#Haas CNC Machine

Explore tagged Tumblr posts

Text

𝐃𝐞𝐛𝐮𝐝𝐝𝐢𝐧𝐠 𝐭𝐡𝐞 𝐦𝐨𝐝𝐞𝐥 𝐨𝐟 𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥 𝐖𝐚𝐬𝐭𝐞: 𝐈𝐬 𝐂𝐍𝐂 𝐌𝐚𝐜𝐡𝐢𝐧𝐠 𝐚 𝐟𝐨𝐫𝐦 𝐨𝐟 𝐰𝐚𝐬𝐭𝐞?

CNC machining removes material, but does that mean it’s truly "wasting" it? In fact, modern CNC machining processes go to great lengths to minimize waste. Here’s how every inch of material is maximized:

High Precision Machining: Modern 5-axis CNC machines provide precise cutting with fine control over every detail, minimizing unnecessary material removal and ensuring maximum material efficiency.

Recycling and Reuse: Materials like aluminum, steel, and titanium can be recycled, melted down, and repurposed into new parts, significantly reducing waste in the manufacturing process.

CAD/CAM Integration: Advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software help optimize design and cutting paths, ensuring material is used efficiently and reducing the need for extra processing.

Design Flexibility: CNC machining can handle complex geometries, allowing designs to be optimized for material use and reducing waste while maintaining precision.

💡 Why Do So Many Factories Still Use CNC Machining? CNC machining’s benefits go beyond material efficiency, offering several other compelling reasons:

Precision and Reliability: For industries requiring extremely high precision, such as aerospace and medical devices, CNC machining delivers unmatched accuracy and consistency.

Material Versatility: CNC can work with a wide range of materials, including metals and plastics, making it highly versatile across various industries.

Speed and Scalability: CNC machining is ideal for both small batches and large-scale production, quickly producing high-quality parts once set up.

Superior Surface Finish: CNC machining provides excellent surface finishes, often reducing or eliminating the need for additional post-processing, something that 3D printing and other additive methods can’t easily achieve.

CNC machining isn’t just about “subtractive” manufacturing—it maximizes material use while ensuring high quality, efficiency, and precision.

🔧 #CNCmachining | #PrecisionManufacturing | #EfficientProduction What’s your take on the difference between CNC machining and 3D printing in terms of material usage? Share your thoughts in the comments below!

Contact Us Get More Info:

GreatLight Metal Technology Co., Ltd

✅ Website: https://glcncmachining.com/ ✅ Website: https://cnc-5-axis.com/ ✅ #10, Xinrong Street, Chongtou Community, Chang'an Town, Dongguan City, Guangdong, China, 523845 ✅ + 86 180 2756 7310 ✅ + 86 180 2756 7310(whatsapp) ✅ [email protected]

#DIsadvantage Of CNC Machine#Haas CNC Machine#Large CNC Machine#PrecIsion CNC Machining#Types Of CNC Machines#What Is A CNC Machines#What Is CNC Machine Operator#Woodworking CNC Machines#5 Axis CNC Machine Price#Benefits Of CNC Machining#Biggest CNC Machine#Carvera Desktop CNC Machine Review#CNC Full Form Machine#CNC Machin

0 notes

Text

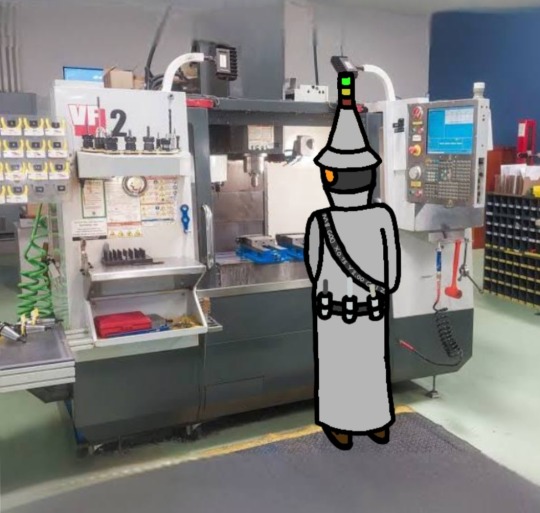

The Manufacturing Wizard inspects a CNC milling machine. His belt is similar to a chain-type automatic tool changer, and he uses it to hold a couple cutting tools.

#kuka haas#manufacturing wizard#my art#manufacturing#cnc machine#I put some G-code on the other belt

9 notes

·

View notes

Text

Totally get the criticism and the theories etc but maybe factor in that Haas is synonymous with a few big things, primarily their CNC machine, not just racing. You know. If you want. No big deal otherwise.

#f1#haas f1 team#this is about guenther steiner and the money laundering joke#the joke is funny! but it doesn't exactly land when the company is SO WELL KNOWN outside of f1 for machining#in fact#haas has always been a personal favorite f1 team bc ive worked with their cnc machines#and then kevin of course

0 notes

Note

Is it something like this? Look at this guy, he's just a little baybey. Just a cute little guy. That's just how mills are idk what to tell you.

