#plywood cutting machine

Explore tagged Tumblr posts

Text

A Comprehensive Review of the Altendorf F 25 Wood Cutting Table Saw Machine

In the world of woodworking, the search for the perfect table saw machine is a constant pursuit. Woodworkers seek a balance of precision, power, and efficiency to elevate their craft. The Altendorf F 25 Wood Cutting Table Saw Machine emerges as a strong contender, offering impressive features tailored for both professional woodworkers and passionate hobbyists. This comprehensive review dives deep into the F 25's functionalities, exploring its strengths, potential drawbacks, and how it can enhance your woodworking experience.

Precision Cutting: The Hallmark of the F 25

The F 25 prioritizes flawless results from the outset. The saw unit boasts a smooth-tilting mechanism for effortless angled cuts at any angle between 0 and 46 degrees. Digital displays for both height and tilt adjustments eliminate guesswork, ensuring consistent accuracy whether you're crafting intricate joinery or tackling repetitive cuts.

The Heart of Accuracy: The Altendorf Sliding Table System

A cornerstone of the F 25's precision is the renowned Altendorf sliding table system. This innovative design allows for effortless material handling, even with bulky or awkward pieces. The table glides effortlessly on rollers, ensuring precise positioning and minimizing material movement during the cutting process. This translates to cleaner cuts with minimal tear-out, especially on delicate materials like plywood or when used for plywood cutting machine table saw applications.

Powerhouse Performance for Demanding Tasks

Don't be fooled by the F 25's compact footprint. This machine packs a serious punch. The robust 4 kW (5.5 HP) motor tackles even the most challenging hardwoods with ease. Need to rip through thick plywood sheets or break down large slabs of solid wood? The F 25 handles it all effortlessly, delivering clean, precise cuts across a wide range of materials. This makes it a perfect choice for professional woodworkers, furniture makers, and serious hobbyists who require a versatile and powerful table saw.

Beyond Precision: Efficiency Reigns Supreme

The F 25 isn't just about making perfect cuts; it's about streamlining your entire workflow. Several features contribute to its impressive efficiency:

Generous Cutting Capacity: With a maximum cutting depth of 104 mm and a cutting width of 1410 mm, the F 25 caters to projects of all sizes. Large panels of plywood or lengthy boards pose no challenge for this machine.

Fixed Crosscut Fence: This rock-solid fence ensures quick and accurate 90-degree cuts, saving you time and effort in setting up repetitive cuts.

Optional Scoring Unit: This attachment helps prevent chipping and tear-out on delicate materials, particularly beneficial for tasks like veneering or working with plywood.

Safety Features for Peace of Mind

The F 25 prioritizes user safety with features like a hand guard to minimize the risk of accidents. This thoughtful design element allows you to work with confidence in your workshop.

Built with Quality, Designed for Performance

The Altendorf F 25 Wood Cutting Table Saw Machine is an investment in your woodworking passion. This high-quality machine is built with durability in mind, ensuring years of reliable performance. The robust construction minimizes vibration during operation, leading to cleaner cuts and a more enjoyable woodworking experience.

A Look at Potential Drawbacks

While the F 25 boasts an impressive feature set, it's important to consider some potential drawbacks:

Price Point: As a high-end machine, the F 25 comes with a premium price tag.

Space Requirements: While compact compared to other industrial saws, the F 25 may not be ideal for workshops with very limited space.

Finding the Right Fit for You

The F 25 is a versatile machine, but it's important to consider your specific needs before making a purchase. Think about the typical projects you undertake, the materials you use most often, and the available space in your workshop. Altendorf may also offer additional configurations or optional features to further tailor the F 25 to your workflow.

The Final Verdict: A Powerful Ally for Woodworkers

The Altendorf F 25 Wood Cutting Table Saw Machine is a compelling choice for woodworkers seeking precision, power, and efficiency. Its innovative features, robust construction, and commitment to user safety make it a worthy investment for both professional and hobbyist woodworkers. If you prioritize flawless results and a streamlined workflow, the F 25 is a powerful ally to elevate your woodworking to the next level.

0 notes

Text

Panel Saw Machine

Panel Saw Machine with Heavy Duty European Slide Sliding Panel saw machine is used to cut chip free or burr free and accurate boards or strips from sheets of Particle Boards, wood, laminates, plywood, MDF and related materials. Panel Saw Machine can also be manufactured to cut Plastic sheets, Aluminium profiles or sheets, precompressed boards, press board, fiberglass, densified wood or insulation sheets. Sliding Panel Saw Machine uses accurate sliding system, with European Style Heavy duty aluminium profile sections.

Features of Sliding Panel Saw Machine: Machine uses high precision guides Cast Iron Spindle mounting Pneumatic Clamping can be provided on request Adjustable speed of spindle as per usage Accurate side and front guide with scales Cast iron main table with extension supports Cost effective system Better clamping system Dust collection ducts for top and bottom side Scorer saw can be added on requirement Accurate Tilting system with dial or digital angle measurement

Optionals of Sliding Panel Saw Machine: Dust collection system Length of working: 1200, 2500, 3000, 3200mm Thickness of cutting can be customised Pneumatic Clamping System Variable feed of spindles main table side, spindle size and related can be customised Electrical cutter up-down and tilting system

Panel Saw Machine, Panel Saw, Plywood Cutting Machine, Sliding Table Saw, Sliding Panel Saw, Saw Panel Machine, Modular Furniture Machine, Panel Saw Machine, sliding table panel saw machine, Sliding Panel Saw at Best Price in India, Panel saw machine manufacturer near me, Panel saw machine price in india, Panel saw machine price, Panel Saw Machine manufacturer in india, Panel Saw Machine Latest Price, Wooden panel saw machine manufacturer in india, Panel saw machine manufacturer in india price, Woodworking panel saw machine manufacturer in india

#Panel Saw Machine#Panel Saw#Plywood Cutting Machine#Sliding Table Saw#Sliding Panel Saw#Saw Panel Machine#Modular Furniture Machine#sliding table panel saw machine#Sliding Panel Saw at Best Price in India#Panel saw machine manufacturer near me#Panel saw machine price in india#Panel saw machine price#Panel Saw Machine manufacturer in india#Panel Saw Machine Latest Price#Wooden panel saw machine manufacturer in india#Panel saw machine manufacturer in india price#Woodworking panel saw machine manufacturer in india

0 notes

Video

youtube

Machine Inutile

Laser cut plywood approx. 10x10x10 cms.

