseling joist gaskets recording gutter pipes recruiting drains rehabilitating rafter tubes reinforcing washers reporting guard valves naming freize sprues nominating rings noting straps doubling nailers drafting circuit hoses dramatizing flanges splitting framing compounds refitting stems interweaving patch unions placing sillcocks sorting slot threads securing mode cutters diverting catharsis plates procuring load thresholds transferring syllogism twine directing switch nuts referring time spools diagnosing knobs discovering locks dispensing hinges displaying hasps resending arc binders retreading grooves retrofitting aesthetics portals seeking stocks shrinking wormholes assembling blocks assessing divers attaining lug boxes auditing nescience passages conserving strikes constructing braces contracting saw catches serving installation irons recognizing fluxes consolidating fuse calipers mapping shims reviewing chop groovers scheduling lag drives simplifying hoists engineering levels enhancing tack hollows establishing finishing blocks

21 notes

·

View notes