#Haas CNC Milling Machines

Explore tagged Tumblr posts

Text

𝐑𝐞𝐯𝐨𝐥𝐮𝐭𝐢𝐨𝐧𝐢𝐳𝐢𝐧𝐠 𝐂𝐍𝐂 𝐌𝐚𝐜𝐡𝐢𝐧𝐢𝐧𝐠: 𝐁𝐫𝐞𝐚𝐤𝐢𝐧𝐠 𝐁𝐨𝐮𝐧𝐝𝐚𝐫𝐢𝐞𝐬

Prepare to have your perception of CNC machining completely transformed! In this video, I'm showcasing groundbreaking projects that push the boundaries of what's possible with CNC technology.

Watch as we demonstrate: ✅ Innovative design approaches that challenge conventional limitations ✅ Advanced machining techniques that deliver stunning precision ✅ Creative applications that merge art with engineering ✅ Unexpected material combinations that open new possibilities

These projects will revolutionize your understanding of CNC capabilities and inspire your next breakthrough innovation.

𝐏𝐫𝐨 𝐢𝐧𝐬𝐢𝐠𝐡𝐭: The most remarkable CNC innovations often come from thinking beyond traditional manufacturing constraints!

Join the #CNCMiracleChallenge: Before watching, share your wildest guess about what we've created. Then prepare to be amazed as we reveal the final masterpiece!

#InteractiveReveal #CNCInnovation #ManufacturingInnovation #EngineeringCreativity

Contact Us Get More Info:

GreatLight Metal Technology Co., Ltd

✅ Website: https://glcncmachining.com/ ✅ Website: https://cnc-5-axis.com/ ✅ #10, Xinrong Street, Chongtou Community, Chang'an Town, Dongguan City, Guangdong, China, 523845 ✅ + 86 180 2756 7310 ✅ + 86 180 2756 7310(whatsapp) ✅ [email protected]

#CNC Machining Centre#CNC Machining Company#CNC Machining Services Birmingham#CNC Machining What Is#CNC Milling Machine Uk#CNC Multitasking Machining Center Manufacturers#CNC Plasma Machine#Desktop CNC Machine Uk#Desktop CNC Machines#Diy CNC Milling Machine#Duties Of CNC Machine Operator#Haas CNC Milling Machines#Hobby CNC Milling Machine#Hobby Milling Machine CNC

0 notes

Note

Is it something like this? Look at this guy, he's just a little baybey. Just a cute little guy. That's just how mills are idk what to tell you.

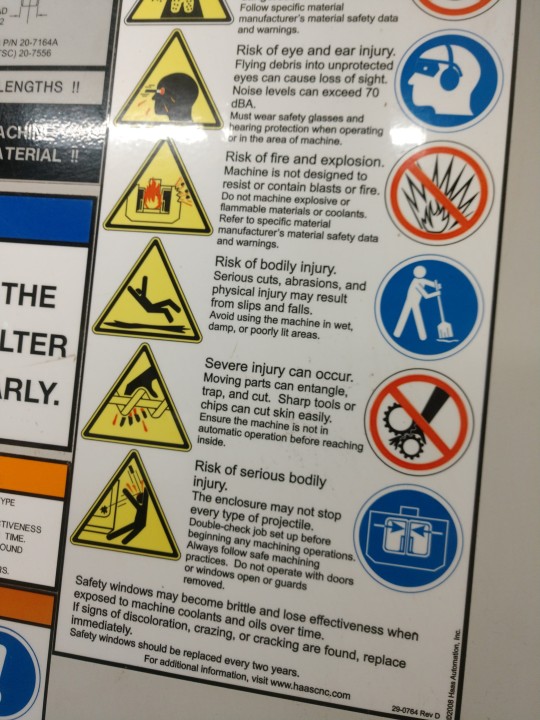

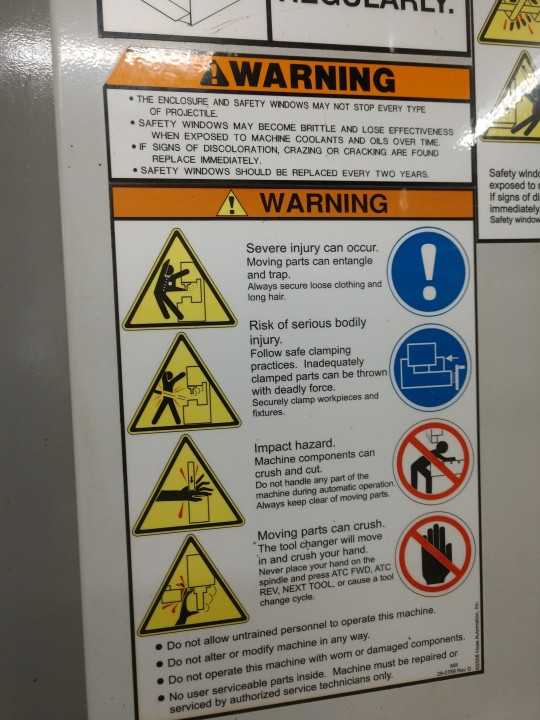

hey heres the whole warning panel from one of the HAAS mini mills at my job, that only like 2 engineers are allowed to touch. personal fav is 3rd image 2 triangles down. owned lmao

splashes of red… very good…

#Did you know that HAAS has a F1 team? I just learned that I think it's kinda cool#HAAS#CNC mill#manufacturing#I like HAAS machines! my high school had two HAAS cnc mills

