#plywood cutter

Explore tagged Tumblr posts

Text

The Best Plywood Cutter for Your Workshop: Unveiling the Altendorf F 45

For woodworkers, conquering plywood projects requires a machine that matches their ambition. Enter the Altendorf F 45, a plywood cutting machine that isn't just another tool in the shed; it's a powerhouse engineered for precision, efficiency, and the satisfaction of achieving flawless results. Is the F 45 the "best" plywood cutter for your workshop? Let's delve into its features and see if it fits the bill.

Powerhouse Performance:

Imagine effortlessly gliding a thick sheet of plywood through the saw, achieving a clean, splinter-free cut. The F 45 makes this a reality with its robust 5.5 kW (7.5 HP) motor. This industrial-grade powerhouse tackles even the most demanding plywood projects without bogging down. Say goodbye to wasted material and time spent wrestling with underpowered machines. The F 45 delivers clean cuts consistently, saving you money and frustration.

Precision Cuts Reign Supreme:

Accuracy is paramount in professional woodworking, and the F 45 doesn't disappoint. With a maximum cutting height of 204 mm and a rip capacity of a whopping 1600 mm, you can handle a vast array of plywood projects. Whether you're crafting intricate cabinetry or building large-scale furniture, the F 45 provides the cutting accuracy you need to bring your vision to life. No more worrying about misaligned cuts or wasted sheets – the F 45 ensures every cut is perfect.

ElmoDrive: The Magic of Control at Your Fingertips

Imagine a system that anticipates your needs. The F 45 boasts the revolutionary ElmoDrive technology, putting you in complete control of the cutting process with phenomenal precision. ElmoDrive allows you to:

Electronically adjust saw blade angles: Rise, fall, and tilt adjustments become effortless with digital controls, eliminating the possibility of human error and ensuring perfect angles for every cut.

Select variable cutting speeds: Optimize performance for different plywood thicknesses and desired finishes. ElmoDrive allows you to fine-tune the cutting speed for maximum precision and minimal material damage.

Benefit from real-time digital readouts for cutting height and width: No more guesswork or relying on rulers. ElmoDrive provides precise digital readouts for cutting height and width, allowing you to replicate cuts with unmatched accuracy.

With ElmoDrive as your co-pilot, achieving consistent, millimetre-perfect cuts becomes second nature.

Effortless Material Handling: No More Plywood Wrangling

Large plywood sheets can be cumbersome to maneuver, potentially leading to misaligned cuts. The F 45 eliminates this challenge with its expansive sliding table, boasting a maximum length of 5,000 mm. Imagine effortlessly gliding even the biggest sheets across the table for precise cuts. This smooth, controlled material handling minimizes the risk of errors and ensures your focus stays on achieving the perfect cut, not wrestling with the material.

Optional Automation: Supercharge Your Workflow (Optional):

For those who crave the ultimate in efficiency, the F 45 offers an optional CNC-controlled rip fence and crosscut fence. These intelligent features:

Move with incredible speed and accuracy: Eliminate time spent on manual adjustments with these lightning-fast, automated fences.

Provide digital readouts for fence position: Guarantee perfect cuts every single time with precise digital readouts.

Allow for the programming of complex cutting sequences: Streamline workflows for high-volume plywood projects. With these optional features, the F 45 becomes an automation powerhouse, ideal for professional workshops handling large-scale projects.

Safety First: Peace of Mind While You Work

Safety is a top priority in any workshop, and the F 45 doesn't compromise. A comprehensive suite of safety features ensures a worry-free work environment, including:

A protective guard that automatically covers the saw blade when not in use, preventing accidental contact.

Electronic safety systems that prevent accidental startups, keeping you safe throughout the cutting process.

User-friendly controls intuitively placed for optimal safety and ease of operation, minimizing the risk of errors.

With these features in place, you can approach each cut with confidence, knowing the F 45 prioritizes your safety while empowering your precision.

Built to Last: A Legacy of German Engineering

Altendorf is renowned for its commitment to quality, and the F 45 exemplifies this legacy. Meticulously crafted with high-grade materials, the F 45 is built to withstand the demanding environment of a professional workshop. This translates to a reliable machine that delivers exceptional cutting accuracy consistently, year after year. With the F 45, you're not just

investing in a machine; you're investing in long-lasting performance and a commitment to exceptional results.

The Best Plywood Cutter: Is the F 45 Right for You?

The Altendorf F 45 undeniably stands out as a top contender in the world of plywood cutting machines. However, with its premium features comes a premium price tag. Here are some factors to consider when deciding if the F 45 is the "best" cutter for your workshop:

Workshop Space: The F 45 has a large footprint. Ensure you have ample space to accommodate it comfortably.

Project Requirements: If you primarily work with smaller plywood sheets or have limited cutting needs, a less powerful machine might suffice.

Budget: The F 45 is a high-end machine. Be sure it aligns with your budget and long-term woodworking goals.

Beyond the F 45: Exploring Other Options

Altendorf offers a wide range of sliding table saws to cater to diverse woodworking needs. If the F 45 doesn't perfectly fit your requirements, consider exploring their other models. You might find a machine that offers the perfect balance of features and price for your specific needs.

