#china cnc machining aluminum parts manufacturers

Explore tagged Tumblr posts

Text

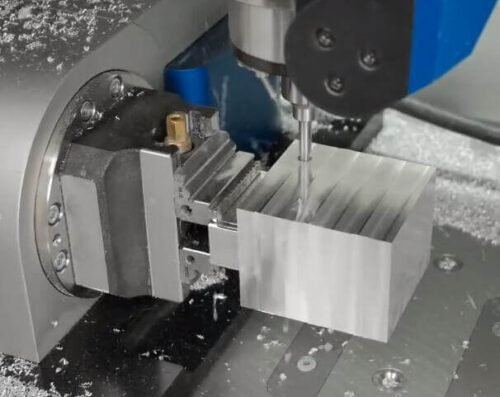

An Overview of CNC Milling: Precision Engineering in the Modern Era

New Post has been published on https://www.cncmachinings.com/blog/an-overview-of-cnc-milling-precision-engineering-in-the-modern-era/

An Overview of CNC Milling: Precision Engineering in the Modern Era

CNC milling stands as a cornerstone in the field of precision engineering, revolutionizing the way components are manufactured across industries. CNC, or Computer Numerical Control, milling utilizes computerized controls to operate and manipulate machine tools, enabling the production of complex parts with high precision and efficiency. This article delves into the intricacies of CNC milling, exploring its mechanisms, applications, and advantages.

Understanding CNC Milling

At its core, CNC milling involves the removal of material from a workpiece using rotary cutters. Unlike traditional milling, where the operation is manually controlled, CNC milling automates the process through computer programming. The design specifications are input into the CNC machine via CAD (Computer-Aided Design) software, which then translates the design into a set of precise instructions for the machine.

The CNC milling machine comprises several key components:

Spindle: The part of the machine that holds and rotates the cutting tool. Table: The platform where the workpiece is secured. Cutting Tools: Various types of milling cutters, each designed for specific types of cuts and materials. Control Panel: The interface through which the operator inputs commands and controls the machine.

The CNC Milling Process

Design Creation: The process begins with the creation of a detailed 3D model using CAD software. Conversion to CNC Code: The CAD model is converted into CNC code (G-code) using CAM (Computer-Aided Manufacturing) software. This code dictates the movements and operations of the machine. Machine Setup: The workpiece is fixed on the machine’s table, and the appropriate cutting tool is installed in the spindle. Execution: The CNC machine follows the G-code instructions, executing precise movements to mill the workpiece into the desired shape.

Applications of CNC Milling

CNC milling is employed across various industries due to its versatility and precision. Some notable applications include:

Aerospace: Manufacturing of intricate components for aircraft engines and structural parts. Automotive: Production of engine components, transmission parts, and custom automotive parts. Medical Devices: Fabrication of surgical instruments, implants, and prosthetic devices. Electronics: Creation of enclosures, heat sinks, and other electronic components.

Advantages of CNC Milling

The adoption of CNC milling offers numerous benefits:

Precision and Accuracy: CNC milling can produce components with extremely tight tolerances, essential for high-precision industries. Repeatability: Once a design is programmed, the machine can produce identical parts consistently, minimizing human error. Efficiency: CNC machines can operate continuously, significantly increasing production rates and reducing lead times. Complexity: The technology allows for the creation of complex geometries that would be challenging or impossible to achieve with manual milling. Material Versatility: CNC milling can work with a wide range of materials, including metals, plastics, and composites.

Challenges and Considerations

While CNC milling offers numerous advantages, it is not without challenges. The initial setup and programming require skilled technicians and can be time-consuming. Additionally, the cost of high-end CNC machines can be substantial, posing an investment barrier for smaller manufacturers. Maintenance and calibration are also critical to ensure the machines operate at peak performance and maintain accuracy over time.

Future Trends in CNC Milling

As technology advances, CNC milling continues to evolve. The integration of Artificial Intelligence (AI) and Machine Learning (ML) is poised to enhance the capabilities of CNC machines, enabling predictive maintenance, real-time quality control, and more efficient programming. Additionally, advancements in materials science may open new possibilities for milling harder and more durable materials.

In conclusion, CNC milling represents a pivotal advancement in manufacturing technology, offering unparalleled precision, efficiency, and versatility. As industries continue to demand high-quality, complex components, CNC milling will undoubtedly remain at the forefront of modern manufacturing processes.

