#china customized cnc milling parts suppliers

Explore tagged Tumblr posts

Text

Top Aluminum CNC Machining Service in China

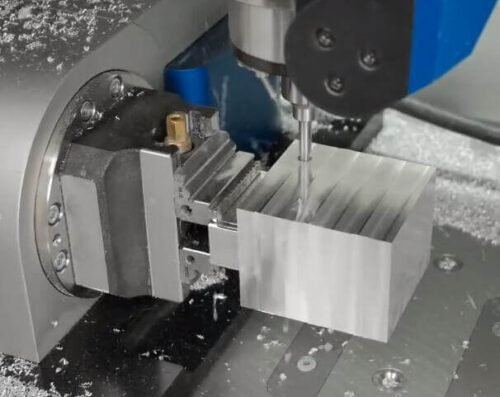

Aluminum CNC machining is a procedure that uses computer numerical control (CNC) machines to produce accurate and complicated Aluminum components. With technological improvements, the demand for high-quality Aluminum parts has skyrocketed. As a result, several Chinese enterprises are providing aluminium CNC machining services to suit the expanding demand.

China has quickly emerged as a top provider of CNC machining services because to its trained labor, superior technology, and cost-effective solutions. This has made it a popular choice for businesses wishing to outsource their CNC machining requirements. Aluminum CNC machining services provide a numerous benefits, including quick turnaround times, competitive pricing, and high-quality goods.

Our Aluminum CNC Machining Capabilities

We specialise in a variety of Aluminum CNC machining services, such as milling, turning, drilling, tapping, and more. Whether you need prototypes, small batches, or large-scale production runs, we can handle projects of any size or complexity. Our staff uses cutting-edge CNC machining equipment to enable quick turnarounds without sacrificing quality.

Benefits of Aluminum CNC Machining

Aluminum is regarded as being lightweight, sturdy, and corrosion-resistant, making it an excellent material for a variety of applications. Aluminium CNC machining allows you to make parts and components that are robust, reliable, and visually appealing. Additionally, aluminum is a cost-effective option that offers excellent thermal conductivity, making it suitable for various industries.

One of the primary benefits of choosing aluminium CNC machining services in China is the country's extensive network of suppliers and manufacturers. This provides organisations with access to a diverse choice of aluminium materials and machining techniques, guaranteeing that they can discover the optimum solution for their individual requirements. Furthermore, Chinese manufacturers are known for their meticulous attention to detail and precision, which ensures that the finished items satisfy the highest standards.

Another advantage of using Aluminum CNC machining Service is cost reduction. The country's competitive labor market and lower production costs result in lower prices for customers. China offers a cost-effective manufacturing choice without sacrificing quality.

In conclusion, Aluminum CNC Machining Service in China offers high-quality precision machining for aluminum parts. With state-of-the-art equipment and experienced technicians, we can produce custom aluminum components with tight tolerances and excellent surface finishes. Whether you need prototypes or large production runs, our CNC machining service can meet your specific requirements efficiently and cost-effectively. Trust us to deliver top-notch aluminum parts that meet your exact specifications and exceed your expectations.

0 notes

Text

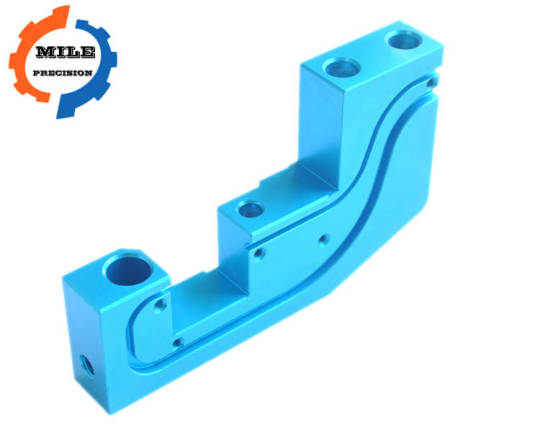

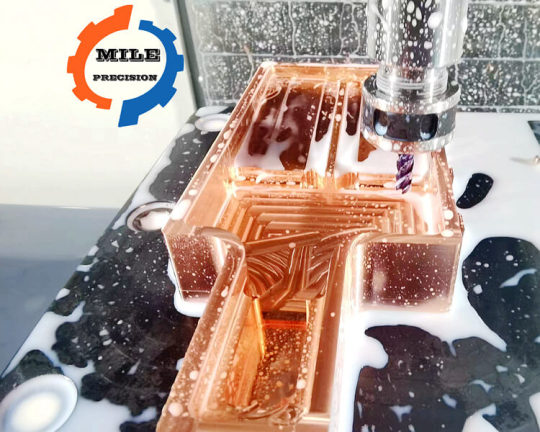

We are an experienced Custom precision machining services supplier, manufacturer in China Our main industrial part products include turned parts, CNC machined parts, metal stamping parts and CNC milling. Products include: hydraulic parts, pneumatic components, auto parts, medical equipment, photographic equipment, injection molding machine parts, etc.

OEM parts manufacturers,

Welcome to our website www.milemetal.com

Contact Us [email protected]

NINGBO MILE PRECISION MACHINERY CO.,LTD

#cnc milling#cnc machining#cnc turning#metal parts#oem parts#oem#stainless steel#stamping#casting#forging#auto parts

0 notes

Text

CNC Machining vs. Traditional Machining: Which is Better?

CNC Machining vs. Traditional Machining: Which is Better?

In the world of manufacturing, precision and efficiency are paramount. As industries continue to evolve, the methods of producing

intricate parts and components have also advanced significantly. Two key players in this evolution are CNC machining and traditional

machining. But the question that lingers is: CNC Machining service vs. Traditional Machining service: Which is Better? Let's embark on

a journey to explore the nuances of these two techniques and uncover the answer.

