#CNC Machine Coolant

Explore tagged Tumblr posts

Text

🚀 Precision in Every Detail! ✨ Witness the raw beauty of this engine casing, flawlessly crafted using state-of-the-art 5-axis CNC machining. 💡 From intricate designs to complex geometries, our precision technology ensures unmatched accuracy and a surface finish so smooth it barely needs post-processing. Perfect for industries like aerospace and automotive, this is machining excellence at its best! 🛠️⚙️

👉 Like, share, and follow for more precision engineering marvels! 🎥

PrecisionMachining #5AxisCNC #CNCmachining #EngineeringExcellence #AerospaceParts #AutomotiveComponents #AdvancedManufacturing #MetalCrafting #SurfaceFinish #TechInnovation

#CNC Machine Basic Knowledge#CNC Machine Coolant#CNC Machine Finance#CNC Machine For Guitar#CNC Machine Game#CNC Machine Manufacturers#CNC Machine Offers For Internet#CNC Machine Operator Hiring#CNC Machine Operator Recruitment#CNC Machine Panel#CNC Machine Purchase#CNC Machine Services#CNC Machine Shop Near Me#CNC Machine Suppliers#CNC Machine Types#CNC Machine What Does It Do#CNC Machine X Carve

1 note

·

View note

Text

High-Speed 90 Degree Angle Head for CNC

Unlock precision in tight spaces with Kuvam Technologies' high-speed 90 degree angle head for CNC. Designed for VMCs, with coolant-through and ATC compatibility, they enable flawless milling, drilling, and tapping at over 5000 RPM. Boost productivity, extend tool life, and achieve superior finishes in complex machining operations. Custom-built for durability with hardened alloy steel.

URL:https://kuvamtechnologies.com/high-speed-90-degree-angle-head-for-cnc/

#High-Speed 90 Degree Angle Head for CNC#CNC right angle head for high-speed machining#precision toolholding attachments for CNC#coolant-through 90 degree angle head CNC

0 notes

Text

Uncloged a cnc machines coolant vent, which cause me to take a nice bath in stagnant coolant.

I very much need a shower now

64 notes

·

View notes

Video

youtube

Slant Bed vs. Flat Bed CNC Lathe: Which One is Perfect for You#SlantBedL...

Are you trying to decide between a Slant Bed CNC Lathe and a Flat Bed CNC Lathe for your machining needs?

In this video, we break down the ultimate comparison between these two CNC lathe designs—from performance and applications to costs and maintenance.

🎯 What You'll Learn in This Video:

Key differences between Slant Bed and Flat Bed CNC Lathes.

Which lathe suits high-speed production and which one is ideal for heavy-duty machining.

Cost analysis and ROI insights for smarter investments.

Expert tips to help you make the right choice for your business.

💡 Highlights:

✔️ Slant Bed Lathes are compact, fast, and precise, perfect for industries like automotive and aerospace.

✔️ Flat Bed Lathes are sturdy, durable, and powerful, ideal for oil, gas, and construction sectors.

👉 Read the full blog for more details:

Click here Video Outline Introduction Welcome to the video! Quick overview of why choosing the right CNC lathe design is critical for your business.

Mention the two CNC lathe types we’ll be comparing: Slant Bed and Flat Bed. Part 1: What Is a CNC Lathe? Brief explanation of CNC lathes and their importance in modern machining. Examples of industries where CNC lathes are indispensable (e.g., aerospace, automotive, oil, gas).

Key features of CNC lathes, such as precision, repeatability, and automation options. Part 2: Design Differences Slant Bed CNC Lathes: Angled bed design (30–45°) for better chip evacuation.

Compact footprint and ergonomic layout. Multi-tool setups with turret systems (e.g., 12-station turrets).

Flat Bed CNC Lathes: Horizontal bed for stability and heavy-duty machining. Larger swing diameters and higher load capacities (up to 5 tons).

Requires manual chip removal or conveyor systems.

Part 3: Performance Metrics Speed and Efficiency: Slant Bed: Up to 4,500 RPM, reducing cycle times by 15–20%.

Flat Bed: Lower speed (up to 2,500 RPM) but higher torque for heavy cuts. Precision and Accuracy: Both achieve tolerances of ±0.002 mm.

Slant Bed: Superior coolant flow reduces thermal expansion by 10%. Flat Bed: Excellent precision under heavy loads but requires frequent chip management.

Part 4: Applications Slant Bed Lathes: High-volume production, ideal for precision parts like pistons and aerospace fittings. Automation-friendly with bar feeders and robots.

Flat Bed Lathes: Heavy-duty machining, perfect for large workpieces like pump shafts and rollers. Popular in industries like oil, gas, and construction. Part 5: Cost and ROI Analysis Initial investment:

Slant Bed: $5,000–$50,000.

Flat Bed: $5,000–$40,000.

Operational Costs: Slant Bed: Lower energy consumption and maintenance costs. Flat Bed: Higher durability for long-term heavy-duty use.

ROI: Slant Bed recovers costs faster in high-production environments (3–4 years). Flat Bed suits long-term heavy-duty projects (4–6 years). Part 6: Final Thoughts and Recommendations Recap the pros and cons of each CNC lathe type.

Advice on choosing the right lathe based on: Workpiece size. Production volume. Industry requirements. Encourage viewers to explore Haishu Machinery’s blog for more details and insights.

#CNCLathe #SlantBedLathe #FlatBedLathe #MachiningSolutions #PrecisionMachining #HaishuMachinery #MetalMachining #CNCManufacturing #Engineering

#youtube#CNCLathe#SlantBedLathe#FlatBedLathe#MachiningSolutions#PrecisionMachining#HaishuMachinery#MetalMachining#CNCManufacturing#Engineering

1 note

·

View note

Text

Maintenance Tips for Your CNC Turning Machine by MechPlus China

As a leading CNC turning machine manufacturing, MechPlus China understands the importance of proper maintenance to ensure precision and efficiency. Regular upkeep not only extends the machine's lifespan but also maximizes productivity and quality. Here are essential maintenance tips from MechPlus China to keep your CNC turning machine running smoothly and efficiently.

Keeping your CNC turning machine in top condition is crucial for optimal performance. Regular maintenance not only extends the machine's lifespan but also ensures precision and efficiency in your operations. Here are essential maintenance tips to keep your CNC turning machine running smoothly.

Daily Inspection and Cleaning

Start each day with a thorough inspection of your CNC turning machine. Check for any signs of wear and tear, and ensure all components are in good working order. Clean the machine daily to remove any debris, chips, and coolant residue. This prevents buildup that can affect performance and accuracy.

Lubrication

Proper lubrication is vital for the smooth operation of your CNC turning machine. Lubricate all moving parts as recommended by the manufacturer. This includes the spindle, guideways, and ball screws. Regular lubrication reduces friction, prevents wear, and extends the machine’s life.

Coolant Maintenance

Maintaining the coolant system is essential for the longevity of your CNC machine. Regularly check the coolant level and concentration. Replace or refill the coolant as needed. Also, clean the coolant tank and filters to avoid contamination that can damage the machine and workpieces.

