#5 axis precision machining

Explore tagged Tumblr posts

Text

CNC precision machining service

#business#design#autos#prototyping#prototype#prototype machining#cnc machining#rapid prototyping#precision machining#machining parts#cnc machining service#cnc services#cnc precision machining#5 axis cnc machining#5 axis precision machining#5 axis cnc#cnc machining parts

4 notes

·

View notes

Text

We provide precision CNC machining services, CNC Milling and Turning (3 axis, 4 axis, 5 axis), can manufacture complex and multi-structure plastic and metal parts.

#cncmachining#5 axis machining#cnc milling services#cnc machining parts#rapid prototyping#precision machining

2 notes

·

View notes

Note

Bro just straight up pouring molten bronze like it's not the coolest thing in the world wtf

Right now I work in a wood & metals fabrication shop and As a man of many hats if I see a piece of machinery I make it my life goal to get my dirty little hands on operating it at least once (when i was on the pour team i did most jobs but pouring from the big crucible of metal was my favorite and i was pretty good at it. never did the crane bc i have a bad sense of direction and you have to be pretty quick when pouring molten metal)

My next target is this thing:

#5 axis cnc i will get you.#i currently specialize in the 3 axis but i havent been able to learn to toolpath this thing bc its significantly more complicated#and also our shop's is kind of .broken#but i toured a shop that had 7 axis cncs in enclosed cabinets and shit literally the most insane precision machining#idk if i would be able to work in a shop like that but a man can dream#m#answers

5 notes

·

View notes

Text

𝐃𝐞𝐛𝐮𝐝𝐝𝐢𝐧𝐠 𝐭𝐡𝐞 𝐦𝐨𝐝𝐞𝐥 𝐨𝐟 𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥 𝐖𝐚𝐬𝐭𝐞: 𝐈𝐬 𝐂𝐍𝐂 𝐌𝐚𝐜𝐡𝐢𝐧𝐠 𝐚 𝐟𝐨𝐫𝐦 𝐨𝐟 𝐰𝐚𝐬𝐭𝐞?

CNC machining removes material, but does that mean it’s truly "wasting" it? In fact, modern CNC machining processes go to great lengths to minimize waste. Here’s how every inch of material is maximized:

High Precision Machining: Modern 5-axis CNC machines provide precise cutting with fine control over every detail, minimizing unnecessary material removal and ensuring maximum material efficiency.

Recycling and Reuse: Materials like aluminum, steel, and titanium can be recycled, melted down, and repurposed into new parts, significantly reducing waste in the manufacturing process.

CAD/CAM Integration: Advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software help optimize design and cutting paths, ensuring material is used efficiently and reducing the need for extra processing.

Design Flexibility: CNC machining can handle complex geometries, allowing designs to be optimized for material use and reducing waste while maintaining precision.

💡 Why Do So Many Factories Still Use CNC Machining? CNC machining’s benefits go beyond material efficiency, offering several other compelling reasons:

Precision and Reliability: For industries requiring extremely high precision, such as aerospace and medical devices, CNC machining delivers unmatched accuracy and consistency.

Material Versatility: CNC can work with a wide range of materials, including metals and plastics, making it highly versatile across various industries.

Speed and Scalability: CNC machining is ideal for both small batches and large-scale production, quickly producing high-quality parts once set up.

Superior Surface Finish: CNC machining provides excellent surface finishes, often reducing or eliminating the need for additional post-processing, something that 3D printing and other additive methods can’t easily achieve.

CNC machining isn’t just about “subtractive” manufacturing—it maximizes material use while ensuring high quality, efficiency, and precision.

🔧 #CNCmachining | #PrecisionManufacturing | #EfficientProduction What’s your take on the difference between CNC machining and 3D printing in terms of material usage? Share your thoughts in the comments below!

