#custom made metal cnc machining parts factory

Explore tagged Tumblr posts

Text

Good Precision in Metalworking of CNC Intelligent Metal Cutting Band Saw Machine

In the realm of metalworking, precision is not just a desirable trait; it is a necessity. The CNC Intelligent Metal Cutting Band Saw Machine stands as a testament to this fact, offering unparalleled accuracy and consistency in the cutting of various metal materials. This machine is a modern engineer, designed to meet the stringent demands of industries that require high-precision metal components.

The CNC Intelligent Metal Cutting Band Saw Machine's precision is a result of its advanced computer numerical control (CNC) system, which allows for the automation of complex cutting processes. This system ensures that each cut is made with exacting detail, reducing the margin of error. The machine's ability to maintain such high levels of precision is a direct result of its sophisticated software and hardware components working in harmony.

One of the key features of the CNC Intelligent Metal Cutting Band Saw Machine is its ability to handle a wide range of materials, from aluminum to steel, with equal ease. The machine's cutting precision is not compromised by the hardness or thickness of the material, thanks to its powerful motor and high-quality blades. The blades, which are often made from carbide or other durable materials, are designed to maintain their sharpness over time, further contributing to the machine's precision.

The CNC Intelligent Metal Cutting Band Saw Machine also boasts a high degree of adjustability, allowing operators to fine-tune the cutting parameters to suit their specific needs. This includes the ability to adjust the speed of the blade, the feed rate, and the angle of the cut. This level of customization ensures that the machine can achieve the desired precision for each unique application.

In addition to its cutting capabilities, the CNC Intelligent Metal Cutting Band Saw Machine also excels in terms of repeatability. This is crucial for industries that require the production of identical parts in large quantities. The machine's CNC system stores the cutting parameters for each job, allowing it to reproduce the same cuts time and time again with absolute precision.

The machine's precision is also supported by its robust construction. The CNC Intelligent Metal Cutting Band Saw Machine is built with heavy-duty materials to ensure stability during operation. This reduces the risk of vibrations or other movements that could affect the accuracy of the cuts. The machine's frame is designed to absorb shocks and maintain rigidity, ensuring that the blade remains true to its path.

Maintenance is another aspect that contributes to the long-term precision of the CNC Intelligent Metal Cutting Band Saw Machine. Regular servicing and blade changes are essential to keep the machine running at good performance. The machine's design allows for easy access to its components, making maintenance a straightforward process.

In conclusion, the CNC Intelligent Metal Cutting Band Saw Machine is a powerhouse of precision in the world of metal cutting. Its advanced CNC system, high-quality components, and user-friendly design all work together to deliver cuts that are accurate, consistent, and repeatable. This machine is a valuable asset to any workshop or factory that demands high standards of precision in their metalworking operations. The CNC Intelligent Metal Cutting Band Saw Machine is not just a machine; it is a symbol of the precision that modern manufacturing has come to expect and rely upon.

0 notes

Text

Leading Bushes Manufacturer – Reliable Solutions for Your Industrial Needs

As a trusted bushes manufacturer, Dynamic Industries is committed to providing high-quality, durable bushes for a wide range of industrial applications. Our bushes are crucial components used in machinery to reduce friction and enhance performance, ensuring smoother and more efficient operations.

At Dynamic Industries, we specialize in the production of a variety of bushings, such as plain bushes, flanged bushes, and custom bushes for specific needs. Our extensive expertise and state-of-the-art technology allow us to offer both standard and customized solutions to meet the unique demands of different industries, including automotive, construction, and heavy machinery.

Quality Manufacturing with Precision Engineering

As a leading bushes manufacturer, we focus on precision engineering to ensure that every bush we produce adheres to the highest quality standards. Our CNC machining process allows us to manufacture bushes with impeccable accuracy, ensuring a perfect fit and reliable performance. Whether you need metal, plastic, or composite bushes, we have the capabilities to provide the ideal solution for your needs.

Our bushes are made from a range of materials, including stainless steel, bronze, and carbon steel, chosen for their strength, corrosion resistance, and durability. This allows us to cater to various applications, from automotive parts to industrial machinery and construction equipment.

Customized Bushes for Diverse Applications

At Dynamic Industries, we understand that each application may require a specific design and material. That’s why we specialize in custom bushes to fit the unique requirements of your machinery. Our team works closely with clients to create tailored solutions, whether it's designing custom flanged bushes, wear-resistant bushes, or high-temperature resistant bushes.

Our commitment to quality ensures that each bush manufactured by Dynamic Industries undergoes rigorous quality checks. This guarantees that our products perform optimally in even the most demanding environments.

Why Choose Dynamic Industries as Your Bushes Manufacturer?

- Precision and Expertise: As a trusted bushes manufacturer, we leverage our years of experience to deliver high-quality products that meet the highest industry standards.

- Durability and Reliability: Our bushes are designed to withstand harsh conditions, offering long-lasting performance and reducing the need for frequent replacements.

- Custom Solutions: We provide tailored bush solutions, ensuring that each component fits perfectly and performs optimally in your machinery.

- Wide Range of Materials: From plastic bushes to metal bushes, we offer a broad selection of materials to suit various industrial applications.

Dynamic Industries is proud to serve a variety of industries, including:

- Automotive: Providing high-performance bushes for vehicles and automotive systems.

- Heavy Machinery: Supplying bushes for construction and mining equipment.

- Industrial Equipment: Offering durable solutions for factory machinery and production lines.

- Aerospace: Providing precise bushings for critical aerospace applications.

Get in Touch with the Leading Bushes Manufacturer

As a top-tier bushes manufacturer, Dynamic Industries is here to fulfill all your bush manufacturing needs. Our commitment to quality, precision, and customer satisfaction sets us apart as a leader in the industry. Whether you require standard bushings or need custom solutions, we are ready to support your business. Contact us today to discuss how we can help optimize your equipment’s performance.

0 notes

Text

CNC Machining Near Me: A Comprehensive Guide to Finding the Right Service Provider

CNC (Computer Numerical Control) machining is essential to producing accurate, high-quality parts in modern manufacturing. Locating the best CNC machining service in your area can significantly impact quality, speed, and cost-effectiveness, whether you're a company seeking dependable production solutions or an individual in need of unique components.

This post will explain what CNC machining is, the advantages of working with a nearby CNC shop, how to locate a service provider in your area, and what to look for when choosing a CNC machining provider. We'll also discuss the many kinds of CNC machining services offered and offer advice on using them to fulfil your production requirements.

What is CNC Machining?

CNC machining is a production technique in which factory equipment and tools are moved using pre programmed software. Cutting, drilling, milling, and turning operations may all be automated using this method, enabling the production of highly intricate and exact pieces out of materials like composites, metal, plastic, and wood.

The automated control system (also known as the "CNC") in these machines is designed to create parts consistently and accurately by following preprogrammed instructions. Numerous industries use this technology extensively, including aerospace, automotive, electronics, medical devices, and consumer goods.

Why Pick CNC Machining Services Offered Locally?

Selecting a nearby CNC machining service offers the following advantages:

Faster Turnaround Times: You can expect faster delivery times When working with a local CNC shop. Long shipping delays won't be an issue, which is crucial if you need components made urgently.

Improved Communication: Quick phone calls or in-person encounters with a nearby provider can improve communication. Working with a neighbouring organization makes it easier to discuss project needs, ask questions, and provide feedback.

Reduced Shipping Costs: Working with a nearby CNC service can save you much money on shipping. This is especially useful if you're ordering bulky, heavy components.

