#Low Volume CNC Machining

Explore tagged Tumblr posts

Text

High-Precision Low Volume CNC Machining & Custom Aluminum Parts | Sanwometal

Did you know that Low volume CNC machining can significantly reduce costs while maintaining precision? Whether you need a few prototype components or a small batch of custom parts, CNC machining ensures accuracy, durability, and efficiency.

At Sanwometal, we specialize in custom machined aluminum parts, offering top-tier solutions tailored to your specifications. Our advanced CNC technology guarantees superior quality and performance for every project.

0 notes

Text

A Buyer's Guide to Choosing Custom CNC Machined Parts Manufacturers

In today's market, the demand for custom CNC machined parts is soaring across industries, including aluminum CNC turning parts. Selecting the perfect CNC machined components manufacturer is essential for quality and value. This article offers a concise guide to help you make an informed choice for your project.

Material Selection: Custom machined parts can be crafted from a variety of materials, including aluminum for CNC turning parts. Choose the right material based on your project's needs, properties, and cost, consulting your CNC machining parts factory for the best fit.

Assess Supplier Capabilities: Not all CNC machined components manufacturers are equal. Evaluate their expertise, experience, and equipment for the required machining processes and complexity, especially for aluminum CNC turning parts. Check their track record and references for reliability and quality.

Quality Control and Assurance: Ensure your chosen CNC machined components manufacturer follows stringent quality control processes, such as ISO 9001 certification, to guarantee precision and quality in your aluminum CNC turning parts.

Lead Time Management: Custom parts often have longer lead times. Understand your CNC machining parts factory's lead times to meet your project deadlines with effective communication & planning.

Pricing and Value: Compare quotes from multiple CNC machined components manufacturers, considering material and machining costs, along with additional services for aluminum CNC turning parts. Prioritize overall value and reliability over the cheapest option.

Effective Communication: Opt for a CNC machining parts manufacturer with strong communication skills. Clear and timely communication is vital for addressing questions or issues during production.

Post-Processing Services: Check if the manufacturer offers post-processing services such as deburring, polishing, anodizing, or painting, especially for aluminum CNC turning parts. Consolidating these services with one vendor can save time and effort.

Packaging and Shipping: Ensure the CNC machining parts factory can package and ship your parts securely to prevent transit damage, including your aluminum CNC turning parts. Confirm they can meet your specific shipping requirements.

Intellectual Property Protection: If your custom CNC machined parts involve proprietary designs or technology, ensure the manufacturer has policies to protect your intellectual property.

The right CNC machined parts manufacturer, including aluminum CNC turning parts, is crucial for your project's success. Considering these factors, you can make an informed decision and establish a productive partnership with a CNC machining parts factory that meets your quality, service, and value requirements.

#custom cnc turning parts#cnc parts manufacturer#cnc turned parts manufacturer#cnc machining parts manufacturer#small batch cnc machining#low volume cnc machining#machining components#machined plastic parts#aluminum parts machining#custom aluminum parts#prototype cnc machining#cnc precision parts

0 notes

Text

Low Volume Manufacturing of CNC Machining

CNC machining low volume manufacturing or small batch manufacturing is the process of producing small batches using computer numerical control (CNC) machines.

Why Choose Low Volume Manufacturing? When the development of new products are in the testing stage, 1-2 samples are not enough to test, and can not meet the conditions of mold opening, or the number of products customized itself is not much, customers often choose precision CNC machining of small quantities. During new product development, small batch production can shorten the R&D and production cycle, and do FMEA to predict the risk before mass production, which is conducive to test market sales, and can also quickly adapt to changes in customer orders and market demand, to achieve inventory minimization and production system flexibility.

