#apparel sewing thread

Explore tagged Tumblr posts

Text

Coats Sets a New Standard with Gral EcoVerde AS for Apparel: Neat seam appearance for apparel sewing thread.

India, 9th August ’23: Coats, a prominent figure in thread and textile manufacturing on a global scale, is delighted to introduce the groundbreaking product Gral EcoVerde AS. Gral EcoVerde AS for Apparel is made from 100% recycled polyester and features low friction lubrication, excellent loop formation, and consistent stitch formation. These properties combine to produce a smooth, even seam that is both visually appealing and durable.

The low friction lubrication in Gral EcoVerde AS for Apparel helps to reduce the friction between the thread and the needle, which helps to prevent the thread from fraying or breaking. This results in a smooth, even seam that is less likely to unravel.

Gral EcoVerde AS for Apparel represents a breakthrough in sustainable threads for apparel manufacturing. It is designed to minimise environmental impact while upholding the highest quality standards. The thread is crafted using eco-friendly materials and processes, ensuring reduced water consumption, a lower carbon footprint, and decreased energy usage.

GRAL Ecoverde AS maintains the exceptional quality and reliability that Coats is renowned for. It is well-suited for diverse applications, including apparel sewing, offering consistent stitching and durability. Brands and manufacturers can seamlessly infuse sustainability into their products while leveraging the expertise and reputation of Coats.

Coats is committed to providing customers with sustainable sewing thread solutions. The thread exemplifies the company's ongoing commitment to advancing environmental practices, ensuring a more sustainable and responsible future for the textile sector. The company believe that this thread will help apparel manufacturers reduce their environmental impact and improve the quality of their products. To learn more about GRAL Ecoverde AS and its sustainable benefits, please visit the website’s product page. https://www.coats.com/en/products/threads/gral/gral-ecoverde-as-for-apparel

About the Author:

Coats is the world’s leading industrial thread company. They are headquartered in the UK, with a workforce of 17,000 in 50 countries across six continents around the world. Coats provide complementary and value-adding products, services and software solutions to the Apparel & Footwear industries. Coats apply innovative techniques to develop high technology Performance Materials threads, yarns and fabrics in areas such as Transportation, Telecoms and Energy, and Personal Protection.

0 notes

Text

Amazon.com: Thread Lightly Crewneck Sweatshirt - Minimalist Neutral Design, Eco-Friendly Clothing, Sustainable Fashion, Comfy Pullover, Forest Green : Clothing, Shoes & Jewelry

#threads#sewing#sewer slide#crafts#agere craft#diy craft#craftycorn#craftblr#hobby#hobbies#holidayfashion#cozy winter apparel#wintergifts#winter#durable winter clothing#winterstyle#church#bible story#bible thoughts#bible art#bible journaling#bibleteaching#bible prophecy#bible devotions#bible reflection#bible fandom#inspirational message sweatshirt#combat anxiety sweatshirt#fluffy sweater#fuzzy sweater

0 notes

Text

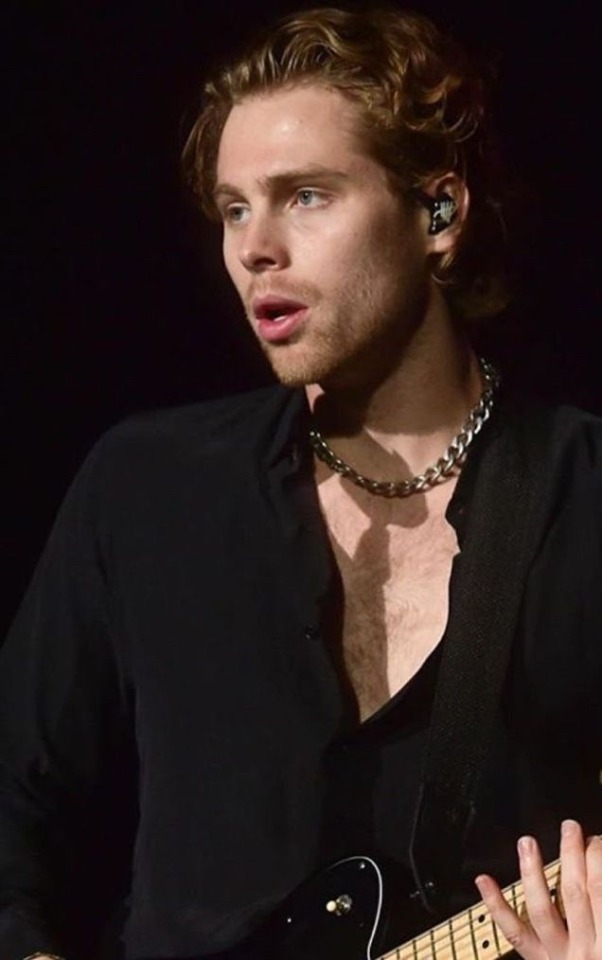

before the stage

prompt. quickly sewing back the loose button of their shirt that came off at the last minute, realising that you two are extremely close (1.2k)

pairing. luke hemmings x assistant!reader

warnings. fluff, employer x assistant feelings, written in 2nd person, frustrated!luke, the black shirt 🥵

divider credits. @cafekitsune

It was almost time for Luke and his band to perform, they had been entirely prepared and surpassed any qualms that threatened to delay their appearance on stage, however in the last moment, another problem appeared, leading Luke to sigh irritatedly. He was wearing a button up, the first one already undone, however it appeared that it didn't matter how much the quality of the satin fabric had cost, a couple of buttons in his midsection had escaped from the threads that held them in place.

The lead singer plucked the black pearls that closed his shirt up from the trodden ground, holding the minuscule clasps in his large hand. To say he was annoyed was an understatement; he didn't even have a backup outfit, he was set on wearing the exact apparel that he had on. "Fuck sake." His tone was bitter, it was as though something always had to go wrong at the last second.

It was just his luck, he thought. "Is something wrong Luke?" The voice cut through his distress as smooth as a knife, the soft sound relaxing the tall man slightly, as he looked to the side to see you - his assistant. He felt his lips incoherently move on their own accord as he fumbled to speak, miming through oxygen that flowed between you. "I- uh." He didn't want to rant to you about something so unimportant in the world, it would make him appear nonchalant to the real problems that tainted the earth.

He had the ability to purchase anything that he wished for due to the success of his music career, and thus he felt petty. "It's nothing." Luke shrugged off the grievance that had the strength to delay his entrance beneath the stage lights, there was no justice in getting worked up over something so minuscule. "Just.. my shirt broke." To emphasise his point in an embarrassed gesture, he braced his hands awkwardly on his hips and looked down at his torso.

A crease fell between your brows, and he felt like an absolute fool. There was a hue of red blossoming on his cheeks as he noticed your eyes scanning along his body, pinpointing the ajar fabric, your pupils staring sternly at his exposed skin. "I have just the thing." Your y/e/c eyes devotedly ogled up at him, glee glowing with an ambience from your eyes as a wide smile sprawled on your lips, leaving the curly haired blonde riddled in confusion.

For a moment you ignored your employer, shuffling with a purpose through your handbag that was slung across your shoulder, all knowing with what your search was for. A sound of diluted happiness prevailed from your throat as you plucked out a small and transparent case, where sewing needles and midnight coloured thread were stored. "Did you find the buttons?" It wouldn't be a problem if he hadn't, as you had a couple of spares loosely dancing around in your bag, however Luke held out his hand.

Luke felt sparks shoot through his body as you took the buttons, your fingers digging gently in the indent lines of his palm, grasping the black spheres and preparing your tools to reattach them. He could have sworn you were an angel sent from heaven to make every day that he spent with you significantly brighter; if there was ever a barricade to his intended path, you always had a solution.

You were always prepared, however in this moment you had to try with great difficulty to ignore the his soft abs from your focused sight. All you had to do was your job, which was to provide support and anything that Luke required, and so with your black reel of thread connected to the button, you grasped the opening of his shirt, knuckles brushing his tender muscles. The contact made him shakily inhale, his heart thumping vigorously within his chest.

He had never meant to form such an unprofessional crush on you, but it was impossible, sure when he interviewed you he couldn't ignore the physical attraction that he felt for you, though it didn't blind him to your listed criteria that was on your resume. "Thanks for this." He quietly spoke, but his words were as clear as day due to the proximity that you shared. One button down, one to go - you felt sufficiently accomplished, and you held the other one, determined to finish this fixing in time.

