#precision tool and manufacturing

Explore tagged Tumblr posts

Text

Understanding the Basics of Tool Manufacturing.

Tools are an integral part of diverse industries, including automotive, construction, aerospace, medicine, and others. Every sector requires tools for various purposes. Screws, bolts, fixtures, moulds, jigs, etc.- tools are the necessary materials for working on a stock piece. Whether you need to assemble or disassemble pieces of products, you cannot do it without using tools. please click the link below for more infomation

https://www.essaypub.com/articles/understanding-the-basics-of-tool-manufacturing-100579.html

#industrial manufacturing#industrial companies#manufacturing companies#manufacturing process#manufacturer#precision machining#production basics#used manufacturing equipment#quality in manufacturing#industrial manufacturing companies#design manufacturing#production and manufacturing#manufacturing company in#production tooling#product production#production machines#production and manufacturing companies#mfg company#used manufacturing#manufacturing productivity#precision tool and manufacturing#production manufacturing company#a manufacturing industry#manufacturing pvt ltd#make in india#made in india#made in up#make in up#made in noida

1 note

·

View note

Text

Why Our High-Precision Rotavator Accessories Are Farmers Top Choice Globally

Introduction to SBJ Nirmal Products

Our Mission and Commitment

SBJ Nirmal Products has always stood for excellence in manufacturing agricultural machinery parts. Our mission is to empower farmers worldwide with reliable, efficient, and affordable rotavator accessories.

Understanding the Needs of Farmers

Farmers require tools and parts that are both dependable and cost-effective. SBJ Nirmal Products ensures that every component meets the highest standards, making farming easier and more productive.

What Sets Our Rotavator Accessories Apart?

High-Precision Engineering

Our rotavator accessories are crafted with advanced engineering techniques to deliver unmatched precision and performance.

Durable and Long-Lasting Materials

We use only the finest materials to ensure that our products can withstand the toughest agricultural conditions.

Compatibility with Global Standards

SBJ’s accessories are designed to fit a wide range of machinery, adhering to international quality standards.

The Range of Rotavator Accessories We Offer

Rotavator Blades

Our blades are sharp, durable, and perfect for soil preparation, ensuring efficiency and longevity.

Shafts and Gearboxes

Essential for smooth operation, these components are engineered to handle heavy-duty tasks with ease.

Bearings and Bushings

Designed to minimize friction and wear, our bearings and bushings enhance the lifespan of farming machinery.

Stub Axles

These components ensure the balance and stability of agricultural equipment, providing reliability in challenging terrains.

Why Farmers Trust SBJ Nirmal Products

Testimonials from Global Farmers

Farmers worldwide vouch for the quality and durability of our products, sharing stories of improved efficiency and reduced costs.

Awards and Certifications

Our commitment to excellence is recognized through numerous awards and certifications, solidifying our reputation as a trusted brand.

Our Global Reach

Exports to Neighboring Countries

SBJ Nirmal Products proudly exports to countries like Bangladesh, Nepal, and Sri Lanka, supporting farmers across borders.

Expanding Presence in International Markets

With a growing demand for our products, we are steadily expanding our reach to serve farmers worldwide.

How Our Accessories Enhance Farming Efficiency

Boosting Productivity

By providing reliable and efficient parts, we help farmers maximize their yields and streamline their operations.

Reducing Downtime and Maintenance Costs

Our durable accessories minimize breakdowns and maintenance needs, saving farmers time and money.

Innovation at SBJ Nirmal Products

Research and Development Initiatives

We continually invest in R&D to develop innovative solutions that meet the evolving needs of the agricultural sector.

Sustainability in Manufacturing

Our eco-friendly practices ensure that we contribute to sustainable farming, reducing waste and environmental impact.

Conclusion

SBJ Nirmal Products has become a global leader in agricultural machinery parts by combining innovation, quality, and affordability. Farmers trust us to deliver the best rotavator accessories, empowering them to achieve success in their fields. Choose SBJ Nirmal Products for a prosperous farming future.

#high-precision rotavator accessories#SBJ Nirmal Products#farmers’ top choice globally#durable farming equipment#rotavator spare parts#precision-engineered machinery#reliable farming tools#global agricultural solutions#advanced farming technology#rotavator parts manufacturer#agricultural machinery accessories#efficient farming tools#SBJ rotavator parts#farming innovation#sustainable agriculture solutions

0 notes

Text

This complete guide will provide an in-depth look at what precision machining is, how it works, and why it’s indispensable in modern manufacturing.

