#plastic recycling processes

Explore tagged Tumblr posts

Text

Imagine a world where the sun doesn’t just give us tans and power to our homes but also transforms our plastic waste into valuable resources. Sounds like science fiction, right? Well, thanks to breakthroughs in plastic recycling processes, we are inching closer to making it a reality.

#plastic recycling processes#epr#ecoex#plastic#epr certificate#recycling#epr services#epr registration

0 notes

Text

A Complete Guide to the Plastic Recycling Process

The plastic recycling process is a vital solution to the global plastic waste crisis. It helps reduce environmental pollution, conserve resources, and promote sustainability. With billions of tons of plastic produced annually, understanding how to reduce plastic waste through recycling is more important than ever. This guide explores the key stages of recycling, types of plastics, and its overall benefits.

Why Recycle Plastic?

Plastic is versatile and durable but poses significant environmental challenges due to its slow decomposition. Recycling offers a way to:

Reduce Plastic Pollution: Keeps plastic out of landfills and oceans.

Conserve Resources: Saves raw materials like petroleum and natural gas.

Lower Energy Consumption: Recycling plastic uses less energy than manufacturing new materials.

Protect Ecosystems: Reduces harm to wildlife caused by plastic waste.

Stages of the Plastic Recycling Process

Collection

Plastic waste is gathered from homes, businesses, and public recycling bins.

Collection systems vary by region and can include curbside pickup or drop-off points.

Sorting

Plastics are sorted by type and color, often using automated systems like infrared scanners.

Sorting ensures only recyclable plastics enter the next stage of the process.

Cleaning

Contaminants like food residue, labels, and adhesives are removed.

Clean plastics are shredded into smaller pieces for easier processing.

Shredding and Resizing

Plastics are shredded into flakes or pellets, which can be used in manufacturing.

This step improves material handling and prepares the plastic for melting.

Melting and Reforming

Plastic flakes are melted and reformed into new products or raw materials.

Advanced technologies allow for the creation of high-quality recycled plastics.

Manufacturing New Products

Recycled plastics are used to create new items, such as bottles, clothing, or construction materials.

Types of Plastics Commonly Recycled

PET (Polyethylene Terephthalate)

Found in water bottles and food containers.

Easily recyclable and turned into fibers or new containers.

HDPE (High-Density Polyethylene)

Used in milk jugs, detergent bottles, and pipes.

Recycled into durable goods like benches and bins.

LDPE (Low-Density Polyethylene)

Found in shopping bags and packaging films.

Often recycled into trash bags and liners.

PP (Polypropylene)

Used in food containers and automotive parts.

Recycled into industrial materials or storage solutions.

How to Reduce Plastic Waste

Choose Reusable Products: Opt for reusable bottles, bags, and containers instead of single-use plastics.

Recycle Correctly: Follow local guidelines to ensure your plastic waste is properly sorted and recycled.

Support Recycled Products: Buy items made from recycled plastic to encourage demand.

Spread Awareness: Educate others about the importance of the plastic recycling process and reducing waste.

Benefits of the Plastic Recycling Process

Reduces Environmental Impact

Recycling prevents tons of plastic from entering ecosystems.

Saves Energy

Recycling plastic uses 88% less energy than producing new plastic.

Creates Jobs

The recycling industry generates employment opportunities in collection, sorting, and processing.

Supports a Circular Economy

Promotes a sustainable system where materials are continuously reused.

The Future of Plastic Recycling

Innovations in technology are making plastic recycling processes more efficient. Chemical recycling, for example, can break down plastics to their original molecules, creating higher-quality recycled materials. Governments and industries worldwide are investing in ways to reduce plastic waste and improve recycling rates.

By participating in plastic recycling and adopting habits to reduce plastic use, we can make a significant impact on the planet's health.