CNC Machining: The Modern Marvel

Imagine a world where machines operate with unparalleled accuracy, tirelessly executing complex tasks with minimal human intervention.

This is the realm of Computer Numerical Control (CNC) machining. Utilizing cutting-edge technology, CNC machines follow pre-programmed

instructions to perform various tasks such as cutting, drilling, milling, and shaping materials with exquisite precision. This method eliminates

the variability introduced by human error and ensures consistent results every time.

Traditional Machining: A Glimpse into the Past

In contrast, traditional machining methods rely heavily on human operators to guide tools through the manufacturing process. These

methods have served industries faithfully for centuries, involving techniques like manual milling, turning, grinding, and shaping. Skilled

machinists use their expertise to control the process, adjusting parameters based on experience and visual cues. However, this human

touch can lead to slight variations in the final product.

So, Which is Better?

As with most questions in the world of manufacturing, the answer depends on various factors. CNC machining undoubtedly shines when

it comes to precision, repeatability, and complex geometries. The ability to program intricate designs into the machine's software ensures

that each part produced is a mirror image of the last, down to the tiniest detail. Moreover, CNC machining allows for automation, reducing

the need for constant monitoring and potentially increasing production speed.

On the other hand, traditional machining methods offer a level of adaptability that CNC machines struggle to match. Skilled machinists can

make real-time adjustments and corrections based on their intuition and experience, which can be crucial when dealing with unconventional

materials or unique situations. Additionally, traditional methods might be more cost-effective for simpler projects or low-volume production runs.

Finding Common Ground

The manufacturing landscape isn't simply black and white; it's a spectrum of techniques that can be combined for optimal results. In fact,

many manufacturing processes today employ a hybrid approach that combines the strengths of both CNC and traditional machining. For

instance, a CNC machine could be used to create a precise base structure, while a skilled machinist adds intricate details by hand.

Unveiling the Bigger Picture

As CNC machining and traditional machining continue to evolve, they coexist in a harmonious dance that caters to the diverse needs of

various industries. From aerospace to automotive, medical to electronics, these methods provide the tools necessary to craft the world

around us. It's worth noting that small businesses and individuals also benefit from these advancements, utilizing CNC machines for

prototypes, custom parts, and personal projects. The accessibility and affordability of CNC machines have democratized the world of

manufacturing, allowing creativity to flourish.

Delving Deeper: The Client Perspective

Let's take a closer look at the clientele who benefit from CNC machining and traditional machining. Individuals like Mark Sheng, a

discerning executive in a Canadian company, prioritize quality over price and prefer products made in China. They seek personalized

service and trusted suppliers who understand their unique requirements. CNC machining, with its ability to deliver consistent quality

and customization, aligns perfectly with such preferences.

Navigating Challenges and Solutions

The manufacturing industry is not without its challenges. Suppliers often struggle with issues such as low efficiency, delayed deliveries,

and fraudulent certifications. These pain points can hinder the manufacturing process and jeopardize client relationships. As a reliable

supplier in the field, REGO addresses these challenges head-on by prioritizing quality control, certifications, logistics, and payment methods.

Conclusion: A Symphony of Innovation

In the grand debate of CNC Machining vs. Traditional Machining, it's not about one technique being superior to the other. Rather, it's

about understanding their strengths and weaknesses and harnessing them to create a symphony of innovation. CNC machining delivers

precision and consistency, while traditional methods offer adaptability and craftsmanship. The wise manufacturer knows when to let each

technique take the lead and when to blend them harmoniously to achieve the perfect result.

So, whether you're crafting components for a space shuttle or bringing your personal project to life, remember that both CNC and traditional

machining have their place in shaping the world we live in. The journey of manufacturing is an ever-evolving one, and by embracing the

best of both worlds, we ensure that innovation and creativity continue to thrive.

0 notes

Text

PEEK material is a new type of semi-crystalline aromatic plastic engineering plastics, with extremely good physical and mechanical properties, in many special areas can replace metals, ceramics and other traditional materials, in reducing the quality, improving the performance of outstanding contribution to become one of today's most popular high-performance engineering plastics. PEEK material's high-temperature thermal performance is very outstanding, can be used for a long time at 260 ℃, instantaneous use Temperature of up to 300 ℃; its rigidity, dimensional stability, the coefficient of linear expansion is small, close to the metal aluminum materials.

What are The Advantages of PEEK CNC Machining?

◆ High-temperature resistance

The United States UL certification long-term use temperature of 260 ℃.

◆ Self-lubricating

With a low coefficient of friction, it can work without oil lubrication and can work in oil, water, weak acid and alkali medium for a long time.

◆ High strength

It has the best mechanical strength among plastics. It also has high rigidity and surface hardness.

◆ Corrosion resistance

It is insoluble in common solvents and has good corrosion resistance to various organic and inorganic chemical reagents.

◆ Abrasion resistance

It has excellent wear resistance in many extremely harsh environments such as high temperatures, high load and strong corrosion.

◆ Hydrolysis resistance

◆ Easy processing

Parts can be processed directly by an injection molding process. Post-processing such as turning, milling, drilling, tapping and ultrasonic welding can be performed.

◆ Flame retardant

◆ Low smoke and non-toxic

◆ Radiation resistance

It has excellent resistance to high dose γ-ray radiation, and the mechanical properties can be retained intact, so it can be used as radiation-resistant parts in nuclear equipment.