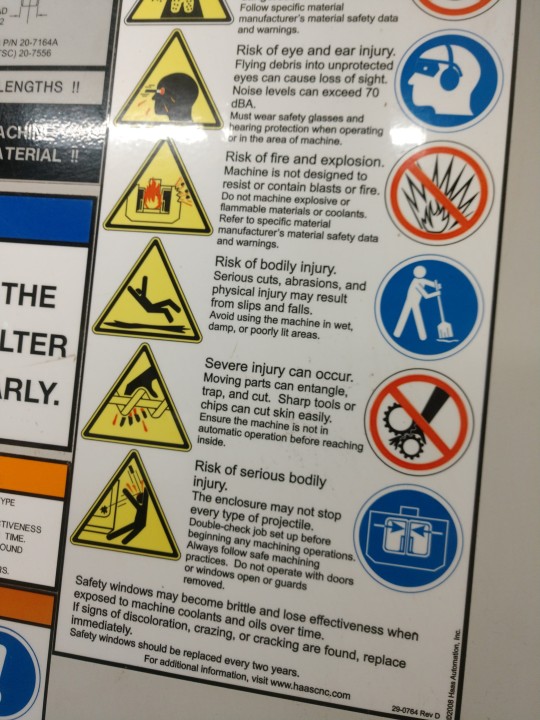

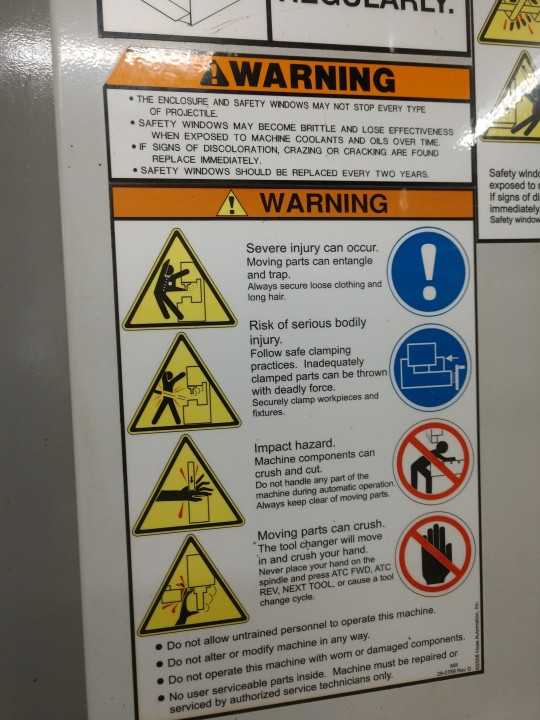

hey heres the whole warning panel from one of the HAAS mini mills at my job, that only like 2 engineers are allowed to touch. personal fav is 3rd image 2 triangles down. owned lmao

splashes of red… very good…

#Did you know that HAAS has a F1 team? I just learned that I think it's kinda cool#HAAS#CNC mill#manufacturing#I like HAAS machines! my high school had two HAAS cnc mills

204 notes

·

View notes

Text

Had a tap blow up while someone was machining today.

Almost caught it on video which would have been helpful as fuck to identify what happened. Running theory is chips got caught in it and so the tap couldn't rotate leading to it snapping.

1 note

·

View note

Text

Formula 1 Car Naming Conventions

With F1 car launches in full force, I have been looking into why teams name their cars the way that they do. Each team has a different naming convention. Some of the naming conventions are easy to understand like RB19. Then there are the many Ferrari naming conventions (SF-23, F1-75, SF1000, etc).

So here are the current naming conventions for each team in order of car launch dates.

Haas

The 2024 Haas car is called the VF-24.

In an article for the 2016 Haas Car Launch, it was explained why they named the car the VF-16.

The first CNC machine manufactured by Haas Automation in 1988. It was unofficially named the VF-1, otherwise known as the Very First 1. For Formula 1, Haas kept the VF and changed the 1 for the last two digits of the year. VF-16 = 2016, VF-23 = 2023, etc.

Williams

The 2024 Williams car is called the FW46.

Every car by Williams has carried the FW prefix, with the first one being the FW06 in 1978. The FW in the name stands for the founder of the team, Sir Frank Williams. Despite the Williams family no longer being involved in the team, the current owners have kept the naming convention as a link to the storied history of Williams Racing.

If the car keeps the same chassis as the previous year, then a B is added to the end of the name to show that it is a B-Spec car (and on a few occasions there have been C-Spec cars).

Stake F1 Team Kick Sauber

The 2024 Sauber car is called the C44.

Sauber made its debut with the C12 in 1993 and has since used this naming convention except for the BMW Sauber years. But after BMW left, Sauber returned to using C and picked up the numbers where it would have been if the naming convention hadn't changed.

The C stands for Peter Sauber's wife Christiane. His first car was called the C1 and since then all Sauber cars (with the exception of the BMW Sauber cars) have used the C for Christiane.

Alpine

The 2024 Alpine car is called the A524.

Since Renault became Alpine in 2021, all of their cars have had the following naming formula: A + 5 + the last two digits of the year.