#precision machining#precision machining components#precision machining tools#precision machining parts#Precision machining manufacturer#Precision#Machining Parts Manufacturer#precision machining company

0 notes

Text

Leading the Way in Surgical Innovation: Mercury S1 Sternum Saw

Mercury Healthcare stands at the forefront as a leading manufacturer and exporter of Sternum Saw in India, offering advanced medical instruments that prioritize precision, safety, and ease of use. Among their most distinguished offerings is the Mercury S1 Sternum Saw, designed to provide exceptional performance in sternotomy procedures. Renowned for its innovative design and superior quality, the Mercury S1 Sternum Saw has become a trusted tool for surgeons worldwide.

Clear Line of Sight and Lightweight Design for Unparalleled Control

The Mercury S1 Sternum Saw offers a clear line of sight, providing surgeons with an unobstructed view of the surgical area for precise incisions. Its lightweight design ensures exceptional control, reducing fatigue and enhancing surgical comfort. This combination of clarity and ease of handling makes it ideal for both routine and complex surgeries, allowing surgeons to perform with confidence and accuracy. Mercury Healthcare continues to be a leading manufacturer and exporter of Sternum Saw in India, trusted by medical professionals for its quality and innovation.

ETO Sterilization and Autoclaving for Quick Turnaround

Efficiency in the surgical setting is vital, and the Mercury S1 Sternum Saw has been designed with this in mind. It can be sterilized using Ethylene Oxide (ETO) or autoclaved, ensuring a quick turnaround time between procedures. This flexibility allows healthcare facilities to maintain a consistent and hygienic workflow, enabling them to meet the demands of busy surgical schedules. By offering multiple sterilization options, Mercury Healthcare continues to set the standard for convenience and reliability in medical instruments, further solidifying its reputation as a leading manufacturer and exporter of Sternum Saw in India.

Convenient Quick-Release Blades and Patented Re-Tention System

The Mercury S1 Sternum Saw features a quick-release blade mechanism for easy, swift blade changes during surgery, improving operational efficiency. Its patented re-tention system securely holds the blade in place, ensuring stability and reducing the risk of complications. By focusing on ease of use and efficiency, Mercury Healthcare maintains its position as a leading manufacturer and exporter of Sternum Saw in India, delivering innovative tools for modern healthcare.

Sterile and Non-Sterile Blades for Enhanced Versatility

Mercury Healthcare understands that flexibility is key in the medical field. As such, the S1 Sternum Saw is compatible with sharp, single-use blades that come in both sterile and non-sterile bulk packs. Surgeons can choose the option that best suits their preferences and the specific requirements of the procedure, ensuring optimal safety and convenience. The availability of these various options further contributes to Mercury Healthcare’s standing as a leading manufacturer and exporter of Sternum Saw in India, committed to offering products that cater to diverse needs in the healthcare industry.

Tapered Blade Protector for Tissue Protection

Safety and tissue protection are essential considerations in any surgical procedure. The Mercury S1 Sternum Saw is designed with a tapered blade protector that helps deflect underlying tissues from direct contact with the blade. This innovative feature adds an extra layer of safety, preventing accidental tissue damage and promoting faster recovery for patients. As a result, surgeons can trust the Mercury S1 Sternum Saw to provide reliable and safe outcomes, enhancing its reputation as a go-to tool for sternotomy surgeries.

Compatible with Original S1 Electro-Mechanical Drive System

For advanced surgical procedures, compatibility with other high-end medical systems is crucial. The Mercury S1 Sternum Saw is fully compatible with the original S1 electro-mechanical drive system. This compatibility ensures that the saw operates seamlessly with existing medical equipment, providing medical professionals with a reliable and efficient tool for sternotomy surgeries.

Conclusion

As a trusted manufacturer and exporter of Sternum Saw in India, Mercury Healthcare sets the standard for high-quality surgical instruments. The Mercury S1 Sternum Saw reflects their commitment to innovation, offering unmatched control, convenience, and safety. With features like clear sight, lightweight design, quick-release blades, and compatibility with the S1 electro-mechanical drive system, Mercury Healthcare is a trusted leader in the medical equipment industry.

