#Specialized metal fabrication for automotive parts

Explore tagged Tumblr posts

Text

Automotive Component Manufacturing Experts | Metalman Auto Ltd.

Metalman Auto Ltd. stands as a Best Automotive Component Manufacturing Experts, delivering precision-engineered solutions to Original Equipment Manufacturers (OEMs) across the automotive industry. With over three decades of experience, we specialize in producing high-quality components for two-wheelers, three-wheelers, passenger vehicles, commercial vehicles, and off-highway vehicles, meeting the exacting standards of performance, reliability, and durability.

Our advanced manufacturing facilities are equipped with cutting-edge technologies, including CNC machining, metal stamping, tubular fabrication, and metal finishing. This allows us to offer a wide range of automotive components, from chassis parts to engine components and body panels. Each product is meticulously crafted to meet the specific needs of our OEM partners, ensuring seamless integration and optimal performance in their vehicles.

At Metalman Auto Ltd., quality is embedded in every step of our manufacturing process. We adhere to ISO-certified quality management systems and employ rigorous testing and inspection procedures to ensure that every component we produce meets or exceeds industry standards. Our commitment to excellence has earned us a reputation as a trusted partner for some of the most renowned names in the automotive industry.

Innovation is at the core of our operations. We continuously invest in research and development to stay ahead of industry trends and provide our clients with the most advanced automotive component solutions. Our team of skilled engineers and technicians works closely with OEMs to develop customized components that meet the unique challenges of today’s automotive market, from electric vehicles (EVs) to autonomous driving technologies.

Partner with Metalman Auto Ltd. to experience the expertise and reliability. best automotive component manufacturing experts. Explore our comprehensive range of services and discover how we can help you drive success in your automotive projects.

#OEM metal fabrication services#Custom metal parts manufacturer for OEMs#Bespoke metal fabrication for automotive industry#Custom metalwork for vehicle manufacturers#Precision metal fabrication for OEMs#Specialized metal fabrication for automotive parts#Tailored metal fabrication solutions for OEMs#Custom steel fabrication for automotive OEMs#Metal parts supplier for automotive industry#OEM metal components manufacturer#Automotive metal fabrication services#Steel and aluminum components for vehicles#Automotive metal body parts supplier#Precision metal parts for automotive applications#Automotive structural components manufacturer#OEM automotive metal components provider#Tube fabrication for automotive applications#Precision tube bending services#Tubular components manufacturer for OEMs#Automotive tubular parts fabrication#Custom tube fabrication for vehicles#Metal tube fabrication for automotive industry#Precision pipe fabrication services#Tubular assembly solutions for automotive OEMs#automotive tools#automotive industry#automotive innovation#automobile#automotive#crack in the chassis

1 note

·

View note

Text

A word on Wardpark/Cumbernauld Studios

@docsama left a comment, on S's birthday, under one of my posts and I promised her an answer with more information, as soon as I got the time. Anyway, here goes - and @docsama, sorry for the delay:

Question is: who owns the Wardpark Film and Television Studios?

The answer was quick to find, in the not-so-old specialized media:

The story begins in 2013, with an ambitious Scottish entrepreneur, Terry Thomson - this guy (courtesy of The Herald, https://www.heraldscotland.com/news/15984820.analysis-three-projects-pipeline-help-productions-make-big-picture/):

He is the owner of the Thomson Pettie Group, based in Carluke (https://www.thomsonpettie.com/about-us), which has nothing to do with cinema:

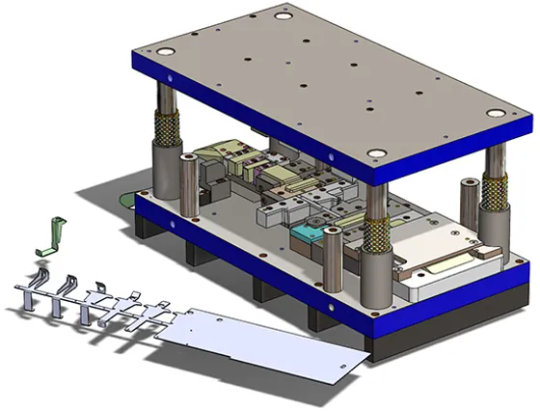

You've read that right: they are 'manufacturers of fabricated metal parts and assemblies', primarily for the national automotive industry. Yet, in 2013, Mr. Thomson agreed to rent what he described as 'a dormant industrial property' - a warehouse, to be exact - to Sony, in order to host the filming and production of OL. Thus, he became the CEO of a newly created entity, The Wardpark Film and Television Studios (https://www.hackmancapital.com/scotlands-largest-most-iconic-film-studio-acquired-by-hackman-capital-partners-and-square-mile-capital/).

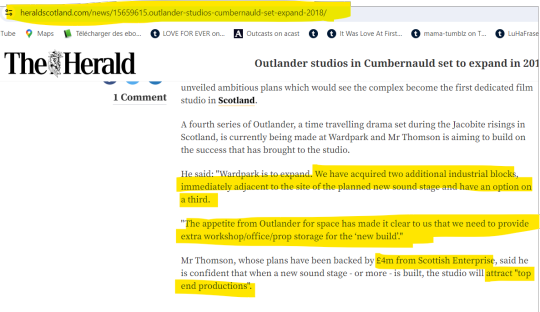

By 2017, Wardpark was doing so well, that a big expansion plan was announced, with the direct support of the Scottish Government, which invested £4 million via Scottish Enterprise, its business support, advice and funding agency:

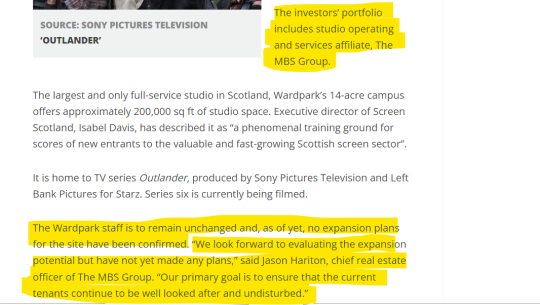

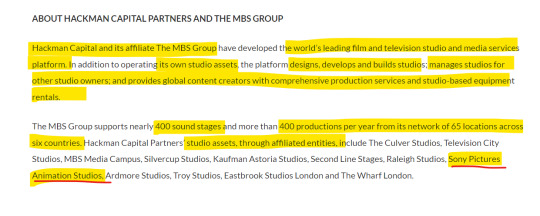

And then, in November 2021, the little engine that could was sold to those two big US investors, Hackman Capital Partners (HCP) and Square Mile Capital Management LLC (now globally rebranded as Affinius Capital). In this montage, Hackman Capital Partners brought its own confirmed film studios and media management expertise...

... while Square Mile most probably funded a sizeable portion of the acquisition, simply because this is what they do best:

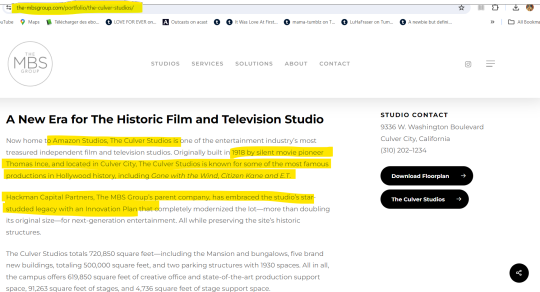

Perhaps an interesting detail: HCP owns and manages both the Culver City based Sony Pictures Animation Studios' Campus and the legendary Culver Studios, now rebranded by Amazon:

Back to Scotland, Wardpark Studio's sale made just about everyone happy. Mr. Thomson kept his CEO job and look who was more than thrilled about the juicy transaction:

Currently, the studio is operated by HCP's subsidiary, The MBS Group:

That means that MBS probably manages just about everything, as far as daily management is concerned, from business operations, staffing and/or property management, to lighting and grip, trucks and generators' fleet, expendables and props. Unless I could see a contract and have a precise idea, I can just enumerate all the services they offer.

