#industrial technology

Explore tagged Tumblr posts

Text

Top-Quality Industrial Electronics Components Services from Computronics Lab

Having access to high-quality, reliable electronic parts is important for the smooth running of many systems in today’s fast-paced business world. The Greater Noida-based Computronics Lab is known for being a reliable source of high-quality industrial electronics parts and services that meet companies’ needs perfectly.

Why Choose Computronics Lab?

1. Varieties of Products

Computronics Lab has a wide selection of industrial electronic components such as sensors, microcontrollers, power sources, and relays, besides others; we have it all. Be it automation, robotics, or components for manufacturing, our stock aims to meet various kinds of industrial touts.

2. Quality Second to None

The company needs to understand that the quality of the components will determine how well or how well your industrial systems will perform. This is why we procure them from reputed manufacturers and undergo stringent quality checks on all products to ensure their flawless workings.

3. Custom-made Solutions

Every industry has its needs. Our staff does not hesitate to work with clients to know their exact needs and develop highly customized solutions designed to meet those exact needs. Thus, you will find the right parts for your projects.

4. Technical Support

Computronics Lab offers more than just parts. We offer technical assistance that is knowledgeable enough to enable you to put together and troubleshoot your system’s components. Our staff are available 24–7 to provide you with installation and operation advice.

5. Competitive Pricing:

We believe in providing value without lowering the standard. Our pricing is established to be competitive so that businesses of all kinds can afford it.

Applications We Serve

People use our industrial technology parts for a lot of different things, like

Automation Systems: You can get more done if your sensors, motors, and devices work well.

Robotics: Our cutting-edge parts let you make complex robotic systems.

Manufacturing Equipment: Use durable, high-performance electronics to keep production lines running smoothly.

Power Systems: Our high-end power electronics systems will make sure that the power is distributed safely.

Partner with Computronics Lab Today

The goal of Computronics Lab is to provide companies with the finest electronics components and support services. Businesses in many different areas choose us because we are known for quality, reliability, and customer-focused solutions.

Don’t wait to talk to us about your business’s tech needs. When you need help driving innovation and practical success, you can count on Computronics Lab.

#computronics lab#buy electronics components online#industrial electronic components#electronics components#industrial technology

0 notes

Text

Invest Smart: The Case for Buying Sensata Technologies Now

Discover Sensata Technologies Holding operations, stock price trends, and investment insights. Learn why this global industrial technology #SensataTechnologiesHolding #ST #Stockpriceforecast #Investmentinsights #Dividendpolicy #Marketanalysis

Sensata Technologies Holding plc is a global industrial technology company. They develop, manufacture, and sell sensors, sensor-rich solutions, electrical protection components, and systems. Their products are used in mission-critical systems to help customers address complex engineering and operating performance requirements. Sensata operates in two main segments: Performance Sensing and Sensing…

#Dividend policy#Financial performance#Industrial technology#Investment#Investment Insights#Investment Opportunities#Long-term growth#Market Analysis#Sensata Technologies Holding#Sensors and solutions#Stock Forecast#Stock Insights#Stock Price Forecast

0 notes

Text

Effective pilot plant scale up is essential for transitioning from small-scale experiments to full-scale production. The process ensures that all parameters are optimized for efficiency, cost-effectiveness, and quality control. Learn more about the importance of pilot plant scale up and how it can significantly enhance your production capabilities.

0 notes

Text

Industrial Technology: What Comes to Your Mind? Let's Explore!

Industrial technology is a broad and dynamic field that encompasses various innovations and methodologies designed to improve manufacturing processes, enhance efficiency, and drive economic growth. When we think about industrial technology, several key concepts come to mind: automation, smart factories, sustainable practices, and advanced manufacturing techniques. This article explores these facets in detail, highlighting the transformative effects of industrial technology and its impact on different sectors. By delving into these aspects, we aim to provide a comprehensive understanding of industrial technology and its future prospects.

The Rise of Automation

Automation is at the forefront of industrial technology, revolutionizing the way goods are produced. The introduction of robotics and automated systems has significantly increased production efficiency and consistency. Automated machines can perform repetitive tasks with precision and speed, reducing the need for manual labor and minimizing human error. For example, automotive manufacturers use robotic arms for assembling parts, painting, and welding, which enhances the production process's speed and accuracy.