Encouragement of the Local Economy: You encourage local companies by selecting a nearby CNC machine shop. This strengthens ties within the community and boosts the local economy.

Customization and Flexibility: Compared to larger, more distant manufacturers, local CNC shops are frequently more willing to offer customized services and can more easily adapt to your individual needs.

How to Locate Local CNC Machining Services

Getting the best CNC machining service in your area may take some investigation. Here are a few strategies to assist you in finding a trustworthy supplier:

Internet search: Doing a quick Google search for "CNC machining near me" will yield many nearby results. This is an excellent place to start looking for local providers. Visit their websites to learn about the industries and services they provide.

Online directories: Location-based directories of CNC machining companies are available on websites such as ThomasNet, MFG.com, and Maker's Row. Thanks to these directories, it is simple to compare various suppliers and their capabilities.

Industry Associations: The National Tooling and Machining Association (NTMA) is one of the professional associations to which many CNC machining firms belong. Visiting these groups' websites might facilitate finding accredited local CNC shops.

Networking: When looking for a dependable CNC machining service, industry contacts or word-of-mouth recommendations might be helpful. Consult suppliers, engineers, or other business owners for recommendations.

Trade Exhibits and Regional Manufacturing Events: Participating in trade exhibits or regional industry gatherings can facilitate reaching out to regional CNC machining suppliers. You can speak with them directly and observe their work in person.

Things to Take Into Account Before Selecting a CNC Machining Service Provider

After compiling a list of possible CNC machining suppliers, you should consider the following aspects before choosing one:

Capabilities: CNC machining shops offer a variety of services. While some offer a wide variety of capabilities, others are specialists in particular industries or materials. Verify if the shop can meet your unique needs, such as precise machining, intricate geometries, or a particular kind of material.

Technology and Equipment: The equipment utilized significantly impacts the quality of the items produced. Depending on your requirements, look for suppliers who employ 3-, 4-, or 5-axis sophisticated CNC equipment. Higher accuracy and efficiency are guaranteed by sophisticated equipment.

Experience and Expertise: A CNC shop's ability to manage challenging tasks will increase with its level of expertise. To determine the company's experience level, review their portfolio, prior projects, and customer endorsements.

Lead Times and Capacity: Find out if the supplier can fulfil your deadlines and their usual lead times. Due to increased demand, certain stores can have lengthier lead times than others, while others might be more accommodating.

Quality Control:Check that the CNC machining service has adequate quality control procedures in place. Numerous suppliers give certificates such as ISO 9001, guarantee compliance with global quality standards. Inquire about their testing protocols, tolerance limits, and inspection methods.

Customer service: A competent supplier of CNC machining needs to be reachable and quick to respond. By communicating clearly and promptly, you can be confident that your project will go smoothly from beginning to end.

Cost: To compare prices, seek quotations from several providers, even if cost shouldn't be the sole consideration. Remember that the best quality is different from what the cheapest option offers.

Types of Services Offered for CNC Machining

You will encounter various machining procedures when looking for CNC machining services. The following are some of the most popular CNC machining services:

CNC milling: In this process, material is removed from a workpiece using rotary cutters. CNC milling is perfect for creating intricate forms, slots, holes, and threads.

CNC turning: In this method, the material is removed by a fixed cutting tool while a revolving workpiece rotates. Bolts and shafts are examples of cylindrical items that CNC frequently turns.

CNC Grinding: Grinding machines use abrasive wheels to remove material from a part's surface. CNC grinding offers high precision and a smooth surface finish.

CNC Drilling: With CNC drilling, holes may be precisely controlled in diameter and depth within a workpiece. This procedure is crucial in sectors like aerospace and automobile manufacturing.

CNC Plasma Cutting: Steel and aluminium can be sliced using a high-speed plasma jet for plasma cutting. This method works well for cutting thick or bulky materials.

CNC Waterjet Cutting: This method is perfect for delicate or heat-sensitive materials since it employs a high-pressure jet of water, often combined with abrasives, to cut the material without producing heat.

Advantages of CNC Turning

When compared to conventional manufacturing techniques, CNC machining has the following benefits:

Accuracy and Precision: CNC machines have high accuracy and can produce products with incredibly tight tolerances. This degree of precision is essential for sectors such as aerospace and medical devices.

Consistency: Even in massive production runs, consistent quality is ensured by CNC machines' ability to create identical components repeatedly without variation.

Efficiency: CNC machining is a very efficient operation because it is automated and requires little human intervention. This results in lower labour costs and quicker manufacturing times.

Flexibility: Metals, polymers, and composites are just a few of the materials that CNC machines can work with. They can make a wide range of goods, from straightforward components to more complex designs, demonstrating their versatility.

Decreased Waste: CNC systems maximize the use of materials, cutting waste and production expenses.

FAQs

What is CNC machining?

CNC machining uses computer-controlled tools, a manufacturing method that produces accurate pieces of various materials, including wood, plastic, and metal. Drilling, turning, and milling are typical CNC operations.

What advantages come with using a nearby CNC machining service?

Local CNC services provide:

Improved communication.

Quicker response times.

Reduced shipping costs.

The ability to customize solutions to match the demands of individual clients.

They also aid in sustaining the regional economy.

How can I pick the best company to provide CNC machining services?

When selecting the best supplier, consider things like their skills, tools, experience, lead times, quality assurance, and customer support. Obtaining estimates from various stores will enable you to evaluate features and costs.

Which materials are compatible with CNC machines?

CNC machines can work with various materials, such as foam, plastics, composites, wood, and metals (steel, aluminium, and titanium). The material selection is based on the particular needs of your project.

Summary

Choosing the best "CNC machining near me" company is crucial to guarantee that your components are manufactured precisely, quickly, and according to your schedule. You can choose a trustworthy CNC shop that fulfils your requirements by concentrating on skills, expertise, equipment, and customer service. Whether you need custom machining, milling, or turning local CNC suppliers have the knowledge and adaptability to make your projects a reality.

0 notes

Text

An Inside Look at China's Leading Hydraulic CNC Press Brake Factories

China's hydraulic CNC press brake business has actually experienced considerable growth in the last few years, driven through the increasing requirement for high-precision metal construction solutions. At the center of this development are leading manufacturers such as Accurl, JFY, and DMT, whose modern facilities display the nation's capabilities in generating first-rate equipment. However what sets these factories aside from their rivals, and what produces their products a staple in sectors worldwide? A closer examination of their production methods, quality control measures, and sector applications shows a complex interaction of technology, knowledge, and innovation that necessitates more expedition.

Leading Hydraulic Press Brake Producers

Among the several hydraulic press brake makers, many key players attract attention for their cutting-edge innovation, precision engineering, and worldwide market presence. These leading hydraulic press brake suppliers have actually created on their own as leaders in the sector, giving top quality products and innovative solutions to satisfy the diverse necessities of customers worldwide. Companies including Accurl, JFY, and DMT project gamers in the worldwide hydraulic press brake market. Accurl is a well-known maker of SHENCHONG CNC press brake, offering a large range of items that satisfy different business, consisting of automobile, aerospace, and development. JFY is actually yet another leading supplier, understood for its own high-precision press brakes that are actually developed to satisfy the stringent needs of the metal manufacture field.