Electrical performance

◆ Dimensional stability

Features of PEEK Non-standard Parts

1. Resistance to dissolution.

2. Both toughness and rigidity.

3. High temperature, high frequency and high voltage electrical performance conditions.

4. Corrosion resistance, anti-aging.

5. Resistance to hydrolysis, high temperature and high pressure can still maintain excellent characteristics.

6. Irradiation resistance wear and corrosion resistance conditions;

7. Resistance to abrasion, anti-static electrical insulation properties;

8. Low soot and toxic gas emissions.

9. Lightweight instead of metal for fiber optic components.

10. Size requirements for precision conditions;

11. Mechanical strength requirements of high components

0 notes

Text

As a professional metal stamping factory in China, Dongguan Orienson Hardware Electrical Co., Ltd. has complete supporting resources, which can provide customers with one-stop hardware products as well as the full set of processing services, we can independently develop and manufacture molds, and provide precision CNC machining services, plastic injection molding service, metal plating services, heat treatment, passivation, grinding, radium carvings and other surface treatment processing technology, besides, assembly services such as metal laser welding, resistance welding, automatic tapping, and automatic riveting is included, Orienson is equipped with a complete inspection and testing instruments to ensure quality from raw material production to delivery, thus reduce the loss and cost of the customer and also offer high-quality and cost-effective prototype metal stamping.

Types of Custom Service Stampings

Assembling ServiceAssembling Service

CNC MachiningCNC Machining

Plastic Injection MoldingPlastic Injection Molding

ElectroplatingElectroplating

Other Surface TreatmentOther Surface Treatment

Automatic TappingAutomatic Tapping

Automatic RivetingAutomatic Riveting

Advantages Of Metal Stamping Supporting ServicesAdvantages Of Metal Stamping Supporting Services

Assembly

Assembly refers to the process of assembing parts according to specifed technical requirements and making them qualifed products.

Products

As an excellent sheet metal stamping manufacturer, we provide highly consistent assembly services at every stage of your production process, from prototyping, proof of concept to mass production.

Professional Team

In addition, our professional automation engineering design team can provide comprehensive assembly.

How Do You Choose Metal Stamping Supporting Services

01

Rich Experience

Service from RED stage to mass production, Our technical team can design, manufacture and maintain.

02

Professional Technology

As an excellent sheet metal stamping manufacturer, we also have the support equipment for tapping machines, riveting machines, automatic assembly lines.

03

Automatic Assembly Line

Our production capability is more than 50 million pieces per month, mold developing and manufacturing capability.

04

R&D Capability

The in-house tool room has LS-WEDM, HS-WEDM, spark machines, grinding machines, milling machines, etc., which can meet all the demands.

05

Highest Cost Effectiveness

Including heat treating, plating, injection molding, CNC machining, etc., we work closely with our customers to ensure the most cost-effective material.

Why Choose Orienson Metal Stamping Supporting Services

Rapid open mold speed, high quality, mature bending process made Orienson widely welcomed by customers. Metal bending parts we produced has been widely used in automobiles, sensor electrical and electronic switches.

Mold speed, high quality, mature bending process

Automobiles, sensors, electrical and electronic switches

Under the guarantee of dimensional accuracy

Committed to providing smooth surface edge rolling parts

Custom Metal Stamping Supporting Services

Impact On Production To Meet Customers' need

Professional One-stop Whole Process CNC Service

Mold Opening, Material Selection

0 notes

Text

Cnc Turning Service

Aerospace CNC Machining - Prototool.com

Aluminium Turning We provide state-of-the-art CNC machining & Injection molding service. Our respective clients provide us with the product design idea along with the preferred material. The rest of the work is done by our experts. We buy quality material, refine the client’s designs, machining the product, and then deliver the finished product to the customer. We are also the market-leading CNC and injection molding material suppliers as well. We are an affiliate of First Part China Limited. Aluminum Cnc Machining

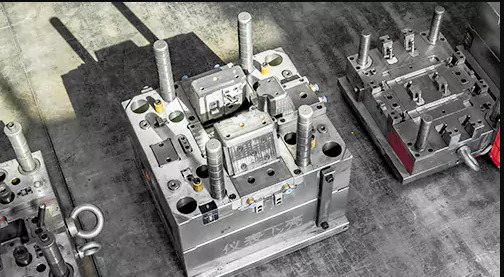

Machining Process of Injection Mold Parts Such as Core, Insert, Lifter and Slide

Aluminum Mold Making Part craftsmen typically provide mold design job books based on molded part task books. To assure the logic and consistency of the mold manufacturing process, optimize the processing process, and improve mold manufacturing progress, each mold factory normally develops a process standard fit for its factory, including using unique injection mold parts. Prototool.com

This article will discuss common injection mold parts, their applications, and things to consider when employing them throughout a factory’s machining process. Cnc Machining Services

The Most Suitable Metal Materials for your CNC Machined Parts

Material selection is essential to any manufacturing process, but engineers and CNC machining service providers must be extremely careful regarding CNC machined parts.

Because this procedure is suitable for a wide range of materials — from metal to fiberglass to wood — it’s easy to select an adequate material but not optimal for the job. However, you may want to select the best metal material for your CNC machining project. Cnc Milling Service

This blog will review several critical considerations to help you choose the best metal material for CNC machined parts.

Designing Top-Quality Plastic Molded Parts: 7 Proven Tips

Cnc Plastic Machining Thousands of designers create injection molded parts. However, a select group in this big community can create parts for injection molders. Before all parts are completely recorded and handed to molders for manufacturing, injection molded product design goes through many development stages. The last stage of development is essential since design adjustments or corrections can no longer be performed without dramatically raising expenses or project delays. So, how can you

ensure that your plastic molded parts are perfectly designed? Here’s a detailed guide on effectively designing the parts.