Alignment and Calibration

Ensure that your CNC turning machine is properly aligned and calibrated. Misalignment can lead to inaccuracies in your machining processes. Regularly check and adjust the machine’s alignment and calibration according to the manufacturer’s guidelines. This ensures precision in your operations.

Check Electrical Components

Inspect the electrical components of your CNC turning machine regularly. Look for any loose connections, worn-out wires, or faulty switches. Address any electrical issues immediately to prevent machine downtime and potential safety hazards.

Monitor Machine Vibration

Excessive vibration can lead to poor machining quality and damage to your CNC turning machine. Monitor the machine for any unusual vibrations or noises during operation. Identify and address the source of the vibration to maintain optimal performance.

Regular Software Updates

Keep your CNC machine’s software up to date. Manufacturers often release updates that improve functionality and fix bugs. Regularly updating the software ensures your machine operates efficiently and takes advantage of the latest technological advancements.

Tool Maintenance

Regularly inspect and maintain the cutting tools used in your CNC turning machine. Sharp and well-maintained tools are crucial for high-quality machining. Replace worn or damaged tools promptly to ensure precise and efficient operation.

Preventive Maintenance Schedule

Implement a preventive maintenance schedule for your quick response machining tool. Follow the manufacturer’s recommended maintenance intervals for all components. Regular preventive maintenance helps identify potential issues before they become major problems, reducing downtime and repair costs.

Training and Safety

Ensure that all operators are properly trained in the maintenance and operation of the CNC turning machine. Regular training updates and adherence to safety protocols are crucial for preventing accidents and ensuring smooth operations.

Document Maintenance Activities

Keep detailed records of all maintenance activities performed on your CNC turning machine. Documenting maintenance helps track the machine’s condition over time and provides valuable information for troubleshooting and repairs with all types of customized machining parts.

In conclusion, regular maintenance of your CNC turning machine is essential for its longevity and performance. By following these tips, you can ensure your machine operates efficiently, reducing downtime and improving the quality of your machining processes. Implement these maintenance practices to keep your CNC turning machine in optimal condition.

#Prototyping solutions#SLA Rapid Prototyping manufacturing#SLS Rapid machining manufacturing#5 Axis CNC machining manufacturing#3D metal printing manufacturing

2 notes

·

View notes

Text

Revolutionizing Precision Manufacturing with CNC Grinding, Gundrilling, and Steering Machines

In order to fulfill demands, business houses including the aerospace and automotive segments are trying out more and more innovations to improve the manufacturing processes in which efficiency and precision are considered vital.

To that note, WIDMA sets itself apart as a brand that personifies innovation and quality. With a lengthy history that dates back to 1984, the brand has consistently raised the standard for the accuracy of machining operations. Setting the standard for innovative solution development, WIDMA expertly blends its unparalleled experience to continuously create and enhance cutting-edge technologies. Here, at the cutting edge of precision engineering, excellence comes from WIDMA's unwavering dedication.

Technologies which revolutionized and brought these changes are Gundrilling, CNC and Steering machines. These machines played a crucial role and revolutionized Precision Manufacturing and ultimately changed the industry once and for all.

CNC Grinding Machines: The Art of Precision

It is considered as the cornerstone of modern precision production. Fully automated, these tools can mold and grind material with acute precision. Complicated medical devices as well as components for the aerospace industry use CNC Grinding machines for producing 100% precise products

Computer-controlled grinding wheels remove the unwanted material. It's precise and meets exact specifications. It is maintained that slightest deviation can lead to complete disaster. In other words CNC ensures highest quality end products.

Gundrilling Machines: Delving Deep into Precision

Gundrilling machines are considered as another cornerstone in precision manufacturing. These machines make holes with accuracy.Therefore industries that require long, narrow holes, such as the automotive sector for engine components and the aerospace industry for aircraft landing gear use these machines.

Gundrilling machines make holes with depth that exceeds their diameter.The precision achieved ensures the components fit seamlessly ,negating risk of malfunction and enhancing product quality. Gundrilling machines operate at high speed. It is empowered with coolant systems to ward off heat and evacuate chips effectively.

Navigating the Future of Automotive Precision

In the car business safety, dependability, and accuracy are essential.Therefore steering machines are crucial. In the automobile industry, steering wheels need to be dependable and so are a crucial unit of manufacture in the automotive industry. Steering machines require a higher level of precision. Modern steering systems use cutting-edge technology like steer-by-wire and electric power steering (EPS).

Steering machines can shape and assemble components with a high level of accuracy.They are intricately designed to handle the intricate modern steering system.They shape the assembled components with tight adjustment and ensure a smooth steering performance.they help in reduction of energy consumption and ensure fuel efficiency .

Synergy of CNC Grinding, Gundrilling, and Steering Machines

It is indisputable that these three work well together. Together they produce intricate parts. Gundrilling machines, for example, are excellent at producing the precisely drilled holes needed for steering machines. Following the drilling of the holes, the dimensional accuracy and surface smoothness are checked using CNC grinding equipment to ensure they meet the required standards.

For instance, when landing gear components are manufactured in the aerospace industry, intricate steering systems with deep holes are created. The integration of CNC grinding machinery and gundrilling equipment ensures that these components not only meet safety standards but also enhance the overall performance and efficiency of the aircraft.

The Future of Precision Manufacturing

In precision production, CNC grinding, gundrilling, and steering machines have become essential instruments. They enable companies to manufacture parts with unmatched precision. By guaranteeing efficiency and safety in a range of applications, they stand well ahead of their competition.

These devices will become progressively more important in determining the direction of manufacturing. They have the potential to enable advances that were previously unthinkable. This is due to their capacity to achieve precision at the nano level.

The continuous pursuit of perfection in precision production through the use of CNC gundrilling, grinding, and steering equipment portends a more promising, secure, and effective future for global industry.

2 notes

·

View notes

Text

7 Essential 4 Axis Components Available in India

Uncover the 7 must-have 4 axis components in India. Elevate your engineering projects with reliable and high-quality components tailored for success.

Top 4 Axis Machining Suppliers in India for Precision Components

In today’s fast-paced manufacturing world, 4 Axis Machining has emerged as a powerful solution for precision engineering. Whether you're in aerospace, automotive, or mold-making, the demand for complex, high-accuracy parts is growing rapidly. To keep up, manufacturers turn to advanced 4 Axis Components India and reliable 4 Axis Machining Suppliers like Sinnar Ureplas — a leading name in the CNC machining industry.

Here’s a breakdown of the 7 essential 4 Axis components that every modern manufacturing unit in India should know about.

1. Rotary Table

The rotary table is the cornerstone of 4 Axis machining. It allows the part to rotate around the X-axis, enabling access to different sides of the workpiece without manual repositioning. High-quality rotary tables improve efficiency, reduce errors, and ensure complex geometries can be machined in one go.a trusted 4 Axis Machining Suppliers , integrates premium rotary tables into their CNC machines for maximum accuracy.

2. Precision Spindle Motor

The spindle motor powers the cutting tool and defines the machine’s ability to handle various materials like aluminum, steel, and titanium. In 4 Axis machining, the spindle must be robust, high-speed, and capable of variable RPMs to ensure smooth surface finishes. As one of the top 4 Axis Components India manufacturers, it uses only industrial-grade spindle motors tailored for demanding applications.