Top Functions and Technical Advantages

The Computer Numerical Control hydraulic press brake's sophisticated design is actually characterized by its own strong steel framework, precision-guided higher ray of light, and high-precision straight resource system, which together give the stability and reliability demanded for sophisticated metal assembly jobs. These components enable the hydraulic Computer Numerical Control press brake machine to provide accurate angle control, minimal deflection, and constant bending outcomes. The hydraulic system of the press brake is made for high performance and integrity, with an adjustable velocity control system that enables smooth and precise activity of the uppermost light beam. The machine's control system is furnished along with advanced program that makes it possible for real-time surveillance and correction of the bending over procedure, ensuring peak outcomes and decreasing inaccuracies.

Manufacturing Facility Tour and Manufacturing Process

youtube

Inside a SHENCHONG CNC press brake factory, the production procedure generally starts with the voucher of raw products, consisting of high-strength steel for the structure and accuracy elements for the machine's several systems. These components undertake rigorous examination to confirm conformity along with industry standards and the factory's quality needs. The creation process includes several phases, featuring machining, assembly, and setting up. The framework and various other structural components are machined to accurate endurances utilizing CNC machining facilities. The machined parts are at that point bonded together making use of sophisticated robotic welding systems to guarantee uniformity and accuracy.

Quality Assurance And Security Measures

Throughout the whole entire production method, stringent quality control and protection solutions are implemented to assure the integrity and functionality of hydraulic CNC press brakes. In China's leading hydraulic Computer Numerical Control press brake factories, an extensive evaluation procedure is actually performed at every stage of production to determine and repair possible problems. The examination process involves visual assessment, dimensional verification, and operational screening to license that the press brakes fulfill global requirements. The manufacturing plants comply with industry-specific safety specifications and regulations to secure a safe functioning setting for staff members. The manufacturing place is furnished along with security attributes like noise decline systems, fire reductions systems, and emergency cessation procedures.

Field Uses and Customer Base

China's hydraulic CNC press brake machine factories deal with a varied customer bottom across different industries, consisting of aerospace, automobile, development, and electronic devices. These manufacturing facilities source Computer Numerical Control press brakes, including SC Shenchong, that are developed to deliver higher preciseness and precision, creating all of them appropriate for applications demanding complicated metal processing making up. In the aerospace industry, hydraulic Computer Numerical Control press brakes are actually utilized to produce plane parts, like segment panels and fuselage components. In the automotive sector, they are utilized to produce body boards and framework components. The building and construction sector uses hydraulic Computer Numerical Control press brakes to create property parts, consisting of metal roofing and covering. The electronic devices sector likewise relies upon these machines to create precision elements, such as metal rooms and cases.

Final Thought

Reliable development of high-precision hydraulic Computer Numerical Control press brakes is guaranteed via stringent quality assurance steps and faithfulness to specialized specs. China's prominent producers, such as Accurl, JFY, and DMT, sustain advanced locations, experienced staffs, and strenuous testing procedures. This leads to reputable press brakes ideal for varied fields. Regular quality and efficiency are actually vital in meeting customer needs, steering development, and keeping competitiveness in the worldwide market. Advanced producing methods permit these manufacturing plants to accommodate progressing field requirements.

Wuxi Shenchong Forging Machine Co., Ltd.

Tianshun Road, Yangshan Industrial Park,

Wuxi, Jiangsu, China 214156

+86-158-9507-5134

0 notes

Text

youtube

Factory custom made cnc laser cutting machining service

We are specialize in cnc laser cutting precision metal machining parts, cnc machining acrylic laser cutting service, stainless steel cnc machining casting parts, cnc turning parts, die casting parts, plastic injection molding parts, 3D printing parts etc.

We also can provide the customized service as per customer's product requirement, demand aluminium cnc machining customization parts, micro machining turned milled brass cnc, machining service plastic cnc peek milling parts etc.

Looking forward to your feedback~

https://mxymachining.com

0 notes

Text

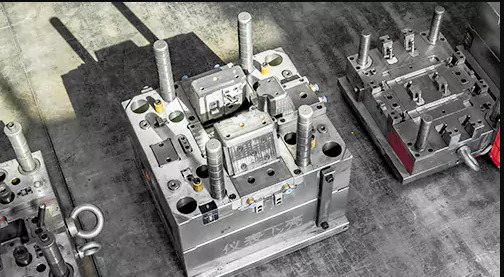

From Gallons to Greatness: The Innovation Behind Package Bucket Moulds

When it comes to packaging large quantities of liquids, such as paints, adhesives, or industrial chemicals, the humble bucket becomes an essential solution. These buckets, often made from plastic or metal, are designed to hold several gallons of liquid while keeping it safe and secure. However, have you ever wondered how these buckets are made and the innovation behind their design? In this article, we will explore the fascinating world of package bucket moulds and the technology that drives their production.

Package bucket moulds are custom-made tools used in the manufacturing process of plastic or metal buckets. These moulds play a crucial role in creating buckets of various sizes and shapes, accommodating different industries' needs. Whether it's a small 1-gallon bucket or a larger 5-gallon one, the moulds are engineered to ensure precise and consistent results.

The process of creating package bucket moulds involves several steps. First, the design and specifications of the bucket are determined, taking into account factors such as capacity, shape, handle design, and any special features required. Once the design is finalized, the mould-making process begins.

Mould making typically involves computer-aided design (CAD) software, which allows engineers to create a digital representation of the bucket mould. This digital model serves as a blueprint for the machining process, where the mould is carved out of a solid block of material, such as steel or aluminum. The level of precision required in the machining process is critical to ensure that the final product meets the desired specifications.

One of the innovative aspects of package bucket moulds is the use of interchangeable inserts. These inserts allow manufacturers to create multiple bucket sizes using the same mould base. By simply swapping out the inserts, manufacturers can accommodate different volume requirements without the need for an entirely new mould. This interchangeability not only saves time and resources but also provides flexibility and cost-effectiveness in the production process.

To ensure optimal functionality and durability, package bucket moulds may undergo additional treatments. For instance, the mould surface can be heat-treated, coated, or polished to enhance its resistance to wear and tear. These treatments help prolong the mould's lifespan, ensuring that it can withstand the demands of high-volume production over an extended period.

The advancement in technology has also contributed to the innovation behind package bucket moulds. Through the use of computer numerical control (CNC) machines, the machining process has become more precise and efficient. CNC machines are capable of executing complex designs with minimal errors, resulting in higher-quality bucket moulds. Additionally, the use of 3D printing technology has gained traction in the mould-making industry. 3D printing allows for rapid prototyping and offers greater design flexibility, enabling manufacturers to explore new possibilities in bucket mould design.

Package bucket moulds are not limited to traditional plastic or metal buckets but can also be used for specialized applications. For example, food-grade buckets made from high-density polyethene (HDPE) are commonly used in the food industry to store ingredients or transport food products. These buckets need to meet specific hygiene and safety standards, and the moulds used to create them must adhere to those requirements.

In conclusion, Gallons package bucket moulds are an integral part of the manufacturing process for larger liquid containers. Their design and engineering ensure the creation of buckets that are durable, efficient, and fit for purpose. The use of interchangeable inserts, precision machining, and technological advancements contribute to the innovation behind these moulds. As industries continue to evolve, we can expect further advancements in package bucket moulds to meet the ever-changing needs and demands of packaging solutions.

#Gallons packge bucket mould Exporter#Gallons packge bucket mould Price#Gallons packge bucket mould Maker

0 notes

Text

The price of a three -in -one number control busbar bending machine

The topic I want to share with you today is that the price of a three -in -one controlling machining machine manufacturer wants to pass the explanation below. You can have more understanding of this aspect!