What Are The Advantages & Features of CNC Low Volume Manufacturing? 1.High precision Products of CNC machining low volume manufacturing with a high precision of +/-0.01mm, finish up to Ra1.6, suitable for oxidation, sandblasting, painting and powder coating, electroplating, polishing, silkscreen, laser engraving and other surface treatment. 2.High flexibility CNC small batch production is highly flexible and can respond quickly to market changes and customer needs, especially suitable for customized products and prototype development. 3.No MOQ CNC machining is flexible for the quantity, 1~1000 pieces can be processed, we have various types of CNC machining machines (3-axis, 4-axis, 5-axis, imported machines) to meet the customer's customized product needs. 4.Rich selection of materials A wide range of materials can be CNC machined, including metal and plastic materials. Commonly customized materials for small batch production are: aluminium alloy, stainless steel, titanium alloy, magnesium alloy, zinc alloy, nickel alloy, copper, steel and so on. 5.Higher production time and cost Small batch manufacturing usually involves more model changeovers and programme setups, which increases production lead time and results in lower productivity. Higher unit costs due to lower production quantities and fixed costs such as depreciation of equipment and maintenance costs that cannot be spread effectively.

Applications for CNC Low Volume Manufacturing 1.Customized products For parts or products that need to be customized, CNC small batch manufacturing allows for a quick response to customer needs. 2.Prototyping During the product development phase, CNC low volume manufacturing allows for rapid prototyping to help designers validate designs and make adjustments. 3.Small batch production For products that are not in high demand, CNC low volume manufacturing can provide flexible production methods and reduce costs. In short, small batch manufacturing is suitable for customized products, R&D trials, medical devices and other areas where uniqueness and flexibility are important.

Matters Needing Attention for CNC Low Volume Manufacturing 1.CNC machining of small batches has two main purposes, one is the product itself has a low demand for customization. The other is the small batch trial production before large-scale production, which can avoid economic losses in large-scale production due to flow design errors and product design problems. Regardless of the type of product you have, it is important to choose the right manufacturer and determine the number of units to be produced in advance before producing small batches. 2.In addition, it is equally important to pay attention to the quality of the product. Generally, these pre-produced products are not put on the market, but are mainly used as trial products to examine whether the actual production matches the design expectations. If the difference is relatively large, it is necessary to make changes to the original design or even overturn the whole design and re-plan it. Therefore, in the small batch trial production must not try to save trouble, the use of materials are best in the actual production will be used.

In summary, CNC low volume manufacturing or small batch manufacturing offers significant advantages in terms of customized products, prototyping and production of small quantities, but there are challenges in terms of cost control and production efficiency.

#design#business#autos#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#low volume manufacturing#small batch#small batch manufacturing#small batch production#low volume production#cnc processing#cnc manufacturing#cnc precision machining

1 note

·

View note

Video

youtube

We specialize in rapid, professional prototyping services, utilizing advanced technologies to deliver high-quality results. Whether you're looking for functional prototypes or appearance samples, we can meet your needs with precision.

Simply upload your 2D and 3D drawings, specify the materials, surface finishes, and quantities, and we will promptly provide you with a free quote.

Contact us today—we look forward to your inquiry!

📞 Contact us: [email protected] 🌐 Visit our website: www.kd-cncmachining.com

#youtube#Prototype parts manufacturing#Rapid prototyping#Functional prototypes#Appearance prototypes#CNC prototyping services#3D printing prototypes#Prototype machining#Custom prototype parts#Prototype development#Low-volume production#Precision prototyping#Prototype design and fabrication#Plastic prototype parts#Metal prototype parts#2D/3D CAD prototypes#Surface finish prototyping#Prototype assembly#Prototype testing#Free prototype quote

0 notes

Text

Elevating Precision Manufacturing: The Role of Mekalite’s CNC Machining Service

In today’s competitive manufacturing landscape, precision, efficiency, and adaptability are key to staying ahead. CNC machining has emerged as a vital technology, enabling manufacturers to produce complex and high-precision parts consistently. At Mekalite, we are redefining excellence in CNC machining services by combining advanced technology, a skilled workforce, and a commitment to quality.

https://mekalite.com/

What is CNC Machining?