The Final Cut: A Powerful Investment for Serious Woodworkers

The Altendorf F 45 isn't just a plywood cutter; it's a statement of dedication to precision and efficiency in professional woodworking. It empowers you to conquer even the most challenging plywood projects with confidence. If you're a seasoned woodworker seeking to elevate your craft, streamline your workflow, and achieve unparalleled results, the F 45 might be the best investment you can make. However, for hobbyists or those with limited space or budgets, exploring other wood cutting table saw machines might be a more practical option.

Regardless of your choice, the F 45 sets a benchmark for what a professional plywood cutting machine table saw can achieve. So, carefully evaluate your needs and workshop setup to find the perfect machine to take your woodworking journey to the next level.

0 notes

Text

Laser Engraving Machines

We are professional laser engraving machines manufacturer company that provides various models to meet your laser engravers & cutting needs. We specialize in high-quality engraving and cutting products.

0 notes

Text

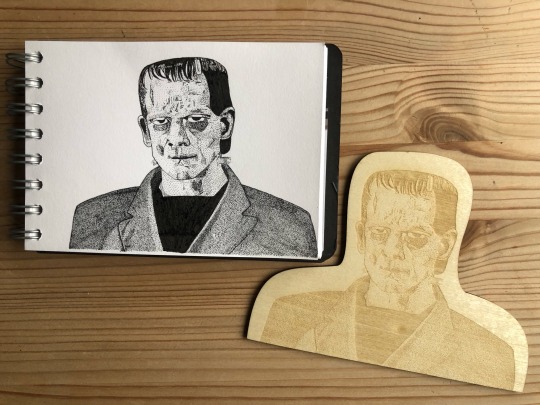

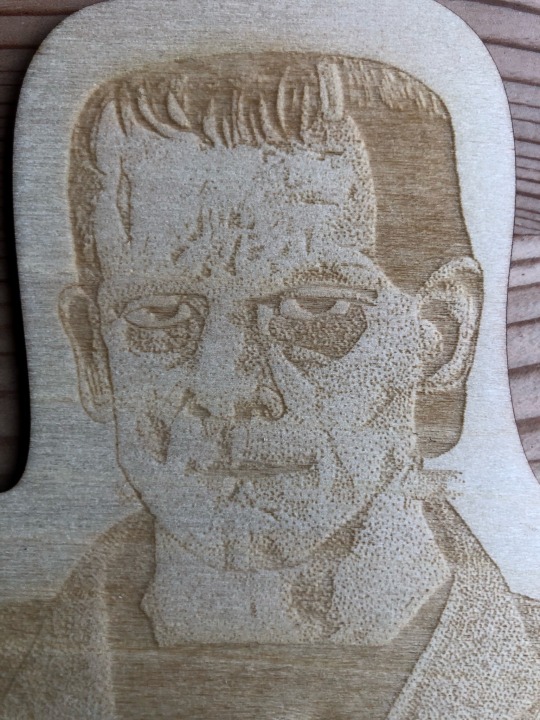

I don't have any new art for my annual Franken-versary, so have this instead :)

I went to a laser-cutting workshop at the end of November and ended up downloading my Frankenstein Monster pen drawing off this Tumblr account onto the computer we were using and getting the laser-cutter to etch it into a thin piece of plywood! I'm not sure that it's a good thing that I could download my art onto a foreign computer and use it, but I'll worry about that another time 😬

I wish I had made it a bit darker, but I'm pretty happy with how it printed out, the detail the laser-cutter managed to get was pretty amazing!

Closeup below cut.

Please don’t use or post on other websites without credit or permission, thanks 🙏

#my art#artists on tumblr#art#artwork#fanart#art of 2024#Frankenstein#Frankenstein 1931#Frankenstein's Monster#Woodwork#Wood Art#Laser Cutter#lasercut#Laser Cut#Universal Monsters#Universal Monsters Fanart#frankenstein 1931 fanart#Universal Horror#Vintage Horror#Classic Horror#Boris Karloff#idk what else to tag

7 notes

·

View notes

Text

fuck you, overpriced one room apartments

the roof of the old house I always wanted now sticks out like a sore thumb

in the fading field I always dreamed of running through

gaudy cookie-cutter plywood apartments stand

on their popsicle stick stilts

never touching the beautiful earth they stole

never knowing my longing

unmoving with my selfish words

because it's final in this lifetime

that's all there is to it, that's the way the cookie crumbles, life isn't fair

I'll never have it

I'll never cross the threshold of that rotten front door

and while I sit and seethe

I mourn those stupid dreams

and I hate to have to disappoint the little girl in me

#poem#poetry#authors#spilled poetry#poems on tumblr#angry poem#homesick#spilled thoughts#spilled ink#fuck you california

7 notes

·

View notes

Text

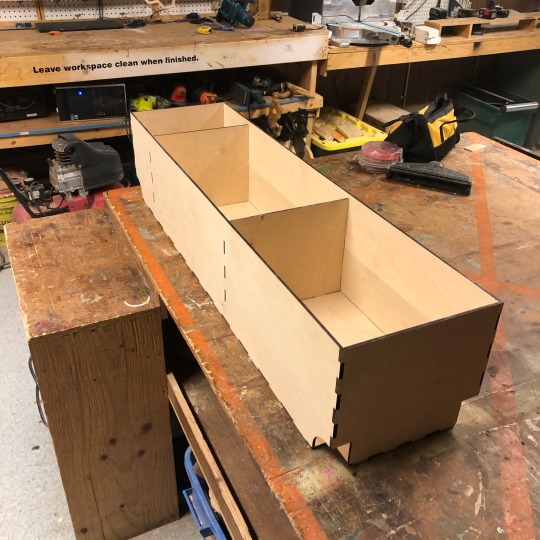

Telescope box V2. After deciding to abandon my first attempt at making a box due to it being too heavy and an awkward size/ shake to carry. So I redesigned it using thinner plywood, made it long and skinny with castor wheels to allow shelling it around for ease of transport. And because it’s now thinner plywood, I was able to design it for the laser cutter. Making assembly much easier (Though at this point I’ve only dry fit it together)