In January 2021, the team explained why the 2021 car was called the A521. The A is for Alpine. The 5 is for A500, which was a prototype for the 1975 F1 season. All of the cars since 2021, have followed this naming convention and have just changed the 21 to correspond with the current year.

Visa Cash App RB

The Visa Cash App RB 2024 car is called the VCARB 01.

There really isn't much about the team as of right now due to the rebrand changing up everything from the previous AlphaTauri stuff. However, VCARB is the acronym for the team name and this is the first car to be run under the rebrand, thus the 01.

Aston Martin

The Aston Martin 2024 car is called the AMR24.

Since 2021, Aston Martin has used the same naming convention: AMR + the last 2 digits of the current year. The AMR stands for Aston Martin Racing.

Ferrari

The 2024 Ferrari car is named the SF-24.

However, unlike the other teams, it is hard to predict what the Ferrari will be named. In recent years, there have been the F1-75, SF21, SF1000, SF90, F14-T, and 150º Italia just to list a few of the names.

For 2024, it is a simple naming convention that has been used in the past. SF = Scuderia Ferrari and then the last two digits of the year the car will be run.

RacingNews365 made a chart of every Ferrari car since 2000 and the meaning behind the name. For the most part, the formula for naming the car is either Ferrari/Scuderia Ferrari + year or important event commemoration.

Ferrari also uses the dash inconsistently which doesn't really mean anything, but is just not the most aesthetically pleasing when looking at a list of all the car names.

Mercedes

The 2024 Mercedes car is called the W15.

All Mercedes cars have had a W in the car name, even the 1954 and 1955 cars. The 2010 Mercedes car was the W01 and since then the team has continued chronologically.

The W stands for Wagen which means car in German.

McLaren

The 2024 McLaren car is called the MCL38.

The numbers have been ascending since almost the beginning with a few B-Spec cars for the most part. However, the beginning letters have changed over the years. Since 2017, McLaren has used MCL. And just as it looks, MCL is short for McLaren.

The 2023 car didn't have the chronological number due to honoring McLaren's 60 years of history.

Red Bull

The 2024 Red Bull car is named the RB 20.

Since its first year, the Red Bull cars have been given the RB designation along with a chronologically ascending number. The RB as expected stands for Red Bull.

The RB 20 marks 20 seasons of Red Bull in Formula One.

#formula 1#f1#naming conventions#car launches#haas f1 team#sauber#stake f1 team#williams racing#alpine#visa cash app rb#vcarb#mercedes#ferrari#scuderia ferrari#mclaren f1#red bull racing#f1 primer

41 notes

·

View notes

Text

this is where the glory of cnc milling machines comes in. look at the beautiful control panel of a haas cnc milling machine.

god i love machining sm. she is gorgeous

nobody:

the most obnoxious idiot on the planet: "what if we replaced the buttons with a touch interface"

28K notes

·

View notes

Text

HAAS Vector Drive – High-Performance CNC Power Solutions

Upgrade your CNC machine with a reliable HAAS Vector Drive from CNC Tools LLC. Ensure optimal performance, precision, and efficiency with our high-quality vector drives. We work with industries worldwide in the aerospace, automotive, engineering, oil field, and manufacturing sectors. Shop now for the best deals!

0 notes

Text

𝐑𝐞𝐯𝐨𝐥𝐮𝐭𝐢𝐨𝐧𝐢𝐳𝐢𝐧𝐠 𝐂𝐍𝐂 𝐌𝐚𝐜𝐡𝐢𝐧𝐢𝐧𝐠: 𝐁𝐫𝐞𝐚𝐤𝐢𝐧𝐠 𝐁𝐨𝐮𝐧𝐝𝐚𝐫𝐢𝐞𝐬

Prepare to have your perception of CNC machining completely transformed! In this video, I'm showcasing groundbreaking projects that push the boundaries of what's possible with CNC technology.

Watch as we demonstrate: ✅ Innovative design approaches that challenge conventional limitations ✅ Advanced machining techniques that deliver stunning precision ✅ Creative applications that merge art with engineering ✅ Unexpected material combinations that open new possibilities

These projects will revolutionize your understanding of CNC capabilities and inspire your next breakthrough innovation.

𝐏𝐫𝐨 𝐢𝐧𝐬𝐢𝐠𝐡𝐭: The most remarkable CNC innovations often come from thinking beyond traditional manufacturing constraints!

Join the #CNCMiracleChallenge: Before watching, share your wildest guess about what we've created. Then prepare to be amazed as we reveal the final masterpiece!