"It's my job." You responded nonchalantly, shrugging his appreciation off as to calm the butterflies that hurtled around in your stomach. "And it's no big deal Luke, it's an easy fix." Oh god, he could feel your breath hitting his chest where he had intentionally opened his shirt, and he could feel sweat brewing against his hairline. You were so focused, and he couldn't help but take in every detail of your face.

As you finished with putting the last button on, you placed the needle and thread back where they belonged, before you grasped the sides of his shirt, readying to put them through their designated loops. As you looked up, and he looked down upon you in his heeled boots, your nose almost touched his chin, and your eyes met in a staring embrace. "Hi." You muttered, hands still on his blouse.

"Hey." He replied, his lips pulling at the sides as his pupils enlarged in their surrounding blue pools. "How long do we have?" The musician enquired, knowing that you had a better sense for time management than he did. You glanced down at your watch, only briefly, and cocked your head. "Enough." You said, your body jumping a little as you felt his hands coil delicately around your hips.

The two of you leaned in, meeting in the middle in a collision of your lips, your hands tugging softly at his natural curls as you melted with satisfaction against one another. It was a slow exchange, full of passion and desire, and you wished it would last longer, however the alarm on your watch alerted you with a beckoning siren, causing you to defiantly pull away and huff lightly. "You have five minutes until you have to go on." You informed him, humming as Luke stroked your cheek.

He wanted nothing more than to lean in and get lost in you, to fall even further than he already had for you. But duty called, and he stood up straight, running his lips against one another as he vowed to never forget the first romantic moment that you shared. "I'll see you after?" Luke asked hopefully, his ocean eyes blazing with a new lease of motivation. Without a doubt you nodded, your hands ensuring that his shirt was done up and brushing down the smooth material to stroke out any creases.

"Of course. And then we could pick up where we left off." Your promise had a giddy expression morphing unto Luke's face, and you watched as he begrudgingly stalked off to meet with the other members of his touring team, excited to view his earth breaking performance from the sidelines. There was never a lyric that you skipped over, although today was different, you were strongly distracted by the leading man, and the before stage moment that you had just shared.

#luke hemmings x reader#luke hemmings imagine#luke hemmings smut#luke hemmings x y/n#luke hemmings oneshot#luke hemmings fanfic#luke hemmings fluff#luke hemmings fic#5sos x reader#5sos imagine#5sos fanfic#5sos fic#5sos fluff

291 notes

·

View notes

Text

February 1. Woohoo, we're out of January and closer to spring, and I have new thread colors to add to my palette!

This is the main type of thread I use for all sorts of fiber and mixed-media artwork: a strong, relatively thick, non-divisible cotton thread that comes in a wide range of colors. DMC size 8 perle cotton (smaller spools) has a better color selection, but Lizbeth size 20 tatting/crochet thread (larger spools) is stronger and stays smoother under all the tension and friction my work involves. Sometimes I use thicker threads, like heavier crochet cotton, for effect, but finer, more textured, or more delicately constructed threads don't work for most of my work. (The main exception is standard sewing thread for machine sewing, delicate embellishments, and apparel.)

10 notes

·

View notes

Text

Whew! Got the sleeves removed from the jacket (apparently my little Swiss Army Knife scissors work pretty well as a makeshift seam ripper), hemmed it with a simple running stitch and then threw a whip stitch around the edge to give it more of a comic-book look - I also used embroidery floss rather than sewing thread so the stitches would be visible

My apparel spikes are supposed to arrive tomorrow so hopefully I can get those added either tomorrow or Thursday

3 notes

·

View notes

Text

Your Comprehensive Guide to Successful Sewing

Guide to Successful Sewing

Whether you're a beginner just starting your sewing journey or an experienced seamstress looking to refine your skills, the Guidelines offer a wealth of knowledge to help you succeed in your sewing projects. This comprehensive collection of educational articles covers all aspects of sewing, from basic techniques to advanced methods. Exploring the Guidelines The Guidelines are organized into various categories, each focusing on different aspects of sewing. Let's take a closer look at what you can find: 1 - Sewing Tools Basic Tools Sewing Tools More Sewing Tools Mats for Rotary Cutters Rotary Mat Q&A Scissors and Shears Rotary Cutters Measuring Tools Marking Tools Tube Turners Part 1 Tube Turners Part 2 2 - Equipment Setting Up a Sewing Room Sewing Machine Basics Buying a Sewing Machine Pressing Equipment Ironing Boards Sergers Presses & Home Pressing Systems Serger Stitches Computerized Sewing Machines 3 - Understanding Patterns Pattern Markings Part 1 Pattern Markings Part 2 4 - Fabric The Right Fabric Preparing to Sew - Fabric and Pattern Preparation Cotton Identifying Fibers & Fabrics Denim - More Than Just Jeans Napped Fabrics Unconventional Fabric Sources Straightening Fabric Grain Sewing with Knits Working with Napped Fabrics Wool Slick Tricks: Laminated Fabrics and Vinyls Sewing with Handwovens Identifying Plaids Sewing with Minkee-like Fabrics 5 -Linings & Interfacings Interfacing 101 6 - Notions Button, Button Pins Invisible Thread Elastic - the Notion that Gives Selecting Snaps Bindings & Tapes Using Bias Tape Rick Rack 7 - Home Dec Bed Coverings Drapery Types Table Treatments: Tablecloths Table Treatments: Placemats, Napkins and Runners Decorating with Quilts 8 - Home Dec How To Pillows Fabric Napkins Covering a Lampshade with Fabric Making Rod Pocket Curtains Tab Top Curtains Making a Shower Curtain Covering a Bench Top Tassels 9 - Quilting Quilting Tools Quilting Terms Notions for Quilters Pre-Cut Quilting Fabrics Quilting Rulers Quilting Designs Making Bias and Bias Binding Binding a Quilt Prairie Points Yo-Yos Seminole Piecing

10 - Fashion/Apparel

Body Types Clothing Care and Repair 11 - General How-To Pressing Pants Simple Seaming Techniques Seam Finishes Part 1 Fold-Down Casings Simple Hems Staystitching Easing, Gathering & Shirring Working with Fold-over Elastic Applied Casings Twin-Needle Sewing Seam Finishes Part 2 Ruffles Working with Stripes Piping Princess Seams Flat Fell Seams Bound and Hong Kong Seam Finishes Beading Part 1 Beading Part 2 12 - Garment How-To Attaching Buttons Easy Waistband Casings Centered Zipper Button Loops Covered Buttons Understitching Dart Basics Topstitching Shirt Collar Pointers Read the full article

6 notes

·

View notes

Note

“After all that happened and all we have been through, I believe that nothing I decide to give you would top the gift of getting along with you again. That little brooch, the hint of hope, the timeless memories that stay in the past… or try to.” Scarlett rambled to herself, wandering side by side, restless, at the same time. “I wouldn’t be able to come up with a better gift even if I tried.”

(Well...)

“Ah... Will any Christmas be like the last? Probably not. I’m only happy I don’t have to give you coal like I once considered.”

“And I know you may not be fond of meaningless gifts…”

“...But, I’m a lady of my word.”

“Don't hate me for this. But maybe you will pamper your inner child with these.”

She delivered a tiny bag with a box inside. A box of...

Yes, crayons.

“I'm being nice and I'm not giving you a book with them. Haha~”

“Merry Christmas~ ”

“There is no inner child and there will absolutely be no pampering, Scarlett. Rest assured, it will take more than some silly box of crayons for me to possibly hate you, though. I can’t promise I’ll make the most of your gift, but I got you something nice as well. Something only someone of your countless, long-lived years can fully appreciate. Who knows, it may even help keep your mind sharp as you age older and older.”

Despite saying everything with a fairly stoic and calm expression, albeit with a slight tinge of exasperation, Ruki hesitantly accepted the box of crayons, planning on shoving it into a drawer never to see the light of day again. Had it been someone else gifting him the coloring utensils, he would assuredly discard the item, and even worse, punish the one who thought it wise to gift a Vampire something so juvenile.

“Well, I’m certainly no artist, but perhaps you can let your creativity run with the wind.”

Handing Scarlett a carefully wrapped present adorned in an almost iridescent silver, the contents of the gift would reveal a knitting and sewing kit, complete with needles and thread of myriads of colors.