Next step is to order the Castor wheels (thankfully I found some that had freaking CAD files I could download so I know the holes I cut in the corners for them will fit nicely)

Then I need to glue up, paint or stain (haven’t decided yet), install all the hardware (hinges, latches, wheels, handles), and then get some foam to line the inside.

When I put it that way, it sounds like a lot of fucking work still to do.

9 notes

·

View notes

Text

The Essentials of Circular Knives and Blades for Cutting.

Explore the fundamentals of circular knives and blades for cutting. Gain valuable knowledge to improve your cutting techniques and equipment selection.

In the world of manufacturing and industrial applications, precision cutting tools are vital for achieving optimal results. Among the most widely used tools for precision cutting are circular knives and circular blades. While both share similar circular designs, each type of blade has unique features that make it suitable for specific tasks. This comprehensive guide delves into the functionality, uses, and advantages of circular knives and circular blades, helping you understand which tool is best for your cutting needs.

What Are Circular Knives?

Circular knives are rotary cutting tools characterized by their circular shape and sharp edges. These knives are typically used in applications that require continuous, smooth, and efficient cuts. The round design of these knives allows for an uninterrupted cutting process, making them ideal for industries that deal with high-volume production or delicate materials.

Circular knives are commonly used in industries such as:

Packaging: Circular knives are essential in the packaging industry, where they are used for cutting various materials such as cardboard, paper, plastic films, and more. The ability to cut with precision and speed ensures that packaging processes are carried out effectively.

Textiles and Fabrics: In the textile industry, circular knives are used to cut fabrics, leather, and other flexible materials. Their sharp, rotating blades make it easy to slice through multiple layers at once, improving production speed and reducing material waste.

Printing and Paper: Circular knives are used in printing presses and paper cutting machines. The blades are capable of cutting through large rolls of paper or other materials in one smooth motion, ensuring high-quality results.

What Are Circular Blades?

Circular blades are similar to circular knives in shape but are typically used in a wider range of cutting tools, such as saws, grinders, and rotary cutters. Circular blades have a fixed or rotating configuration and are designed for cutting a variety of materials, including metals, wood, and plastic.

Some key applications of circular blades include:

Woodworking: In the woodworking industry, circular blades are used in saws for cutting through wood, plywood, and other similar materials. The blades are designed to handle tough materials while delivering clean and precise cuts.

Metalworking: Circular blades are commonly used for cutting through metals in the manufacturing and metalworking industries. Whether it’s cutting sheet metal, pipes, or other metal components, circular blades provide the strength and sharpness needed for accurate cuts.

Concrete Cutting: Specialized circular blades are used in concrete cutting, especially in construction and demolition. These blades are designed with diamond-tipped edges that allow them to slice through tough materials such as concrete, asphalt, and stone.

Key Differences Between Circular Knives and Circular Blades

While circular knives and circular blades may look similar, they are designed for different applications. Here’s a breakdown of the key differences:

Design and Functionality:

Circular knives are typically designed for continuous rotary motion, making them ideal for slicing through flexible materials such as paper, fabric, and plastic films.

Circular blades are generally used in more rigid cutting tools like saws, grinders, and rotary cutters. They are versatile enough to cut through both soft and hard materials, such as wood, metal, and concrete.

Material Compatibility:

Circular knives are usually employed in industries where precision cutting of delicate materials is crucial. They are frequently used in packaging, textiles, and printing, where the material needs to be sliced smoothly without fraying or damaging the edges.

Circular blades are typically used in construction, woodworking, and metalworking, where tougher materials need to be cut. The blades are often made of durable materials like high-carbon steel, carbide, or diamond for improved longevity and cutting power.

Cutting Speed and Efficiency:

Circular knives are designed to operate at high speeds and deliver continuous cuts, allowing for high productivity in environments like packaging and textile manufacturing.

Circular blades, depending on the application, are typically slower but more powerful. The emphasis with circular blades is on strength and endurance, especially when cutting through tougher materials.

Benefits of Circular Knives and Circular Blades

Both circular knives and circular blades offer several benefits, making them indispensable tools in various industries. Here are some of the advantages:

Precision and Accuracy: Both tools are designed for highly accurate cuts. Circular knives, with their rotating blades, are ideal for smooth, precise cuts on flexible materials. Circular blades, on the other hand, provide clean cuts on tougher materials.

Durability: Both circular knives and circular blades are built to withstand heavy use and maintain sharpness over time. High-quality materials such as steel, carbide, and diamond are often used in their construction, ensuring durability and long-lasting performance.