0 notes

Text

Catalytic process vaporizes plastic bags and bottles, yielding gases to make new, recycled plastics

A new chemical process can essentially vaporize plastics that dominate the waste stream today and turn them into hydrocarbon building blocks for new plastics. The catalytic process, developed at the University of California, Berkeley, works equally well with the two dominant types of post-consumer plastic waste: polyethylene, the component of most single-use plastic bags; and polypropylene, the stuff of hard plastics, from microwavable dishes to luggage. It also efficiently degrades a mix of these types of plastics. The process, if scaled up, could help bring about a circular economy for many throwaway plastics, with the plastic waste converted back into the monomers used to make polymers, thereby reducing the fossil fuels used to make new plastics. Clear plastic water bottles made of polyethylene tetraphthalate (PET), a polyester, were designed in the 1980s to be recycled this way. But the volume of polyester plastics is minuscule compared to that of polyethylene and polypropylene plastics, referred to as polyolefins.

Read more.

#Materials Science#Science#Catalysts#Plastics#Polymers#Materials processing#UC Berkeley#Waste#Recycling

54 notes

·

View notes

Text

actually i'm still mad about the chairs and i'm going to scream about it

I was drawn in by the caption "recycled plastic" because the colour clarity on them was so lovely, I thought maybe the artist had figured out some way to reclaim and recycle plastic without losing the integrity of hue, but the purple slightly tipped me off: there's not a lot on the market in that shade. I know this because I love it.

So I went on a search for an artist with a deep material and chemical understanding and instead I found a FUCKING MACHINE

and I'm STILL MAD

#i know i know i should try to be better about sourcing things#yadda yadda yadda#but also artists are some of the most fascinating people out there#ESPECIALLY furniture/sculpture artists#so i am justified in thinking 'wow someone developed a complicated chemical process to solve the plastic recycling problem#'and they put it to the use of beautiful chairs? amazing'#anyway. i'm still mad!#we hate ai here

5 notes

·

View notes

Text

♻️ Want to make money AND save the planet? 🌍 Discover 10 profitable business ideas from plastic waste and start your green business today! 🚀 FOLLOW for more! 💰🔥 #PlasticBusiness #GreenStartup #RecyclingProfit #EcoEntrepreneur #WasteRevolution

#business ideas from plastic waste#business ideas with waste plastic#manufacturing business ideas#new business ideas#plastic business ideas#plastic recycling business#plastic recycling business ideas#plastic recycling machine#plastic recycling process#plastic waste#plastic waste business#plastic waste business ideas#plastic waste management business#recycling business#waste plastic business#waste plastic recycling business#what are waste plastic business ideas

0 notes

Text

Eastman Chemical’s Advanced Plastic Recycling: A Game Changer for the Circular Economy

Introduction Plastic pollution is a growing environmental challenge, with millions of tons of waste ending up in landfills and oceans every year. While traditional recycling methods help reduce some waste, they have limitations in handling complex plastic materials. Eastman Chemical is leading the way with its advanced plastic recycling technology, offering a sustainable solution to the plastic…

#Advanced plastic recycling technology#Circular economy and plastic recycling#Eco-friendly plastic recycling solutions#Molecular recycling process#Plastic Recycling#Sustainable plastic waste management

0 notes

Text

Okay yeah that's what I thought

Well maybe then you should read the op again bc it was very much about companies being like "oh we're so proud of using plastic instead of animal products 🥰" like they gave a single shit about it, bc no matter what plastic is STILL bad for the environment, and if they did gave a single shit they would use durable methods of tanning, make more durable products and work only with materials from organic and animal wellbeing focused farms, and makes it so it's still somehow affordable.