“Old ladies typically idle their time knitting, no? That being said, I figured this would be the most opportune present for you. Merry Christmas, Scarlett. I can’t wait to see what kind of apparel you come up with. Perhaps I should’ve bought a cane for you as well? We can never predict when you’ll need more support to get from one place to the other. Should worse come to worst…”

Without warning, both of the Vampire’s arms coiled around Scarlett, lifting her off her feet in his embrace as he let out a dark chuckle before gazing into her radiant amethysts.

“…You can rely on me rather than a cane. Kidding, of course. But it’s true that I will always be here for you.”

#diabolik lovers#ruki mukami#mukami ruki#ask#rp#scarlett wakahisa#kindan-no-kanojo#rukilett#christmas 2022#diabolik lovers rp

8 notes

·

View notes

Photo

Here is my artistic rendition of a clan of Celtic warriors on the march to battle! I leave it open to interpretation what tribe of Celts these guys are. They could be Gauls or Britons on the march to kick some Roman butt. They could be Picts on the march to battle with invading Saxons. They could be Gaels looking to put down a rival clan. Regardless of how you see it, the ogham inscription at the center sews a common thread among all interpretations. It reads, “VICTORY!” Apparel, prints and more with this new artwork can be found at this link --> https://celtichammerclub.threadless.com/ ➖ #celtichammerclub #celt #celtic #celticart #celtictattoo #celticknot #celticspiral #irish #scottish #welsh #cornish #british #warrior #fashion #style #history #celticmusic #originalart #originalconcept https://www.instagram.com/p/Cp0oZhOOv_g/?igshid=NGJjMDIxMWI=

#celtichammerclub#celt#celtic#celticart#celtictattoo#celticknot#celticspiral#irish#scottish#welsh#cornish#british#warrior#fashion#style#history#celticmusic#originalart#originalconcept

9 notes

·

View notes

Text

Jacquard Loom Machine - 3 Fabrics & Its Importance In Various Industries

What is a Jacquard Loom Machine?

The Jacquard Loom Machine is a device fitted to a loom that simplifies the process of manufacturing textiles with such complex patterns as brocade, damask, and matelasse. It is known as one of the most advanced weaving machines around the globe.

A jacquard textile machine is used to weave the type of fabric known as a Jacquard. They were created in 1804 by the french engineer and silk manufacturer Joseph Marie Jacquard. It is capable of producing complex patterns on fabric through the use of punched cards. Plain, satin, velvet, and lace are the fabrics that were woven with the jacquard textile machine. There is an increase in the application of this technology in recent decades.

Let’s discuss the fabrics and how jacquard loom machines are used in various industries.

Brocade:

Brocade is a class of richly decorative subtle-woven fabrics, often made in colored silks and sometimes with gold and silver threads. One of the most popular machines used for weaving brocades is the computer jacquard machine. Brocade has patterns that can be woven right into the fabric as opposed to embroidered fabrics. It is additionally known as embossed cloth. Earlier, brocade was formerly used for decorative clothing, although now, it is used widely.

Where is the Brocade fabric used?

Homeware: Curtains and heavy silk drapes

Accessories: Tie, pocket squares, pillows

Furniture: Ornamental Chairs with brocade cushions and sofas with brocade patterns

Damask:

Damask is a type of fabric characterized by its flat and reversible pattern. It is typically made of silk, cotton, or synthetic fibers and is often used for table linens, upholstery, and clothing. The pattern is created by weaving the warp and weft threads of different colors in a specific manner to create a reversible design. The name “damask” originates from the city of Damascus in Syria, where the fabric was first produced.

Where are Damask fabrics used?

Apparels:

Damask is essentially used for evening wear, jackets, and other stuff clothing items that are meant to be somewhat weather-resistant.

Accessories:

Scarves, handbags, and luggage are some of the common uses of damask in everyday wear.

Decor:

Damask is regularly used in upholstery for home decor. Damask can sometimes be seen on light rugs as well.

Additionally, Damask is used in a wide variety of products, including wallpapers and suitcases, including fabrics with a damask-inspired pattern. Other frequent plastic accessories with damask designs include glass cases, laptop cases, phone cases, and many other plastic accessories.

Matelasse Fabric Matelasse is a type of fabric with a raised, quilted surface resembling a woven basket. The word "matelasse" comes from the French term for "quilted." It is usually made of cotton or silk and is often used for bedspreads, curtains, and upholstery. Matelasse fabric is characterized by its intricate patterns and soft, plush feel. An interesting fact is that in the sewing industry, a “figured fabric” is an example of what is known as a Matelasse Fabric. This fabric has a complicated weave structure. It is manufactured using cotton, silk, or rayon. The fabric has a flexible surface with a quilted appearance, additionally, the fabric is opaque in appearance.

Where is Matelasse Fabric used?

Home Furnishing:

Curtains, bedsheets, pillowcases, bed skirts, cushion covers, etc.

Computerized Jacquard Loom is the best fabric weaver as it can carry out any weave pattern and produce endless fabrics. It started the manufacturing and consumerism industrial revolutions. Due to the demand for simple, minimal, and adaptable fabrics, there is a considerable increase in favor of industrial looms among designers and apparel firms.

Alidhra Weavetech is one of the most known and famous for being armed with innovative and cost-effective weaving and twisting machinery, as well as Jacquard machine solutions in the world. Weavetech is known for its innovation, creativity, excellence, and integrity.

If you are looking for a textile manufacturing machinery industry in India, look no further and give us a call and Contact us today.

Original Source: https://weavetech.com/blog-detail/30/jacquard-loom-machine---3-fabrics-its-importa/