#InteractiveReveal #CNCInnovation #ManufacturingInnovation #EngineeringCreativity

Contact Us Get More Info:

GreatLight Metal Technology Co., Ltd

✅ Website: https://glcncmachining.com/ ✅ Website: https://cnc-5-axis.com/ ✅ #10, Xinrong Street, Chongtou Community, Chang'an Town, Dongguan City, Guangdong, China, 523845 ✅ + 86 180 2756 7310 ✅ + 86 180 2756 7310(whatsapp) ✅ [email protected]

#CNC Machining Centre#CNC Machining Company#CNC Machining Services Birmingham#CNC Machining What Is#CNC Milling Machine Uk#CNC Multitasking Machining Center Manufacturers#CNC Plasma Machine#Desktop CNC Machine Uk#Desktop CNC Machines#Diy CNC Milling Machine#Duties Of CNC Machine Operator#Haas CNC Milling Machines#Hobby CNC Milling Machine#Hobby Milling Machine CNC

0 notes

Text

I've been thinking about buying a used mill and lathe for my basement. I work for a major manufacturer of metal cutting machines and would love to use / tinker with them in my spare time. One thing I've tried to search for / look into on youtube & elsewhere is cutting wood using a metal cutting cnc like a Haas or Makino. I find hardly an info on it. There must be a reason, no?

Is it because of price? Most of my "wood cnc" search results come up with routers that appear to cut mostly flat items. Nothing very 3d.

With some of the medium size horizontal cnc's I deal with, you could take a giant 3' diameter 4' high log and cut out a life size bust of Trump if you wanted to. It might not have any practical use but it could be a real attention getter.

0 notes

Text

Comprehensive Analysis of Machine Tools Market Growth: US$ 114.3 Bn by 2031

Astute Analytica, a prominent market research firm, has recently published a comprehensive report that offers an extensive analysis of the global Machine Tools market. This report goes beyond mere statistics, providing deep insights into various critical aspects such as market segmentation, key players, market valuation, and regional overviews. It serves as a valuable resource for businesses and stakeholders seeking to navigate this evolving industry landscape.

Market Valuation

The report includes a thorough evaluation of the market valuation, drawing from historical data, current trends, and future projections. By employing rigorous analytical methods, it effectively captures the growth trajectory of the market. This detailed assessment allows businesses to understand the factors driving growth and make informed decisions regarding investments and strategic initiatives.

Global machine tools market is estimated to generate a revenue of US$ 114.3 Bn by 2031 from US$ 75.2 bn in 2022, registering a CAGR of 4.7% over the period 2023-2031.

A Request of this Sample PDF File@- https://www.astuteanalytica.com/request-sample/machine-tools-market

Comprehensive Market Overview

Astute Analytica's report provides a holistic overview of the global Machine Tools market. It encapsulates a wide array of information related to market dynamics, including growth drivers, challenges, and opportunities. Stakeholders can leverage these insights to formulate effective strategies and maintain a competitive edge in the market.

Key Players in the Market

The report identifies and profiles the major players who are influencing the global Machine Tools market. Through meticulous research, it presents a clear view of the competitive landscape, detailing the strategies, market presence, and significant developments of leading companies. This section is vital for stakeholders who wish to understand the positioning and actions of their competitors.

Key Companies:

Ace Micromatic Group

Amada Co. Ltd.

CHIRON Group

Dalian Machine Tool Group Corporation (DMTG)

DMG MORI

Doosan Machine Tools Co. Ltd.

Electronica Hitech Engineering Pvt. Ltd.

Georg Fischer Ltd

Gleason Corporation

GROB-WERKE GmbH & Co. KG

Haas Automation Inc.

Hyundai WIA

JTKET Corporation

Komatsu Ltd.

MAG IAS GmbH

Makino

Okuma Corporation

Schuler AG

Spinner Machine Tools

Yamazaki Mazak Corporation

Other Prominent Players

For Purchase Enquiry: https://www.astuteanalytica.com/industry-report/machine-tools-market

Segmentation Analysis

A crucial component of the report is the segmentation analysis, which delves into various market segments based on industry verticals, applications, and geographic regions. This detailed examination provides stakeholders with a nuanced understanding of market dynamics, enabling them to identify opportunities for growth and areas for investment.

Market Segmentation:

By Product

Milling Machine

Lathe Machine

Laser Machine

Drilling Machine

Turning Machine

Grinding Machine

Electrical Discharge Machine

Machining Centers

By Automation Type

CNC Machine Tools

Conventional Machine Tools

By Industry

Automotive

Aerospace and Defense

Construction Equipment

Power and Energy

Industrial

Others

By Sales Channel

Dealers and Distributors

Events and Exhibitions

By Region

North America

The U.S.

Canada

Mexico

Europe

Western Europe

The UK

Germany

France

Italy

Spain

Rest of Western Europe

Eastern Europe

Poland

Russia

Rest of Eastern Europe

Asia Pacific

China

India

Japan

Australia & New Zealand

ASEAN

Malaysia

Singapore

Thailand

Indonesia

Cambodia

Vietnam

Rest of ASEAN

Rest of Asia Pacific

Middle East & Africa

UAE

Saudi Arabia

Turkey

Egypt

South Africa

Nigeria

Rest of MEA

South America

Argentina

Brazil

Columbia

Rest of South America

Research Methodology

Astute Analytica is recognized for its rigorous research methodology and dedication to delivering actionable insights. The firm has rapidly established a solid reputation by providing tangible outcomes to clients. The report is built on a foundation of both primary and secondary research, offering a granular perspective on market demand and business environments across various segments.