Corporations don't give a single shit about animals or environment and that was what the post was about, not about the consumer side of the problem.

companies will be like “we’re so proud we don’t make anything with feathers, leather or fur” and then make stuff out of synthetic materials that will not decompose but will shed micro-plastics with every wash like…..yas so good for the animals so animals rights

#google is you friend but so are reading comprehension skills#the only plastic based materials that i can accept as eco friendly are the 100% recycled ones#which exist i mean there's still the microplastic problem but at least it's not creating more plastic#you're right this is a capitalism and consumerism problem first but pls note that it wasn't what the post was about#btw 'natural' tanning methods can also have a bad impact locally if you don't follow safety protocols#using bio-produced poison to make a product rot-proof is still using poison#don't touch that shit‚ don't inhale it and don't fucking release the used water in the wild without filtering#bio poisons are easier to process than mineral ones but they're STILL poisons that's the whole fucking point of tanning#that being said they're still processable when a oak tree die the whole ground around it doesn't become toxic for ages#it's all a matter of proportions#but bio-tanned leather as a by-product of reasonable meat industry? should be good in theory#same with fur‚ and wool is sustainable and animal-friendly as long as we don't overconsume#'vegetal' leather is full bullshit tho it's plastic in disguise

37K notes

·

View notes

Text

As of 2023, the Indian plastic processing industry comprised ~30,000 units using injection moulding, blow moulding, extrusion, and calendaring to create a wide range of products.

The plastics industry was home to about 50,000 industries as of 2023, most of which are micro, small, and medium-sized enterprises (MSMEs). These enterprises contribute INR 3,633 billion to India’s economy and employ more than 50,000 people.

The plastic industry in India market size is estimated at INR 3,938 billion in 2024 and is expected to reach INR 4,466 billion by 2029, growing at a CAGR of over 6.5% during the forecast period (2024-2029).

Plastic Recycling and Government Initiatives

In February 2022, India released updated EPR guidelines for plastic packaging to strengthen existing rules. The guidelines promote a circular economy by encouraging the use of sustainable packaging that is reusable, recyclable, or compostable. The guidelines also require the use of recycled plastic content in packaging, supporting investments in recycling infrastructure.

Along with the ban on selected single-use plastics announced in August 2021, the new EPR guidelines aim to improve the collection and management of plastic waste in India.

Want to know more about UJA Market Report- Plastic Recycling. Click in the link.

#UJA Market Report#Plastic Recycling#plastic processing industry#plastic industry#public health#uja global advisory#uja global#uja

0 notes

Text

When self-described “ocean custodian” Boyan Slat took the stage at TED 2025 in Vancouver this week, he showed viewers a reality many of us are already heartbreakingly familiar with: There is a lot of trash in the ocean.

“If we allow current trends to continue, the amount of plastic that’s entering the ocean is actually set to double by 2060,” Slat said in his TED Talk, which will be published online at a later date.

Plus, once plastic is in the ocean, it accumulates in “giant circular currents” called gyres, which Slat said operate a lot like the drain of the bathtub, meaning that plastic can enter these currents but cannot leave.

That’s how we get enormous build-ups like the Great Pacific Garbage Patch, a giant collection of plastic pollution in the ocean that is roughly twice the size of Texas.

As the founder and CEO of The Ocean Cleanup, Slat’s goal is to return our oceans to their original, clean state before 2040. To accomplish this, two things must be done.

First: Stop more plastic from entering the ocean. Second: Clean up the “legacy” pollution that is already out there and doesn’t go away by itself.

And Slat is well on his way.

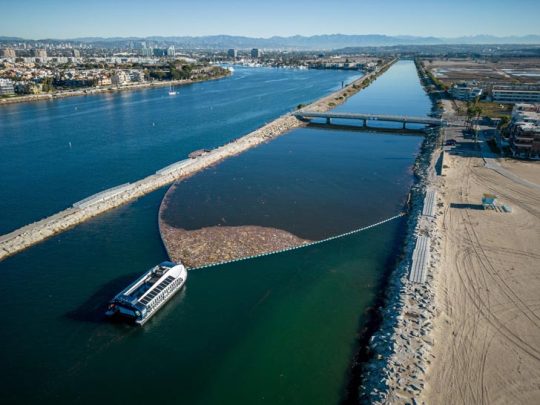

Pictured: Kingston Harbour in Jamaica. Photo courtesy of The Ocean Cleanup Project

When Slat’s first TEDx Talk went viral in 2012, he was able to organize research teams to create the first-ever map of the Great Pacific Garbage Patch. From there, they created a technology to collect plastic from the most garbage-heavy areas in the ocean.