5 notes

·

View notes

Photo

Getting ready to visit a fashion factory? This is for you, because your first visit can be A LOT to process. The good news is, figuring out what the heck you just walked into and if everything you saw was “normal” is something almost every new fashion brand struggles with after they leave that first meeting. So, I’m here to help make your life a little easier. And explain all the inner workings of a factory with A Look Behind The Seams of one of my favorite Italian clothing manufacturers. Let's break down all that sewing factory chaos. BUT BEFORE WE GET STARTED... I love helping startup brand founders succeed, so I created a bunch of free guides that will help you with your business. They won’t be free forever, so make sure to grab them while you can. WHAT YOU WILL LEARN ABOUT GARMENT FACTORIES Background info on this post Why clothing factories might appear super messy How and why space is optimized The importance of scrap paper and waste bins Why everything looks like a fire hazard The purpose of thread everywhere Why there are so many old binders The best place to find design inspiration, literally ever I mean, even just reading this table of contents, things sound totally chaotic. Let’s break it all down. WHAT THE HECK DID I JUST SEE? Here’s what usually happens. Founders set up their first appointment to meet with their clothing manufacturing partner in person. They are all excited to go. But after the meeting, when I ask them how it went, they are left feeling beyond confused. That’s because they leave not fully understanding everything they just witnessed. Often, they even question whether the sewing factory is competent enough to produce their products or if they are ethical. For example, a client of mine visited one of my favorite cut + sew factories in New York City and after they left, they told me they were uncomfortable working with them because the space was too cramped and messy. From the looks of it, they thought the sewing factory seemed unprofessional. Darling. (Said in my best Meryl Streep Devil Wears Prada voice). If a factory is good enough for some of the biggest names in New York fashion week, I am sure it’s good enough for you. So, to help you not freak out on your first fashion factory visit. I created this post. INSIDE THE INNER WORKINGS OF AN ITALIAN CLOTHING MANUFACTURER I was lucky enough to tour Italy this summer thanks to Italian Artisans. And, visit some of their partner factories that do everything from knitwear, to wovens, to accessories, and more. Full disclosure. They didn’t pay me a cent. I funded the entire month myself because I wanted to be able to write honestly about my experience. Anyway, my goal for the content I created during the trip was to give people a feel for what apparel manufacturing is all about. No sugar coating, no staged photo ops – just the reality of it all. So, when the first thing Jacopo said to me was, “Oh my God, it’s so messy in here. We didn’t have time to clean up for you. We are desperately trying to get things out so they are in time for Milan fashion week,” I knew it would be a perfect teaching moment. Because the truth is, sometimes (read, often) the messiest, craziest fashion factories are the best. And the ones that look like they popped out of Pinterest . . . Well, truth gun (Cougar Town reference), they probably look that perfect because they don’t have actual clients and no one is doing any real work in them. So, let me take you on a tour… WHY SEWING FACTORIES NEED TO OPTIMIZE THEIR SPACE Fashion factories are experts in making the most of every inch of space they have. And that is because they have to to be profitable. THIN PROFIT MARGINS First, let’s talk about the razor-thin margins most factories need to operate on. With a brand, if you buy something from a factory for $10, you will generally be able to sell it at wholesale for about $20, or direct to consumer for $40. That means your profit will be between $10-$30. So, if you order 1,000 shirts, you can make anywhere from $10,000-$30,000 on the order. Not bad. Factories, on the other hand, make a profit of about 5-20 percent, depending on the order. So, if the sewing factory sells you 1,000 shirts for $10 each, that means their entire profit will be anywhere between $500-$2,000 (even though the brand is paying them $10,000). Now, if you were wondering why it’s so hard to find suppliers that want to take on small MOQs, it’s because the money the factory can make on tiny orders is measly compared to the money the brand can make. So, the next time you try to nickel and dime a sewing factory for better prices, please remember this insight into their margins. BTW, For help finding low MOQ suppliers, you can check out this article. Okay, now that you understand the tiny margins factories are working with, let’s talk about some of their overhead costs. EXPENSIVE REAL ESTATE Historically, factories are near major fashion centers. There is the New York City Garment District and Downtown LA. In Delhi, the main factory area is Noida, and in Italy, many luxury Italian fashion houses are located around Como and Milan. But over the years, these areas have become increasingly expensive, meaning the price of rent has gone up. In New York City, I have seen many factories downsize their spaces and move out of the garment district to places like Jersey City and Brooklyn, where they can find cheaper rents. However, many of the factories I know that moved further out of the city then lost customers because their customers did not want to make the schlep to another state or borough to meet with them. That’s the problem with packing up and moving to a cheaper space. Brands are lazy, and because they tend to be more profitable, most are still based where the action is. Because of this, some factories then packed up again and moved back to the city, paying a premium on their rent, to be closer to their customers offices. Because every single square foot cuts away from the factories bottom line (especially in places like New York City), out of necessity, factories need to make the most out of every single inch of space they have. And that’s a big part of the reason things in factories tend to look pretty chaotic. MAKING SENSE OF THE MESS IN A SEWING FACTORY Now that you know why factories need to optimize their space, let’s go inside the fashion factory, and I will explain some of the methods behind their madness. FABRIC ROLLS AT THE DOOR I can’t tell you how many times I have walked into a factory and had to step over a roll or two of fabric. That is because, in small factories, there is only one door in and out. So when fabric is delivered, many factories leave the rolls that are going to be used first right there and move the rolls that aren’t for immediate product to storage areas. So, when you step over a roll of fabric at the entrance, I can almost guarantee it won’t be there tomorrow because it is going to be used right away. THE FACTORY FLOOR AND VERTICAL STORAGE It takes a lot of table space to unroll fabrics, cut them, organize them, sew them into garments, check the garments for quality control issues, press and iron them, and then pack them up.. The other thing that often happens is that customers end up using factories as free storage. When they have leftover tags, labels, heck, even rolls of fabric, they often leave them at the factory for the next order. And all of this cuts into the factory’s limited space. Because of this, factories are really good at using space vertically. There is almost always storage under every single table, and you will often see things stacked up to the ceilings. And paper patterns often hang on the walls. SHOWROOMS AND ARCHIVES Factories often have showrooms and archives, which serve as resources for small fashion brands. These garment samples are tools for clients to look at for inspiration and use as a reference for future designs. They also serve as examples of what the sewing factory has made in the past, and as examples of what type of quality a client can expect. SCRAP PAPER EVERYWHERE One of the first things you might notice when you walk into a factory are the scraps of paper literally everywhere. From scrap paper on the walls to scrap paper pinned onto garments. Seriously, it looks like a crazy person with amnesia is working there. But it all actually makes a lot of sense. POST-IT NOTES ON CLOTHES