A good after-sales service. As a customer, when buying an automatic winding tie machine, it is not just the price of the product and the quality of the product. After -sales service is also an important factor that must be considered. If the product has various quality problems during use, it is easy to cause inconvenience to people's lives. Therefore, when people choose automatic winding tie machines, they must also make careful considerations on the after -sales service of their products. Finally, when buying an automatic winding tie machine, you must carefully consider, observe carefully, ensure quality problems, and make a wise choice.

The use of and self -inspection of the twisted wire is used in the most common wires and cables. The twisted devices used in this category include two types: high -speed twisted wire and single twisting machine. These two are also the most common twisted devices. Sanhe, one -number control mother arrangement processing machine manufacturer price

CNC busbar bending machine should remove foreign bodies and metal debris on the machine tools and molds every day. Check whether the installation of the mold is firm, whether the electrical switch, the cable, and the fastening parts are normal, and whether it is loose. Before the machine tool maintenance or wiper, the upper model should be placed on the mode and put it down until the work is completed. If you need to boot or other operations, you should select the mode in manual and ensure safety. The parent line machine industry's factory store summarizes the following aspects of maintenance content as follows:

The price of a three -in -one control parent row machining machine manufacturer The three -axis control and the fixture are automatically compared to the middle technology, so that the pressure head can better press on the reasonable stress point, automatically find the start processing zero point, and increase the use of the head. Pressurers make the workpiece more stable, and the processing surface effect is better.

Nowadays, the manufacturers of piercing machinery in my country are trying to continue to innovate, so its development prospects are very broad. Faced with the popularity of customers in the market, this is also moving towards maturity and improvement. Our company has also developed and produced automated tie machines, making it the most development potential in the tie market. Equipment.

In short, the step -step -step -step -step -steps are based on the fault, and the real causes and faults of the faulty are judged as soon as possible. These fault disposal methods do not have strict boundaries in actual use. Sometimes only one method can eliminate the failure to eliminate the fault. It may also be carried out at the same time. Its effect depends on the experience of maintenance technicians and its depth of understanding and grasp of system principles and layout. This is not only the quality that the maintenance personnel must have, but at the same time, the maintenance personnel have made high requirements. It requires the CNC parent maintenance personnel to be familiar with the layout and design ideas of the parent machine. Quickly find the cause of the fault and judge the fault position. In addition, in order to perform on -site surveying and mapping for certain circuits and parts, as a senior maintenance personnel, they should also have a certain ability to draw engineering drawings. Sanhe, one -number control mother arrangement processing machine manufacturer price

The operator should operate in accordance with the bus processing machine operation manual, and must not operate the damage and damage of the composition of the personnel, equipment. The mold and accessories of the bus processor must be intact. Familiar with the structure, performance and operation method of the machine. Or dismantle the mold, it must be stopped by the person who familiarize the machine according to the rules of the rules. When the machine starts, do not put the hand or part of the body between the upper and lower molds to avoid accidents. In the end The degree, the blade of the blade becomes blunt, should be grinded or changed in time. Persist in oil cleaning and the oil circuit is unobstructed. Each class adds lubricating oil to each unit motion component. When normal phenomenon, you must stop and check immediately. Turn off the work button of each unit when not working, and turn off the power switch on the operation disk

0 notes

Text

As a professional metal stamping factory in China, Dongguan Orienson Hardware Electrical Co., Ltd. has complete supporting resources, which can provide customers with one-stop hardware products as well as the full set of processing services, we can independently develop and manufacture molds, and provide precision CNC machining services, plastic injection molding service, metal plating services, heat treatment, passivation, grinding, radium carvings and other surface treatment processing technology, besides, assembly services such as metal laser welding, resistance welding, automatic tapping, and automatic riveting is included, Orienson is equipped with a complete inspection and testing instruments to ensure quality from raw material production to delivery, thus reduce the loss and cost of the customer and also offer high-quality and cost-effective prototype metal stamping.

Types of Custom Service Stampings

Assembling ServiceAssembling Service

CNC MachiningCNC Machining

Plastic Injection MoldingPlastic Injection Molding

ElectroplatingElectroplating

Other Surface TreatmentOther Surface Treatment

Automatic TappingAutomatic Tapping

Automatic RivetingAutomatic Riveting

Advantages Of Metal Stamping Supporting ServicesAdvantages Of Metal Stamping Supporting Services

Assembly

Assembly refers to the process of assembing parts according to specifed technical requirements and making them qualifed products.

Products

As an excellent sheet metal stamping manufacturer, we provide highly consistent assembly services at every stage of your production process, from prototyping, proof of concept to mass production.

Professional Team

In addition, our professional automation engineering design team can provide comprehensive assembly.

How Do You Choose Metal Stamping Supporting Services

01

Rich Experience

Service from RED stage to mass production, Our technical team can design, manufacture and maintain.

02

Professional Technology

As an excellent sheet metal stamping manufacturer, we also have the support equipment for tapping machines, riveting machines, automatic assembly lines.

03

Automatic Assembly Line

Our production capability is more than 50 million pieces per month, mold developing and manufacturing capability.

04

R&D Capability

The in-house tool room has LS-WEDM, HS-WEDM, spark machines, grinding machines, milling machines, etc., which can meet all the demands.

05

Highest Cost Effectiveness

Including heat treating, plating, injection molding, CNC machining, etc., we work closely with our customers to ensure the most cost-effective material.

Why Choose Orienson Metal Stamping Supporting Services

Rapid open mold speed, high quality, mature bending process made Orienson widely welcomed by customers. Metal bending parts we produced has been widely used in automobiles, sensor electrical and electronic switches.

Mold speed, high quality, mature bending process

Automobiles, sensors, electrical and electronic switches

Under the guarantee of dimensional accuracy

Committed to providing smooth surface edge rolling parts

Custom Metal Stamping Supporting Services

Impact On Production To Meet Customers' need

Professional One-stop Whole Process CNC Service

Mold Opening, Material Selection

0 notes

Text

Cnc Turning Service

Aerospace CNC Machining - Prototool.com

Aluminium Turning We provide state-of-the-art CNC machining & Injection molding service. Our respective clients provide us with the product design idea along with the preferred material. The rest of the work is done by our experts. We buy quality material, refine the client’s designs, machining the product, and then deliver the finished product to the customer. We are also the market-leading CNC and injection molding material suppliers as well. We are an affiliate of First Part China Limited. Aluminum Cnc Machining

Machining Process of Injection Mold Parts Such as Core, Insert, Lifter and Slide

Aluminum Mold Making Part craftsmen typically provide mold design job books based on molded part task books. To assure the logic and consistency of the mold manufacturing process, optimize the processing process, and improve mold manufacturing progress, each mold factory normally develops a process standard fit for its factory, including using unique injection mold parts. Prototool.com

This article will discuss common injection mold parts, their applications, and things to consider when employing them throughout a factory’s machining process. Cnc Machining Services

The Most Suitable Metal Materials for your CNC Machined Parts

Material selection is essential to any manufacturing process, but engineers and CNC machining service providers must be extremely careful regarding CNC machined parts.

Because this procedure is suitable for a wide range of materials — from metal to fiberglass to wood — it’s easy to select an adequate material but not optimal for the job. However, you may want to select the best metal material for your CNC machining project. Cnc Milling Service

This blog will review several critical considerations to help you choose the best metal material for CNC machined parts.