#Best manufacturer and supplier of India#Mercury S1 Sternum Saw#Leading manufacturer and exporter in India#Surgical instruments#Medical equipment India#Precision surgical tools#Lightweight surgical saw

1 note

·

View note

Text

Automotive Component Manufacturing Experts | Metalman Auto Ltd.

Metalman Auto Ltd. stands as a Best Automotive Component Manufacturing Experts, delivering precision-engineered solutions to Original Equipment Manufacturers (OEMs) across the automotive industry. With over three decades of experience, we specialize in producing high-quality components for two-wheelers, three-wheelers, passenger vehicles, commercial vehicles, and off-highway vehicles, meeting the exacting standards of performance, reliability, and durability.

Our advanced manufacturing facilities are equipped with cutting-edge technologies, including CNC machining, metal stamping, tubular fabrication, and metal finishing. This allows us to offer a wide range of automotive components, from chassis parts to engine components and body panels. Each product is meticulously crafted to meet the specific needs of our OEM partners, ensuring seamless integration and optimal performance in their vehicles.

At Metalman Auto Ltd., quality is embedded in every step of our manufacturing process. We adhere to ISO-certified quality management systems and employ rigorous testing and inspection procedures to ensure that every component we produce meets or exceeds industry standards. Our commitment to excellence has earned us a reputation as a trusted partner for some of the most renowned names in the automotive industry.

Innovation is at the core of our operations. We continuously invest in research and development to stay ahead of industry trends and provide our clients with the most advanced automotive component solutions. Our team of skilled engineers and technicians works closely with OEMs to develop customized components that meet the unique challenges of today’s automotive market, from electric vehicles (EVs) to autonomous driving technologies.

Partner with Metalman Auto Ltd. to experience the expertise and reliability. best automotive component manufacturing experts. Explore our comprehensive range of services and discover how we can help you drive success in your automotive projects.

#OEM metal fabrication services#Custom metal parts manufacturer for OEMs#Bespoke metal fabrication for automotive industry#Custom metalwork for vehicle manufacturers#Precision metal fabrication for OEMs#Specialized metal fabrication for automotive parts#Tailored metal fabrication solutions for OEMs#Custom steel fabrication for automotive OEMs#Metal parts supplier for automotive industry#OEM metal components manufacturer#Automotive metal fabrication services#Steel and aluminum components for vehicles#Automotive metal body parts supplier#Precision metal parts for automotive applications#Automotive structural components manufacturer#OEM automotive metal components provider#Tube fabrication for automotive applications#Precision tube bending services#Tubular components manufacturer for OEMs#Automotive tubular parts fabrication#Custom tube fabrication for vehicles#Metal tube fabrication for automotive industry#Precision pipe fabrication services#Tubular assembly solutions for automotive OEMs#automotive tools#automotive industry#automotive innovation#automobile#automotive#crack in the chassis

1 note

·

View note

Text

Exploring the Different Sizes and Thicknesses of Precut Shims

This article explains Precut shims are thin, flat pieces of material, typically metal, that are pre-manufactured to specific dimensions and ready for immediate use. Unlike custom shims that require on-site cutting, precut shims are designed for convenience and precision, ensuring that you can quickly and easily fill gaps, level components, or adjust alignments in various applications.

Key Features of Precut Shims:

Precision: Manufactured to exact dimensions, providing consistent results.

Material Options: Available in various materials, including stainless steel, brass, and aluminum.

Ease of Use: Ready to use right out of the package, saving time on the job.

It further explains some applications of various sizes and thicknesses of precut shims like Automotive Industry, Construction, Manufacturing, Aerospace.

It also explains some benefits of precut shims that make them a preferred choice in many industries:

Time-Saving:

Precut shims are ready to use, eliminating the need for on-site cutting and reducing downtime.

Consistency:

Manufactured to precise specifications, precut shims offer consistent quality and performance, ensuring uniform results across projects.

Versatility:

Available in various sizes, thicknesses, and materials, precut shims can be used in a wide range of applications, from automotive to construction.

Cost-Effective:

By reducing the need for custom fabrication and minimizing waste, precut shims can save you money in the long run.

Precision:

The accuracy of precut shims ensures that your components fit together perfectly, reducing wear and tear and extending the life of your equipment.