Moreover, automation extends beyond physical production. Process automation tools streamline administrative and operational tasks, such as inventory management and quality control. These tools use software to monitor and optimize workflows, ensuring that processes run smoothly without human intervention. The integration of automation in industries has not only boosted productivity but also improved workplace safety by handling hazardous tasks. For instance, in the food and beverage industry, automated systems manage packaging and sorting, ensuring high hygiene standards and reducing contamination risks.

Smart Factories and Industry 4.0

The concept of smart factories is a cornerstone of Industry 4.0, the current trend of automation and data exchange in manufacturing technologies. Smart factories leverage the Internet of Things (IoT), artificial intelligence (AI), and machine learning to create interconnected systems that communicate and optimize production processes autonomously. These technologies enable real-time monitoring and analysis of manufacturing operations, leading to enhanced decision-making and efficiency.

In a smart factory, machines are equipped with sensors that collect data on various parameters such as temperature, pressure, and machine performance. This data is then analyzed to predict maintenance needs, optimize energy usage, and improve product quality. For instance, predictive maintenance systems use data analytics to identify potential equipment failures before they occur, reducing downtime and maintenance costs. Companies like Siemens and General Electric are at the forefront of implementing smart factory technologies, leading to significant improvements in productivity and cost savings.

Sustainability and Green Manufacturing

Sustainability is becoming increasingly important in industrial technology. Green manufacturing practices focus on reducing environmental impact through energy-efficient processes, waste reduction, and the use of sustainable materials. Technologies such as additive manufacturing (3D printing) play a crucial role in promoting sustainability by minimizing material waste and enabling the production of complex designs that traditional methods cannot achieve.

Additionally, renewable energy sources like solar and wind power are being integrated into manufacturing processes to reduce carbon footprints. Companies are also investing in technologies that enhance recycling and reuse of materials, contributing to a circular economy. These efforts not only help protect the environment but also reduce costs and improve corporate social responsibility. For example, Tesla’s gigafactories use a combination of solar power and energy storage systems to minimize environmental impact while maintaining high production efficiency.

Advanced Manufacturing Techniques

Advanced manufacturing techniques such as 3D printing, CNC machining, and laser cutting have transformed the production landscape. These technologies enable manufacturers to produce high-precision parts quickly and cost-effectively. For example, 3D printing allows for rapid prototyping, where designers can create and test multiple iterations of a product in a short time, significantly speeding up the development cycle.

CNC (Computer Numerical Control) machining uses computer-controlled machines to manufacture complex parts with high accuracy. This technology is essential for industries that require precise components, such as aerospace and medical device manufacturing. Laser cutting, on the other hand, offers a high degree of precision and flexibility, making it ideal for cutting intricate designs in various materials, from metals to plastics. Companies like Boeing and Airbus use these advanced manufacturing techniques to produce components that meet stringent safety and performance standards.

Enhancing Workforce Skills

The integration of advanced technologies in industrial processes necessitates a skilled workforce capable of operating and maintaining these sophisticated systems. As a result, there is a growing emphasis on workforce training and development. Companies are investing in upskilling programs to equip employees with the necessary skills to handle advanced machinery and software.

Training programs often include hands-on experience with new technologies, as well as courses in data analysis, programming, and maintenance. Virtual reality (VR) and augmented reality (AR) are also being used to provide immersive training experiences, allowing workers to practice in a simulated environment before applying their skills in the real world. This approach not only enhances learning outcomes but also ensures that employees are well-prepared for the technological demands of modern manufacturing. For example, Ford uses VR training for its assembly line workers to improve efficiency and safety without disrupting actual production.

Supply Chain Digitalization

Digitalization of supply chains is another significant development in industrial technology. Digital supply chains leverage technologies like IoT, blockchain, and AI to enhance transparency, efficiency, and responsiveness. These technologies enable real-time tracking of goods, automated inventory management, and improved demand forecasting.

Blockchain technology, in particular, is being used to ensure the traceability and authenticity of products. By providing a secure and immutable record of transactions, blockchain helps prevent counterfeiting and ensures that products meet regulatory standards. AI-driven analytics can also predict supply chain disruptions and optimize logistics, reducing lead times and costs. Companies like Walmart and IBM have implemented blockchain solutions to enhance supply chain transparency and efficiency, leading to better product traceability and reduced fraud.

