#5 Axis CNC Milling Machine

Explore tagged Tumblr posts

Text

𝐑𝐞𝐯𝐞𝐚𝐥𝐢𝐧𝐠 𝐭𝐡𝐞 𝐇𝐞𝐚𝐫𝐭 𝐨𝐟 𝐭𝐡𝐞 𝐂𝐚𝐫: 𝐇𝐨𝐰 𝐂𝐍𝐂 𝐂𝐚𝐫𝐯𝐞𝐬 𝐚 𝐒𝐭𝐞𝐞𝐫𝐢𝐧𝐠 𝐊𝐧𝐮𝐜𝐤𝐥𝐞

From a rough blank to a precision-finished product, every step in the machining process is a testament to the perfect fusion of technology and craftsmanship. In this post, we take you behind the scenes to explore:

🔩 How CNC machines transform raw materials with unparalleled precision.

🔩 The intricate steps involved in carving a steering knuckle.

🔩 The role of advanced tools and meticulous craftsmanship in achieving perfection.

Whether you’re passionate about automotive engineering or intrigued by manufacturing technologies, this deep dive showcases the artistry and innovation behind every steering knuckle.

𝐃𝐢𝐝 𝐲𝐨𝐮 𝐤𝐧𝐨𝐰? Precision machining ensures not just durability but also optimal performance for critical automotive components.

Check out the video and tell us: What part of the CNC machining process fascinates you the most? Share your thoughts in the comments below!

Contact Us Get More Info:

GreatLight Metal Technology Co., Ltd

✅ Website: https://glcncmachining.com/ ✅ Website: https://cnc-5-axis.com/ ✅ #10, Xinrong Street, Chongtou Community, Chang'an Town, Dongguan City, Guangdong, China, 523845 ✅ + 86 180 2756 7310 ✅ + 86 180 2756 7310(whatsapp) ✅ [email protected]

#Machining #CNC #ThreadTapping #Metalworking #Manufacturing #cncmachine #cncmachining #cncmachinist #cncmilling #cncturning #cncprogramming #foryou

#CNC Machining For Medical Imaging#CNC Milling Machine For Sale#CNC Routers Machines#CNC Screw-Machining For Aviation#Diy CNC Machine#Haas CNC Milling Machine#Laser CNC Machine#Mazak CNC Machine#Mini CNC Milling Machine#What Is CNC Milling Machine#What Is CNC Routers Machine#5 Axis CNC Milling Machine#Advantages Of CNC Machine#Budget CNC Machine

0 notes

Text

5 axis cnc machining parts service

#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#machining parts#precision machining#5 axis cnc machining#5 axis milling#5 axis cnc milling#5 axis cnc#cnc 5 axis machining#cnc machining service#cnc machining parts#precision cnc machining#precision cnc milling#cnc milling#cnc milling machining

2 notes

·

View notes

Text

We provide precision CNC machining services, CNC Milling and Turning (3 axis, 4 axis, 5 axis), can manufacture complex and multi-structure plastic and metal parts.

#cncmachining#5 axis machining#cnc milling services#cnc machining parts#rapid prototyping#precision machining

2 notes

·

View notes

Text

Unlock advanced precision and efficiency in your projects with our CNC Milling Machine 5 Axis CNC Machining Center for Graphite, perfect for intricate designs and high-quality finishes.

#CNC Milling Machine 5 Axis CNC Machining Center for Graphite#Graphite Milling Machines#CNC precision engraving machine#Graphite Lathe#Graphite Milling

0 notes

Text

CNC / VMC Machining Job Work & CNC Machining Components in India— Pitrukrupa Engineering

Pitrukrupa Engineering is country’s leading Manufacturer, Exporter and Supplier firm offering high performing CNC Milling and Turning Components since its inception in 2009.

Our CNC Machining Work

We are offering CNC Machining job Work to our clients. For accomplishing this work, experts bank on innovative machines and important tools.

CNC Machining Work

CNC Job Work

Precision Machining Work

VMC Machining Work

Milling Machining Work

HMC Machining Work

CNC Turning Machining Work

EDM Wire Cutting Work

CNC laser Cutting Work

CNC Bending Work

CNC Machining Components & Parts

We are offering CNC Components to our clients. For accomplishing this work, experts bank on innovative machines and important tools.