There is a long standing trope among makers, of pointless or overly complicated machines, in the US they are known as Rube Goldberg and in the UK as Heath Robinson and the Swiss artist Jean Tinguely made some magnificent automata in this vein that are sometimes referred to as 'machines inutile' , useless machines.

I wanted to confirm for myself that laser cut plywood gears could function as bevel gears about a ninety degree bend and decided to make a small machine inutile to test this.

So we have a small square base column with eight gears driven by a single crank and it does nothing but turn the gears, it is essentially a fidget spinner.

In actual fact it is not quite useless, as it does indeed turn gears that are at 90 deg to each other, and it also demonstrates that even number gear loops can turn, odd number gear loops do not. So had this had three or five sides the gears would not have turned and the machine would have been genuinely useless.

1 note

·

View note

Text

Plywood Cut to Sizes Melbourne | Viking Woodworks

Viking Woodworks is an Australian based family enterprise and was established in 2010. Since then Viking Woodworks has expanded the services it offers. We have achieved this by listening to our customers every step of the way, our customers and our staff are our most important assets.

0 notes

Text

The Transmutation Crew

It wasn’t uncommon to see a construction crew that was entirely identical these days.

It wasn’t cloning, not exactly. With the advent that was transmutation technology, even duplication wasn’t out of the question, but these copied crews did not come from mitosis.

Transmutation was the simple conversion of one material to another. Using a small sample of rare material and converting cheap shit into it. Clay could become ultrahard steel, paint could become a thick gold coating. Construction sites were rife with the machines, letting off heavy bangs as entire freshly built structures were changed at the atomic level into sturdy workings of titanium and diamond.

Like anything on a construction site, there was an expected level of risk. One would fear the conversion of a man becoming hard rock, but this technology had laws. Like became like, inanimate struggled to be animate and vice versa. This risk was rather functionally pretty harmless.

Foreman Adams operates the transmutator, the closest position to the samples of once-rare resources stored at its core. Foreman Adams flips the switched to convert cheap plywood to mahogany, and his own signal echoes outwards as well.

3 men taking a break just a little too close look at their new shared faces, clade in the same belt tucked shirt and blue jeans that had been pristine a decade ago, but were now clung with dust. 2-year-old boots they could all remember shelling out a fair bit of money for, worth it for how well they’d held up.

These new memories always sat comfortably by the original mind. One of the men, Dustin, wouldn’t think twice about how one half of him had been so much shorter a second ago whilst the other felt that he’d functionally teleported away from the machine that his original self was still operating. Dustin would just down the rest of his water and stretch his new bulkier form, absent-mindedly wondering if Adams would let him come home with him that night. Spend a night with his foreman’s rocking husband, reenact countless memories of that man getting fucked by small armies of Adams.

These transformations were typically temporary. Selfhood was overpowering and most people’s identities would win out in the end, shoving off the new skin and memories after a night of rest. Possibly retaining a few errant qualities of the shift that fit well into the original self, acquiring a small amount of muscle or confidence for their trouble. That took practice though, so most of them expected the new kids to fall under the influence of one of their elders for a bit. Or for forever, either or.

A college drop-out they’d picked up a while back hadn’t been on the job for a day before one of their veterans, Roland, had unwillingly taken him under his wing. A single blast and that kid’s face had seemingly shifted permanently, all his shaggy hair shortening into a clean cut and scraggly beard rapidly becoming well-kept. They’d expected the new appearance to fade in a month, but it had been a few too many by this point and it was safe to assume the Rolands would remain a pair. Not that those two were complaining, all buddy buddy between themselves, the drop-out assuming Roland’s identity so much that none on the crew even got to learn his old name. Roland happy to share his house and cigarettes with a man who shared all of his tastes.

Some people were suited to their own self. Call it narcissistic, but each of them enjoyed their turn. It was why operator duty of the transmutator was always an alternating duty. Each of them enjoying a day to themselves, in a way. It was bonding, being this vulnerable. The whole crew having access to every single one of each other’s deep internal lives, understanding it as they did. Mateo’s love for partying, shared across each of the crew after work, picking up chicks and twinks as an identical legion. Archie’s drinking problems, leading his identically bodied friends to embrace the man’s passion for football, all of them shouting for the same team as they lay across each other on a too small couch in one of their living rooms. Lucas’s daredevil tendencies leading five or six of them with broken arms and ecstatic grins in the hospital, regretting nothing and daring to do more the next go around.

This job was one of absolute connection and it wasn’t for the faint of heart. Countless amounts of prospective workers turning away when their soul wasn’t willing to play with new faces, was too rigid to go with the flow. The ones that stayed embraced it, trading jabs and inside jokes as they got to know each other from the inside out. Jose’s body craved a good steak no matter the time. Dallas’s brain was somehow still closeted, despite having fucked countless genders in everyone of his buddies’ bodies. Archie would get amusingly embarrassed even when another one of himself joked about how much they masturbated, especially so when the definition of masturbation was quite stretched in their cases.