Material Selection and Its Implications:

Cnc Rapid Prototyping Materials are typically specified early in the design process, and both parties must agree. Molders can sometimes get large amounts of specialized resins at steep savings. Customers can benefit from these offers. For example, a designer can save tens of thousands of dollars if they select an ABS grade that matches the ABS grade that molders buy in bulk. Prototool.com

Due to viscosity, high glass content, or crystallinity, designers may discover that certain high-performance resins are not suited for molders. Resins can be chosen for certain physical or chemical resistance qualities. However, they can be difficult to mold and keep to specified tolerances. Molders must adhere to the prescribed resin and integral part specifications to mold the part. Cnc Turning Service

The Most Common Types of Machining Services and Processes

Consumer Electronics Manufacturers Machining services are crucial in manufacturing, as they shape and transform raw materials into finished products. Various machining services are available, each with its unique set of benefits and applications. From milling to drilling and turning, machining methods have revolutionized how products are made. This article will explore the seven most common types of machining methods, their advantages, and the industries that use them.

Understanding these services will help businesses determine the best machining processes for their manufacturing needs.

This article will discuss the seven different machining services and how they are conducted in the plastic injection molding/manufacturing industry. High Volume Manufacturing

Prior Materials Preparation and Pre-Molding Considerations for Effective Plastics Injection Molding

High-volume Production In plastics injection molding, the work done to prepare the mold before adding material to it and molding plastic to make a product is of critical importance. It includes evaluating and setting up for a wide variety of processes, such as material processing performance inspection (determination of plastic fluidity, moisture content, etc.); dyeing and granulating of raw materials before processing; preheating and drying of granules; cleaning and preheating of inserts; mold testing and cylinder cleaning, etc.; and so on. Prototool.com

Having a sound comprehension of all the procedures involved and commencing with the appropriate strategy to evaluate and prepare the material is crucial for ensuring the effectiveness of the plastic injection molding process. Now, in the event that you are uninformed of what occurs before the use of high-tech machinery, the phase of mold

inserting, and the phase of production form, let’s go ahead and investigate many aspects of preparing the production setup before formally beginning the production process.

Injection mold China

4-Axis CNC – The Various Features and Important Details about It

4-axis CNC machines are advanced versions of 3-axis CNC centers that have revolutionized the field of workpiece shaping. With the installation of the fourth axis, these machines have significantly enhanced the quality of machining. Injection Molding Manufacturers

A 4-axis CNC machine has four axes, which allows it to perform intricate operations such as milling, turning, drilling, and more. This multi-tasking capability allows the machines to perform multiple jobs simultaneously. In this comprehensive guide, we will explore the features and capabilities of 4-axis CNC machines to provide you with a complete understanding of their capabilities. Injection Molding Services

More Information - https://prototool.com/

0 notes

Text

China Machining Parts

Chinese CNC machining services supplier offers high precision CNC milling service and custom CNC machined parts cheaply in China.China machining service? Here today, we will share you top 10 cnc machining service provider from China who offer good machining service. I hope this information will be helpful to you!

https://www.sagemetalparts.com/blog/top-10-china-cnc-machining-service-provider/

0 notes

Text

China Cnc Machining Service Suppliers

We are a complete CNC milling service China provider of entire thermoplastic materials such as TPE, FEP, PFA, PTFE, PEEK, etc. We also provide eco-friendly substitutes to all our customers. Our services are including production, quality, CNC molding, tool relocation and prototype development. We also allow our clients for the effective quote management as well as order tracking.

0 notes

Text

Rapid Traverse

Fast navigate developments should be performed cautiously in a CNC going machine to forestall crashes. Uncommon consideration should be paid to the shifting lengths of the cutting apparatuses and that they are so near other machine parts and the workpiece. Another thought is the area of the device before and toward the fruition of the fast developments. For example, if the instrument is an ID…

View On WordPress

#4 axis cnc machining service factory#china alu cnc machining#china cnc machine for cutting foam#china cnc steel turned machining parts suppliers#china custom aluminum milling suppliers#china customized cnc milling parts suppliers#china customized cnc service#china luminum cnc milling machining suppliers#china precision machining parts suppliers#china precision mini metal lathe#china titanium grinding service manufacturers#china tooling cnc machining suppliers#cnc carbon fibre machining#cnc cutting service carbon fibre manufacturers#cnc lathe parts suppliers#cnc machined carbon fiber parts factory#cnc machining turning parts manufacturers#cnc milling aluminum part factory#cnc precision machining factory#cnc turning made in china#cnc turning parts suppliers#cnc turning precision titanium parts#cnc turning stainless steel parts china#custom cnc machined precision machining titanium parts factory#medical parts machining suppliers china#precision cnc machining service factory#precision grinding machine manufacturers china#precision stainless steel cnc turned parts manufacturers#prefessional cnc milling parts factory#quality instrument machining service

1 note

·

View note

Text

Noses

New Post has been published on https://www.cncmachinings.com/noses/

Noses

Addition Size

The fifth situation of cnc copper precision parts factory indicates one factor of the addition size. Since embeds arrive in an assortment of shapes, a general strategy was created to characterize their size paying little mind to shape. By deciding the biggest circle that can fit inside the edges of the supplement, most addition shapes can be measured. This size is known as the engraved circle (LC.).

High precision steel machinery parts made in china shows an engraved hover on two diverse addition shapes. As appeared, inch arrangement engraved circle measurements are indicated as the quantity of 1/8ths of an inch. For instance, a supplement with a size assignment of “3” can fit a 3/8″ measurement engraved hover inside its edges.

Addition Thickness

The 6th situation of cnc micro machining brass part factory determines another part of the supplement size, its thickness. The thickness of a supplement is noted regarding the quantity of 1/16ths of an inch. For instance, an addition with a size assignment of “2” measures 2/16″ or 1/8″ (diminished) thick.

Device Nose Radius/Cutting Point

The seventh situation of cnc cutting service carbon fibre manufacturers indicates the cutting point. For turning embeds, the cutting point is regularly a sweep. As talked about already, the sweep on the device tip gives solidarity to the supplement and influences the surface completion and cutting power. Addition nose radii are noted in the framework as the quantity of 1/64ths of an inch. For instance, a “1” implies that the apparatus has a nose range of 1/64″ .

cnc machining watch

Maker’s Option

Positions eight through ten of quality precision machined electronics components give discretionary space to the maker to make extraordinary notes about extra data.

