#cnc machine services

Explore tagged Tumblr posts

Text

🚀 Precision in Every Detail! ✨ Witness the raw beauty of this engine casing, flawlessly crafted using state-of-the-art 5-axis CNC machining. 💡 From intricate designs to complex geometries, our precision technology ensures unmatched accuracy and a surface finish so smooth it barely needs post-processing. Perfect for industries like aerospace and automotive, this is machining excellence at its best! 🛠️⚙️

👉 Like, share, and follow for more precision engineering marvels! 🎥

PrecisionMachining #5AxisCNC #CNCmachining #EngineeringExcellence #AerospaceParts #AutomotiveComponents #AdvancedManufacturing #MetalCrafting #SurfaceFinish #TechInnovation

#CNC Machine Basic Knowledge#CNC Machine Coolant#CNC Machine Finance#CNC Machine For Guitar#CNC Machine Game#CNC Machine Manufacturers#CNC Machine Offers For Internet#CNC Machine Operator Hiring#CNC Machine Operator Recruitment#CNC Machine Panel#CNC Machine Purchase#CNC Machine Services#CNC Machine Shop Near Me#CNC Machine Suppliers#CNC Machine Types#CNC Machine What Does It Do#CNC Machine X Carve

1 note

·

View note

Text

Precision Machining Services at JBC Machine Inc.

We leverage state-of-the-art software and equipment to offer an array of services at JBC Machine Inc. From 3D milling to boring, drilling, and threading, our commitment to precision shines through. Rely on us for customized solutions, ensuring your machining needs are met with top-notch accuracy and efficiency.

#CNC Milling Turning Service#CNC Machine Services#Custom Machine Services#Custom CNC Machining#Custom Machining Services

0 notes

Text

901 notes

·

View notes

Text

CNC precision machining service

#business#design#autos#prototyping#prototype#prototype machining#cnc machining#rapid prototyping#precision machining#machining parts#cnc machining service#cnc services#cnc precision machining#5 axis cnc machining#5 axis precision machining#5 axis cnc#cnc machining parts

4 notes

·

View notes

Text

We provide precision CNC machining services, CNC Milling and Turning (3 axis, 4 axis, 5 axis), can manufacture complex and multi-structure plastic and metal parts.

#cncmachining#5 axis machining#cnc milling services#cnc machining parts#rapid prototyping#precision machining

2 notes

·

View notes

Text

Best CNC laser cutting machine in India

As of my last knowledge update in January 2022, I don't have specific information on the latest CNC laser cutting machines available in India. However, I can provide you with some popular CNC laser cutting machine manufacturers that were well-regarded globally. It's important to note that advancements in technology and new models may have been introduced since then.

TRUMPF: TRUMPF is a globally recognized company for manufacturing high-quality CNC laser cutting machines. They offer a range of laser cutting solutions for various industries.

Amada: Amada is another well-known brand in the CNC machinery industry, including laser cutting machines. They have a reputation for producing reliable and efficient equipment.

Bystronic: Bystronic is a Swiss manufacturer known for its advanced laser cutting systems. They provide solutions for sheet metal processing and have a presence in India.

Mazak: Yamazaki Mazak Corporation, commonly known as Mazak, is a Japanese company that produces CNC laser cutting machines. They are known for their precision and innovation.

Han's Laser: Han's Laser is a Chinese company with a global presence, manufacturing laser cutting machines. They offer a variety of models suitable for different applications.

LVD: LVD is a Belgian company specializing in sheet metalworking equipment, including laser cutting machines. They are known for their innovative solutions.

When considering the best CNC laser cutting machine for your specific needs, factors such as the machine's power, cutting capabilities, ease of use, support services, and overall reputation of the manufacturer are important to consider.

To find the latest and best CNC laser cutting machines in India, it's recommended to check with local distributors, attend industry exhibitions, and explore online reviews and forums for updated information. Additionally, contacting the manufacturers directly or consulting with industry experts can help you make an informed decision based on your specific requirements.

We Provide:-

Best CNC laser cutting machine in India CNC punching services in pune Best MIG Welding Machine Pre-Treatment for Surface Preparation in pune Best CNC bending services India Best SS fabrication services in India Best spot welding services in pune Best tube, pipe, and angle cutting services in pune Best automotive manufacturers in pune Best manufacturing and assembly services

#best cnc laser cutting machine in india#CNC punching services in pune#best MIG Welding Machine#Pre-Treatment for Surface Preparation in pune#best CNC bending services india#best SS fabrication services in india#best spot welding services in pune#best tube#pipe#and angle cutting services in pune