Designing Top-Quality Plastic Molded Parts: 7 Proven Tips

Cnc Plastic Machining Thousands of designers create injection molded parts. However, a select group in this big community can create parts for injection molders. Before all parts are completely recorded and handed to molders for manufacturing, injection molded product design goes through many development stages. The last stage of development is essential since design adjustments or corrections can no longer be performed without dramatically raising expenses or project delays. So, how can you

ensure that your plastic molded parts are perfectly designed? Here’s a detailed guide on effectively designing the parts.

Material Selection and Its Implications:

Cnc Rapid Prototyping Materials are typically specified early in the design process, and both parties must agree. Molders can sometimes get large amounts of specialized resins at steep savings. Customers can benefit from these offers. For example, a designer can save tens of thousands of dollars if they select an ABS grade that matches the ABS grade that molders buy in bulk. Prototool.com

Due to viscosity, high glass content, or crystallinity, designers may discover that certain high-performance resins are not suited for molders. Resins can be chosen for certain physical or chemical resistance qualities. However, they can be difficult to mold and keep to specified tolerances. Molders must adhere to the prescribed resin and integral part specifications to mold the part. Cnc Turning Service

The Most Common Types of Machining Services and Processes

Consumer Electronics Manufacturers Machining services are crucial in manufacturing, as they shape and transform raw materials into finished products. Various machining services are available, each with its unique set of benefits and applications. From milling to drilling and turning, machining methods have revolutionized how products are made. This article will explore the seven most common types of machining methods, their advantages, and the industries that use them.

Understanding these services will help businesses determine the best machining processes for their manufacturing needs.

This article will discuss the seven different machining services and how they are conducted in the plastic injection molding/manufacturing industry. High Volume Manufacturing

Prior Materials Preparation and Pre-Molding Considerations for Effective Plastics Injection Molding

High-volume Production In plastics injection molding, the work done to prepare the mold before adding material to it and molding plastic to make a product is of critical importance. It includes evaluating and setting up for a wide variety of processes, such as material processing performance inspection (determination of plastic fluidity, moisture content, etc.); dyeing and granulating of raw materials before processing; preheating and drying of granules; cleaning and preheating of inserts; mold testing and cylinder cleaning, etc.; and so on. Prototool.com

Having a sound comprehension of all the procedures involved and commencing with the appropriate strategy to evaluate and prepare the material is crucial for ensuring the effectiveness of the plastic injection molding process. Now, in the event that you are uninformed of what occurs before the use of high-tech machinery, the phase of mold

inserting, and the phase of production form, let’s go ahead and investigate many aspects of preparing the production setup before formally beginning the production process.

Injection mold China

4-Axis CNC – The Various Features and Important Details about It

4-axis CNC machines are advanced versions of 3-axis CNC centers that have revolutionized the field of workpiece shaping. With the installation of the fourth axis, these machines have significantly enhanced the quality of machining. Injection Molding Manufacturers

A 4-axis CNC machine has four axes, which allows it to perform intricate operations such as milling, turning, drilling, and more. This multi-tasking capability allows the machines to perform multiple jobs simultaneously. In this comprehensive guide, we will explore the features and capabilities of 4-axis CNC machines to provide you with a complete understanding of their capabilities. Injection Molding Services

More Information - https://prototool.com/

0 notes

Text

The Future of Manufacturing: Custom CNC Parts and Their Endless Possibilities

The manufacturing industry has come a long way in the last few decades, and the advent of computer numerical control (CNC) machining has revolutionized the way custom parts are made. CNC machining parts manufacturer have emerged, producing precise and intricate custom CNC parts that were previously impossible to create with traditional manufacturing methods. In this article, we'll explore the future of manufacturing with custom CNC parts and their endless possibilities.

Precision and Speed

One of the most significant advantages of CNC machining is its precision and speed. The machines use computer programming to control the cutting and shaping of materials, allowing for consistent and exact parts every time. CNC machining can also produce parts at a much faster rate than traditional methods, resulting in quicker turnaround times and increased efficiency.

Design Flexibility

CNC machining also offers design flexibility that was not possible before. The machines can create parts in various shapes and sizes, making it ideal for custom-made parts that require unique designs. This flexibility is especially valuable in the aerospace, medical, and automotive industries, where precision and intricate designs are crucial.

Material Versatility

CNC machining can work with various materials, including metals, plastics, and composites. This versatility allows for the creation of parts that can withstand extreme temperatures, pressure, and other harsh environments. As technology advances, the range of materials that CNC machines can work with will likely expand, further increasing the possibilities of custom CNC parts.

Cost-Effective

Custom CNC parts can also be cost-effective in the long run. Although the initial investment in CNC machining equipment may be high, the machines can produce parts at a lower cost per unit than traditional manufacturing methods. This cost-effectiveness is due to the automation and precision of CNC machines, resulting in reduced waste, increased efficiency, and lower labor costs.

Endless Possibilities

The future of manufacturing with custom CNC parts is undoubtedly bright, with endless possibilities for innovation and creativity. As technology continues to evolve, CNC machining parts factories and manufacturers will be able to produce parts with even greater precision, flexibility, and speed. These advancements will not only benefit the manufacturing industry but also a wide range of fields that rely on custom-made parts.

In conclusion, Custom CNC parts are the future of manufacturing, and the possibilities are endless. With precision, speed, design flexibility, material versatility, and cost-effectiveness, CNC machining will continue to revolutionize the way we create custom parts for years to come.

1 note

·

View note

Text

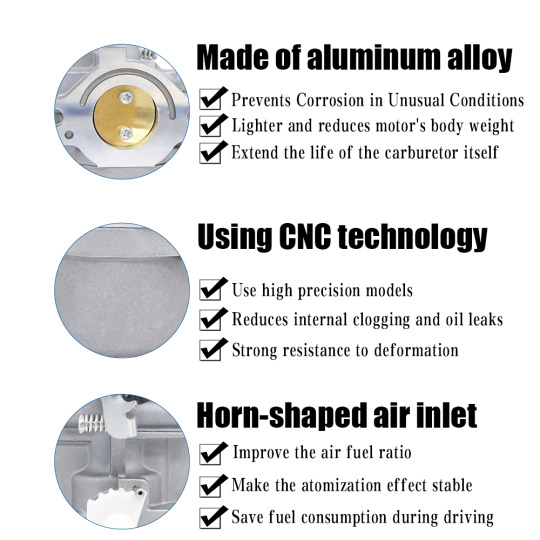

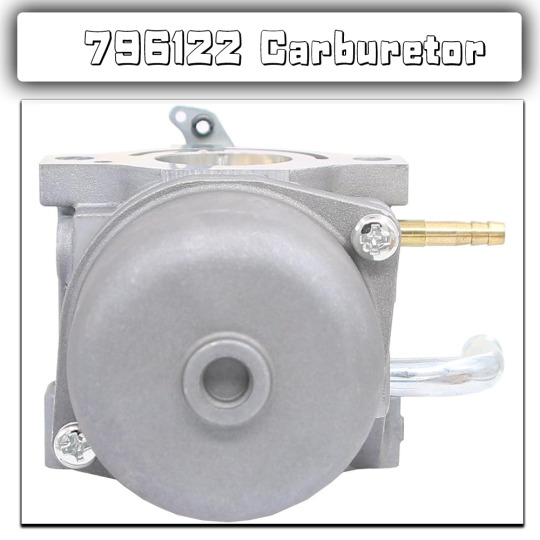

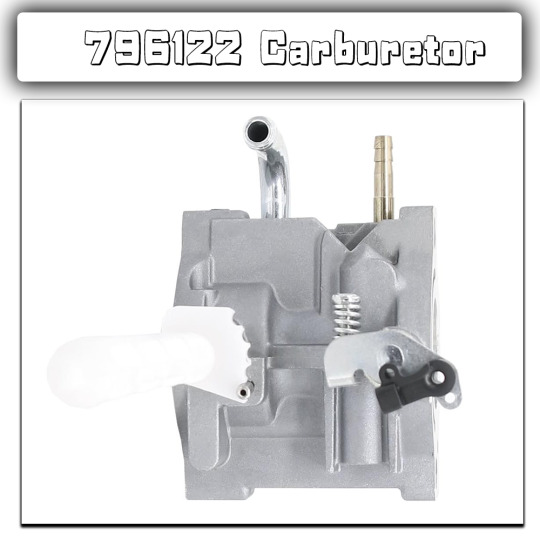

796122 794593 696737 793161 Carburetor Compatible for Briggs & Stratton Ariens MTD Cub Cadet Snowblower Snowthrower Tractor

Link:

bit.ly/3ZpO24k

ALL WELL STRUCTURED - Smooth surface, enhanced air intake holes to improve airflow structure, steady performance, and sensitive reaction. Wonderfully constructed.