Chip Former

To additional assistance with chip control, carbide producers contribute a lot of innovative work into making a working surface on supplements to additionally refine the arrangement of chips. These chipformer calculations may in some cases seem like resplendent bits of workmanship, yet they are logically refined examples characterized for explicit cutting conditions. Supplements are accessible with chipformers intended for explicit material sorts, hardness conditions, and whether roughing or completing is to be performed.

Numerous producers incorporate assignments for their different styles of chipformers toward the finish of the ANSI recognizable proof. China precision titanium machining manufacturers shows three diverse chipformer calculations and their assignments.

Supplement Grade

By and large an addition made of hard carbide will forfeit sturdiness, and an intense supplement will forfeit hardness. These properties make up the supplement grade and should be coordinated to every application. Workpiece material, the activity type (completing, medium roughing, or weighty roughing), and machining conditions (heat treatment, inflexibility, interferences, chip clearing, cutting liquid flexibly, and so on) all impact the determination of the correct carbide grade. cnc machining parts manufacturers shows the normalized

ISO distinguishing pieces of proof for different workpiece material sorts. Inside each ISO workpiece material code, numerous evaluations are offered going from intense (milder) to wear safe (harder). Harder evaluations can deal with more effect. Wear safe evaluations last more and stand up better to unforgiving materials. It is essential to take note of that most carbide makers have formulated their own restrictive evaluation assignments, and it is generally best to allude to the applications inventory for each brand.

This article is from http://www.cncmachinings.com

#carbon fibrecnc machine#china carbon fibre cnc cutting parts#china cnc milling parts factory#china custom aluminum milling suppliers#china custom machining services#china customized cnc milling parts suppliers#china grinding machining#china precision mini metal lathe#china precision titanium machining manufacturers#china steel part machining#china tooling cnc machining suppliers#cnc carbon fibre parts manufacturers#cnc copper precision parts factory#cnc cutting service carbon fibre manufacturers#cnc machining parts manufacturers#cnc micro machining brass part factory#cnc milling parts components factory#cnc precision steel parts suppliers#custom precision cnc machining plastic parts china#high precision cnc machining auto titanium parts factory#high precision high speed fine milling machine manufacturers china#high precison steel machinery parts made in china#medical device parts die cast suppliers china#plastic or metal machining parts made in china#quality precision machined electronics components#steel turning parts manufacturers#surface grinder suppliers china#Featured Articles

1 note

·

View note

Text

Choose a Good Way for Turning

Posted from 5 axis machining China blog

Choose a Good Way for Turning

A dry cycling is a turning way used by cnc turning parts aluminum manufacturers china. Any one or a blend of these strategies might be used to validate a program and arrangement to guarantee wellbeing preceding creation. Realistic recreation permits confirmation of the ways the apparatus will take by watching a reenacted PC model cut the part on a presentation screen. This should be possible at a PC with reenactment programming before stacking the program in the machine, or on the MCU show on machines with realistic recreation capacity. china 4 axis cnc machining service suppliers shows realistic part recreation on a presentation screen.

Realistic reproduction is a fast method to investigate evident programming issues however doesn’t examine a genuine machine arrangement or little situating blunders. A dry run is a more legitimate visual validate and is generally done in the machine after the instruments and workpiece have been set. Conventionally speaking,”dry running” alludes to running a machine with impaired capacities to kill the potential for impacts. This can be accomplished by eliminating tooling, eliminating the workpiece, cutting a wax portrayal of the workpiece, handicapping certain pivot movements, or crippling shaft work. A few machines are furnished with a “Dry Run” mode. This mode will generally disregard the modified feed rates and make all developments at a quicker (or more slow, in the event that you decided) rate. Dry running is additionally normally managed without coolants to assist with perceivability and to keep the work zone clean.

A dry cycle resembles a dry run however will run the program at the real modified feed rates. This can be useful in demonstrating that there are no G0/G1 code blunders or feed rate mistakes. With a dry cycle, the shaper or workpiece might be eliminated so no crashes can happen. A dry cycle is finished utilizing a similar machine “Auto” or “Memory’ mode that will be utilized to make the last part.

The protected counterbalance technique is similar as the dry-run system in light of the fact that the machine will be genuinely executing the program yet not really cutting the workpiece. The thing that matters is that all machine capacities are empowered (with the exception of maybe coolant) and the apparatuses and workpiece are introduced. Wellbeing is guaranteed by deliberately setting the work beginning in either the X-or Z-hub at a protected separation from the workpiece. With this technique, the program can be validated and upon effective consummation, the balances can be progressively drawn nearer to the part. This strategy can be rehashed until the program and arrangement are considered safe.

Regardless of which procedure is utilized by cnc turning/milling parts factory for demonstrate out, alert is the key. There are two different lines of guard to forestall impacts by making machine movement more sensible and shock developments preventable. These controls are the supersede controls and single-block mode. Supersedes give the capacity to moderate or even stop the customized feed rates and rapids. Most machine control boards are furnished with variable supersede handles for this.

Single-block mode permits the capacity to execute just each square of the program in turn. In this mode, the machine won’t progress to the following square until the cycle-start button is squeezed once more. This permits lines of the program to be seen on the MCU screen and checked preceding them being executed. The single-block mode is ordinarily actuated by a switch or catch on the machine control board.