Contact Us Get More Info:

GreatLight Metal Technology Co., Ltd

✅ Website: https://glcncmachining.com/ ✅ Website: https://cnc-5-axis.com/ ✅ #10, Xinrong Street, Chongtou Community, Chang'an Town, Dongguan City, Guangdong, China, 523845 ✅ + 86 180 2756 7310 ✅ + 86 180 2756 7310(whatsapp) ✅ [email protected]

#DIsadvantage Of CNC Machine#Haas CNC Machine#Large CNC Machine#PrecIsion CNC Machining#Types Of CNC Machines#What Is A CNC Machines#What Is CNC Machine Operator#Woodworking CNC Machines#5 Axis CNC Machine Price#Benefits Of CNC Machining#Biggest CNC Machine#Carvera Desktop CNC Machine Review#CNC Full Form Machine#CNC Machin

0 notes

Text

Unlock advanced precision and efficiency in your projects with our CNC Milling Machine 5 Axis CNC Machining Center for Graphite, perfect for intricate designs and high-quality finishes.

#CNC Milling Machine 5 Axis CNC Machining Center for Graphite#Graphite Milling Machines#CNC precision engraving machine#Graphite Lathe#Graphite Milling

0 notes

Text

#5 axis brush tufting machine manufacturer#5 axis tufting machines india#brush tufting equipment india#advanced brush tufting equipment india#precision tufting machines india#5 axis brush manufacturing machinery#tufting machine suppliers india

0 notes

Text

Axis of Resistance Summary: October 8, 2024 Al-Aqsa Flood's Harvest of Good Tidings

📍AQABA, TUBAS GOVERNORATE, WEST BANK Saraya Al-Quds Brigades 🔻Fierce battles with forces storming the town 🔻Targeted forces surrounding the besieged house with heavy barrages of bullets + explosives: direct hits

Al-Aqsa Martyrs’ Brigades 🔻Fierce clashes with machine guns + explosives on forces around besieged house in the town of Aqaba

📍EAST-CENTRAL GAZA Saraya Al-Quds + Al-Nasser Salah Al-Din Brigades 🔻Bombed command & control HQ in Juhr Al-Dik with mortars

📍”NETZARIM” AXIS, GAZA CITY Martyr Abu Ali Mustafa + Al-Nasser Salah al-Din Brigades 🔻Bombarded command & control site with heavy mortars

📍AL-TAWAM, NORTHWEST GAZA CITY Al-Qassam Brigades 🔻Liquidated soldier at point-blank range + targeted rescue unit with Ra'adiya anti-personnel explosive device: killed & wounded

Al-Aqsa Martyrs' Brigades 🔻Fierce clashes with automatic weapons on infantry force in the incursion axis: confirmed casualties

📍JABALIA CAMP, NORTH GAZA Al-Qassam Brigades 🔻Detonated high-impact IED device on personnel carrier near Beitna Foundation HQ in the west 🔻Clashed with special force in Block 2: killed & wounded 🔻Clashed with force from zero-distance in Block 2 area: killed & wounded, helivac’d

Al-Aqsa Martyrs’ Brigades 🔻Bombed command & control HQ in the civil administration area of the east with mortars

📍SOUTHERN OCCUPIED INTERIOR Al-Aqsa Martyrs’ Brigades 🔻Bombed "Sderot" & Gaza envelope settlements with rocket barrage

📍HAIFA DISTRICT, OCCUPIED INTERIOR Hezbollah 🔻Targeted Haifa and the "Krayot" with large rocket barrage

📍OCCUPIED INTERIOR Islamic Resistance in Iraq 🔻Targeted 5 objectives in 5 separate operations in central & northern occupied Palestine with developed Arqab cruise missiles + drones

📍OCCUPIED INTERIOR Islamic Resistance in Iraq 🔻Carried out special operation, using drones, targeting a vital objective

📍NORTHERN OCCUPIED INTERIOR Islamic Resistance in Iraq 🔻Drone-attacked vital target