CNC Lathe Machining Component

5 Axis Milling Components

4 Axis Milling Components

CNC Turn Mill Components

CNC Turn Mill Machining Parts

Aerospace and Defence Machining Parts Manufacturing

Aluminium And Steel Precision Welding Fabrication

Aluminium High Pressure Die Casting

Aluminium Extrusion

For More Details Click Here : https://www.pitrukrupaengineering.com/

#Machining Job Work#CNC Machining Work#CNC Job Work#5 Axis Milling Components#4 Axis Milling Components#CNC Turn Mill Machining Parts

0 notes

Text

When I was in high school there was no separation between the machining classes and engineering classes, so I assumed all engineers knew how to use a mill and lathe.

In my first week of college, someone mentioned something about HASS classes (humanities, arts, and social sciences) being required, and I thought that meant HAAS, the CNC brand. I was extremely disappointed to learn that it wasn't a requirement for every engineering major to learn how to use a HAAS CNC milling machine.

agricultural engineer at my work grew up on a farm in a time when being a farmer also meant being a carpenter (his words) and a couple days ago a piece of stupidly crucial wood equipment broke in our lab and i helped him build a new one in like 2 hours thats actually very sturdy and looks like it was actually done right on the first try because it was and i realized how incredibly powerful of a skill it is to be able to make like, a competent set of shelves, a piece of handmade equipment to specifications, etc and be able to at least have an idea of how to make bigger things and i cannot stop thinking about it now. like he was telling me about how when he was in college it was required for engineering majors to learn how to make the stuff they were designing so he had to take proper woodworking and metalworking classes too and they dont do that as much anymore. and how he has relatives that run a woodshop and build like tables and standing clocks and stuff. imagine somebody asking you for a table or clock and you can just make it and it looks nice and works well for a long time and you can fix it if it breaks. maybe im just gen z but whoa

#genuinely thought it was a requirement that every engineer would learn how to use a cnc machine#the heartbreak i felt when I realized this was not the case 😔 💔 ☹️ and only very specific majors/minors ever interact with a lathe#it's ok I'm going out of my way to learn more about 5 axis cnc mills#engineering#machining

6K notes

·

View notes

Text

EXPLORING THE 5 COOL PARTNER SELLER ELECTRONICS PRODUCTS-Part1

Exploring the 5 Cool Partner Seller Electronics Products

Prologue

Are you an electronics enthusiast looking to expand your electronics project repertoire? Want to take your skills to the next level by exploring new and exciting products? Look no further than our list of five cool electronics products from partner sellers!

Whether you’re interested in building your own smart home devices, experimenting with sensors, or creating your own robot, these products are sure to inspire you. They cover a lot of application areas, from loop detectors used to monitor vehicle count in parking garages to Arduino CNC shields used in CNC machines, from simple pulse sensors used to detect cardiovascular pulse signals from fingertip to RGB LED panel light used in smart home, these products are unique, compact, and functional. Not only are these products fun to build and use but they’re also designed to help you learn new skills and techniques along the way.

What’s more, these products all come from trusted partner sellers who are committed to developing high-quality products. They’re happy to provide technical support for customers who have questions, so you can be sure you’re getting the best in electronics.

So get ready to dive into the world of electronics and explore these five cool partner seller products. You’re sure to find something that piques your interest and takes your own electronics projects to the next level.

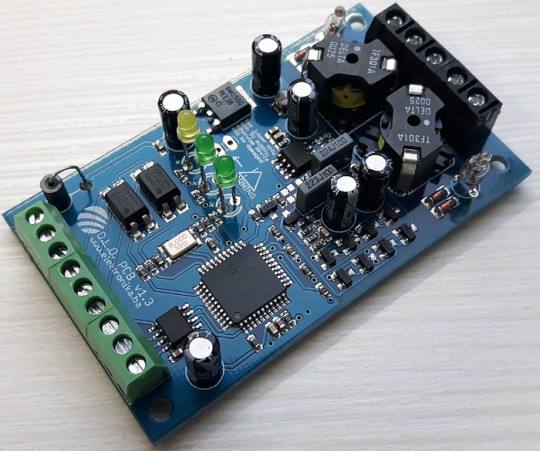

Inductive Loop Vehicle Detector by Elektronika-ba

Whether you need to monitor occupancy and count vehicles in parking garages, control vehicle access at door and barrier controls, or facilitate traffic light installations and traffic controllers, the inductive loop detector is the perfect solution. It can even detect the direction and speed of vehicle traffic, making it an invaluable tool for a variety of traffic-related applications. In addition, this device can function as a stand-alone speed trap and can be easily interfaced with Arduino.

