#CNC Machine Panel

Explore tagged Tumblr posts

Text

🚀 Precision in Every Detail! ✨ Witness the raw beauty of this engine casing, flawlessly crafted using state-of-the-art 5-axis CNC machining. 💡 From intricate designs to complex geometries, our precision technology ensures unmatched accuracy and a surface finish so smooth it barely needs post-processing. Perfect for industries like aerospace and automotive, this is machining excellence at its best! 🛠️⚙️

👉 Like, share, and follow for more precision engineering marvels! 🎥

PrecisionMachining #5AxisCNC #CNCmachining #EngineeringExcellence #AerospaceParts #AutomotiveComponents #AdvancedManufacturing #MetalCrafting #SurfaceFinish #TechInnovation

#CNC Machine Basic Knowledge#CNC Machine Coolant#CNC Machine Finance#CNC Machine For Guitar#CNC Machine Game#CNC Machine Manufacturers#CNC Machine Offers For Internet#CNC Machine Operator Hiring#CNC Machine Operator Recruitment#CNC Machine Panel#CNC Machine Purchase#CNC Machine Services#CNC Machine Shop Near Me#CNC Machine Suppliers#CNC Machine Types#CNC Machine What Does It Do#CNC Machine X Carve

1 note

·

View note

Text

CNC Wood Cutting Machine, Surface Planer & Wood Planer

Shree Umiya offers advanced CNC wood cutting machines, surface planers, & wood planers. Experience superior quality for all your woodworking tasks

#cnc wood cutting machine#surface planer#wood planer#woodworking machinery#panel saw machine manufacturer#Woodworking Machinery Manufacturer

0 notes

Text

cnc press brake machine

Down acting hybrid cnc press brake

#cnc bending machine#panel bender#press brake#cnc press brake#down acting press brake#press brake machines#dual servo hybrid cnc press brake#up-acting hybrid cnc press brake#cnc press brake machine

0 notes

Text

RAGOS CNC panel bender video

#cnc bending machine#press brake#panel bender#Sheet Metal Panel Benders#panel bender machine#panel bender cnc#panel bender vs folding machine

1 note

·

View note

Text

CNC machine PCB damaged inspite of having a stabilizer

We had a case where a VMC machine already having a stabilizer installed for it. However one of PCB was damaged in spite of having stabilizer. This is situation that happened after 4 years of installations. The stabilizer was from reputed make and was in good working condition. The CNC machine is from reputed international make. Why did the CNC machine get damaged inspite of having stabilizer…

View On WordPress

#CNC machines. • Automation equipments like PLC panels#cnc phase converter#Equipower#Equipower home voltage protector#Equipower lite#Equipower plus#mainline voltage protector#MSS#MSS OVCD#MSS powersys#MSS powertech#neutral. open indications in spike guard#power kavach#spike protection

0 notes

Text

To run a woodworking business, you need your equipment to work properly. That is why, when your woodworking machinery shows signs of damage, you must fix it before things worsen. If you are looking for reliable machinery services in Australia, the one to trust is FORZA Machinery.

FORZA Machinery has been a trusted supplier of high-quality woodworking equipment for over two decades. Our job is to find the best machinery that fits your requirements. You can also trust us when it comes to repairs and machine services. If your wild belt sander needs maintenance, we are the ones to call.

If you are looking for reliable machinery services in Australia, you can put your faith in FORZA Machinery. Get to know more about who we are and what we offer by calling us at 1300 4 FORZA. You can also email us at [email protected].

#edge banding machine#cnc routers australia#edge bander#machinery service#woodworking machinery#panel saws#wide belt sander

1 note

·

View note

Video

youtube

How to use STARMA cnc wood turning lathe machine panel operation of 4 fu...

#youtube#How to use STARMA cnc wood turning lathe machine panel operation of 4 function About this 4 function with auto feeding cnc wood lathe machin

0 notes

Text

Everyone is afraid of China. And why shouldn’t they be? They have a large industrial base, paid for by American industrialists. They have a lot of money, given to them by American industrialists. And they have tiny, quirky cars, which I desire more than my next breath. It’s an unbeatable combo, and the only way to compete is to play a different game.