One thing you might notice on a lot of the clothes in a garment factory is that there are post-its and tiny scraps of paper pinned and stapled all over garments. These are notes for future alterations. So, there might be a scrap of paper stuck to a sleeve that says, “Reduce 2 inches.” And, another scrap of paper with a note that says, “Change the seam to a French seam.” There might even be little pieces of fabric tacked onto the sample to show what colors or what types of fabrics go where in the next sample set. Now, you might be wondering, aren’t all of these changes in the tech pack? In a working sewing factory setting, a lot of people prefer notes over techpacks. That is because it makes it a lot easier for people to physically see what needs to be changed without having to look at an Excel spreadsheet. SKETCHES Papers with sketches and CADs (computer aided designs - think sketches of the clothes made in Adobe Illustrator or Photoshop) are usually all over the place. Attached to boards on the wall, in plastic sheet protectors, and pinned onto the physical samples. These sketches serve two different purposes. The sketches on the wall are a way to view the entire collection. There might even be notes next to these sketches letting everyone know if the sample was made, needs to be made, or if something is delaying the process (like if fabric is missing and when it can be expected to arrive at the factory). Basically, the sketches on the wall show everyone very clearly what styles are in works in the factory. The sketches that are attached to the garment help the pattern makers and sewers ensure that the end garment looks the way it should. The truth is, many people who work in sewing factories (not in Italy, but in other parts of the world) are illiterate and don’t know how to read. But everyone can understand images, which is why as industry pros love them. Even if the sewers know how to read and write, using images tends to speed up their sewing and prevent mistakes. Using images also help the sewing factory catch the brand's mistakes. Here’s an example of that. Sometimes a tech pack will have the wrong measurements on it. Say you want to create a short sleeve; the measurements on the tech pack might accidentally measure for a long sleeve shirt. When the factory sees the sketch of the dress with short sleeves and realizes there is a discrepancy in the measurements, they will most likely call the brand and clarify exactly what the company wants instead of doing the wrong thing. CALCULATIONS Did you know that patternmaking is basically math class? It’s like the least artistic part of the garment process, and generally, good patternmakers have above-average math (especially geometry) skills. So, when you go over to the area of the factory where the patternmaker works, you will probably find tons of scraps of paper with really rough sketches with numbers and math equations on them. GARBAGE BINS FULL OF ROLLED-UP PAPERS In a lot of factories, you will find garbage bins filled with rolled-up papers. Like, literally overflowing. But this isn’t trash. These papers are cutting markers, and it would actually be horrible if they got thrown out. Cutting markers are long sheets of paper with clothing patterns on them. They are laid over fabric that help guide the factory workers on how to cut the fabric to get the most pattern pieces possible using the least amount of fabric (read, helps brands save money by using less materials). The trash bin is usually just a makeshift storage container for these papers. TINY BOBBINS OF SEWING THREADS One last random thing you might notice about a sewing factory is that there is so much thread. It’s everywhere. I once got tangled in a snagged thread, and it all felt very No Doubt Walking In The Spider Webs - click here if you can’t get that song out of your head now… But, there is a really specific reason for this. It is for a sewing instruction called DTM, or dyed to match. Did you ever notice how seams in clothes almost always match the fabric? If the shirt is black, the thread is also black. On blue jeans, they use blue thread. And the thread almost exactly matches whatever specific shade of color the fabric is. This is no accident. And it’s why factories save thread. Because the more colors they have on hand, the better chance they have of exactly matching your fabric. Now, this is super helpful in the sample-making process – for just a few garments that need a quick turnaround or a mini order with an MOQ of 10 pieces. However, during bulk, you might need to order your own DTM threads. WHAT'S WITH ALL THE BINDERS? It is not uncommon for a factory’s walls to put the library in Beauty and the Beast to shame (I don’t know why I’m throwing in all these pop culture references today, but I’m just in that kind of mood). This is because good factories will document, print, and save everything. TECH PACKS ARE LIVING AND BREATHING DOCUMENTS I already mentioned tech packs a few times. But this is something else worth knowing. A tech pack isn’t just something you make and then send out to the factory and forget about. It is a living document that is constantly changing with updates. Every time a change gets made to the tech pack, it is recorded. It is basically the ledger of the entire life of the style. So, because of all the changes, new pages are constantly being printed out (and the old ones are always saved). By the end of a season, there might be 3, 4, or even 5 or more binders full of all these documents and revisions for 1 brand. And, after the season is over, the factory saves all of this for years. That is because sampling from 2023, might not go into production until 2024. Also, if there is ever a similar style being made in the future, they can go back into their records and save a ton of time and money on development. PHOTOS During sampling and even bulk production, the sewing factory will take pictures of everything, print them out, and add them to the binder for a record of how everything looks. This also protects the factory in case of damages during shipping. I had this happen with one of my ex clients before. I sent all of their samples to them, and their warehouse damaged everything. They wanted me to refund them, saying I sent them damaged clothes. But I went back to my pre-shipment photos, and I was able to prove to them that the damage did not come from my side. FYI, as a brand you also should always take photos of what you are sending to a factory. This way, if a factory sends something back with a stain or damage on it, you can show them a photo of what condition the garment was sent to them in. IT’S NOT JUST PAPER IN THE BINDERS Swatches of fabric are usually cut and stapled onto the papers. This allows whoever is using the binder to see exactly what type of fabric will be used. The type of fabric affects everything in the sewing factory, from the pattern, to the types of machines used to sew the garment. Also, button, zipper, label, and even hang tag references are in the binders as well. All of this stuff is bulky and takes up space in the binders really quickly. That is why so many binders might be needed for just one brand’s collection. YOUR SEWING FACTORY’S HOARDING COULD BE YOUR SECRET DESIGN WEAPON Remember how I said factories save everything? This is probably the coolest part about that. FABRIC LIBRARY Many factories will have their own fabric libraries where they save small cuttings of each fabric that has passed through the space. They sometimes even keep records of the suppliers the fabrics came from and how to contact them for more. (hello, fabric sourcing made easy). TRIM LIBRARY And, just like the fabric library, there will sometimes be a trim library. The trim library will have samples of embellishments, labels, tags, and even embroidery. DESIGN LIBRARY And lastly, there is the design library for past samples. This particular sewing factory in Italy had generations worth of samples. And let me tell you, I was in heaven. This is the kind of quality stuff that just can't find anymore. And, is hard to find in vintage stores that are all picked through. If a factory has a design library, also known as a sample room, I urge you to spend as much time as possible exploring it. WHAT DO YOU THINK? The next time you visit your factory, are you going to look at what is going on in a whole new way? Let me know in the comments. Source link