We can also provide a pre-programmed PIC chip to meet your project requirements.

Specifications

Number of operating modes: 4

Tuning: Automatic

Detection type: Presence/Pulse

Presence time: Adjustable in 3 steps

Pulse duration: 250 ms / 500 ms

Signal filtering: Adjustable in 2 steps (NORMAL, HIGH)

Loop inductance: 20 uH — 1000 uH

Frequency range: 20 kHz — 145 kHz

Frequency selection: 2 combinations (LOW, HIGH)

Sensitivity: Maximum 0.0025% Δf/f, adjustable in 8 steps

Detection speed: 10 ms by default, adjustable

Start-up time: ~ 1 second per channel (or longer if the frequency is not stable)

Temperature range: -35°C — 120°C

Sensor protection: Galvanic isolation + gas discharge tube for lightning protection

Don’t settle for less — click here to learn more about the Inductive Loop Vehicle Detector and experience the compact, yet cool detector!

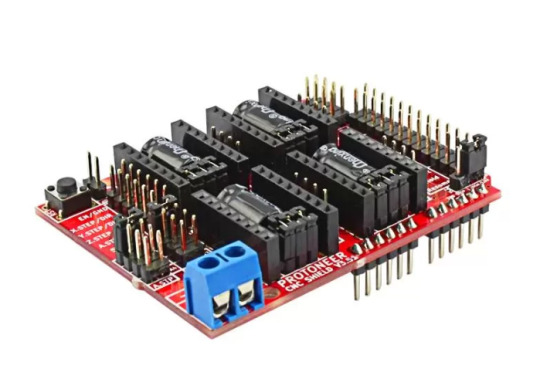

Arduino CNC Shield V3.51 by Protoneer

Designed by Protoneer, this kit is packed with features to ensure high precision control of your stepper motors, you can use it to easily build small CNC routers, DIY laser cutters, 3D printers, or any project that requires precise stepper motor control.

Our latest version 3.51 includes several enhancements to make assembly and installation even easier. We’ve added end-stop and probe signal filtering circuitry to eliminate false triggers and allow the use of unshielded cables for end-stops and probes. We’ve also increased the size of the solder pads for easier assembly and updated the probe pin labels to make installation a breeze.

With the Arduino CNC Shield Kit, you’ll have everything you need to build your own CNC router or mill with ease.

Features

Includes Noise Filers on all end stops and the probing pin. (New in V3.51)

GRBL 0.9 compatible. (Open source firmware that runs on an Arduino UNO that turns G-code commands into stepper signals https://github.com/grbl/grbl)

4-Axis support (X, Y, Z, A-Can duplicate X, Y, Z or do a full 4th axis with custom firmware using pins A4 and A3)

2 x End stops for each axis (6 in total)

Coolant enable

Uses removable Pololu A4988 compatible stepper drivers. (A4988, DRV8825 and others)(Not Included)

Jumpers to set the Micro-Stepping for the stepper drivers. (Some drivers like the DRV8825 can do up to 1/32 micro-stepping )

Compact design.

Stepper Motors can be connected with 4-pin molex connectors or soldered in place.

Runs on 12–36V DC. (At the moment only the Pololu DRV8825 drivers can handle up to 36V so please consider the operation voltage when powering the board.)

Don’t wait — click here to see more about the Arduino CNC Shield V3.51 and start your next project today!