We are going to build mid-sized, boring sedans, and then sell them into the Chinese market in exchange for tiny quirky cars and exotic sports electrics. For our prototype, we have chosen to clone the Plymouth Volare. Panel gap is actually better than the original car by far, because we’ve used CNC machining (an old 3D printer we found in the dumpster, with a plasma cutter duct-taped to the end of it) to produce immaculate replicas of the original panel. And our welder is only high on modern synthetic drugs, not the impure and unpredictable strains of the 1960s. That means consistency, and a return on your investment.

Do we think that the Chinese market will buy these cars? There’s a pretty good chance. They sport a lot of features that every market wants. Four wheels. A steering wheel. A trunk. And if the doors are closed and the windows are rolled up, you probably won’t get wet in the rain.

Powertrain is a problem, we agree. It’s a lot of startup cost to open a factory that is capable of manufacturing to the precision tolerances required to produce an internal combustion engine. That’s why we picked the Volare. Those cars came with an un-killable slant-six engine. They’re so unkillable, actually, that we didn’t have to build new ones, just pull ‘em of the junkyard and spray-paint ‘em: they’re good to a few million kilometers, so there’s no need to actually do a rebuild. That’s recycling, which is environmentally friendly (if you don’t think too hard about what’s in the spray cans we’re using.)

Last, investors shouldn’t fret about trade secrets. While these cars haven’t been made for a half-century, there’s not enough of them left in existence to use as a reference to copy from. Any imitators will have to buy at least one of our cars, and maybe two or three, if our quality control doesn’t get better. That’s called guaranteed sales.

There’s been a lot of fear about American workers leaking secrets to China, as opposed to the more traditional format where American managers sell them in large chunks to China instead. Here at Switch Industries, we guarantee our investors that none of us know how to dial long distance. Half of our employees are too young to even have seen a phone, and they definitely don’t use email. Maybe a few of them might know how to switch to Pinyin on their computer keyboards, so we’ve pried the control key off of every keyboard in the office.

179 notes

·

View notes

Note

I'm involved in a project that requires casting some residential circular-arch doors out of concrete, one side at a time. I was considering designing the embellishments with digital tools and having them cut with a CNC machine for the mold, but it seems like a lot of trouble and I already know how to design things in the physical world. My question: what did you carve your beautiful embellished doors from, was it expensive, and do you think it'd work to cast a rubber mold from?

That sounds like a really cool project!

The carved panels on the doors I made were made in mdf-board. It's pretty cheap, about the same as plywood, and you can carve it like wood with a multitool - with the right bit, it's pretty fast work! (I talk about the different bits I use in this post.)

As long as the relief doesn't have any wierdly angled deep nooks and crannies, you should absolutely be able to make a rubber cast from it! Especially if you put down a base coat of somewhat glossy paint first, to make all the surfaces smooth and non-porous!

(Mandatory word of caution - carving mdf means a lot of sawdust, and it's a health-hazard to breathe it in. So do it outside, if you can, and wear a mask and goggles!)

The board on the doors is actually quite thin, about 10-12mm - the layered paint helps accentuate the 3D depth of the carvings. If you want a physically deeper relief, it'll be more work to carve it and the mdf sheets are more expensive the thicker they are.

That said, even a relatively shallow pattern can be very striking!

This divider was carved from 10mm mdf, so the carvings are just a few mm deep, but even without paint, it makes for a pretty effect! 🙂

If you do go ahead with it, feel free to share pictures! I'd love to see what you end up making! 😀