At no point in time did S and C own anything of those studios. As for the Executive Producer part, that is another discussion entirely. I could be coaxed to write something about it, if you really want to know why Those Two are EPs and what does that really, really mean - because once again, I have seen and read a LOT of bullshit in here, especially in the Desperate Housewives Disgruntled Tumblrettes' corner.

Thank you for asking. It was fun to research and write and I hope it brought more clarity to you.

100 notes

·

View notes

Text

Mastering Precision Sheet Metal Fabrication: Where Art Meets Science

Precision sheet metal fabrication is the artful synergy of craftsmanship and scientific knowledge. Whether it's in the automotive industry, electronics manufacturing, or medical equipment production, precision sheet metal plays a pivotal role. In this blog post, we delve deep into the world of precision sheet metal and explore how this art and science intertwine.

Defining Precision Sheet Metal

Precision sheet metal fabrication is a highly specialized manufacturing process that encompasses various methods of cutting, bending, stamping, and welding metal sheets. The goal of these processes is to produce parts and components to exact specifications and dimensions without compromising the quality of the metal material. These parts are typically used in applications that demand high levels of precision, requiring meticulous control and inspection at every step.

Applications of Precision Sheet Metal

Precision sheet metal finds wide-ranging applications across various industries, including but not limited to:

Electronics Manufacturing: Precise enclosures, panels, and connectors are essential to ensuring the safety and stability of internal components in electronic products.

Medical Equipment: Medical devices often require highly precise components to ensure accurate measurements and operations.

Aerospace Industry: Aerospace demands lightweight, high-strength components, and precision sheet metal is key to achieving this goal.

Automotive Manufacturing: Various components in automobiles, including bodywork, chassis, and engine parts, rely on precision sheet metal fabrication.

The Craftsmanship of Precision Sheet Metal

The manufacturing process of precision sheet metal is an art that marries precision with expertise. It involves critical steps such as:

Design and Planning: Careful design and planning are necessary before commencing fabrication, ensuring accuracy and consistency.

Material Selection: Choosing the right metal material is crucial for the performance of the final product.

Cutting and Stamping: Employing cutting and stamping machinery to shape the metal sheets into the desired form.

Bending and Shaping: Utilizing bending and shaping operations to curve metal sheets into the required shapes.

Welding and Assembly: Welding individual components together to assemble the final product.

Quality Control

The essence of precision sheet metal lies in quality control. Rigorous quality control procedures and inspection methods ensure that every component meets specifications. This includes the use of high-precision measuring tools, visual inspections, and material testing.

Conclusion

Precision sheet metal fabrication is a domain where craftsmanship and scientific knowledge beautifully converge. Its wide-ranging applications, from electronics to aerospace, make it indispensable in our modern world. Through continual refinement of processes and quality control methods, precision sheet metal fabrication will continue to play a pivotal role in supporting our modern way of life and technological advancements. It's a testament to how art and science work hand in hand to create excellence in manufacturing.

#aviation#sheet metal fabrication#sheet metal manufacturing#sheet metal stamping#sheet metal design#sheet metal market#robots#robotics

8 notes

·

View notes

Text

The Complete Guide to Wing Nuts Manufacturers

Introduction

Wing nuts are an essential part in a number of industries, saving time and hassle by allowing quick attachment and detachment of parts without the need for specialized tools. These versatile fasteners are so popular among applications that require frequent adjustments or disassembly. Do you know where these small yet indispensable components come from? This blog delves into the world of wing nut manufacturers, how significant they are, production processes, and tips on how to choose the right wing nut manufacturer.

What are Wing Nuts?

A wing nut is a nut with two large metal "wings" on either side that can be easily turned and tightened by hand. They are commonly used in applications where a tool-less, quick assembly or disassembly is desired. Common materials used for the production of wing nuts include steel, stainless steel, brass, or plastic. Wing nuts are offered in various sizes and styles for different applications.

Role of Wing Nuts Manufacturers

Wing nuts manufacturers are companies that produce fasteners that serve the requirements of industries that include construction, furniture assembly, aerospace, and automotive. They make sure wing nuts meet specific durability, functionality, and safety standards. Here is what goes into their production:

Material Selection

The choice of material is dependent on the application. For instance:

Stainless steel for corrosion resistant applications outdoors and in the marines.

Brass for the aesthetic purpose

Plastic when the need for light and non-conductive applies.

Design and Engineering

Ergonomic designs are incorporated for wing nuts in order to ease handling. Manufacturers generally use computer aided design software where they come up with precise designs and tailor them towards specific applications.

Manufacturing Process

Casting: Used mainly for creating intricate shapes. Mainly used with plastic or massive metal wing nuts.

Stamping: Cheap on metal wing nuts, with pressing of the metal sheet into a desired shape.

Injection Molding: Applied more to plastic wings, enabling mass-produced parts with good quality.

Machining: The fabrication process of more precision wing nuts. It is used where high-grade aerospace and industrial needs are considered.

Quality Control:

The processes guarantee that the wing nuts meet the industry standards as indicated by the ISO, DIN, or ANSI specifications. There may also be tensile strength tests, corrosion resistance checks, and dimensional accuracy test.

Uses of Wing Nuts

Wing nuts are used for various applications that include:

Assembly of Furniture: Tool-less, fast assembly for shelves, tables, and chairs.

Plumbing: Fixing of fixtures and fittings in households and commercial locations.

Aerospace: Wing nuts are used which are light weight and corrosion resistance in aircraft interior.

Automobile: Used in securing battery terminals, clamps, and many other parts of an automobile.

DIY projects: It is one of the favorite items used by hobbyists and crafters.

How to Choose the Right Wing Nuts Manufacturer

Selecting the right manufacturer is crucial to ensure quality, reliability, and cost-effectiveness. Here are some factors to consider:

Experience and Expertise:

Look for manufacturers with a proven track record in producing wing nuts for your specific industry. Experienced manufacturers are more likely to understand your needs and deliver consistent quality.

Material Options:

A good manufacturer should offer a wide range of materials to suit different applications.

Customization Capabilities:

Whether you require specific sizes, designs, or materials, choose a manufacturer that can provide customized solutions.

Certifications and Standards:

Ensure the manufacturer adheres to international quality standards, such as ISO 9001, to guarantee product reliability.

Production Capacity and Lead Times:

Assess whether the manufacturer can meet your volume and timeline requirements without compromising quality.

Cost Efficiency:

While cost is important, it shouldn't be a sacrifice for quality. Compare quotes from multiple manufacturers to get the best value.

The Future of Wing Nuts Manufacturing

The wing nuts industry continues to evolve with advancements in materials science and manufacturing technologies. 3D printing and automation are becoming increasingly prominent, enabling manufacturers to produce high-quality wing nuts with greater efficiency and customization capabilities. Moreover, sustainable manufacturing practices are gaining traction, with an emphasis on recycling and eco-friendly materials.

Conclusion

Wing nuts may be small in size, but their role in ensuring the safety and functionality of countless applications is immense. Thus, the proper choice of manufacturer would ensure that one gets high-quality, reliable products. Understanding production processes, material options, and critical factors in choosing a manufacturer is what will enable you to make an informed decision that meets your specific needs.

Whether you are looking for wing nuts for industrial purposes or for your next DIY project, the information contained here will help you make informed decisions in finding the right wing nuts manufacturers.

FAQ

1. What materials are commonly used to manufacture wing nuts?

Wing nuts are typically made from materials like steel, stainless steel, brass, and plastic. The choice of material depends on the application, such as stainless steel for corrosion resistance or plastic for lightweight needs.

2. How are wing nuts made?

Wing nuts are produced using methods such as casting, stamping, injection molding, or machining. The manufacturing process depends on the material and required precision.

