#precision computerized lathe machining parts

Explore tagged Tumblr posts

Text

What is CNC Machining?

CNC machining is a cuttingedge manufacturing process that utilizes computer numerical control systems to precisely shape and form various materials.

In the realm of modern manufacturing, CNC machining stands as a cornerstone technology. CNC, short for Computer Numerical Control, refers to a process that utilizes computerized controls to operate machine tools with remarkable precision.

In fact, at the heart of CNC machining is a complex software program. The program is carefully crafted by experienced engineers and technicians to define the exact movement and operation of the machine. Whether milling machines, lathes or other specialized equipment, CNC systems ensure that every cutting, drilling or forming operation is performed with the highest precision.

CNC machining has many advantages, mainly its ability to produce highly complex and complex parts. Guided by a computer program, machine tools can create detailed geometries and fine features that are extremely difficult or even impossible to achieve with traditional machining methods. This makes it ideal for applications in industries such as aerospace, automotive, electronics and medical devices.

There is another feature -- precision. The computer-controlled system can maintain extremely tight tolerances, ensuring that the finished part meets the exact specifications required for its intended use. This level of accuracy is critical in many applications, as even the slightest deviation can lead to performance issues or product failures.

Moreover, CNC machining offers high repeatability. Once a program is developed and tested, the same part can be produced consistently over and over again with minimal variation. This is particularly important for mass production or when multiple identical parts are needed for an assembly.

A wide variety of materials can be processed through CNC machining, from metals such as steel, aluminum, and titanium to plastics, composites, and even wood. This versatility enables manufacturers to select the material that best suits their specific application while taking into account factors such as strength, durability, weight and cost.

In conclusion, CNC machining is a powerful and essential manufacturing process that combines advanced technology with precision and versatility. It enables the production of high-quality parts with complex geometries and tight tolerances, playing a vital role in the development of a wide range of products across various industries.

0 notes

Text

PRECISION CNC, VMC, Machining 4 and 5 Milling Job Work — Pitrukrupa Engineering

Pitrukrupa Engineering is country’s leading Manufacturer, Exporter and Supplier firm offering high performing CNC Milling and Turning Components since its inception in 2009.

Our CNC Job Work Services and CNC Products

CNC Job Work CNC Machining Work We are offering CNC Components to our clients. For accomplishing this work, experts bank on innovative machines and important tools.

Precision Machining Work Precision machining relies on the use of advanced, computerized machine tools

VMC Machining Work VMC Machines are chiefly used to turn raw blocks of metal like aluminum, steel and other metal components.

Milling Machining Work Milling Job Work is the machining process of using rotary cutters to remove material from a workpiece by advancing

4 Milling Components For accomplishing this work, experts bank on innovative machines and important tools. 4 Axis Milling Components

5 Axis Milling Components We are offering CNC Components 5 Axis Milling Components to our clients. For accomplishing this work, experts bank on innovative machines and important tools. We are counted amidst the trustworthy manufacturer, exporter and supplier of a wide range of 5 Milling Components.

HMC Machining Work We are engaged in manufacturing, exporting and supplying our clients a high quality range of CNC EDM Components.

CNC Turning Machining Work We are offering CNC Turn Mill Machining Work to our clients. For accomplishing this work, experts bank on innovative machines and important tools.

CNC Lathe Machining Component CNC Lathe Machining Component For accomplishing this work, experts bank on innovative machines and important tools.

CNC Turn Mill Components With the help of our deft professionals and advanced structure, integrated with latest equipment, we are offering CNC Turn Mill Components.

CNC Turn Mill Machining Parts With the help of our deft professionals and advanced structure, integrated with latest equipment, we are offering CNC Turn Mill Machining Parts.

EDM Wire Cutting Work EDM Wire Cutting Work are essential to the manufacturing industry because of their precision and speed.

CNC laser Cutting Work A CNC laser cutter features a laser head containing a laser focusing lens and a nozzle.

CNC Bending Work CNC Bending Work can bend sheet metal work from just a few mm across to sections many metres long on the largest industrial machines.

AEROSPACE AND DEFENCE MACHINING PARTS MANUFACTURINGCNC machining is commonly used to manufacture various electronics components used in aircraft systems such as control panels, connectors, sensor housing and instrument cluster components.

Aluminium And Steel Precision Welding Fabrication Aluminium And Steel Precision Welding Fabrication bimetallic transition insert is definitely the best way to weld steel to aluminum for structural applications.

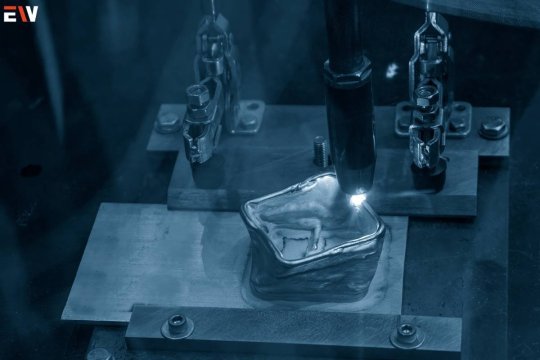

Aluminium High Pressure Die Casting Aluminium High Pressure Die Casting manufacturing process that produces accurately, defined, smooth and textured-surfaced metal parts.