#4 axis cnc milling machine china#Aerospace cnc machining#aluminum cnc machining parts china#auto parts cnc make factory#auto parts cnc make manufacturers china#Engineering#Machining#Prototyping#Featured Articles

0 notes

Text

Precision and Efficiency: The Ultimate Guide to Low Volume CNC Machining and Custom Machined Aluminum Parts

Did you know that Low volume CNC machining is transforming the manufacturing industry in China? With the growing demand for custom machined aluminum parts, businesses are turning to specialized CNC machining services to achieve high-quality, precision-engineered components without the high costs of mass production . At Sanwometal, we specialize in providing cutting-edge CNC machining solutions tailored for low-volume production. Whether you need prototypes, specialized components, or custom-finished aluminum parts, we ensure top-tier accuracy and efficiency.

0 notes

Text

𝐃𝐞𝐛𝐮𝐝𝐝𝐢𝐧𝐠 𝐭𝐡𝐞 𝐦𝐨𝐝𝐞𝐥 𝐨𝐟 𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥 𝐖𝐚𝐬𝐭𝐞: 𝐈𝐬 𝐂𝐍𝐂 𝐌𝐚𝐜𝐡𝐢𝐧𝐠 𝐚 𝐟𝐨𝐫𝐦 𝐨𝐟 𝐰𝐚𝐬𝐭𝐞?

CNC machining removes material, but does that mean it’s truly "wasting" it? In fact, modern CNC machining processes go to great lengths to minimize waste. Here’s how every inch of material is maximized:

High Precision Machining: Modern 5-axis CNC machines provide precise cutting with fine control over every detail, minimizing unnecessary material removal and ensuring maximum material efficiency.

Recycling and Reuse: Materials like aluminum, steel, and titanium can be recycled, melted down, and repurposed into new parts, significantly reducing waste in the manufacturing process.

CAD/CAM Integration: Advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software help optimize design and cutting paths, ensuring material is used efficiently and reducing the need for extra processing.

Design Flexibility: CNC machining can handle complex geometries, allowing designs to be optimized for material use and reducing waste while maintaining precision.

💡 Why Do So Many Factories Still Use CNC Machining? CNC machining’s benefits go beyond material efficiency, offering several other compelling reasons:

Precision and Reliability: For industries requiring extremely high precision, such as aerospace and medical devices, CNC machining delivers unmatched accuracy and consistency.

Material Versatility: CNC can work with a wide range of materials, including metals and plastics, making it highly versatile across various industries.

Speed and Scalability: CNC machining is ideal for both small batches and large-scale production, quickly producing high-quality parts once set up.

Superior Surface Finish: CNC machining provides excellent surface finishes, often reducing or eliminating the need for additional post-processing, something that 3D printing and other additive methods can’t easily achieve.

CNC machining isn’t just about “subtractive” manufacturing—it maximizes material use while ensuring high quality, efficiency, and precision.

🔧 #CNCmachining | #PrecisionManufacturing | #EfficientProduction What’s your take on the difference between CNC machining and 3D printing in terms of material usage? Share your thoughts in the comments below!

Contact Us Get More Info:

GreatLight Metal Technology Co., Ltd

✅ Website: https://glcncmachining.com/ ✅ Website: https://cnc-5-axis.com/ ✅ #10, Xinrong Street, Chongtou Community, Chang'an Town, Dongguan City, Guangdong, China, 523845 ✅ + 86 180 2756 7310 ✅ + 86 180 2756 7310(whatsapp) ✅ [email protected]

#DIsadvantage Of CNC Machine#Haas CNC Machine#Large CNC Machine#PrecIsion CNC Machining#Types Of CNC Machines#What Is A CNC Machines#What Is CNC Machine Operator#Woodworking CNC Machines#5 Axis CNC Machine Price#Benefits Of CNC Machining#Biggest CNC Machine#Carvera Desktop CNC Machine Review#CNC Full Form Machine#CNC Machin

0 notes

Text

Automation and Smart Technologies: Transforming the Machine Tools Market

Market Overviews

In 2023, the machine tools industry generated income of USD 78.8 billion in 2023, which is projected to experience a CAGR of 4.4% over the forecast period, to attain USD 105.6 billion by the end of the decade. This is primarily attributable to the fact that the precision and proficiency in making are the key indicators for minimum wastage and alteration. Machine tool, which has a very high precision level, can help to avoid material wastages and cost reduction at the time of assembly of the part.