3. What industries use wing nuts the most?

Industries like furniture assembly, plumbing, aerospace, automotive, and DIY projects commonly use wing nuts for their ease of assembly and disassembly.

4. Can wing nuts be customized?

Yes, many manufacturers offer customization options, including specific sizes, materials, and designs tailored to unique applications.

5. How do I choose a reliable wing nuts manufacturer?

Look for manufacturers with extensive experience, a wide range of material options, adherence to quality standards, and the capacity to meet your production and timeline requirements.

#ananka#fasteners#linkedin#article#blog#anankafasteners#wingnuts#nuts#nutmanufacturer#manufacturer#fastenersmanufacturer#wingsnutmanufacturer#mumbai#supplier#hex#bolt#usa#uk

0 notes

Text

Bulk Chemicals in Chennai: Fuelling the Growth of Diverse Industries

Chennai is the capital city of Tamil Nadu and has been considered as one of the major industrial centers in South India. This city has turned out to be a significant hub for manufacturing, cars, chemicals, and medicines due to its good location, strong infrastructure, and a developed industrial environment. Among the key resources supporting this developing economy are bulk chemicals in Chennai, which are of prime importance in many industrial processes in textiles, automotive, pharmaceuticals, water treatment, and many more.

What Are Bulk Chemicals?

Bulk chemicals are big quantities of chemicals produced and sold in large amounts, mainly for industrial use. They are mostly transported in big containers such as tankers, drums, or bulk carriers since they are produced in such big quantities. They are used in making products, creating formulas, and as raw materials for producing other products in various industries. Bulk chemicals can be acids and solvents to plastics and special chemicals.

Significance of Bulk Chemicals in the Industrial Scenario of Chennai

Major industries in the city include automobile manufacturing, textiles, pharmaceuticals, chemicals, and food processing. The reasons for its industrial growth are mainly the easy availability and utilization of bulk chemicals. The continuous production efficiency, along with a reduced cost and quality consistency, by these sectors demand a steady supply of bulk chemicals.

In the car industry, large quantities of chemicals such as oils, paints, and adhesives are required for the manufacture of car parts and construction of cars. In the textile industry in Chennai, large quantities of chemicals like colors, dyes, and finishing products are required to produce various types of fabrics. The drug industry also requires bulk chemicals since large quantities of compounds and chemicals are required for the preparation and manufacture of medicines.

Major Bulk Chemicals Used in Industries of Chennai

Acid and Bases: Strong acids, such as sulfuric acid, hydrochloric acid, and nitric acid, along with caustic soda (sodium hydroxide), are used commonly in Chennai for various purposes. These chemicals play an important role in industries that involve metal cleaning, water treatment, and fertilizer manufacturing.

Solvents: Bulk solvents like toluene, acetone, ethanol, and methanol are used across several sectors, particularly in manufacturing paints, coatings, and adhesives. These solvents are also pivotal in the pharmaceutical and petrochemical industries for various chemical reactions and formulations.

Polymers and Plastics: The polymers such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC) are a part of important basic materials in the manufacturing industries of Chennai. These bulk chemicals are used to manufacture several products including packaging materials, car parts, and building materials.

Fertilizers and Agricultural Chemicals: Large chemicals like ammonia, urea, and phosphoric acid are required for the manufacture of fertilizers that support farming. These fertilizers are used in large quantities in the regions surrounding Chennai, which is a major hub for agriculture.

Water Treatment Chemicals: Chlorine, alum, and various coagulants are major chemicals used to treat water. This is highly required in factories and the city's water supply. Because Chennai faces problems with water scarcity, there is a high requirement for these chemicals.

Supply Chain and Infrastructure for Bulk Chemicals in Chennai

Chennai has good infrastructure that helps supply bulk chemicals to industries. The city is close to important ports like Chennai Port and Ennore Port, which makes it easy to import and export bulk chemicals. Also, a strong road and rail network makes sure chemicals are transported on time to different industrial areas in and near the city.

Most of the chemical suppliers and distributors in Chennai are striving to obtain and provide large quantities of chemicals. This provides them with a huge range of products so that businesses do not have to wait to get raw materials. In general, these suppliers operate at the manufacturer's level and ensure quick delivery so that handling stock becomes easier and less expensive.

Environmental Issues and Sustainable Practices

Availability of bulk chemicals in Chennai supports the growth of the industrial sector; however, associated environmental issues during chemical manufacturing and usage also require attention. Usage of bulk chemicals, especially for large-scale uses, has environmental impacts if their management is not proper. Government and industries are adopting sustainable methods in Chennai: using eco-friendly chemicals, ensuring less generation of waste, and safe disposal of by-products of chemical production.

Industries in Chennai are giving more importance to green chemistry innovations. These include safe, biodegradable chemicals and processes that reduce harm to the environment.

Conclusion

Bulk chemicals Chennai play a significant role in the city's different industrial sectors. They help businesses in automotive, textiles, pharmaceuticals, and water treatment make high-quality products efficiently and at lower costs. As the need for these chemicals keeps increasing, industries should practice sustainable methods that lessen harm to the environment and ensure they can last a long time. With its strong infrastructure and expanding industrial base, Chennai will definitely stand as an important center for the bulk chemicals industry in India.

0 notes

Text

All you need to know about Custom Rapid Prototypes – HLH Rapid

In manufacturing, product development needs to be fast, precise, and flexible. Custom rapid prototyping helps industries quickly turn CAD designs into real products. From unique ideas to testing, these prototypes are changing how businesses innovate.

Brief Summary of Custom Rapid Prototyping

Custom rapid prototyping involves creating tailored models or components directly from a digital design file. Using techniques such as 3D printing, CNC machining, and injection molding, these prototypes are crafted to meet specific project needs, ensuring they are precise and fit for their intended purpose.

Unlike standard prototyping, custom rapid prototypes are designed with the end user’s unique requirements in mind. This personalization enables better testing, improved functionality, and faster iterations.

Key Advantages of Custom Rapid Prototyping

Speed to Market

Rapid prototyping drastically reduces lead times, enabling businesses to bring their products to market faster. Customization ensures that every iteration is closer to the final product, saving time on revisions.

Cost Efficiency

By identifying design flaws early, custom prototypes eliminate the need for costly adjustments in later production stages. Additionally, producing only what’s needed minimizes waste.

Design Flexibility

With custom prototypes, designers can test multiple variations without committing to full-scale production. This flexibility fosters innovation and creativity.

Functional Testing

Custom prototypes are not just visual models, they can be functional parts. This allows businesses to assess performance, durability, and usability in real-world conditions.

Enhanced Communication

Physical prototypes make it easier for teams, stakeholders, and clients to visualize the product, bridging the gap between concept and reality.

Popular Methods for Creating Custom Prototypes

1. 3D Printing (Additive Manufacturing)

Ideal for complex geometries and quick turnarounds, 3D printing is perfect for producing intricate designs using materials like resin, nylon, and metals.

2. CNC Machining

For high-precision prototypes with superior surface finishes, CNC machining excels. It’s commonly used for metal and plastic parts requiring tight tolerances.

3. Vacuum Casting

This process replicates prototypes using silicone molds, offering excellent detail and material options for small production runs.

4. Sheet Metal Fabrication

A great choice for creating durable and functional prototypes in industries like aerospace and automotive.

Applications of Custom Rapid Prototyping

Aerospace: Lightweight, high-strength parts for testing and assembly.

Automotive: Prototypes for components like engine parts, dashboards, and lighting systems.

Medical Devices: Custom models for surgical tools, implants, and diagnostics equipment.

Consumer Products: Iterations of gadgets, packaging, and home appliances.

Why Choose Custom Prototypes?

Custom rapid prototypes are designed specifically for your project, ensuring they meet your goals. Whether you need unique dimensions, specialized materials, or a specific functionality, custom prototypes allow for unmatched precision and personalization.