Tonight, the guys would likely all go home in Pedro’s truck. Each of them shrugging off the man’s high vis vest in a pile of replicated clothing by the door. Pairs of them fitting into a shower before relaxing outside with their small army of clones. Inevitably curling up with as many as could fit on the bed, enjoying the way their shared brains didn’t mind the overbearing closeness of so many bodies. The newest of their crew would spend too long in the bathroom, acquainting themselves with every curve of Pedro’s older body as the veterans fought over blankets as their favorite talk show murmured in front of them. They’d probably fuck a bit, then pass out. Wake up to some of them in their own bodies as the remaining clones made breakfast, acting as good hosts for their “guests”.

They was nothing closer than a construction crew these days. Nothing like transmutation to make you trust them like you trust yourself, literally placing your life in their hands.

It was the good life, and twenty of the same face could attest to that.

#copy#identical#shapeshift#male shapeshift#clones#clone by conversion#male cloning#cloning#male tf#male transformation#personality change#my writing

126 notes

·

View notes

Text

Sorry for being so quiet here, this has been my major January project and he's kept me really busy!

Cicada, soft wall sculpture. Materials: fabric, embroidery thread, glass beads, wire, cardboard, plywood, rope trim, and a lot of trial and error

New techniques I learned for this guy: making a 3d cardboard frame/skeleton, sewing a unique 3d shape, wire framing, using a jigsaw (to cut the plywood for the back panel), various hand sewing techniques because my sewing machine still scares me a little. He's about 3' long from the top of the head to the tip of the wings and about 10" wide from the flat back panel to the top of the back.

I'm really stoked about how this guy came out, and I might be making some (much smaller) matching bug brooches in the very near future

12 notes

·

View notes

Text

I got this ~1950s mini sewing machine when someone was giving it away locally, so I've started restoring it. This is before...

There was live woodworm eating into the wood panels, the paint was flaking off, and there were rust spots on the exposed metal. The mechanism was actually in decent working order though.

I started with the wood. For the base I just ordered a piece of plywood cut to the right size, because I don't have a table saw to easily cut down big panels.

For the table, I laser-cut layers of 2mm plywood in slightly different sizes to create the right profile in the sides of the slot. Here it is before and after sanding the edges to nice curves.

Today I got started on the metalwork. First, dissassembling everything. It was scary but I took lots of pictures to keep track of how everything goes back together, so I can hopefully retrace my steps later.

The hardest part was removing the hand-crank wheel. It was really tightly wedged and I ended up having to hammer the metal in the centre of the wheel to release it. 😬

But it all came apart with no damage eventually.

Today I stripped off the flaking paint. Just many rounds of applying paint stripper, waiting, scrubbing, and repeating. Eventually got it all cleared off though.

Next will be cleaning all the other parts of rust, and then repainting. I won't be able to exactly match the old colour so I'm thinking I might do something totally different, but I haven't decided yet.

16 notes

·

View notes

Note

I'm involved in a project that requires casting some residential circular-arch doors out of concrete, one side at a time. I was considering designing the embellishments with digital tools and having them cut with a CNC machine for the mold, but it seems like a lot of trouble and I already know how to design things in the physical world. My question: what did you carve your beautiful embellished doors from, was it expensive, and do you think it'd work to cast a rubber mold from?

That sounds like a really cool project!

The carved panels on the doors I made were made in mdf-board. It's pretty cheap, about the same as plywood, and you can carve it like wood with a multitool - with the right bit, it's pretty fast work! (I talk about the different bits I use in this post.)

As long as the relief doesn't have any wierdly angled deep nooks and crannies, you should absolutely be able to make a rubber cast from it! Especially if you put down a base coat of somewhat glossy paint first, to make all the surfaces smooth and non-porous!

(Mandatory word of caution - carving mdf means a lot of sawdust, and it's a health-hazard to breathe it in. So do it outside, if you can, and wear a mask and goggles!)

The board on the doors is actually quite thin, about 10-12mm - the layered paint helps accentuate the 3D depth of the carvings. If you want a physically deeper relief, it'll be more work to carve it and the mdf sheets are more expensive the thicker they are.

That said, even a relatively shallow pattern can be very striking!

This divider was carved from 10mm mdf, so the carvings are just a few mm deep, but even without paint, it makes for a pretty effect! 🙂

If you do go ahead with it, feel free to share pictures! I'd love to see what you end up making! 😀

14 notes

·

View notes

Text

Once again, my enemies have done to me what they always do: get angry at me for getting impatient at Home Depot. And in a way, they’re right. It is both of our faults that I got upset. The workers are trying their best, and sometimes they have more pressing duties (customer pooped in the display toilet?) than coming to help me cut some plywood on the saw. That’s not their fault. What is their fault is that they once, years ago, showed me the key that they use to unlock the plywood-cutting saw’s safety interlock, and didn’t notice me taking several pictures of it with my phone before uploading it to a lock-breaking website operated by an unaccountable offshore artificial metamind.

They shouldn’t be too mad: sure, I did use their key-cutting machine to make a copy of that key, but I paid for it, just like any other sucker. That’s the right thing to do. If anything, they saved some money by my work of piracy, because I didn’t have to wait for an employee to come by and use the key-cutting machine, either. I’d love a business where customers walk in, serve themselves, and then give me some money. It would leave me with a lot of free time to waste at Home Depot waiting for someone to come by and slowly operate the power tool I already know how to use.

I do hear you saying now: if you’re so fucking handy, then how come you didn’t take it home and cut it yourself? The answer is that today’s modern plywood sheets are too big to fit into my delectable shitbox of a van, which was only made for three or four years in a suburb of Chengdu. Even now, getting any information about the model requires officially applying through the Chinese embassy, and often times all you’ll get back is “it is very suspicious that you keep asking so many questions about this.” I still keep trying, though, which probably means I won’t get to visit the factory in which it was made, or at least the Party representative who shows me around it won’t be very gracious when she spots me trying to shove mufflers into my pockets. So I have to hack the plywood in half and kind of jam it in there at an angle with the hatch propped open. And I can’t turn right very sharply or it will all fall out into traffic.