204 notes

·

View notes

Text

The Top 10 Machine Shop Auction Sites to Check Out

When it comes to finding high-quality machinery, tools, and equipment for your workshop, machine shop auctions are a great way to score significant deals. These auctions offer a wide range of products from well-known brands at competitive prices. Whether you’re a professional machinist or a hobbyist, these sites can help you find everything from CNC machines to precision tools. Below are the top 10 machine shop auction sites to check out for your next purchase.

1. BidSpotter

BidSpotter is one of the largest and most reputable online auction sites for industrial equipment, including machine shop tools. It hosts auctions from various sectors such as manufacturing, construction, and metalworking. With a user-friendly interface and detailed listings, BidSpotter allows buyers to find and bid on used and new machine tools. It also offers live auctions, enabling you to participate in real-time bidding.

2. IronPlanet

IronPlanet is known for offering a wide variety of heavy equipment, including machine shop auctions. It allows you to bid on items like lathes, mills, drills, and CNC equipment. IronPlanet also provides equipment inspection reports, ensuring that buyers have a clear understanding of the machinery’s condition before placing bids. The platform’s mobile app makes it easy to keep track of auctions on the go.

3. Machinery Network Auctions

Machinery Network Auctions specializes in the sale of used industrial equipment, including machine shop tools and machinery. They feature regular auctions and provide detailed descriptions and photographs of each item, allowing buyers to make informed decisions. Machinery Network is ideal for those looking for high-quality equipment from trusted manufacturers like Haas, Mori Seiki, and Okuma.

4. GovDeals

GovDeals is a government surplus auction site that features a broad selection of machine shop equipment, from tools to large machinery. Government agencies often sell off their surplus equipment through this platform, which means buyers can find well-maintained machines at affordable prices. GovDeals is an excellent choice for those looking to purchase machines that have been previously used in public sector applications.

5. Ritchie Bros. Auctioneers

Ritchie Bros. is a global leader in heavy equipment auctions, and it frequently features industrial equipment auctions, including machine shop auctions. The site offers a variety of bidding options, such as online and onsite auctions, and provides detailed equipment condition reports. Ritchie Bros. has a large network of buyers and sellers, making it a great platform for finding used machines and tools from a wide range of industries.

6. HGR Industrial Surplus

HGR Industrial Surplus specializes in the sale of industrial equipment, including machinery, tools, and parts for machine shops. Their auction platform offers everything from CNC machines to hand tools, all at discounted prices. HGR frequently holds online and onsite auctions, allowing buyers to bid on high-quality equipment and often find deals from reputable manufacturers.

7. Thomas Industrial Auctions

Thomas Industrial Auctions is a trusted auction site for machine shops, featuring both live and online auctions of industrial equipment. The site is known for its regular machinery auctions, which offer a variety of products, including CNC machines, fabrication equipment, and more. They also provide detailed descriptions and photographs of each lot, helping buyers make educated purchasing decisions.

8. Surplus Industrial Equipment

Surplus Industrial Equipment is a great place to find quality used machine shop tools and machinery. They hold frequent online auctions that feature a wide range of equipment, including drills, lathes, presses, and CNC machines. The site provides detailed information on each item, and many of the auctions include equipment that is still in excellent working condition.

9. Machinesused.com

Machinesused.com specializes in the sale of pre-owned machine tools, including CNC machines, grinders, lathes, and mills. The site features both live and online machine shop auctions, where you can place bids on machinery from top brands. Machinesused.com also offers financing options, which can make it easier to purchase high-cost equipment.

10. Industrial Auction Hub

Industrial Auction Hub is an online auction platform that focuses on the sale of industrial equipment, including machine shop auctions. This site offers a wide selection of machinery, from heavy-duty machines to precision tools. Industrial Auction Hub regularly hosts auctions featuring tools, equipment, and machines from well-known manufacturers, allowing buyers to find exactly what they need for their workshop.

Conclusion

Machine shop auctions offer an excellent opportunity to acquire high-quality machinery and tools at competitive prices. With the right auction platform, you can find a wide range of equipment that suits your specific needs. From CNC machines to lathes, the sites listed above provide a great variety of options for those in the machine shop industry. Be sure to do your research, check the condition of the items you’re bidding on, and stay updated on upcoming auctions to make the best purchase decisions.