Conclusion

Custom rapid prototyping is transforming industries by making innovation faster, more efficient, and highly accurate. With advanced manufacturing methods, businesses can quickly bring their ideas to life. Whether you're creating a new product or improving an old one, custom prototypes make the process smoother and more successful.

Need custom rapid prototypes for your next product development? Contact us to learn how we can help you with your next project. Submit your CAD file here

0 notes

Text

Your Go-To Machine Shop in Oxnard: Precision, Reliability, and Expertise

At Force Fabrication Inc., we understand that choosing the right machine shop is critical for your project’s success. Whether you need CNC machining, precision sheet metal fabrication, or expert welding services, we’re here to deliver exceptional results that exceed your expectations.

Why Choose Force Fabrication Inc.?

Located in Oxnard, CA, Force Fabrication Inc. is not just another machine shop. We pride ourselves on our expertise, state-of-the-art equipment, and customer-first approach. Our team is dedicated to providing high-quality solutions tailored to your needs. With years of experience, we’ve earned clients' trust across industries, from aerospace to automotive and everything in between.

Here’s what sets us apart:

Precision and Quality:

We are meticulous in every aspect of our work, ensuring that every component meets your specifications. Our CNC machining services utilize cutting-edge technology for unparalleled accuracy.

Comprehensive Services:

From sheet metal fabrication to custom welding, we offer a wide range of services to handle projects of all sizes and complexities.

Customer-Focused Approach:

Your satisfaction is our top priority. We work closely with you from concept to completion, providing updates and addressing your concerns.

Compliance and Standards:

We adhere to the highest industry standards as an ISO9001:2015 Registered and ITAR Registered company.

CNC Machining: Precision at Its Best

Our CNC machining services are designed for clients who demand precision, consistency, and reliability. We can produce intricate parts with tight tolerances using advanced machinery, whether for prototypes or full-scale production.

Here’s how we can help:

Custom Components: Perfect for industries requiring unique parts tailored to specific applications.

Efficiency and Speed: Our CNC machines ensure quick turnaround times without compromising on quality.

Material Versatility: We work with a variety of materials, including aluminum, steel, and specialized alloys.

If you need top-tier CNC machining services, don’t hesitate to call us at 805-754-2235.

1 note

·

View note

Text

Applications of CNC Rotary Tables in Various Industries [Infographic]

CNC rotary tables have become indispensable in modern manufacturing. They enhance the capabilities of CNC machines by adding an additional axis of movement. These versatile tools play a pivotal role in improving precision, efficiency, and flexibility across various industries. Below, we explore the key applications of CNC rotary tables and how they contribute to diverse sectors.

1. Aerospace Industry

In the aerospace industry, precision is non-negotiable. CNC rotary tables are used to machine complex components such as turbine blades, engine parts, and structural elements. Their ability to handle intricate geometries and maintain tight tolerances ensures the production of reliable and high-performance aerospace components. The rotary table's multi-axis capabilities allow manufacturers to achieve precision milling, drilling, and contouring, meeting the stringent requirements of aerospace engineering.

2. Automotive Industry

The automotive sector relies heavily on CNC rotary table for producing gears, camshafts, and other critical engine parts. These tables enable manufacturers to perform high-precision machining, ensuring consistency and quality in mass production. Additionally, their use in the creation of custom automotive components supports the growing demand for electric vehicles (EVs) and other innovations in the industry.

3. Medical Device Manufacturing

CNC rotary tables are essential in the medical industry for fabricating intricate components like surgical instruments, orthopedic implants, and prosthetics. The rotary table's high precision allows for the creation of small, complex parts that meet the strict regulatory standards of the healthcare sector. Moreover, their versatility enables manufacturers to work with a variety of materials, including stainless steel, titanium, and specialized medical-grade alloys.

4. Energy Sector

From wind turbines to oil and gas equipment, the energy sector benefits from the capabilities of CNC rotary tables. These tools are used to produce large, heavy-duty components such as flanges, rotors, and pipe connectors. Their robust construction and precise movement ensure reliable performance even in demanding applications, making them a vital asset in energy production and distribution.

5. Tool and Die Manufacturing

The tool and die industry relies on CNC rotary tables for creating molds, dies, and other specialized tools. These components often require intricate details and high accuracy, which rotary tables provide. By enabling simultaneous multi-axis machining, they help manufacturers reduce production time and achieve superior surface finishes.

6. Electronics and Semiconductor Industry

Miniaturization and precision are essential in the electronics sector. CNC rotary tables are used to machine micro-components for semiconductors, circuit boards, and other electronic devices. Their capability to handle small-scale, high-precision tasks ensures optimal performance in the production of cutting-edge electronic equipment.

7. Jewelry and Watchmaking

Artisans in the jewelry and watchmaking industries use CNC rotary tables to craft intricate designs and detailed engravings. These tables enable precise machining of precious metals, ensuring consistency and quality in luxury products. The ability to achieve complex patterns and fine details makes rotary tables invaluable in these highly specialized fields.

Benefits of CNC Rotary Tables

Enhanced Precision: Ideal for applications requiring tight tolerances.

Increased Efficiency: Reduces production time by enabling multi-axis machining.

Versatility: Suitable for various materials and industries.

Cost-Effectiveness: Streamlines production processes, minimizing waste.

Also Read: 4 Benefits of Using Industrial CNC Rotary Table From China

Conclusion

CNC rotary tables are a cornerstone of modern manufacturing, enabling industries to achieve unparalleled precision and efficiency. From aerospace and automotive to medical and electronics, these tools are instrumental in driving innovation and meeting the demands of a competitive market.

Explore the advanced CNC rotary tables from SilverCNC and discover how they can elevate your manufacturing processes. Whether you need precision, versatility, or efficiency, SilverCNC offers solutions tailored to your industry’s unique requirements.

To read more information visit https://tinyurl.com/yk3b7spt and call now at +86 180 9892 0890 or email us at [email protected]

0 notes

Text

Understanding Round Bars: Types, Applications, and Benefits

Nova Steel Corporation is a significant Round bar manufacturer in India. We specialize in producing high-quality round bars that meet industrial requirements. These Round Bars are available in a variety of sizes, forms, and dimensions, and they may also be adjusted to meet our clients' individual needs. Our high-quality Round Bars are specifically designed for steel manufacturing facilities, the petrochemical industry, fire prevention systems, synthetic enterprises, dispatching/shipping organizations, and so on. As a leading round bar manufacturer in India, we provide a comprehensive range of round bar solutions to fulfill a wide range of requirements.

What is a Round Bar?

A round bar, also known as a metal rod or solid cylindrical bar, is a long, circular metal product made from materials like stainless steel, carbon steel, aluminum, brass, or other alloys. It is manufactured through processes like hot rolling, cold rolling, or forging, depending on the intended application and required properties. Round bars are available in different diameters and lengths, making them highly customizable and adaptable to meet specific industry needs.

Types of Round Bars

Round bars come in various types based on the materials they are made from and their properties. Below are some of the most common types:

Stainless Steel Round Bar: Stainless steel round bars are corrosion-resistant, strong, and durable. They are widely used in construction, food processing, marine, and pharmaceutical industries.

Mild Steel Round Bar: Made from low-carbon steel, mild steel round bars are cost-effective, easy to weld, and ideal for general fabrication purposes. They are often used in building frames, fences, and grills.

Aluminum Round Bar: Lightweight, corrosion-resistant, and highly malleable, aluminum round bars are often used in aerospace, automotive, and lightweight construction projects.

Copper Round Bar: Copper round bars have excellent thermal and electrical conductivity. They are extensively used in electrical and plumbing applications.

Carbon Steel Round Bar: Known for their high strength and durability, carbon steel round bars are ideal for heavy-duty applications in the automotive, construction, and industrial sectors.