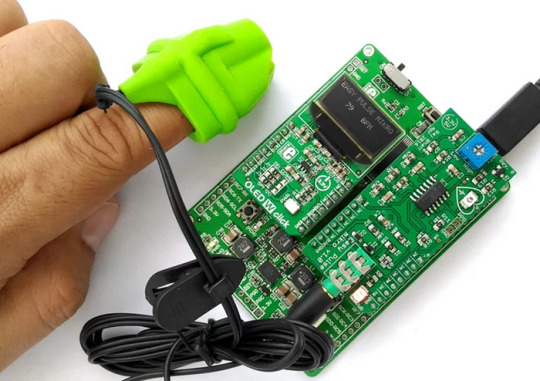

Easy Pulse Mikro by Embedded Lab

What’s more, the Easy Pulse Mikro is designed in the convenient Mikro bus form factor, making it easy to integrate with a wide range of mikroElektronika’s development boards. With all necessary instrumentation and amplification built right in, this powerful sensor provides a clean and precise analog PPG waveform output that’s routed to the AN pin of the mikroBus connector.

Whether you’re a hobbyist, student, or professional developer, the Easy Pulse mikro is the perfect tool for monitoring heart rate and other vital signs.

Click here to see more about the Easy Pulse mikro.

Features

Compatible with mikroBus socket.

Filtered and amplified analog PPG signal output

On-board potentiometer for adjusting amplifier gain, if needed (rotate clock-wise for increasing gain)

Onboard LED for indicating heartbeat. It flashes synchronously with the heartbeat on detecting the pulse from the fingertip.

2 notes

·

View notes

Text

5-axis milling machine machining aluminum parts. #5axis #cncmachine #cncmachining #cnc #machine #cncmachinist #cncrouter #cncporn #cncmill #cncmilling #cncplasma #cnclathe #cnccutting #cnclaser #cnctools #machinist #tools #cncprogramming #mold #components #machinetools #jinsucnc #servo #cncoperator #factory #machining #aluminum #cncmillingmachine #instagram #fyp

3 notes

·

View notes

Text

🔥Year-end sprint! The 5-axis CNC machine is running at full capacity, working overtime to rush the New Year's orders, and every cut is ingenious! 🎉Can you guess what masterpiece we are working on? #CNCProcessing #CraftsmanSpirit #NewYearNewAtmosphere

#CNC Machine Plywood#CNC Machine Programming Course#CNC Machining Center#CNC Machining For Medical Imaging#CNC Milling Machine For Sale#CNC Routers Machines#CNC Screw-Machining For Aviation#Diy CNC Machine#Haas CNC Milling Machine#Laser CNC Machine#Mazak CNC Machine#Mini CNC Milling Machine#What Is CNC Milling Machine#What Is CNC Routers Machine#5 Axis CNC Milling Machine

0 notes

Text

Summary Analysis of CNC Milling Process

In modern manufacturing, CNC milling technology is widely used for its high precision and flexibility. Whether it's a mechanical part, an automotive component, or a component for a medical device, CNC milling provides excellent machining results.

What is CNC Milling?

CNC milling is a computer-controlled machining process that utilises a rotating tool to cut a workpiece. CNC milling allows for greater accuracy and consistency than traditional manual milling. It is often combined with other machining methods (e.g. turning, drilling) to meet different and diverse manufacturing needs.

Workflow of CNC Milling

Design stage In the initial stages of CNC milling, designers use Computer-Aided Design (CAD) software to create a model of the product. Commonly used software includes SolidWorks and Autodesk, which are tools that help designers accurately draw the shape and dimensions of the desired part.

Programming stage Once the design is complete, the CAD file needs to be converted to G-code, a language that CNC machines can understand. With Computer-Aided Manufacturing (CAM) software, the design files are converted into machine-executable instructions that enable automated machining.

Machine setting During the machine set-up phase, the workpiece needs to be fixed to the table and a suitable tool selected. At the same time, the operator needs to set the initial co-ordinates to ensure accurate positioning during machining.

Advantages of CNC Milling

High precision and dimensional stability CNC milling allows for micron-level machining accuracy, ensuring consistency from part to part.

Complex shapes can be processed Whether it's a simple flat surface or a complex three-dimensional structure, CNC milling can handle it with ease.

Efficient production capacity Due to its high degree of automation, CNC milling can significantly increase productivity and shorten lead times.

Applications of CNC Milling

CNC milling technology is used in a wide range of industries, including:

Mechanical parts: Used in the manufacture of key components in a variety of mechanical equipment.

Automotive parts: High-precision parts for the automotive industry, such as engine components.

Medical device parts: Ensure the reliability and safety of medical devices.