Beneficiaries of the Report

The insights presented in this report are invaluable for a range of stakeholders, including:

Industry Value Chain Participants: Those directly or indirectly involved in the Machine Tools market need to stay informed about leading competitors and current market trends.

Analysts and Suppliers: Individuals seeking up-to-date insights into this dynamic market will find the report particularly beneficial.

Competitors: Companies looking to benchmark their performance and assess their market positions can leverage the data and analysis provided in this research.

Astute Analytica's report on the global Machine Tools market is an essential resource that empowers stakeholders with the knowledge needed to navigate and thrive in this competitive landscape.

Download Sample PDF Report@- https://www.astuteanalytica.com/request-sample/machine-tools-market

About Astute Analytica:

Astute Analytica is a global analytics and advisory company that has built a solid reputation in a short period, thanks to the tangible outcomes we have delivered to our clients. We pride ourselves in generating unparalleled, in-depth, and uncannily accurate estimates and projections for our very demanding clients spread across different verticals. We have a long list of satisfied and repeat clients from a wide spectrum including technology, healthcare, chemicals, semiconductors, FMCG, and many more. These happy customers come to us from all across the globe.

They are able to make well-calibrated decisions and leverage highly lucrative opportunities while surmounting the fierce challenges all because we analyse for them the complex business environment, segment-wise existing and emerging possibilities, technology formations, growth estimates, and even the strategic choices available. In short, a complete package. All this is possible because we have a highly qualified, competent, and experienced team of professionals comprising business analysts, economists, consultants, and technology experts. In our list of priorities, you-our patron-come at the top. You can be sure of the best cost-effective, value-added package from us, should you decide to engage with us.

Get in touch with us

Phone number: +18884296757

Email: [email protected]

Visit our website: https://www.astuteanalytica.com/

LinkedIn | Twitter | YouTube | Facebook | Pinterest

0 notes

Text

The Top 10 Machine Shop Auction Sites to Check Out

When it comes to finding high-quality machinery, tools, and equipment for your workshop, machine shop auctions are a great way to score significant deals. These auctions offer a wide range of products from well-known brands at competitive prices. Whether you’re a professional machinist or a hobbyist, these sites can help you find everything from CNC machines to precision tools. Below are the top 10 machine shop auction sites to check out for your next purchase.

1. BidSpotter

BidSpotter is one of the largest and most reputable online auction sites for industrial equipment, including machine shop tools. It hosts auctions from various sectors such as manufacturing, construction, and metalworking. With a user-friendly interface and detailed listings, BidSpotter allows buyers to find and bid on used and new machine tools. It also offers live auctions, enabling you to participate in real-time bidding.

2. IronPlanet

IronPlanet is known for offering a wide variety of heavy equipment, including machine shop auctions. It allows you to bid on items like lathes, mills, drills, and CNC equipment. IronPlanet also provides equipment inspection reports, ensuring that buyers have a clear understanding of the machinery’s condition before placing bids. The platform’s mobile app makes it easy to keep track of auctions on the go.

3. Machinery Network Auctions

Machinery Network Auctions specializes in the sale of used industrial equipment, including machine shop tools and machinery. They feature regular auctions and provide detailed descriptions and photographs of each item, allowing buyers to make informed decisions. Machinery Network is ideal for those looking for high-quality equipment from trusted manufacturers like Haas, Mori Seiki, and Okuma.

4. GovDeals

GovDeals is a government surplus auction site that features a broad selection of machine shop equipment, from tools to large machinery. Government agencies often sell off their surplus equipment through this platform, which means buyers can find well-maintained machines at affordable prices. GovDeals is an excellent choice for those looking to purchase machines that have been previously used in public sector applications.

5. Ritchie Bros. Auctioneers

Ritchie Bros. is a global leader in heavy equipment auctions, and it frequently features industrial equipment auctions, including machine shop auctions. The site offers a variety of bidding options, such as online and onsite auctions, and provides detailed equipment condition reports. Ritchie Bros. has a large network of buyers and sellers, making it a great platform for finding used machines and tools from a wide range of industries.

6. HGR Industrial Surplus

HGR Industrial Surplus specializes in the sale of industrial equipment, including machinery, tools, and parts for machine shops. Their auction platform offers everything from CNC machines to hand tools, all at discounted prices. HGR frequently holds online and onsite auctions, allowing buyers to bid on high-quality equipment and often find deals from reputable manufacturers.

7. Thomas Industrial Auctions

Thomas Industrial Auctions is a trusted auction site for machine shops, featuring both live and online auctions of industrial equipment. The site is known for its regular machinery auctions, which offer a variety of products, including CNC machines, fabrication equipment, and more. They also provide detailed descriptions and photographs of each lot, helping buyers make educated purchasing decisions.

8. Surplus Industrial Equipment

Surplus Industrial Equipment is a great place to find quality used machine shop tools and machinery. They hold frequent online auctions that feature a wide range of equipment, including drills, lathes, presses, and CNC machines. The site provides detailed information on each item, and many of the auctions include equipment that is still in excellent working condition.