Brass Round Bar: Brass round bars are corrosion-resistant, easy to machine, and aesthetically appealing. They are widely used in decorative, plumbing, and electrical fittings.

We are Round Bars Supplier In:

Round Bars Supplier in Hyderabad

Round Bars Supplier in Bangalore

Round Bars Supplier in Chennai

Round Bars Supplier in Mumbai

Round Bars Supplier in Gujarat

Applications of Round Bars

Round bars have numerous applications across industries due to their durability, strength, and flexibility. Here are some of their primary applications:

Construction and Infrastructure: Round bars are used as reinforcements, braces, and structural elements in buildings, bridges, and other civil engineering projects.

Automotive Industry: They are commonly used for manufacturing automotive components such as axles, shafts, and fasteners.

Manufacturing Tools and Machinery: Round bars serve as raw materials for producing tools, machine parts, and precision components like bearings, rods, and gears.

Aerospace Industry: Aluminum and stainless steel round bars are used for making lightweight, high-strength components for aircraft and space applications.

Energy Sector: In renewable energy projects and power plants, round bars are used to build turbines, generators, and pipelines.

Fabrication and Engineering: Round bars are highly customizable, making them ideal for machining, fabrication, and the production of fasteners, nuts, bolts, and rivets.

Household and Decorative Applications: Brass and stainless steel round bars are often used for decorative railings, furniture frames, and household fittings.

Benefits of Using Round Bars

Round bars offer several advantages that make them an excellent choice for various applications:

Versatility: Round bars can be customized in terms of diameter, length, and material to suit specific applications.

Durability: Materials like stainless steel and carbon steel ensure long-lasting performance, even in harsh conditions.

Corrosion Resistance: Stainless steel, aluminum, and brass round bars provide excellent resistance to rust and corrosion.

Ease of Machining: Round bars are easy to cut, weld, and shape, making them highly adaptable to meet unique design requirements.

Cost-Effectiveness: Round bars made from mild steel or carbon steel are affordable, durable, and reliable for general-use applications.

Strength and Stability: Round bars offer exceptional mechanical strength, making them suitable for load-bearing and structural applications.

Round Bar Manufacturer in India

Our round bars come in a variety of materials, including stainless steel, carbon steel, alloy steel, and aluminum, with varying diameters, lengths, and surface treatments. When you pick us as your Round Bars Supplier in India, you can be sure that you will receive high-quality products. Our round bars go through rigorous quality control methods to ensure dimensional correctness, mechanical characteristics, and consistent surface polish. We are also a leading provider of MS plate weight charts.

As industries continue to innovate and grow, the demand for high-quality round bars will remain strong, underscoring their importance in building a stronger, more efficient, and modern world.

#Round Bars Manufacturer in India#Round bars suppliers#Round bars suppliers in India#ms plate weight chart

0 notes

Text

The Most Easily Recyclable Car Components

When scrapping a car, it's important to know that many of its components can be easily recycled, reducing waste and benefiting the environment. Cash For Cars Adelaide mentioned here are some of the most easily recyclable car components:

1. Metals (Steel and Aluminum)

Body Panels: The car’s frame and body panels are usually made of steel, which is highly recyclable.

Engine and Transmission: These components are also primarily made of metal and can be melted down and reused in new manufacturing.

2. Batteries

Lead-Acid Batteries: Car batteries are among the most recyclable parts of a vehicle. The lead, plastic, and acid can be reclaimed and reused.

Lithium-Ion Batteries: Used in electric and hybrid vehicles, these batteries can also be recycled, though the process is more complex.

3. Catalytic Converters

Catalytic converters contain precious metals like platinum, palladium, and rhodium, which can be extracted and reused in new converters or other products.

4. Tires

Old tires can be recycled into rubber mulch, asphalt, or used in various industrial applications. Some scrap yards also resell usable tires.

5. Glass

Windows and Windshields: Automotive glass can be crushed and recycled into new glass products or even fiberglass insulation.

6. Plastic Components

Bumpers, Dashboards, and Interiors: Many of the plastic components inside and outside the car can be recycled. They are typically sorted by type and processed into new plastic materials.

7. Fluids

Oil, Coolant, and Transmission Fluid: These fluids are drained and recycled or refined for reuse. Proper disposal prevents environmental contamination.

8. Radiators

Radiators are typically made of aluminum and copper, both of which are highly recyclable materials.

9. Electronics

Wiring and Circuits: The electrical systems in a car contain copper and other valuable metals that can be extracted and recycled.

Sensors and Modules: These can also be recycled, though the process might be more specialized.

10. Seats and Upholstery

Foam and Fabric: The foam inside seats can be recycled or repurposed, and certain fabrics can be reused in other applications.

Conclusion Nearly every part of a car can be recycled, from its metal frame to its fluids and electronics. By understanding the recyclability of these components, you contribute to a more sustainable approach to vehicle disposal, helping to reduce waste and conserve resources.

Source URL : The Most Easily Recyclable Car Components

0 notes

Text

Custom Cutting Dies: High-Precision Tools for Accurate and Efficient Production

It can be said that in manufacturing industry, accuracy and speed are the keys to success. This is especially true for the industrial area where material such as paper, rubber or plastic require distinguishing in order to match particular specifications. This reality underlines the significance of custom cutting dies within the setting up of both uncooked and semi-end products in response to their particular calls for.

• Unparalleled Precision: Produce specific thinning attachments, where the fabricators obtain highly accurate designs of the needed forms because of cutting machines. They have boiled it down to a science and pushed doors to new levels of belief, it is unimagined.

• Enhanced Efficiency: Use of custom cutting dies helps to minimize wastage of cloth material and at the same time increase on production. They can just healthy into automatic machines to make the production faster without compromise the standard.

• Tailored Solutions: Writing about client slicing dies, Armstrong asserted that their big strength is that they could meet certain, specific needs. In any case, design or cloth, custom dies make up a specialized answer with flexibility to be an important tool in numerous fields.

Custom cutting dies have converted the manufacturing procedure, offering an amalgamation of performance, precision and adaptableness. With the proper custom slicing die, the opportunities

are infinite, fueling creativity, and pushing the boundaries of what can be accomplished in layout and manufacturing techniques.

Driving Transformation: Special Focus on the Automotive Stamping Companies

The world of the car enterprise is currently expanding and going through the change of the new horizons of improve, ergo, performance, and sustainability. When examining the vast array of procedures that instill life to our motors, one way remains discreet and obscured from our eyes yet it gives definition to the sophisticated beauty and potency of the motor – automotive stamping companies.

• Advancements in Automotive Stamping

Automotive stamping organizations, in large part unsung heroes, extensively have an impact on the very last product's excellent, integrity, and lifeline. These agencies have relentlessly championed many technological improvements together with excessive-velocity stamping and modern die stamping, steering the car enterprise toward remarkable product precision and cost effectiveness.

• Global Impact and Sustainability

There’s an increasing name for lighter, more potent, and more sustainable motors, forcing the industry to be seeking for new materials and sophisticated strategies. In response, stamping groups worldwide are adopting high-strength, lightweight steels and precision stamping technology, to deliver awesome overall performance at the same time as additionally lowering environmental effect.

• The Future Road-map

With the appearance of electric automobiles (EVs) and autonomous using, the call for unique additives and complicated shapes is surging. To meet those needs, automobile stamping agencies are actually moving gears toward extra flexible manufacturing methods and pioneering the adoption of AI and robotics, which paint a vibrant image of the future dynamics inside the automobile enterprise.

Cutting-Edge Success: The Mastery Behind Cutting Die Manufacturers

Explored the sector of precision engineering and original equipment’s manufacturing fit on the core of manufacturing company, the cutting die makers. These pioneers shape and fashion the most complex structures with great accuracy, creating great expectations internally the overall production assembly around the world.