“We imagined a very long, u-shaped barrier … that would be pushed by wind and waves,” Slat explained in his Talk.

This barrier would act as a funnel to collect garbage and be emptied out for recycling.

But there was a problem.

“We took it out in the ocean, and deployed it, and it didn’t collect plastic,” Slat said, “which is a pretty important requirement for an ocean cleanup system.”

Soon after, this first system broke into two. But a few days later, his team was already back to the drawing board.

From here, they added vessels that would tow the system forward, allowing it to sweep a larger area and move more methodically through the water. Mesh attached to the barrier would gather plastic and guide it to a retention area, where it would be extracted and loaded onto a ship for sorting, processing, and recycling.

It worked.

“For 60 years, humanity had been putting plastic into the ocean, but from that day onwards, we were also taking it back out again,” Slat said, with a video of the technology in action playing on screen behind him.

To applause, he said: “It’s the most beautiful thing I’ve ever seen, honestly.”

Over the years, Ocean Cleanup has scaled up this cleanup barrier, now measuring almost 2.5 kilometers — or about 1.5 miles — in length. And it cleans up an area of the ocean the size of a football field every five seconds.

Pictured: The Ocean Cleanup's System 002 deployed in the Great Pacific Garbage Patch. Photo courtesy of The Ocean Cleanup

The system is designed to be safe for marine life, and once plastic is brought to land, it is recycled into new products, like sunglasses, accessories for electric vehicles, and even Coldplay’s latest vinyl record, according to Slat.

These products fund the continuation of the cleanup. The next step of the project is to use drones to target areas of the ocean that have the highest plastic concentration.

In September 2024, Ocean Cleanup predicted the Patch would be cleaned up within 10 years.

However, on April 8, Slat estimated “that this fleet of systems can clean up the Great Pacific Garbage Patch in as little as five years’ time.”

With ongoing support from MCS, a Netherlands-based Nokia company, Ocean Cleanup can quickly scale its reliable, real-time data and video communication to best target the problem.

It’s the largest ocean cleanup in history.

But what about the plastic pollution coming into the ocean through rivers across the world? Ocean Cleanup is working on that, too.

To study plastic pollution in other waterways, Ocean Cleanup attached AI cameras to bridges, measuring the flow of trash in dozens of rivers around the world, creating the first global model to predict where plastic is entering oceans.

“We discovered: Just 1% of the world’s rivers are responsible for about 80% of the plastic entering our oceans,” Slat said.

His team found that coastal cities in middle-income countries were primarily responsible, as people living in these areas have enough wealth to buy things packaged in plastic, but governments can’t afford robust waste management infrastructure.

Ocean Cleanup now tackles those 1% of rivers to capture the plastic before it reaches oceans.

Pictured: Interceptor 007 in Los Angeles. Photo courtesy of The Ocean Cleanup

“It’s not a replacement for the slow but important work that’s being done to fix a broken system upstream,” Slat said. “But we believe that tackling this 1% of rivers provides us with the only way to rapidly close the gap.”

To clean up plastic waste in rivers, Ocean Cleanup has implemented technology called “interceptors,” which include solar-powered trash collectors and mobile systems in eight countries worldwide.

In Guatemala, an interceptor captured 1.4 million kilograms (or over 3 million pounds) of trash in under two hours. Now, this kind of collection happens up to three times a week.

“All of that would have ended up in the sea,” Slat said.

Now, interceptors are being brought to 30 cities around the world, targeting waterways that bring the most trash into our oceans. GPS trackers also mimic the flow of the plastic to help strategically deploy the systems for the most impact.