LONG LASTING - Since that the carburetor is operating in gas fluid, it was made with the best finish possible to prevent rusting of the metal.

HIGH PERFORMANCE - The ideal mixing of air and fuel, with the right ratio, produces a lot of power and torque. Your engine will run like new with this perfect upgrade over the factory one!

EASY INSTALLATION - Before shipping, everything was thoroughly checked; no adjustments were required; direct fit. As shown in the package.

Replace Part Number: 796122 794593 793161 696737

Fitment: For Briggs & Stratton 796122 794593 793161 696737 Carb

Our company mainly specializes in carburetor products,

If you are interested, you can visit our homepage to see the relevant product information

The surface and bore of each carburetor we manufacture are finely processed by CNC machines.

The dimensions of each carburetor are very accurate

We offer OEM and ODM services to manufacture ATV, UTV and other types of carburetors according to your customized purchase requirements.

Carburetors are produced with an accuracy of about 1mm

We have a complete product quality control program to improve the quality of your products

Please give us a chance, we are very grateful for your support and love for our products

#carb#carburetor#motorcycle#harleydavidson#racing#driving#video#news#travel#motorvehicle#nowplaying#art#roads#history#love#hospitality#tourism#manufacturing#engineering#engine#B2B#wheel#memories#outdoor#life

1 note

·

View note

Text

Leading Bushes Manufacturer — Reliable Solutions for Your Industrial Needs

As a trusted bushes manufacturer, Dynamic Industries is committed to providing high-quality, durable bushes for a wide range of industrial applications. Our bushes are crucial components used in machinery to reduce friction and enhance performance, ensuring smoother and more efficient operations.

At Dynamic Industries, we specialize in the production of a variety of bushings, such as plain bushes, flanged bushes, and custom bushes for specific needs. Our extensive expertise and state-of-the-art technology allow us to offer both standard and customized solutions to meet the unique demands of different industries, including automotive, construction, and heavy machinery.

Quality Manufacturing with Precision Engineering

As a leading bushes manufacturer, we focus on precision engineering to ensure that every bush we produce adheres to the highest quality standards. Our CNC machining process allows us to manufacture bushes with impeccable accuracy, ensuring a perfect fit and reliable performance. Whether you need metal, plastic, or composite bushes, we have the capabilities to provide the ideal solution for your needs.

Our bushes are made from a range of materials, including stainless steel, bronze, and carbon steel, chosen for their strength, corrosion resistance, and durability. This allows us to cater to various applications, from automotive parts to industrial machinery and construction equipment.

Customized Bushes for Diverse Applications

At Dynamic Industries, we understand that each application may require a specific design and material. That’s why we specialize in custom bushes to fit the unique requirements of your machinery. Our team works closely with clients to create tailored solutions, whether it’s designing custom flanged bushes, wear-resistant bushes, or high-temperature resistant bushes.

Our commitment to quality ensures that each bush manufactured by Dynamic Industries undergoes rigorous quality checks. This guarantees that our products perform optimally in even the most demanding environments.

Why Choose Dynamic Industries as Your Bushes Manufacturer?

Precision and Expertise: As a trusted bushes manufacturer, we leverage our years of experience to deliver high-quality products that meet the highest industry standards.

Durability and Reliability: Our bushes are designed to withstand harsh conditions, offering long-lasting performance and reducing the need for frequent replacements.

Custom Solutions: We provide tailored bush solutions, ensuring that each component fits perfectly and performs optimally in your machinery.

Wide Range of Materials: From plastic bushes to metal bushes, we offer a broad selection of materials to suit various industrial applications.

Dynamic Industries is proud to serve a variety of industries, including:

Automotive: Providing high-performance bushes for vehicles and automotive systems.

Heavy Machinery: Supplying bushes for construction and mining equipment.

Industrial Equipment: Offering durable solutions for factory machinery and production lines.

Aerospace: Providing precise bushings for critical aerospace applications.

Get in Touch with the Leading Bushes Manufacturer

As a top-tier bushes manufacturer, Dynamic Industries is here to fulfill all your bush manufacturing needs. Our commitment to quality, precision, and customer satisfaction sets us apart as a leader in the industry. Whether you require standard bushings or need custom solutions, we are ready to support your business. Contact us today to discuss how we can help optimize your equipment’s performance.

0 notes

Text

Cutting Tool in Turning Process

New Post has been published on http://www.cncmachinings.com/cutting-tool-in-turning-process/

Cutting Tool in Turning Process

Metal lathe turning is part of Klarm Machining service as it offers cheap cnc turning and milling metal machining factory work.

Cutting-Tool Installation

When mounting cutting apparatuses for turning machines, ensure that they face the right heading as indicated by the shaft pivot. In certain machines the apparatus will be situated straight up and in others, upside down. Continuously be certain that a mounted device is on focus. Some instrument holder connectors have a change component to calibrate the device’s tallness, while others require the utilization of shim material for change.

Opening working instruments can regularly require the most consideration during establishment and arrangement since their arrangement is basic. The device should be corresponding to the shaft pivot so the instrument’s body doesn’t rub within surface of the opening during machining. Some device holder connectors have squaring agents for this.

The equilibrium can be confirmed by running a dial pointer the long way along the device in two planes. Coolant lines ought to be associated and their spouts focused on the cutting zone after each device is mounted. Extraordinary consideration ought to be paid to guarantee that coolant spouts won’t meddle with the workpiece and workholding gadgets as the tomahawks move.

Cutting-Tool Offsets for Turning

When setting a cutting apparatus for a turning place, the area of the instrument tip should be characterized in the X and the Z tomahawks. This area is estimated as a separation from the turret reference position to the apparatus tip. When instrument estimations have been resolved, those apparatus balance estimations are put away in the machine’s math balance page. This page likewise contains a zone for characterizing information for device nose sweep size and quadrant direction.

As the cutting devices wear, the area of their forefronts changes. Wear counterbalances might be utilized to redress and adapt to wear as the apparatus is utilized during creation. Be certain that the wear balance an incentive for the balance number being set is gotten back to a standard of zero preceding figuring and entering the calculation esteem.

Apparatus Geometry Offsets

To decide the underlying apparatus length, the workpiece should initially have a set up work balance so the part face is Z-zero. For this progression, the workpiece root turns into the reference highlight decide the situation of the device tip.