This article is from http://www.5axismachiningchina.com/

#car parts cnc precision manufacturers china#china 4 axis cnc machining service suppliers#china cnc lathe processing parts manufacturers#china cnc machining parts manufacturers#china cnc machining service#china custom titanium cutting suppliers#china swiss turning machine#chinese stainless steel part machining manufacturers#cnc aluminum milling parts and service factory#cnc cutting carbon fiber factory#cnc maching aluminum milling parts made in china#cnc turning parts aluminum manufacturers#cnc turning parts aluminum manufacturers china#cnc turning/milling parts factory#discount carbon steel precision cnc lathe machining service#milling machining companies#precision cnc titanium machining suppliers#precision milling part made in china#small metal parts manufacturers china

0 notes

Photo

New Post has been published on https://www.injectionmouldchina.com/to-analyze-the-vents/

to Analyze the vents

The measure of air dislodged will be roughly equivalent to the volume of the injected plastic. The term”approximately”is utilized here to suggest that the air will grow to some degree when reached by the hot plastic dissolve. In any case, the warmed air will likewise C00l to some degree as it f10Ws past the outside of the shape, For these reasons, the investigation here will accept that the volumetric stream pace of the air will approach the volumetric low pace of the soften.

Next, it is important for oem rapid plastic prototype factory to distinguish the areas where the venting is required. These areas may appear glaringly evident, however 0n closer thought these areas may not be So paltry to recognize. There are commonly three unique kinds of areas where venting is fundamental.The first sort of vent is required where the liquefy meets at an edge of the shape’s splitting plane or other shut-off surface.

The second sort of vent is required where two melts meet to shape a sew or weld line. The third sort of vent is required where the dissolve joins at a dead pocket in the shape. Every one of these situations will next be quickly examined.

cnc plastic prototyping manufacturers china recommends numerous likely areas of gas traps and relating vent areas around the bezel’s splitting plane and shut-off surfaces. A portion of these vents, including the four areas close to the entryways and the four areas at the corners may not be fundamental since the soften stream is transcendently outspread. Since the stream is spiral, the liquefy should arrive at the edges of the form without catching any air, and keep dislodging the air further into the unfilled hole. In this way, there is no requirement for a vent at those areas. Nonetheless, the specific dissolve front conduct may change marginally and it isn’t extraordinary for the dissolve to trap gas at areas along the splitting line as shown in cnc high precision machining parts factory. While the vents close to the entryway and at the corner might be considered as discretionary, the form architect may decide to indicate vent areas at these areas to evade potential shape changes later. The vent locations toward the finish of stream showed at base left of Fig. 8.2 ought to be incorporated since a noteworthy portion of the uprooted air from the pit will probably exit here.

The second sort of vent is required where two dissolve fronts meet in china custom design prototyping manufacturers. For this situation, two sunken liquefy fronts can meet up and structure a capturement from which the air can’t get away. AS shown in Fig.8.3, a vent is consequently required on an interior surface of the form depression, Usually, ejector pins are demarked to give such venting capacities 0n the outside of the shape depression.

The third kind of vent 0CCUI’S at dead pockets in the shape. The specific areas are not generally self-evident, So three models are given by rapid prototype services. In the left detail, the soften streams from the depression surface along the length of the chief, and eventually traps the air toward the finish of the chief. In the middle detail, two liquefy fronts come together at a rib, pushing the air to the top right on target of the rib. In the correct detail, the dissolve front streams slantingly aCr0Ss a rib. Because of a pattern in the rib, the air can be caught in this edge of the shape hole. There are around twenty such dead pockets in the bezel plan that may require venting.

The above conversation and further investigation demonstrate that there are around three dozen vent areas that the shape creator may wish to consider. It is improbable that these vent areas are important. Moreover, the expansion of vents is typically a generally straightforward activity that can be cultivated after the form is assembled and tried. Thus, it is genuinely regular for the form originator to at first determine vents at just the most basic vent areas.

this article is from https://www.injectionmouldchina.com.

#brass prototype suppliers china#china cnc plastic milling service suppliers#china custom design prototyping manufacturers#china custom micro machining#china fixture prototyping manufacturers#china plastic cnc machining factory#china plastic prototyping manufacturers#china plastic tapping parts and service suppliers#cnc abs pom parts china#cnc high precision machining parts factory#cnc medical device rapid prototyping manufacturers china#cnc precision machining factory#oem rapid plastic prototype factory#rapid prototype services#rapid prototyping service china#rp prototype manufacturers china#Plastic Mold