• Expertise in Quality and Precision: Die reducing producers occupy the middle level in a world that never ceases to pursue the ideal. Due to the ability to shape, thin and inscribe materials made of paper, plastic, fabric, and metal those industry specialists provide high-quality performance products to a range of sectors.

• Technological Innovation at its Finest: The die cutting industry tends to be dynamic most of the time with fresh trends and inventions reddening working environments. Die slicing now requires advanced AI tooling and modern equipment, leading to increased competency and higher than expected performance in shipping products out.

• Environmental Stewardship: The reducing producers are not only obsessive about potency and quality but also about sustainability. Understanding their roles in sustaining our environment, they have equal applied environmental solutions to their operations. These include energy conserving devices and systems as well as ways and means of minimizing the amounts of wastes.

The cutting die manufacturers are real experienced players in their industry. Anchoring definition: The manufacturers who set the highest standards when creating the components with precision, adopting new technological advancements and engaging in deliberate and sustainable environment-friendly production practices are the backbone of several industries.

Innovative Excellence: Unveiling the Importance of a Leading Tool Manufacturing Company

Sailing through the relatively now somewhat a more threatening market of today requires nothing less than optimal performance and accuracy and creativity. And this is exactly in which device production companies make a quintessential entry. The accuracy and depth of their work means that they are not limited simply to the creation of equipment: the industries in which they are located put them right there at the center of many areas.

Tool Manufacturing Company is one such organization and the key pioneer for the development of device manufacturing and precision engineering brand. It is the symbol of innovation, nice and consistent value delivery.

• Innovation-Driven: we are at the modern-day of the era in which we offer excellent solutions that drive development for industries. The R& D of their company is inconstant striving — to develop liberal apparels that fulfill the new needs of an unexpectedly progressing society.

• Continuous Improvement: Self-imposed pressures of search for perfection and desire to innovate on their products and services placed us. Apart. Extending from revamping their manufacturing manner to similarly optimizing the capability of their equipment, they assigned a superior price to continual improvement.

The manufacturing organizations of tools – of which we are part – are not just suppliers; we are partners in progress. They occupy a main and unique position in modernization of processes, increase of efficiency and utilizing potential improvements for defining further development in industries.

Unveiling the Titans of tool Manufacturing Companies

In the context of global industrialization, the tool manufacturing enterprise bureaucracy one of the primary cogs within the wheel. Tool manufacturing companies serves as a basis stone for lots economic sectors via offering the important device to execute diverse important duties.

• We stand as one of the main giants in the tool manufacturing international. Known for its vast range of mining and production gadget, we embodies a spirit for innovation and satisfactory and is recommended for his or her use of superior era.

• No dialog about the tool manufacturing enterprise is ever entire without the point out of us. With a lineage spanning over many years, their recognition for delivering exceptional nice and sundry product traces stays unscathed.

These companies are not simply commercial enterprise entities but spearheads of the tool manufacturing region. They have an impact on industry traits and global manufacturing requirements at the same time as offering reliable, revolutionary, and exquisite products that lead the way in shaping the future of several industries.

Conclusion

Success in the industrial sector depends on precision and speed, especially when working with materials like plastic, rubber, and paper. Custom cutting dies revolutionize the production process by providing unmatched precision, increased productivity, and customized solutions. By promoting technical advancements, using lightweight, high-strength steels, and using precision stamping technology, automotive stamping businesses are revolutionizing the sector. With the emergence of electric cars and autonomous driving, they are also concentrating on the future of the auto industry.

Offering a variety of stamping die offerings and manufacturing alternatives, Metal Stamping Dies is dedicated to supporting you locate the ideal solutions on your local desires. We have interaction with all applicable parties to maximise your ROI and provide brilliant value. Our customizable services are designed to decorate your business operations and pressure success.

Contact us at (647) 294-5240 or through e mail at [email protected] to examine more or book an appointment.

0 notes

Text

Top Benefits of OEM Metal Fabrication and OEM Fabrication Services

OEM metal fabrication and OEM fabrication are essential services that play a crucial role in various industries, from automotive to aerospace and beyond. These services involve the process of creating custom metal parts and components that are designed to meet the specific needs of original equipment manufacturers (OEMs). By leveraging advanced technology and skilled craftsmanship, OEM metal fabrication offers numerous benefits that can significantly improve the efficiency, quality, and cost-effectiveness of manufacturing operations.

What is OEM Metal Fabrication?

OEM metal fabrication refers to the custom manufacturing of metal parts and structures designed for specific applications, using raw metal materials such as steel, aluminum, or stainless steel. These parts are tailored to meet the exact specifications provided by the OEM, ensuring that they fit seamlessly into the final product. OEM metal fabrication is a highly specialized field that involves various processes, including cutting, welding, forming, and assembly, to create precise components that meet rigorous industry standards.

Why Choose OEM Fabrication Services?

Choosing OEM fabrication services offers several key advantages for businesses looking to streamline their manufacturing processes. Here are some of the top benefits of utilizing OEM fabrication services:

Customization and Precision One of the primary advantages of OEM metal fabrication is the ability to create custom-designed parts that meet specific requirements. OEMs can specify the exact dimensions, materials, and designs needed, ensuring that the final product meets all necessary performance standards. This level of customization ensures high precision and reduces the risk of errors or inefficiencies in the production process.

Enhanced Quality Control With OEM fabrication, manufacturers can maintain strict quality control throughout the production process. Since the parts are made to precise specifications, the final product is more likely to perform optimally and have a longer lifespan. Quality assurance is often integrated into every stage of OEM metal fabrication, from material selection to post-production testing, ensuring that all components meet industry regulations and safety standards.

Cost-Effectiveness Although custom OEM metal fabrication services may initially seem more expensive than standard manufacturing methods, they can ultimately save money in the long run. By producing high-quality, durable parts that are tailored to fit specific applications, businesses can reduce waste, lower the likelihood of product failures, and decrease the need for repairs and replacements. Additionally, the efficiency gained from using precisely manufactured components can reduce overall production time, further lowering costs.

Improved Design Flexibility OEM fabrication services provide manufacturers with greater design flexibility, enabling them to innovate and develop new products without being constrained by existing manufacturing limitations. Whether it’s a unique shape, size, or specialized material, OEM fabrication allows businesses to create complex and intricate designs that may not be possible with traditional manufacturing methods.

Faster Turnaround Times In many cases, OEM fabrication can lead to faster turnaround times for production. Since OEM metal fabrication companies use highly specialized equipment and experienced craftsmen, they can streamline the production process, reducing lead times and ensuring timely delivery of the final product. This is particularly important for industries that require rapid prototyping or fast production cycles.

Conclusion

OEM metal fabrication and OEM fabrication services offer a wealth of benefits for manufacturers across various sectors. By providing custom-designed, high-quality, and cost-effective components, OEM fabrication helps businesses improve efficiency, reduce waste, and achieve better overall performance. Whether you're looking to create a single prototype or scale up production, working with an experienced OEM fabrication service provider can ensure that your manufacturing process is optimized for success.

0 notes

Text

Why My Lathe Machine Is Better Than Yours?

At Ambica Enterprises, we pride ourselves on delivering top-tier lathe machines that surpass industry standards. With a commitment to precision engineering, cutting-edge technology, and unparalleled craftsmanship, our lathe machines set a benchmark in the manufacturing world. Here’s why our lathe machines are better than yours.

1. Superior Build Quality

Our lathe machines are constructed with premium-grade materials that ensure durability and long-lasting performance. The robust cast iron body minimizes vibrations, enhancing accuracy and extending the machine's lifespan. Every component is crafted to withstand heavy-duty use while maintaining consistent output.

2. Unmatched Precision and Accuracy

Precision is at the heart of our lathe machines. Equipped with advanced spindle systems, precision-ground bedways, and high-tolerance components, our machines ensure exceptional accuracy. Tight tolerances mean flawless machining of even the most intricate parts, making them ideal for industries demanding high precision.