14 notes

·

View notes

Text

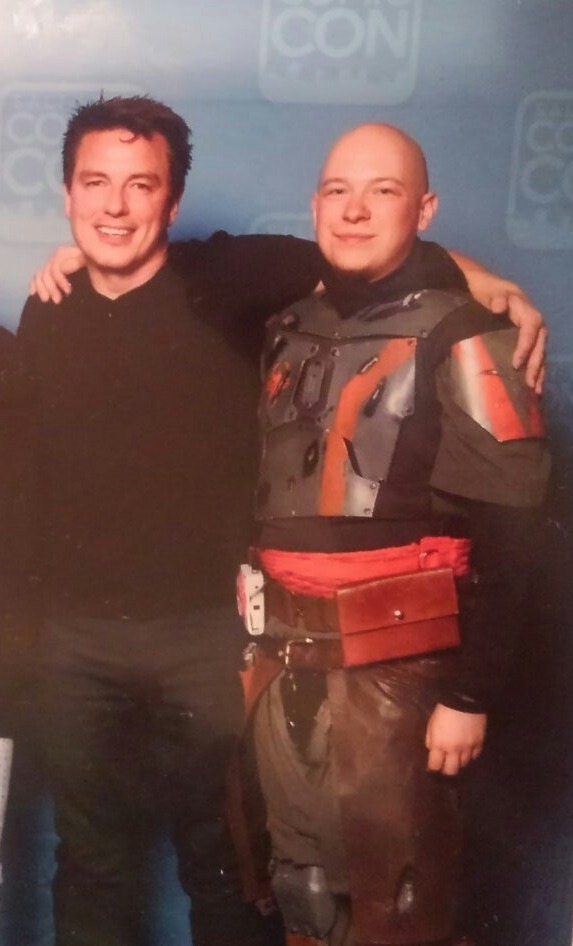

Throwback to the beginnings of my costuming journey. Though this armor has since been retired, mainly due to my unfortunate physical growth, I think back on these times fondly. I like to think the time and care I put into my first build shows, but I may be a touch biased.

The completion of this armor lead to a great many things in my life. Some of the most fun I've ever had, some of the best friends I've ever made, and some of the coolest opportunities I never thought I'd have.

In 2016 I was invited to attend a convention in Salt Lake where I met the man himself, big boss Boba Fett, Jeremy Bulloch. While it was a brief (but incredibly cool) opportunity, he wasn't the only hero I got to meet that weekend. While attending a panel for Mark Hamill, I also got a high five from Jason David Frank (RIP). Another man I've loved and respected for as long as I can possibly remember.

While manning the Star Wars Costuming Clubs booth that same year, along with a new friend, we were blown away by a random surprise visit by Michael Rooker. Though I regret missing this opportunity to get a picture, the conversation we had without a massive group of people interrupting him, is all the memory of the event I need. What a genuinely cool guy.

Over the years my armor evolved and grew with me, but continued to open doors I never thought possible. Growing up in the middle of nowhere, no real money to my name, and no opportunities to truly geek out with the people left in my hometown, I never thought that Comic Cons and costume groups would be part of my life. I had followed what the 501st Legion was doing since I was a kid, and was truly blown away when I saw them on tv marching in the Rose Bowl Parade in 2007. Still, I never thought anything like that would exist in Montana. At that point, the Mandalorian Mercs were just starting, so I hadn't even heard of them yet.

By the time I started college, I was made aware of the existence of the MMCC. Sitting in my dorm dreaming that I'd have the money, time, space, skills, etc, to start a build of my own some day. Then one day in 2015, I saw this helmet for sale from Headshot Props, and I knew it was time. I had to make this purchase. I checked my accounts, moved some stuff around, skipped getting groceries for a few weeks, and 2 months later, there it was in all of its glory. Sitting at my doorstep when I got off work, I don't think I had ever been that excited. I took it inside, ripped open the box, knocked off just enough of the sharp edges to put it on without cutting myself, and low and behold... it didn't fit.

Motivation: demolished. Faith: gone.

I was, frustrated, to say the least. I'm the type of person to take setbacks like this extremely personally because of how often it seems like it happens to me. I set it on the shelf and looked at it for a few days. I knew there was nothing I could do about a return because the dimensions were posted, and I measured my head. It should have fit. I didn't take into account the cheeks of the helmet being a tighter spot, and my bigass fivehead just wasn't gonna do it without breaking the helmet. I had to do something though. I sanded the hell out of the inside of the cheeks to the point that you could see light through them, and I could get the helmet on, though it wasn't a pleasant experience. I then took my heat gun, thinking there's no way this will work, heated the resin just enough to push the cheeks out that little bit extra, and I'll be damned. It was just enough. The helmet was still tight, but it fit, and it was back to game on.