For the Z-pivot, the running handwheel is accustomed to bring the apparatus tip to the workpiece face and ignite the part utilizing a piece of shim material or an antenna gauge. This positions the device tip at a known area comparative with the workpiece inception. For instance, if the instrument is ignited the part face of Z-zero with a 0.010″- thick shim, the 0.010″ shim thickness is deducted from the current supreme Z-hub position to compute the apparatus’ length counterbalance. Numerous controls make this interaction simpler by permitting the shim thickness to be gone into the math counterbalance page and will at that point figure the instrument length consequently. Setting the tolerance closely so as to get china precision cnc machining oem parts

This article is from http://www.cncmachinings.com/

#cheap cnc turning and milling metal machining factory work#china custom machine design#china customtitanium parts#china metal machining suppliers#china precision cnc machining oem parts#china steel tapped machining service suppliers#china titanium cnc turned parts manufacturers#cnc components companies#cnc lathe parts china#cnc precision brass parts china#cnc precision parts suppliers china#cnc turning and milling metal combined machining manufacturer suppliers#custom made metal cnc machining parts factory#high precision stamped parts suppliers china#micro-grinding machine factory#other machined ptfe manufacturers china#Featured Articles

0 notes

Text

Grooving and Parting

Posted from 5 axis machining China blog

Grooving and Parting

The machine will regularly be utilized to perform cutting to machine scores or breaks on workpieces. These sections might be expected to acknowledge O-rings or holding rings, go about as an alleviation for stringing, or to give leeway on shoulders to mating parts. They might be straight or require an extraordinary slicing instrument profile to make a shape inside the depression, like structure cutting. carbon fibre cnc cutting parts ilustrates some score shapes that can be machined on the machine.

It is additionally very normal to play out a cutoff (or separating) procedure on the machine that utilizes a unique limited slicing device to remove the end workpiece to an ideal length. This activity is regularly canceled separating or essentially separating. Cutting and cutoff activities can be performed on work held in hurls or collets.

Here and there a similar device can be utilized for both standard cutting and cutoff activities. Particular cutting instruments are accessible in numerous shapes and sizes, including square (90 degrees), halfway span, full sweep, or custom structure. Cutoff devices are accessible with a cutting face that is calculated either to one side or option to limit the measure of whole material left on the part that is cut off. Both cutting and cutoff instruments are accessible in HSS or embedded carbide types. china wire cutting edm suppliers shows a few instances of cutting and cutoff apparatuses.

Both scoring and separating activities require extraordinary consideration due to the generous width of the cutting device and huge measure of contact between the apparatus and the workpiece. Cutting and cutoff tasks require amazingly unbending arrangements. Be certain the instrument tip is on focus and keep the apparatus as short as conceivable to limit vibration and prattle. Here are general strides for scoring and cutting off.

Set the instrument at 90 degrees to the machine’s methodologies with the goal that the sides of the device won’t rub the sidewalls of the score and make unreasonable warmth.

Position the device at the ideal area with the carriage.

Lock the carriage to the approaches to forestall undesirable carriage development.

Set axle velocities to around one-fourth to 33% of those utilized for turning. In the event that vibration happens during cutting, lower axle speed until it stops.

Start the shaft.

Feed the instrument with the cross slide to the ideal profundity or until the part is totally cut off. Stopping intermittently will break the chip so it falls from the work. Constantly apply a liberal measure of slicing liquid to the instrument. custom precision cnc machining shows a cutting activity. Inner sections can be machined with exhausting bars that hold devices like those utilized for outer cutting tasks. The apparatus is situated inside the opening at the ideal area and took care of straight into the workpiece as when performing outside scoring. Additional consideration must be taken while machining inward furrows, as when exhausting, on the grounds that the cutting device regularly can’t be seen. The device may likewise should be eliminated from the opening much of the time to clear chips so it doesn’t tie during the cutting activity.

When cutting both outer and inner notches, at times the furrow to be machined might be more extensive than the width of the accessible instrument. In cases this way, the depression can be cut in steps.

The huge measure of hardware contact during scoring and separating produces considerable warmth that can cause extension of the workpiece. To keep this development from squeezing the sharp edge of the cutting apparatus on the sidewalls of the cut, continually apply a liberal measure of cutting liquid when performing scoring and separating.

#carbon fibre cnc cutting parts#cheap cnc turning and milling metal machining factory work#china brass machined components#china cnc titanium milling parts and service suppliers#china wire cutting edm suppliers#cnc carbon fiber parts manufacturers#cnc machined components brands#cnc machining services copper parts suppliers#cnc machining titanium parts#cnc milling precision parts china#cnc precision brass parts china#cnc precision parts suppliers china#cnc turning parts aluminum suppliers#cnc turning titanium alloy parts factory#custom made metal cnc machining parts factory#custom precision cnc machining#metal stamping camera parts made in china#other machined ptfe manufacturers china#precision cnc machining parts company#precision grinding machine made in china#precision surface grinder china#precision surface grinding machine made in china#super hard cnc cutter factory#swiss machining service suppliers

0 notes

Text

Rapid Traverse

Fast navigate developments should be performed cautiously in a CNC going machine to forestall crashes. Uncommon consideration should be paid to the shifting lengths of the cutting apparatuses and that they are so near other machine parts and the workpiece. Another thought is the area of the device before and toward the fruition of the fast developments. For example, if the instrument is an ID…

View On WordPress

#4 axis cnc machining service factory#china alu cnc machining#china cnc machine for cutting foam#china cnc steel turned machining parts suppliers#china custom aluminum milling suppliers#china customized cnc milling parts suppliers#china customized cnc service#china luminum cnc milling machining suppliers#china precision machining parts suppliers#china precision mini metal lathe#china titanium grinding service manufacturers#china tooling cnc machining suppliers#cnc carbon fibre machining#cnc cutting service carbon fibre manufacturers#cnc lathe parts suppliers#cnc machined carbon fiber parts factory#cnc machining turning parts manufacturers#cnc milling aluminum part factory#cnc precision machining factory#cnc turning made in china#cnc turning parts suppliers#cnc turning precision titanium parts#cnc turning stainless steel parts china#custom cnc machined precision machining titanium parts factory#medical parts machining suppliers china#precision cnc machining service factory#precision grinding machine manufacturers china#precision stainless steel cnc turned parts manufacturers#prefessional cnc milling parts factory#quality instrument machining service

1 note

·

View note

Text

Behind the Scenes of System76: Industrial Design

Since moving into a factory space in 2018, System76 has delved deeper and deeper into manufacturing hardware in-house. Three years later, we’ve introduced five Thelio desktops, fine-tuned the hardware, developed our fully configurable Launch keyboard, and optimized our production processes. Helming the design process is Mechanical Engineer John Grano, who wears a number of different hats here. We sat down with John this week to discuss industrial design and the team behind our beautiful open source hardware.

How would you describe industrial design for people unfamiliar with the term?

To me, industrial design is basically the art of making something into a usable product. In industrial design, you have to balance looks and function, and that drives your form. It’s kind of like hardware UX in that it’s really important to have the right feel. If you can make the system connect better with people, they’ll like it more. Adding that softness we do with Thelio, like slightly rounded edges and darker wood, it makes it a little more approachable to have a semi-natural looking system and not something that’s blinking at you with red lights all the time.

System76 itself is a group of hardcore programmers and people that are really into Linux, but I think the idea of trying to democratize Linux is extremely important. If you can create something that doesn’t have that robotic aesthetic, it will provide people with something that feels more familiar and usable. No one really wants to go sit in a car that looks like a square with wheels on it. They want something that makes them feel something, maybe openness or comfort, when they’re in it.

What inspired you to get into mechanical engineering, and how did you end up at System76?