Home Depot says you should “do it yourself.” This is a noble pursuit, and, if anything, my core ethos. Of course, what they actually mean is “fuck it up, and buy materials to do it at least twice.” Their hypocrisy is laid bare in this exact situation, but worry not. I made sure to run off a few more orders from other customers before the orange-aproned Gestapo cottoned onto the sound of basic competence. With any luck, they too will become impatient with the doddering pace of hardware-store monopolists. I could use a second pair of eyes to watch my back while I’m working the key cutting machine next time.

234 notes

·

View notes

Text

A poem by Brian Brodeur

THE CARPENTER'S TALE

There's going to be an accounting. And it'll be the weird stats that come out of somewhere. And this is one of the stranger ones.

—Kerry Breen, This American Life, 8/13/2021

Most of us laughed at being called "essential" in those first weeks of New York's quarantine. We'd grease a hinge or patch a rotten sill,

replacing sunk beams under a snack machine, painting classrooms. Though it felt like cheating, I'd never seen the schools look so pristine.

Then, in April, at our team meeting, our boss clears his throat and his voice softens. Putting down the cruller he's been eating,

he says, "Next week, we start building coffins." One of us laughs. Another spills his coffee. I tell my boss, "Get out of here. Build coffins."

He looks up from his clipboard and glares at me, then gives us all the plans his boss gave him: "We'll be building coffins for the city."

On Monday, I show up at this school gym outfitted as a shop. On cinderblocks, beside the bleachers with the lights turned dim,

our prototype: a six-foot plywood box standing on its end where the feet would be. Above the prototype and scoreboard clocks,

a championship banner's "Victory" had begun to sag where flags of UN nations cling to the ceiling. Under Germany,

we set up cutting and assembly stations, a place where we can urethane the boards. Electricians rig fans for ventilation

and 10 of us plug in extension cords. We stack up drafts of plywood on the floor— a draft is 50 sheets. Our only words

concern the lack of Mets and Yankees scores, how hot the gym gets, who brought Gatorade. We run through 2x4s and they bring more—

wash, rinse, repeat. I mean, we're getting paid, but after so long it occurs to me: My god, they really need this many made?

No one gives us an end. We build 150, stacking them from one side of the gym to the other, five coffins high—no one can see

above the shrink-wrapped freight pallets of them. I back the forklift into the elevator and drive down Concourse near the stadium

and down another street to a tractor trailer. The forklift's so slow people honk at me. Honk at a guy carrying coffins—or

scream at me to move. This goes on three weeks. I find it—I don't know—bizarre, I guess, not one person ever stops to ask me

what I'm doing, everyone obsessed with toilet paper. Then, passing on foot, a guy who speaks Spanish stops to zip his vest

and says, "Morte," finger-slicing his throat. "Sí," I say, and he just shakes his head and walks away. I slam the trailer shut.

Our team built 450 in the end, and there were other teams in other districts across the whole Department of Ed.

No one I tell has ever heard of this. Why would they? Not exactly good PR— Guess what we used schools for. You'll never guess. …

But now that things are waning, more and more I feel alright, like I can let it out. It wasn't war—if it had been a war

we'd know what happened, what it was about, how much we'd lost, what people did out there. I'm sure someone will make a final count,

and we'll deal with each last expenditure, but that's years off, and this is not a war.

Brian Brodeur

More poems by Brian Brodeur are available through his website.

38 notes

·

View notes

Text

DIY Military Knife made with ACMER P2 33W.

Machine: ACMER P2 33W

Software: LightBurn

Material: 3mm Plywood

Cutting Speed: 400mm/min

Cutting Power: 100%

#ACMER#EngraveYourLoveWithACMER#laserengraving#lasercutting#ACMERP2#ACMERP3#LightBurn#diy#MilitaryKnife

2 notes

·

View notes

Text

The Best Plywood Cutter for Your Workshop: Unveiling the Altendorf F 45

For woodworkers, conquering plywood projects requires a machine that matches their ambition. Enter the Altendorf F 45, a plywood cutting machine that isn't just another tool in the shed; it's a powerhouse engineered for precision, efficiency, and the satisfaction of achieving flawless results. Is the F 45 the "best" plywood cutter for your workshop? Let's delve into its features and see if it fits the bill.

Powerhouse Performance:

Imagine effortlessly gliding a thick sheet of plywood through the saw, achieving a clean, splinter-free cut. The F 45 makes this a reality with its robust 5.5 kW (7.5 HP) motor. This industrial-grade powerhouse tackles even the most demanding plywood projects without bogging down. Say goodbye to wasted material and time spent wrestling with underpowered machines. The F 45 delivers clean cuts consistently, saving you money and frustration.

Precision Cuts Reign Supreme:

Accuracy is paramount in professional woodworking, and the F 45 doesn't disappoint. With a maximum cutting height of 204 mm and a rip capacity of a whopping 1600 mm, you can handle a vast array of plywood projects. Whether you're crafting intricate cabinetry or building large-scale furniture, the F 45 provides the cutting accuracy you need to bring your vision to life. No more worrying about misaligned cuts or wasted sheets – the F 45 ensures every cut is perfect.

ElmoDrive: The Magic of Control at Your Fingertips

Imagine a system that anticipates your needs. The F 45 boasts the revolutionary ElmoDrive technology, putting you in complete control of the cutting process with phenomenal precision. ElmoDrive allows you to:

Electronically adjust saw blade angles: Rise, fall, and tilt adjustments become effortless with digital controls, eliminating the possibility of human error and ensuring perfect angles for every cut.

Select variable cutting speeds: Optimize performance for different plywood thicknesses and desired finishes. ElmoDrive allows you to fine-tune the cutting speed for maximum precision and minimal material damage.