2 notes

·

View notes

Text

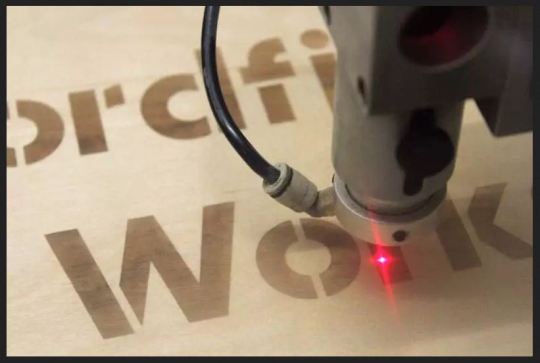

#lasercutting #cncprocessing #cnc #cncservices

#cnc milling service#cnc car parts#online cnc machining services#sheet metal fabrication#sheet metal processing services#custom sheet metal fabrication#cnc turning services#cnc machining services#online cnc precision machining

2 notes

·

View notes

Text

High Quality Laser Cutting and Services in london

London, a hub of innovation and technology, has witnessed a surge in the utilization of laser cutting services across various industries. Laser cutting has revolutionized manufacturing processes, offering unparalleled precision, speed, and versatility. In this article, we will explore the significance of laser cutting services in London and delve into the benefits they bring to businesses and…

View On WordPress

#cnc cutting london#CNC cutting Shoreditch#CNC Machining London#CNC routing London#High Quality Laser Cutting Services#Laser cutting#Laser cutting east London#laser cutting london#laser cutting services#Laser Cutting Services in London#laser cutting shoreditch

3 notes

·

View notes

Text

Know About The Significance of CNC Machining Companies

An age of industrial accuracy like none before has arrived thanks to CNC machining. Traditional machining techniques sometimes require manual involvement, which might lead to irregularities and human mistakes. On the other hand, CNC machining uses computer-controlled instructions to accurately control tools and equipment. In addition to guaranteeing consistency in completed goods, this degree of precision also lessens the demand for frequent quality control inspections.

Unlimited Possibilities

CNC machining businesses provide a wide range of capabilities, from straightforward two-dimensional cuts to intricate multi-axis operations. This adaptability enables manufacturers to create complex geometries and forms that were previously thought to be impossible. CNC machining provides options for both sides of the spectrum, whether it's manufacturing a huge number of standardized components or developing prototypes with a specific design in mind.

Reduced Turnaround Times: The days of laborious hand setups and modifications in manufacturing are long gone. CNC machining services automate most of the manual work, streamlining the production process. Manufacturing lead times are greatly shortened as a result of this setup time reduction and the ability to conduct automated, uninterrupted operations. Now, businesses can react quickly to market needs and design modifications without compromising on quality or efficiency.

Cost-Effectiveness

The long-term advantages of CNC machining technology are without a doubt worth the initial financial outlay, which might be significant. Once set up, the devices can run independently with little assistance from humans. Reduced labor costs, fewer mistake rates, and improved resource utilization result from this. Additionally, the accuracy of CNC machining reduces material waste, which helps to reduce total costs.

CNC machining businesses are at the vanguard of innovation, according to Innovation Unleashed. They constantly push the limits of what is possible by integrating cutting-edge software, simulation tools, and additive manufacturing processes. Complex design creation and quick prototype iteration have enabled ground-breaking developments in industries including aerospace, healthcare, automotive, and electronics.

Personalization and Customization

Personalization and customization are crucial in today's consumer-driven environment. CNC machining companies that provide CNC machining meet this need by giving customers the freedom to design one-of-a-kind items or small batches that are suited to certain specifications. This degree of personalization boosts consumer satisfaction while also creating new market opportunities and specialized markets.

#CNC Machining#CNC Machining services#CNC Machining companies#Custom CNC Machining Service#Online CNC Machining Services#3 axis CNC machines

3 notes

·

View notes

Text

An aluminum alloy belt disc with sandblasting and anodizing surface treatment, removing coarse material, the accuracy can reach to 0.002.

Website: https://www.ympcnc.com

Email: [email protected]

Mobile: +86 18938911183

2 notes

·

View notes

Text

https://www.rambabumfg.com/best-concrete-pump-parts-manufacturing-india.php

Precision CNC Machining Services India – Rambabu MFG

Get top-quality CNC machining services in India with Rambabu MFG. We offer precision engineering, custom solutions, and competitive pricing to meet your industrial needs.

0 notes

Text

Precision Metal Part Manufacturing with Fuson Precision Machining

Fuson offers a wide range of sheet metal services, including laser cutting, bending, stamping, and welding. Their CNC-based equipment allows for precise fabrication of complex shapes and components, making it ideal for a variety of applications, from automotive to electronics and everything in between. Whether you're creating prototypes or producing large quantities of metal parts, Fuson has the capabilities to handle your project with efficiency and accuracy.