Overall understanding the different sizes and thicknesses of precut shims is crucial for selecting the right one for your project. Whether you're aligning machinery, leveling a structure, or fine-tuning a precision component, choosing the right precut shim can make all the difference.

Take your time to measure the gap accurately, consider the load requirements, and select a shim sheet that meets your specific needs. With the right precut shim, you can achieve a precise fit, improve the longevity of your equipment, and ensure the success of your project.

#PrecutShims#Shims#Hardware#Tools#MechanicalEngineering#DIY#Workshop#Industrial#Precision#Manufacturing#Engineering#Technical#Mechanical#PrecisionEngineering#Machining#Fabrication#Assembly#Maintenance#Repair#Troubleshooting#ProblemSolving

0 notes

Text

Press Tools Manufacturers for Quality Tooling Solutions| CMD PPL

CMD Precision Products offers top press tools and press components. Get reliable, high-quality manufacturing solutions for all your precision needs.

0 notes

Text

See how industrial models are changing the way we design and make things. This blog looks at why these detailed 3D models are so important. They help us visualize designs better, ensure everything fits perfectly, improve how we talk about projects, and make planning and testing smoother. Find out why these models are key in fields like aerospace and automotive, and how they help in creating great designs.

#Industrial models#Modern design#Aerospace engineering#Automotive design#Precision engineering#3D modeling#Design innovation#Manufacturing processes#Engineering tools#Design excellence#Industrial design#Model making#Production planning#Visual simulations#Engineering models

1 note

·

View note

Video

youtube

Mazak Smooth Technology: Mazak Integrex i 250H ST AG

#youtube#Mazak Integrex i 250H ST AG#Balancing Cutting#Gear Skiving#Hobbing#Endmilling#Engraving#CNC Machining#Machine Tools#Metal Cutting#Manufacturing Technology#Mazak Smooth Technology#CNC Turning#CNC Milling#Gear Manufacturing#Precision Engineering#Machine Tool Demonstration#Metalworking#Industrial Machinery#High-speed cutting#High-precision machining#Hobbing technology#Gear skiving technology#Engraving capabilities#Endmilling capabilities

0 notes

Text

Precision tools holders Manufacturer in Germany | Birla precision

Birla precision is the top Precision tools holder Manufacturer in Germany. Our precision tool holders are manufactured and exported from Germany, ensuring high-quality and reliable performance. With a focus on precision engineering, our tool holders are designed to provide secure and accurate tool positioning for various machining applications. Made with durable materials and advanced manufacturing techniques, our precision tool holders are built to withstand heavy-duty use and deliver consistent results. Whether you are in the automotive, aerospace, or general manufacturing industry, our precision tool holders are the ideal choice for your machining needs. Trust in the precision and quality of our German-made tool holders for your machining operations.

0 notes

Text

What are the most used tools in manufacturing?

To find tool and die shops near you, you can visit the website "Precision Metal Stamping Manufacturers" and navigate to their directory of tool and die shops. This directory provides a comprehensive list of companies specializing in tool and die manufacturing, allowing you to locate shops in your vicinity easily. Simply enter your location or browse through the listed companies to find the nearest options for your needs. Whether you require custom tooling solutions or standard die manufacturing services, this directory offers a convenient way to connect with reputable shops in your area.

Contact Us for - Unbelievable Facts About Progressive Tool Manufacturing

0 notes

Text

The Optical Profile Projector’s astonishing Qualities

Greetings! Obtaining the right tool has become a difficult task in this competitive market. Simply reach out to a precision measurement tools manufacturer! In today’s technology, precision and accuracy are paramount, driving the need for advanced measurement tools that can meet the demanding standards of modern manufacturing. One such indispensable tool is the Optical Profile Projector, a sophisticated optical instrument designed for precision measurement and quality control. Continue reading to explore the amazing qualities of the Optical Profile Projector and outline the compelling reasons why businesses and industries are eager to invest in this cutting-edge technology

https://atoznewsprime.com/the-optical-profile-projectors-astonishing-qualities/

0 notes

Text

Precision Machining Solutions for All Types of Industries

Looking for unparalleled accuracy and reliability in machined components? At Petron Thermoplast, we specialize in delivering high-quality precision machining solutions tailored to meet the unique needs of diverse industries.