Aluminium Extrusion Aluminum extrusion is a process by which aluminum alloy material is forced through a die with a specific cross-sectional profile.

For More Details Click Here : https://www.pitrukrupaengineering.com/

0 notes

Text

Streamlining Production with Innovative CNC Milling Solutions

Computer Numerical Control (CNC) milling and turning are integral components of the modern manufacturing industry. These processes leverage computer systems and machine tools to create precise parts and components, thus enabling efficient, high-volume production. In this article, we will explore the fundamentals of CNC milling and turning their differences, and how they work together to streamline production.

Understanding CNC Milling

CNC milling is a machining process that utilizes computerized controls to remove layers of material from a workpiece. There are various types of CNC milling machines, including vertical, horizontal, and benchtop models, each suited to specific manufacturing tasks. The CNC milling process involves three primary phases: design creation, program input, and execution. This technology is used across a wide array of industries, including automotive, aerospace, and consumer products, for its remarkable precision and flexibility.

Understanding CNC Turning

CNC turning, on the other hand, involves the rotation of the workpiece while a cutting tool moves in a linear motion. This process is typically performed using lathes or turning centers, and it's known for its ability to deliver precise, fast, and repeatable results. Like milling, the CNC turning process also involves design creation, program input, and execution. Industries such as healthcare, electronics, and construction are leveraging CNC turning for producing intricate and detailed components.

Comparing CNC Milling and Turning

While both CNC milling and turning are critical manufacturing techniques, they differ in their operation, applications, and the types of parts they produce. Milling machines are preferred for flat or irregular surfaces, while turning machines are used for cylindrical parts. The choice between milling and turning hinges largely on the part's complexity, volume, and material. In general, milling is best suited for intricate parts that require multiple cuts and angles, whereas turning can deliver high precision on simpler components.

The Future of CNC Milling and Turning

Technological advancements are continually reshaping the realm of CNC milling and turning. Innovations like 3D printing and AI-assisted manufacturing are making CNC processes faster, more accurate, and more adaptable. These advancements are poised to boost manufacturing efficiency and precision, propelling the industry into a future of unprecedented productivity. In Canada, CNC milling and turning are rapidly evolving, with industries embracing the technology to enhance their production capabilities.

Conclusion

In conclusion, both CNC milling and CNC turning are essential components of modern manufacturing in Canada. Whether it's CNC milling Canada industries rely on for precision parts or CNC turning Canada companies leverage for cylindrical components, these techniques play a pivotal role in delivering high-quality products across a multitude of sectors. As technological innovation continues to drive advancements in these processes, the future of CNC milling and turning in Canada is undoubtedly bright and full of potential.

Discover the best-in-class CNC milling and turning solutions in Canada. Experience precision like never before with our CNC milling Canada and CNC turning Canada services. Contact us today!

0 notes

Text

Precision in Motion: Exploring the World of Metal CNC Machining

Share Post:

LinkedIn

Twitter

Facebook

Reddit

Metal CNC machining represents the pinnacle of precision engineering, offering unparalleled accuracy, efficiency, and versatility in the fabrication of metal components and parts. In this comprehensive overview, we delve into the intricacies of metal CNC machining, exploring its technology, applications, benefits, and the future of precision manufacturing.

Understanding Metal CNC Machining

CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls to automate the operation of machine tools, such as lathes, mills, and routers. Metal CNC machining specifically focuses on the fabrication of metal components, utilizing specialized CNC machines equipped with cutting tools to shape and refine metal workpieces with exceptional precision.

Key Components:

1. CAD (Computer-Aided Design)

The design phase begins with the creation of a digital model of the desired part using CAD software. This digital model serves as the blueprint for the machining process.

2. CAM (Computer-Aided Manufacturing)

CAM software translates the CAD model into instructions for the CNC machine, generating tool paths and specifying machining operations such as milling, drilling, and turning.

3. CNC Machine

The CNC machine executes the programmed instructions, utilizing cutting tools to remove material from the workpiece and create the desired shape and features with high precision.

4. Cutting Tools

Various cutting tools, such as end mills, drills, and inserts, are used to remove material from the workpiece during the machining process. These tools are selected based on factors such as material type, geometry, and surface finish requirements.

What are its Applications?

CNC machining finds wide-ranging applications across industries and sectors, including:

1. Aerospace: Precision components for aircraft, spacecraft, and satellites, such as engine parts, structural components, and avionics.

2. Automotive: Engine components, transmission parts, chassis components, and precision tooling for automotive manufacturing.

3. Medical: Surgical instruments, implants, prosthetics, and medical device components require high precision and biocompatibility.

4. Electronics: Enclosures, heat sinks, connectors, and components for electronic devices and consumer electronics.

5. Industrial Manufacturing: Tooling, fixtures, molds, and production components for various manufacturing processes.

Benefits of Metal CNC Machining

1. Precision and Accuracy

CNC machining offers unparalleled precision and accuracy, with the ability to achieve tight tolerances and intricate geometries that are difficult or impossible to replicate with traditional machining methods.