CNC (Computer Numerical Control) machining is a process that uses computerized controls to operate machinery and tools with high accuracy. This enables the production of intricate parts from a variety of materials, including metals and plastics, while maintaining tight tolerances. CNC machining is critical in industries such as aerospace, automotive, medical devices, and electronics.

Why Choose Mekalite for CNC Machining?

Mekalite sets itself apart by offering a comprehensive approach to CNC machining, ensuring every project is handled with precision and care.

Advanced Machinery and Capabilities Our cutting-edge, multi-axis CNC machines allow us to handle even the most complex designs with precision and consistency. Whether you need rapid prototyping, low-volume manufacturing, or full-scale production, Mekalite’s technology enables us to meet your unique needs.

Customized Solutions We understand that every project is different. Mekalite works closely with each client to understand their specific requirements, delivering tailored solutions that align with their design and functionality goals.

Strict Quality Assurance At Mekalite, quality is our top priority. Our rigorous quality control protocols cover every step of the production process, from material selection to final inspection. This commitment ensures every part meets the industry’s highest standards.

Industries Served by Mekalite

Mekalite’s CNC machining services support a diverse range of industries, including:

Aerospace: High-precision components for engines, structural parts, and aircraft interiors.

Automotive: Custom engine parts, suspension components, and detailed bodywork.

Medical: Surgical instruments, implants, and diagnostic equipment requiring tight tolerances.

Electronics: Housing frames, connectors, and precision parts for delicate devices.

Benefits of Partnering with Mekalite

Choosing Mekalite as your CNC machining service provider offers numerous advantages:

High Precision and Accuracy Our state-of-the-art CNC machines, combined with skilled operators, enable us to achieve exceptional accuracy and repeatability across all projects.

Wide Range of Materials Mekalite’s expertise spans across various materials, from metals like stainless steel and aluminum to specialized plastics. This flexibility allows for innovative product designs and customized applications.

Cost Efficiency and Scalability With automated processes and minimal manual intervention, CNC machining reduces labor costs while enhancing efficiency. Whether you need a single prototype or a large production run, Mekalite’s scalable services can adapt to your requirements.

Timely Deliveries Time is crucial in manufacturing. Our efficient workflows and commitment to meeting deadlines ensure that your projects are completed on schedule, every time.

Looking Ahead: Mekalite’s Commitment to Innovation

Mekalite is committed to staying ahead of industry trends and technological advancements. By continually investing in the latest CNC machinery and refining our processes, we aim to provide even more innovative and reliable solutions to our clients. Our vision is to be a trusted partner in helping businesses achieve new levels of success through precision manufacturing.

Conclusion

CNC machining is revolutionizing the manufacturing industry, and Mekalite is at the forefront of this transformation. Our combination of cutting-edge technology, tailored solutions, and a dedication to quality makes us a preferred partner for businesses across various sectors.

If you’re looking for a reliable CNC machining service provider that delivers precision and value, Mekalite is here to help. Contact us today to discuss your next project!

https://mekalite.com/

2 notes

·

View notes

Text

Are you looking for a reliable and precise low-volume manufacturing service?

Look no further! 🌟

At ProtoTech Machining, we are not just a manufacturer; we innovate with precision.🛠️

Our company specializes in top-notch low-volume manufacturing services that are tailored to various industry needs such as aerospace, medical, automotive, robotics, and many other sectors. From CNC machining to Rapid prototyping and Sheet Metal Fabrication, our expert team can leverage cutting-edge technologies to turn complex designs into reality. 🚀

Plus, whether you need 3D printing, 5-axis, or Swiss CNC machining, we have the best capabilities to provide innovative and cost-effective solutions without compromising quality. ✨

So don’t wait any longer! Contact us now and let us be your partner in all your manufacturing needs. 📞

Browse https://prototech-machining.com/low-volume-manufacturing/ to learn more.