3. Advanced Technological Integration

We integrate the latest CNC technology into our lathe machines for automated, precise, and repeatable operations. Our models feature user-friendly control panels, customizable settings, and pre-programmed machining cycles for enhanced productivity.

4. High-Speed Performance

Our lathe machines are designed for high-speed operation without sacrificing precision. Powerful motors, optimized gearboxes, and advanced spindle speeds enable efficient machining of various materials, from soft metals to tough alloys.

Also Check - https://www.lathemachine.org/

5. Customization for Specific Needs

We understand that different industries have unique requirements. That’s why we offer customizable lathe machines, including special attachments, tool holders, and additional automation features, ensuring seamless integration into your production line.

6. User-Centric Design

Operator comfort and safety are crucial. Our lathe machines feature ergonomically designed control panels, easy-access maintenance points, and comprehensive safety features such as emergency stop buttons, automatic shutdowns, and protective guards.

7. Rigorous Quality Control

Before leaving our facility, each lathe machine undergoes stringent quality control tests to ensure flawless performance. From alignment checks to operational simulations, every machine meets the highest industry standards.

8. Exceptional After-Sales Support

We offer comprehensive after-sales service, including installation assistance, technical training, and 24/7 customer support. Our expert technicians provide maintenance services, ensuring your lathe machines remain in top condition.

9. Proven Industry Reputation

With decades of experience, Ambica Enterprises has earned a reputation for excellence and reliability. Our machines are trusted by leading manufacturers worldwide, reflecting our unwavering commitment to quality.

10. Cost-Effective Investment

While superior in quality, our lathe machines are competitively priced, offering an excellent return on investment. Lower maintenance costs, extended machine life, and high operational efficiency ensure long-term savings.

Applications Across Multiple Industries

Our lathe machines serve a broad range of industries, including automotive manufacturing, aerospace, tool and die making, and precision engineering. Whether you need prototype development, mass production, or custom fabrication, our machines deliver results that exceed expectations.

Why Choose Ambica Enterprises?

Unmatched Expertise: Decades of industry experience.

Global Reach: Trusted by companies worldwide.

Customer-Centered Approach: Personalized service from consultation to after-sales support.

Technological Leadership: Constant innovation for superior performance.

Conclusion:

Choosing a lathe machine from Ambica Enterprises means investing in precision, reliability, and performance. Our machines are engineered to outperform and outlast the competition, making them the perfect choice for professionals committed to quality and excellence.

Upgrade your manufacturing capabilities with Ambica Enterprises’ premium lathe machines—where innovation meets craftsmanship.

0 notes

Text

Metal Machining & Cylindrical Grinding: Precision at Its Finest

Metal machining and cylindrical grinding are essential processes in modern engineering, enabling the manufacturing of components with unparalleled precision and durability. These processes play a pivotal role in various industries, such as aerospace, automotive, power generation, and heavy machinery. From crafting new parts to repairing damaged ones, machining and grinding ensure components meet the most stringent requirements for size, finish, and functionality. At WWG Engineering, the Machining Workshop is the hub where these crucial operations take place, powered by state-of-the-art equipment and skilled professionals.

The Machining Workshop at WWG Engineering

The Machining Workshop at WWG Engineering was established with very specific objectives:

To manufacture new components and fabricate parts through machining and grinding.

To perform pre-machining and undercutting, preparing surfaces for Surface Engineering processes in both repair and new manufacturing.

To provide final machine turning, facing, and grinding finishing for Thermal Spray Coated, Cold Spray Coated, or Welded surfaces.

This well-equipped workshop allows WWG Engineering to offer comprehensive surface and cylindrical grinding capabilities. These capabilities enable the company to grind various materials on both external and internal faces, ensuring polished and finished components that meet the highest tolerances and form integrity. Whether it is for new manufacturing or repairing existing parts, the workshop stands as a center of precision and excellence in the field of metalworking.

Precision Metal Machining

Metal machining involves removing material from a work piece to achieve the desired shape, size, and finish. The process utilizes a wide range of tools, including lathes, milling machines, and horizontal boring machines, each selected based on the specific requirements of the job. At WWG Engineering, machining operations range from simple tasks such as threading to the creation of complex shapes like tapers and spheres.

One of the major strengths of WWG Engineering lies in its versatility. Whether a client needs small or large components, the workshop is equipped to handle it. The lathe machines in the workshop can accommodate work pieces from short to 10 meters long, offering flexibility for various machining needs. With its expertise in machining, WWG Engineering ensures that every project, from small parts to larger industrial components, is completed with precision and efficiency.

The Art of Cylindrical Grinding

Cylindrical grinding is a specialized form of grinding used to shape the exterior or interior of a workpiece, ensuring that it meets exact dimensional specifications. WWG Engineering offers both small and large cylindrical grinding machines, enabling the handling of a wide variety of work piece sizes. Whether grinding small shafts or large crankshafts, the team is experienced in producing highly polished, finished components to the tightest tolerances.

The process involves rotating the work piece around a central axis while it is ground with an abrasive wheel. This ensures even material removal and a smooth surface finish. Cylindrical grinding is commonly used to achieve fine tolerances, often in conjunction with other machining processes such as turning and milling. WWG Engineering excels in this field, offering grinding services that guarantee dimensional accuracy, surface finish, and form integrity.

Surface Engineering and Finishing

Metal surfaces often undergo additional treatments after machining or grinding to improve their durability, resistance to wear, or appearance. At WWG Engineering, surface engineering involves processes such as thermal spray coating, cold spray coating, and welding. After these treatments, the surfaces often require final finishing, which includes machine turning, facing, and cylindrical grinding.

The final finishing process is critical to ensuring that coated surfaces meet the exact specifications required for their intended applications. For instance, thermal spray-coated parts often need to be ground and polished to achieve a smooth, durable finish. WWG Engineering’s expertise in combining machining and grinding with advanced surface engineering technologies allows them to deliver high-quality, long-lasting components that meet the most demanding industry standards.

Comprehensive Machine Capability

WWG Engineering's workshop is equipped with a comprehensive range of machines, enabling it to undertake a variety of precision machining services. The available equipment includes:

Small, medium, and large lathe machines, capable of handling short to 10-meter-long work pieces.

Small and large cylindrical grinding machines, for external and internal grinding of different-sized components.

Small and large crankshaft grinding machines, for precision grinding of crankshafts.

Milling machines and other specialized tools for creating complex shapes and machining precise components.

Horizontal boring machines, used for machining large parts that require deep holes or large-diameter bores.

Polishing machines, used to achieve high-quality surface finishes after machining and grinding.

This extensive range of equipment allows WWG Engineering to provide efficient, effective solutions for various machining and grinding challenges. Whether it is manufacturing new components or repairing worn-out parts, the workshop’s capability ensures that all work is done to exacting standards, ensuring client satisfaction.

Expertise and Experience

WWG Engineering’s reputation in the field of metal machining and cylindrical grinding stems from its experience, expertise, and commitment to delivering high-quality results. The company has built a strong team of skilled machinists and engineers who work together to ensure that every project is completed with precision. From initial design to final finishing, the team’s attention to detail and focus on quality ensures that components meet the highest standards.

With advanced technologies and a deep understanding of machining and grinding processes, WWG Engineering continues to be a trusted partner for industries that require precision-engineered components. Whether you need simple machining tasks or complex grinding services, WWG Engineering is equipped to provide solutions tailored to your exact needs.

Conclusion

Metal machining and cylindrical grinding are critical processes that ensure the precision, functionality, and longevity of industrial components. At WWG Engineering, the Machining Workshop stands as a testament to the company’s commitment to delivering high-quality, reliable machining and grinding services. With a comprehensive range of machines and equipment, as well as a team of skilled professionals, WWG Engineering continues to push the boundaries of precision engineering, delivering solutions that meet the most demanding industry standards.