0 notes

Text

Computer Numerical Control Machines Market

CNC Machines Market Size, Share, Trends: DMG MORI Co., Ltd. Leads

Integration of IoT and AI in CNC Machines

Market Overview:

The Computer Numerical Control (CNC) Machines Market is expected to develop at a CAGR of 6.8% from 2024 to 2031. According to estimates, the market will grow from XX USD in 2024 to YY USD by 2031. Asia-Pacific now dominates the industry, accounting for the vast majority of worldwide sales. Key factors include increased industrial automation, greater demand for precision engineering, and increased acceptance of Industry 4.0 technology. The manufacturing sector is developing, particularly in emerging markets, and driving stable expansion in the market. Factors such as increased need for mass production with shorter lead times, a greater emphasis on efficiency and precision in manufacturing processes, and the requirement for complicated component manufacture all contribute to market growth. Furthermore, the incorporation of cutting-edge technology such as artificial intelligence and machine learning into CNC machines promotes industry innovation.

DOWNLOAD FREE SAMPLE

Market Trends:

The CNC machine market is seeing a substantial shift towards the integration of Internet of Things (IoT) and artificial intelligence (AI) technologies. This transition is primarily being driven by the industry's push for smart manufacturing and the implementation of Industry 4.0 principles. IoT-enabled CNC machines provide real-time monitoring, predictive maintenance, and increased operational efficiency, whereas AI integration enables adaptive control, optimised toolpaths, and better decision-making processes. The trend of IoT and AI integration is projected to accelerate as manufacturers attempt to gain a competitive advantage through increased productivity and flexibility.

Market Segmentation:

Milling machines have established themselves as the dominant category in the CNC machine industry, owing to their versatility, precision, and broad variety of applications across several industries. These machines are capable of conducting sophisticated cutting operations on a wide range of materials, making them essential in current production processes. According to recent industry data, CNC milling machines account for about YY% of the global CNC machine market. Advances in multi-axis milling technology have reinforced the segment's market dominance, ensuring its continuous expansion and supremacy in the CNC industry.

Market Key Players:

The CNC machines market is highly competitive, with major players focusing on technological innovation and strategic alliances. Key companies such as DMG MORI Co., Ltd., Haas Automation, Inc., FANUC Corporation, Yamazaki Mazak Corporation, Okuma Corporation, Doosan Machine Tools Co., Ltd., Hyundai WIA, Makino Milling Machine Co., Ltd., GF Machining Solutions Management SA, and JTEKT Corporation dominate the market.

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

CNC Milling Machines Market Report

CNC Milling Machines Market Report: A Comprehensive Analysis of the Global Market

Industry Dimensions

The global CNC Milling Machines Market size was valued at USD 82.48 billion in 2023 and is projected to reach from USD 89.52 billion in 2024 to USD 172.31 billion by 2032, growing at a CAGR of 3.92% during the forecast period (2024–2032). CNC milling machines are computer-controlled machines that use rotating cutters to remove material from a workpiece. These machines are widely used in various industries, such as automotive, aerospace, and electronics, for precision machining and manufacturing.

Get Your Exclusive Sample of the CNC Milling Machines Market Report Today starting at just USD 1850! : https://straitsresearch.com/report/cnc-milling-machines-market/request-sample

Industry Key Trends

Some of the key trends in the CNC Milling Machines Market include:

Increasing demand for precision machining: The demand for precision machining is increasing, driven by the growing need for complex and intricate parts in various industries.

Advancements in technology: Advancements in technology, such as the development of more advanced CNC controls and the use of artificial intelligence and machine learning, are driving growth in the market.

Growing adoption of Industry 4.0: The growing adoption of Industry 4.0, which involves the use of automation, robotics, and data analytics to improve manufacturing efficiency, is driving growth in the market.

Increasing focus on energy efficiency: The increasing focus on energy efficiency is driving growth in the market, as companies seek to reduce their energy consumption and costs.

CNC Milling Machines Market Size and Share

The global CNC Milling Machines Market size is projected to reach USD 172.31 billion by 2032, growing at a CAGR of 3.92% during the forecast period.

CNC Milling Machines Market Statistics

Some of the key statistics in the CNC Milling Machines Market include:

Market size: The global CNC Milling Machines Market size was valued at USD 82.48 billion in 2023.

Growth rate: The market is projected to grow at a CAGR of 3.92% during the forecast period.

Segmentation: The market can be segmented by product type, axis type, and end-user.

Regional Trends

The global CNC Milling Machines Market can be segmented into several regions, including:

North America: The North American market is driven by the presence of major industries, such as automotive and aerospace, which require precision machining and manufacturing.

APAC: The APAC market is driven by the growing demand for precision machining and manufacturing in countries, such as China, Japan, and South Korea.

Europe: The European market is driven by the presence of major industries, such as automotive and aerospace, which require precision machining and manufacturing.

LAMEA: The LAMEA market is driven by the growing demand for precision machining and manufacturing in countries, such as Brazil and South Africa.