“We can already stop up to one-third of all the plastic entering our oceans once these are deployed,” Slat said.

And as soon as he finished his Talk on the TED stage, Slat was told that TED’s Audacious Project would be funding the deployment of Ocean Cleanup’s efforts in those 30 cities as part of the organization’s next cohort of grantees.

While it is unclear how much support Ocean Cleanup will receive from the Audacious Project, Head of TED Chris Anderson told Slat: “We’re inspired. We’re determined in this community to raise the money you need to make that 30-city project happen.”

And Slat himself is determined to clean the oceans for good.

“For humanity to thrive, we need to be optimistic about the future,” Slat said, closing out his Talk.

“Once the oceans are clean again, it can be this example of how, through hard work and ingenuity, we can solve the big problems of our time.”

-via GoodGoodGood, April 9, 2025

#ocean#oceans#plastic#plastic pollution#ocean cleanup#ted talks#boyan slat#climate action#climate hope#hopepunk#pollution#environmental issues#environment#pacific ocean#rivers#marine life#good news#hope

6K notes

·

View notes

Text

RPET Sheets Manufacturer & Supplier in Gujarat, India - Lyka Global Plast

In today’s environmentally conscious world, businesses seek sustainable solutions to reduce their carbon footprints. Lyka Global Plast, based in Gujarat, India, stands out as a leading manufacturer and supplier of RPET (Recycled Polyethylene Terephthalate) sheets, offering high-quality, eco-friendly materials to industries worldwide. With a commitment to sustainability and innovation, Lyka Global Plast provides a green alternative to virgin plastics, contributing to environmental conservation and economic efficiency.

Why Choose Lyka Global Plast for RPET Sheets?

1. Eco-Friendly Manufacturing

Lyka Global Plast is dedicated to reducing environmental impact through sustainable manufacturing processes. By recycling PET plastics into RPET sheets, the company minimizes waste, conserves resources, and significantly reduces CO2 emissions. This approach supports a circular economy, ensuring that waste materials are reused rather than discarded.

2. High-Quality Products

Lyka’s RPET sheets are durable, versatile, and tailored to meet diverse industrial needs. Whether for packaging, construction, or automotive applications, these sheets deliver exceptional performance while maintaining environmental benefits.

3. Advanced Recycling Technology

With cutting-edge recycling facilities, Lyka Global Plast transforms used PET materials into high-grade RPET sheets. These processes not only lower energy consumption but also ensure that the sheets meet global quality standards, making Lyka a preferred supplier for businesses worldwide.

4. Wide Industry Applications

Lyka’s RPET sheets are used in various industries:

Packaging: Food-safe and customizable for different products.

Construction: Ideal for insulation and durable panels.

Automotive: Lightweight and strong, reducing vehicle weight and fuel consumption.

Textiles: Utilized in creating sustainable fabrics.

RPET Sheets: A Sustainable Choice for Businesses

Carbon Footprint Reduction

By using RPET sheets, industries significantly lower their carbon footprints. Producing RPET emits up to 79% less CO2 compared to virgin PET. Lyka Global Plast ensures that every sheet contributes to global efforts to combat climate change.

Cost-Effective Alternative

RPET is not only environmentally friendly but also economically viable. Lyka Global Plast provides RPET sheets at competitive prices, helping businesses save costs while aligning with sustainable practices.

Promoting Circular Economy

Lyka’s RPET sheets exemplify the principles of a circular economy. By converting waste into valuable products, the company reduces dependency on raw materials and fosters resource efficiency.

Why Gujarat is the Hub for RPET Sheets

As one of India’s leading industrial states, Gujarat offers an ideal location for Lyka Global Plast. With its well-established infrastructure, access to raw materials, and proximity to key markets, the state enables Lyka to efficiently serve clients across India and beyond.