0 notes

Video

tumblr

KUNSHAN CARSAI AUTO PARTS INDUSTRY CO., LTD https://www.carsai-precisionparts.com/ Whatsapp&WeChat: +8615212743691 email: [email protected] --------------------- China cnc engineering prototyping parts factory customization cheapest price manufacturing mill engineering parts list,engineering parts supplier,engineering parts catalog,engineering parts website,engineering parts and services,engineering parts hs code,engineering parts manufacturers,engineering parts online,engineering parts accessories company,engineering parts and services puerto rico,engineering parts aircraft,parts engineering and manufacturing,tissue engineering parts a b & c,tissue engineering parts a,hunter engineering parts and service,engineering parts brisbane,engineering parts buy,engineering brake parts,engineering parts sdn bhd,hamilton engineering boiler parts,ireland engineering bmw parts,engineering replacement body parts,combustion engineering boiler parts,b.t. engineering parts co. ltd,engineering parts companies in karachi,parts engineering company,engineering car parts,engineering compass parts,engineering custom parts,parts engineering compressor,h & c engineering parts supplies,engineering parts diagram,engineering drawing parts,engineering drawing parts list,engineering design parts,engineering parts list definition,plastic parts engineering drawing,dema engineering parts,dk engineering parts,hamilton engineering evo parts,precision engineering engine parts,engineering diesel engine parts,electrical engineering parts,europa engineering parts,electronic engineering parts,enduro engineering parts,environmental engineering parts,engineering parts for projects,engineering for parts,hill engineering ferrari parts,triangle engineering fan parts,gto engineering ferrari parts,surface engineering for parts made by additive manufacturing,pbs engineering fiat parts,better engineering parts washer for sale,extreme engineering gun parts,coleman engineering generator parts,kato engineering generator parts,reverse engineering gun parts,gto engineering parts,genetic engineering parts,giltrap engineering parts,gloucester engineering parts,engineering spare parts hs code,vulcan engineering harley parts,custom parts engineering hospers ia���mace engineering holden parts,engineering machinery spare parts hs code,engineering goods spare parts hs code,hunter engineering parts,h-e parts engineering pty ltd,h-e parts engineering,engineering parts item,ace engineering parts (india) private limited,jet parts engineering inc,kauffman engineering inc parts,better engineering impulse parts washer,cambridge engineering inc parts,boeing spares engineering parts interchangeability,zero engineering parts japan,xk engineering jaguar parts,ace engineering jeep parts,jancy engineering parts,jetline engineering parts,pt asia parts engineering jakarta,j&r engineering m68 parts,azusa engineering kart parts,keene engineering parts,kato engineering parts,engineering parts list template,engineering lathe parts,mechanical engineering parts list,engineering spare parts list,mason engineering parts llc,engineering parts mechanical,parts engineering meaning,engineering moulded parts,engineering motorsport parts,engineering machined parts,engineering materials parts,engineering many parts,engineering parts near me,engineering parts naming conventions,mechanical engineering parts name,nc engineering parts,neb engineering parts,engineering of parts,civil engineering parts of a building,merkur engineering parts order,reverse engineering obsolete parts,engineering definition of parts list,parts of engineering drawing,parts of engineering report,engineering parts products,engineering plastic parts,engineering plastic parts manufacturers in pune,chill parts engineering pte ltd,ames engineering pontiac parts,wright engineering plough parts,reverse engineering plastic parts,q-engineering,sierra engineering rv parts,base engineering remote parts,randolph engineering replacement parts,aerospace engineering racing parts,hunter engineering replacement parts,viking engineering rover parts,wheeler engineering replacement parts,jet parts engineering revenue,engineered parts supply,engineering parts & services,engineering spare parts,engineering spare parts management,engineers transit parts,lc engineering toyota parts,transit engineering trailer parts,bond engineering turned parts ltd,aircon parts engineering thailand co,sprint engineering triumph parts,engineering and technology parts,engineering used parts,uk engineering parts,engineering parts vector,interstate engineering vacuum parts,creative engineering vw parts,integrated engineering vw parts,rothenbacher engineering vw parts,viking engineering parts,v1 engineering parts,v1 engineering parts list,engineering parts washer,engineering works parts,better engineering parts washer,better engineering parts washer manual,better engineering parts washer pump,kenco engineering wear parts,yuyao engineering & parts sdn b

2 notes

·

View notes

Text

Injection Moulding Service

Aerospace CNC Machining - Prototool.com

Aluminium Turning We provide state-of-the-art CNC machining & Injection molding service. Our respective clients provide us with the product design idea along with the preferred material. The rest of the work is done by our experts. We buy quality material, refine the client’s designs, machining the product, and then deliver the finished product to the customer. We are also the market-leading CNC and injection molding material suppliers as well. We are an affiliate of First Part China Limited. Aluminum Cnc Machining

Machining Process of Injection Mold Parts Such as Core, Insert, Lifter and Slide

Aluminum Mold Making Part craftsmen typically provide mold design job books based on molded part task books. To assure the logic and consistency of the mold manufacturing process, optimize the processing process, and improve mold manufacturing progress, each mold factory normally develops a process standard fit for its factory, including using unique injection mold parts. Prototool.com

This article will discuss common injection mold parts, their applications, and things to consider when employing them throughout a factory’s machining process. Cnc Machining Services

The Most Suitable Metal Materials for your CNC Machined Parts

Material selection is essential to any manufacturing process, but engineers and CNC machining service providers must be extremely careful regarding CNC machined parts.

Because this procedure is suitable for a wide range of materials — from metal to fiberglass to wood — it’s easy to select an adequate material but not optimal for the job. However, you may want to select the best metal material for your CNC machining project. Cnc Milling Service

This blog will review several critical considerations to help you choose the best metal material for CNC machined parts.

Designing Top-Quality Plastic Molded Parts: 7 Proven Tips

Cnc Plastic Machining Thousands of designers create injection molded parts. However, a select group in this big community can create parts for injection molders. Before all parts are completely recorded and handed to molders for manufacturing, injection molded product design goes through many development stages. The last stage of development is essential since design adjustments or corrections can no longer be performed without dramatically raising expenses or project delays. So, how can you

ensure that your plastic molded parts are perfectly designed? Here’s a detailed guide on effectively designing the parts.

Material Selection and Its Implications:

Cnc Rapid Prototyping Materials are typically specified early in the design process, and both parties must agree. Molders can sometimes get large amounts of specialized resins at steep savings. Customers can benefit from these offers. For example, a designer can save tens of thousands of dollars if they select an ABS grade that matches the ABS grade that molders buy in bulk. Prototool.com

Due to viscosity, high glass content, or crystallinity, designers may discover that certain high-performance resins are not suited for molders. Resins can be chosen for certain physical or chemical resistance qualities. However, they can be difficult to mold and keep to specified tolerances. Molders must adhere to the prescribed resin and integral part specifications to mold the part. Cnc Turning Service

The Most Common Types of Machining Services and Processes

Consumer Electronics Manufacturers Machining services are crucial in manufacturing, as they shape and transform raw materials into finished products. Various machining services are available, each with its unique set of benefits and applications. From milling to drilling and turning, machining methods have revolutionized how products are made. This article will explore the seven most common types of machining methods, their advantages, and the industries that use them.

Understanding these services will help businesses determine the best machining processes for their manufacturing needs.