To purchase the report: https://straitsresearch.com/buy-now/cnc-milling-machines-market

CNC Milling Machines Market Segmentations

The global CNC Milling Machines Market can be segmented into several categories, including:

By Product Type:

Vertical CNC Milling Machines

Horizontal CNC Milling Machines

Universal CNC Milling Machines

By Axis Type:

3-Axis

4-Axis

Others

By End-User:

Automotive

Electrical and Electronics

Aerospace and Defense

Others

For more details: https://straitsresearch.com/report/cnc-milling-machines-market/segmentation

Top Players in CNC Milling Machines Market

Some of the top players in the CNC Milling Machines Market include:

Doosan

Five

F-Zimmermann

JTEKT

Makino

Ace Micromatic Group

DMG MORI SEIKI

The CHIRON Group

GF Machining Solutions Management

HYUNDAI WIA

Gleason Corporation

GROB-WERKE

Haas Automation

Detailed Table of Content report: @https://straitsresearch.com/report/cnc-milling-machines-market/toc

0 notes

Text

this is where the glory of cnc milling machines comes in. look at the beautiful control panel of a haas cnc milling machine.

god i love machining sm. she is gorgeous

nobody:

the most obnoxious idiot on the planet: "what if we replaced the buttons with a touch interface"

28K notes

·

View notes

Text

Grinding Machinery Market Outlook, Competitive Strategies And Forecast

The global grinding machinery market size was estimated at USD 5.63 billion in 2023 and is anticipated to grow at a CAGR of 4.3% from 2024 to 2030. The growing construction and automotive industry is expected to drive the market demand. The automotive industry demands high-precision components with tight tolerances and fine surface finishes for engine parts, transmission components, and chassis elements, driving the demand for precision grinding machines. Moreover, the aerospace industry requires components with the highest levels of quality, reliability, and safety, leading to a growing demand for grinding machines to machine complex aerospace components such as turbine blades, engine casings, and structural components.

The demand for grinding machinery is rising across various industries, driven by the need for precision components and the growth of sectors like automotive, aerospace, and construction. Grinding machines are highly valued for their precision, efficiency, and ability to automate industrial processes. They are widely used in aerospace, machinery manufacturing, and automotive industries, where tight tolerances and high-quality finishes are critical.

Gather more insights about the market drivers, restrains and growth of the Grinding Machinery Market

Key Grinding Machinery Company Insights

Some of the key players operating in the market include Amada Machine Tools Co., Ltd., Junker Group, and Haas Automation, Inc.

• Amada Machine Tools Co., Ltd. offers diversified products specializing in automation machines, combination machines, high precision CNC lathe machines, bending, joining, and cutting such as laser combination machines, punch machines, and shearing machines. The company also offers AMADA Industry 4.0 solutions, V-factory, AMADA Order Manager, and IoT Remote Support to meet challenging production deadlines, complex production processes, and limited access to real-time data innovations. Incorporating advanced IoT-based support helps the company penetrate the CNC machining and turning centers market. The company has a presence in over 100 countries and a total of 35 manufacturing facilities worldwide. It generated 38.8% of revenue from Japan, 26.3% from North America, 19.6% from Europe, and over 15% from Asia Pacific in the fiscal year 2022.

• Haas Automation, Inc. manufactures vertical mills, multi-axis lathe & mill machines, horizontal mills, automation systems, and rotaries & indexers. The products are manufactured at the company’s expansive facility in Oxnard, California. To maintain accuracy and product quality, the company produces all essential parts required for machine manufacturing internally. Its 1.1 billion-square-foot premises leverage lean manufacturing techniques and just-in-time production strategies to enhance the efficiency of its production by reducing the cost. This approach allows the company to offer machines at lower prices with superior quality by transferring the benefits of cost savings to the customers.

Recent Developments

• In May 2024, UNITED GRINDING, a leading manufacturer of grinding machinery, launched two innovative products to enhance automation and productivity in the tool-grinding industry. The first is the HELITRONIC VISION 400 L, a high-end tool-grinding machine that offers advanced capabilities. The second is the fully automatic HELICHECK PLUS measuring machine, which is part of the "Automated Tool Production" (ATP) system. The launch of these new products by UNITED GRINDING demonstrates the company's commitment to providing advanced grinding machinery that improves efficiency, productivity, and automation in tool manufacturing applications. These innovations cater to the growing demand for precision tools across various industries, including aerospace, automotive, and general engineering.

• In February 2024, Nidec Machine Tool Corporation, a subsidiary of Nidec Corporation, announced the development of the world's first high-accuracy polishing (grinding) method for mass-producing internal gears used in automotive drive units, transmissions, and robotic joints. While advanced polish-machining techniques for external gears in mass production have been available, Nidec's breakthrough addresses the challenge of achieving the required accuracy and productivity for internal gears, which traditional grinding, honing, or skiving methods have been unable to match. This innovative solution from Nidec is poised to revolutionize the manufacturing of critical internal gear components, catering to the growing demand in the automotive and robotics industries, where precision and efficiency are paramount.