Hezbollah 🔻Targeted forces in "Shlomi" settlement with rocket barrage 🔻Targeted forces in "Hanita" settlement with rocket barrage 🔻Targeted artillery position in "Dishon" with rocket barrage 🔻Targeted artillery position in "Dalton" with rocket barrage 🔻Targeted forces near "Yiron" settlement with rocket barrage 🔻Targeted forces in “Metulla” with rocket barrage 🔻Targeted forces in “Metulla” settlement with rockets 🔻Targeted forces “Ya’ara” settlement attack drones squadron

📍BORDERLANDS Hezbollah 🔻Targeted forces near Marj site with rocket barrage 🔻Targeted forces at Al-Baghdadi site with attack drones squadron: targets hit precisely 🔻Targeted forces in Al-Manara orchards with rocket barrage 🔻Targeted forces in “Avivim” with rocket barrage 🔻Targeted forces in “Yiftah” with rocket barrage

📍BORDER VICINITY, SOUTH LEBANON Hezbollah 🔻Bombarded force supported by bulldozers & vehicles with artillery shells + rockets as they advanced towards Al-Labouna border area, forced retreat: certain casualties 🔻Targeted forces in near Maroun Al-Ras with rocket barrage

#free palestine#palestine#gaza#free gaza#jerusalem#current events#yemen#palestine news#israel#tel aviv#lebanon#south lebanon#hezbollah#north gaza#borderlands#gaza city

2 notes

·

View notes

Text

Top Boons of 5-axis CNC Machining

5 axis machining is now the most feasible choice for all types of machining jobs, not only the most difficult ones that require longer tool reach. 5-axis CNC machining is widely utilized for the most complex and precise jobs. This manufacturing approach is expected to provide significantly improved precision.

5-axis custom machining services provide a variety of advantages

Higher speed

5-axis machining allows the use of shorter cutting tools since the head may be lowered and the cutter is directed to the surface. You might expect better outcomes by increasing cutting speed and tool vibration.

Increased productivity

One of the most time-consuming parts of 3-axis machining is setting up a workpiece many times because it needs to be reoriented. This is required if an item needs to be machined on all or multiple sides, as the cutting tool remains at a fixed angle. A machinist must be physically present to rotate the component once machining on one side is completed for these 3-axis operations, and this human need can be a significant bottleneck in production.

5-axis machining by 5 axis machining manufacturer significantly minimizes the need for repeated setups since the movement of the table or spindle allows the cutting tool to approach the workpiece from various angles without removing it from the machine and resetting it. This leads to higher productivity throughout the whole process.

Hiring a dependable 5-axis machining services

Make sure your production team has been in operation for a significant amount of time. They should be highly experienced and qualified to ensure the quality of the job and timely completion. A corporation should be dependable and trustworthy.

Before selecting a firm, do not be afraid to ask questions regarding their 5-axis machining capabilities. A machine must also be of superior quality and capable of doing this task within a certain timeframe.

Inquire about the pricing of their services. Make sure you pay for what you get, and that the price matches the quality of the goods. Also, be informed of the materials they will be employing.

Main Source: https://bolesolutions.mystrikingly.com/

#5 axis machining manufacturer#5 Axis Machining Supplier#5 axis machining services China#5 Axis Machining Center

2 notes

·

View notes

Text

High precision 5-axis CNC machining service

#design#business#autos#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#5 axis cnc machining#5 axis precision machining#5 axis cnc#5 axis#high precision#cnc precision machining

2 notes

·

View notes

Text

GD prototyping precision metal parts cnc machining,We can customize cnc machining services according to customer requirements.

0 notes

Text

Are you looking for a reliable and precise low-volume manufacturing service?

Look no further! 🌟

At ProtoTech Machining, we are not just a manufacturer; we innovate with precision.🛠️

Our company specializes in top-notch low-volume manufacturing services that are tailored to various industry needs such as aerospace, medical, automotive, robotics, and many other sectors. From CNC machining to Rapid prototyping and Sheet Metal Fabrication, our expert team can leverage cutting-edge technologies to turn complex designs into reality. 🚀

Plus, whether you need 3D printing, 5-axis, or Swiss CNC machining, we have the best capabilities to provide innovative and cost-effective solutions without compromising quality. ✨

So don’t wait any longer! Contact us now and let us be your partner in all your manufacturing needs. 📞

Browse https://prototech-machining.com/low-volume-manufacturing/ to learn more.