Benefit from real-time digital readouts for cutting height and width: No more guesswork or relying on rulers. ElmoDrive provides precise digital readouts for cutting height and width, allowing you to replicate cuts with unmatched accuracy.

With ElmoDrive as your co-pilot, achieving consistent, millimetre-perfect cuts becomes second nature.

Effortless Material Handling: No More Plywood Wrangling

Large plywood sheets can be cumbersome to maneuver, potentially leading to misaligned cuts. The F 45 eliminates this challenge with its expansive sliding table, boasting a maximum length of 5,000 mm. Imagine effortlessly gliding even the biggest sheets across the table for precise cuts. This smooth, controlled material handling minimizes the risk of errors and ensures your focus stays on achieving the perfect cut, not wrestling with the material.

Optional Automation: Supercharge Your Workflow (Optional):

For those who crave the ultimate in efficiency, the F 45 offers an optional CNC-controlled rip fence and crosscut fence. These intelligent features:

Move with incredible speed and accuracy: Eliminate time spent on manual adjustments with these lightning-fast, automated fences.

Provide digital readouts for fence position: Guarantee perfect cuts every single time with precise digital readouts.

Allow for the programming of complex cutting sequences: Streamline workflows for high-volume plywood projects. With these optional features, the F 45 becomes an automation powerhouse, ideal for professional workshops handling large-scale projects.

Safety First: Peace of Mind While You Work

Safety is a top priority in any workshop, and the F 45 doesn't compromise. A comprehensive suite of safety features ensures a worry-free work environment, including:

A protective guard that automatically covers the saw blade when not in use, preventing accidental contact.

Electronic safety systems that prevent accidental startups, keeping you safe throughout the cutting process.

User-friendly controls intuitively placed for optimal safety and ease of operation, minimizing the risk of errors.

With these features in place, you can approach each cut with confidence, knowing the F 45 prioritizes your safety while empowering your precision.

Built to Last: A Legacy of German Engineering

Altendorf is renowned for its commitment to quality, and the F 45 exemplifies this legacy. Meticulously crafted with high-grade materials, the F 45 is built to withstand the demanding environment of a professional workshop. This translates to a reliable machine that delivers exceptional cutting accuracy consistently, year after year. With the F 45, you're not just

investing in a machine; you're investing in long-lasting performance and a commitment to exceptional results.

The Best Plywood Cutter: Is the F 45 Right for You?

The Altendorf F 45 undeniably stands out as a top contender in the world of plywood cutting machines. However, with its premium features comes a premium price tag. Here are some factors to consider when deciding if the F 45 is the "best" cutter for your workshop:

Workshop Space: The F 45 has a large footprint. Ensure you have ample space to accommodate it comfortably.

Project Requirements: If you primarily work with smaller plywood sheets or have limited cutting needs, a less powerful machine might suffice.

Budget: The F 45 is a high-end machine. Be sure it aligns with your budget and long-term woodworking goals.

Beyond the F 45: Exploring Other Options

Altendorf offers a wide range of sliding table saws to cater to diverse woodworking needs. If the F 45 doesn't perfectly fit your requirements, consider exploring their other models. You might find a machine that offers the perfect balance of features and price for your specific needs.

The Final Cut: A Powerful Investment for Serious Woodworkers

The Altendorf F 45 isn't just a plywood cutter; it's a statement of dedication to precision and efficiency in professional woodworking. It empowers you to conquer even the most challenging plywood projects with confidence. If you're a seasoned woodworker seeking to elevate your craft, streamline your workflow, and achieve unparalleled results, the F 45 might be the best investment you can make. However, for hobbyists or those with limited space or budgets, exploring other wood cutting table saw machines might be a more practical option.

Regardless of your choice, the F 45 sets a benchmark for what a professional plywood cutting machine table saw can achieve. So, carefully evaluate your needs and workshop setup to find the perfect machine to take your woodworking journey to the next level.

0 notes

Text

Pooja Room Work At Hyderabd

Pooja room design work at Beeramguda, Hyderabad - Moderate ganapati structure cutting and bells as per the customer request. Work done with Plywood and Takewood colour decolam.

Fully closer box type open floor pooja room design at Pragati nagar, Kukatpally. Two doored hand cutting designery work at nuwood. Inside one shelf, two drawer's to keep pooja items seperatly.

Pooja room desing work at Bachupally, Hyderabad. Customer intrested to keep swastik, Om and poorna kumbham's on it. Meterial used white decolam, plywood.

Pooja room design work at Lingampally, Hyderabad.Full Ganesha, Om with Marwadi design. Plywood with Chocolate colour decolam.

Pooja room design Ameenpur, Beeramguda Hyderabad. Two Ganesha CNC Cutting designery doors with flower designs. Used plywood and chocolate colour decolam

Pooja Shelf designery work at Borabanda, Hyderabad. Swastik and Om Machine cutting, Used Pink colured decolam and plywood.

Pooja Shelf design at Kukatpally Housing Board Colony, Hyderabad. CNC cutting ganesha on plywood covered with takewood decolam.

Small Pooja box doors design work on takewood done at Jalavayu vihar colony, JNTU Kukatpally, Hyderabad.

Full size pooja room doors work at sainagar colony, Pragatinagar, Kukatpally, Hyderabad. CNC cutting on Gurjan plywood pasted white decolam.

Full sized pooja room doors Tamil Om (lord murugan emblem), Swasthik, lotus flower on top bells gold coloured. CNC cutting on nuwood matt finish black and gold colour used.

Box type pooja room design work at Rainbow vista villas, Kukatpally, Hyderabad. Chain with bells, Om, Swasthik, Ganesha, Poorna kumbham and Pooja lamps work done on Plywood and red decolam.

Pooja room and arch design at SR Nagar, Ameerpet, Hyderabad. Wall sides covered with plywood and doors added, chain bells, two sides ganesha and poorna kumbham.