The course of the next few months brought on a ton of changes. I was lucky enough to be working at a sign shop at the time I began this journey, and that shop had a seemingly endless supply of foamed PVC board and a flatbed CNC machine. I was able to trace out my armor design and just have it cut right there! Barely even had to trim and sand anything! It was amazing! I started learning skills I never even knew I wanted. Using a heat gun to form shapes, learning to paint, kit bashing parts to make in-universe looking props, it just never seemed to end! Halfway through my build, I moved, but I didn't let that move ruin my motivation. In that tote was a pile of loose parts and a helmet. Within a month of moving into my new place, it was wearable. Rough, but wearable. Around Halloween that year, I had met up with some local guys that were also building armor, and we handed out candy at the Zoo! It was amazing, and I had so much fun. Met some of my future best friends that day.

Over the years of doing local events, I've been humbled on a few occasions. Mostly from people who joined the group later on that have told me their journey started when they saw me at one event or the other. That's such an incredible feeling and honestly makes all the time, effort, money, stress, blood, and love I've put into this build worth it.

If you've stuck with this post this far, I applaud you. You can probably tell I'm not much of a writer and I'm all over the place with no real conclusion to any of it. I'm really just reminiscing. This weekend I will be parting out this original kit, or at least most of it, in order to help new costumers, new friends, get a foothold in their build, and hopefully motivate them to continue.

If you've ever wanted to build a costume, regardless of what fandom it's for, don't let anyone tell you not to do it. Buy it, build it; piece by piece or all it once, it doesn't matter. Just do it. Solid chance you'll never regret it.

3 notes

·

View notes

Text

Transforming a solid steel column into a precise wheel in one seamless operation—this is the pinnacle of 𝐟𝐢𝐧𝐞 𝐰𝐨𝐫𝐤𝐦𝐚𝐧𝐬𝐡𝐢𝐩 and cutting-edge 𝟓-𝐚𝐱𝐢𝐬 𝐂𝐍𝐂 𝐭𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐲. In this demonstration, we showcase:

✅ Unparalleled precision in every contour and curve ✅ The efficiency of machining complex geometries in a single setup ✅ The capability to deliver rapid prototyping with flawless results

𝐏𝐫𝐨 𝐭𝐢𝐩: Achieving such precision requires meticulous planning, the right toolpath strategies, and top-quality materials like stainless steel and titanium alloys.

Curious about how 5-axis machining can elevate your projects? Let us know your thoughts or share your experience in the comments below!

#CNCMachining #5AxisCNC #PrecisionEngineering #RapidPrototyping #GreatLightMachining

Contact Us Get More Info:

GreatLight Metal Technology Co., Ltd

✅ Website: https://glcncmachining.com/ ✅ Website: https://cnc-5-axis.com/ ✅ #10, Xinrong Street, Chongtou Community, Chang'an Town, Dongguan City, Guangdong, China, 523845 ✅ + 86 180 2756 7310 ✅ + 86 180 2756 7310(whatsapp) ✅ [email protected]

#CNC Machine Basic Knowledge#CNC Machine Coolant#CNC Machine Finance#CNC Machine For Guitar#CNC Machine Game#CNC Machine Manufacturers#CNC Machine Offers For Internet#CNC Machine Operator Hiring#CNC Machine Operator Recruitment#CNC Machine Panel

0 notes

Text

CNC Wood Cutting Machine, Surface Planer & Wood Planer

Shree Umiya offers advanced CNC wood cutting machines, surface planers, & wood planers. Experience superior quality for all your woodworking tasks

#wood planer#surface planer#cnc wood cutting machine#woodworking machinery#panel saw machine manufacturer#Woodworking Machinery Manufacturer#panel saw