9. Machinesused.com

Machinesused.com specializes in the sale of pre-owned machine tools, including CNC machines, grinders, lathes, and mills. The site features both live and online machine shop auctions, where you can place bids on machinery from top brands. Machinesused.com also offers financing options, which can make it easier to purchase high-cost equipment.

10. Industrial Auction Hub

Industrial Auction Hub is an online auction platform that focuses on the sale of industrial equipment, including machine shop auctions. This site offers a wide selection of machinery, from heavy-duty machines to precision tools. Industrial Auction Hub regularly hosts auctions featuring tools, equipment, and machines from well-known manufacturers, allowing buyers to find exactly what they need for their workshop.

Conclusion

Machine shop auctions offer an excellent opportunity to acquire high-quality machinery and tools at competitive prices. With the right auction platform, you can find a wide range of equipment that suits your specific needs. From CNC machines to lathes, the sites listed above provide a great variety of options for those in the machine shop industry. Be sure to do your research, check the condition of the items you’re bidding on, and stay updated on upcoming auctions to make the best purchase decisions.

0 notes

Text

Computer Numerical Control Machines Market

CNC Machines Market Size, Share, Trends: DMG MORI Co., Ltd. Leads

Integration of IoT and AI in CNC Machines

Market Overview:

The Computer Numerical Control (CNC) Machines Market is expected to develop at a CAGR of 6.8% from 2024 to 2031. According to estimates, the market will grow from XX USD in 2024 to YY USD by 2031. Asia-Pacific now dominates the industry, accounting for the vast majority of worldwide sales. Key factors include increased industrial automation, greater demand for precision engineering, and increased acceptance of Industry 4.0 technology. The manufacturing sector is developing, particularly in emerging markets, and driving stable expansion in the market. Factors such as increased need for mass production with shorter lead times, a greater emphasis on efficiency and precision in manufacturing processes, and the requirement for complicated component manufacture all contribute to market growth. Furthermore, the incorporation of cutting-edge technology such as artificial intelligence and machine learning into CNC machines promotes industry innovation.

DOWNLOAD FREE SAMPLE

Market Trends:

The CNC machine market is seeing a substantial shift towards the integration of Internet of Things (IoT) and artificial intelligence (AI) technologies. This transition is primarily being driven by the industry's push for smart manufacturing and the implementation of Industry 4.0 principles. IoT-enabled CNC machines provide real-time monitoring, predictive maintenance, and increased operational efficiency, whereas AI integration enables adaptive control, optimised toolpaths, and better decision-making processes. The trend of IoT and AI integration is projected to accelerate as manufacturers attempt to gain a competitive advantage through increased productivity and flexibility.

Market Segmentation:

Milling machines have established themselves as the dominant category in the CNC machine industry, owing to their versatility, precision, and broad variety of applications across several industries. These machines are capable of conducting sophisticated cutting operations on a wide range of materials, making them essential in current production processes. According to recent industry data, CNC milling machines account for about YY% of the global CNC machine market. Advances in multi-axis milling technology have reinforced the segment's market dominance, ensuring its continuous expansion and supremacy in the CNC industry.

Market Key Players:

The CNC machines market is highly competitive, with major players focusing on technological innovation and strategic alliances. Key companies such as DMG MORI Co., Ltd., Haas Automation, Inc., FANUC Corporation, Yamazaki Mazak Corporation, Okuma Corporation, Doosan Machine Tools Co., Ltd., Hyundai WIA, Makino Milling Machine Co., Ltd., GF Machining Solutions Management SA, and JTEKT Corporation dominate the market.

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

CNC Milling Machines Market Report

CNC Milling Machines Market Report: A Comprehensive Analysis of the Global Market

Industry Dimensions

The global CNC Milling Machines Market size was valued at USD 82.48 billion in 2023 and is projected to reach from USD 89.52 billion in 2024 to USD 172.31 billion by 2032, growing at a CAGR of 3.92% during the forecast period (2024–2032). CNC milling machines are computer-controlled machines that use rotating cutters to remove material from a workpiece. These machines are widely used in various industries, such as automotive, aerospace, and electronics, for precision machining and manufacturing.

Get Your Exclusive Sample of the CNC Milling Machines Market Report Today starting at just USD 1850! : https://straitsresearch.com/report/cnc-milling-machines-market/request-sample

Industry Key Trends

Some of the key trends in the CNC Milling Machines Market include:

Increasing demand for precision machining: The demand for precision machining is increasing, driven by the growing need for complex and intricate parts in various industries.

Advancements in technology: Advancements in technology, such as the development of more advanced CNC controls and the use of artificial intelligence and machine learning, are driving growth in the market.

Growing adoption of Industry 4.0: The growing adoption of Industry 4.0, which involves the use of automation, robotics, and data analytics to improve manufacturing efficiency, is driving growth in the market.

Increasing focus on energy efficiency: The increasing focus on energy efficiency is driving growth in the market, as companies seek to reduce their energy consumption and costs.