Pooja room doors work at Srinagar colony, Ameerpet, Hyderabad. Chain bells, ganesha, Om and poorna kumbham. Used ash colour decolam greenply plywood.

Pooja room design cnc cutting on century plywood with half white decolam work at Chintal, Balanagar, Hyderabad.

Pooja room work at Motinagar , Hyderabad. Chain bells, ganesha, Om and poorna kumbham. Used back blue lighting ash colour decolam greenply plywood.

Pooja room doors at Beeramguda, Lingampally, Hyderabad. CNC cutting flowewrs, bells ganesha's. Used Gurjan 710 plywood rose wood colour decolam.

Pooja room design raw map to design ganesha, om, chain bells and poorna kumbham for cnc cutting.

Full box pooja room design work at Ameerpet. Open floor room design four sides covered with greenply plywood,Top side temple top design. Chain bells, Ganesha, Om, Poorna kumbhams and two draws for pooja essencials to keep. Used plywood and maroon colour decolam.

Takewood Carving full sized doors with arch work at Balanagar. Pooja lamps, Ganesha and Bells design carved on takewood used spray polish for shining.

Home Decode - Wardrobe | Cubboards Designs Hyderabad

Cub board work at Bollaram Alwal. Gurjan plywood with decolam white and yellow combination to match room colours.

Bedroom wardrobes work at Bollaram, Alwal. White decolam with white and pink rainbow line to match room colours as per customer interested.

Bed room wardrobe work at Alwal. Gurjan plywood with red and white decolam for white background room.

Bed room Wordrobe with middle dressing included with drawers at Alwal. Greenply plywood with red decolam and stainless steel handles. Customer special interest on red due to her flore marble are white ceiling white.

Bedroom Wordrobe work at Kompally. Gurjan plywood with takewood and chocolate colored decolam at first floor.

Bed room Cubboard work at Suchtra circle Hyderabad. 18mm plywood with white and chocolate colored decolam y shaped design and stainless steel handles with openeble two mirrors almara type.

Bedroom Cubboard work at Banjara Hills. Customer most enthusiast on music, we Disigned for him a Seperate cool design with white glowsy finish decolam and light blue matching for their bed with dressing table incuded with 2 drawers.

Wordrobe work at Banjara hills, Customer is a doctor he wanted a glowsy finish work. we used High glosy orage decolam with panther strikes, Moderated small doors with sqare shaped knobs, bottom stainless steel long handles.

Bedroom cubboard work at Kalyan nagar, Motinagar Hyderabad. White decolam with chocolate colour strips.

Master Bedroom Wordrobe work at Beeramguda, Hyderabad. White and chocolate coloured decolam as per the customer interest.

Sliding Wordrobe work near TV9, Banjarahills, Hyderabad. Blue and White decolam with dressing table included. Stainless stell sliding handles and master strokes at bottom and top with middle round white design.

Bed Room Cubboard work at Godavarikhani, Telangana. Gurjan plywood Pink Structred and white decolam combination 12" stainless steel handles 6 mm Grue Model.

Bed room wardrobe work at Banjarahills, Hyderabad. 18 mm Gurjan plywood with two Almarahs white and Meroon coloured decolam doors, included cnc edge cutting edge for dressing table with two drawers with copper colour handles.

Crockery unit design Nizampet Hyderabad. Ceiling flap with cubboards, side shelf doors, microwave oven placement. Takewood with cholate mix, White and cream colour high glossy decolam for dining hall.

Master bedroom sliding door wardrobe work at Nizampet Hyderabad. Takewood with cholate mix, White and cream colour high glossy decolam for light yellow background wall coloured bed room.

crockery unit design work nizampet Hyderabad. Sajja with cubboards, side shelf doors, microwave oven placement. Takewood with cholate mix, White and cream colour high glossy decolam for dining hall.

Master Bedroom Sliding wardrobe design work at Nizampet Hyderabad. Ceiling flap with cubboards, Takewood with cholate mix, White and cream colour high glossy decolam for bedroom with sliding handles.

Sliding wardrobe work for children bedroom at Hanamkonda. Sliding doors with takewood meroon shade decolam .

Children Bedroom wardrobe work at Balaji Hills, Nizampet, Hyderabad. Digital decolam with white background, blue flowers, butterflies and ash shades.

Multi colour sliding wardrobe work at Yousufguda. On Greenply Plywood Orange, Green and Pink decolam with sliding handles with soft close channels.

Master bedroom cubboard design work at Chintal, Hyderabad. Black and white decolam as per the customer believe's Astrology.

Master bedroom sliding doors with soft closer wardrobe work at Sanathnagar, Hyderabad. Century plywood with White and takewood decolam.

Master bedroom cubboard with sliding and soft closer work at Cherlapally, Hyderabad. White and rose wood decolam.

Sliding Wardrobe design at Vinayaka Nagar, ECIL, Hyderabad. Black and Digital decolam with soft close sliding.

Bedroom Profile Wardrobe Sliding soft closer work at Srinagar Colony, Hyderabad. Red rosewood, Glossy white Acrolic Sheets with Alluminium Borders.

Bedroom Wardrobe work at Banjrahills, Hyderabad. High glossy white and grey decolam with long wood handles.

Children bedroom cubboard work at Miyapur. High glow takewood and black mixing decolam with dressing room .

Master bedroom cubboard work at Lingampally, Bhel, Hyderabad. Sliding soft closer wardrobe with Takewood dark with Cream colour decolam.

Kitchen cubboard work at Bollaram, Alwal, Hyderabad. Kitchen grocery keeping cubboards with White and Grey coloured decolam.