0 notes

Text

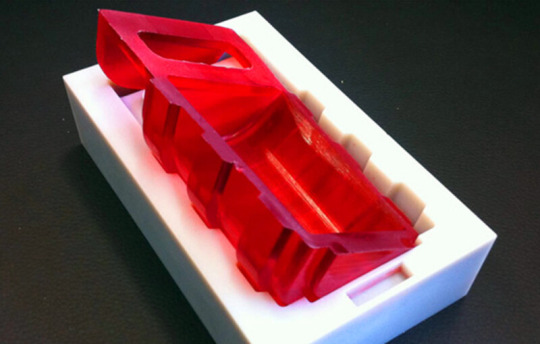

Learn About the Basics of Vacuum casting

Within the dynamic realm of production and prototyping, urethane casting is a unique technology that provides cost-effectiveness, accuracy, and diversity. Urethane casting has become the industry standard for a variety of applications, from complex prototypes to small-batch production runs, including consumer electronics, medical equipment, and the automotive and aerospace sectors.

Gratitude Casting of Urethane

The first step in the procedure is to create a master pattern, which is usually done via fast prototyping techniques like CNC machining or 3D printing. The silicone molds that are made from this master pattern are used to pour polyurethane resin into. The resin mimics the fine features of the master design once it has dried, producing pieces that are excellent and ready for manufacturing.

Flexibility throughout Sectors

The adaptability of urethane casting across sectors is one of its most noteworthy benefits. Urethane casting may be used for a variety of purposes, including the production of end-use components and prototypes for new product development. For instance, urethane casting makes it possible to quickly iterate ideas for dashboard panels, interior trim, and lighting fixtures in the car industry. Similar to this, urethane casting makes it easier and faster to produce unique medical device housings, surgical instruments, and prosthetic components in the medical profession. Vacuum casting also offers flexibility.

Benefits Compared to Conventional Approaches

When compared to conventional production techniques like CNC machining and injection molding, urethane casting has several significant benefits. The most important factor is cost-effectiveness. Because urethane casting requires less tooling up front, it's a great option for low-volume production runs if standard tooling costs are too high. Urethane casting also has a short turnaround time, which enables companies to quickly develop and refine ideas without having to wait for long lead periods.

Additionally, the design freedom provided by urethane casting makes it feasible to produce intricate surface details, undercuts, and complicated geometries that would be difficult or impossible to accomplish with alternative manufacturing processes. This versatility also applies to the choice of material, since a variety of polyurethane resins are available to satisfy certain performance needs, including those related to hardness, flexibility, and chemical resistance. You can Explore vacuum casting also.

Follow our Facebook and Twitter for more information about our product.

#vacuum casting#vacuum casting services#Urethane Casting#Explore vacuum casting#Custom Vacuum Casting Services

2 notes

·

View notes

Text

Exploring the World of Precision Machining

In the world of manufacturing, precision is paramount. The ability to create intricate and accurate components is a game-changer, and it's made possible by cutting-edge machinery. This article'll delve into the fascinating realm of precision machining, focusing on CNC grinding machines, gun drilling machines, and steering machines. These technological marvels have revolutionised the manufacturing industry, and we'll uncover their significance in this journey.

CNC Grinding Machine: Precision at Its Finest

When achieving unparalleled precision in machining, CNC grinding machine takes centre stage. These machines are designed to smooth and shape materials with incredible accuracy. With computer numerical control (CNC) technology at their core, CNC grinding machines efficiently execute complex tasks. They are the artisans of the manufacturing world, sculpting components to perfection.

The Anatomy of a CNC Grinding Machine

To truly appreciate the capabilities of a CNC grinding machine, it's essential to understand its components. We'll break down each part's role in creating precision components from the grinding wheel to the control panel. The grinding wheel, driven by advanced motors, meticulously removes material, while the CNC control unit orchestrates the entire process. It's a symphony of motion and control resulting in unparalleled precision components.

Gundrilling Machine: Drilling with Precision

Gundrilling is a specialised drilling process used in various industries, including aerospace and medical device manufacturing. Gundrilling machine is the unsung heroes of precision drilling, capable of creating deep and accurate holes. Let's delve into gun drilling and discover how these machines make the impossible possible.

The Marvel of Deep Hole Drilling

Gundrilling machines excel in drilling deep, straight holes with minimal deviation. We'll explore the techniques and technologies that enable these machines to achieve such precision in drilling. The secret lies in specialised tooling and coolant systems that ensure the drill bit remains cool and sharp, even during extended drilling operations. This combination of engineering prowess and cutting-edge technology results in flawlessly drilled holes that meet the strictest tolerances.