3. Ball Screws and Linear Guideways

These components are critical for accurate movement and positioning of the machine's axes. Ball screws ensure zero backlash, while linear guideways reduce friction and wear. Together, they provide smooth, precise movements that are essential in industries where micron-level tolerances matter. Suppliers like Sinnar Ureplas ensure these components meet global ISO standards.

4. Control System (CNC Controller)

The CNC controller acts as the brain of the machine, interpreting G-code and managing all motion commands. For 4 Axis machining, a high-performance controller is a must—it allows for dynamic movement along X, Y, Z, and A axes. Leading 4 Axis Machining Suppliers in India, including, utilize top-tier controllers like Siemens and Fanuc to ensure smooth operation and easy integration.

5. Workholding Fixtures

Workholding plays a vital role in 4 Axis machining. Special fixtures and clamps are needed to secure parts while allowing rotation on the fourth axis. Custom fixtures designed for high-precision tasks are part of the core offering from expert4 Axis Components India manufacturers like ensuring your workpiece stays stable even during complex milling.

6. Coolant Delivery Systems

Coolants keep tools from overheating and help remove chips from the cutting area. In 4 Axis setups, high-pressure coolant delivery systems are engineered to reach difficult angles. Efficient coolant systems improve tool life and surface finish—something that Sinnar Ureplas emphasizes in all their CNC machinery designs.

7. Tool Changers

Automated tool changers reduce downtime by allowing multiple tools to be used in a single cycle. In 4 Axis machining, tool changers must be fast, accurate, and compatible with various tool holders. As a trusted name among 4 Axis Components India integrates automatic tool changers that boost production capabilities and ensure seamless transitions between different machining operations.

Why Choose Sinnar Ureplas for 4 Axis Components in India?

is a pioneer in providing advanced CNC solutions. With a robust infrastructure, ISO-certified quality systems, and a team of highly skilled professionals, they are setting benchmarks for 4 Axis Components India. Their machines are known for:

Precision and repeatability

Customizable solutions

Quick delivery timelines

Affordable pricing with premium performance

Whether you're looking to upgrade your production capabilities or source high-quality components, Sinnar Ureplas offers everything you need under one roof.

The rise of 4 Axis machining has revolutionized manufacturing in India. Understanding and investing in the right components—like rotary tables, spindle motors, and tool changers—can drastically improve efficiency and accuracy. With trusted 4 Axis Machining Suppliers like Sinnar Ureplas, Indian manufacturers can access world-class components and achieve global competitiveness.

Visit: https://sinnar-ureplas.com/4-axis-machining-manufacturers-suppliers-india.phpContact: +91 8975322242

0 notes

Text

Sikka Sales – Precision Traub Parts and Collets for Efficient CNC Operations

When it comes to high-precision CNC machining, the smallest component can make the biggest impact.

The quality of collets, Traub accessories, and tool-holding components directly influences machining efficiency, repeatability, and output quality.

One name that consistently delivers on all these fronts is Sikka Colletsin.

Established in 1978, Sikka has earned its place as a leading collet manufacturer in India and a globally recognized collet exporter.

Known for reputation, delivery, and quality, Sikka Sales Corporation is the trusted source for premium Traub collets, ER collets, DIN collets, 5C collets, collet chucks, feed fingers, and other vital Traub parts designed for modern CNC operations.

Why Collets Are Critical in CNC Machining

Precision machining begins with how well your workpiece is held. Collets provide high concentricity, consistent clamping force, and minimal runout.

They are essential for industries where dimensional accuracy, surface finish, and process speed are non-negotiable.

Sikka’s range of collets and Traub accessories supports CNC lathes, SPMs, automatic Traub machines, and toolrooms — delivering unmatched grip strength and reliability even at high speeds.

Comprehensive Product Portfolio by Sikka Colletsin

Traub Collets

Sikka manufactures a wide range of Traub collets including A-25, A-32, A-42, and A-60, suitable for Traub automatic lathes and sliding head machines. These are engineered to withstand the demands of high-speed, high-precision production.

ER Collets

Our ER collets are designed for CNC machining centers and milling operations, offering 1mm clamping flexibility and high elasticity for various tool sizes.

DIN Collets

Designed to meet European DIN standards, DIN collets from Sikka are ideal for users seeking compatibility with European machines without compromising on precision.

5C Collets

Sikka's 5C collets are popular in toolrooms and are perfect for short production runs, inspection fixtures, and light-duty CNC setups.

Collet Chucks & Feed Fingers

We manufacture robust collet chucks and feed fingers that integrate seamlessly with Traub and CNC machines. Our designs ensure firm clamping, longer tool life, and quick part changeover.

Precision Traub Accessories for Modern Machines

Beyond collets, Sikka Colletsin provides a full range of Traub accessories and components to streamline operations and enhance productivity. These include:

Expanding mandrels

Milling adaptors

Split sleeves

Spindles & fixtures

CNC revolving centers

SPM collets

Each part is manufactured under strict quality control to ensure durability and compatibility with global CNC standards.

Why Choose Sikka Colletsin?

Heritage of Quality

With over four decades of engineering excellence, Sikka is a name synonymous with precision and consistency. As a top collet manufacturer, we serve thousands of satisfied clients across India and abroad.

Trusted Collet Exporter in India

Sikka Colletsin is a preferred collet exporter for industries across Germany, Japan, the UAE, and Southeast Asia. We maintain full compliance with international specifications and ensure fast, secure global delivery.

Manufacturing Expertise

Our in-house team of engineers and toolmakers has extensive experience in designing and producing all types of collets, collet chucks, Traub parts, and specialty CNC tooling components.

Tailored Solutions

Need a specific geometry or size? We provide customized collets and accessories to suit unique machine configurations and project needs.

Applications Across Industries

Sikka Collets are widely used in:

Automotive & Auto-ancillary

Aerospace Components

Medical Device Manufacturing

Watch and Micro-part Machining

General Engineering & Toolrooms

Maintenance Tips for Long-Lasting Collets and Accessories

To maximize performance and durability:

Clean collets after each use to remove swarf and coolant

Apply anti-rust lubricant before storage

Check for surface wear or cracks regularly

Replace damaged collets to maintain toolholding precision

Use matched collet chucks and feed fingers to prevent misalignment

Frequently Asked Questions

Q1: What makes Sikka a top collet manufacturer in India? Our ISO-certified processes, vast product range, and long-standing industry presence since 1978 make Sikka a trusted leader in the collet manufacturing space.

Q2: Do you export collets internationally? Yes. Sikka is a leading collet exporter in India, shipping high-quality Traub collets, DIN collets, and ER collets to customers globally.

Q3: What types of machines are your collets compatible with? Our collets and accessories are suitable for Traub machines, CNC turning centers, milling machines, and SPMs.

Q4: Do you offer customized tooling solutions? Absolutely. We specialize in custom collets, adaptors, and Traub parts designed to meet client-specific machining requirements.

Conclusion: Choose Sikka Colletsin for CNC Precision That Performs

When you choose Sikka Sales, you're investing in over 45 years of tool-holding innovation, machining accuracy, and customer satisfaction. From Traub collets and collet chucks to feed fingers, DIN collets, and more — every product we manufacture is a testament to our uncompromising quality and engineering precision.