Efficiency: Circular knives and circular blades are both designed to maximize efficiency in production processes. Circular knives ensure continuous, smooth cuts, increasing the speed of cutting processes in industries such as packaging and textiles. Circular blades, with their power and strength, enable efficient cutting of tougher materials, leading to reduced downtime and fewer blade replacements.

Versatility: Circular knives and circular blades come in a variety of sizes, shapes, and materials, making them suitable for a wide range of applications. Whether you’re cutting paper, fabric, wood, metal, or concrete, there’s a circular blade or knife designed for the job.

Choosing the Right Circular Knife or Circular Blade for Your Needs

When selecting a circular knife or circular blade for your application, there are several factors to consider:

Material Type: Consider the material you’ll be cutting. If you’re working with flexible materials such as paper or fabric, a circular knife may be the best option. For tougher materials like wood, metal, or concrete, a circular blade is more appropriate.

Cutting Speed: Circular knives are designed for high-speed, continuous cutting. If your production process requires fast, uninterrupted cuts, a circular knife may be ideal. For tasks that demand strength and power over speed, a circular blade will provide the durability you need.

Blade Material: The material of the blade impacts its longevity and performance. High-carbon steel blades are durable and effective for general cutting needs, while carbide and diamond blades are suitable for more demanding applications such as metalworking and concrete cutting.

Blade Size and Configuration: Choose the appropriate size and configuration for your specific cutting needs. Circular knives typically come in smaller sizes suited for precise cuts, while circular blades range from small to large, depending on the thickness and hardness of the material being cut.

Both circular knives and circular blades are essential tools in many industrial sectors, providing efficiency, precision, and durability in cutting operations. Whether you need to cut delicate fabrics or tough metals, selecting the right tool for the job can significantly improve productivity and reduce operational costs. By understanding the unique features and applications of each, you can make an informed decision and ensure your cutting processes run smoothly.

Explore our selection of high-quality circular knives and circular blades today and discover the ideal solution for your cutting needs. With the right tools in hand, you can achieve flawless cuts, enhance production speed, and maintain the high standards required in your industry.

Visit : https://www.perfectknives.net/circular-knives.php

Contact : +91 9822050035

0 notes

Text

4×8 Flatbed Laser CNC Engraving Cutting Machine

In the world of precision cutting and engraving, a 4×8 flatbed laser CNC engraving cutting machine is a game-changer. Whether you’re a professional engraver or a hobbyist looking to explore the possibilities of laser cutting and engraving, investing in this advanced machine can revolutionize your craft.

4×8 Flatbed Laser CNC Engraving Cutting Machine

A 4×8 flatbed laser CNC engraving cutting machine is a versatile tool that combines the precision of laser technology with the automation of computer numerical control (CNC). This machine features a large flatbed surface, measuring 4 feet by 8 feet, which allows for the cutting and engraving of various materials with ease. The laser beam is controlled by a CNC system, which follows a pre-programmed design to create intricate patterns, shapes, and engravings on the material’s surface.

The 4×8 refers to the bed size, which is 4 feet by 8 feet (approximately 1.2 meters by 2.4 meters). This large working area is ideal for handling large sheets of material. The power of the laser affects the types of materials you can cut and the thickness. Typical power ranges from 40W for light engraving up to 150W or more for cutting thicker materials.

Applications Laser engraving and cutting machine:

4×8 flatbed laser CNC engraving and cutting machine can significantly enhance your production capabilities, providing high precision and versatility for a wide range of applications.

Advertising Industry: acrylic engraving and cutting, cutting and engraving of double- color plate and other advertising material

Leather Processing Industry: leather, fabric carved hollow

Arts And Crafts Industry: paper cutting, wood, bamboo products, leather, shell, ivory and other materials’ engraving and cutting

Model Industry: construction model, aviation and maritime models, wooden toys’ cutting.

Packaging Industry: printed rubber plate engraving and cutting, plywood cutting and laser cutter template cutting.

Decoration Industry: electrical and electronic industry materials engraving and cutting.

Advantages of 4×8 Laser CNC Engraving Cutting Machines

1. Precision and Accuracy

One of the key advantages of 4×8 flatbed laser engraving cutting machines is their exceptional precision and accuracy. The combination of laser technology and CNC control ensures that every cut and engraving is executed with utmost precision. This level of accuracy allows for intricate and complex designs, giving you the freedom to create stunning and detailed artwork.

2. Versatility

4×8 flatbed laser CNC engraving cutting machines are incredibly versatile, capable of working with a wide range of materials. From wood and acrylic to metal and leather, these machines can handle various materials with ease. This versatility opens up endless possibilities for your projects, whether you’re creating signage, personalized gifts, or intricate artwork.

3. Speed and Efficiency

Compared to traditional cutting and engraving methods, 4×8 flatbed laser CNC engraving cutting machines offer significantly faster speeds and higher productivity. The combination of laser technology and CNC automation allows for swift and precise cutting and engraving processes. This means you can take on larger projects and meet tight deadlines without compromising on quality.

4. Customization Options

4×8 flatbed laser CNC engraving cutting machines can be customized to suit your specific needs and requirements. You can choose the laser power, cutting speed, and engraving depth that best aligns with your projects. This customization ensures that you have the right settings to achieve the desired results, whether you’re working on delicate engravings or robust cutting tasks.