#prototechmachining#3dprinting#cncmachining#technologies#swisscncmachining#manufacturing#innovative#metalfabrication#aerospace#medical#automative#robotics

2 notes

·

View notes

Text

EXPLORING THE 5 COOL PARTNER SELLER ELECTRONICS PRODUCTS-Part1

Exploring the 5 Cool Partner Seller Electronics Products

Prologue

Are you an electronics enthusiast looking to expand your electronics project repertoire? Want to take your skills to the next level by exploring new and exciting products? Look no further than our list of five cool electronics products from partner sellers!

Whether you’re interested in building your own smart home devices, experimenting with sensors, or creating your own robot, these products are sure to inspire you. They cover a lot of application areas, from loop detectors used to monitor vehicle count in parking garages to Arduino CNC shields used in CNC machines, from simple pulse sensors used to detect cardiovascular pulse signals from fingertip to RGB LED panel light used in smart home, these products are unique, compact, and functional. Not only are these products fun to build and use but they’re also designed to help you learn new skills and techniques along the way.

What’s more, these products all come from trusted partner sellers who are committed to developing high-quality products. They’re happy to provide technical support for customers who have questions, so you can be sure you’re getting the best in electronics.

So get ready to dive into the world of electronics and explore these five cool partner seller products. You’re sure to find something that piques your interest and takes your own electronics projects to the next level.

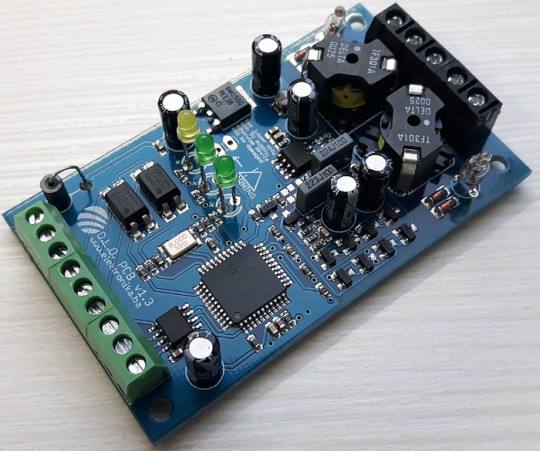

Inductive Loop Vehicle Detector by Elektronika-ba

Whether you need to monitor occupancy and count vehicles in parking garages, control vehicle access at door and barrier controls, or facilitate traffic light installations and traffic controllers, the inductive loop detector is the perfect solution. It can even detect the direction and speed of vehicle traffic, making it an invaluable tool for a variety of traffic-related applications. In addition, this device can function as a stand-alone speed trap and can be easily interfaced with Arduino.

We can also provide a pre-programmed PIC chip to meet your project requirements.

Specifications

Number of operating modes: 4

Tuning: Automatic

Detection type: Presence/Pulse

Presence time: Adjustable in 3 steps

Pulse duration: 250 ms / 500 ms

Signal filtering: Adjustable in 2 steps (NORMAL, HIGH)

Loop inductance: 20 uH — 1000 uH

Frequency range: 20 kHz — 145 kHz

Frequency selection: 2 combinations (LOW, HIGH)

Sensitivity: Maximum 0.0025% Δf/f, adjustable in 8 steps

Detection speed: 10 ms by default, adjustable

Start-up time: ~ 1 second per channel (or longer if the frequency is not stable)

Temperature range: -35°C — 120°C

Sensor protection: Galvanic isolation + gas discharge tube for lightning protection

Don’t settle for less — click here to learn more about the Inductive Loop Vehicle Detector and experience the compact, yet cool detector!