Contact Lyka Global Plast Today

For high-quality RPET sheets that combine sustainability, durability, and cost-efficiency, trust Lyka Global Plast—Gujarat’s premier RPET manufacturer and supplier. Visit their website at Lyka Global Plast to learn more and place your orders. Make the switch to sustainable materials today!

#RPET sheets manufacturer Gujarat#Recycled PET sheets supplier India#Best RPET sheet company Gujarat#Eco-friendly packaging RPET#Top RPET supplier in India#RPET sheets for industrial packaging#Sustainable plastics Gujarat#PET sheet recycling process India#Low-carbon RPET sheets India#Leading RPET exporter Gujarat

0 notes

Text

getting too mad about biodegradable plastics sighing filling the spray bottle with cold water

#op#we already have compostable plastic it just needs to be processed at high temperatures in an industrial setting#biodegradables also have a lot of requirements. some are anaerobic some arent. some need high temps#saw an article that suggested expecting the public to recycle was unrealistic (true) but also argued for biodegradables/compostables#girl how do you intend to collect the new plastic#and even if it could break down in the environment. is there really any kind of waste we can dump into the ocean that wont cause issues.#bonus: this has a pretty limited use case. and wax paper is better for food storage.

0 notes

Text

Best Manufacturer & Exporter of Self Tapping Screws in India: Dasset Engineering

Self-tapping screws are essential components in various industries, known for their ability to create their own threads as they are driven into materials. In India, one company stands out for its excellence in manufacturing and exporting these vital fasteners—Dasset Engineering. Renowned for its commitment to quality, innovation, and customer satisfaction, Dasset Engineering has established itself as a leader in the self-tapping screw industry.

Why Self-Tapping Screws?

Before delving into Dasset Engineering’s contributions, it is crucial to understand why self-tapping screws are so valuable. Unlike traditional screws that require pre-drilled holes, self-tapping screws can create threads as they are driven into materials. This feature makes them incredibly versatile and efficient, reducing the need for additional tools and saving time during assembly. They are widely used in automotive, construction, electronics, and woodworking industries due to their convenience and reliability.

Dasset Engineering: A Legacy of Excellence

Dasset Engineering has built a strong reputation over the years as a top manufacturer and exporter of self-tapping screws. Their success can be attributed to several key factors:

Quality Assurance

Quality is the cornerstone of Dasset Engineering’s operations. The company employs stringent quality control measures at every stage of production, from raw material selection to the final inspection. Their self-tapping screws are made from high-grade materials, ensuring durability, strength, and corrosion resistance. This commitment to quality ensures that their products meet and exceed industry standards, providing customers with reliable and long-lasting solutions.

Advanced Manufacturing Facilities

Dasset Engineering boasts state-of-the-art manufacturing facilities equipped with the latest machinery and technology. These advanced facilities enable the company to produce a wide range of self-tapping screws in various sizes, designs, and specifications. Their manufacturing process is streamlined and efficient, allowing for high-volume production without compromising on quality.

Innovative Designs

Innovation is at the heart of Dasset Engineering’s product development strategy. The company continually invests in research and development to create innovative screw designs that cater to the evolving needs of different industries. Their self-tapping screws are designed for optimal performance, with features such as sharp cutting edges, precise threading, and superior holding power. This dedication to innovation ensures that Dasset Engineering remains at the forefront of the industry.

Customization Options

Understanding that different projects have unique requirements, Dasset Engineering offers customization options for their self-tapping screws. Customers can specify dimensions, materials, coatings, and other parameters to meet their specific needs. This flexibility makes Dasset Engineering a preferred choice for businesses looking for tailored solutions.

Global Reach

As a leading exporter, Dasset Engineering has a strong presence in international markets. Their self-tapping screws are in high demand worldwide, thanks to their reputation for quality and reliability. The company has a robust logistics network that ensures timely delivery to customers across the globe, making them a trusted partner for businesses in various industries.