Optical product parts: For the production of optical instruments and related products.

Frequently Asked Questions

What materials can be CNC milling machined? CNC milling is suitable for a wide range of materials, including metals (e.g. aluminium, steel), plastics, wood, and more. However, for some materials, such as ceramics or certain composites, the machining is more difficult and requires special handling.

What are the limitations of CNC milling? Despite its advanced technology, CNC milling has some limitations. For example, machining may be limited for internal vertical angles or very complex small structures.In addition, high hardness materials may lead to faster tool wear, which can affect productivity.

Comparison of CNC milling with other manufacturing technologies The advantages and disadvantages of each can be seen when comparing CNC milling with other manufacturing techniques such as 3D printing. CNC milling is generally superior to 3D printing in terms of accuracy and surface finish, but 3D printing has advantages in rapid prototyping and complex geometries. In terms of cost-effectiveness, the choice of technology depends on specific project needs and budget.

Summary

In summary, CNC milling is an indispensable manufacturing technology that plays an important role in several industries with its efficiency, precision and flexibility.

#prototyping#prototype#rapid prototyping#prototype machining#precision machining#cnc machining#cnc milling#machining parts#cnc milling 5 axis#cnc milling machining#cnc milling turning#precision cnc milling#cnc milling parts

1 note

·

View note

Text

Simultaneous 5-axis CNC milling is an advanced processing technique that can manufacture high-precision and complex part. Every part will be perfectly splendid machined by 5 axis milling.

0 notes

Photo

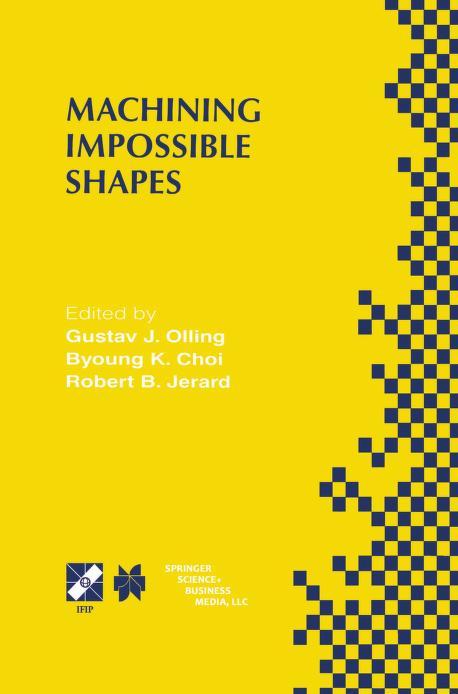

This book is essential reading for researchers and practitioners in computer science, technical managers and software specialists This book provides a comprehensive treatment of the subject of sculptured surface machining in terms of user needs, CAM software solutions and theoretical research results and issues. State-of-the-art capabilities of the best commercial CAM systems are compared to user needs, and advanced academic research is presented. Among the topics covered are the following: Generative NC for dies and molds; 5-axis machining of impellers; Cutting simulation and NC verification; Virtual machining; CAPP for die and mold machining; NURBS-based CNC interpolators

Cutting Molds/Dies from Scan data

Experiences from a Quantum Leap Improvement in Turbine Manufacturing

A Generative Approach for Die Pattern Machining

Geometric Contributions to 3-Axis Milling of Sculptured Surfaces

Efficiency of Multi-Axis NC Machining of Sculptured Part Surfaces

Best-Fit of Sculptured Surfaces

Point-based Geometric Modelling

Virtual Machining and the Manufacturing Model

Virtual CNC with Performance Error Modeling

Fast Simulation of Sculptured Surface Milling with 3-Axis NC Machine

Simulation of Ball-nose End Milling Operations — Selection of Geometric Resolution Parameters

Machining Process Modeling for Intelligent Rough Machining of Sculptured Parts

Bridging the Gap Between Tool Path Generation for Sculptured Surface Machining and Computer Aided Process Modelling Techniques

Automatic Five-Axis CNC Feedrate Selection via Discrete Mechanistic, Geometric, and Machine Model Integration