5. Ease of Use

Despite their advanced capabilities, 4×8 flatbed laser CNC engraving cutting machines are designed to be user-friendly. The CNC software allows for easy design creation and modification, and the machine’s interface is intuitive and straightforward. This means that even beginners can quickly learn how to operate the machine and unleash their creativity without any technical hurdles.

laser CNC engraving and cutting machine FAQ

1. What materials can I work with using a 4×8 flatbed laser CNC engraving cutting machine?

A 4×8 flatbed laser CNC engraving cutting machine can work with a wide range of materials, including wood, acrylic, metal, leather, fabric, paper, and more. The versatility of these machines allows you to explore various creative possibilities.

2. Can I create intricate designs and engravings with a 4×8 flatbed laser CNC engraving cutting machine?

Absolutely! The precision and accuracy of these machines make it possible to create intricate and detailed designs and engravings. Whether you’re working on fine jewelry pieces or intricate signage, a 4×8 flatbed laser CNC engraving cutting machine can handle the task with ease.

3. How long does it take to learn how to operate a 4×8 flatbed laser CNC engraving cutting machine?

The learning curve for operating a 4×8 flatbed laser CNC engraving cutting machine can vary depending on your prior experience and familiarity with similar technologies. However, these machines are designed to be user-friendly, and with proper training and practice, you can quickly learn how to operate them effectively.

4. Can I customize the settings of a 4×8 flatbed laser CNC engraving cutting machine?

Yes, you can customize the settings of a 4×8 flatbed laser CNC engraving cutting machine to suit your specific needs. You can adjust parameters such as laser power, cutting speed, and engraving depth to achieve the desired results for your projects.

5. How do I maintain a 4×8 flatbed laser CNC engraving cutting machine?

Regular maintenance is essential to ensure the optimal performance and longevity of your machine. This includes cleaning the machine regularly, checking and replacing consumables (such as lenses and mirrors), and following the manufacturer’s guidelines for maintenance. It’s also advisable to have a reliable technical support system in place for any troubleshooting or assistance you may need.

0 notes

Video

youtube

How Jigsaw Puzzles Are Made? (Mega Factories Video)

Feb 5, 2021 A jigsaw puzzle is a tiling puzzle that requires the assembly of often oddly shaped interlocking and mosaiced pieces. Typically, each individual piece has a portion of a picture; when assembled, the jigsaw puzzle produces a complete picture.

Most modern jigsaw puzzles are made out of paperboard since they are easier and cheaper to mass-produce than the original wooden models. An enlarged photograph or printed reproduction of a painting or other two-dimensional artwork is glued onto the cardboard before cutting. This board is then fed into a press. The press forces a set of hardened steel blades of the desired shape through the board until it is fully cut. This procedure is similar to making shaped cookies with a cookie cutter. The forces involved, however, are tremendously greater and a typical 1000-piece puzzle requires a press that can generate upwards of 700 tons of force to push the knives of the puzzle die through the board. A puzzle die is a flat board, often made from plywood, which has slots cut or burned in the same shape as the knives that are used. These knives are set into the slots and covered in a compressible material, typically foam rubber, which serves to eject the cut puzzle pieces.

New technology has enabled laser-cutting of wooden or acrylic jigsaw puzzles. The advantage of cutting with a laser is that the puzzle can be custom cut into any size, any shape, with any size (or any number) of pieces. Many museums have laser cut acrylic puzzles made of some of their more important pieces of art so that children visiting the museum can see the original piece and then assemble a jigsaw puzzle of the image that is also in the same shape as the piece of art. Acrylic is used because the pieces are very durable, waterproof, and can withstand continued use without the image fading, or the pieces wearing out, or becoming frayed. Also, because the print and cut patterns are computer-based, lost pieces can be manufactured without remaking the entire puzzle.

Video Credit: www.ravensburger.com & www.clementoni.com

This video is part of our ‘How Everyday Things are Made’ series.

0 notes

Text

ACMER P2 33W Review: Laser Engraver and Cutter Tests Settings

✍ https://3dwithus.com/acmer-p2-33w-review-laser-engraver-cutter-tests-settings

📹 https://youtu.be/pPgQD6fD2ww

Review by Phil Macey 3DPUK TECH

Phil Macey has tested the ACMER P3 33W through a series of laser cutting and engraving projects. He explored various materials, including plywood, anodized aluminium, slate stone, acrylic, and stainless steel. Check out the complete review on 3DWithUs or the video on YouTube.

0 notes

Text

History of Puzzles

The first "Jigsaw" was produced by engraver John Spilsbury in around 1760. It consisted of a map that had been glued onto a flat piece of wood which had then been cut following the borders of the countries. Since then, jigsaws saw some rapped growth especially nearing the end of the 18th century due to the rise in Lithographic printing as well as the invention of the Tredle jigsaw meant that puzzle makers could now create even more intricately shapes pieces which aren't as common in modern puzzles seen today. The shape of the pieces isn't the only thing that has changed over the years. For example, the material used to create puzzles evolved from plywood to paperboard and now due to new technology/laser cutters, acrylic.

0 notes

Note

hello! 👋

How are you doing?

Hi there!

I'll put it under a break because I really don't want to bomb people's feeds with my *feelings* uwu

Well, I have been better. Adding the Au to my ADHD has been a whirlwind of emotions for me. Not all good ones either. I went in seeking to rule it out not rule it in. It explains a lot, don't get me wrong. But I am so scared of unmasking because I have seen how it can change people. I don't like change. I don't want to change. I'm very high masking, but I function very poorly as far as keeping a stable life goes. Executive function in the trash at all times.