Future Prospects of Industrial Technology

The future of industrial technology looks promising, with continuous advancements expected to drive further innovation and efficiency. Emerging technologies such as quantum computing, nanotechnology, and advanced materials hold the potential to revolutionize manufacturing processes even further. Quantum computing, for example, could solve complex optimization problems that are currently beyond the capabilities of classical computers, leading to unprecedented improvements in production efficiency and product design.

Nanotechnology enables the manipulation of materials at the molecular level, allowing for the creation of materials with unique properties and enhanced performance. This technology is already being used in industries such as electronics, medicine, and energy to develop more efficient and durable products. Advanced materials, including composites and smart materials, offer improved strength, flexibility, and functionality, opening up new possibilities for innovative product designs. For example, the development of graphene-based materials promises to revolutionize sectors ranging from electronics to energy storage.

In Conclusion

Industrial technology encompasses a wide range of innovations and practices that are transforming the manufacturing landscape. From automation and smart factories to sustainable practices and advanced manufacturing techniques, these technologies are driving efficiency, productivity, and sustainability in industries worldwide. As we continue to explore and develop new technologies, the potential for further advancements and improvements is immense. Embracing these innovations will not only enhance industrial processes but also contribute to economic growth and environmental sustainability. By staying informed and adapting to these changes, businesses can remain competitive and thrive in the ever-evolving industrial landscape.

0 notes

Text

Explore the transformative power of advanced amplifiers for modern industrial automation. These innovative solutions enhance efficiency by streamlining systems, improve precision with accurate signal amplification, and offer superior control for optimized performance. Designed for easy integration and built to withstand harsh industrial conditions, our amplifiers provide reliable and durable operation. Investing in these advanced amplifiers is a cost-effective choice, yielding significant long-term savings through increased productivity, reduced errors, and lower maintenance costs.

#automation#industrial and marine automation#industrial equipment#industrial#industrial spare parts#industrial parts supplier#industrialautomation#industrial innovation#amplifier#industrial technology#industrial automation equipment

0 notes

Text

Explore the world of industrial heating solutions with our comprehensive guide on maximizing heat output using open coil and tubular heaters. Discover the benefits, applications, and key differences between these two versatile heating options. Whether you're in HVAC, manufacturing, or chemical processing, this blog provides valuable insights to help you make informed decisions for your heating needs.

#Industrial Heating#Open Coil Heaters#tubular heater manufacturers#Heat Output#Manufacturing#Industrial Technology

0 notes

Text

Load Port Module: The Essential Link Between Wafer Transport System and Process Tool

A Load Port Module serves as the interface between a wafer transport system and a semiconductor process tool such as an etcher or deposition system. It facilitates the safe and ultra-clean transfer of wafers from cassettes stored in the transport system into the vacuum environment of the process chamber for semiconductor fabrication steps. Let's take a closer look at the key components and functions of this critical module. Wafer Cassette Access The front end of a loadlock in Load Port Module includes a cassette-loading station where standard 25mm wafer cassettes containing up to 25 wafers can be automatically loaded and unloaded. A robotic handler on the transport system sets the cassette into place and latches it securely. An environmentally sealed door then closes to maintain isolation of the cleanroom air from the vacuum system. Sensor inputs confirming cassette presence and door closure status are relayed to the process tool's control system. Vacuum-Compatible Design Since wafers must be transferred between the atmospheric cassette environment and high-vacuum process chambers, a Load Port Module needs vacuum-compatible construction. Chambers, bellows sections, and sealing joints are machined from non-outgassing stainless steel or aluminum alloys certified for ultra-high vacuum contact. Viton O-rings, metal gaskets, and precision actuators enable dependable closure and integrity testing of all interfaces down to vacuum pressures below 1x10^-7 Torr. Wafer Transfer Mechanisms Various transfer mechanisms are incorporated into load port designs depending on the specific process tool interface. Common configurations include a linear motor-driven blade that reaches into the cassette to pick wafers one at a time or a robotic arm capable of lifting an entire shelf of wafers simultaneously. Cameras and light sources aid alignment while sensors confirm contact and monitor for particles during extraction and placement into the loadlock chamber. Loadlock Chamber Contained within the load port housing is a small, sealable loadlock chamber where wafers can be coated or undergo vacuum bake-out procedures before entering the process chamber. Magnetic or mechanical end effectors gently grip wafers during transfer to stationary wafer pedestals inside the chamber. A turbo pump then evacuates air from the chamber to prepare for opening the valve to the process tool. Closing this valve isolates the loadlock to allow venting back to atmospheric pressure for wafer removal. Chemical Delivery Ports Some advanced load port designs accommodate ports for purge gas, chemical, or vapor delivery into the loadlock chamber or direct wafer surfaces. This enables pre-etch surface treatment, post-process cleaning, or thin film deposition capabilities directly on the wafers without needing to move them to a dedicated tool. Integrated mass flow controllers ensure precise chemical dosing and vacuum-safe plumbing routes all lines to the chamber.