#prototechmachining#3dprinting#cncmachining#technologies#swisscncmachining#manufacturing#innovative#metalfabrication#aerospace#medical#automative#robotics

2 notes

·

View notes

Text

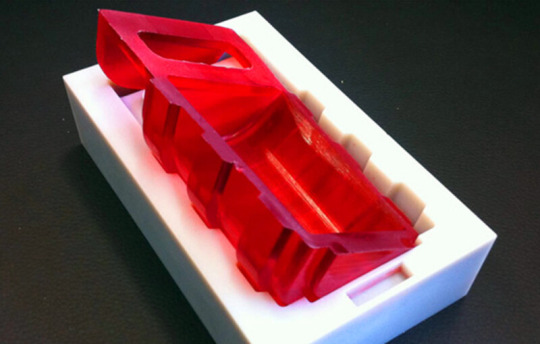

Learn About the Basics of Vacuum casting

Within the dynamic realm of production and prototyping, urethane casting is a unique technology that provides cost-effectiveness, accuracy, and diversity. Urethane casting has become the industry standard for a variety of applications, from complex prototypes to small-batch production runs, including consumer electronics, medical equipment, and the automotive and aerospace sectors.

Gratitude Casting of Urethane

The first step in the procedure is to create a master pattern, which is usually done via fast prototyping techniques like CNC machining or 3D printing. The silicone molds that are made from this master pattern are used to pour polyurethane resin into. The resin mimics the fine features of the master design once it has dried, producing pieces that are excellent and ready for manufacturing.

Flexibility throughout Sectors

The adaptability of urethane casting across sectors is one of its most noteworthy benefits. Urethane casting may be used for a variety of purposes, including the production of end-use components and prototypes for new product development. For instance, urethane casting makes it possible to quickly iterate ideas for dashboard panels, interior trim, and lighting fixtures in the car industry. Similar to this, urethane casting makes it easier and faster to produce unique medical device housings, surgical instruments, and prosthetic components in the medical profession. Vacuum casting also offers flexibility.

Benefits Compared to Conventional Approaches

When compared to conventional production techniques like CNC machining and injection molding, urethane casting has several significant benefits. The most important factor is cost-effectiveness. Because urethane casting requires less tooling up front, it's a great option for low-volume production runs if standard tooling costs are too high. Urethane casting also has a short turnaround time, which enables companies to quickly develop and refine ideas without having to wait for long lead periods.

Additionally, the design freedom provided by urethane casting makes it feasible to produce intricate surface details, undercuts, and complicated geometries that would be difficult or impossible to accomplish with alternative manufacturing processes. This versatility also applies to the choice of material, since a variety of polyurethane resins are available to satisfy certain performance needs, including those related to hardness, flexibility, and chemical resistance. You can Explore vacuum casting also.

Follow our Facebook and Twitter for more information about our product.

#vacuum casting#vacuum casting services#Urethane Casting#Explore vacuum casting#Custom Vacuum Casting Services

2 notes

·

View notes

Text

GD prototyping is a Prototypes&low volume manufacturer, provide (3&4&5axis)CNC machining, 3d printing, sheet metal, vacuum casting rapid tooling and surface finish. https://www.gd-prototyping.com/

2 notes

·

View notes

Text

2 notes

·

View notes

Text

Precision and Efficiency: The Ultimate Guide to Low Volume CNC Machining and Custom Machined Aluminum Parts

Did you know that Low volume CNC machining is transforming the manufacturing industry in China? With the growing demand for custom machined aluminum parts, businesses are turning to specialized CNC machining services to achieve high-quality, precision-engineered components without the high costs of mass production . At Sanwometal, we specialize in providing cutting-edge CNC machining solutions tailored for low-volume production. Whether you need prototypes, specialized components, or custom-finished aluminum parts, we ensure top-tier accuracy and efficiency.

0 notes

Text

What to Look for in a CNC Machine Shop

What to Look for in a CNC Machine Shop

Machine shops are responsible for the creation of many of the products we come to rely on. Their work ensures that these items are manufactured with precision and quality to match the original design. Look for a cnc machine shop that provides a comfortable workflow and treats their employees well like the family owned Bates Machine & Mfg. You should also make sure they can keep your product private and secure by asking them to sign a non-disclosure agreement before working with them.