0 notes

Text

Plastic CNC machining services

#prototyping#prototype#rapid prototyping#prototype machining#cnc machining#precision machining#machining parts#cnc plastic part#plastic cnc#cnc plastic#plastic machining#plastic cnc machining#cnc plastic machining#cnc machining service#cnc machining plastic parts#cnc machining parts#cnc plastic parts

2 notes

·

View notes

Text

Ultimate Guide to Precision CNC Machining: From Design to Delivery

Precision CNC machining services are essential for creating high-accuracy components used in industries like aerospace, automotive, and medical. This process involves designing parts using CAD software, selecting the right materials, and utilizing advanced CNC machines to achieve tight tolerances. Quality control and post-processing ensure durability and functionality, while timely delivery completes the cycle. Companies like Pangea Technologies excel in providing end-to-end precision CNC machining services, combining cutting-edge technology, skilled engineering, and rigorous quality checks. Whether for prototypes or large-scale production, Pangea Technologies delivers reliable, high-quality solutions, making them a trusted partner in precision manufacturing.

Understanding Precision CNC Machining Services

Precision CNC machining services involve the use of computer-controlled machines to manufacture parts with exceptional accuracy and consistency. These services are essential for industries such as aerospace, automotive, medical, and electronics, where even the smallest deviation can lead to significant issues. CNC machining ensures tight tolerances, high repeatability, and the ability to work with a variety of materials, including metals, plastics, and composites. Companies like Pangea Technologies specialize in providing state-of-the-art precision CNC machining services, leveraging advanced technology and skilled engineers to meet the most demanding requirements.

The Design Phase: Turning Ideas into Reality

The first step in precision CNC machining is the design phase. Engineers and designers use CAD (Computer-Aided Design) software to create detailed 3D models of the component. This phase is critical because it determines the feasibility, functionality, and manufacturability of the part. Pangea Technologies collaborates closely with clients during this phase, offering design-for-manufacturability (DFM) feedback to optimize the design for CNC machining. This ensures that the final product is not only functional but also cost-effective to produce.

Material Selection: The Foundation of Quality

Choosing the right material is crucial for the success of any precision CNC machining project. Factors such as strength, durability, thermal resistance, and machinability must be considered. Common materials used in CNC machining include aluminum, stainless steel, titanium, brass, and engineering plastics. Pangea Technologies provides expert guidance on material selection, helping clients choose the best option for their specific application. Their extensive material inventory ensures that clients have access to high-quality raw materials for their projects.

Machining Process: Precision at Its Finest

Once the design and material are finalized, the machining process begins. CNC machines, such as mills, lathes, and multi-axis machining centers, are programmed to follow the CAD model’s specifications. These machines use cutting tools to remove material from the workpiece, shaping it into the desired form. Precision CNC machining services offered by Pangea Technologies utilize advanced equipment, such as 5-axis CNC machines, to produce complex geometries with unparalleled accuracy. Their commitment to quality ensures that every part meets the highest standards.

Quality Control: Ensuring Perfection

Quality control is a critical aspect of precision CNC machining. Each part undergoes rigorous inspection using tools like coordinate measuring machines (CMMs), optical comparators, and surface finish testers. This ensures that the final product adheres to the specified tolerances and quality standards. Pangea Technologies employs a comprehensive quality control process, combining advanced inspection techniques with skilled technicians to guarantee the accuracy and reliability of every component.

Post-Processing: Adding the Finishing Touches

After machining, parts often require post-processing to enhance their appearance, functionality, or durability. Common post-processing techniques include anodizing, powder coating, polishing, heat treatment, and plating. These processes not only improve the part’s performance but also protect it from environmental factors like corrosion and wear. Pangea Technologies offers a wide range of post-processing services, ensuring that every component meets the client’s exact requirements. Their expertise in finishing techniques adds value to the precision CNC machining process.

Delivery: Bringing Your Vision to Life

The final step in the precision CNC machining journey is delivery. Once the parts have passed all quality checks and post-processing, they are carefully packaged and shipped to the client. Timely delivery is essential to ensure that the client’s production schedule remains on track. Pangea Technologies prides itself on its efficient logistics and reliable delivery services. Their commitment to customer satisfaction ensures that every project is completed on time and to the highest standards.

Conclusion

Precision CNC machining services are at the heart of modern manufacturing, enabling the production of high-quality, complex components with unmatched accuracy. From design to delivery, every step in the process requires expertise, advanced technology, and a commitment to quality. Companies like Pangea Technologies exemplify the best in precision CNC machining services, offering end-to-end solutions that meet the needs of diverse industries. By combining cutting-edge technology, skilled engineers, and a customer-centric approach, Pangea Technologies ensures that every project is a success. Whether you’re developing a prototype or scaling up production, partnering with a trusted provider like Pangea Technologies can help you achieve your goals with precision and efficiency. Embrace the future of manufacturing with precision CNC machining services that deliver results you can count on.