2. Efficiency and Productivity

CNC machines operate with high speed and efficiency, allowing for rapid production of metal components with minimal downtime and waste. Automated tool changes, material handling, and process monitoring further enhance productivity.

3. Versatility and Flexibility

CNC machining can accommodate a wide range of materials, including metals such as aluminum, steel, titanium, and brass. Moreover, CNC machines are capable of machining complex shapes and features, making them highly versatile for diverse manufacturing applications.

4. Consistency and Repeatability

With CNC machining, each part produced is identical to the next, ensuring consistency and repeatability in quality and performance. This reliability is essential for industries with stringent quality standards and regulatory requirements.

Future Trends in Metal CNC Machining

1. Advanced Materials

As demand grows for lightweight, high-strength materials, such as titanium alloys and composites, metal CNC machining will continue to evolve to accommodate the machining challenges posed by these advanced materials.

2. Additive Manufacturing Integration

The integration of additive manufacturing (3D printing) with CNC machining processes, known as hybrid manufacturing, offers new possibilities for producing complex metal parts with enhanced efficiency and functionality.

3. Smart Manufacturing Technologies

Advancements in automation, robotics, artificial intelligence, and data analytics are transforming CNC machining into a smarter, more interconnected ecosystem, enabling predictive maintenance, real-time monitoring, and optimization of manufacturing processes.

4. Sustainable Practices

With a growing emphasis on sustainability and environmental stewardship, CNC machining will increasingly adopt eco-friendly practices, such as recycling metal chips and coolant, energy-efficient machining processes, and reduction of material waste.

Conclusion

Metal CNC machining stands at the forefront of precision manufacturing, offering unparalleled capabilities, efficiency, and versatility in the fabrication of metal components and parts. From aerospace to automotive, medical to electronics, CNC machining plays a critical role in driving innovation and advancement across industries. As technology continues to evolve and demand for high-quality, custom metal components grows, CNC machining will remain indispensable for delivering precision in motion and shaping the future of manufacturing.

Also Read: Industrial IoT: Transforming Manufacturing through Connected Intelligence

#metalcnc#PrecisionEngineering#manufacturing#Technology#cncmachining#metalfabrication#aerospace#medical#electronics#industrialmanufacturing

0 notes

Text

CNC Machines: Precision Engineering Redefined for Advanced Manufacturing

CNC (Computer Numerical Control) machines stand at the forefront of modern manufacturing, revolutionizing precision engineering and shaping the landscape of industrial production. This informative content delves into the technology, types, and wide-ranging applications of CNC machines, showcasing their pivotal role in advanced manufacturing.

Technology Behind CNC Machines: CNC machines rely on computerized systems to control and execute intricate machining operations with unparalleled precision. The integration of advanced software and control algorithms allows for the automated and precise manipulation of tools, resulting in high-quality, complex components.

Types of CNC Machines: The realm of CNC machining encompasses various types of machines, each tailored for specific applications. These include CNC milling machines, lathes, routers, plasma cutters, and more. The choice of machine depends on the nature of the task, material, and desired outcome.

Applications Across Industries: CNC machines find applications across diverse industries, including aerospace, automotive, healthcare, and electronics. In aerospace, CNC machining ensures the fabrication of intricate components with tight tolerances, while in healthcare, it facilitates the production of custom medical devices and implants.

Precision and Accuracy: One of the defining features of CNC machines is their unmatched precision and accuracy. The computer-controlled nature eliminates the margin for human error, ensuring consistent quality in every manufactured part. This precision is critical for industries where exact specifications are paramount.

Efficiency and Automation: CNC machines enhance manufacturing efficiency through automation. Once programmed, these machines can operate continuously, reducing downtime between tasks and enabling high-volume production. This efficiency not only saves time but also contributes to cost-effectiveness in large-scale manufacturing.

Customization and Prototyping: CNC machining allows for the customization of parts and rapid prototyping. This flexibility is invaluable for product development, enabling engineers and designers to iterate designs quickly and bring concepts to life with precision and speed.

CNC machines epitomize the synergy between technology and manufacturing, offering a level of precision and efficiency that has transformed the industrial landscape. From intricate aerospace components to personalized medical devices, the impact of CNC machines reverberates across sectors, showcasing their pivotal role in shaping the future of advanced manufacturing.

Easily locate precision CNC Machines with the JD app (Justdial app). Download now to connect with top suppliers, revolutionizing your manufacturing processes with cutting-edge technology. Simplify your search with the JD app.

0 notes

Text

The Revolution of Manufacturing: Automatic CNC Lathe

The Revolution of Manufacturing: Automatic CNC Lathe In the realm of manufacturing, precision, efficiency, and consistency are paramount. These elements are the driving force behind the evolution of manufacturing technologies, leading to the development of Computer Numerical Control (CNC) machines. Among these, the Automatic CNC Lathe stands out as a revolutionary tool that has transformed the industry.Get more news about Automatic Cnc Lathe,you can vist our website!