If I were in the stages of grief I would be in denial or anger right now. I'm so tired. My subconscious self is going insane. And in turn, it's wrecking my mental health. Depression and anxiety like crazy. I had to sit in the car for 15 minutes yesterday so that I could gear myself up to ask someone to cut some plywood for me at Lowe's. My husband told me if I was that anxious I could just come back home. But no, I needed my damn plywood for my laser cutter. I wanted to puke coming out of Petsmart with some cat food because just being in the building and someone talking to me unexpectedly shook me up. I'm so sensitive right now.

And I can't cry. God damn it, I cannot cry to save my life. I get close, but the tears never come. Thanks mental health cocktail of meds. They keep me feeling ok and not severely depressed, don't get me wrong. But the side effect is that it is so hard to cry over sadness. I want to cry so badly. I just want a release of all these pent up emotions. Journaling only does so much.

It'll pass. I know it will. But it feels like I just pulled from the center of a new skein of yarn and got a ball of tangled up yarn barf. I can't cut the yarn, so I have to sit here and untangle my emotions. But I have no idea where the tail end of the yarn went. I can't find it in all the barf. Everything is a mess and my brain is tired. Everything seems a bit overwhelming and I don't feel like breaking things up into smaller chunks like I know I need to.

I was going to go to my local NAMI chapter meeting tonight, but I feel so on edge that I don't think I can go. There has been so much change in my life in the past few months so that probably isn't helping at all. I feel so busy doing nothing at all. My mind is always on, but my thoughts are at their normal pace. I think it's the subconscious that is bombarding me.

So, overall I just feel bombarded. By everything. I can actively feel the stress in my shoulders today. I feel the slightest bit dizzy just sitting at the computer. My dysautonomia flares up with stress, so it's dizzy time I guess. Kinda want to puke, ngl. So, not doing well, but I will get through it.

Thank you so much for asking, I needed to get that out.

1 note

·

View note

Video

youtube

I knead to make some dough!

16 x 10 x 8 cm plywood automaton.

The title of the piece is a response to the question "What does a poor baker say?"

I am beginning to get used to my new laser cutter but the fact that I am making small automata on a machine with a bed about 5 times that my previous cutter had, has me hearing my tutors at Uni saying "You have to consider the scale of these things."

For most of them bigger was inevitably better, one young woman in the year above me, who made the most beautiful but tiny prints, used to get this all the time and once turned in a 2 cm square print precisely in the centre of an A1 sheet of very expensive Hahnemuhle print paper. She is on the academic staff there now.

0 notes

Text

Plywood Laser Cut

I created multiple cogs made from plywood. I used a laser cutter to cut their shape. I used a laser cutter because I was using plywood, and plywood is the optimal material for what I plan to do with my project. I wanted to have 3D cogs, but creating them all out of sculpey would be far too time consuming and tedious, and they all wouldn’t look the same. So to combat this, I used the laser cutter which can create them in less than 10 minutes.

I have experience with a laser cutter, but only with a program called InkScape. I haven’t used Illustrator before, so I didn’t know what any of the buttons did or how to create an optimal design for the laser cutter to recognise.

To save time, I used a vector of a cog I found online. I found it difficult to create a path, which is needed for the laser cutter to follow. I. found it difficult because I didn’t understand what all of the options on illustrator did. Although I did know that I had to use the ‘trace’ option to get the desired line work. I also had problems with the program not being able to separate the traced lines from the actual photo, which was really annoying because I couldn’t delete the photo to see the linework.

The lines kept doubling up, There were two lines for each thick line it would trace from the image, but we eventually figured out how to remove one of them just to leave the lines I wanted. I copy and pasted them and changed their sizes to create variety in their shapes which would be useful for the project.

This was also another reason I created different sizes, they can be stacked on top of each other to create more interesting layered designs.

I sent this to print on the laser cutter. The laser cutter shows how long it will take to complete each cut, which is helpful for time management.

This is what the laser cutter looks like while it’s cutting the plywood, which is really cool to look at.

These are what all of the different sizes looked like after they were done. I didn’t do any more of the largest one, since they are too big to fit anywhere on or around the model. In hindsight, I could’ve done a few more sizes. Some of them are too big but the others are too small. Overall I’m really happy with how they look and I like how clean they are. I think the smallest one is interesting, the gear teeth are so small that they look spiky. I also think I could’ve had more variety in the size of the gap in the centre which would’ve added more for me to work with. I also decided to keep the inside pieces, as they might look cool on the model? I also think they’ll be useful for layering the fog pieces to create a three dimensional effect.

0 notes

Text

Laser Cutter for Diy Toy & Art Craft Gift

Craft Laser Cutter- Laser Cutting Machine for Crafts

The craft laser cutter is the best for starting a business for the arts. It provides strong R&D strength and can provide excellent product quality and standard scientific management. IGOLDENLASER craft laser cutter can offer small thermal deformations, low noise, high cutting precision, no pollution, and automatic self-cutting.

When using a craft laser cutter we make sure that it can meet a wide application range, high machining precision, good quality, easy automation, flexible process, and more. We offer OEM&ODM service with 7/24 after-sales service.