This article will discuss the seven different machining services and how they are conducted in the plastic injection molding/manufacturing industry. High Volume Manufacturing

Prior Materials Preparation and Pre-Molding Considerations for Effective Plastics Injection Molding

High-volume Production In plastics injection molding, the work done to prepare the mold before adding material to it and molding plastic to make a product is of critical importance. It includes evaluating and setting up for a wide variety of processes, such as material processing performance inspection (determination of plastic fluidity, moisture content, etc.); dyeing and granulating of raw materials before processing; preheating and drying of granules; cleaning and preheating of inserts; mold testing and cylinder cleaning, etc.; and so on. Prototool.com

Having a sound comprehension of all the procedures involved and commencing with the appropriate strategy to evaluate and prepare the material is crucial for ensuring the effectiveness of the plastic injection molding process. Now, in the event that you are uninformed of what occurs before the use of high-tech machinery, the phase of mold

inserting, and the phase of production form, let’s go ahead and investigate many aspects of preparing the production setup before formally beginning the production process.

Injection mold China

4-Axis CNC – The Various Features and Important Details about It

4-axis CNC machines are advanced versions of 3-axis CNC centers that have revolutionized the field of workpiece shaping. With the installation of the fourth axis, these machines have significantly enhanced the quality of machining. Injection Molding Manufacturers

A 4-axis CNC machine has four axes, which allows it to perform intricate operations such as milling, turning, drilling, and more. This multi-tasking capability allows the machines to perform multiple jobs simultaneously. In this comprehensive guide, we will explore the features and capabilities of 4-axis CNC machines to provide you with a complete understanding of their capabilities. Injection Molding Services

More Information - https://prototool.com/

0 notes

Text

China Custom Machining

Chinese CNC machining services supplier offers high precision CNC milling service and custom CNC machined parts cheaply in China.Are you looking for China machining service? Here today, we will share you top 10 cnc machining service provider from China who offer good machining service. I hope this information will be helpful to you!

https://www.sagemetalparts.com/blog/top-10-china-cnc-machining-service-provider/

0 notes

Text

NagualMetal Precision Manufacturing Limited.

CNC Sheet Metal NPM is specialist manufacturer of CNC sheet metal in China for many consumer and industrial products. We provide a complete turnkey solution for your CNC sheet metal requirements.

Some of the CNC sheet metal services we provide include:

CNC turret punching Laser cutting Guillotining CNC Folding and Bending Metal Rolling Band Sawing Tube Bending Product Assembly

NPM is committed to producing high quality CNC sheet metal components and providing excellent service and support to our customers. Our dedicated and highly experienced staff and constantly updated processes and machinery have enabled NagualMetal to grow and remain competitive in China’s CNC sheet metal industry. Each member of our company

NagualMetal CNC Machining in china Branch of NagualMetal is a specialist China manufacturer and supplier offering the full range of CNC/EDM engineering services, comprising CNC Machining, CNC Milling, CNC Lathe Turning, EDM Wire Cutting and EDM Eroding. Computer Assisted Manufacturing (CAM) programs are run on customer 2D or 3D CAD data files. CAM programs are then directly downloaded to one of our CNC machines for automated machining.

Our lead times are fast, depending on the nature and volume of work. Automatic tool changers, high speed spindles, and fast feed rates allow us to machine components efficiently and accurately.

A wide range of materials such as aluminium, steel, hardened tool steel, stainless steel cast iron, brass, copper, polycarbonate, ABS, acrylic, PET, nylon and more can be machined to suit your needs.

NagualMetal is an experienced Precision Manufacturer specializing in precision tooling, automated manufacturing equipment, and prototypes requiring close tolerance. Our wire cut EDM services are perfect for tooling assemblies and EDM intensive component parts. Along with top quality services, our operation offers quick turn delivery, and can assist you with every aspect of your project, from design to manufacturing.

Our staff of experienced machining professionals can assist you in solving the most challenging CNC machining and manufacturing tasks. From complex 3-D machining to simple hole drilling, we can be your first choice for CNC and EDM. Email RFQ and Drawings to:

[email protected] Follow are the informations about our precision parts by CNC machining.

--------------------

● Materials for CNC Precision machining parts

We can process product materials are:

An aluminum alloy series: all aluminum and aluminum alloy (ASTM Grade from 1050-7475), commonly used are: 2011,5052,6061,7075, etc.

(2) Copper Alloy Series: all copper and copper alloy, copper, copper, brass, bronze, phosphor (the ASTM grades from C11000 to C38000), commonly used: C11000, C22000, C26000

(3) Stainless Steel Series: all the basic machining stainless steel, the ASTM grades (JIS grade corresponds to the basic, together with the SUS can): 201,301,303,304,314,316,420,430,630

Steel series: all the basic machining steel can be processed, for example: 20 # steel, 45 steel, easy to cut iron (common SUM24L, SUM22, Y12, Y15)

● CNC Precision machining parts accuracy

Machining accuracy: IT6 level, such as the 10mm dimensions, tolerances can be done 0.009mm, 20mm size tolerances can be 0.013mm

● Maximum size of Precision parts suit to CNC machining

Lathe parts (turning parts , such as axes, coupling,bushing, thread rod , etc.) following the outer diameter of 300mm, length less than 150mm

Milling parts (box, cylinder, etc.) 800mm long, 330mm wide, 120mm high

Branch of NagualMetal is specialized in making various springs parts,including disc springs,extension springs,compression springs,snap springs,wave springs,flat spiral springs,drum springs,leaf springs,pagoda springs,spring lamination and kinds of stamping parts etc. With powerful technology,good producing equipment and pretty quality,the factory passed ISO9000:2008 quality system and obtained good public praise in this field. Following the concepts of development born of innovation and quality based of constant. The company is dedicating to be internationally competitive and to be the world-known spring supplier.

#stamping cnc machining cnc lather#cnc milling#Branch of NagualMetal is specialized in making various springs parts

1 note

·

View note