The Automatic CNC Lathe is a high-precision, high-efficiency automated machine tool. Equipped with multi-station turret or power turret, the machine has a wide range of processing performance, capable of handling linear cylindrical, slant cylindrical, arc and a variety of threads, grooves, worms and other complex parts. With good rigidity and powerful headstock, it is possible to realize high-speed turning of various materials from black metal to non-ferrous metals.

The advent of Automatic CNC Lathes has brought about significant changes in the manufacturing industry. The first is the increase in productivity. Unlike manual lathes that require constant supervision, automatic lathes can operate independently for extended periods. This frees up operators to focus on other tasks, thereby increasing overall productivity.

Secondly, Automatic CNC Lathes ensure exceptional precision and consistency. The machine’s computer controls can maintain exact dimensions across multiple production runs. This level of precision is crucial in industries such as aerospace and automotive where even the slightest deviation can have significant consequences.

Moreover, these machines offer remarkable flexibility. With their computerized controls, changing the specifications of a part is as simple as altering the program. This makes them ideal for custom manufacturing jobs with low volume runs.

However, like any other technology, Automatic CNC Lathes come with their own set of challenges. The initial cost for these machines can be quite high, making it a significant investment for small businesses. Additionally, they require skilled operators to program and maintain them.

Despite these challenges, the benefits offered by Automatic CNC Lathes far outweigh the drawbacks. As technology continues to advance, we can expect these machines to become more accessible and even more efficient.

In conclusion, the Automatic CNC Lathe represents a significant leap forward in manufacturing technology. Its ability to combine high precision with efficiency and flexibility has made it an invaluable tool in modern manufacturing. As we look towards the future, there is no doubt that these machines will continue to play a pivotal role in driving innovation in the industry.

0 notes

Text

Machine tools are operated and manipulated with computerized controls as part of CNC or computer numerical control machining. They can manufacture complex parts and components from a variety of materials using lathes, mills, routers, and grinders.

Multinational & giant corporations used to be the only companies that used CNC machining as a production process. Despite this, small and medium-sized companies are increasingly adopting CNC machining as competition in the business world intensifies.

Importance of CNC Machining in Prototype Design

CNC machining, one of the most effective prototyping methods, stands out among the many options. By using CNC machines, you can design digital products, input data into computers, and direct the CNC machines.

Human errors are considerably reduced by using CNC machining, resulting in an increase in prototyping efficiency. The skilled work of freelance CNC programmers will enable industries to turn concepts into detailed technical drawings, enabling them to manufacture flawless parts from the first to the last iteration.

Accuracy

CNC machining services with a proven track record consistently meet the appropriate tolerances for extended production runs. For shorter runs, they may also use a different machine to ensure accuracy and use a more precise cut when operating at a tighter tolerance.

Choosing Variety of Components

The CNC machines used by reliable CNC machining service providers, including CNC Design Services specialists, are flexible enough to accommodate various cutting materials to satisfy the prototyping needs of customers across a wide range of industries.

CNC machining provides significant advantages to customers today, which often prefer to visualize prototypes in multiple materials. With CNC machines, same design prototypes can be made using steel, aluminium, or rigid plastic with only a few adjustments to the cutting tool speed and feed rate.

Modification

It is often necessary to modify, adjust, or overhaul the original design when customer requirements or job demands demand it. The CNC machining experts operating CNC machines are well suited for managing these changes. A few keystrokes and a few seconds can change the G-code quickly.

Customers appreciate the ability to test multiple iterations in real-time & observe the results. CNC machining experts can reduce costs and time significantly by modifying G-codes and tweaking prototypes.

Read more

0 notes

Text

A Look Inside the World of Metalworking Machinery: Highlights from the Expo

Enter the fascinating world of metalworking machines! Manufacturers, engineers, and hobbyists showcased industry-leading products and technologies at the recent exhibition. The blog covered this thrilling event's highlights, from precise cutting tools to cutting-edge welding technology. Brace yourselves for some genuinely remarkable advancements. Jump in!

What is metalworking machinery?

The Expo showcases prominent metalworking machinery expo, which is essential to the industry. This year's show has everything from CNC equipment to sanding machines that smooth metal surfaces.

Welding equipment joins metal parts. Welder robots can execute various welding operations concurrently with accuracy, making them appealing. Other metalworking machinery:

Cutterheads use saws, punches, and lasers to cut metal forms.

Forming and bending machines employ hot irons, hammers, or pressured steam to form aluminum and steel.

Lathes: These old machines use a spinning cutting head to make circular things from wood, plastic, or metal.

Milling machines cut fabric sheets and wooden blocks using rotary blades.

Types of metalworking machinery

Manufacturers have several metalworking machinery choices. CNC, waterjet, lathe, and mill equipment can handle almost any job. We'll examine several standard metalworking machines and their characteristics in this post.

CNC Machines

CNC metalworking machines are the most popular. A computer system regulates the machine's motions to generate items according to the manufacturer's specifications. Lasers and 3D printers on many CNC machines improve precision.