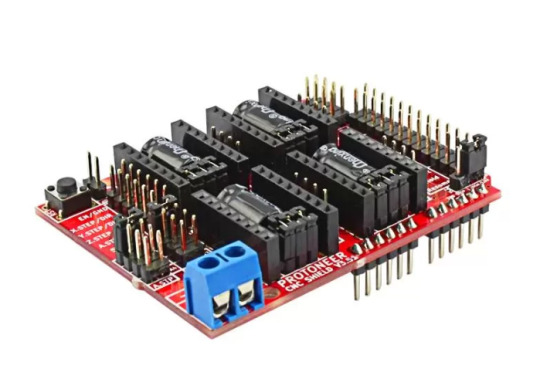

Arduino CNC Shield V3.51 by Protoneer

Designed by Protoneer, this kit is packed with features to ensure high precision control of your stepper motors, you can use it to easily build small CNC routers, DIY laser cutters, 3D printers, or any project that requires precise stepper motor control.

Our latest version 3.51 includes several enhancements to make assembly and installation even easier. We’ve added end-stop and probe signal filtering circuitry to eliminate false triggers and allow the use of unshielded cables for end-stops and probes. We’ve also increased the size of the solder pads for easier assembly and updated the probe pin labels to make installation a breeze.

With the Arduino CNC Shield Kit, you’ll have everything you need to build your own CNC router or mill with ease.

Features

Includes Noise Filers on all end stops and the probing pin. (New in V3.51)

GRBL 0.9 compatible. (Open source firmware that runs on an Arduino UNO that turns G-code commands into stepper signals https://github.com/grbl/grbl)

4-Axis support (X, Y, Z, A-Can duplicate X, Y, Z or do a full 4th axis with custom firmware using pins A4 and A3)

2 x End stops for each axis (6 in total)

Coolant enable

Uses removable Pololu A4988 compatible stepper drivers. (A4988, DRV8825 and others)(Not Included)

Jumpers to set the Micro-Stepping for the stepper drivers. (Some drivers like the DRV8825 can do up to 1/32 micro-stepping )

Compact design.

Stepper Motors can be connected with 4-pin molex connectors or soldered in place.

Runs on 12–36V DC. (At the moment only the Pololu DRV8825 drivers can handle up to 36V so please consider the operation voltage when powering the board.)

Don’t wait — click here to see more about the Arduino CNC Shield V3.51 and start your next project today!

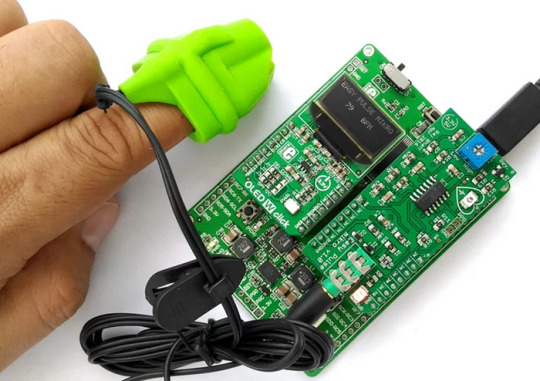

Easy Pulse Mikro by Embedded Lab

What’s more, the Easy Pulse Mikro is designed in the convenient Mikro bus form factor, making it easy to integrate with a wide range of mikroElektronika’s development boards. With all necessary instrumentation and amplification built right in, this powerful sensor provides a clean and precise analog PPG waveform output that’s routed to the AN pin of the mikroBus connector.

Whether you’re a hobbyist, student, or professional developer, the Easy Pulse mikro is the perfect tool for monitoring heart rate and other vital signs.

Click here to see more about the Easy Pulse mikro.

Features

Compatible with mikroBus socket.

Filtered and amplified analog PPG signal output

On-board potentiometer for adjusting amplifier gain, if needed (rotate clock-wise for increasing gain)

Onboard LED for indicating heartbeat. It flashes synchronously with the heartbeat on detecting the pulse from the fingertip.

2 notes

·

View notes

Text

Witness the precision of 5-axis CNC machining, where each movement mirrors the fluidity of a Kung Fu master—strategic, dynamic, and harmonious. Experience the dance of technology and artistry in perfect synchronization.