The major reason for the growth of automation and robotics in machining technologies can be identified in the weak workforce in the high-level manufacturing industry of the developed countries and greater use of these techniques in the aerospace, defense, medical device, marine and other sectors.

The progress of Industry 4.0 has conversed multiple innovations like artificial intelligence, big data, robots and automation, allowing more efficacy, productivity and flexibility across major sectors. One of the factors, which increased the use of machine tools in the metal fabrication and industrial manufacturing industries, is the growth of the pressure on manufacturers for good quality products with efficiency, sustainability and acceptable lead time and no possible errors. An example is, automotive industry introduced visual inspection system in their production, this had a great impact in PPM defects.

Key Insights

The metal cutting category held a larger market share of around 70% in 2023 globally.

Metal cutting machine tools is an important part of the industry, which includes automotive, aerospace, defense, mechanical engineering, and medical devices industries for precise shaping of metal and alloys such as iron, steel aluminum, titanium, and copper.

This category contains a huge range of different machinery like crurshers, grinding machines, turning machines, milling machine, electrical discharge machine (EDM) and many other.

Of them, milling machine markets outshine because of their capability to generate accurate cuts of metal, making them primarily engineered by manufacturers.

In contrast, the metal forming machines are used for bending, shaping, and other processes that are associated with metalworking.

The CNC category held a larger market share of around 75% in the global machine tools market in 2023 and is the fastest-growing in the automation segment.

CNC machines reduce manufacturing time and error rates by using CAD and CAM software to receive design instructions from a computer.

They are able to accomplish more tasks in one line prompt then one would be able to give. Therefore, there is a reduction in level of guided instruction.

Numerous types of production equipment like milling, grinding, turning, lathing, drilling and electrical discharge machining can be also merged with CNC technology.

Standard tools like change-handing on the lathe machine or milling with a handheld machine necessitates a higher level of expertise and may not conform to the set shape.

CNC technology is preferred over conventional machine tools for higher precision and more efficient production.

APAC held the largest revenue share in the global machine tools market in 2023 due to increasing industrialization and population growth in countries like China and India.

Competition among emerging economies to become manufacturing powerhouses, coupled with government initiatives like Make in India, Made in China 2025, and Making Indonesia 4.0, has created a favourable investment environment.

Significant growth is also observed in the IT sector of North America.

Source: P&S Intelligence

#Machine Tools Market Share#Machine Tools Market Size#Machine Tools Market Growth#Machine Tools Market Applications#Machine Tools Market Trends

1 note

·

View note

Text

Aluminium CNC turning parts in china

Looking for precision-engineered aluminum CNC turning parts in China? Hsmolds.net offers top-notch manufacturing solutions. With a commitment to quality and expertise in CNC machining, they deliver precise components tailored to your specifications. Whether for automotive, aerospace, or electronics, their aluminum parts meet rigorous standards. Trust Hsmolds.net for reliable, efficient, and cost-effective CNC machining solutions in China.

0 notes

Text

Understanding Aluminum Machining Parts and Surface Finishes

https://www.aludiecasting.com/how-much-does-it-cost-to-anodize-aluminum/

Understanding the processes involved in aluminum machining parts, anodizing aluminum, and various surface finishes is vital for anyone in the manufacturing sector. By leveraging advanced techniques like HPDC casting and CNC machining services in China, businesses can optimize production while ensuring high-quality results. Whether you're looking to create a prototype or produce large quantities, these methods offer efficient and cost-effective solutions.

Anodize aluminum cost

0 notes

Text

Custom Various CNC Machine parts Stainless steel parts, aluminum alloy parts, copper processing parts, OEM Service.Focus on metal parts processing services for 20 years,Global Service. OEM/ODM Service. China Manufacturer. Factory Direct Price

1 note

·

View note

Text

youtube

Cnc turning aluminum machining services

We make cnc lathe milling machining parts service parts, cnc turning milling machining parts, cnc turning parts manufacture, cnc turning milling parts, 5 axis cnc milling machining parts, cnc machining china manufacturer, cnc custom machining milling turning parts, milling turning service cnc machining parts, high precision cnc machining service.

-------------------------------------------

https://mxymachining.com

0 notes

Text

youtube

Custom cnc machining parts manufacturer

We make high precision cnc machining accessories, cnc machining aluminum cnc turning part, cnc machining small parts, titanium cnc machining customized part, machining services custom cnc machining service, cnc turning milling machining parts, customized fabrication cnc machining copper parts, cnc custom machining parts.