Customer-Centric Approach

Dasset Engineering’s success is also driven by its customer-centric approach. The company prioritizes customer satisfaction by offering excellent after-sales support, technical assistance, and responsive service. Their team of experts is always ready to assist customers with their queries and provide guidance on the best solutions for their projects.

Conclusion

Dasset Engineering stands out as the best manufacturer and exporter of self-tapping screws in India, thanks to its unwavering commitment to quality, innovation, and customer satisfaction. Their advanced manufacturing facilities, innovative designs, and customer-centric approach make them a trusted partner for businesses across various industries. Whether you are in the automotive, construction, electronics, or woodworking sector, Dasset Engineering offers reliable and high-performance self-tapping screws that meet your needs and exceed your expectations.

#PET bottle recycling process explained#Plastic bottle lifecycle analysis#Importance of PET bottle recycling#Steps in PET bottle recycling#Environmental impact of PET recycling#Sustainable PET bottle management#PET bottle disposal and recycling#Recycling journey of plastic bottles#PET bottle recycling technology#Benefits of PET bottle recycling#Circular economy and PET recycling#Innovations in PET bottle recycling#PET recycling best practices#PET bottle recycling facilities#Role of Lyka Global Plast in PET recycling#Impact of PET recycling on the environment#Challenges in PET bottle recycling#Consumer awareness of PET recycling#Future of PET bottle recycling#PET recycling trends and insights#PET bottle recycling process steps#Sustainable solutions for plastic bottle disposal#PET bottle recycling initiatives worldwide#Environmental benefits of PET bottle recycling#PET bottle recycling impact on climate change#Effective PET bottle waste management strategies#PET bottle recycling rates and statistics#Innovations in PET bottle recycling technology#Circular economy principles in PET recycling#Best practices for PET bottle collection and sorting

0 notes

Text

6 Reasons Why Plastic Recycling in India is Important

Plastic is everywhere — from packaging and electronics to household items and construction materials. But as the use of plastic continues to rise, so does the burden it places on the environment. In India, where millions of tons of plastic waste are generated each year, Plastic Recycling Industry In India plays a crucial role in addressing both environmental and economic challenges.

Here are 6 compelling reasons why plastic recycling is vital for India:

1. Reduces Environmental Pollution

India generates nearly 3.5 million tonnes of plastic waste annually, much of which ends up in landfills, rivers, and oceans. Recycling helps divert this waste from the environment, significantly reducing soil, air, and water pollution caused by plastic degradation and burning.

2. Conserves Natural Resources

Plastic is derived from non-renewable resources such as petroleum and natural gas. Recycling reduces the need for virgin plastic production, thereby conserving these finite natural resources and lowering the energy consumption associated with extraction and processing.

3. Supports a Circular Economy

Recycling promotes the concept of a circular economy, where plastic products are reused, repurposed, or recycled rather than discarded. This approach not only minimizes waste but also extends the lifecycle of materials, creating a more sustainable production-consumption model.

4. Generates Employment Opportunities

India’s informal recycling sector employs lakhs of workers—from rag pickers to small-scale recyclers. Expanding and formalizing plastic recycling can create thousands of additional jobs, improve working conditions, and provide steady income for many marginalized communities.

5. Reduces Carbon Footprint

Manufacturing new plastic products from raw materials consumes more energy and emits more greenhouse gases compared to using recycled plastic. By recycling, India can significantly reduce its carbon emissions, helping combat climate change and meet global sustainability goals.

6. Fulfills Government Regulations and Corporate Responsibility

With initiatives like the Plastic Waste Management Rules (2016, amended 2022) and Extended Producer Responsibility (EPR), recycling has become not just important but mandatory. Companies are now accountable for the plastic they produce, and recycling plays a key role in helping them meet compliance targets and sustainability commitments.

Final Thoughts

Plastic Recycling Industry In India is more than just an environmental necessity—it's a social, economic, and regulatory imperative. As citizens, businesses, and policymakers come together to tackle the plastic crisis, scaling up recycling efforts can pave the way for a cleaner, greener, and more sustainable future for all.