Tags: #CNCmachining #5AxisMachining #KungFu #PrecisionEngineering #ManufacturingMarvels #TechArtistry #DynamicMotion #EngineeringExcellence

0 notes

Text

CNC Gear Hobbing Manufacturer: Precision, Efficiency, and Innovation

Gears are an essential component of modern machinery, playing a crucial role in industries such as automotive, aerospace, industrial equipment, and renewable energy. As technology advances, manufacturers demand highly precise, durable, and efficient gears. This is where CNC gear hobbing manufacturers come into play, providing state-of-the-art solutions for high-quality gear production. If you are looking for a trusted CNC gear hobbing manufacturer, this guide will help you understand why choosing the right partner is essential for your business.

What is CNC Gear Hobbing?

CNC gear hobbing is a highly efficient gear-cutting process that utilizes Computer Numerical Control (CNC) technology to automate and optimize the machining of gear teeth. This method ensures high accuracy, consistency, and repeatability in gear production, making it the preferred choice for industries that require precision-engineered gears.

The key steps involved in CNC gear hobbing include:

Mounting the gear blank on a CNC hobbing machine.

Programming the CNC system with the exact gear specifications.

Rotating the hob and workpiece in synchronization to cut the gear teeth accurately.

Performing quality control checks to ensure compliance with industry standards.

Why CNC Gear Hobbing is the Best Choice

Industries around the world are shifting towards CNC gear hobbing due to its numerous advantages. Here are some key reasons why manufacturers prefer this method:

1. Exceptional Precision

CNC gear hobbing machines operate with high accuracy, ensuring that each gear meets exact specifications. This precision is crucial for applications that require tight tolerances and flawless performance.

2. Consistent Quality

Once programmed, CNC gear hobbing machines can produce identical gears repeatedly with minimal variation, ensuring consistent quality across production batches.

3. Higher Production Efficiency

Automation significantly reduces manual intervention, speeds up the manufacturing process, and minimizes material waste, making CNC gear hobbing a cost-effective and time-efficient solution.

4. Versatile Gear Production

CNC gear hobbing machines can produce various types of gears, including:

Spur gears

Helical gears

Worm gears

Sprockets

Splines

5. Cost-Effective Manufacturing

Despite the initial investment in CNC gear hobbing machines, manufacturers benefit from long-term cost savings through reduced labor costs, faster production times, and lower defect rates.

Industries That Rely on CNC Gear Hobbing

CNC gear hobbing manufacturers serve a wide range of industries, including:

Automotive: Producing gears for transmissions, differentials, and powertrains.

Aerospace: Manufacturing high-precision gears for aircraft engines and navigation systems.

Industrial Machinery: Creating gears for pumps, compressors, and heavy equipment.

Renewable Energy: Producing gears for wind turbines and solar tracking systems.

Robotics: Manufacturing small, intricate gears for robotic applications.

These industries demand high-performance gears, and CNC gear hobbing manufacturers ensure that every component meets the highest quality standards.

How CNC Gear Hobbing Works

The CNC gear hobbing process consists of the following steps:

Workpiece Setup: The gear blank is mounted securely onto the hobbing machine.

CNC Programming: The machine is programmed with precise gear specifications.

Gear Cutting: The rotating hob cuts the gear teeth into the workpiece with extreme precision.

Quality Control: Each gear undergoes rigorous inspection to ensure it meets industry standards.

Finishing and Delivery: Additional finishing processes, such as grinding or heat treatment, may be applied before the gears are shipped to customers.

Features of Modern CNC Gear Hobbing Machines

Advanced CNC gear hobbing machines come with innovative features to enhance production efficiency and gear quality, including:

Multi-Axis Control: Enables complex gear designs with high precision.

High-Speed Spindles: Increases production speed while maintaining accuracy.

Automated Tool Changes: Minimizes downtime and enhances efficiency.