#Surface Engineering Technology#Engineering Service Company#Engineering Service Provider#Engineering Solutions#Cylindrical Grinding Machine#Metal Machining Services in Singapore

0 notes

Text

Custom Stainless Steel Fabrication: Precision and Quality in Every Project

When it comes to creating durable, functional, and aesthetically pleasing metal structures, Custom Stainless Steel Fabrication is often the go-to solution for a wide range of industries. Whether it's for construction, manufacturing, or creative design, stainless steel’s versatility and longevity make it a preferred choice. At Barra Steel, we specialize in providing high-quality stainless steel fabrication services that are tailored to meet your exact specifications. Let’s explore why precision and quality matter in every project and how our team ensures your project’s success from start to finish.

What is Custom Stainless Steel Fabrication?

Custom Stainless Steel Fabrication is the process of designing, shaping, and assembling stainless steel into specific forms to meet the requirements of a particular project. This can include everything from custom-made steel beams and frames to intricate decorative elements for interior design. By using advanced fabrication techniques, we ensure the final product meets both aesthetic and functional needs.

Why Choose Custom Stainless Steel Fabrication?

Durability and Strength: Stainless steel is known for its exceptional strength and resistance to corrosion, making it ideal for both indoor and outdoor applications. Custom fabrication ensures you get the exact strength and durability needed for your specific project.

Precision: Custom fabrication allows for precise measurements and cuts, ensuring that each piece fits perfectly into your design, whether for structural or aesthetic purposes. At Barra Steel, we pride ourselves on delivering accurate, high-quality results.

Aesthetic Appeal: Stainless steel has a sleek, modern appearance that is highly sought after in architectural and design projects. Custom fabrication gives you the freedom to create unique designs that meet your style and functional needs.

Versatility: Stainless steel can be used in a wide variety of industries, including construction, automotive, architecture, food processing, and more. Custom fabrication allows you to harness the full potential of stainless steel for your project, whatever its requirements.

The Barra Steel Difference

At Barra Steel, we stand out as a leader in Custom Stainless Steel Fabrication. Our team of experienced fabricators uses cutting-edge technology and top-quality materials to bring your vision to life. Here’s what sets us apart:

Skilled Craftsmanship: Our fabricators have years of experience and attention to detail, ensuring that every project, no matter how big or small, is executed to the highest standard.

State-of-the-Art Equipment: We invest in advanced machinery and tools that allow us to work with precision, resulting in products that meet the exact specifications required.

Customer-Centric Approach: At Barra Steel, we believe in a personalized approach. We work closely with our clients to understand their needs and deliver solutions that exceed expectations.

Applications of Custom Stainless Steel Fabrication

Custom stainless steel fabrication can be applied in numerous industries and projects. Some of the most common applications include:

Architectural Elements: Custom railings, staircases, and structural supports that provide both strength and style.

Industrial Equipment: Tanks, pipelines, and machinery parts designed to withstand harsh environments.

Kitchen and Food Processing: Custom stainless steel counters, shelves, and equipment for hygiene and durability.

Home and Commercial Design: Custom furniture, countertops, and decorative elements for both residential and commercial spaces.

Quality Control at Barra Steel

We understand that quality is non-negotiable. That’s why Barra Steel employs strict quality control measures at every stage of the fabrication process. From the selection of materials to the final inspection, we ensure that every component meets our high standards. Our commitment to quality guarantees that you receive products that are not only functional but also durable and aesthetically pleasing.

Contact Us Today

If you're looking for high-quality Custom Stainless Steel Fabrication services, look no further than Barra Steel. Our team is ready to assist you with your next project, ensuring precision and quality every step of the way.

Call Us: 03 9768 2477

Email Us: [email protected]

At Barra Steel, we are committed to providing the highest level of craftsmanship and customer service. Reach out today to discuss how we can bring your stainless steel fabrication project to life with precision and excellence.

By choosing Barra Steel for your Custom Stainless Steel Fabrication needs, you're selecting a company that prioritizes quality, precision, and customer satisfaction in every project.

#Custom Stainless Steel Fabrication#Barra Steel#Stainless Steel Fabrication#Stainless Steel Solutions#Precision Metal Fabrication#Custom Metal Fabrication

0 notes

Text

What to Look For in a Dallas CNC Machine Shop

What to Look For in a Dallas CNC Machine Shop

Whether you’re looking for a precision-machined component for your car or a tool for construction, a Dallas CNC machine shop can help. Bates Machine & Mfg. in Farmersville, Texas can produce parts that meet your specifications and provide high quality products at a competitive price.

Precision-machined components

CNC machining is an integral part of the manufacturing process. It allows for greater flexibility and customization, allowing manufacturers

to respond to consumer demand and market changes quickly. This is especially important in the competitive manufacturing sector, where it can be challenging to compete with low prices and fast delivery times. Precision CNC machining is a critical component in many industries, from aerospace to the automotive industry. The technology is essential in fabricating high-quality, dependable components that can withstand harsh environments and rigorous use. It also plays a vital role in the medical industry, where it helps produce precise instruments and devices for surgery and diagnostics. Dedicated machinists enjoy good, dependable wages, and health insurance and vacation time are available to them. Moreover, they can choose their own work hours. This allows them to balance their family life with a career that they love. They can also choose to change careers if they want to.

Quality control inspections

A CNC machining company should follow strict quality control inspections throughout the product lifecycle. This includes the ideation phase, design phase, feasibility study, analysis phase, pilot production, testing, and bulk production phases. This helps to reduce production errors and ensure that the final product meets customer requirements. Inspections are conducted in-process using programmed probes. These help to verify key features and tolerances during the machining process, while also providing real-time feedback. They also allow the QC team to monitor the progress of the work and make necessary adjustments as needed. A good machine shop will address quality issues as soon as they arise. This will involve implementing practical corrective actions, such as adjusting machine settings or retraining employees. It should also invest in regular maintenance and calibration to prevent avoidable errors. In addition, it should rely on reputable suppliers and conduct batch tests to ensure that raw materials are consistent. They should also document the results of each inspection and test to demonstrate that they meet industry standards.

Safety measures

Many machine shop employees need to wear protective eyewear due to the use of small particles or chips that could damage their eyesight. The use of compressed air can also send these particles flying through the air and may cause damage to the eyes. Using safety glasses is an easy way to prevent eye injuries and keep workers safe. A crushing injury can occur when someone becomes caught between two moving parts of a machine or heavy machinery falls on them. These injuries are extremely dangerous and require immediate medical attention. Keeping machines clean, following lockout/tagout protocols, and providing training on how to operate machinery are some of the ways to prevent these types of injuries. Localized special hazard fire suppression systems are one of the most effective tools manufacturers can employ to protect CNC machines and other expensive equipment in their facilities. These systems are designed to monitor, control, and extinguish CNC equipment fires before they spread, ensuring compliance with regulatory requirements and minimizing costly downtime for the facility.

Experience

The right metal fabrication and cnc machine shop will be able to handle your project from start to finish. They will also be able to provide quality work and excellent customer service. In addition, they will have a strong understanding of all aspects of machining processes and CAD/CAM software. They will be able to implement best practices and technologies to improve productivity and enhance product quality. A reputable Dallas CNC machine shop like Bates Machine & Mfg. will follow strict quality control inspections throughout the manufacturing process to ensure that their products meet the client’s specifications. They also make sure that their equipment is up-to-date. In addition, they will maintain a high level of professionalism and confidentiality by signing a non-disclosure agreement with their clients. Another advantage of working with a CNC machine shop is its ability to produce high-quality parts at an affordable price. This means you can save money on labor and production costs, while still achieving the same results as you would with a traditional machining method. Read the full article

0 notes