Milling Simulation with an adaptive Strategy

Deformed Swept Volume Analysis to NC Machining Simulation with Cutter Deflection

Segmentation and Surface Fitting in Reverse Engineering

Surface Reconstruction from Point Clouds

Reverse Engineering Employing a Wrap-Around SurfaceTriangle Set

Manufacturability of Reverse Engineered CAD-models : a case study

https://archive.org/details/springer_10.1007-978-0-387-35392-0

3 notes

·

View notes

Text

The Evolution Of Precision Machining: Exploring Advanced Turning And Milling Solutions

In the world of modern manufacturing, precision and efficiency are paramount. Industries such as automotive, aerospace and heavy engineering demand high-performance machinery that delivers accurate and consistent results. As a result, machining technologies have significantly evolved, giving rise to sophisticated solutions like Vertical Turning Lathe, 5-Axis Turnmill and Special-Purpose Machines. These innovations have revolutionized production capabilities, enhancing productivity and reducing turnaround times.

The Role Of Vertical Turning Lathe In Modern Manufacturing

A Vertical Turning Lathe (VTL) is an essential tool for machining large, heavy workpieces that cannot be efficiently handled on horizontal lathes. Unlike traditional lathes, a VTL positions the workpiece vertically, allowing gravity to aid in stability and precision. This configuration is ideal for processing large-diameter components used in industries like energy, construction and railways.

One of the primary advantages of using a VTL is its ability to handle complex operations in a single setup. By incorporating advanced automation and CNC technology, manufacturers can achieve high levels of accuracy and repeatability, ultimately improving overall efficiency.

5-Axis Turnmill: Combining Turning And Milling For Maximum Efficiency

A 5-Axis Turnmill machine is a game-changer in precision machining. By integrating turning and milling operations into a single setup, it minimizes material handling and significantly reduces production time. Traditional machining often requires multiple machines and setups, leading to inefficiencies and alignment issues. However, with a 5-axis turnmill, manufacturers can complete intricate operations in one go, ensuring superior accuracy and consistency.

This technology is particularly beneficial for industries requiring complex geometries, such as aerospace and medical device manufacturing. The ability to maneuver the tool from multiple angles enables precise machining of intricate components with minimal errors, making it an invaluable asset in modern production lines.

Special-Purpose Machines: Tailored Solutions For Unique Manufacturing Needs

Not all machining requirements fit within standard machine configurations. This is where Special-Purpose Machines (SPMs) come into play. These machines are specifically designed to perform dedicated operations efficiently, often customized for specific production tasks.

(SPMs) come into play. These machines are specifically designed to perform dedicated operations efficiently, often customized for specific production tasks.

SPMs are widely used in mass-production environments where repetitive precision machining is required. They offer superior efficiency compared to general-purpose machines, as they eliminate unnecessary movements and optimize processing time. Industries like automotive and defence rely heavily on SPMs for manufacturing precision-engineered parts in high volumes.

Conclusion: WIDMA Leading The Way In Advanced Machining Solutions

When it comes to advanced machining technologies, WIDMA stands out as a leader in innovation and precision. With decades of expertise in designing cutting-edge machining solutions, WIDMA offers state-of-the-art Vertical Turning Lathe, 5-Axis Turnmill and Special-Purpose Machines tailored to meet the evolving demands of modern industries.

By focusing on automation, precision and reliability, WIDMA ensures that manufacturers achieve optimal efficiency while maintaining exceptional quality standards. Whether it’s high-speed drilling, multi-axis milling, or specialized machining solutions, WIDMA continues to push the boundaries of technology, enabling businesses to stay ahead in a competitive market.

With its unwavering commitment to excellence, WIDMA remains a trusted partner for industries seeking advanced machining solutions that drive efficiency, accuracy and innovation.

0 notes

Text

Ultimate Guide to Precision CNC Machining: From Design to Delivery

Precision CNC machining services are essential for creating high-accuracy components used in industries like aerospace, automotive, and medical. This process involves designing parts using CAD software, selecting the right materials, and utilizing advanced CNC machines to achieve tight tolerances. Quality control and post-processing ensure durability and functionality, while timely delivery completes the cycle. Companies like Pangea Technologies excel in providing end-to-end precision CNC machining services, combining cutting-edge technology, skilled engineering, and rigorous quality checks. Whether for prototypes or large-scale production, Pangea Technologies delivers reliable, high-quality solutions, making them a trusted partner in precision manufacturing.