0 notes

Text

Transforming a solid steel column into a precise wheel in one seamless operation—this is the pinnacle of 𝐟𝐢𝐧𝐞 𝐰𝐨𝐫𝐤𝐦𝐚𝐧𝐬𝐡𝐢𝐩 and cutting-edge 𝟓-𝐚𝐱𝐢𝐬 𝐂𝐍𝐂 𝐭𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐲. In this demonstration, we showcase:

✅ Unparalleled precision in every contour and curve ✅ The efficiency of machining complex geometries in a single setup ✅ The capability to deliver rapid prototyping with flawless results

𝐏𝐫𝐨 𝐭𝐢𝐩: Achieving such precision requires meticulous planning, the right toolpath strategies, and top-quality materials like stainless steel and titanium alloys.

Curious about how 5-axis machining can elevate your projects? Let us know your thoughts or share your experience in the comments below!

#CNCMachining #5AxisCNC #PrecisionEngineering #RapidPrototyping #GreatLightMachining

Contact Us Get More Info:

GreatLight Metal Technology Co., Ltd

✅ Website: https://glcncmachining.com/ ✅ Website: https://cnc-5-axis.com/ ✅ #10, Xinrong Street, Chongtou Community, Chang'an Town, Dongguan City, Guangdong, China, 523845 ✅ + 86 180 2756 7310 ✅ + 86 180 2756 7310(whatsapp) ✅ [email protected]

#CNC Machine Basic Knowledge#CNC Machine Coolant#CNC Machine Finance#CNC Machine For Guitar#CNC Machine Game#CNC Machine Manufacturers#CNC Machine Offers For Internet#CNC Machine Operator Hiring#CNC Machine Operator Recruitment#CNC Machine Panel

0 notes

Text

Cnc Tool Grinding Machines Market Size, Trends, Restraints & Future Outlook 2032

Global CNC Tool Grinding Machines Market Overview The Global CNC Tool Grinding Machines Market is currently experiencing steady growth driven by advancements in manufacturing technology and increasing demand for high-precision tooling. Valued at approximately USD 1.2 billion in 2024, the market is projected to grow at a compound annual growth rate (CAGR) of around 6-7% over the next 5 to 10 years. This growth is fueled by the rising adoption of automated machining processes, increased focus on tool life optimization, and the growing complexity of components in sectors such as automotive, aerospace, and industrial machinery. Key factors influencing market expansion include the integration of Industry 4.0 principles, the rise of smart manufacturing, and the demand for high-speed, high-accuracy grinding solutions that reduce downtime and improve operational efficiency. Additionally, emerging economies investing in industrial infrastructure modernization contribute significantly to the market’s size and growth trajectory. Global CNC Tool Grinding Machines Market Dynamics Drivers: The primary growth drivers include increasing automation in manufacturing plants, rising need for precision and consistency in tool grinding, and the expansion of end-user industries such as automotive and aerospace. Enhanced machine capabilities with multi-axis CNC technology allow for complex tool geometries, boosting productivity and reducing errors. Restraints: Despite positive momentum, challenges such as high capital investment, complex maintenance requirements, and a shortage of skilled operators can limit market expansion. Additionally, fluctuating raw material costs and geopolitical tensions may disrupt supply chains, impacting production timelines and costs. Opportunities: There are significant opportunities in adopting AI-driven diagnostics, real-time monitoring systems, and cloud-based machine controls that enable predictive maintenance and enhanced machine uptime. Growing environmental regulations are pushing manufacturers to develop more energy-efficient, sustainable grinding machines, opening avenues for innovation and competitive differentiation. Regulatory frameworks emphasizing workplace safety and emissions control are shaping the development of next-generation CNC tool grinding machines. Compliance with stringent standards encourages manufacturers to innovate in eco-friendly and low-noise machinery designs. Download Full PDF Sample Copy of Global Cnc Tool Grinding Machines Market Report @ https://www.verifiedmarketresearch.com/download-sample?rid=424522&utm_source=PR-News&utm_medium=361 Global CNC Tool Grinding Machines Market Trends and Innovations Emerging trends include the integration of artificial intelligence (AI) and machine learning algorithms for adaptive grinding processes, improving precision and reducing human intervention. Hybrid grinding machines combining conventional grinding with laser or ultrasonic technologies are gaining traction for enhanced performance and reduced cycle times. Collaborative ventures between CNC machine tool manufacturers and software developers are facilitating the creation of smart grinding ecosystems. These platforms leverage IoT connectivity to enable real-time data analytics, remote diagnostics, and seamless integration with manufacturing execution systems (MES). Another key innovation is the development of eco-friendly grinding coolants and lubricants that minimize environmental impact and improve operator safety. The push towards digital twins and virtual simulation allows manufacturers to optimize machine settings before actual production, reducing trial-and-error costs. Global CNC Tool Grinding Machines Market Challenges and Solutions The market faces several challenges, including supply chain disruptions caused by geopolitical uncertainties and raw material scarcity. These issues lead to increased lead times and cost volatility. Manufacturers can mitigate these risks by diversifying suppliers,

adopting localized sourcing strategies, and investing in inventory management technologies. Pricing pressures due to intense competition and commoditization of basic machine models pose another challenge. Companies can overcome this by focusing on value-added services such as predictive maintenance, extended warranties, and customizable machine solutions tailored to specific industry needs. Regulatory barriers related to emissions and workplace safety require ongoing investments in R&D for compliance-ready technologies. Collaborative efforts between industry bodies and regulatory agencies can help streamline certification processes and encourage innovation while maintaining safety standards. Global CNC Tool Grinding Machines Market Future Outlook The CNC Tool Grinding Machines market is poised for sustained growth driven by technological advancements and expanding end-user demand. The evolution towards smart factories and digitalized production environments will necessitate more sophisticated grinding solutions capable of real-time adaptation and enhanced precision. Investment in AI, IoT, and sustainable manufacturing practices will be primary growth factors shaping the market over the next decade. Furthermore, increasing adoption in emerging regions such as Asia-Pacific, Latin America, and Eastern Europe will provide significant growth opportunities. In conclusion, the global CNC tool grinding machines market is on a strong growth path, with innovation and sustainability at the core of its future development. Companies that can effectively navigate technological changes and regulatory requirements while addressing supply chain and pricing challenges will lead the competitive landscape. Global Cnc Tool Grinding Machines Market Competitive Landscape The Global Cnc Tool Grinding Machines Market competitive landscape is characterized by intense rivalry among key players striving to gain market share through innovation, strategic partnerships, and expansion initiatives. Companies in this market vary from established global leaders to emerging regional firms, all competing on parameters such as product quality, pricing, technology, and customer service. Continuous investments in research and development, along with a focus on sustainability and digital transformation, are common strategies. Mergers and acquisitions further intensify the competition, allowing companies to broaden their portfolios and geographic presence. Market dynamics are influenced by evolving consumer preferences, regulatory frameworks, and technological advancements. Overall, the competitive environment fosters innovation and drives continuous improvement across the Global Cnc Tool Grinding Machines Market ecosystem. Get Discount On The Purchase Of This Report @ https://www.verifiedmarketresearch.com/ask-for-discount?rid=424522&utm_source=PR-News&utm_medium=361 Global Cnc Tool Grinding Machines Market Segmentation Analysis The Global Cnc Tool Grinding Machines Market segmentation analysis categorizes the market based on key parameters such as product type, application, end-user, and region. This approach helps identify specific consumer needs, preferences, and purchasing behavior across different segments. By analyzing each segment, companies can tailor their strategies to target high-growth areas, optimize resource allocation, and improve customer engagement. Product-based segmentation highlights variations in offerings, while application and end-user segmentation reveal usage patterns across industries or demographics. Regional segmentation uncovers geographical trends and market potential in emerging and developed areas. Global Cnc Tool Grinding Machines Market, By Type Global Cnc Tool Grinding Machines Market, By Application Global Cnc Tool Grinding Machines Market, By End User Global Cnc Tool Grinding Machines Market, By Geography • North America• Europe• Asia Pacific• Latin America• Middle East and Africa For More Information or Query, Visit @ https://www.verifiedmarketresearch.com/product/cnc-tool-grinding-machines-market/