----------------------------------------------

0 notes

Text

Customized Manufacturer of Car Chain Case

Product Name:Die-casting moulds and parts

Material:Stainless Steel , Brass , Copper , Aluminum alloy .

Technics:High-speed CNC, EDM, wire cutting, closing device, drilling, engraving machine and mold department.

Application:Auto parts series, fishing gear series, electric chain saw series, water pump die casting series, electric and pneumatic series, etc.

Size:Customize by Ningheng

Certification:ISO9001 ,TS16949

Brand:Ningheng

0 notes

Text

Top Aluminum CNC Machining Service in China

Aluminum CNC machining is a procedure that uses computer numerical control (CNC) machines to produce accurate and complicated Aluminum components. With technological improvements, the demand for high-quality Aluminum parts has skyrocketed. As a result, several Chinese enterprises are providing aluminium CNC machining services to suit the expanding demand.

China has quickly emerged as a top provider of CNC machining services because to its trained labor, superior technology, and cost-effective solutions. This has made it a popular choice for businesses wishing to outsource their CNC machining requirements. Aluminum CNC machining services provide a numerous benefits, including quick turnaround times, competitive pricing, and high-quality goods.

Our Aluminum CNC Machining Capabilities

We specialise in a variety of Aluminum CNC machining services, such as milling, turning, drilling, tapping, and more. Whether you need prototypes, small batches, or large-scale production runs, we can handle projects of any size or complexity. Our staff uses cutting-edge CNC machining equipment to enable quick turnarounds without sacrificing quality.

Benefits of Aluminum CNC Machining

Aluminum is regarded as being lightweight, sturdy, and corrosion-resistant, making it an excellent material for a variety of applications. Aluminium CNC machining allows you to make parts and components that are robust, reliable, and visually appealing. Additionally, aluminum is a cost-effective option that offers excellent thermal conductivity, making it suitable for various industries.

One of the primary benefits of choosing aluminium CNC machining services in China is the country's extensive network of suppliers and manufacturers. This provides organisations with access to a diverse choice of aluminium materials and machining techniques, guaranteeing that they can discover the optimum solution for their individual requirements. Furthermore, Chinese manufacturers are known for their meticulous attention to detail and precision, which ensures that the finished items satisfy the highest standards.

Another advantage of using Aluminum CNC machining Service is cost reduction. The country's competitive labor market and lower production costs result in lower prices for customers. China offers a cost-effective manufacturing choice without sacrificing quality.

In conclusion, Aluminum CNC Machining Service in China offers high-quality precision machining for aluminum parts. With state-of-the-art equipment and experienced technicians, we can produce custom aluminum components with tight tolerances and excellent surface finishes. Whether you need prototypes or large production runs, our CNC machining service can meet your specific requirements efficiently and cost-effectively. Trust us to deliver top-notch aluminum parts that meet your exact specifications and exceed your expectations.

0 notes

Text

From Concept to Creation: China's Mold Makers Redefining the Industry

In the intricate world of manufacturing, where precision and innovation reign supreme, the role of mold makers is paramount. These artisans are the architects behind the scenes, transforming concepts into tangible creations that drive industries forward. In China, a country renowned for its manufacturing prowess, mold makers are redefining the industry with their unparalleled expertise and dedication to excellence. In this article, we delve into the journey from concept to creation, exploring how China's mold makers are shaping the future of manufacturing.

A Tradition of Excellence

China's rich manufacturing heritage spans centuries, and at the heart of this tradition lies a legacy of craftsmanship and innovation. Mold making, in particular, has long been regarded as a highly skilled art form, passed down through generations of skilled artisans.

Today, China's mold makers continue this tradition of excellence, blending time-honored techniques with modern innovations to create molds of unparalleled quality and precision. From intricate injection molds for plastic components to large-scale molds for automotive parts, these craftsmen are capable of producing a wide range of molds to meet the diverse needs of customers across various industries. Check my blog Aluminum die Casting

Conceptualization and Design

The journey from concept to creation begins with the conceptualization and design phase, where ideas are transformed into tangible blueprints for mold fabrication. China's mold makers leverage advanced CAD/CAM software and simulation tools to create detailed 3D models of the desired components, allowing for precise visualization and analysis of every aspect of the mold design.