Waterjet Cutters

High-pressure waterjets cut metal swiftly and effortlessly. These devices make automobile and aircraft components because water cuts metals efficiently. Jewelers and amateurs who cut complex precious metal objects use them.

Lathes, Mills

Lathes and mills form metals via rotating action. Mills can grind metals into particular forms, whereas lathes can make almost any shape. Both devices take plenty of experience to achieve correct results, therefore

Highlights from the Expo of Metalworking Machinery

The metalworking equipment exhibition showcased machines for welding, cutting, and fabrication. Top five:

Waterjet cutting technique saves money.

Robotic welders that accelerate arc welding are on show.

CNC machining is preferred for high-quality items because it is more precise and efficient than conventional machining.

Modern milling methods allow for more complex forms and features, making them ideal for aviation components and medical implants.

Metalworking tools may suit every purpose, From hand tools to computerized equipment.

Conclusion

Metalworkers found the Metalworking Machinery Expo eye-opening. This year's show included everything from the newest CNC machines and plasma cutters to sheet metal forming and bending equipment. The tour of the world's most considerable stamping press, which can create 2 tons of steel per hour, and the latest X-Ray vision software used to verify components before manufacturing were highlights. 3D printing technology that is altering industrial metal production was also shown. This year's exhibition will satisfy your desire for future study with so much fresh material.

0 notes

Text

what is Machining Services

Machining services refer to the professional services offered by specialized companies or individuals that involve the manufacturing, modification, or repair of machine parts using various machining techniques and equipment. These services are typically provided to businesses or individuals who require specific components or parts for their machinery or equipment.

Machining services encompass a wide range of activities, including:

CNC Machining: Computer Numerical Control (CNC) machining is a process that utilizes computerized controls and precision cutting tools to remove material from a workpiece and create the desired shape. CNC machining services provide accurate and repeatable production of complex parts with tight tolerances.

Manual Machining: Manual machining involves the use of manual tools and machines, such as lathes, milling machines, drills, and grinders, to shape and fabricate parts. Skilled machinists operate these machines, following technical drawings or instructions to produce components.

Turning: Turning is a machining process that involves rotating a workpiece while a cutting tool removes material to create cylindrical shapes. Turning services are used to create parts such as shafts, pins, and cylindrical components.

Milling: Milling is a machining process that uses rotating multi-point cutting tools to remove material from the workpiece. It can produce a variety of shapes, including flat surfaces, slots, gears, and complex profiles. Milling services are commonly used for creating molds, prototypes, and precision parts.

Drilling: Drilling services involve creating holes in a workpiece using a rotating cutting tool called a drill bit. Drilling can be performed manually or using CNC machines, depending on the complexity and accuracy requirements.

Grinding: Grinding services utilize abrasive wheels to remove material and create smooth and precise surfaces. It is commonly used for achieving tight tolerances, surface finishing, and creating special profiles or shapes.

Welding and Fabrication: Some machining services also offer welding and fabrication capabilities to join and assemble machined parts or create complete structures or systems.

Machining services provide several benefits to businesses and individuals, including:

Customization: Machining services can create parts that are tailored to specific requirements, allowing for unique designs, sizes, and functionalities.

Precision and Accuracy: Skilled machinists and advanced machining equipment ensure high levels of precision and tight tolerances, resulting in parts that meet strict quality standards.

Efficiency and Cost-effectiveness: Outsourcing machining services can be more cost-effective than setting up in-house machining capabilities. It allows businesses to focus on their core competencies while relying on experts for the machining requirements.

Expertise and Knowledge: Machining Services providers have extensive experience and expertise in machining techniques, materials, and industry standards. They can provide valuable advice and recommendations to optimize part design and manufacturing processes.

Machining services are utilized across various industries, including aerospace, automotive, manufacturing, medical, electronics, and more, where precise and high-quality machined components are crucial for the functioning of machinery, equipment, and systems.

1 note

·

View note

Text

CNC precision machine

Last time we introduced Spark Erosion Machine we use in the manufacturing of SMC molds. Today we are gonna to talk about another machine we use to improve the machining accuracy – CNC precise machines.

CNC (Computer Numerical Control) precision machine is a type of machine tool that uses computerized control and precision tools to produce high-precision parts. The machine is programmed using a set of instructions that control the movement of cutting tools, achieving high accuracy and repeatability during the manufacturing process.

CNC precision machines are used in various industries, including aerospace, automotive, and medical treatment, where accuracy and accuracy are crucial. These machines are capable of machining SMC molds with complex shapes and features while ensuring high-quality surface finish. Some examples of CNC precision machines include CNC lathes, CNC milling machines, and CNC milling machines.

In short, as a well-known compression mold manufacturer at home and abroad, if you have any needs, then MDC Mould will be your best choice.

0 notes

Text

CNC Machining Services: Unlocking Precision and Efficiency in Manufacturing

As technology continues to evolve, it's no surprise that the manufacturing industry has undergone a massive transformation over the years. One of the most significant innovations that have revolutionized the sector is Computer Numerical Control (CNC) machining. CNC machining services have become an integral part of the manufacturing process, enabling businesses to produce high-quality products with minimal human intervention.