About Us: Verified Market Research Verified Market Research is a leading Global Research and Consulting firm servicing over 5000+ global clients. We provide advanced analytical research solutions while offering information-enriched research studies. We also offer insights into strategic and growth analyses and data necessary to achieve corporate goals and critical revenue decisions. Our 250 Analysts and SMEs offer a high level of expertise in data collection and governance using industrial techniques to collect and analyze data on more than 25,000 high-impact and niche markets. Our analysts are trained to combine modern data collection techniques, superior research methodology, expertise, and years of collective experience to produce informative and accurate research. Contact us: Mr. Edwyne Fernandes US: +1 (650)-781-4080 US Toll-Free: +1 (800)-782-1768 Website: https://www.verifiedmarketresearch.com/ Top Trending Reports https://www.verifiedmarketresearch.com/ko/product/south-africa-grain-market/ https://www.verifiedmarketresearch.com/ko/product/south-america-food-enzymes-market/ https://www.verifiedmarketresearch.com/ko/product/south-africa-smart-grid-network-market/ https://www.verifiedmarketresearch.com/ko/product/asean-e-commerce-logistics-market/ https://www.verifiedmarketresearch.com/ko/product/europe-south-east-asia-and-middle-east-pickled-vegetables-market/

0 notes

Text

Tube Sheet Drilling: Precision Engineering for Heat Exchanger Efficiency

Introduction to Tube Sheet Drilling

Tube sheet drilling is a highly specialized machining process used to create accurate and aligned holes in tube sheets—critical components in heat exchangers, boilers, pressure vessels, and condenser systems. These precision-drilled holes allow for the insertion and secure mounting of heat exchange tubes, ensuring optimal thermal transfer efficiency and mechanical stability.

With increasing demands in petrochemical, oil & gas, power generation, and chemical industries, high-precision tube sheet drilling has become more essential than ever for leak-proof, high-pressure, and high-temperature applications.

What is a Tube Sheet?

A tube sheet is a thick metal plate, typically made from carbon steel, stainless steel, copper alloys, or nickel-based alloys, that holds tubes in position within a heat exchanger or similar device. These plates are drilled with hundreds or even thousands of holes, each of which must be precisely located and dimensioned to ensure proper tube alignment and flow dynamics.

Tube sheets may be:

Flat or flanged

Cladded or solid

Fixed or floating

The integrity of tube sheet drilling directly influences the operational efficiency and lifespan of the entire equipment.

Key Features of Tube Sheet Drilling

1. Ultra-Precision Hole Placement

Hole pitch accuracy within ±0.02 mm

Accurate alignment for seamless tube-to-sheet welding or expansion

Support for complex configurations like square, triangular, or staggered pitch patterns

2. Custom Hole Diameters

Hole diameters typically range from 10 mm to 50 mm

Precision tools for countersinking, reaming, and chamfering as per design requirements

3. CNC and Multi-Spindle Drilling Options

CNC drilling offers repeatability, speed, and automation

Multi-spindle heads reduce cycle time by drilling multiple holes simultaneously

Option to program tool paths, feed rates, and depths

4. Compatibility with Multiple Materials

High-speed steel and carbide-tipped drill bits for superior performance

Capability to drill cladded tube sheets (e.g., stainless steel + carbon steel)

Coolant-fed tools and optimized cutting conditions to handle exotic alloys

Applications of Tube Sheet Drilling

1. Heat Exchangers

Critical for U-tube heat exchangers, shell & tube designs, and double-pipe configurations

Precise drilling ensures efficient thermal conductivity and mechanical locking

2. Boilers and Pressure Vessels

Supports high-pressure operations

Helps in achieving zero-leakage expansion joints

3. Oil Refineries and Chemical Plants

Used in corrosive environments where precision and metallurgy are key

Hole alignment ensures uninterrupted flow of process fluids

4. Power Generation and Nuclear Plants

Used in superheaters, economizers, and condenser systems

Requires radiographic inspection compliance for nuclear-grade tube sheets

Tube Sheet Drilling Process: Step-by-Step

1. Design and Layout Preparation

3D CAD models or 2D technical drawings created for hole mapping

Pitch, margin, and hole count are finalized

2. Material Preparation

Tube sheets undergo annealing, cleaning, and marking

Plate thickness checked (often ranges from 20 mm to 200 mm)

3. CNC Drilling Operation

CNC-controlled drill head moves in X-Y coordinates

Drilling depth, diameter, and tolerance pre-set for each hole

Coolant system active to prevent heat build-up and tool wear

4. Finishing

Chamfering or reaming if needed

Deburring for smooth hole edges

Non-destructive testing (NDT) to check hole accuracy and spacing

Advanced Technologies in Tube Sheet Drilling

1. Deep Hole Drilling Machines

Capable of handling thick tube sheets over 150 mm

Specialized gun drilling or BTA (Boring & Trepanning Association) methods used

2. Laser Drilling (For Special Alloys)

Non-contact, heat-concentrated drilling

Used where traditional tooling may not work (e.g., titanium, Inconel)

3. Robotic Drilling Systems

Fully automated arms integrated with CAD/CAM

Ideal for custom tube sheets or small production batches

Quality Control and Inspection

1. Dimensional Inspection

Coordinate Measuring Machines (CMM) used for verifying hole positions

Ensures compliance with ASME, TEMA, and ISO standards

2. Surface Integrity Checks

Inspection for burrs, cracks, or work hardening

Use of penetrant testing (PT) and ultrasonic testing (UT)

3. Fit-Up Verification

Tube insertion test to validate hole alignment and tightness

Simulates real working conditions under thermal and hydraulic stress

Choosing the Right Tube Sheet Drilling Partner

When selecting a supplier for tube sheet drilling, consider the following:

Experience in large-diameter tube sheets

Capability for high-volume or prototype jobs

Access to modern CNC drilling machines

Compliance with international QA/QC standards

In-house NDT and post-drilling inspection systems

Conclusion

Tube sheet drilling is more than just a machining task—it is an engineering-critical operation that demands micron-level accuracy, repeatability, and material adaptability. As industries continue to evolve towards energy efficiency and system reliability, precision-drilled tube sheets form the backbone of high-performance heat exchange systems. Investing in advanced tube sheet drilling solutions means investing in long-term operational safety, energy conservation, and system longevity.