18 notes

·

View notes

Text

DIY Salvaged Spool Ottoman

Project by Shelly:

i know ottomans aren’t the most indispensable piece of furniture in the house, but is it criminal to say they bring me the most joy? i think upholstery maven shelly (aka ModHomeEcTeacher) would agree with me; she’s made a whole collection of smart looking ottomans using a range of found fabrics and materials. i am so excited to follow her instructions and craft an adorable plaid ottoman of my very own, just in time to welcome fall. click here to see more of shelly’s amazing work, including her tutorials on everything from upholstering with rugs to aligning atomic legs. thanks, shelly! –kate

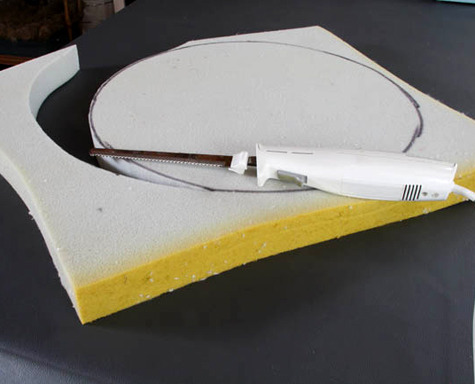

When Lowes stopped selling the pre-cut wood circles I used to construct my ottoman frames, it was a dark day. I soon discovered that cutting perfect circles with a hand-held jigsaw wasn’t easy, or even really possible. Weeks later, while roaming the store searching for an alternative, I discovered the empty electrical spools that are routinely discarded. Two perfectly cut round pieces of 5/8” plywood with a removable cardboard cylinder in the middle? Now we’re talking. With a tiny bit of carpentry, I came up with a way to easily re-work these into frames for my upholstered ottomans. I would label this as a mid-level DIY project that you could complete in a weekend. Once you get the hang of it, you these would make fantastic handmade gifts for friends and family. –Shelly

Materials:

-1 20” diameter empty electrical wire spool (hardware stores usually throw these out, so ask about picking them up instead) -8 pre cut 1”x 2”x 6” pieces of wood (a hardware store will cut these for you) -Wood glue -32 1 ¾” screws -A piece of foam (anywhere from 3” to 6” thick and at least ½” larger all around than the wood) -Spray adhesive (Elmers makes a spray adhesive available at the craft store) -Scrap fabric ( this to attach around the ottoman frame measuring about 8” x 65”. An option would be to use a bendable piece of cardboard) -1 ½ yard of cotton or dacron batting -1 ½ yard of 54” wide fabric -¾” yard of scrap fabric to cover the bottom of the finished ottoman -Thread and straight pins -Staples -4 screw on leg plates (hardware store) -4 fabulous ottoman legs (look around for good legs on cruddy, inexpensive Goodwill furniture)

Tools:

-Big marker -Drill -3/32” drill bit and a 3/8” drill bit -Electric knife -Electric stapler -Scissors -Measuring tape -Flat head screwdriver -Pliers (crescent or needle nose) -Sewing machine

Instructions:

Making the frame:

1. Take the spool apart and make a pattern by tracing the circle on a large piece of paper, adding ½” all around for the seam allowance. The pattern will be used for cutting out the foam, batting, fabric and a dustcover for the bottom. Lay aside.

2. Glue and screw 6-8 posts evenly around the outside edge of one wooden circle, then add the other piece of wood on top of the posts and attach. Be sure to keep the wood circles aligned.

Padding:

1. Use the staple gun to attach the long piece of cotton muslin around the outside edges of the top and bottom circles. Keep fabric pulled taut. The fabric serves to fill in the open spaces between the support posts. Cut off excess fabric. (Option: use bendable cardboard)

2. Trace the pattern onto the foam and cut the foam using the electric knife. Keep the knife blades perpendicular to the foam to get a crisp, even cut.

3. Use spray adhesive to glue the foam to the top of the ottoman frame.

4. Trace the pattern onto the batting, cut out. Also, cut out a long strip of batting equal to the total height of the ottoman, from the top of the foam to the bottom edge, plus two extra inches.

5. Pin the batting strip to the batting circle, starting 1” from the short end of the strip and ending 1” from the other end. Stitch in place.

6. Remove from under the sewing machine and stitch the open seam closed and go back and complete stitching that section of the band to the batting top.

7. Trim off the excess seam allowance, turn the batting covering right side out and pull it down on top of the ottoman frame.

8. Measure and mark the batting band (all the way around the covering ) so that it will be stapled evenly from the top seam to the bottom EDGE of the frame. Do not attach the batting to the underneath side of the wood. Attach it to the edge and cut off the excess batting.

Sewing and Upholstering:

1. To make the fabric covering, which is a bit like a snug slipcover, trace the pattern onto the fabric and cut it out. You’ll need to cut a band of fabric 3” longer than the height of the ottoman and 5” wider than the circumference. If you need to stitch two pieces together to get a long enough piece for the band, split the circumference measurement in two and add 3 extra inches to each piece.

2. To prepare the fabric covering for stitching, fold one short end of the cut fabric band over 1” with wrong sides together. With the right side of the band to the right side of the fabric circle, patterns matching, pin and begin stitching at the folded short edge all the way around to the other short end. Overlap the excess fabric 2” past the folded short end. Cut off any excess fabric beyond the 2”. Pin and stitch the overlapping fabric to the seam.

3. Turn the fabric covering right side out and topstitch the folded seam closed from the bottom of the band to the top seam.

4. Pull the fabric covering down over the dacron covered ottoman. Adjust the fabric pattern and straighten so the pattern or plaid is aligned.

5. Pull the fabric down firmly and staple in place evenly and snugly.

Upholstery Tip: It works best to start with one section and attach with a few staples, move to the opposite side and do the same. Then repeat for the other sides. Attach the fabric between the set staples by smoothing and easing in the fabric.