Global Grinding Machinery Market Report Segmentation

This report forecasts revenue growth at global, regional & country levels and provides an analysis of the industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global grinding machinery market based on type, application, and region:

Type Outlook (Revenue, USD Billion, 2018 - 2030)

• Non-precision Grinder

o Bench Grinder

o Portable Grinder

o Pedestal Grinder

o Flexible Grinder

• Precision Grinder

o Cylindrical Grinding Machines

o Surface Grinding Machines

o Centre-less Grinding Machines

o Tool and Cutter Grinding Machines

Application Outlook (Revenue, USD Billion, 2018 - 2030)

• Automotive

• Aerospace

• Medical

• Construction

• Industrial Manufacturing

• Electrical and Electronics

• Marine Industry

• Others

Regional Outlook (Revenue, USD Billion, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o UK

o Germany

o France

o Italy

o Spain

• Asia Pacific

o Japan

o China

o India

o Australia

o South Korea

• Latin America

o Brazil

o Argentina

• Middle East & Africa

o South Africa

o Saudi Arabia

o UAE

Order a free sample PDF of the Grinding Machinery Market Intelligence Study, published by Grand View Research.

#Grinding Machinery Market#Grinding Machinery Market Size#Grinding Machinery Market Share#Grinding Machinery Market Analysis#Grinding Machinery Market Growth

0 notes

Text

CNC Production Outsourcing

CNC Milling Production Outsourcing In a competitive manufacturing market, companies and even small inventors and hobbyists need to be able to provide their customers with high-quality products in a timely manner. Outsourcing CNC milling work to Bates Machine & Mfg. in Farmersville, Texas is a great way to improve your company’s efficiency and competitiveness by reducing production costs and improving the quality of your final products. In-house machining can be costly, especially for smaller businesses that may not have the financial resources to invest in CNC equipment and train new employees. Outsourcing to a professional machining shop can save you money and time, as well as provide your business with access to state-of-the-art technology. Another benefit of outsourcing your cnc machining is faster completion times. Outsourcing companies typically have better machinery and a team of technicians who can help you get your products to the market quicker. This is especially important in a competitive manufacturing environment, where quick product launches can give you an edge over the competition. Outsourcing also gives you the flexibility to scale your production to match your current demand. This is a great option for companies and small businesses who experience a spike in industry or marketplace demand, as it allows them to quickly adapt their production capacity without the need to invest in new equipment or hire additional staff. This can significantly reduce your overall project costs and boost your bottom line.

Common Production Outsourcing CNC Materials

• Aluminum – 2024-T351 , 6061-T6 , 6063-T3 , 7075 ,Plate , Cast • Brass – Naval 464, Alloy 360 , Alloy 260 Yellow , Bronze • Copper – ETP, Oxygen Free 102, Alloy 110 • Steel – C1018 , 1045 , 1144 Hi Stress ,12l14 , 1215 , 4140 , 8620 • Stainless Steel – 303 , 304 , 316 , 420 , 17-4 PH , Tool • Plastics – ABS, Acrylic, Delrin, HDPE, Nylon , Polycarbonate (Lexan), TeflonCNC Machines Haas VF2SSYT Mill 30" x 20" x 20" Leadwell V30i Mill 30" x 20" x 26" Leadwell T-7 Lathe Hurco KMB-1Manual MachinesMazak Lathe 20" x 120"Okuma Lathe 20" x 60"2x Nardini MS-1440 Lathes4x Bridgeport MillsAlliant MillDoAll Surface GrinderOther EquipmentKalamazoo H 310A Automatic BandsawRamco Horizontal BandsawHobart Vertical BandsawEpilog Helix 50w Laser EngraverLincoln Arc WelderMiller Mig Welder5000 lb. ForkliftVarious deburring and polishing equipmentProduction Machining Outsourcing Production outsourcing is the practice of contracting someone outside of your company to do part or all of a product's production. This can save companies money on production costs, especially when labor and equipment are concerned. It can also reduce the need for expensive facilities that require significant maintenance overheads. This can also help companies avoid high startup costs associated with new machinery, technology upgrades, depreciation, and recurring expenses like rent, insurance, utilities, and real estate taxes.Additional Production Outsoursing Services Offered Parts Manufacturing Laser Engraving Welding/Fabrication Read the full article

0 notes

Text

Manufacturing Machines

Explore a wide selection of manufacturing machines at The Equipment Hub, where quality meets reliability. Our inventory includes high-performance machinery for various machining applications, from CNC mills and lathes to grinders and drill presses. We offer both new and used equipment from trusted brands like Haas, Mazak, and Mori Seiki, ensuring exceptional precision and efficiency for your manufacturing processes. Each machine is thoroughly inspected to guarantee top-notch performance, whether you're running a small shop or a large production facility. With competitive pricing, expert support, and nationwide shipping, find the right manufacturing machines for your needs at The Equipment Hub.