CNC Milling Machines Market Size and Share

The global CNC Milling Machines Market size is projected to reach USD 172.31 billion by 2032, growing at a CAGR of 3.92% during the forecast period.

CNC Milling Machines Market Statistics

Some of the key statistics in the CNC Milling Machines Market include:

Market size: The global CNC Milling Machines Market size was valued at USD 82.48 billion in 2023.

Growth rate: The market is projected to grow at a CAGR of 3.92% during the forecast period.

Segmentation: The market can be segmented by product type, axis type, and end-user.

Regional Trends

The global CNC Milling Machines Market can be segmented into several regions, including:

North America: The North American market is driven by the presence of major industries, such as automotive and aerospace, which require precision machining and manufacturing.

APAC: The APAC market is driven by the growing demand for precision machining and manufacturing in countries, such as China, Japan, and South Korea.

Europe: The European market is driven by the presence of major industries, such as automotive and aerospace, which require precision machining and manufacturing.

LAMEA: The LAMEA market is driven by the growing demand for precision machining and manufacturing in countries, such as Brazil and South Africa.

To purchase the report: https://straitsresearch.com/buy-now/cnc-milling-machines-market

CNC Milling Machines Market Segmentations

The global CNC Milling Machines Market can be segmented into several categories, including:

By Product Type:

Vertical CNC Milling Machines

Horizontal CNC Milling Machines

Universal CNC Milling Machines

By Axis Type:

3-Axis

4-Axis

Others

By End-User:

Automotive

Electrical and Electronics

Aerospace and Defense

Others

For more details: https://straitsresearch.com/report/cnc-milling-machines-market/segmentation

Top Players in CNC Milling Machines Market

Some of the top players in the CNC Milling Machines Market include:

Doosan

Five

F-Zimmermann

JTEKT

Makino

Ace Micromatic Group

DMG MORI SEIKI

The CHIRON Group

GF Machining Solutions Management

HYUNDAI WIA

Gleason Corporation

GROB-WERKE

Haas Automation

Detailed Table of Content report: @https://straitsresearch.com/report/cnc-milling-machines-market/toc

0 notes

Text

Grinding Machinery Market Outlook, Competitive Strategies And Forecast

The global grinding machinery market size was estimated at USD 5.63 billion in 2023 and is anticipated to grow at a CAGR of 4.3% from 2024 to 2030. The growing construction and automotive industry is expected to drive the market demand. The automotive industry demands high-precision components with tight tolerances and fine surface finishes for engine parts, transmission components, and chassis elements, driving the demand for precision grinding machines. Moreover, the aerospace industry requires components with the highest levels of quality, reliability, and safety, leading to a growing demand for grinding machines to machine complex aerospace components such as turbine blades, engine casings, and structural components.

The demand for grinding machinery is rising across various industries, driven by the need for precision components and the growth of sectors like automotive, aerospace, and construction. Grinding machines are highly valued for their precision, efficiency, and ability to automate industrial processes. They are widely used in aerospace, machinery manufacturing, and automotive industries, where tight tolerances and high-quality finishes are critical.

Gather more insights about the market drivers, restrains and growth of the Grinding Machinery Market

Key Grinding Machinery Company Insights

Some of the key players operating in the market include Amada Machine Tools Co., Ltd., Junker Group, and Haas Automation, Inc.

• Amada Machine Tools Co., Ltd. offers diversified products specializing in automation machines, combination machines, high precision CNC lathe machines, bending, joining, and cutting such as laser combination machines, punch machines, and shearing machines. The company also offers AMADA Industry 4.0 solutions, V-factory, AMADA Order Manager, and IoT Remote Support to meet challenging production deadlines, complex production processes, and limited access to real-time data innovations. Incorporating advanced IoT-based support helps the company penetrate the CNC machining and turning centers market. The company has a presence in over 100 countries and a total of 35 manufacturing facilities worldwide. It generated 38.8% of revenue from Japan, 26.3% from North America, 19.6% from Europe, and over 15% from Asia Pacific in the fiscal year 2022.

• Haas Automation, Inc. manufactures vertical mills, multi-axis lathe & mill machines, horizontal mills, automation systems, and rotaries & indexers. The products are manufactured at the company’s expansive facility in Oxnard, California. To maintain accuracy and product quality, the company produces all essential parts required for machine manufacturing internally. Its 1.1 billion-square-foot premises leverage lean manufacturing techniques and just-in-time production strategies to enhance the efficiency of its production by reducing the cost. This approach allows the company to offer machines at lower prices with superior quality by transferring the benefits of cost savings to the customers.

Recent Developments

• In May 2024, UNITED GRINDING, a leading manufacturer of grinding machinery, launched two innovative products to enhance automation and productivity in the tool-grinding industry. The first is the HELITRONIC VISION 400 L, a high-end tool-grinding machine that offers advanced capabilities. The second is the fully automatic HELICHECK PLUS measuring machine, which is part of the "Automated Tool Production" (ATP) system. The launch of these new products by UNITED GRINDING demonstrates the company's commitment to providing advanced grinding machinery that improves efficiency, productivity, and automation in tool manufacturing applications. These innovations cater to the growing demand for precision tools across various industries, including aerospace, automotive, and general engineering.