CNC machining is a manufacturing process that utilizes computerized systems to control machine tools such as lathes, mills, routers, and grinders. It involves the use of CAD (Computer-Aided Design) software to create 3D models of the product, which are then translated into machine code for the CNC machines to execute. The CNC machines are highly efficient and precise, delivering exceptional accuracy and consistency in the finished products.

If you're looking for a CNC machining supplier for your business, here are some of the key selling points to consider:

Precision and Accuracy

Precision is everything in the manufacturing industry. Whether you're producing aerospace components or medical devices, the parts must be produced with exact specifications. CNC machines are incredibly accurate and can produce parts with tolerances as low as 0.001mm. This level of precision is impossible to achieve through manual machining processes. With CNC machining, you can be confident that your parts will meet the required standards and specifications.

Reduced Lead Times

In today's fast-paced world, businesses must deliver products quickly to remain competitive. CNC machining services enable businesses to produce parts faster than traditional machining methods. The machines can run 24/7, which means that you can get your parts produced within a shorter lead time. This increased efficiency saves businesses both time and money in the long run.

Wide Range of Materials

CNC machining services can work with a wide range of materials, including metals, plastics, and composites. CNC machines can handle materials that are difficult to machine manually, such as titanium and Inconel. This versatility allows businesses to produce a wide range of products, from automotive components to medical devices.

Consistency and Repeatability

CNC machining is highly consistent and repeatable, which means that you can produce identical parts with the same level of accuracy and precision every time. This is crucial in industries such as aerospace and medical, where even the slightest deviation from the required specifications can result in catastrophic consequences. With CNC machining, you can be confident that your parts will be produced to the exact same standards every time.

Cost-Effective

Although CNC machining services can be more expensive than traditional machining methods, they offer long-term cost savings. CNC machines are highly efficient, reducing material waste and minimizing the need for manual labor. The machines can also run unattended, reducing labor costs. With CNC machining, you can produce high-quality parts at a lower cost per unit.

Customization

CNC machining services offer a high level of customization, enabling businesses to produce unique parts that meet specific requirements. With CAD software, you can create 3D models of your parts, which can be modified and tweaked until you achieve the desired design. CNC machines can then produce the parts with high accuracy and precision, ensuring that your unique specifications are met.

Reduced Risk of Error

Manual machining processes are prone to errors, which can result in costly rework and delays. CNC machines, on the other hand, are highly automated, reducing the risk of error. The machines are programmed to follow precise instructions, eliminating the possibility of human error. This reduces the risk of costly mistakes and ensures that the parts are produced to the required specifications.

In conclusion, CNC machining services offer businesses numerous benefits, including precision, efficiency, consistency, and cost savings. If you're looking for a CNC machining supplier

0 notes

Text

System to Operate the CNC Machine

New Post has been published on http://www.cncmachinings.com/system-to-operate-the-cnc-machine/

System to Operate the CNC Machine

The Cartesian arrange framework that recognizes the area of the source on the workpiece is known as the work coordinate system (WCS). The beginning of the WCS can be set up anyplace on the workpiece for simplicity of programming. The machine to get the precision machined components china has its very own organize arrangement called the machine coordinate system (MCS).

The inception of the machine facilitate framework is in a fixed, manufacturing plant set area and can’t be changed or moved. The MCS is utilized for the machine’s own reference purposes and encourages it to monitor how far every hub can move before it runs out of movement. The separation from the starting point of the MCS to the beginning of the WCS is known as the work balance. This distance is estimated when the machine is arrangement and is put away in the control.

Catalyst and Homing

The absolute initial step for china precision machining manufacturers to working any CNC machine is controlling it up appropriately. Since there are various machine varieties, allude to a particular machine’s manual for the right strategy. After the machine has been appropriately turned on, most machines require a reference get back to the machine home position. This interaction is known as the homing strategy. Review that the machine moves its tomahawks by pivoting a ball screw with a servo engine. Once more, this engine can screen and change hub position by how far its shaft turns. At the point when the machine power is turned off and the MCU is not, at this point ready to screen and change hub position, its tomahawks essentially forget about their positions. Subsequently, every time a CNC machine is fueled up from a complete closure, it should be homed.

The homing technique is utilized to precisely re-empower reference to the MCS. When the machine knows where every pivot is situated, the machine will know its restrictions of movement. By homing, the machine is likewise ready to review the situation of the WCS that was dynamic before the machine was shut down. This forestalls the work counterbalance from being reset each time the machine is controlled up.

Each machine requires explicit strides to play out the homing system. These means can likewise be found in a particular machine’s working manual, however the essential advances are as per the following:

Select “zero-return” or “home”mode on the machine control board.

Run every pivot toward the path toward the machine’s home situation with the run bolt keys. In the event that the machine tomahawks were at that point at home position, they should be run away from and afterward back toward home position.