Get More Insights On This Topic: Load Port Module

#Load Port Module#Semiconductor Industry#Manufacturing#Automation#Material Handling#Robotics#Semiconductor Equipment#Integrated Systems#Industrial Technology#Port Logistics#Container Handling

0 notes

Text

Exploring the Dynamics of the X-ray Inspection System Market: Trends, Innovations, and Future Prospects

In today's rapidly evolving industrial landscape, quality control and assurance have become paramount. Manufacturers across various sectors are constantly seeking advanced solutions to ensure the integrity and safety of their products. Among these solutions, X-ray inspection systems have emerged as indispensable tools for non-destructive testing and quality assessment. The X-ray inspection system market is witnessing significant growth, driven by technological advancements, stringent regulatory requirements, and the increasing demand for high-quality products.

One of the key drivers propelling the growth of the X-ray inspection system market is the rising emphasis on product quality and safety. In industries such as automotive, electronics, aerospace, and food processing, the need to detect defects, contaminants, and irregularities in products has never been greater. X-ray inspection systems offer a non-invasive method of inspecting internal structures, ensuring that even the smallest defects are identified with precision. As a result, manufacturers can maintain compliance with industry standards and regulations while safeguarding their reputation and brand integrity.

Moreover, technological advancements have led to the development of more sophisticated X-ray inspection systems with enhanced capabilities. Modern systems are equipped with advanced imaging techniques, such as computed tomography (CT), which provide three-dimensional insights into the internal structures of objects. This enables manufacturers to detect defects hidden within complex assemblies and materials, thereby improving the overall quality and reliability of their products. Additionally, the integration of artificial intelligence and machine learning algorithms has further enhanced the efficiency and accuracy of X-ray inspection systems, allowing for real-time defect detection and analysis.

The X-ray inspection system market is also benefiting from the growing adoption of Industry 4.0 principles in manufacturing processes. As industries embrace automation, connectivity, and data analytics, X-ray inspection systems are being seamlessly integrated into smart production lines. These systems can be networked with other manufacturing equipment, allowing for seamless data exchange and process optimization. Furthermore, the incorporation of IoT-enabled sensors enables remote monitoring and predictive maintenance of X-ray inspection systems, minimizing downtime and maximizing productivity.

In terms of application, the X-ray inspection system market spans a wide range of industries and sectors. In the automotive industry, these systems are used for inspecting welds, castings, and assemblies to ensure structural integrity and safety compliance. In electronics manufacturing, X-ray inspection systems are employed to detect defects such as voids, cracks, and solder joint irregularities in printed circuit boards (PCBs) and semiconductor devices. Similarly, in the food and pharmaceutical industries, these systems play a crucial role in detecting contaminants, foreign objects, and packaging defects, thereby ensuring product safety and regulatory compliance.

Looking ahead, the future of the X-ray inspection system market looks promising, driven by ongoing technological innovations and the increasing adoption of quality control measures across industries. With the continuous evolution of imaging techniques, software algorithms, and hardware components, X-ray inspection systems are expected to become more efficient, reliable, and versatile. Additionally, as industries continue to prioritize sustainability and environmental responsibility, there is a growing demand for X-ray inspection systems that are energy-efficient and eco-friendly.

In conclusion, the X-ray inspection system market is experiencing robust growth driven by the need for advanced quality control solutions across various industries. Technological advancements, regulatory requirements, and the shift towards Industry 4.0 are key factors shaping the market dynamics. As manufacturers strive to maintain high standards of quality and safety, X-ray inspection systems are poised to play a central role in ensuring product integrity and reliability in the years to come.