Crafts Laser Cutter Features

The craft laser cutter adopts international advanced technology and a unique cutting database to carry out different cutting materials. Below is the following features craft laser cutter:

Can cut a wider range of materials

Provide faster speed in productions

Better quality and lower cost

Offer lower power consumption

Can automatically avoid obstacle

Have a high power lasers

Suitable for different industrial applications

Art Laser Cutter

Art Laser Cutter Specifications

Below is the following specification for a craft laser cutting machine:

Working area ranging from 900*600mm to 2000*3000mm

Laser power from 60W to 200W

Single, dual, and four laser cutting heads are available

Honeycomb, blade knife, and mesh conveyor belt working table available

Optional camera system available

Straight-line speed up to 600mm/s

Supporting up to 20mm thickness materials

Cutting precision ±0.01mm

Application of Art Craft Laser Cutter

Craft laser cutters are made to suit the different applications for art. It helps to make a lot of things that use for homes, office, kitchenware, and other materials such as:

Plywood puzzles

Wooden toys

Acrylic crafts

Plastic decorations

PU leather artcrafts

Paper artworks

Fabric appliques and accessories

and many more.

Toy Laser Cutting Machine

CO2 Laser Cutter for Toy Production IGOLDENLASER offers a high-precision CO2 laser cutter for cutting and engraving materials to produce a variety of toys. These machines offer contactless and ultra-high precision processing methods. It can also cut and engrave a variety of materials such as wood, textiles, plastic foils, acrylic, and more.

With CO2 laser cutters, the materials for toy making are not clamped. Therefore, you can assure that this machine can cut materials even with the most complicated details with minimal waste and breakage.

IGOLDENLASER offers custom laser cutting machines for toy production. The machines are designed to provide consistent high-quality cutting. Our toy laser cutting machines can offer burr-free edges. Thus, post-processing operation is not totally required. Our machines can provide you maximum efficiency in toy manufacturing because of their simple operation and high throughput rates.

IGOLDENLASER offers custom laser-cut toys according to your requirements. We offer factory direct supply machines and cost-effective rates. OEM/ODM services and designs are available to meet your needs. All our machines are guaranteed to have controlled quality, multi-functional, extreme cutting versatility, and precise cutting.

Due to the flexible processing of our laser cutting machines, it can produce different toys such as the following:

Model planes are made by cutting a balsa wood

Invitation cards made from cutting paper

Teddy bear by plush fabric

Model railway by acrylic

Toy balls by PU leather

and more.

Advantages of Our Laser Cutting Machines for Toy Industries

Our laser cutters are manufactured to provide advantageous processing to toy industries.

Complicated cuts with minimal material damage Doesn’t fray and offers precise cut edges

Performs cutting and engraving

Can process a variety of material Less material wastage

Easy to operate and manpower saving Affordable price and low maintenance fee.

IGOLDENLASER CO2 laser cutter

The CO2 laser cutter adopts CO2 laser source (CO2 laser cutting technology) to cut and engrave non metals and soft metals. Therefore, some people also call it dual use CO2 laser cutting machine or mixed laser cutting machine. And it is consisted of various CO2 laser kits, such as laser generator, laser cutting head, laser cutter frame, laser cutting system, laser lens, laser mirror, laser power supply, water chiller, air compressor, and other many CO2 laser CNC kits.

CO2 laser machine usually uses CO2 gas to process non-metal materials such as wood, paper, leather, cloth, epoxy resin, acrylic, wool, plastic, rubber, ceramic tile, crystal, jade, bamboo, etc. While the auxiliary gases include nitrogen, helium, xenon, and hydrogen is also permitted. Since CNC CO2 laser has high energy conversion efficiency of up to 25% and good stability, it can also cut some thin metal materials such as aluminum and brass. In addition, the CO2 laser power is optional. So you can choose a 40W CO2 laser cutter for sale, 50W wood laser machine, 60W acrylic laser cutting machine, 80W CO2 laser cutting and engraving machine, 100W laser engraver, 130W CNC CO2 laser cutting machine, 150W CO2 laser cutter, 300W wood cutting laser cutter, etc.

CO2 laser cutter Advantages

1.Wide range of processing: CO2 laser engraver can engrave and cut almost any non-metal material and has a very wide application in manufacturing industry, art industry, and medical industry.

2.Safe and reliable: adopting non-contact processing, CO2 CNC laser cutter for sale will not harm the surface of the machined part or deform the material.

3.Eco-friendly: the diameter of beam and spot is small generally less than 0.5mm, it has the features of material saving, safety and environmental protection.

4.High-speed and fast: it can immediately perform high-speed engraving and cutting according to the drawings output by the computer.

5.Low cost: it has low maintenance costs and only needs inexpensive replacement parts. Especially for small batch processing services, laser processing is cheaper.

0 notes

Text

Suffer my moment to breathe and think.

So the Wegman's cheese department bull pit was really great. It was a little crowded when we had 5 or 6 people at the same time during busy seasons but there was enough room for everyone to work without bumping butts with people working behind them.

So. The grey things were cold cases, and the black were mostly steel workstations with shelving underneath. The two green sticks represent a couple of wood cabinets with doors. Everything else was open.