0 notes

Photo

Getting ready to visit a fashion factory? This is for you, because your first visit can be A LOT to process. The good news is, figuring out what the heck you just walked into and if everything you saw was “normal” is something almost every new fashion brand struggles with after they leave that first meeting. So, I’m here to help make your life a little easier. And explain all the inner workings of a factory with A Look Behind The Seams of one of my favorite Italian clothing manufacturers. Let's break down all that sewing factory chaos. BUT BEFORE WE GET STARTED... I love helping startup brand founders succeed, so I created a bunch of free guides that will help you with your business. They won’t be free forever, so make sure to grab them while you can. WHAT YOU WILL LEARN ABOUT GARMENT FACTORIES Background info on this post Why clothing factories might appear super messy How and why space is optimized The importance of scrap paper and waste bins Why everything looks like a fire hazard The purpose of thread everywhere Why there are so many old binders The best place to find design inspiration, literally ever I mean, even just reading this table of contents, things sound totally chaotic. Let’s break it all down. WHAT THE HECK DID I JUST SEE? Here’s what usually happens. Founders set up their first appointment to meet with their clothing manufacturing partner in person. They are all excited to go. But after the meeting, when I ask them how it went, they are left feeling beyond confused. That’s because they leave not fully understanding everything they just witnessed. Often, they even question whether the sewing factory is competent enough to produce their products or if they are ethical. For example, a client of mine visited one of my favorite cut + sew factories in New York City and after they left, they told me they were uncomfortable working with them because the space was too cramped and messy. From the looks of it, they thought the sewing factory seemed unprofessional. Darling. (Said in my best Meryl Streep Devil Wears Prada voice). If a factory is good enough for some of the biggest names in New York fashion week, I am sure it’s good enough for you. So, to help you not freak out on your first fashion factory visit. I created this post. INSIDE THE INNER WORKINGS OF AN ITALIAN CLOTHING MANUFACTURER I was lucky enough to tour Italy this summer thanks to Italian Artisans. And, visit some of their partner factories that do everything from knitwear, to wovens, to accessories, and more. Full disclosure. They didn’t pay me a cent. I funded the entire month myself because I wanted to be able to write honestly about my experience. Anyway, my goal for the content I created during the trip was to give people a feel for what apparel manufacturing is all about. No sugar coating, no staged photo ops – just the reality of it all. So, when the first thing Jacopo said to me was, “Oh my God, it’s so messy in here. We didn’t have time to clean up for you. We are desperately trying to get things out so they are in time for Milan fashion week,” I knew it would be a perfect teaching moment. Because the truth is, sometimes (read, often) the messiest, craziest fashion factories are the best. And the ones that look like they popped out of Pinterest . . . Well, truth gun (Cougar Town reference), they probably look that perfect because they don’t have actual clients and no one is doing any real work in them. So, let me take you on a tour… WHY SEWING FACTORIES NEED TO OPTIMIZE THEIR SPACE Fashion factories are experts in making the most of every inch of space they have. And that is because they have to to be profitable. THIN PROFIT MARGINS First, let’s talk about the razor-thin margins most factories need to operate on. With a brand, if you buy something from a factory for $10, you will generally be able to sell it at wholesale for about $20, or direct to consumer for $40. That means your profit will be between $10-$30. So, if you order 1,000 shirts, you can make anywhere from $10,000-$30,000 on the order. Not bad. Factories, on the other hand, make a profit of about 5-20 percent, depending on the order. So, if the sewing factory sells you 1,000 shirts for $10 each, that means their entire profit will be anywhere between $500-$2,000 (even though the brand is paying them $10,000). Now, if you were wondering why it’s so hard to find suppliers that want to take on small MOQs, it’s because the money the factory can make on tiny orders is measly compared to the money the brand can make. So, the next time you try to nickel and dime a sewing factory for better prices, please remember this insight into their margins. BTW, For help finding low MOQ suppliers, you can check out this article. Okay, now that you understand the tiny margins factories are working with, let’s talk about some of their overhead costs. EXPENSIVE REAL ESTATE Historically, factories are near major fashion centers. There is the New York City Garment District and Downtown LA. In Delhi, the main factory area is Noida, and in Italy, many luxury Italian fashion houses are located around Como and Milan. But over the years, these areas have become increasingly expensive, meaning the price of rent has gone up. In New York City, I have seen many factories downsize their spaces and move out of the garment district to places like Jersey City and Brooklyn, where they can find cheaper rents. However, many of the factories I know that moved further out of the city then lost customers because their customers did not want to make the schlep to another state or borough to meet with them. That’s the problem with packing up and moving to a cheaper space. Brands are lazy, and because they tend to be more profitable, most are still based where the action is. Because of this, some factories then packed up again and moved back to the city, paying a premium on their rent, to be closer to their customers offices. Because every single square foot cuts away from the factories bottom line (especially in places like New York City), out of necessity, factories need to make the most out of every single inch of space they have. And that’s a big part of the reason things in factories tend to look pretty chaotic. MAKING SENSE OF THE MESS IN A SEWING FACTORY Now that you know why factories need to optimize their space, let’s go inside the fashion factory, and I will explain some of the methods behind their madness. FABRIC ROLLS AT THE DOOR I can’t tell you how many times I have walked into a factory and had to step over a roll or two of fabric. That is because, in small factories, there is only one door in and out. So when fabric is delivered, many factories leave the rolls that are going to be used first right there and move the rolls that aren’t for immediate product to storage areas. So, when you step over a roll of fabric at the entrance, I can almost guarantee it won’t be there tomorrow because it is going to be used right away. THE FACTORY FLOOR AND VERTICAL STORAGE It takes a lot of table space to unroll fabrics, cut them, organize them, sew them into garments, check the garments for quality control issues, press and iron them, and then pack them up.. The other thing that often happens is that customers end up using factories as free storage. When they have leftover tags, labels, heck, even rolls of fabric, they often leave them at the factory for the next order. And all of this cuts into the factory’s limited space. Because of this, factories are really good at using space vertically. There is almost always storage under every single table, and you will often see things stacked up to the ceilings. And paper patterns often hang on the walls. SHOWROOMS AND ARCHIVES Factories often have showrooms and archives, which serve as resources for small fashion brands. These garment samples are tools for clients to look at for inspiration and use as a reference for future designs. They also serve as examples of what the sewing factory has made in the past, and as examples of what type of quality a client can expect. SCRAP PAPER EVERYWHERE One of the first things you might notice when you walk into a factory are the scraps of paper literally everywhere. From scrap paper on the walls to scrap paper pinned onto garments. Seriously, it looks like a crazy person with amnesia is working there. But it all actually makes a lot of sense. POST-IT NOTES ON CLOTHES One thing you might notice on a lot of the clothes in a garment factory is that there are post-its and tiny scraps of paper pinned and stapled all over garments. These are notes for future alterations. So, there might be a scrap of paper stuck to a sleeve that says, “Reduce 2 inches.” And, another scrap of paper with a note that says, “Change the seam to a French seam.” There might even be little pieces of fabric tacked onto the sample to show what colors or what types of fabrics go where in the next sample set. Now, you might be wondering, aren’t all of these changes in the tech pack? In a working sewing factory setting, a lot of people prefer notes over techpacks. That is because it makes it a lot easier for people to physically see what needs to be changed without having to look at an Excel spreadsheet. SKETCHES Papers with sketches and CADs (computer aided designs - think sketches of the clothes made in Adobe Illustrator or Photoshop) are usually all over the place. Attached to boards on the wall, in plastic sheet protectors, and pinned onto the physical samples. These sketches serve two different purposes. The sketches on the wall are a way to view the entire collection. There might even be notes next to these sketches letting everyone know if the sample was made, needs to be made, or if something is delaying the process (like if fabric is missing and when it can be expected to arrive at the factory). Basically, the sketches on the wall show everyone very clearly what styles are in works in the factory. The sketches that are attached to the garment help the pattern makers and sewers ensure that the end garment looks the way it should. The truth is, many people who work in sewing factories (not in Italy, but in other parts of the world) are illiterate and don’t know how to read. But everyone can understand images, which is why as industry pros love them. Even if the sewers know how to read and write, using images tends to speed up their sewing and prevent mistakes. Using images also help the sewing factory catch the brand's mistakes. Here’s an example of that. Sometimes a tech pack will have the wrong measurements on it. Say you want to create a short sleeve; the measurements on the tech pack might accidentally measure for a long sleeve shirt. When the factory sees the sketch of the dress with short sleeves and realizes there is a discrepancy in the measurements, they will most likely call the brand and clarify exactly what the company wants instead of doing the wrong thing. CALCULATIONS Did you know that patternmaking is basically math class? It’s like the least artistic part of the garment process, and generally, good patternmakers have above-average math (especially geometry) skills. So, when you go over to the area of the factory where the patternmaker works, you will probably find tons of scraps of paper with really rough sketches with numbers and math equations on them. GARBAGE BINS FULL OF ROLLED-UP PAPERS In a lot of factories, you will find garbage bins filled with rolled-up papers. Like, literally overflowing. But this isn’t trash. These papers are cutting markers, and it would actually be horrible if they got thrown out. Cutting markers are long sheets of paper with clothing patterns on them. They are laid over fabric that help guide the factory workers on how to cut the fabric to get the most pattern pieces possible using the least amount of fabric (read, helps brands save money by using less materials). The trash bin is usually just a makeshift storage container for these papers. TINY BOBBINS OF SEWING THREADS One last random thing you might notice about a sewing factory is that there is so much thread. It’s everywhere. I once got tangled in a snagged thread, and it all felt very No Doubt Walking In The Spider Webs - click here if you can’t get that song out of your head now… But, there is a really specific reason for this. It is for a sewing instruction called DTM, or dyed to match. Did you ever notice how seams in clothes almost always match the fabric? If the shirt is black, the thread is also black. On blue jeans, they use blue thread. And the thread almost exactly matches whatever specific shade of color the fabric is. This is no accident. And it’s why factories save thread. Because the more colors they have on hand, the better chance they have of exactly matching your fabric. Now, this is super helpful in the sample-making process – for just a few garments that need a quick turnaround or a mini order with an MOQ of 10 pieces. However, during bulk, you might need to order your own DTM threads. WHAT'S WITH ALL THE BINDERS? It is not uncommon for a factory’s walls to put the library in Beauty and the Beast to shame (I don’t know why I’m throwing in all these pop culture references today, but I’m just in that kind of mood). This is because good factories will document, print, and save everything. TECH PACKS ARE LIVING AND BREATHING DOCUMENTS I already mentioned tech packs a few times. But this is something else worth knowing. A tech pack isn’t just something you make and then send out to the factory and forget about. It is a living document that is constantly changing with updates. Every time a change gets made to the tech pack, it is recorded. It is basically the ledger of the entire life of the style. So, because of all the changes, new pages are constantly being printed out (and the old ones are always saved). By the end of a season, there might be 3, 4, or even 5 or more binders full of all these documents and revisions for 1 brand. And, after the season is over, the factory saves all of this for years. That is because sampling from 2023, might not go into production until 2024. Also, if there is ever a similar style being made in the future, they can go back into their records and save a ton of time and money on development. PHOTOS During sampling and even bulk production, the sewing factory will take pictures of everything, print them out, and add them to the binder for a record of how everything looks. This also protects the factory in case of damages during shipping. I had this happen with one of my ex clients before. I sent all of their samples to them, and their warehouse damaged everything. They wanted me to refund them, saying I sent them damaged clothes. But I went back to my pre-shipment photos, and I was able to prove to them that the damage did not come from my side. FYI, as a brand you also should always take photos of what you are sending to a factory. This way, if a factory sends something back with a stain or damage on it, you can show them a photo of what condition the garment was sent to them in. IT’S NOT JUST PAPER IN THE BINDERS Swatches of fabric are usually cut and stapled onto the papers. This allows whoever is using the binder to see exactly what type of fabric will be used. The type of fabric affects everything in the sewing factory, from the pattern, to the types of machines used to sew the garment. Also, button, zipper, label, and even hang tag references are in the binders as well. All of this stuff is bulky and takes up space in the binders really quickly. That is why so many binders might be needed for just one brand’s collection. YOUR SEWING FACTORY’S HOARDING COULD BE YOUR SECRET DESIGN WEAPON Remember how I said factories save everything? This is probably the coolest part about that. FABRIC LIBRARY Many factories will have their own fabric libraries where they save small cuttings of each fabric that has passed through the space. They sometimes even keep records of the suppliers the fabrics came from and how to contact them for more. (hello, fabric sourcing made easy). TRIM LIBRARY And, just like the fabric library, there will sometimes be a trim library. The trim library will have samples of embellishments, labels, tags, and even embroidery. DESIGN LIBRARY And lastly, there is the design library for past samples. This particular sewing factory in Italy had generations worth of samples. And let me tell you, I was in heaven. This is the kind of quality stuff that just can't find anymore. And, is hard to find in vintage stores that are all picked through. If a factory has a design library, also known as a sample room, I urge you to spend as much time as possible exploring it. WHAT DO YOU THINK? The next time you visit your factory, are you going to look at what is going on in a whole new way? Let me know in the comments. Source link