1. Reliability

Planes, trains, and automobiles wouldn’t exist without the tireless work of machinists in machine shops. These unsung heroes are the

backbone of innovation across industries. Look for a shop that prioritizes adherence to deadlines and quality standards. Ensure that they have certifications, such as ISO 9001, to demonstrate their commitment to precision and consistency in production. It’s also important to consider how long a company has been in business. Family owned businesses tend to keep employees longer, and the best machinists often rise through the ranks. This ensures that the right people are at the helm of projects and provides opportunities for growth. Moreover, family-focused businesses are often less expensive than larger competitors. As such, they can provide more competitive quotes. This benefits both the client and the machine shop.

2. Timely Delivery

A CNC machine shop’s speed of delivery directly impacts end customers, so it’s important to assess their turnaround time. A reputable shop will be transparent about their capabilities and capacity and work closely with you to meet your production goals. Choose a shop with flexible capacities that can adapt to changing requirements in the future. This flexibility can help you stay competitive, especially in industries where demand fluctuates. Assess a CNC machine shop’s commitment to confidentiality, particularly for projects involving proprietary designs or sensitive data. A trusted partner with stringent confidentiality measures reduces your risk of a costly mistake and enhances your brand reputation. Evaluate the shop’s environmental responsibility and sustainability practices, too. A machining company that uses energy-efficient machines and adheres to environmental standards will have positive implications for your manufacturing operations.

3. Flexibility

Machine shops rely on CNC machines that enable automation and precise replication, ensuring efficiency in mass production. The machines facilitate a variety of machining techniques such as drilling, milling, turning, and grinding. Machinists also utilize manual equipment, which can reduce turnaround times. This allows them to work on a project immediately without waiting for the machine to complete its programming. A one-stop CNC fabricating shop brings all the necessary machinery and expertise under one roof to save you time. They also offer a range of digital communication channels to ensure that they are able to respond to inquiries in the manner that is most convenient to customers. They also maintain data privacy and confidentiality when working on proprietary designs.

4. Customer Service

The state-of-the-art equipment and machinery in a CNC machine shop might have an impressive “flash,” but it’s the people who work in that shop that make the biggest difference. If they treat you with a lack of respect and don’t care about the quality of your product, it might not be worth working with them in the long run. Family owned shops are more likely to understand that even the most dedicated employee needs a life outside of their shop walls. They are more likely to prioritize their employees’ well-being, which makes them happier in turn and helps to produce higher quality work. CNC machines can accommodate low- and high-volume production, making them ideal for businesses that need to create a prototype or actual products. They also adhere to stringent quality assurance and control processes to ensure that each finished product meets the required specifications.

5. Experience

A shop that treats its employees well will create a culture that is positive, empowered, and successful for everyone involved. This is especially important for CNC manufacturers who rely on the ideas of their employees to help streamline operations and improve efficiency. A quality CNC machine shop will also be transparent about its capabilities and will not promise things it cannot deliver. Make sure that the shop you choose has certifications and adheres to industry standards. The best way to find a shop with all of these qualities is to visit one and speak with the team. Look for people who are eager to help and have your best interests in mind. The shop should also provide convenient channels for communication like phone, email, and live chat. Read the full article

0 notes

Text

Low volume cnc machining parts from Dongguan Guanjie Precision Technology Co., Ltd.

2 notes

·

View notes

Text

Advancements in Gear Cutting Technology: Enhancing Precision and Efficiency

Gears are the heart of many mechanical systems, driving industries ranging from automotive and aerospace to robotics and industrial machinery. The demand for precise, efficient, and durable gears has propelled advancements in gear cutting technology. These innovations have transformed manufacturing processes, improving precision, speed, and cost-effectiveness. In this article, we explore the latest developments in gear cutting technology and their impact on modern manufacturing.