Manufacturing Machines

0 notes

Text

Find Reliable Haas CNC Machines Near You for Enhanced Manufacturing Solutions

If you're searching for Haas CNC machines near me, you’re in luck! Haas Automation is a leading name in the CNC machining industry, known for producing high-quality and reliable equipment. Whether you're a manufacturer, machinist, or hobbyist, finding the right CNC machine can significantly enhance your production capabilities.

At Phillips Corporation, we provide a wide range of Haas CNC machines tailored to various applications, from milling and turning to advanced automation solutions. Our knowledgeable team can help you select the perfect machine that meets your specific needs, ensuring optimal performance for your projects.

Not only do we offer the latest Haas machines, but we also provide comprehensive support services, including installation, training, and maintenance. This means you can have peace of mind knowing that expert help is available whenever you need it.

When searching for Haas CNC machines near me, consider visiting Phillips Corporation. Our dedicated team is committed to helping you maximize your machining capabilities with top-notch equipment and service. Elevate your manufacturing processes today by choosing Haas CNC machines from a trusted local provider!

0 notes

Text

When I was in high school there was no separation between the machining classes and engineering classes, so I assumed all engineers knew how to use a mill and lathe.

In my first week of college, someone mentioned something about HASS classes (humanities, arts, and social sciences) being required, and I thought that meant HAAS, the CNC brand. I was extremely disappointed to learn that it wasn't a requirement for every engineering major to learn how to use a HAAS CNC milling machine.

agricultural engineer at my work grew up on a farm in a time when being a farmer also meant being a carpenter (his words) and a couple days ago a piece of stupidly crucial wood equipment broke in our lab and i helped him build a new one in like 2 hours thats actually very sturdy and looks like it was actually done right on the first try because it was and i realized how incredibly powerful of a skill it is to be able to make like, a competent set of shelves, a piece of handmade equipment to specifications, etc and be able to at least have an idea of how to make bigger things and i cannot stop thinking about it now. like he was telling me about how when he was in college it was required for engineering majors to learn how to make the stuff they were designing so he had to take proper woodworking and metalworking classes too and they dont do that as much anymore. and how he has relatives that run a woodshop and build like tables and standing clocks and stuff. imagine somebody asking you for a table or clock and you can just make it and it looks nice and works well for a long time and you can fix it if it breaks. maybe im just gen z but whoa

#genuinely thought it was a requirement that every engineer would learn how to use a cnc machine#the heartbreak i felt when I realized this was not the case 😔 💔 ☹️ and only very specific majors/minors ever interact with a lathe#it's ok I'm going out of my way to learn more about 5 axis cnc mills#engineering#machining

6K notes

·

View notes

Text

𝐑𝐞𝐯𝐞𝐚𝐥𝐢𝐧𝐠 𝐭𝐡𝐞 𝐇𝐞𝐚𝐫𝐭 𝐨𝐟 𝐭𝐡𝐞 𝐂𝐚𝐫: 𝐇𝐨𝐰 𝐂𝐍𝐂 𝐂𝐚𝐫𝐯𝐞𝐬 𝐚 𝐒𝐭𝐞𝐞𝐫𝐢𝐧𝐠 𝐊𝐧𝐮𝐜𝐤𝐥𝐞

From a rough blank to a precision-finished product, every step in the machining process is a testament to the perfect fusion of technology and craftsmanship. In this post, we take you behind the scenes to explore:

🔩 How CNC machines transform raw materials with unparalleled precision.

🔩 The intricate steps involved in carving a steering knuckle.

🔩 The role of advanced tools and meticulous craftsmanship in achieving perfection.

Whether you’re passionate about automotive engineering or intrigued by manufacturing technologies, this deep dive showcases the artistry and innovation behind every steering knuckle.

𝐃𝐢𝐝 𝐲𝐨𝐮 𝐤𝐧𝐨𝐰? Precision machining ensures not just durability but also optimal performance for critical automotive components.

Check out the video and tell us: What part of the CNC machining process fascinates you the most? Share your thoughts in the comments below!

Contact Us Get More Info:

GreatLight Metal Technology Co., Ltd

✅ Website: https://glcncmachining.com/ ✅ Website: https://cnc-5-axis.com/ ✅ #10, Xinrong Street, Chongtou Community, Chang'an Town, Dongguan City, Guangdong, China, 523845 ✅ + 86 180 2756 7310 ✅ + 86 180 2756 7310(whatsapp) ✅ [email protected]

#Machining #CNC #ThreadTapping #Metalworking #Manufacturing #cncmachine #cncmachining #cncmachinist #cncmilling #cncturning #cncprogramming #foryou

#CNC Machining For Medical Imaging#CNC Milling Machine For Sale#CNC Routers Machines#CNC Screw-Machining For Aviation#Diy CNC Machine#Haas CNC Milling Machine#Laser CNC Machine#Mazak CNC Machine#Mini CNC Milling Machine#What Is CNC Milling Machine#What Is CNC Routers Machine#5 Axis CNC Milling Machine#Advantages Of CNC Machine#Budget CNC Machine

0 notes

Text

Do you need top-tier CNC machining service for your plastic and metal parts?