0 notes

Photo

Getting ready to visit a fashion factory? This is for you, because your first visit can be A LOT to process. The good news is, figuring out what the heck you just walked into and if everything you saw was “normal” is something almost every new fashion brand struggles with after they leave that first meeting. So, I’m here to help make your life a little easier. And explain all the inner workings of a factory with A Look Behind The Seams of one of my favorite Italian clothing manufacturers. Let's break down all that sewing factory chaos. BUT BEFORE WE GET STARTED... I love helping startup brand founders succeed, so I created a bunch of free guides that will help you with your business. They won’t be free forever, so make sure to grab them while you can. WHAT YOU WILL LEARN ABOUT GARMENT FACTORIES Background info on this post Why clothing factories might appear super messy How and why space is optimized The importance of scrap paper and waste bins Why everything looks like a fire hazard The purpose of thread everywhere Why there are so many old binders The best place to find design inspiration, literally ever I mean, even just reading this table of contents, things sound totally chaotic. Let’s break it all down. WHAT THE HECK DID I JUST SEE? Here’s what usually happens. Founders set up their first appointment to meet with their clothing manufacturing partner in person. They are all excited to go. But after the meeting, when I ask them how it went, they are left feeling beyond confused. That’s because they leave not fully understanding everything they just witnessed. Often, they even question whether the sewing factory is competent enough to produce their products or if they are ethical. For example, a client of mine visited one of my favorite cut + sew factories in New York City and after they left, they told me they were uncomfortable working with them because the space was too cramped and messy. From the looks of it, they thought the sewing factory seemed unprofessional. Darling. (Said in my best Meryl Streep Devil Wears Prada voice). If a factory is good enough for some of the biggest names in New York fashion week, I am sure it’s good enough for you. So, to help you not freak out on your first fashion factory visit. I created this post. INSIDE THE INNER WORKINGS OF AN ITALIAN CLOTHING MANUFACTURER I was lucky enough to tour Italy this summer thanks to Italian Artisans. And, visit some of their partner factories that do everything from knitwear, to wovens, to accessories, and more. Full disclosure. They didn’t pay me a cent. I funded the entire month myself because I wanted to be able to write honestly about my experience. Anyway, my goal for the content I created during the trip was to give people a feel for what apparel manufacturing is all about. No sugar coating, no staged photo ops – just the reality of it all. So, when the first thing Jacopo said to me was, “Oh my God, it’s so messy in here. We didn’t have time to clean up for you. We are desperately trying to get things out so they are in time for Milan fashion week,” I knew it would be a perfect teaching moment. Because the truth is, sometimes (read, often) the messiest, craziest fashion factories are the best. And the ones that look like they popped out of Pinterest . . . Well, truth gun (Cougar Town reference), they probably look that perfect because they don’t have actual clients and no one is doing any real work in them. So, let me take you on a tour… WHY SEWING FACTORIES NEED TO OPTIMIZE THEIR SPACE Fashion factories are experts in making the most of every inch of space they have. And that is because they have to to be profitable. THIN PROFIT MARGINS First, let’s talk about the razor-thin margins most factories need to operate on. With a brand, if you buy something from a factory for $10, you will generally be able to sell it at wholesale for about $20, or direct to consumer for $40. That means your profit will be between $10-$30. So, if you order 1,000 shirts, you can make anywhere from $10,000-$30,000 on the order. Not bad. Factories, on the other hand, make a profit of about 5-20 percent, depending on the order. So, if the sewing factory sells you 1,000 shirts for $10 each, that means their entire profit will be anywhere between $500-$2,000 (even though the brand is paying them $10,000). Now, if you were wondering why it’s so hard to find suppliers that want to take on small MOQs, it’s because the money the factory can make on tiny orders is measly compared to the money the brand can make. So, the next time you try to nickel and dime a sewing factory for better prices, please remember this insight into their margins. BTW, For help finding low MOQ suppliers, you can check out this article. Okay, now that you understand the tiny margins factories are working with, let’s talk about some of their overhead costs. EXPENSIVE REAL ESTATE Historically, factories are near major fashion centers. There is the New York City Garment District and Downtown LA. In Delhi, the main factory area is Noida, and in Italy, many luxury Italian fashion houses are located around Como and Milan. But over the years, these areas have become increasingly expensive, meaning the price of rent has gone up. In New York City, I have seen many factories downsize their spaces and move out of the garment district to places like Jersey City and Brooklyn, where they can find cheaper rents. However, many of the factories I know that moved further out of the city then lost customers because their customers did not want to make the schlep to another state or borough to meet with them. That’s the problem with packing up and moving to a cheaper space. Brands are lazy, and because they tend to be more profitable, most are still based where the action is. Because of this, some factories then packed up again and moved back to the city, paying a premium on their rent, to be closer to their customers offices. Because every single square foot cuts away from the factories bottom line (especially in places like New York City), out of necessity, factories need to make the most out of every single inch of space they have. And that’s a big part of the reason things in factories tend to look pretty chaotic. MAKING SENSE OF THE MESS IN A SEWING FACTORY Now that you know why factories need to optimize their space, let’s go inside the fashion factory, and I will explain some of the methods behind their madness. FABRIC ROLLS AT THE DOOR I can’t tell you how many times I have walked into a factory and had to step over a roll or two of fabric. That is because, in small factories, there is only one door in and out. So when fabric is delivered, many factories leave the rolls that are going to be used first right there and move the rolls that aren’t for immediate product to storage areas. So, when you step over a roll of fabric at the entrance, I can almost guarantee it won’t be there tomorrow because it is going to be used right away. THE FACTORY FLOOR AND VERTICAL STORAGE It takes a lot of table space to unroll fabrics, cut them, organize them, sew them into garments, check the garments for quality control issues, press and iron them, and then pack them up.. The other thing that often happens is that customers end up using factories as free storage. When they have leftover tags, labels, heck, even rolls of fabric, they often leave them at the factory for the next order. And all of this cuts into the factory’s limited space. Because of this, factories are really good at using space vertically. There is almost always storage under every single table, and you will often see things stacked up to the ceilings. And paper patterns often hang on the walls. SHOWROOMS AND ARCHIVES Factories often have showrooms and archives, which serve as resources for small fashion brands. These garment samples are tools for clients to look at for inspiration and use as a reference for future designs. They also serve as examples of what the sewing factory has made in the past, and as examples of what type of quality a client can expect. SCRAP PAPER EVERYWHERE One of the first things you might notice when you walk into a factory are the scraps of paper literally everywhere. From scrap paper on the walls to scrap paper pinned onto garments. Seriously, it looks like a crazy person with amnesia is working there. But it all actually makes a lot of sense. POST-IT NOTES ON CLOTHES One thing you might notice on a lot of the clothes in a garment factory is that there are post-its and tiny scraps of paper pinned and stapled all over garments. These are notes for future alterations. So, there might be a scrap of paper stuck to a sleeve that says, “Reduce 2 inches.” And, another scrap of paper with a note that says, “Change the seam to a French seam.” There might even be little pieces of fabric tacked onto the sample to show what colors or what types of fabrics go where in the next sample set. Now, you might be wondering, aren’t all of these changes in the tech pack? In a working sewing factory setting, a lot of people prefer notes over techpacks. That is because it makes it a lot easier for people to physically see what needs to be changed without having to look at an Excel spreadsheet. SKETCHES Papers with sketches and CADs (computer aided designs - think sketches of the clothes made in Adobe Illustrator or Photoshop) are usually all over the place. Attached to boards on the wall, in plastic sheet protectors, and pinned onto the physical samples. These sketches serve two different purposes. The sketches on the wall are a way to view the entire collection. There might even be notes next to these sketches letting everyone know if the sample was made, needs to be made, or if something is delaying the process (like if fabric is missing and when it can be expected to arrive at the factory). Basically, the sketches on the wall show everyone very clearly what styles are in works in the factory. The sketches that are attached to the garment help the pattern makers and sewers ensure that the end garment looks the way it should. The truth is, many people who work in sewing factories (not in Italy, but in other parts of the world) are illiterate and don’t know how to read. But everyone can understand images, which is why as industry pros love them. Even if the sewers know how to read and write, using images tends to speed up their sewing and prevent mistakes. Using images also help the sewing factory catch the brand's mistakes. Here’s an example of that. Sometimes a tech pack will have the wrong measurements on it. Say you want to create a short sleeve; the measurements on the tech pack might accidentally measure for a long sleeve shirt. When the factory sees the sketch of the dress with short sleeves and realizes there is a discrepancy in the measurements, they will most likely call the brand and clarify exactly what the company wants instead of doing the wrong thing. CALCULATIONS Did you know that patternmaking is basically math class? It’s like the least artistic part of the garment process, and generally, good patternmakers have above-average math (especially geometry) skills. So, when you go over to the area of the factory where the patternmaker works, you will probably find tons of scraps of paper with really rough sketches with numbers and math equations on them. GARBAGE BINS FULL OF ROLLED-UP PAPERS In a lot of factories, you will find garbage bins filled with rolled-up papers. Like, literally overflowing. But this isn’t trash. These papers are cutting markers, and it would actually be horrible if they got thrown out. Cutting markers are long sheets of paper with clothing patterns on them. They are laid over fabric that help guide the factory workers on how to cut the fabric to get the most pattern pieces possible using the least amount of fabric (read, helps brands save money by using less materials). The trash bin is usually just a makeshift storage container for these papers. TINY BOBBINS OF SEWING THREADS One last random thing you might notice about a sewing factory is that there is so much thread. It’s everywhere. I once got tangled in a snagged thread, and it all felt very No Doubt Walking In The Spider Webs - click here if you can’t get that song out of your head now… But, there is a really specific reason for this. It is for a sewing instruction called DTM, or dyed to match. Did you ever notice how seams in clothes almost always match the fabric? If the shirt is black, the thread is also black. On blue jeans, they use blue thread. And the thread almost exactly matches whatever specific shade of color the fabric is. This is no accident. And it’s why factories save thread. Because the more colors they have on hand, the better chance they have of exactly matching your fabric. Now, this is super helpful in the sample-making process – for just a few garments that need a quick turnaround or a mini order with an MOQ of 10 pieces. However, during bulk, you might need to order your own DTM threads. WHAT'S WITH ALL THE BINDERS? It is not uncommon for a factory’s walls to put the library in Beauty and the Beast to shame (I don’t know why I’m throwing in all these pop culture references today, but I’m just in that kind of mood). This is because good factories will document, print, and save everything. TECH PACKS ARE LIVING AND BREATHING DOCUMENTS I already mentioned tech packs a few times. But this is something else worth knowing. A tech pack isn’t just something you make and then send out to the factory and forget about. It is a living document that is constantly changing with updates. Every time a change gets made to the tech pack, it is recorded. It is basically the ledger of the entire life of the style. So, because of all the changes, new pages are constantly being printed out (and the old ones are always saved). By the end of a season, there might be 3, 4, or even 5 or more binders full of all these documents and revisions for 1 brand. And, after the season is over, the factory saves all of this for years. That is because sampling from 2023, might not go into production until 2024. Also, if there is ever a similar style being made in the future, they can go back into their records and save a ton of time and money on development. PHOTOS During sampling and even bulk production, the sewing factory will take pictures of everything, print them out, and add them to the binder for a record of how everything looks. This also protects the factory in case of damages during shipping. I had this happen with one of my ex clients before. I sent all of their samples to them, and their warehouse damaged everything. They wanted me to refund them, saying I sent them damaged clothes. But I went back to my pre-shipment photos, and I was able to prove to them that the damage did not come from my side. FYI, as a brand you also should always take photos of what you are sending to a factory. This way, if a factory sends something back with a stain or damage on it, you can show them a photo of what condition the garment was sent to them in. IT’S NOT JUST PAPER IN THE BINDERS Swatches of fabric are usually cut and stapled onto the papers. This allows whoever is using the binder to see exactly what type of fabric will be used. The type of fabric affects everything in the sewing factory, from the pattern, to the types of machines used to sew the garment. Also, button, zipper, label, and even hang tag references are in the binders as well. All of this stuff is bulky and takes up space in the binders really quickly. That is why so many binders might be needed for just one brand’s collection. YOUR SEWING FACTORY’S HOARDING COULD BE YOUR SECRET DESIGN WEAPON Remember how I said factories save everything? This is probably the coolest part about that. FABRIC LIBRARY Many factories will have their own fabric libraries where they save small cuttings of each fabric that has passed through the space. They sometimes even keep records of the suppliers the fabrics came from and how to contact them for more. (hello, fabric sourcing made easy). TRIM LIBRARY And, just like the fabric library, there will sometimes be a trim library. The trim library will have samples of embellishments, labels, tags, and even embroidery. DESIGN LIBRARY And lastly, there is the design library for past samples. This particular sewing factory in Italy had generations worth of samples. And let me tell you, I was in heaven. This is the kind of quality stuff that just can't find anymore. And, is hard to find in vintage stores that are all picked through. If a factory has a design library, also known as a sample room, I urge you to spend as much time as possible exploring it. WHAT DO YOU THINK? The next time you visit your factory, are you going to look at what is going on in a whole new way? Let me know in the comments. Source link