Understanding Precision CNC Machining Services

Precision CNC machining services involve the use of computer-controlled machines to manufacture parts with exceptional accuracy and consistency. These services are essential for industries such as aerospace, automotive, medical, and electronics, where even the smallest deviation can lead to significant issues. CNC machining ensures tight tolerances, high repeatability, and the ability to work with a variety of materials, including metals, plastics, and composites. Companies like Pangea Technologies specialize in providing state-of-the-art precision CNC machining services, leveraging advanced technology and skilled engineers to meet the most demanding requirements.

The Design Phase: Turning Ideas into Reality

The first step in precision CNC machining is the design phase. Engineers and designers use CAD (Computer-Aided Design) software to create detailed 3D models of the component. This phase is critical because it determines the feasibility, functionality, and manufacturability of the part. Pangea Technologies collaborates closely with clients during this phase, offering design-for-manufacturability (DFM) feedback to optimize the design for CNC machining. This ensures that the final product is not only functional but also cost-effective to produce.

Material Selection: The Foundation of Quality

Choosing the right material is crucial for the success of any precision CNC machining project. Factors such as strength, durability, thermal resistance, and machinability must be considered. Common materials used in CNC machining include aluminum, stainless steel, titanium, brass, and engineering plastics. Pangea Technologies provides expert guidance on material selection, helping clients choose the best option for their specific application. Their extensive material inventory ensures that clients have access to high-quality raw materials for their projects.

Machining Process: Precision at Its Finest

Once the design and material are finalized, the machining process begins. CNC machines, such as mills, lathes, and multi-axis machining centers, are programmed to follow the CAD model’s specifications. These machines use cutting tools to remove material from the workpiece, shaping it into the desired form. Precision CNC machining services offered by Pangea Technologies utilize advanced equipment, such as 5-axis CNC machines, to produce complex geometries with unparalleled accuracy. Their commitment to quality ensures that every part meets the highest standards.

Quality Control: Ensuring Perfection

Quality control is a critical aspect of precision CNC machining. Each part undergoes rigorous inspection using tools like coordinate measuring machines (CMMs), optical comparators, and surface finish testers. This ensures that the final product adheres to the specified tolerances and quality standards. Pangea Technologies employs a comprehensive quality control process, combining advanced inspection techniques with skilled technicians to guarantee the accuracy and reliability of every component.

Post-Processing: Adding the Finishing Touches

After machining, parts often require post-processing to enhance their appearance, functionality, or durability. Common post-processing techniques include anodizing, powder coating, polishing, heat treatment, and plating. These processes not only improve the part’s performance but also protect it from environmental factors like corrosion and wear. Pangea Technologies offers a wide range of post-processing services, ensuring that every component meets the client’s exact requirements. Their expertise in finishing techniques adds value to the precision CNC machining process.

Delivery: Bringing Your Vision to Life

The final step in the precision CNC machining journey is delivery. Once the parts have passed all quality checks and post-processing, they are carefully packaged and shipped to the client. Timely delivery is essential to ensure that the client’s production schedule remains on track. Pangea Technologies prides itself on its efficient logistics and reliable delivery services. Their commitment to customer satisfaction ensures that every project is completed on time and to the highest standards.

Conclusion

Precision CNC machining services are at the heart of modern manufacturing, enabling the production of high-quality, complex components with unmatched accuracy. From design to delivery, every step in the process requires expertise, advanced technology, and a commitment to quality. Companies like Pangea Technologies exemplify the best in precision CNC machining services, offering end-to-end solutions that meet the needs of diverse industries. By combining cutting-edge technology, skilled engineers, and a customer-centric approach, Pangea Technologies ensures that every project is a success. Whether you’re developing a prototype or scaling up production, partnering with a trusted provider like Pangea Technologies can help you achieve your goals with precision and efficiency. Embrace the future of manufacturing with precision CNC machining services that deliver results you can count on.