ProtoTech Machining has got you covered!🌟

Whether you are looking for custom parts in plastic or metal, our cutting-edge CNC milling, turning, and routing solutions can produce and deliver parts with great precision and on time. From 5-axis machining on our robust HAAS UMS rotary table to intricate rapid tooling and large-scale routing, we have state-of-the-art facilities and technology to deliver exactly what you want. 🛠️

What’s more? We can also offer full material traceability, certifications, and comprehensive inspection tools to ensure unmatched quality. 🔍

Need more information? Please visit us at https://prototech-machining.com/cnc-machining/ and book a meeting with our experts! 📅

#prototechmachining#precisionmachining#cncmiling#cncturning#cncrouting#routingsolutions#machining#certifications#rapid#tooling#inspectiontools

1 note

·

View note

Note

ASHHH🥺💕

Hi hi

Miss you so much! How are you? How’s life?

I ALSO LOVE THE NEW THEME HELLO??? Looks so good oh my gosh

HIIII ANG!!💓💓

I missed you too & was patiently waiting for your return!!

I’ve been good, life’s been good. school has been keeping me kinda busy. I learned how to use a cnc machine (it’s like metal milling? hard to explain) and talked formula 1 racing with my professor and another student so that was kinda funny. the cnc machine “brand” is called Haas and the student was like “if you’re a formula 1 fan….they have a team.” and I was like 🤯 I bet he was not expecting me to talk about racing lol.

I have a lot to work on writing wise, wanna start another part in my sugar daddy jjun series and have a lot of stuff in my inbox to get to. spring break is coming so hopefully I can catch up!!

1 note

·

View note

Text

How to Spot Quality Equipment at Machine Shop Auctions

When browsing machine shop equipment auctions, it’s crucial to know how to spot quality items. Auctions are excellent for finding well-priced machinery and tools, but without careful evaluation, there’s a risk of buying faulty or worn-out equipment. Here’s a guide to help you identify quality equipment at these auctions.

1. Research the Equipment Types in Demand

Before attending a machine shop equipment auction, do some research on the equipment types you’re interested in. Each category, from milling machines to CNC lathes, has its quality benchmarks. Knowing the specifications and expected lifespan of the tools you need can help you quickly filter out poor-quality items. Review online forums, and machinery sales websites, or consult with industry experts to understand the market standards for each piece.

2. Examine Visual Condition Closely

A good inspection begins with a detailed visual assessment. Check for obvious signs of wear and tear that might indicate excessive use or lack of maintenance. Look for:

- Rust: Rust can compromise the structural integrity of metal equipment. Minor surface rust may not be a dealbreaker, but extensive rust, especially on critical components, suggests neglect.

- Welding or Repairs: Signs of past repairs or welding work may indicate previous damage. This isn’t necessarily a dealbreaker, but it’s best to understand the nature of the repairs and how they impact functionality.

- Cleanliness: While auctioned equipment often shows signs of use, machinery that appears clean and well-kept may have been better maintained.

3. Assess Operational Readiness

Many machine shop equipment auctions allow potential buyers to inspect machinery while in operation. If possible, test the equipment to ensure that all moving parts work smoothly and without unusual noise. Equipment that operates without stalling, rattling, or struggling under pressure is a good sign. Take note of any resistance or roughness in moving parts, as these can indicate wear on the gears or bearings.

4. Check the Maintenance Records

Some sellers may provide maintenance records, especially for high-value machinery like CNC machines or larger lathes. A consistent record of servicing, calibration, and part replacements shows that the equipment was cared for and maintained at a professional level. When possible, ask the auction manager or the equipment owner for these records to get a better sense of the equipment's history.

5. Inspect Tooling and Accessories

Tooling and accessories that come with machine shop equipment are often valuable on their own. Look for any extras like cutting tools, holders, clamps, and adapters, that can add significant value to your purchase. Assess the condition of these accessories—worn-out or broken tools might indicate heavy use. Conversely, if the equipment comes with well-kept accessories, it suggests that the previous owner maintained the machinery carefully.

6. Pay Attention to Brand Reputation

Certain brands have a reputation for quality and longevity in the machine shop industry. Research the brands available at the auction and prioritize those known for reliability, such as Haas for CNC machinery or Bridgeport for milling machines. Lesser-known brands might be tempting for their lower prices, but it’s essential to research their track record in terms of durability and parts availability.

7. Look for Signs of Obsolescence

When investing in machine shop equipment, ensure it isn’t outdated or difficult to repair. Older machines can sometimes be cost-effective, but they might lack modern functionality and safety features. Additionally, sourcing parts for older equipment can be a challenge. Look up the model and confirm that parts and support are still available from the manufacturer or aftermarket suppliers.