#X-ray inspection#inspection systems#industrial technology#quality control#non-destructive testing#manufacturing#market trends

0 notes

Text

5 Trends Reshaping Industrial Technology in 2023

5 Trends Reshaping Industrial Technology in 2023 The industrial technology landscape is undergoing rapid transformation, with emerging trends poised to redefine the way businesses operate and innovate. In 2023, we’re witnessing the convergence of powerful technologies that are reshaping industrial processes, enhancing efficiency, and fortifying security. This article delves into five key trends…

View On WordPress

#Automotive Technology#industrial technology#latest technology#latest technology blog#modern technology#New Technology#technology 2023

0 notes

Text

An 80s era Apple portable/laptop computer prototype.

#apple#apple computer#apple prototypes#computers#the 80s#the 1980s#80s aesthetic#vintage computers#vintage tech#vintage technology#electronics#vintage electronics#industrial design#product design#apple products

2K notes

·

View notes

Text

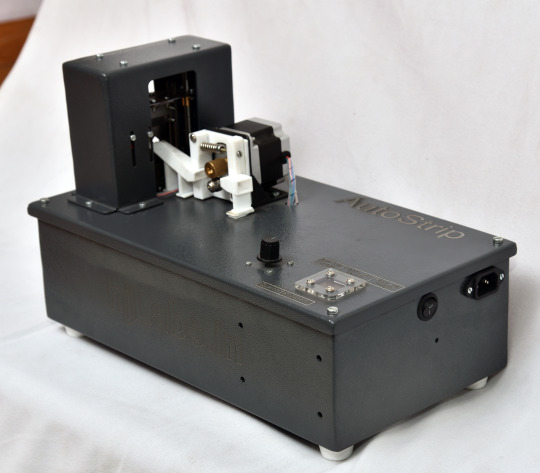

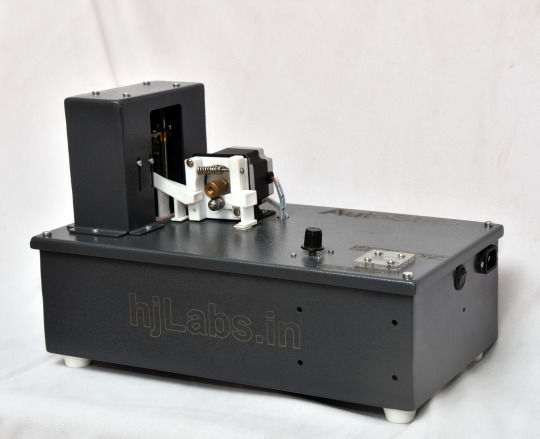

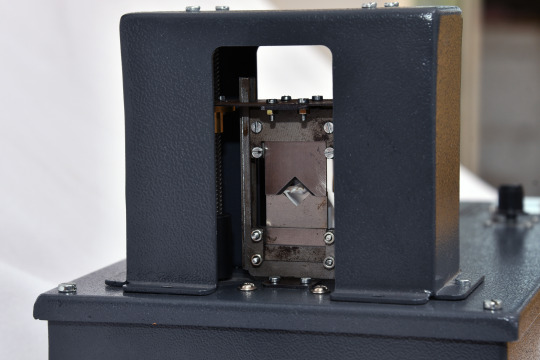

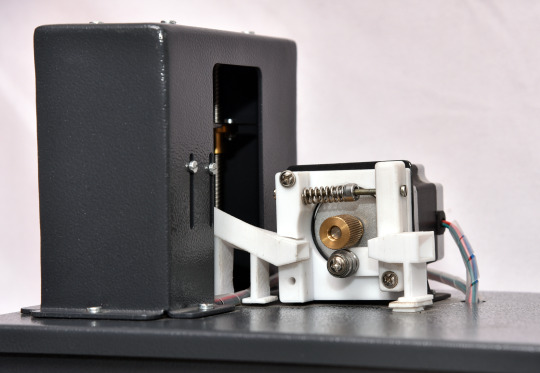

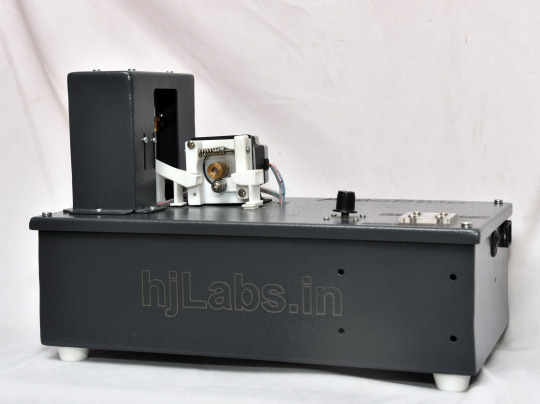

🔌 Ultimate Cable Processing Machine | Boost Efficiency & Precision! Discover the Future Today!