Visit Website - https://petronthermoplast.com/precision-machining/

Contact No. - +91-8218684097

Request for Quotation - [email protected]

#precisionmachining #industrialsolution #machining #engineering #manufacturing #machine #customsolutions #engineeringsolutions #machinedparts #manufacturingexcellence #PrecisionMachining #EngineeringSolutions #CNCmachining #ManufacturingInnovation #PetronThermoplast

#precision machining#precision machining components#precision machining tools#precision machining parts#Precision machining manufacturer#Precision#Machining Parts Manufacturer#precision machining company

0 notes

Text

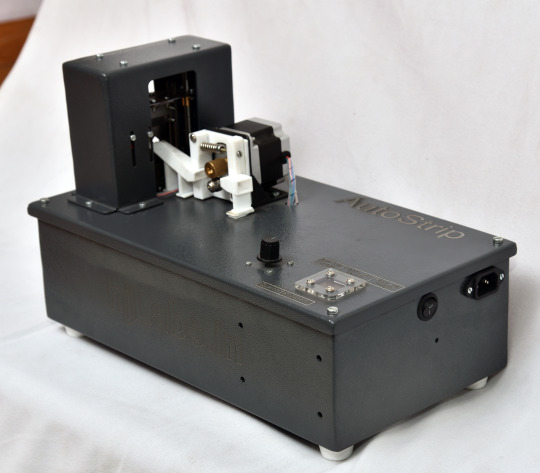

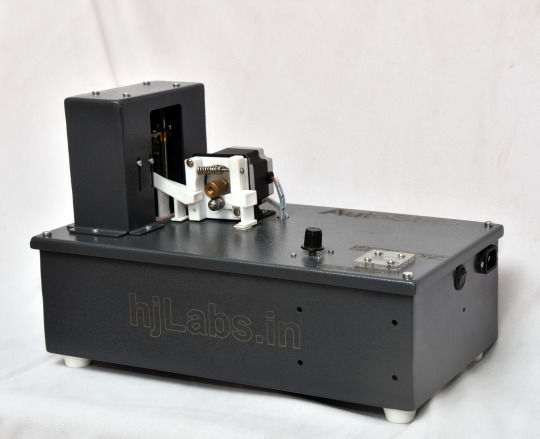

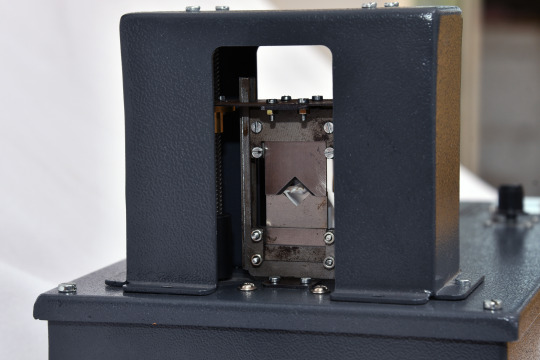

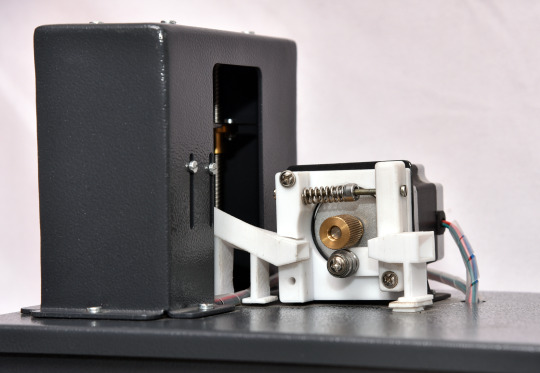

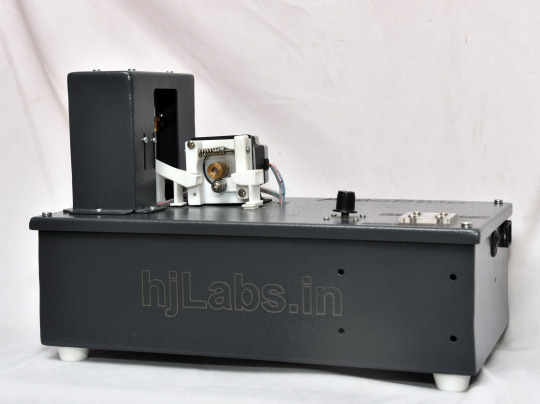

🔌 Ultimate Cable Processing Machine | Boost Efficiency & Precision! Discover the Future Today!