The two rectangles in the middle were also steel workstations with shelving. We'd generally cut cheese or make cheese spreads or specialty things for the big feature case (on the bottom) on the center tables, and then we'd have to take it to the red scale to price and label. There was enough room on those tables for 4 cheese cutters and counter space to wrap and stack the cheese that was cut.

That was the only thing we had to take turns on. There was also a cart that was used for pricing and labeling, so whomever was pricing and labeling had the cart until they were done and then they'd hand it off to whomever needed it.

The purple are the BIG double sink, and the only place we couldn't easily see out onto the floor around us was right behind the sink because a splash guard was put there to make sure we didn't splash water on the food in the cold case on the other side. That splash guard was also used as a sign board and was where we'd post promotions and seasonal specials, etc. It was opaque black.

While washing dishes was the only time we weren't expected to also interact with customers. We were to wash dishes until the dishes were done, but the sink was right there with everything else and if a customer really needed someone who was washing dishes, we were available.

There were two small, open cold cases on either side of the big glass case, and on the other side of every work station was a half-wall and then another open cold case. The whole work area was surrounded by cheese that was easily available to customers and we were equally visible while we were working.

The only area that was different was the blue rectangle which was on a separate, smaller steel table because it needed to be lower down to be easy to use. That was the electric cheese grater we used to grind up Parmesan. Capital P, the real shit.

Exit 1 led to the olive bar, and exit 2 led to tea and the big cheese cooler.

We did have a large cooler and a large work room that we shared with the deli, though deli used the work room and we didn't because we didn't need to. That's where the ovens were.

We also had a smaller segment of another department's cooler elsewhere which is where olives were kept. For the most part, the cheese was put out immediately after it arrived which worked because the cold cases are plentiful (there were more along the wall that I didn't put in the picture) and if it wasn't put out it went into the cooler.

The whole section was very efficient. We were never bumping into each other or having to wait for one or another to get through a single entry. Clean up was VERY easy and if you asked nicely, whomever was washing dishes would wash yours if they didn't feel like dealing with customers at the moment.

It was a pleasant place to work even when it was busy.

The gas station bull put is stressful and inefficient.

One entry.

We are constantly in each other's way and if a vendor or customer follows us in there, we're trapped. If I'm on the opposite side of the store I have to book it all the way around and to the front to deal with a customer so you'll hear CLOMPCLOMPCLOMPCLOMP while I walk as fast as my disable old lady ass can manage.

Three registers though only two are for customers (the other is for the lottery).

Poorly built and designed glass cases in the front with glass tops so we can't put anything heavy on top (the registers are on chunks of plywood and cut up cabinet parts so they don't sit directly on the glass) and we can't see through the tops at all, so they might as well be wood.

The counters are completely covered in small displays and appliances so it's difficult to see out. They just replaced one small counter top display (lime green) with a taller one. I can see less out that side, now.

Blue things are fridges/cold cases the one in the back being where I have to make sandwiches (it's a narrow strip on top, not the whole top), orange is the little hot case that I'm not allowed to fill.

Purple are extra cigarette displays/storage and the chewing tobacco and tobacco-free pouches etc. plus an extra storage for that, too. One of those was also just replaced with a taller one. I used to be able to peek between there toward the darker green rectangle which is where customers wait, but I can't see through anymore.

I may have been a little too generous with the space available to walk around the purple displays.

Overhead at the customer place is the drop down cigarette holders.

The customer place is also the only place I can see out of relatively easily, though my view is cut off at the top by the cigarette drop-down.

There's a small marble-top table (brown) with a small shelf underneath that's supposed to be for working on sandwiches but there's always weird stuff on there, like there's been a filthy drawer slider on there since I started working there and a pen holder and papers.

Little grey thing is a tiny hand wash sink with no counter space around it. Can't wash dishes, there. Under the sink is a cabinet that is A. DISASTER. That's where cleaning stuff is kept.

The sink cabinet and the cabinet on the other side of the little table are missing a side, so stuff falls out around and under the table all of the time.

Under every surface that isn't blue is a cabinet with one shelf. They're full of random stuff. Not efficient nor effective storage. Nothing is labelled.

Every cabinet is painted chip board. The paint is sticky and wearing off.

It all butts up on a wall, and behind that wall is the tiny bit of storage I'd mentioned a while back and the big sink.

But like... I'd have to think long and hard about how to make that space more efficient because everything that's in there has to be. There's nowhere else for any of it.

1 note

·

View note

Text

Week 2 - Workshop Attempts

In this project, I used the cutter to produce plywood into various forms and sizes. However, due to my limited experience with the cutter, I have not yet successfully cut along the intended sketch lines.

Since the task did not involve refining the pieces, I focused on constructing multiple works that explore different methods of achieving literal balance, while also striving to incorporate visual balance. Throughout this process, I discovered three balancing techniques:

1. Against: I positioned the largest piece upright and counterbalanced it by placing several smaller pieces against from its sides.

2. Mirror: Each side of the structure reflects the other. The aim was to achieve equilibrium in visual weight rather than exact physical symmetry.

3. Triangular: Putting a center line, evenly distributing weight on both sides, and converging three lines at a top point.

Achieving literal balance, but I have not construct visual balance as the wood pieces are not symmetrical and some smaller pieces have not contribute to the overall balance at all.

A noted drawback of this exploration is the lack of a relationship between the work and its surrounding site.

0 notes