Experience unmatched efficiency with our 🚀 Auto Wire Cutting & Stripping Machine. Say goodbye to manual labor with our 🔧 #InnovativeTool. Ideal for electrical, automotive, and telecommunications industries.👩🔧👨🏭. For purchases, message us on WhatsApp or Telegram at 📱 +917016525813. Buy now : https://hjlabs.in/product/%f0%9f%94%8c-industrial-wire-cable-cutting-stripping-machine-precision-automatic-cutter-for-efficient-production/ #WireStripper #AutomationTech #ElectricalTools #TimeSaver 🎯 https://youtu.be/hi66O8-YRXs https://www.youtube.com/watch?v=MlTAD-kieaw 3d Design and Code files on grabcad : https://grabcad.com/library/automatic-wire-cutter-and-stripper-machine-1 only cutting machine : https://www.youtube.com/watch?v=TzW5WMWv-x8 Acrylic version : https://www.youtube.com/watch?v=bnWMskTA5V4 https://linktr.ee/hemangjoshi37a WhatsApp & Telegram : +917016525813 Email : [email protected] Place a custom order on hjLabs.in : https://hjLabs.in ----------------------------------------------------------------------------- Checkout Awesome Videos : SWiBoard - A Killer Gadget to Boost Your Boring Switchboard : https://youtu.be/BrakSGmQZB8 રુધિર વહીનીઓ અને એના કર��યો. : https://youtu.be/T7mMcEYNKyQ મનુષ્યમાં પરિવહન તંત્ર | परिसंचरण तंत्र : https://youtu.be/vxa6o_wrWnY હદય અને હદયના ધબકારા : https://www.youtube.com/watch?v=9v3MK6oTOeA AutoCut V2 - Automatic Wire Cutting Machine : https://www.youtube.com/watch?v=bnWMskTA5V4 મનુષ્યમાં ઉત્સર્જન-તંત્ર : https://www.youtube.com/watch?v=UUGI-CFKsWI

#industrial wire cutter#cable stripping machine#automatic cable cutter#precision wire processing#efficiency#manufacturing equipment#automation#wire and cable industry#quality control#productivity#industrial technology#wire cutting technology#cable stripping equipment#industrial automation#electrical industry#manufacturing solutions#wire processing machinery#cutting-edge tools#automation benefits#production efficiency#cable management#wire manufacturing

1 note

·

View note

Text

Robert Ziegelmair - A Dedicated Professional | Podomatic

Robert Ziegelmair's successful career as a truck driver is characterized by dedication, expertise, and a commitment to safety.

1 note

·

View note

Video

tumblr

He didn’t invent anything

#tiktok#bill gates#technology history#technology#tech bros#tech billionaires#philanthropy#billionaire#taxes#it industry#india#wages and salaries#wages#outsourcing

14K notes

·

View notes

Photo

📺 Retro Futurism: 'Videosphere TV set' (1970-71) by Victor Company of Japan (JVC). A pioneer of home entertainment, displayed at Museum für Angewandte Kunst Köln. Original title: 'Videosphere TV set'

#70s#design#retro#japanese#technology#product design#1970#museum für angewandte kunst köln#victor company of japan#industrial#jvc#futurism#minimalist

745 notes

·

View notes

Text

forever bitter that the sonic ova home isnt used in any sonic media

if sonic is gonna settle anywhere its gonna be where nature has reclaimed itself.

#grrrr still thinking about it#just squatting in the wreckage of human technology in the middle of a jungle#its got that nature vs industrialization vibe that always reves me up#just sjfsgjns#if i was a capable writer i would go off about this#seeing sonic and tails in a neat shack drives me up the wall like crazy#or in the middle of a city ew#they are here in my mind forever and always#when ever someone talks about sonic and tails' house im always confused cus this is where they live in my mind#put them back there please

4K notes

·

View notes