Steering Machines: Navigating the Future

In the automotive industry, precision is essential, and steering systems play a critical role. Steering machine is responsible for crafting components that ensure smooth and reliable steering performance. Join us as we navigate through the world of steering machines and their contribution to the automotive realm.

Crafting the Perfect Steering Component

Steering machines are tasked with creating components that must withstand immense forces while maintaining precision. We'll unravel the challenges and innovations that drive the development of these essential components. From forging to precision machining, steering components undergo rigorous processes that demand the utmost precision. Advanced materials and quality control measures ensure that each element meets stringent safety and performance standards.

Conclusion

In the world of precision machining, where every micrometer matters, CNC grinding machines, gun drilling machines, and steering machines shine as unsung heroes. Their precision and accuracy make the impossible possible, shaping industries and driving innovation.

To learn more about the world of precision machining and the remarkable machines that power it, visit WIDMA. Discover a world where precision knows no bounds and technology meets craftsmanship in perfect harmony.

3 notes

·

View notes

Text

youtube

Nick Newman helped design a modular construction system so anyone with just a mallet and a drill can build their own home. Since co-founding U-Build in 2020, he has built— and watched others build— furniture, garden sheds, tiny homes, and full-sized houses, so it makes sense he’d use the flat-pack box system to turn the company work van into his full-time home.

[Watch our first video featuring Nick's U-Build universal home-build system, a CNC-cut flat-pack design anybody can assemble to make a home: • U-Build hands-on:... ]

According to Newman, "the U-Build construction system is something like if IKEA and LEGO had a baby. So, it's these big boxes that can be assembled with a mallet and a screwdriver. Effectively, you start out with your individual panels, which are cut with precision using a CNC machine, and it's designed with this kind of locking system so you can basically put the pieces together: it would always be on the 'right' configuration." Watch it at 25:45.

[Video timeline]

— Nick Newman out in London on his electric campervan: 00:10

— Explaining EV's lack of congestion charge in London: 00:20

— Charging the van in central London: 00:50

— Thunderstorm: 2:20

— Stealth setup: 03:00

— EV van conversion into vanlife camper: 3:30

— Conversion with U-Build boxes ("building blocks") timelapse: 3:42

— Explanation of a U-Build minimum unit of construction, the box: 03:50

— Kirsten interviews Nick Newman: 04:20

— U-Build's modularity put to the test inside a van: 05:10

— Locking system for drawers (inspired by the ones on commercial aircraft): 06:30 and 14:50

— Festival build out of U-Build blocks: 07:15

— Sink: 0832

— Current van living interior: 11:30

— Adapting working straps to vanlife: 12:00

— Folding clothes: 13:05

— Hammock setup: 19:28

— At Stroud, Gloucestershire: 20:45

— U-Build's workshop under construction on an old empty factory: 21:30

— Describing U-Build as a self-build system: 25:45

— On using empty buildings: 22:10

— "People could stay in a house like this for really cheap": 22:15

— Warehouse spaces to solve housing emergencies? 22:30

— Out in Herefordshire: 36:28

— Student-built house with U-Build: 36:35

He started using the fully-electric Sprinter van as a temporary home while on overnight work trips. The U-Build system involves assembling CNC-cut, formaldehyde-free plywood boxes as building blocks which then bolt together to create a rigid frame for a structure.

The conversion cost him less than £2,000 (about $2,400, or €2,300). The system is entirely demountable, so the boxes can be reused over and over: it was easy for Newman to take the boxes he was working with daily and rearrange them in the van to build a bed, kitchen (U-Scrub), storage, and toilet (U-Poo).

Newman left a shared warehouse where he was paying £800 for a tiny, windowless bedroom for vanlife in central London, and because the van is electric, he doesn’t pay congestion charges (£15/day). He has tricked out the van to appear in drive mode so he can use the vehicle’s battery and air conditioning and heating while parked.