Integrated Cooling Systems: Prevents overheating and prolongs tool life.

User-Friendly Interfaces: Simplifies programming and machine operation.

Benefits of Choosing a CNC Gear Hobbing Manufacturer

Partnering with a trusted CNC gear hobbing manufacturer brings several advantages:

1. Improved Gear Quality

Precision manufacturing ensures that gears perform reliably under demanding conditions.

2. Higher Production Output

Automated processes enable manufacturers to meet high demand efficiently.

3. Competitive Market Position

Manufacturers using CNC gear hobbing can offer high-quality gears, giving them an edge over competitors.

4. Reduced Manufacturing Costs

Efficiency gains lead to lower operational costs and improved profitability.

5. Custom Gear Solutions

Manufacturers can provide tailored solutions to meet specific customer requirements.

Why Choose Gear Hobbing Solutions for CNC Gear Hobbing?

At Gear Hobbing Solutions, we take pride in being a leading CNC gear hobbing manufacturer, offering cutting-edge technology, expertise, and exceptional customer service. Here’s what sets us apart:

Expertise and Experience

With years of experience in the industry, we understand the complexities of gear manufacturing and deliver solutions that exceed expectations.

State-of-the-Art Technology

Our CNC gear hobbing machines are equipped with advanced features to ensure precision, efficiency, and consistency.

Customization Options

We work closely with our clients to develop custom gears tailored to their specific applications.

Commitment to Quality

We adhere to stringent quality control measures and are ISO-certified to ensure our gears meet international standards.

Comprehensive Support

From consultation and design to production and delivery, we provide end-to-end support to ensure your project’s success.

The Future of CNC Gear Hobbing

The future of CNC gear hobbing manufacturers looks promising, with advancements in technology shaping the industry. Key trends include:

AI Integration: Leveraging machine learning for predictive maintenance and optimized production.

IoT Connectivity: Enabling real-time monitoring and remote control of CNC machines.

Sustainable Manufacturing: Developing energy-efficient and eco-friendly gear production methods.

These innovations will further enhance the precision, efficiency, and cost-effectiveness of CNC gear hobbing.

Conclusion

CNC gear hobbing is revolutionizing gear manufacturing by delivering high-precision, efficient, and cost-effective solutions. As a leading CNC gear hobbing manufacturer, Gear Hobbing Solutions is committed to providing top-quality gears that meet the needs of various industries.

If you are looking for a trusted CNC gear hobbing manufacturer, contact us today. Let us help you enhance your gear production capabilities and achieve new levels of efficiency and reliability.

0 notes

Text

Top 5 Benefits of CNC Press Brake Bending in Sheet Metal Fabrication

Introduction

In the world of metal fabrication, precision and efficiency are key factors in producing high-quality products. CNC Press Brake Bending is a game-changing technology that has revolutionized sheet metal fabrication. This advanced bending process utilizes computer-controlled machinery to achieve unparalleled accuracy, consistency, and speed. Whether you're working with aluminium, stainless steel, or mild steel, CNC Press Brake Bending ensures the perfect bend every time.

1. High Precision and Accuracy

One of the standout advantages of CNC Press Brake Bending is its ability to deliver exceptional precision. Traditional bending methods often rely on manual adjustments, which can lead to inconsistencies and errors. However, CNC (Computer Numerical Control) technology eliminates human errors by automating the bending process.

Tight Tolerances: CNC press brakes can achieve tolerances as tight as ±0.1mm, ensuring that every bend meets exact specifications.

Consistent Bends: Whether it's the first piece or the thousandth, CNC technology ensures uniformity in every product.

Multi-Axis Control: Advanced CNC press brakes feature multi-axis programming, allowing for complex bends with high accuracy.

By leveraging CNC Press Brake Bending, manufacturers can produce components with unparalleled precision, reducing rework and material waste.

2. Enhanced Efficiency and Speed

Speed is a critical factor in any manufacturing process, and CNC Press Brake Bending significantly improves production efficiency. Unlike manual bending machines, CNC press brakes can complete complex bending tasks in a fraction of the time.