• In February 2024, Nidec Machine Tool Corporation, a subsidiary of Nidec Corporation, announced the development of the world's first high-accuracy polishing (grinding) method for mass-producing internal gears used in automotive drive units, transmissions, and robotic joints. While advanced polish-machining techniques for external gears in mass production have been available, Nidec's breakthrough addresses the challenge of achieving the required accuracy and productivity for internal gears, which traditional grinding, honing, or skiving methods have been unable to match. This innovative solution from Nidec is poised to revolutionize the manufacturing of critical internal gear components, catering to the growing demand in the automotive and robotics industries, where precision and efficiency are paramount.

Global Grinding Machinery Market Report Segmentation

This report forecasts revenue growth at global, regional & country levels and provides an analysis of the industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global grinding machinery market based on type, application, and region:

Type Outlook (Revenue, USD Billion, 2018 - 2030)

• Non-precision Grinder

o Bench Grinder

o Portable Grinder

o Pedestal Grinder

o Flexible Grinder

• Precision Grinder

o Cylindrical Grinding Machines

o Surface Grinding Machines

o Centre-less Grinding Machines

o Tool and Cutter Grinding Machines

Application Outlook (Revenue, USD Billion, 2018 - 2030)

• Automotive

• Aerospace

• Medical

• Construction

• Industrial Manufacturing

• Electrical and Electronics

• Marine Industry

• Others

Regional Outlook (Revenue, USD Billion, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o UK

o Germany

o France

o Italy

o Spain

• Asia Pacific

o Japan

o China

o India

o Australia

o South Korea

• Latin America

o Brazil

o Argentina

• Middle East & Africa

o South Africa

o Saudi Arabia

o UAE

Order a free sample PDF of the Grinding Machinery Market Intelligence Study, published by Grand View Research.

#Grinding Machinery Market#Grinding Machinery Market Size#Grinding Machinery Market Share#Grinding Machinery Market Analysis#Grinding Machinery Market Growth

0 notes

Text

CNC Production Outsourcing

CNC Milling Production Outsourcing In a competitive manufacturing market, companies and even small inventors and hobbyists need to be able to provide their customers with high-quality products in a timely manner. Outsourcing CNC milling work to Bates Machine & Mfg. in Farmersville, Texas is a great way to improve your company’s efficiency and competitiveness by reducing production costs and improving the quality of your final products. In-house machining can be costly, especially for smaller businesses that may not have the financial resources to invest in CNC equipment and train new employees. Outsourcing to a professional machining shop can save you money and time, as well as provide your business with access to state-of-the-art technology. Another benefit of outsourcing your cnc machining is faster completion times. Outsourcing companies typically have better machinery and a team of technicians who can help you get your products to the market quicker. This is especially important in a competitive manufacturing environment, where quick product launches can give you an edge over the competition. Outsourcing also gives you the flexibility to scale your production to match your current demand. This is a great option for companies and small businesses who experience a spike in industry or marketplace demand, as it allows them to quickly adapt their production capacity without the need to invest in new equipment or hire additional staff. This can significantly reduce your overall project costs and boost your bottom line.

Common Production Outsourcing CNC Materials

• Aluminum – 2024-T351 , 6061-T6 , 6063-T3 , 7075 ,Plate , Cast • Brass – Naval 464, Alloy 360 , Alloy 260 Yellow , Bronze • Copper – ETP, Oxygen Free 102, Alloy 110 • Steel – C1018 , 1045 , 1144 Hi Stress ,12l14 , 1215 , 4140 , 8620 • Stainless Steel – 303 , 304 , 316 , 420 , 17-4 PH , Tool • Plastics – ABS, Acrylic, Delrin, HDPE, Nylon , Polycarbonate (Lexan), TeflonCNC Machines Haas VF2SSYT Mill 30" x 20" x 20" Leadwell V30i Mill 30" x 20" x 26" Leadwell T-7 Lathe Hurco KMB-1Manual MachinesMazak Lathe 20" x 120"Okuma Lathe 20" x 60"2x Nardini MS-1440 Lathes4x Bridgeport MillsAlliant MillDoAll Surface GrinderOther EquipmentKalamazoo H 310A Automatic BandsawRamco Horizontal BandsawHobart Vertical BandsawEpilog Helix 50w Laser EngraverLincoln Arc WelderMiller Mig Welder5000 lb. ForkliftVarious deburring and polishing equipmentProduction Machining Outsourcing Production outsourcing is the practice of contracting someone outside of your company to do part or all of a product's production. This can save companies money on production costs, especially when labor and equipment are concerned. It can also reduce the need for expensive facilities that require significant maintenance overheads. This can also help companies avoid high startup costs associated with new machinery, technology upgrades, depreciation, and recurring expenses like rent, insurance, utilities, and real estate taxes.Additional Production Outsoursing Services Offered Parts Manufacturing Laser Engraving Welding/Fabrication Read the full article

0 notes