The Importance of Gear Cutting in Modern Industries

Gear cutting is the process of forming the teeth or cogs on a gear, a critical step in ensuring functionality and performance. Precise gear cutting ensures smooth motion, efficient power transfer, and reduced wear in mechanical systems. In industries where reliability is paramount, such as aerospace and automotive, even minor errors in gear production can have significant consequences.

Traditional Gear Cutting Methods and Their Limitations

Traditional gear cutting methods like gear hobbing, shaping, and milling have served industries for decades. While effective, they have certain limitations:

Manual Processes: Conventional methods often required manual adjustments, which could lead to inconsistencies.

Time-Intensive: Processes like milling individual teeth were slow and labor-intensive.

Precision Challenges: Achieving tight tolerances with older machinery was difficult.

Tool Wear: Frequent tool wear increased production costs and downtime.

These challenges highlighted the need for advanced technologies to improve efficiency and precision.

Advancements in Gear Cutting Technology

1. CNC Gear Cutting

Computer Numerical Control (CNC) machines have revolutionized gear manufacturing by automating the cutting process.

Key Features:

High precision and repeatability.

Ability to produce complex gear profiles.

Reduced human intervention and error.

Impact: CNC gear cutting has significantly increased production speed and quality, making it the standard in many industries.

2. Additive Manufacturing (3D Printing)

Additive manufacturing is gaining traction in the production of custom and prototype gears.

Key Features:

Layer-by-layer construction for intricate designs.

Minimal material waste compared to traditional methods.

Flexibility in creating unique or low-volume gears.

Impact: While still developing for large-scale applications, 3D printing offers exciting possibilities for rapid prototyping and complex geometries.

3. Gear Grinding Technology

Advancements in gear grinding have improved the finishing process, achieving unparalleled precision and surface quality.

Key Features:

High-precision grinding wheels for micro-level accuracy.

Reduced noise and improved durability of gears.

Impact: Gear grinding is essential for high-performance industries like aerospace and automotive, where precision is critical.

4. Advanced Materials and Coatings

Innovations in materials and surface coatings have enhanced tool durability and gear performance.

Key Features:

Carbide and diamond-coated tools for longer lifespan.

Gears made from lightweight yet strong materials such as advanced composites.

Impact: These developments reduce wear, enhance gear strength, and improve efficiency in high-stress environments.

5. Smart Manufacturing and Industry 4.0

Smart manufacturing integrates advanced technologies like AI, IoT, and data analytics into gear production.

Key Features:

Real-time monitoring of machine performance and gear quality.

Predictive maintenance to reduce downtime.

Automated process adjustments based on data insights.

Impact: Industry 4.0 has enabled manufacturers to optimize efficiency, reduce costs, and maintain consistent quality.

Benefits of Modern Gear Cutting Technology

Enhanced Precision: Achieving micro-level accuracy ensures gears operate smoothly and efficiently.

Increased Productivity: Automation reduces production time and increases throughput.

Cost Efficiency: Advanced tools and processes minimize material waste and tool wear.

Flexibility: Modern methods accommodate custom designs and low-volume production.

Improved Gear Performance: High-quality gears are more durable, efficient, and quieter in operation.

Applications of Advanced Gear Cutting Technology

Automotive Industry

Precision-cut gears ensure smooth operation in engines, transmissions, and drivetrains, improving fuel efficiency and performance.

Aerospace Industry

Aerospace gears require exceptional precision to withstand high stress and extreme conditions, making advanced cutting technologies indispensable.

Robotics

Custom gears produced with CNC and 3D printing enable accurate movements and durability in robotic systems.

Industrial Machinery

High-efficiency gears power heavy-duty machinery used in manufacturing, mining, and energy production.

Challenges in Adopting Advanced Gear Cutting Technologies

While advancements have transformed gear cutting, challenges remain:

High Initial Investment: CNC machines, advanced grinders, and additive manufacturing equipment require significant capital.

Skilled Workforce: Operating and maintaining modern machinery demands specialized training.