Automated Programming: Once the design is input into the CNC system, the machine executes bends automatically, minimizing setup time.

Rapid Tool Changes: Modern CNC press brakes come with automatic tool-changing capabilities, reducing downtime between projects.

Simultaneous Operations: CNC technology allows multiple bends to be performed in a single setup, increasing overall production speed.

With faster cycle times and optimized workflows, CNC Press Brake Bending enables manufacturers to meet high-volume production demands without compromising on quality.

3. Versatility in Design and Material Handling

Another significant advantage of CNC Press Brake Bending is its versatility in handling different materials and complex designs. Whether the requirement is for simple bends or intricate multi-step formations, CNC press brakes can accommodate various shapes, sizes, and thicknesses.

Wide Range of Materials: CNC press brakes can bend a variety of metals, including stainless steel, aluminium, copper, and titanium.

Complex Geometries: CNC-controlled back gauges and customizable tooling allow for intricate bends and detailed designs.

Variable Thicknesses: The same machine can work with thin sheets or thick plates without requiring significant adjustments.

This flexibility makes CNC Press Brake Bending the ideal choice for industries such as aerospace, automotive, construction, and electronics, where precision and customization are crucial.

4. Cost-Effectiveness and Waste Reduction

Cost efficiency is a critical aspect of any manufacturing process. CNC Press Brake Bending helps businesses save money by reducing waste, minimizing errors, and improving overall productivity.

Reduced Material Waste: CNC-controlled bending ensures precise calculations, minimizing material wastage due to errors.

Lower Labor Costs: Automation reduces the need for manual intervention, lowering labour expenses.

Energy Efficiency: Modern CNC press brakes are designed to optimize energy consumption, reducing operational costs.

Minimal Rework: Accurate bending means fewer defects, leading to less rework and material scrapping.

By investing in CNC Press Brake Bending, businesses can streamline their manufacturing processes, reduce costs, and increase profitability.

5. Improved Safety and Operator Comfort

Safety is a top priority in any metal fabrication facility. Traditional press brakes require skilled operators to manually adjust and align metal sheets, which can lead to workplace injuries. CNC Press Brake Bending enhances safety by automating most of the bending process.

Reduced Manual Handling: CNC systems control the bending force and positioning, minimizing the need for manual adjustments.

Safety Sensors and Guards: Modern CNC press brakes are equipped with laser safety systems and light curtains to prevent accidents.

Ergonomic Work Environment: CNC automation reduces physical strain on operators, creating a safer and more comfortable workspace.

By implementing CNC Press Brake Bending, manufacturers can ensure a safer working environment while maintaining high production efficiency.

Conclusion

In today's competitive manufacturing industry, CNC Press Brake Bending plays a vital role in achieving high-quality, precision sheet metal fabrication. With benefits such as unmatched accuracy, increased efficiency, versatile design capabilities, cost-effectiveness, and improved safety, CNC press brakes have become an indispensable tool for modern metal fabrication companies. Whether for small-scale custom projects or large-scale industrial production, CNC press brake bending ensures consistency, reliability, and superior results.

Contact Us Today!

At Yash Lasertek, we specialize in CNC Press Brake Bending services, delivering precision, efficiency, and cost-effective solutions for all your metal fabrication needs. Our advanced CNC press brakes are designed to handle complex projects with utmost accuracy.

Visit Us to learn more about how our CNC press brake bending services can benefit your next project.

Call us today to discuss your requirements and get a customized solution tailored to your needs!

#CNCPressBrakeBending#SheetMetalFabrication#MetalBending#PrecisionEngineering#ManufacturingTechnology#MetalFabrication#CNCBending#PressBrakeTechnology

0 notes

Text

The Unimill 5-AX is a high-performance 5-axis CNC machine designed for precision machining and complex operations. Its advanced features and robust design make it ideal for industries like aerospace, automotive, and mold manufacturing, ensuring accuracy and efficiency.

0 notes