As every hub is sent the fitting way, most machines will naturally finish the strategy by quickly moving the pivot and afterward easing back as a sensor or switch is drawn nearer. At the point when the switch is reached, the encoder of the servo will locate the home situation of the encoder haggle reference its position.

When the encoder home position is discovered, the machine will zero the machine organize framework. The machine is then prepared for set up or to begin machining utilizing the past arrangement.

A few machines are furnished with total encoders which don’t forget about pivot position when the machine is fueled off. These machines require no homing technique upon fire up.

This article is from http://www.cncmachinings.com/

#big cnc machined part factory#china custom machine design#china customtitanium parts#china medical device machining#china precision machine parts#china precision machining manufacturers#china steel tapped machining service suppliers#cnc carbon fibre service suppliers#cnc components companies#cnc micro machining brass part manufacturers#cnc titanium turned machinig parts suppliers#communication device metal parts mold suppliers china#custom made metal cnc machining parts factory#high precision machining parts factory#high precision stamped parts suppliers china#high-quality fixture part machining#other machined ptfe manufacturers china#precision computerized lathe machining parts#precision machined optical components factory#Featured Articles

0 notes

Text

Set Up the Workingholding in CNC Machining

Set Up the Workingholding in CNC Machining

When the workholding gadget is picked, it is mounted by the maker’s rules. When utilizing a hurl, machinable delicate jaws are frequently utilized in china professional cnc machining center. Delicate jaws can be redone to oblige the state of the workpiece. Frequently, the jaws are exhausted while introduced on the hurl to build up the right grasping sweep where the jaw contacts the part. It is a…

View On WordPress

#china cnc machining aluminum parts manufacturers#china cnc prototyping service#china electronic aluminium machined parts manufacturers#china precision machining manufacturers#cnc brass turning made in china#cnc machining aluminum parts made in china#cnc micro machining brass part manufacturers#cnc milling precision copper parts china#communication device metal parts mold suppliers china#custom machine parts suppliers china#high demand cnc machining parts suppliers china#high precision machining parts factory#high precison aluminium parts china#high-quality fixture part machining#lathe turning part suppliers#precision cnc milling parts factory#precision computerized lathe machining parts#precision machined components china#precision turned parts buy

0 notes

Text

How is a CNC parallel lathe made? And how does it work? Find out in the guide that

Southlathe.comhas dedicated to one of the most popular machines in the manufacturing industry thanks to its great potential: the numerically controlled parallel lathe.

How is a CNC parallel lathe made? And how does it work? Find out in the guide that Techmec.it has dedicated to one of the most popular machines in the manufacturing industry thanks to its great potential: the numerically controlled parallel Guangzhou CNC Lathe products.

Numerical Control (CN) parallel lathes, often abbreviated as CNC (Computerized Numerical Control) parallel lathe, are the machine tools that have made it possible to automate industrial production, reaching quality levels never seen before. All the information relating to the machining is defined according to a particular language that contains the instructions of the program or part program . The most famous language for machine tools is G-code, but there are many others, developed by various manufacturers, which extend (or replace) the characteristics of G-code .

In the control unit, an electronic microprocessor completes the processing, instruction after instruction, controlling the actuator members, such as the motor that carries out the translation of the slide.

It is important that the control unit knows the position and the effective speed of the machine tool axes; the information is acquired through transducers . In this way, it will be possible to correct in real time the positions that differ from the theoretical trajectory, by performing, for this purpose, a feedback. The transducers can be found directly on the axis through an optical scale (more precise solution) and / or on the motor through an encoder (more economical solution).

Although a CNC lathe involves more expense than a manual parallel lathe , the potential of such a machine is enormous. These lathes in fact allow to perform very complex pieces with good precision (even in the order of a hundredth of a millimeter or less), in large batches (greater than 10 pieces) and with a shorter cycle time. Moreover, thanks to the high precision, it is possible to work with a view to reducing waste ( six-sigma approach).

Since these machines do not need constant human surveillance, the cost of labor is reduced and, in the case of an automated system for loading and unloading pieces, the presence of the operator is required only in the production and maintenance phases. However, it is necessary to consider the professional figure of the CNC programmer whose task is to develop the work cycles and the code with the instructions, thanks also to the use of CAM (Computer-Aided Manufacturing) tools or developing it directly on the machine.

How CNC parallel lathe is made

The main components of the numerically controlled parallel lathe are as follows.

Bed - Although the bed base conceptually performs the same function as that of the manual lathe , in the CNC parallel lathe it is much heavier, rigid and sturdy since, in CNC machine tools, higher installed powers are had and the machining is performed at much higher speeds. compared to traditional machines. The high mass of the bed also helps to attenuate any vibrations coming from the ground towards the lathe (and vice versa). The guides for the slide and the housing for the spindle bearings are obtained on the bed . The guides are roller cage or ball cage in order to reduce friction and thus increase positioning accuracy.

Slide and tool turret - The slide is normally placed on the opposite side of the operator and is supported by the guides inclined by about 60 °, thus making the process easier to control. The slide moves longitudinally (Z axis) and the transverse carriage (X axis) is present on it. On the top, there is the tool turret that can accommodate up to 12 tools with quick coupling, selected according to the instruction of the part program .