Experience unmatched efficiency with our 🚀 Auto Wire Cutting & Stripping Machine. Say goodbye to manual labor with our 🔧 #InnovativeTool. Ideal for electrical, automotive, and telecommunications industries.👩🔧👨🏭. For purchases, message us on WhatsApp or Telegram at 📱 +917016525813. Buy now : https://hjlabs.in/product/%f0%9f%94%8c-industrial-wire-cable-cutting-stripping-machine-precision-automatic-cutter-for-efficient-production/ #WireStripper #AutomationTech #ElectricalTools #TimeSaver 🎯 https://youtu.be/hi66O8-YRXs https://www.youtube.com/watch?v=MlTAD-kieaw 3d Design and Code files on grabcad : https://grabcad.com/library/automatic-wire-cutter-and-stripper-machine-1 only cutting machine : https://www.youtube.com/watch?v=TzW5WMWv-x8 Acrylic version : https://www.youtube.com/watch?v=bnWMskTA5V4 https://linktr.ee/hemangjoshi37a WhatsApp & Telegram : +917016525813 Email : [email protected] Place a custom order on hjLabs.in : https://hjLabs.in ----------------------------------------------------------------------------- Checkout Awesome Videos : SWiBoard - A Killer Gadget to Boost Your Boring Switchboard : https://youtu.be/BrakSGmQZB8 રુધિર વહીનીઓ અને એના કર્યો. : https://youtu.be/T7mMcEYNKyQ મનુષ્યમાં પરિવહન તંત્ર | परिसंचरण तंत्र : https://youtu.be/vxa6o_wrWnY હદય અને હદયના ધબકારા : https://www.youtube.com/watch?v=9v3MK6oTOeA AutoCut V2 - Automatic Wire Cutting Machine : https://www.youtube.com/watch?v=bnWMskTA5V4 મનુષ્યમાં ઉત્સર્જન-તંત્ર : https://www.youtube.com/watch?v=UUGI-CFKsWI

#industrial wire cutter#cable stripping machine#automatic cable cutter#precision wire processing#efficiency#manufacturing equipment#automation#wire and cable industry#quality control#productivity#industrial technology#wire cutting technology#cable stripping equipment#industrial automation#electrical industry#manufacturing solutions#wire processing machinery#cutting-edge tools#automation benefits#production efficiency#cable management#wire manufacturing

1 note

·

View note

Text

Patterson Mold & Tool

Industrial Machinery Manufacturing

Address- 1005 Portwest Dr #5971, St Charles, MO, USA 63303

Phone- +1 (636) 940-9988

Email- [email protected]

Website- https://pattersonmold.com/

The experienced manufacturing experts at Patterson Mold and Tool are dedicated to helping you bring your ideas and products to life with the highest level of innovation, precision, and quality. Whether you need a custom mold for a specific product, a tool or process for manufacturing, precision machined components, or product engineering services, we have the expertise and resources to deliver exceptional results. We pride ourselves on our ability to collaborate closely with our clients to understand their unique needs and provide customized solutions that exceed their expectations. Contact us today to learn more about how we can help you with your next project.

Business Hours- Mon-Fri: 7AM - 5:30PM.

Follow On-

Facebook

LinkedIn

#Precision component manufacturing#Tool and die services#Product engineering services#New product development

1 note

·

View note

Text

Top Quality Tools And Die Manufacturers in Noida, India, UK, USA, UAE, & Germany

Raamps is a rapidly growing name in Tools And Die Manufacturers in Noida, India, UK, USA, UAE, & Germany. The company's cutting-edge manufacturing facilities and skilled workforce enable them to produce high-quality tools and dies for a range of applications. With a focus on innovation and efficiency, Raamps strives to deliver superior products that meet the needs of their customers. Their commitment to quality, reliability, and customer satisfaction has earned them a reputation as a leading tools and die manufacturer. Raamps' global presence and dedication to continuous improvement make them an excellent partner for businesses seeking reliable and high-quality tools and dies.

Call Us: (+91) - 9818588668

Email id: [email protected]

Address: J-60, Site V, Kasna Industrial Area Greater Noida - 201310 UP(INDIA)

URL: https://raampsindustries.com/tool-die/

#Tools And Die Manufacturers#Sheet Metal Stamping Manufacturers#Precision Sheet Metal Components manufacturers

0 notes