During this phase, mold makers work closely with clients to understand their unique requirements and preferences, ensuring that the final design meets their specifications. Whether it's optimizing for manufacturability, enhancing part functionality, or minimizing material waste, mold makers strive to deliver innovative solutions that exceed expectations.

Precision Engineering

Precision is the hallmark of every mold crafted by China's mold makers, and precision engineering lies at the core of their craft. Once the design is finalized, mold makers utilize state-of-the-art CNC machining equipment and advanced manufacturing techniques to fabricate the mold with incredible accuracy and precision.

From rough machining to finishing operations, every step of the manufacturing process is meticulously executed to ensure tight tolerances and smooth surface finishes. Quality control measures are implemented throughout the process to verify dimensional accuracy and integrity, guaranteeing that the final mold meets the highest standards of excellence.

Innovation and Adaptability

Innovation is a driving force behind China's mold making industry, with mold makers constantly seeking new ways to improve efficiency, quality, and performance. From adopting cutting-edge materials to developing novel manufacturing techniques, these craftsmen are at the forefront of innovation in the field of mold making.

One area where innovation has been particularly transformative is in the use of additive manufacturing, or 3D printing, for mold prototyping and production. This technology allows mold makers to rapidly create prototypes and iterate on designs with unprecedented speed and flexibility, reducing time-to-market and enabling greater customization.

Collaboration and Partnership

Collaboration and partnership are fundamental to the success of China's mold makers, who understand the importance of working together to drive progress and innovation. Mold makers collaborate closely with clients, suppliers, and industry partners to gain valuable insights, access to new technologies, and opportunities for co-innovation.

Through collaborative efforts, mold makers can tackle complex challenges, explore new market opportunities, and drive advancements in mold making technology. By fostering a culture of collaboration and partnership, China's mold makers are paving the way for a brighter and more innovative future in manufacturing.

Embracing Sustainability

In recent years, there has been a growing emphasis on sustainability and environmental responsibility in the manufacturing industry, and China's mold makers are rising to the challenge. Many mold makers have implemented eco-friendly practices and initiatives to minimize their environmental footprint and promote sustainable manufacturing.

From using recycled materials and energy-efficient equipment to reducing waste and emissions, mold makers are taking proactive steps to protect the planet and preserve its resources for future generations. By prioritizing sustainability, they are not only reducing costs and enhancing efficiency but also making a positive impact on the environment and society as a whole.

Looking Ahead: Shaping the Future of Manufacturing

As China's mold makers continue to drive innovation and push the boundaries of what is possible, the future of manufacturing looks brighter than ever. With ongoing investments in technology, research, and development, they are poised to remain at the forefront of the industry, driving progress and shaping the future of manufacturing on a global scale.

From automotive and aerospace to electronics and consumer goods, the applications for precision molds are vast and diverse. With their unparalleled expertise, dedication to quality, and commitment to innovation, China's mold makers are well-positioned to meet the evolving needs of customers and drive progress in manufacturing for years to come.

1 note

·

View note

Text

Daily maintenance records of aluminum bending machine

Hot wind system. The equipment is equipped with two adjustable temperature 220V hot air guns. Preheat the mold head before winding, and the coils are treated with hot air treatment for the coil after winding.

The above is the matters that should be paid attention to using the copper row processing machine. Everyone must pay attention when using it. I hope these can help everyone in the future.

The method of bending unit is as follows: First of all, add lubricating oil to the movement part; when the bending processing is performed, the corresponding convex and concave mold should be selected according to the width and thickness of the processing materials; The required width, thickness, and angle adjustment to stop the sales axis and place it in different positioning holes; by adjusting the stroke switch position, the bending angle of the workpiece can be changed; For bending processing, the bending unit is adjusted according to the material specifications, width, and thickness according to the material specifications, width, and thickness.

After more than ten years of development, the company has now become China's largest parent line processing equipment professional manufacturer after more than ten years of development. The company covers an area of more than 26,000 square meters, of which the construction area is more than 16,000 square meters. The company now has 120 sets of processing equipment, of which: CNC processing center, large dragon door milling, CNC busbar machine, etc. There are currently 227 employees, including 15%of engineering and technical personnel, involving multiple majors such as machinery, computers, electronics, engineering, economic, and information management. The company has taken the lead in passing the ISO9001: 2000 quality management system certification in the same industry in 2003. In 2008, it was honored by high -tech enterprises in Jinan, Shandong Province. Welcome to call: 0531-

Non -densely rowing coils are very mature to use the automatic bus system. During the winding process, users need to pay special attention to the setting of the winding parameters, the adjustment of each supporting attachment, and various auxiliary operations in the winding process.