0 notes

Text

5 Key Industries That Rely on Precision CNC Machining Services

Precision CNC machining services play a crucial role in various industries, ensuring high accuracy, efficiency, and quality in manufacturing. The aerospace industry depends on CNC machining for complex components like turbine blades and aircraft parts. In the automotive sector, CNC machining helps produce engine components, transmission parts, and custom prototypes. The medical industry relies on CNC machining for surgical instruments, implants, and medical devices requiring extreme precision. The electronics industry benefits from CNC machining in manufacturing circuit boards, connectors, and enclosures. Lastly, the defense and military sector uses CNC machining for weapon systems, armor, and specialized equipment. These industries trust CNC technology for its reliability, repeatability, and ability to create intricate parts with tight tolerances.

Aerospace Industry: High-Tolerance Manufacturing

The aerospace industry demands extreme precision, reliability, and high-performance materials. Precision CNC machining services are essential for producing complex aircraft components such as turbine blades, engine housings, and landing gear parts. Advanced CNC milling and turning processes ensure tight tolerances, superior surface finishes, and compliance with stringent FAA and aerospace standards. The ability to machine lightweight materials like titanium and aluminum makes CNC machining a cornerstone of aerospace manufacturing.

Automotive Industry: Enhancing Efficiency and Performance

The automotive sector relies on CNC machining for manufacturing critical engine components, transmission systems, and brake parts. CNC lathes, milling machines, and multi-axis machining centers produce high-precision parts that enhance vehicle performance, fuel efficiency, and durability. The rapid prototyping capabilities of CNC machining also allow for the development of innovative automotive technologies, such as electric vehicle (EV) components and advanced driver-assistance systems (ADAS).

Medical Industry: Precision and Compliance in Healthcare

In the medical field, precision cnc machining services plays a vital role in producing surgical instruments, prosthetics, and complex implants. Medical-grade materials such as stainless steel, titanium, and PEEK require high-precision machining to meet FDA and ISO standards. Multi-axis CNC milling and micromachining ensure accuracy in producing intricate components like orthopedic screws, dental implants, and diagnostic equipment. CNC machining’s ability to maintain biocompatibility and sterility makes it indispensable in medical device manufacturing.

Electronics Industry: Micro-Machining for High-Tech Devices

The electronics industry benefits from CNC machining’s ability to manufacture precision components for circuit boards, connectors, and semiconductor equipment. Miniature parts require tight tolerances and ultra-fine machining to ensure optimal performance. CNC micro-machining processes enable the production of heat sinks, enclosures, and housings for consumer electronics, telecommunications, and industrial automation systems. The demand for miniaturization and advanced materials like copper and aluminum alloys makes CNC machining crucial in the electronics sector.

Defense and Military Industry: Durable and High-Performance Parts

The defense industry depends on precision cnc machining services for producing robust components used in firearms, armored vehicles, missile systems, and aerospace defense applications. CNC machining ensures high-strength materials like titanium, Inconel, and hardened steels meet the stringent requirements of military-grade equipment. Multi-axis CNC machining and EDM processes enhance precision and durability, ensuring mission-critical parts withstand extreme conditions and heavy operational loads.

Energy Sector: Precision in Renewable and Traditional Power Systems

From wind turbines to oil and gas extraction equipment, the energy sector requires high-precision CNC-machined parts. CNC machining supports the production of turbine blades, drilling components, and heat exchangers that must endure high pressures, extreme temperatures, and corrosive environments. Advanced CNC processes, such as 5-axis milling and CNC turning, allow for the fabrication of intricate components for renewable energy solutions, including solar panel frames and hydroelectric turbines.

Industrial Equipment Manufacturing: Custom Machined Components

Industrial machinery and automation systems rely on CNC machining for custom parts, gears, and bearings. CNC-machined components improve the efficiency and longevity of manufacturing equipment, robotics, and conveyor systems. With CNC milling, turning, and grinding, manufacturers can create durable and precise machine parts for diverse industrial applications. CNC machining’s adaptability ensures compatibility with materials like stainless steel, brass, and engineered plastics, meeting the high demands of industrial production.

Conclusion

Precision CNC machining services are the backbone of numerous industries, ensuring the production of high-quality, reliable, and complex components. Whether in aerospace, automotive, medical, electronics, defense, energy, or industrial manufacturing, CNC machining delivers accuracy, efficiency, and consistency. As technology advances, CNC machining continues to evolve, driving innovation and meeting the growing demands of modern industry. The combination of automation, multi-axis capabilities, and high-tolerance machining ensures CNC machining remains a critical force in global manufacturing.

0 notes