The U-Build (and Studio Bark) team recently bought an abandoned warehouse in Stroud (Gloucestershire) for less than the price of a tiny studio in London. While they decide what to do with the space, they have installed U-Build dwellings (built in a half day) to use as bedrooms and private offices. It’s the same model as the SHED Project, where they worked with a London-based guardian company to provide quick-build homes from U-Build kits to provide housing for those in need in exchange for building surveillance.

https://u-build.org/

https://www.instagram.com/ubuild/

Nick's YouTube channel: / @electric.vanlife

Here's our story covered by Autoevolution: https://www.autoevolution.com/news/th...

On *faircompanies: https://faircompanies.com/videos/u-bu...

#kirsten dirksen#solarpunk#building#house#sustainable architecture#sustainable building#architecture#Nick Newman#U-Build#electric vehicles#sustainable housing#electric van#London#uk#england#Studio Bark#Stroud#Gloucestershire#Youtube

6 notes

·

View notes

Text

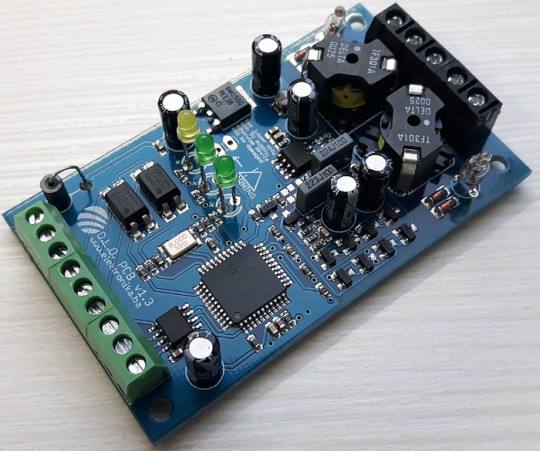

EXPLORING THE 5 COOL PARTNER SELLER ELECTRONICS PRODUCTS-Part1

Exploring the 5 Cool Partner Seller Electronics Products

Prologue

Are you an electronics enthusiast looking to expand your electronics project repertoire? Want to take your skills to the next level by exploring new and exciting products? Look no further than our list of five cool electronics products from partner sellers!

Whether you’re interested in building your own smart home devices, experimenting with sensors, or creating your own robot, these products are sure to inspire you. They cover a lot of application areas, from loop detectors used to monitor vehicle count in parking garages to Arduino CNC shields used in CNC machines, from simple pulse sensors used to detect cardiovascular pulse signals from fingertip to RGB LED panel light used in smart home, these products are unique, compact, and functional. Not only are these products fun to build and use but they’re also designed to help you learn new skills and techniques along the way.

What’s more, these products all come from trusted partner sellers who are committed to developing high-quality products. They’re happy to provide technical support for customers who have questions, so you can be sure you’re getting the best in electronics.

So get ready to dive into the world of electronics and explore these five cool partner seller products. You’re sure to find something that piques your interest and takes your own electronics projects to the next level.

Inductive Loop Vehicle Detector by Elektronika-ba

Whether you need to monitor occupancy and count vehicles in parking garages, control vehicle access at door and barrier controls, or facilitate traffic light installations and traffic controllers, the inductive loop detector is the perfect solution. It can even detect the direction and speed of vehicle traffic, making it an invaluable tool for a variety of traffic-related applications. In addition, this device can function as a stand-alone speed trap and can be easily interfaced with Arduino.

We can also provide a pre-programmed PIC chip to meet your project requirements.

Specifications

Number of operating modes: 4

Tuning: Automatic

Detection type: Presence/Pulse

Presence time: Adjustable in 3 steps

Pulse duration: 250 ms / 500 ms

Signal filtering: Adjustable in 2 steps (NORMAL, HIGH)

Loop inductance: 20 uH — 1000 uH

Frequency range: 20 kHz — 145 kHz

Frequency selection: 2 combinations (LOW, HIGH)

Sensitivity: Maximum 0.0025% Δf/f, adjustable in 8 steps

Detection speed: 10 ms by default, adjustable

Start-up time: ~ 1 second per channel (or longer if the frequency is not stable)

Temperature range: -35°C — 120°C

Sensor protection: Galvanic isolation + gas discharge tube for lightning protection

Don’t settle for less — click here to learn more about the Inductive Loop Vehicle Detector and experience the compact, yet cool detector!