0 notes

Text

Industrial Sewing Machine Market

Industrial Sewing Machine Market Share, Segmentations and Forecast by 2032

Market Definition

Industrial sewing machines are designed for heavy-duty use in various industries, including apparels, shoes, bags, home textiles, and car products. These machines are built to withstand high volumes of production and are equipped with advanced features such as automatic threading, tension control, and stitch selection.

Market Size and Growth Prospects

The global Industrial Sewing Machine Market size was valued at USD 3012 Million in 2023 and is projected to reach from USD XX Million in 2024 to USD 4785 Million by 2032, growing at a CAGR of 5.2% during the forecast period (2024–2032).

Download Free Sample Report with Complimentary Analyst Consultation: https://straitsresearch.com/report/industrial-sewing-machine-market/request-sample

Drivers in the Industrial Sewing Machine Market

The growth of the industrial sewing machine market is driven by several factors, including:

Increasing demand for industrial sewing machines in various industries

Advancements in technology and design

Growing importance of automation and efficiency in manufacturing processes

Rising demand for customized and high-quality products

Key Developments in the Industrial Sewing Machine Market

The report highlights several key developments in the industrial sewing machine market, including:

The increasing adoption of automated and computerized sewing machines

The growing trend of Industry 4.0 and smart manufacturing

The rising demand for sustainable and eco-friendly sewing machines

Top Key Players

The report highlights the top key players in the industrial sewing machine market, including:

Juki Corporation

Jack Sewing Machine Co. Ltd

Zoje Sewing Machine Co. Ltd.

ShangGong Group

Barudan Co. Ltd.

ZSK Machines

Happy Japan Inc.

Feiya Group Co. Ltd

Mitsubishi Electric Corporation

Seiko Sewing Machine co., Ltd.

Segmentation Analysis of the Industrial Sewing Machine Market

The global Industrial Sewing Machine Market is segmented based on type, application, and sales channel.

By Type

General Swing Machines

Embroidery Machines

Quilting Machines

Others

By Application

Apparels

Shoes

Bags

Home Textiles

Car Products

By Sales Channel

Direct Channel

Indirect Channel

Market Segmentation: https://straitsresearch.com/report/industrial-sewing-machine-market/segmentation

Regional Insights

North America: The region’s growth is driven by technological adoption in the apparel and automotive industries, with the U.S. and Canada leading the market.

Europe: Europe’s emphasis on high-quality textile production and sustainability supports demand, particularly in Germany, Italy, and France.

Asia-Pacific: APAC is the fastest-growing region, attributed to expanding textile and garment manufacturing hubs in China, India, and Southeast Asia.

Latin America, Middle East, and Africa (LAMEA): Emerging economies in Latin America and Africa are witnessing increased adoption of industrial sewing machines for apparel production and other applications.

Buy Full Report (Exclusive Insights): https://straitsresearch.com/buy-now/industrial-sewing-machine-market

0 notes

Text

Electronic Top & Bottom Feed Lockstitch

An Electronic Top & Bottom Feed Lockstitch Sewing Machine is an advanced industrial sewing machine that uses electronic control systems to manage its top and bottom feed mechanisms. This type of Lockstitch machine is commonly used in garment manufacturing, upholstery, and other textile industries where consistent stitching quality is required. Below is an overview of the key features and functionality of this machine:

Key Features Of Electronic Top & Bottom Feed Lockstitch:

Lockstitch Mechanism: It utilizes a Feed Lockstitch, the most common stitch type used in sewing, where the top and bottom threads interlock to form a secure seam. This stitch is known for its strength and durability.

Top and Bottom Feed: Top Feed: The top feed mechanism ensures that the fabric is fed smoothly from above. It helps in preventing shifting or slippage of the material, especially with thick or slippery fabrics.

Bottom Feed: The bottom feed, typically provided by the machine’s feed dogs, works in tandem with the top feed to ensure that the fabric moves evenly through the machine.

Combined Feed: The combination of top and bottom feed is ideal for sewing multiple layers of fabric or fabrics that tend to shift during sewing, such as leather or heavy-duty materials.

Electronic Control: The electronic control system allows precise adjustments for stitch length, speed, and tension, providing better control over stitching quality.

Automated Features: Electronic machines can include features such as automatic thread trimming, needle position control, and programmable stitching patterns.

Stitch Length Control: Most modern electronic Feed Lockstitch machines have digital controls that allow easy adjustment of the stitch length, helping to create fine or bold stitches based on the application.

Speed Control: Electronic machines often have variable speed settings that can be adjusted for different types of fabric and production requirements.

Energy Efficiency: Being electronically controlled, these machines are generally more energy-efficient and provide consistent performance over time.