1 note

·

View note

Text

Introduction: The Precision Problem in Exotic Metal Machining

Industrial business owners across the U.S. know the value of high-performance metals like Inconel, tungsten, tantalum, and niobium. These exotic metals are essential in aerospace, defense, and energy applications for their resistance to heat, corrosion, and wear. However, machining them comes with a unique set of challenges.

This article explores the technical hurdles and offers proven best practices for machining exotic metals—helping manufacturers achieve superior performance and cost efficiency.

Why Machining Exotic Metals Is So Challenging

Exotic metals aren't like your standard stainless steels or aluminum. They behave differently under heat and pressure. Here's why machining them requires more than just upgraded tools:

1. Extreme Hardness & Brittleness

Tungsten and molybdenum are notoriously brittle.

Inconel work-hardens quickly, dulling tools fast.

2. Thermal Expansion Issues

High-temperature resistance = poor heat dissipation.

Causes built-up edge (BUE) and rapid tool wear.

3. Non-Standard Tooling

Requires carbide, ceramic, or even diamond tooling.

Standard high-speed steel (HSS) won’t cut it.

4. Chip Control Problems

Metals like titanium and Inconel produce stringy, unbroken chips.

Leads to poor surface finish and machine jams.

Best Practices for Machining Exotic Metals

To counteract these issues, follow these proven best practices:

✅ Use Rigid Setups

Ensure minimal vibration and tool deflection.

CNC lathes and 5-axis machines improve precision.

✅ Apply Proper Coolant Strategies

Use high-pressure, targeted coolant delivery.

Improves chip evacuation and tool life.

✅ Optimize Speeds and Feeds

Lower speeds with higher feeds often work best.

Prevents excessive heat and work hardening.

✅ Invest in Coated Carbide or Ceramic Tools

Ideal for high-temp alloys like Inconel.

CVD-coated inserts enhance durability.

✅ Conduct Test Cuts

Especially when working with ultra-hard or rare alloys.

Helps calibrate for material-specific behavior.

Commonly Used Exotic Metals and Their Machining Tips

Metal

Key Tip

Inconel

Use negative rake inserts, reduce heat via flood coolant

Tungsten

Keep feed rate high to avoid brittleness cracks

Titanium

Use sharp, coated tools; avoid rubbing cuts

Tantalum

Use slow speed & shallow passes to minimize tool load

Long-Term Benefits of Mastering Exotic Metal Machining

Improved product life in high-stress environments

Better ROI from less tool wear and reduced scrap

Access to high-margin industries like aerospace, medical, and energy

Mastering these methods not only improves machining results but positions your shop as a premium supplier for exotic metal components.

Q&A Section: What Business Owners Want to Know

Q: What are the best tools for machining Inconel? A: Use coated carbide tools with negative rake geometry. Invest in high-pressure cooling systems to prevent overheating.

Q: Is it worth outsourcing exotic metal machining? A: For small shops without specialized tools or expertise, outsourcing is often more cost-effective and reduces the risk of part failure.

Q: How can I reduce tool costs when machining exotic metals? A: Use tool life monitoring systems, rotate inserts frequently, and opt for multi-functional cutting tools when possible.

Conclusion: Step Ahead with Smarter Machining

Exotic metals offer unmatched performance in extreme environments—but only when machined correctly. With the right tools, techniques, and a well-trained team, your facility can turn these technical materials into industrial-grade masterpieces.

If you're looking to upgrade your shop’s capabilities or want access to high-quality exotic metals, Accro‑Met’s machining-grade alloys are engineered for precision and performance.

📞 Call to Action

Ready to enhance your shop’s performance with premium exotic metals? Explore our product catalog, or contact our technical team for custom machining support. Let Accro‑Met help you cut smarter, not harder.

machining exotic metals

"This article explores the technical hurdles and offers proven best practices for machining exotic metals..."

Inconel machining, tungsten machining, metal fabrication best practices

"Use coated carbide tools for Inconel machining or optimize feeds when working on tungsten machining tasks..."

how to machine exotic metals, best practices for machining Inconel

"Need expert guidance on how to machine exotic metals? Follow these essential tips."

heat-resistant alloys, precision cutting, carbide inserts

"Exotic alloys like Inconel are classified as heat-resistant alloys and demand precision cutting tools like carbide inserts."

0 notes

Text

Exploring the World of Precision Machining

In the world of manufacturing, precision is paramount. The ability to create intricate and accurate components is a game-changer, and it's made possible by cutting-edge machinery. This article'll delve into the fascinating realm of precision machining, focusing on CNC grinding machines, gun drilling machines, and steering machines. These technological marvels have revolutionised the manufacturing industry, and we'll uncover their significance in this journey.

CNC Grinding Machine: Precision at Its Finest

When achieving unparalleled precision in machining, CNC grinding machine takes centre stage. These machines are designed to smooth and shape materials with incredible accuracy. With computer numerical control (CNC) technology at their core, CNC grinding machines efficiently execute complex tasks. They are the artisans of the manufacturing world, sculpting components to perfection.

The Anatomy of a CNC Grinding Machine

To truly appreciate the capabilities of a CNC grinding machine, it's essential to understand its components. We'll break down each part's role in creating precision components from the grinding wheel to the control panel. The grinding wheel, driven by advanced motors, meticulously removes material, while the CNC control unit orchestrates the entire process. It's a symphony of motion and control resulting in unparalleled precision components.

Gundrilling Machine: Drilling with Precision

Gundrilling is a specialised drilling process used in various industries, including aerospace and medical device manufacturing. Gundrilling machine is the unsung heroes of precision drilling, capable of creating deep and accurate holes. Let's delve into gun drilling and discover how these machines make the impossible possible.

The Marvel of Deep Hole Drilling

Gundrilling machines excel in drilling deep, straight holes with minimal deviation. We'll explore the techniques and technologies that enable these machines to achieve such precision in drilling. The secret lies in specialised tooling and coolant systems that ensure the drill bit remains cool and sharp, even during extended drilling operations. This combination of engineering prowess and cutting-edge technology results in flawlessly drilled holes that meet the strictest tolerances.

Steering Machines: Navigating the Future

In the automotive industry, precision is essential, and steering systems play a critical role. Steering machine is responsible for crafting components that ensure smooth and reliable steering performance. Join us as we navigate through the world of steering machines and their contribution to the automotive realm.

Crafting the Perfect Steering Component

Steering machines are tasked with creating components that must withstand immense forces while maintaining precision. We'll unravel the challenges and innovations that drive the development of these essential components. From forging to precision machining, steering components undergo rigorous processes that demand the utmost precision. Advanced materials and quality control measures ensure that each element meets stringent safety and performance standards.

Conclusion

In the world of precision machining, where every micrometer matters, CNC grinding machines, gun drilling machines, and steering machines shine as unsung heroes. Their precision and accuracy make the impossible possible, shaping industries and driving innovation.

To learn more about the world of precision machining and the remarkable machines that power it, visit WIDMA. Discover a world where precision knows no bounds and technology meets craftsmanship in perfect harmony.