The way my brain works lends itself well to engineering, for better or for worse. There’s a lot of really solid engineers who don’t have much creativity, and then there are a lot of people who have great creative ability, but can’t do math. I kind of fluctuate in the middle; I wouldn’t say I’m the best at math or the most creative person in the entire world, but I have enough of each that the combination pushed me towards mechanical engineering. I like working with my hands, and it’s more of a study of how things work in the real world versus computer science, which is a purely digital and nontangible practice.

During school I worked mainly as a bike mechanic, and that helped me to think about how to build things better. That led me to my first internship at a bike company working in a wind tunnel, which was really fun. Realizing that I could probably never get a job there—or at least one that would pay me enough to live—I started working at an environmental engineering company, where I prototyped scientific sampling systems for R&D that would process materials with all these gasses at really high heat and tried not to die. It was kind of fun making these large-scale systems that were basically just gigantic science experiments, but I didn’t really have the creative outlet I wanted in terms of making something that looks good.

One of the main things that drew me to System76 was being able to have a solid influence on what tools we were able to use and how we were going to push the design. In the past three years, it’s pretty wild to see what we’ve been able to accomplish coming from a completely empty warehouse to being able to crank out parts.

I had also previously, while working at these scientific instrument companies, been working with a local company to design and develop a cargo bicycle, so I had that experience as well in terms of consumer product development with overseas manufacturing. I think that helped get me in the door here.

Let’s talk a bit about your team. Who do you collaborate with on a typical day?

It’s a very small team and everyone does a lot. I pretty much lead the mechanical engineering team slash design team...slash manufacturing team. Being a small company, we are all wearing a bunch of different hats. Aside from doing the initial design work on all of our Thelio desktops and the Launch keyboard, I also program our laser-punch machine and our brake press and run through all of the design for manufacturing hang ups that show up. Those changes tend to be a result of our current tools, and internal capabilities.

Crystal came on last August as our first CNC Machinist. She heads up all of the machining, trains our operators, makes sure our parts are coming out in a nice clean fashion, and has done a lot of work on minimizing machine time and maximizing the parts we can get out. She also provides really great feedback on what's possible and what kind of special fixtures or tools we'll need to make for a specific part. Around the same time we picked up our first Haas 3-axis CNC mill to start working on the Launch project. That led to some other opportunities to make parts for Thelio and improve the feel of some of the parts that we were pumping out.

We just hired Cary, who came from a similar background as me in consumer product development, as well as low-scale scientific machine development. He’s going to help build manufacturing tools for us, and he’s only been here now for two or three weeks. Going forward, Cary will be heading up the Thelio line long-term, and I’ll be moving to some interesting R&D work.

And Zooey?

Zooey doesn’t really do much. She just kind of sits there and waits for people to feed her their lunch. I take her out for walks during the day so she can get away from everyone petting her. She doesn’t like when they do that.

What was the R&D process like for Launch?

Launch is a less complicated product in that we don’t have to deal with things like cooling. Even dropping a PCB into aluminum housing deals with multiple processes, like using the laser and CNC machine. This was a start to looking at those processes to see how much time it takes to produce parts, the costs going into making them, and monitoring the cutting quality. You have to be familiar with the machines and know what you’re looking for when you see a tool going dull.

We first let the software experts do their thing and optimize a layout they wanted for their programming life. Then I was given that template, built a couple of sheet metal chassis that we wired up to test that layout, and made a bunch of little changes to that to get that right secret sauce for our keyboard-centric workflow in Pop!_OS. Once we got a sheet metal product that we were sure was going to be usable, we decided officially that we were going to pursue making a keyboard. That came with a whole new set of manufacturing requirements that we would have to look into.

We spent a ton of time working on pocket profile. When you look at a Launch, you’ll see that it’s not a perfect rectangle. That’s because when you’re using a mill, you have a round tool, so you can go through and get close to a pretty small radius on the corner, but you can never make it exact. If we wanted to get a very small, tight pocket, we’d have to use a very small cutter that takes an extremely long period of time.

We’re taking raw billet, which are these huge 12-foot-long sticks of aluminum that we cut down to get our final product. We went with a rounded rectangle so that we could use our cutter and decrease the overall time to machine that part. There was a lot of work in that and making sure the pockets were all 13.95mm versus 13.9mm versus 14.1mm.

We also did a lot of R&D on how we go about putting the angle bar on. Magnetic assembly seemed to be a good idea. We went from trying to glue magnets in to doing what's called press fitting. The bars come right out of powder coating while they’re nice and warm, when the aluminum is slightly larger than when it cools down. Those magnets aren’t actually adhered to anything in the bars; they’re squeezed in nice and tight from the aluminum cooling and contracting around them. That’s called a press fit, and doing that makes the process faster and less expensive.

It’s similar with the bottoms of Launch; we have steel plates that we press fit into that part as opposed to gluing or screwing, but that we do before powder coating; steel rusts, and we don’t want someone opening up their keyboard in a year and finding a little bit of rust floating underneath their super high-end PCB. So we do that, sand it down, use our media blaster to clean off the surface from the tool paths you see from the mill, and then we powder coat it through and through.

Word on the Denver streets is that Thelio Major is getting a redesign soon. What does that entail?

We’re bringing Thelio Major a lot more in line with Thelio Mega in terms of a different PCI mount for graphics cards, because we know that’s been a pain point for a lot of our users. We want to provide a little bit more robust installation for these graphics cards, which continue to increase in size and weight. The NVIDIA 3000-series cards are almost a pound heavier in some instances, and that’s a lot of weight to be shipping across the country.

We also want to continue to make Thelio Major cooler and quieter when it’s running with these new GPUs. Our new brake press allows us to make radius bends on parts, so we’re starting to run through R&D of a laser-welded external. It’s a wholesale departure from us using custom brackets and 3M VHB tape. That will provide a nicer finished product to our end user, and it’ll allow us to make our product faster with less material and less steps.

What qualities do you look for when adding someone to the team?

Creativity is extremely important. As a small manufacturing company, our priorities can shift on a day or in an afternoon where we don’t have the full line of product anymore. There are all sorts of examples in the past few years of times where you have to react pretty quickly. The motherboard’s been EOL’d, or we have to change our sheet metal design, build a new part, things like that. Making sure that someone can adapt to those changes on a moment’s notice is one of the key parts of the job.

We also want people who get excited about a new challenge and have the desire to keep improving something. I look for people who like to make things and go back in and refine it and not hold it up on this pillar. It’s good to not look at something like it’s perfect.

You have a lot of love for your Audi. What do you love about it over other options?

I like German cars. We have a family of them. They’re high-performance and not too expensive if you do all the work on it yourself. There’s a huge after-market community that tunes and changes these cars, which is pretty fun. Plus I prefer the metric system. Having a standard system drives me nuts, because what the [REDACTED] are fractions?

My real love, though, is bikes. I love tuning and riding bikes, and I love that more than I like to work on cars. It comes out of tinkering. I work with carbon fiber, I’ve done a lot of repairs on bikes over the years—there’s a certain sense of freedom you get from riding a bike that you can’t get from anything else. Not motorcycles, not cars.

#Launch#keyboard#mechanical keyboard#Thelio#desktop#System76#linux#open source#manufacturing#us manufacturing#industrial design#mechanical engineering#Pop!_OS#Ubuntu#desktops#laptops#servers#hardware#software#firmware#motherboard#metric#magnets#dog#press fit#prototype#art#Denver#Colorado

42 notes

·

View notes