Attach Legs:

1. Measure and mark the bottom of the ottoman base for leg attachment. Place the leg plates on the marks to make sure they are equidistant from each other. Mark the center hole of the plates. Use the 3/8”drill bit to drill out the center hole. You can also do this step prior to putting the fabric on (as shown below).

2. Cut out a dustcover from scrap fabric and attach it to the bottom of the ottoman by folding the edge under ½”.

3. Locate the drilled holes, line the leg plates up, screw the leg plates on using a Phillips head screwdriver or the drill. Attach the legs to the plates.

VOILA!

4 notes

·

View notes

Text

youtube

Nick Newman helped design a modular construction system so anyone with just a mallet and a drill can build their own home. Since co-founding U-Build in 2020, he has built— and watched others build— furniture, garden sheds, tiny homes, and full-sized houses, so it makes sense he’d use the flat-pack box system to turn the company work van into his full-time home.

[Watch our first video featuring Nick's U-Build universal home-build system, a CNC-cut flat-pack design anybody can assemble to make a home: • U-Build hands-on:... ]

According to Newman, "the U-Build construction system is something like if IKEA and LEGO had a baby. So, it's these big boxes that can be assembled with a mallet and a screwdriver. Effectively, you start out with your individual panels, which are cut with precision using a CNC machine, and it's designed with this kind of locking system so you can basically put the pieces together: it would always be on the 'right' configuration." Watch it at 25:45.

[Video timeline]

— Nick Newman out in London on his electric campervan: 00:10

— Explaining EV's lack of congestion charge in London: 00:20

— Charging the van in central London: 00:50

— Thunderstorm: 2:20

— Stealth setup: 03:00

— EV van conversion into vanlife camper: 3:30

— Conversion with U-Build boxes ("building blocks") timelapse: 3:42

— Explanation of a U-Build minimum unit of construction, the box: 03:50

— Kirsten interviews Nick Newman: 04:20

— U-Build's modularity put to the test inside a van: 05:10

— Locking system for drawers (inspired by the ones on commercial aircraft): 06:30 and 14:50

— Festival build out of U-Build blocks: 07:15

— Sink: 0832

— Current van living interior: 11:30

— Adapting working straps to vanlife: 12:00

— Folding clothes: 13:05

— Hammock setup: 19:28

— At Stroud, Gloucestershire: 20:45

— U-Build's workshop under construction on an old empty factory: 21:30

— Describing U-Build as a self-build system: 25:45

— On using empty buildings: 22:10

— "People could stay in a house like this for really cheap": 22:15

— Warehouse spaces to solve housing emergencies? 22:30

— Out in Herefordshire: 36:28

— Student-built house with U-Build: 36:35

He started using the fully-electric Sprinter van as a temporary home while on overnight work trips. The U-Build system involves assembling CNC-cut, formaldehyde-free plywood boxes as building blocks which then bolt together to create a rigid frame for a structure.

The conversion cost him less than £2,000 (about $2,400, or €2,300). The system is entirely demountable, so the boxes can be reused over and over: it was easy for Newman to take the boxes he was working with daily and rearrange them in the van to build a bed, kitchen (U-Scrub), storage, and toilet (U-Poo).

Newman left a shared warehouse where he was paying £800 for a tiny, windowless bedroom for vanlife in central London, and because the van is electric, he doesn’t pay congestion charges (£15/day). He has tricked out the van to appear in drive mode so he can use the vehicle’s battery and air conditioning and heating while parked.

The U-Build (and Studio Bark) team recently bought an abandoned warehouse in Stroud (Gloucestershire) for less than the price of a tiny studio in London. While they decide what to do with the space, they have installed U-Build dwellings (built in a half day) to use as bedrooms and private offices. It’s the same model as the SHED Project, where they worked with a London-based guardian company to provide quick-build homes from U-Build kits to provide housing for those in need in exchange for building surveillance.

https://u-build.org/

https://www.instagram.com/ubuild/

Nick's YouTube channel: / @electric.vanlife

Here's our story covered by Autoevolution: https://www.autoevolution.com/news/th...

On *faircompanies: https://faircompanies.com/videos/u-bu...

#kirsten dirksen#solarpunk#building#house#sustainable architecture#sustainable building#architecture#Nick Newman#U-Build#electric vehicles#sustainable housing#electric van#London#uk#england#Studio Bark#Stroud#Gloucestershire#Youtube

6 notes

·

View notes

Text

Hello!

This is a digital product.

This vector design consists of four separate layers. You can use a 3D Cat Paw design to decorate your home or to diverify the interior at work. Also, the multi-layered Cat Paw will be the most unique gift for family and friends among other gifts.

If you like our vector design and are cutting with a CNC laser machine, this design is for you. You can also use it for cutting paper with other machines such as Silhouette, Cricut and other brands.

Feel free to contact me if you need a different file format or size.

After downloading you will receive 1 ZIP folder, it will contain the following file formats.

.Ai

.SVG

.DWG

.EPS

.DXF

.PNG

.PDF

Unzip the ZIP-folder before use

+ Dimensions of the finished product Multilayer Cat Paw

+ 10X10 INCHES (Standart Cardstock)

+ Numbered layer pages.

Materials for use: plywood, cardboard, paper, plexiglass.

For commercial use, you can only sell the product that was made according to my drawings.

Cat Paw 3D Mandala SVG files, Animal Mandala Files for Laser cutting, DXF Cat Paw Floral Templates for cnc router machine,

Cat Paw Multilayer Blueprint, Plywood cutting, wall art home, Laser cut dxf, Paper art, Cat Paw Mandala SVG, 3D Cat Paw SVG files, Cat Paw Multilayer Laser Cut, Cricut SVG

#craft#hand crafted#paper art#paper cutout#papercraft#shadow box#svgforcricut#svgcuttingfiles#svgcutfiles#svg bundle#svg#svgdesigns#svgfiles#caturday

4 notes

·

View notes