3 notes

·

View notes

Text

Maximizing Machining Precision with Traub Collet & Accessories and Modern CNC Chucking Systems .

In the competitive world of high-precision manufacturing, Traub Collet & Accessories are indispensable tools that ensure maximum accuracy, reliability, and productivity. These components are specifically designed for use in Traub machines and are recognized for their exceptional build quality, consistency in clamping force, and long service life. Industries that rely on precision turning—like aerospace, automotive, and electronics—find Traub collets invaluable for minimizing tolerances and achieving repeatable results.

From increasing grip strength to reducing machine vibrations during operations, Traub collets and their supporting accessories are engineered for maximum performance in demanding environments. Their compatibility with Traub CNC turning centers makes them a go-to choice for both OEMs and contract manufacturers.

The Engineering Behind Traub Collet Systems

At their core, Traub collets are high-performance tool-holding components that clamp a workpiece or cutting tool with great precision. The geometry and metallurgy of these collets are tailored to meet rigorous industrial demands. These systems can hold various profiles—from round bars to hex and square profiles—ensuring flexibility across product lines.

Salient Features of Traub Collets:

Precision Machining: Ground to tight tolerances for minimal run-out.

Robust Construction: Typically manufactured using high-carbon steel or special alloy materials for durability.

Corrosion Resistance: Many collets are surface-hardened or treated to withstand coolant and environmental wear.

Custom Variants: Available in segmented or solid configurations for various turning requirements.

Each feature works to reduce part rejection, shorten machining cycles, and ultimately improve profitability in production environments.

Boosting Efficiency with Essential Accessories

In addition to the primary collet unit, Traub Collet & Accessories include several supportive components that enhance machine utility:

1. Clamping Cylinders

These are responsible for applying consistent hydraulic or pneumatic pressure to the collet system, ensuring repeatable clamping force.

2. Guide Bushings

Provide superior axial support for slender parts, reducing deflection and improving surface finish.

3. Tool Holders and Sleeves

Allow users to adapt collets for various diameters or tool types with minimal setup time.

4. End Stops and Locators

These components allow precise length setting for batch machining, reducing measuring errors.

By integrating these accessories, machining setups become faster, more flexible, and capable of handling larger production volumes without sacrificing quality.

Where Traub Collet Systems Shine

A wide array of industries benefit from the use of Traub Collet & Accessories, especially those where precision, speed, and repeatability are non-negotiable:

Automotive: For the production of bushings, shafts, nuts, and connectors.

Medical: Manufacturing of bone screws, dental tools, and surgical components.

Aerospace: High-tolerance small parts used in avionics and control systems.

Watchmaking and Jewelry: Delicate parts where micron-level tolerances are crucial.

With increased automation in manufacturing processes, Traub systems are also being integrated into robotic loading and unloading systems, reducing manual intervention and increasing overall throughput.

Exploring the Power of the CNC Collet Chuck

In contrast to brand-specific systems like Traub, the CNC Collet Chuck is a more universal tool-holding solution that fits a wide variety of CNC lathes and milling machines. These chucks are ideal for applications that require extreme precision and flexibility in terms of clamping diameters and speeds.

Why Choose CNC Collet Chucks?

Versatility: Compatible with various machine types and suitable for both tool and workpiece holding.

High Speed: Ideal for applications involving rapid spindle speeds without compromising safety.

Repeatability: Excellent for batch production where every micron counts.

Compact Design: Takes up less space in the spindle area, which allows for greater machining clearance.

The CNC collet chuck has become a standard in precision machine shops due to its flexibility, adaptability, and high reliability under varying loads and temperatures.

Types of CNC Collet Chucks

Understanding the types of CNC Collet Chuck available can help in choosing the right one for your operation:

1. Pull-back Collet Chuck

The most common type, suitable for general-purpose turning. As the collet is pulled into the chuck body, it tightens around the part.

2. Dead-Length Collet Chuck

Ideal for maintaining consistent part length during repeated operations. The collet remains stationary while the sleeve closes over it.

3. Push-Type Collet Chuck

Used in applications where components need to be pushed firmly against a fixed stop for better repeatability.

Each of these chuck types comes in different sizes and designs depending on the application, spindle nose size, and torque requirements.

CNC Collet Chucks in Automated Production Lines

With the rise of smart manufacturing, CNC Collet Chuck systems have become even more valuable. When integrated with robotic arms, tool changers, and palletized workholding systems, CNC collet chucks contribute to seamless and automated production lines.

For example, in a robotic cell performing multiple operations (turning, facing, drilling), collet chucks can be preloaded with specific collets to handle a wide variety of parts without requiring manual setup changes. This improves productivity, minimizes human error, and reduces downtime between batch changes.

Maintenance Tips for Longevity

To maintain top performance, both Traub Collet & Accessories ,CNC Collet Chuck systems require regular maintenance.

Here are a few tips:

Daily Cleaning: Remove chips, swarf, and coolant residue to prevent clamping issues.

Lubrication: Use high-quality lubricants to keep the clamping mechanism smooth and efficient.

Periodic Inspection: Check for signs of wear or micro-cracks and replace parts as needed.

Calibration: Ensure collet clamping forces remain within the specified tolerance to maintain part integrity.

Preventive maintenance not only extends the life of your tooling system but also ensures consistently high-quality production outcomes.

Combining the Best of Both Worlds

Many advanced manufacturing environments use a hybrid approach, incorporating both Traub Collet & Accessories for Traub machines and CNC Collet Chuck systems for other CNC equipment. This dual-system strategy enables companies to diversify their production capabilities without being restricted to a single machine brand or setup.

For instance, a facility might use Traub collets for specialized operations that require high spindle speeds and repeatability while using CNC collet chucks for custom, short-run parts across multiple workstations. The result is an agile production floor capable of handling a wide variety of projects with unmatched efficiency.

The Role of Technology in Future Chucking Systems

The next generation of chucking systems will be even smarter, integrating technologies such as:

Sensor-Based Feedback: Real-time monitoring of clamping force, temperature, and vibration.

IoT Connectivity: Linking chucks to a central dashboard for preventive diagnostics and alerts.

Automated Changeover Systems: Using servo-motors and PLCs to automatically switch collets based on part programs.

AI Optimization: Using machine learning to recommend the best clamping method based on part geometry and material.

As industries move toward digital twins, predictive maintenance, and AI-driven machining, the synergy between collet systems like Traub Collet & Accessories and CNC Collet Chuck units will become a cornerstone of smart factories.

Final Verdict

Investing in high-quality tooling like Traub Collet & Accessories and CNC Collet Chuck solutions is no longer a luxury—it's a necessity. As machining tolerance requirements grow tighter and production schedules become more aggressive, your ability to hold a tool or part accurately can make or break the project.

By understanding the strengths of each system and how they can complement one another, manufacturers can build a more agile, precise, and productive workshop. From manual to fully automated systems, collet and chuck technologies will continue to evolve, driving the future of modern manufacturing.