Material Limitations: Certain advanced materials are costly or difficult to work with using current tools.

Despite these challenges, the long-term benefits often outweigh the initial hurdles, making these technologies essential for competitive industries.

Future of Gear Cutting Technology

The future of gear cutting lies in further integration of digital technologies and sustainable practices. Key trends include:

AI-Driven Manufacturing: AI will enhance quality control and process optimization.

Sustainability: Eco-friendly materials and energy-efficient machines will drive the industry forward.

Hybrid Manufacturing: Combining additive and subtractive methods will unlock new possibilities for gear design and production.

Conclusion

Advancements in gear cutting technology have redefined how gears are manufactured, enhancing precision, efficiency, and performance across industries. Innovations like CNC machining, additive manufacturing, and smart manufacturing have addressed traditional challenges, enabling manufacturers to produce high-quality gears at a lower cost.

As technology continues to evolve, gear cutting processes will become even more sophisticated, paving the way for smarter, more efficient mechanical systems. Embracing these advancements ensures that industries remain competitive in an increasingly demanding and dynamic market.

0 notes

Text

0 notes

Text

0 notes

Text

As a purchasing manager responsible for acquiring sheet metal components, selecting the right supplier is crucial. Opting for bespoke sheet metal housings from V and F Sheet Metal offers numerous advantages that can significantly benefit your projects.

Tailored Precision and Design Flexibility

Bespoke sheet metal housings are custom-made to fit your product's exact dimensions and specifications. This precision ensures a perfect fit, eliminating the need for modifications that can compromise functionality or aesthetics. Unlike standard off-the-shelf options, bespoke designs provide enhanced flexibility, allowing for complex shapes, cutouts, and features tailored to your unique requirements. This adaptability is particularly beneficial in industries where precision is critical, such as lighting and electronics.

Advanced Manufacturing Capabilities

V and F Sheet Metal employs state-of-the-art equipment to deliver high-quality bespoke sheet metal housings. Their Trumpf 3030 3KW fibre laser cutting machine ensures precise and clean cuts, accommodating a wide range of sheet metal thicknesses. Additionally, their CNC bending machines, including the Safan e-Brake and Trumpf 7036, provide accurate and consistent bending to your exact specifications. These advanced technologies enable V and F to handle both low-volume prototypes and high-volume production runs efficiently.

Comprehensive Services and Expertise

With over 35 years of experience, V and F Sheet Metal offers a complete sub-contract sheet metal fabrication service. Their expertise extends to various industries, including electronics, lighting, heating, and audio. They provide services such as CNC punching, laser cutting, CNC bending, welding, and press work. Moreover, their in-house design and engineering team can assist in developing bespoke sheet metal housings that meet both functional and aesthetic requirements. This comprehensive approach ensures that all aspects of your project are handled with professionalism and expertise.

Material Versatility and Finishing Options

V and F Sheet Metal works with a wide variety of materials, including aluminium, steel, and stainless steel. This material versatility allows you to choose the most suitable option for your application, considering factors like weight, strength, and corrosion resistance. Additionally, they offer various finishing processes, such as powder coating, wet painting, and screen printing, to enhance the durability and appearance of your bespoke sheet metal housings.

Cost-Effective Solutions

While bespoke sheet metal housings may seem more expensive upfront, they can be cost-effective in the long run. By ensuring a perfect fit and reducing the need for modifications, you can minimize waste and assembly time. Furthermore, V and F Sheet Metal's advanced manufacturing processes and experienced team contribute to efficient production, potentially lowering overall costs.

Conclusion

Choosing bespoke sheet metal housings from V and F Sheet Metal provides tailored precision, design flexibility, advanced manufacturing capabilities, comprehensive services, material versatility, and cost-effective solutions. Their extensive experience and commitment to excellence make them an ideal partner for your sheet metal component needs. By collaborating with V and F, you can ensure that your projects meet the highest standards and achieve optimal performance.

0 notes