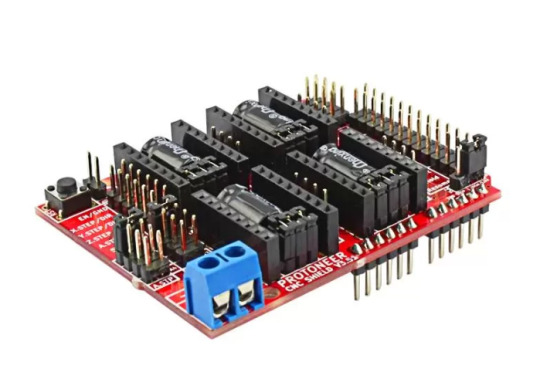

Arduino CNC Shield V3.51 by Protoneer

Designed by Protoneer, this kit is packed with features to ensure high precision control of your stepper motors, you can use it to easily build small CNC routers, DIY laser cutters, 3D printers, or any project that requires precise stepper motor control.

Our latest version 3.51 includes several enhancements to make assembly and installation even easier. We’ve added end-stop and probe signal filtering circuitry to eliminate false triggers and allow the use of unshielded cables for end-stops and probes. We’ve also increased the size of the solder pads for easier assembly and updated the probe pin labels to make installation a breeze.

With the Arduino CNC Shield Kit, you’ll have everything you need to build your own CNC router or mill with ease.

Features

Includes Noise Filers on all end stops and the probing pin. (New in V3.51)

GRBL 0.9 compatible. (Open source firmware that runs on an Arduino UNO that turns G-code commands into stepper signals https://github.com/grbl/grbl)

4-Axis support (X, Y, Z, A-Can duplicate X, Y, Z or do a full 4th axis with custom firmware using pins A4 and A3)

2 x End stops for each axis (6 in total)

Coolant enable

Uses removable Pololu A4988 compatible stepper drivers. (A4988, DRV8825 and others)(Not Included)

Jumpers to set the Micro-Stepping for the stepper drivers. (Some drivers like the DRV8825 can do up to 1/32 micro-stepping )

Compact design.

Stepper Motors can be connected with 4-pin molex connectors or soldered in place.

Runs on 12–36V DC. (At the moment only the Pololu DRV8825 drivers can handle up to 36V so please consider the operation voltage when powering the board.)

Don’t wait — click here to see more about the Arduino CNC Shield V3.51 and start your next project today!

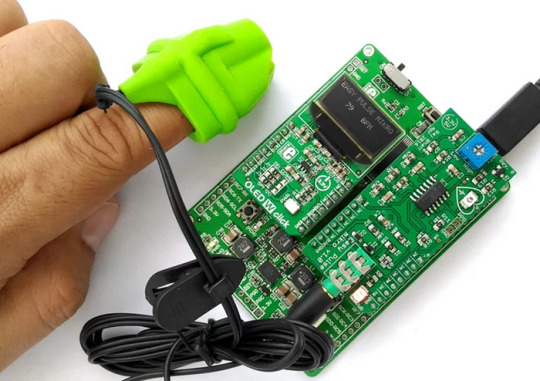

Easy Pulse Mikro by Embedded Lab

What’s more, the Easy Pulse Mikro is designed in the convenient Mikro bus form factor, making it easy to integrate with a wide range of mikroElektronika’s development boards. With all necessary instrumentation and amplification built right in, this powerful sensor provides a clean and precise analog PPG waveform output that’s routed to the AN pin of the mikroBus connector.

Whether you’re a hobbyist, student, or professional developer, the Easy Pulse mikro is the perfect tool for monitoring heart rate and other vital signs.

Click here to see more about the Easy Pulse mikro.

Features

Compatible with mikroBus socket.

Filtered and amplified analog PPG signal output

On-board potentiometer for adjusting amplifier gain, if needed (rotate clock-wise for increasing gain)

Onboard LED for indicating heartbeat. It flashes synchronously with the heartbeat on detecting the pulse from the fingertip.

2 notes

·

View notes