0 notes

Text

304/316 Stainless Steel Vertical Float Switch: Reliable Liquid Level Management for Harsh Environments

Engineered for Extreme Conditions

Military-grade construction: CNC-machined 304/316 stainless steel withstands 2000-hour salt spray tests (ASTM B117)

Wide operational range: -40°C to 120°C temperature tolerance with IP67 waterproof sealing

Space-saving design: 220mm vertical profile fits 3"+ diameter tanks/pipes

Technical Superiority

▪ Dual-circuit flexibility: Configurable NO/NC contacts (SPDT) for PLC/DCS integration ▪ High-load capacity: 1.5A@200VDC switching eliminates need for auxiliary relays ▪ Custom wiring: Standard 350mm cable with optional lengths up to 1000mm

Industry-Proven Applications

✔ Water Treatment: Prevents dry-running in sewage pumps, controls filter backwash cycles ✔ Industrial Machinery: Coolant level monitoring in CNC equipment, boiler safety cutoffs ✔ HVAC Systems: Humidifier tank auto-refill, condensate drain management

Performance benchmark: 8x longer service life than plastic floats with <0.3% annual failure rate

Installation Best Practices

For vibration-prone environments, recommend using stabilizing brackets. Magnetic mechanism inspection advised every 24 months. Includes 3-year warranty with 24/7 technical support.

0 notes

Text

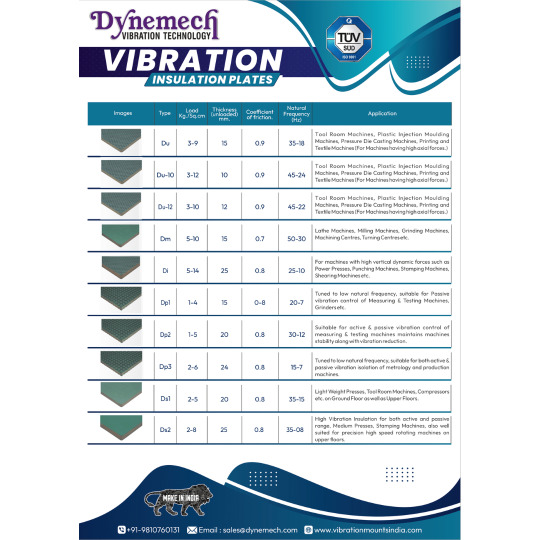

Dynemech Anti-Vibration Insulation Sheet- Advanced Vibration Control | Enhanced Equipment Stability | Industrial-Grade Durability

The Dynemech Anti-Vibration Insulation Sheet represents a next-generation solution in Vibration Isolation Technology, specifically engineered for modern industrial environments where machine precision, stability, and longevity are critical.

Manufactured from a high-performance synthetic composite material, this insulation sheet is designed to deliver maximum resistance to compressive loads while providing superior damping of vibrations, shocks, and structure-borne noise. Its chemically inert composition ensures long-lasting resistance to a wide array of contaminants including water, coolants, industrial oils, hydraulic fluids, and fuels typically present on the shop floor.

Tool room machine, plastic injection moulding machines, pressure die casting machines, printing and textile machine (For Machine having high axial forces)

Engineered for Industrial Excellence

🔹 Premium Synthetic Composite Build

Formulated using advanced polymers and composite reinforcements, this sheet delivers a unique balance of strength, flexibility, and resilience—ensuring optimal vibration absorption without compromising structural stability.

🔹 Defined Load-Bearing Characteristics

Each Insulation Sheet comes with a calibrated stress value, enabling engineers and installers to match the material’s load-bearing capacity to the specific weight and footprint of the machine. It can be installed directly under equipment without additional mounting accessories, offering a plug-and-play solution for industrial setup.

🔹 No Permanent Deformation

Unlike traditional rubber or low-grade elastomer pads, Dynemech Anti-Vibration Insulation Plates do not deform plastically under heavy static loads, as long as the machine’s weight remains within the rated load capacity. This guarantees consistent performance, dimensional stability, and long service life.

🔹 Outstanding Fluid and Chemical Resistance

The sheet’s chemically resistant formulation safeguards against deterioration due to exposure to oils, grease, cutting fluids, cleaning agents, fuel spills, and other aggressive substances. This makes it ideal for continuous use in demanding manufacturing environments.

🔹 Effortless Installation & Maintenance-Free Operation

No grouting, anchoring, or foundation modification is required. Simply position the Insulation Sheets beneath the equipment’s mounting points according to the specified load distribution. Once in place, they require no maintenance and can function effectively over many years.

Advantages at a Glance:

✅ Reduces Vibrations, Shocks & Structure-Borne Noise ✅ Enhances Machine Accuracy & Operational Stability ✅ Prolongs Equipment and Tooling Life ✅ Protects Floors from Dynamic Load Damage ✅ Improves Operator Safety and Comfort ✅ No Downtime, No Foundation Work, No Anchors ✅ Resistant to Wear, Tear, Fluids & Temperature Fluctuations

Ideal Applications:

CNC Machines & Machining Centers

Industrial Compressors & Pumps

Textile Machinery

Hydraulic Presses & Forging Hammers

Generator Sets & Heavy Motors

Precision Measuring Equipment

Printing & Packaging Machines

Food Processing & Pharmaceutical Machinery

Why Choose Dynemech Anti-Vibration Insulation Plates?

With decades of expertise in Vibration Control systems, Dynemech Anti-Vibration Insulation Plates stands as a trusted name in precision machine mounting solutions. Our Anti-Vibration Insulation Sheets are tested under rigorous industrial standards to ensure unmatched performance, reliability, and return on investment.

Dynemech Systems has designed, engineered and developed the most extensive line of Anti Vibration Pads, silent blocks, shock and noise control products. We are also specializing in manufacturing of anti-vibration controlling pad, machinery mounts, spring mounts, and variety of anti-vibration pads. Dynemech Systems manufactures world-renowned Anti-Vibration Pads.

Dynemech Systems offers an ideal solution in Anti Vibration Pad. Made from a combination of high quality rubber polymers and cork, this ideal combination ends up to make up a product that has excellent resistance to ageing, compression set, water and oil.

Dynemech’s Anti Vibration Pads are widely used in: Refrigeration Plants, Compressors, Conveyors, Air Conditioning Plants, Diesel Generators, Business Machines, Fans, Motors, Power / Impact Presses, Pumps, CNC Machines etc.

Our range of silent block are ideal for controlling machine vibration. Our rubber based products are ideal in controlling both active and passive vibrations coming from various industrial machines.

If you'd like, I can also provide:

A technical data table with load ratings, thickness, sizes, etc.

A comparison chart against traditional rubber pads or cork sheets

A one-page brochure layout with images and branding suggestions

To learn more about our products: https://www.vibrationmountsindia.com/products/

#AntiVibration, #MachineMounting, #IndustrialSolution,s #VibrationIsolation, #MachineryStability, #PrecisionMachinery, #VibrationControl, #IndustrialEquipment, #Dynemech, #SmartManufacturing, #AntiVibration, #MachineMounting, #IndustrialSolutions, #VibrationIsolation

Call Us: +91-9810760131

Email: [email protected]

Website: www.vibrationmountsindia.com

#AntiVibration#MachineMounting#IndustrialSolution#s#VibrationIsolation#MachineryStability#PrecisionMachinery#VibrationControl#IndustrialEquipment#Dynemech#SmartManufacturing#IndustrialSolutions

0 notes