8. Estimate Repair Costs and Factor Them In

Some auctioned equipment may have minor issues that require repair or maintenance. If you spot an item with small mechanical issues but the potential for longevity, estimate the repair costs. Simple repairs, like replacing belts or bearings, are often affordable and can justify purchasing a machine at a lower price. However, costly or complex repairs (e.g., motor replacement on CNC machinery) may not be worth the investment.

9. Be Cautious of “As-Is” Terms

Most machine shop equipment auctions sell items on an “as-is” basis, meaning there are no guarantees on condition. While this is common, it places more responsibility on the buyer to assess quality carefully. Be extra cautious and scrutinize each piece thoroughly, as the “as-is” condition often means you won’t have recourse if the equipment turns out to be faulty.

10. Consult with a Specialist When in Doubt

If you’re new to purchasing at machine shop equipment auctions or if you’re planning to buy high-value equipment, consider bringing a specialist or technician. A knowledgeable person can spot potential issues and help you avoid costly mistakes. Their insights can be invaluable, especially for evaluating intricate machinery like CNC mills or lathes.

Final Thoughts

Machine shop equipment auctions offer great opportunities to acquire quality machinery at reduced prices. However, evaluating each piece’s quality before bidding is essential to ensure you’re making a wise investment. With these tips, you’ll be better prepared to navigate machine shop equipment auctions, identify quality machinery, and find the right equipment for your workshop needs.

0 notes

Text

Global CNC Machines Product Market Size, Trends, Growth, Analysis, Forecast till 2030

Global CNC Machines Product Market

CNC machines are also known as Computer Numerical Control Machines. CNC machine products are used to control various machine tools, equipments, and 3D printers through computer device implementation. These products have attained unmatched importance due to their various advantages such as precision significant cost saving, and timely performance delivery.

Market Drivers

Increase in advancements in production technology is expected to raise the demand for Computer Numerical Control machine Product market. Also, increase in adoption of automated manufacturing especially in automobiles and industrial sector which is expected to positively influence the global CNC machine Product market. Increase in government initiatives which are expected to propel the market growth over the forecast period. Furthermore, key manufacturers are focusing on latest technological trends in the field of computer numerical control software to improve flexibility and connectivity of machines with operators on the shop floor area. It is expected to enhance the demand for CNC machine products market during this forecast period.

Read More@ https://qualiketresearch.com/reports-details/CNC-Machines-Product-Market

Market Key Players

Various key players are discussed in this report such as Bosch Rexroth AG, Fagor Automation, Dalian Machine Tool Group Corporation (DMTG), HAAS Automation, Inc., FANUC Corporation, Hurco Companies, Inc., Mitsubishi Electric Corporation, Heidenhain Corporation, Sandvik AB, and Okuma Corporation, Soft Servo Systems Inc.

Market Restraints

High investment cost required for implementation of CNC machines is the restraint which is expected to hinder the global CNC Machines Product Market growth. Also, lack of skilled professionals will limit the global CNC Machines Product Market growth over the forecast period.

Market Segmentation

Global CNC Machines Product Market is segmented into type such as Mills, Lathe, Routers, Grinders, and Others. Further, market is segmented into end use such as Aerospace & Defense, Automotive, Construction Equipment, Power & Energy, Industrial, and Others.

Also, Global CNC Machines Product Market is segmented on the basis of five regions such as North America, Latin America, Europe, Asia Pacific, and Middle East & Africa.

Request A Sample@ https://qualiketresearch.com/request-sample/CNC-Machines-Product-Market/request-sample

Market Taxonomy

By Type

Mills

Lathe

Routers

Grinders

Others

By End User

Aerospace & Defense

Automotive

Construction Equipment

Power & Energy

Industrial

Others

By Region

North America

Latin America

Europe

Asia Pacific

Middle East & Africa

Key Questions Addressed by the Report

What are the Key Opportunities in Global CNC Machines Product Market?

What will be the growth rate from 2019 to 2030?

Which segment/region will have highest growth?

What are the factors that will impact/drive the Market?

What is the competitive Landscape in the Industry?

What is the role of key players in the value chain?

What are the strategies adopted by key players?

About Us:

QualiKet Research is a leading Market Research and Competitive Intelligence partner helping leaders across the world to develop robust strategy and stay ahead for evolution by providing actionable insights about ever changing market scenario, competition and customers.

QualiKet Research is dedicated to enhancing the ability of faster decision making by providing timely and scalable intelligence.

QualiKet Research strive hard to simplify strategic decisions enabling you to make right choice. We use different intelligence tools to come up with evidence that showcases the threats and opportunities which helps our clients outperform their competition. Our experts provide deep insights which is not available publicly that enables you to take bold steps.

Contact Us

6060 N Central Expy #500 TX 75204, U.S.A

+1 214 660 5449

1201, City Avenue, Shankar Kalat Nagar,

Wakad, Pune 411057, Maharashtra, India

+91 9284752585

Sharjah Media City , Al Messaned, Sharjah, UAE.

+971 56 846 4312

0 notes