Motors and drives - The controlled axes of the CNC parallel lathe are moved by brushless or stepper motors . These motors are then connected to the ball screws which transform the rotary motion into translational motion of the axes. Steel balls are interposed between the screw and the nut which transform the sliding friction into rolling friction. In this way, overall low friction and limited wear are achieved, as well as clearance clearance by means of axial preloading of the nut.

Spindle - The self-centering spindle is set in rotation by the spindle shaft which is in direct engagement with the electric motor or rotated by belts. The control unit continuously controls the spindle speed , keeping the cutting speed constant throughout the processing and thus overcoming the limits of manual machines that have a gearbox with toothed wheels, which allows you to choose only from a limited number of speed. The chuck can be operated by an oleodynamic control that allows you to select the clamping force of the piece at will. On the opposite side of the spindle there is the counterhead for the processing of long and slender pieces, also operated by the hydraulic unit.

youtube

3 notes

·

View notes

Text

Understanding Precision CNC Machining

Computerized Numerically Controlled (CNC) machines are devices which use computer programming to precisely fabricate parts. CNC machining works the opposite of how 3D printers work. While a 3D printer adds material to create a part, a CNC machine removes material from a solid block until the part is what remains, in what is known as a reductive process. With modern CNC machine services, a Computer-Aided Design (CAD) program is used to generate a model of the component to be built. This model is then sent to the CNC machine, which then takes a block of material such as aluminum and creates the component in the model.

There are different types of CNC machines for different applications, including drilling machines, which spin a bit against a stationary block, lathes, which spin the block of material and use a stationary cutter, and CNC cutting machines, which can move around the material block on different axes to cut exactly where needed.

CNC machines are accurate down to thousandths of an inch, and order of magnitude more precise than is physically possible for human craftsman or other forms of.

CNC machining is extremely precise, allowing parts to be made to very close tolerances. Parts can be made very quickly; changes in design are easily resent to the machine. This makes CNC machine services great for prototyping and pre-production work. Once a product is ready for mass production, CNC machining is able to precisely reproduce the design infinitely, allowing projects to move to large scale without sacrificing the quality of the part.

CNC machine servicing is a versatile manufacturing process which can not only help fabricate new products, but can also be used in repairing equipment and recreating parts which otherwise may no longer be available.

Hamilton Machine Company is your Nashville area experts in CNC machining. We have the space for big projects and the commitment for smaller jobs. Whether you are just beginning your product prototyping or need extensive repairs on equipment, we can help.

CNC machine servicing is one of the many capabilities of Hamilton Machine Company. We also do welding, hydraulics, and truck repair. Hamilton has on site services capable of coming to you for job site repairs and fabrication work, with emergency maintenance service available 24/7. Learn more about CNC machining and all the other services we offer to keep your production running smoothly.

#cnc machine#cnc machining#cnc machine tool#cnc cutting machines#precision cnc machining#machine#machine shop#cnc machine services#nashville#startup#business#machinery shop

1 note

·

View note

Text

How to make precision machining parts of medical equipment by CNC machining?

Items processed and manufactured by CNC include various surgical instruments used in medical operations, such as trocar (skin piercing device), bone drill and saw. When CNC is used toprecision machined parts for medial devices, the parts are usually milled with 3–5 axes or turned with a movable tool CNC lathe. The most common types of machines used in the manufacturing ofprecision machined parts for medial devices,include CNC milling machine, lathe processing, drilling machine processing and computerized milling machine.

Reliability and high quality are the top priorities of medical parts processing. Therefore, the medical device industry has put forward new requirements for precision machining parts of professional medical devices. Difficult to machine materials, complex workpiece shapes and frequent CNC small batch production have put forward high requirements for cutters used to process professional medical devices. It is mainly shown in:

The requirements for CNC machine tools are relatively high

Advanced medical equipment processing equipment such as Swiss automatic lathes, multi spindle machine tools and rotary workbenches are completely different from commonly seen machining centers and lathes. They are very small in size and compact in structure; To meet this requirement, the structure of the tool also needs special design. The size of the tool should be very small, and the rigidity of the tool should also be guaranteed.

High requirements for cnc machining efficiency

For medical devices, the most important thing is the processing efficiency, that is, the processing rhythm. It is required to replace the blade in the shortest time.

From The Workpiece Itself

It is very different from other mechanical parts.Medical devices implanted into the human body are required to have a very good surface finish, high accuracy and no deviation. This requires that the design of the knife blade structure and the design of the blade coating meet high processing requirements.

Picture of medical equipment

Tolerances within the micrometer range are common in the medical industry, and selecting the right tool requires keen insight and rich experience. On the one hand, even drilling small holes requires the use of lubricants to reduce friction, reliably dissipate heat and handle fine iron chips at the blade; On the other hand, when producing cutting-edge medical devices (without burrs), it is necessary to use sharp and stable cutting tools to make theprecision machined parts for medial devicesmore stable.

0 notes