0 notes

Text

5 Key Industries That Rely on Precision CNC Machining Services

Precision CNC machining services play a crucial role in various industries, ensuring high accuracy, efficiency, and quality in manufacturing. The aerospace industry depends on CNC machining for complex components like turbine blades and aircraft parts. In the automotive sector, CNC machining helps produce engine components, transmission parts, and custom prototypes. The medical industry relies on CNC machining for surgical instruments, implants, and medical devices requiring extreme precision. The electronics industry benefits from CNC machining in manufacturing circuit boards, connectors, and enclosures. Lastly, the defense and military sector uses CNC machining for weapon systems, armor, and specialized equipment. These industries trust CNC technology for its reliability, repeatability, and ability to create intricate parts with tight tolerances.

Aerospace Industry: High-Tolerance Manufacturing

The aerospace industry demands extreme precision, reliability, and high-performance materials. Precision CNC machining services are essential for producing complex aircraft components such as turbine blades, engine housings, and landing gear parts. Advanced CNC milling and turning processes ensure tight tolerances, superior surface finishes, and compliance with stringent FAA and aerospace standards. The ability to machine lightweight materials like titanium and aluminum makes CNC machining a cornerstone of aerospace manufacturing.

Automotive Industry: Enhancing Efficiency and Performance

The automotive sector relies on CNC machining for manufacturing critical engine components, transmission systems, and brake parts. CNC lathes, milling machines, and multi-axis machining centers produce high-precision parts that enhance vehicle performance, fuel efficiency, and durability. The rapid prototyping capabilities of CNC machining also allow for the development of innovative automotive technologies, such as electric vehicle (EV) components and advanced driver-assistance systems (ADAS).

Medical Industry: Precision and Compliance in Healthcare

In the medical field, precision cnc machining services plays a vital role in producing surgical instruments, prosthetics, and complex implants. Medical-grade materials such as stainless steel, titanium, and PEEK require high-precision machining to meet FDA and ISO standards. Multi-axis CNC milling and micromachining ensure accuracy in producing intricate components like orthopedic screws, dental implants, and diagnostic equipment. CNC machining’s ability to maintain biocompatibility and sterility makes it indispensable in medical device manufacturing.

Electronics Industry: Micro-Machining for High-Tech Devices

The electronics industry benefits from CNC machining’s ability to manufacture precision components for circuit boards, connectors, and semiconductor equipment. Miniature parts require tight tolerances and ultra-fine machining to ensure optimal performance. CNC micro-machining processes enable the production of heat sinks, enclosures, and housings for consumer electronics, telecommunications, and industrial automation systems. The demand for miniaturization and advanced materials like copper and aluminum alloys makes CNC machining crucial in the electronics sector.

Defense and Military Industry: Durable and High-Performance Parts

The defense industry depends on precision cnc machining services for producing robust components used in firearms, armored vehicles, missile systems, and aerospace defense applications. CNC machining ensures high-strength materials like titanium, Inconel, and hardened steels meet the stringent requirements of military-grade equipment. Multi-axis CNC machining and EDM processes enhance precision and durability, ensuring mission-critical parts withstand extreme conditions and heavy operational loads.

Energy Sector: Precision in Renewable and Traditional Power Systems

From wind turbines to oil and gas extraction equipment, the energy sector requires high-precision CNC-machined parts. CNC machining supports the production of turbine blades, drilling components, and heat exchangers that must endure high pressures, extreme temperatures, and corrosive environments. Advanced CNC processes, such as 5-axis milling and CNC turning, allow for the fabrication of intricate components for renewable energy solutions, including solar panel frames and hydroelectric turbines.

Industrial Equipment Manufacturing: Custom Machined Components

Industrial machinery and automation systems rely on CNC machining for custom parts, gears, and bearings. CNC-machined components improve the efficiency and longevity of manufacturing equipment, robotics, and conveyor systems. With CNC milling, turning, and grinding, manufacturers can create durable and precise machine parts for diverse industrial applications. CNC machining’s adaptability ensures compatibility with materials like stainless steel, brass, and engineered plastics, meeting the high demands of industrial production.

Conclusion

Precision CNC machining services are the backbone of numerous industries, ensuring the production of high-quality, reliable, and complex components. Whether in aerospace, automotive, medical, electronics, defense, energy, or industrial manufacturing, CNC machining delivers accuracy, efficiency, and consistency. As technology advances, CNC machining continues to evolve, driving innovation and meeting the growing demands of modern industry. The combination of automation, multi-axis capabilities, and high-tolerance machining ensures CNC machining remains a critical force in global manufacturing.

0 notes