The working surface is treated by the mirror surface. The desktop is chrome and grinded, and the working surface is accurate and stable. And the surface of the bus processor is painted and rusted by phosphate.

This machine uses a powerful 32 -bit design chip with a faster operation speed and higher reliability. The counting light sensor, synchronized casual lines, with self -detection, including setting errors, speeding tracking and speed calibration. Randomly lifting the spindle speed, the spindle climb time can be determined by itself.

0 notes

Text

Aluminum CNC Machining

AL is one of the most common materials used in CNC machining. Aluminum is highly machinable and relatively inexpensive, making it ideal for CNC machining.

Xintao usually machine it three or even four times faster than other commonly machined materials, such as steel and titanium. Because CNC machining of aluminum can reduce many tools and we only need to change the machining process flow for parts with more complex machining styles.

The Advantages of Using Aluminum For CNC Machining

1. The density of aluminum is very small, only 2.7g/cm³, although it is relatively soft, it can be made into various aluminum alloys, such as hard aluminum, super hard aluminum, rust-proof aluminum, cast aluminum, etc.. These aluminum alloys are widely used in aircraft, automobile, train, ship and other manufacturing industries.

2. Aluminum is second only to silver, copper and gold in terms of electrical conductivity, and the oxide film on the surface of aluminum not only has the ability to resist corrosion, but also has a certain degree of insulation.

3, aluminum surface oxide film not only has the ability to resist corrosion, but also has a certain degree of insulation.

4. Aluminum has good ductility

5. Aluminum has a silver-white luster, which is more beautiful than other materials.

6. The reflection performance of aluminum sheet is also very good, and has the function of sound absorption.

What Are Some Common Applications of Aluminum CNC Machining?

The density of aluminum parts is very small, so it is often used in space rockets, space shuttles, artificial satellites, airplanes, ships and other above.

Aluminum parts have good electrical conductivity, so in the electrical manufacturing industry, wire and cable industry and radio industry has a wide range of uses.

Aluminum parts have good thermal conductivity, commonly used in radiators, exchangers and other precision parts

Aluminum parts are more beautiful, often used in consumer products, such as laser swords, cell phone parts, etc.

0 notes

Text

Look For CNC Machining Metal Materials

As an advanced CNC metal machining manufacturer in Guangdong, China, Flourish Legend is committed to providing high-quality and precision custom parts and component solutions. With years of experience and excellent technical capabilities, we can machine various metal materials, including aluminum, stainless steel, brass, steel, copper, titanium, and more. These materials are widely used in various industries, including automotive manufacturing, electronic devices, medical instruments, aerospace, and more.

Types of CNC Metal Materials Available

CNC Machining Aluminium

Flourish Legend specializes in CNC machining of aluminum alloys. With advanced technology and precision equipment, we ensure high precision and stringent quality standards in manufacturing complex aluminum alloy parts and meeting your fine machining requirements. We strive to deliver premium and durable aluminum alloy products that meet your highest expectations.

CNC Machining Stainless Steel

CNC machining stainless steel can provide precision products for various industries, the durability, corrosion resistance and aesthetics of stainless steel products make them the first choice in industries such as aerospace, automotive and medical. Use CNC technology to meet complex designs and tight tolerances, create complex product shapes, and improve product performance while maintaining the inherent strength and longevity of the material.

CNC Machining Tool Steels

CNC machining of tool steel enables high-precision part manufacturing. With its excellent hardness, wear resistance and heat resistance, tool steel is widely used in fields such as molds, knives and mechanical parts. CNC machining technology ensures the consistency of precision design and tight tolerances to manufacture components such as blades and molds. This process enables the fabrication of complex shapes, improving performance and reliability in harsh environments while maintaining the strength and durability of the material. Whether in the automotive, aerospace or manufacturing industries, CNC machining of tool steels provides the key support for the production of high-quality parts.

0 notes

Text

Aluminium CNC turning parts in china

Looking for precision-engineered aluminum CNC turning parts in China? Hsmolds.net offers top-notch manufacturing solutions. With a commitment to quality and expertise in CNC machining, they deliver precise components tailored to your specifications. Whether for automotive, aerospace, or electronics, their aluminum parts meet rigorous standards. Trust Hsmolds.net for reliable, efficient, and cost-effective CNC machining solutions in China.

0 notes