0 notes

Text

Chemists discover common plastic pigment promotes depolymerization

It turns out that the black plastic lid atop your coffee cup has a superpower. And the Stache Lab at Princeton Chemistry, which uncovered it, is exploiting that property to recycle at least two major types of plastic. Their startling mechanism for promoting depolymerization relies on an additive that many plastics already contain: a pigment called carbon black that gives plastic its black color. Through a process called photothermal conversion, intense light is focused on plastic containing the pigment that jumpstarts the degradation. So far, researchers have shown that carbon black can depolymerize polystyrene and polyvinyl chloride (PVC), two of the least recycled plastics in the planet's waste stream. Through a process called photothermal conversion, intense light is focused on plastic containing the pigment that jumpstarts the degradation.

Read more.

#Materials Science#Science#Plastics#Pigments#Materials processing#Carbon#Photothermal#Recycling#Waste#Princeton University

25 notes

·

View notes

Photo

The 7 R’s of Sustainability:

Did you know that ‘recycling’ is step 6 of the 7 Rs of sustainability? The other R’s are just as important even if they are often forgotten.

Rethink- Do I really need to buy this? The point of this step is to stop and think.

Refuse- Does this product damage the environment? If so, refuse to spend your money on it. i.e. single use plastics, harsh chemicals

Reduce- How much of this do I really need? Buy less! Buy in bulk when you can as it often equals less packaging to throw out.

Reuse- Can I use this product again? Can I fix what I have so that I don’t need to buy something new? Reuse that plastic water bottle a few times. And instead of buying new, try thrift shopping, flea markets, yard sales etc.

Repurpose- Unlimited creativity! Does this item have another use? i.e. old torn clothes can be rags or plastic cups can be planters.

Recycle- Can I recycle this? Not everything can be. There are also some important steps to making sure your recycling is done properly. If unsure, look up local recycling regulations.

Rot- Can I compost this? Food waste, yard clippings, newspapers and many other items can be composted instead of being tossed in the trash. Composting is surprisingly simple and helps reduce harmful greenhouse gasses from entering the atmosphere.

What is the point of the R’s? The number one benefit of the 7 R’s are the reduction of the amount of waste sent to incinerators and landfills. The EPA website provides a lot of useful information. Other benefits that we can reap from implementing these concepts in our life are (as listed on the EPA website): • Prevents pollution caused by reducing the need to harvest new raw materials • Saves energy from not making a new product • Reduces greenhouse gas emissions that contribute to climate change • Helps sustain the environment and natural resources for future generations • Saves money from processing our waste • Increases economic security by tapping a domestic source of materials • Helps create jobs in the recycling and manufacturing industries in the United States

https://www.northglenn.org/government/departments/public_works/trash/recycling.php https://www.nrdc.org/stories/composting-101 https://www.epa.gov/recycle https://www.northglenn.org/Recycling%20Article.pdf

6K notes

·

View notes

Text

How to Make Plastic Pellets Manufacturing from Recycled Plastic

Who knew waste could be so profitable? 💡💰 Start your Plastic Granules Manufacturing Business today grow! 🌱♻️ Follow for more tips to turn ideas into income! 🚀 #PlasticRecycling #RecyclingHacks #RecyclingRevolution #PlasticRecycling #Business

Plastic Pellets are small particles produced by recycling raw materials or plastic waste. They are essential raw materials for making various plastic products such as bottles, containers, packaging materials, pipes and furniture. Plastic Pellets come in different types such as HDPE (high-density polyethene), LDPE (low-density polyethene), PP (polypropylene) and PET (polyethene terephthalate),…

#how to set up a plastic Pellets business#how to set up a plastic Pelletsbusiness#plastic dana business#plastic dana making machine#plastic granulator#plastic granulator machine#plastic granules#plastic pelletizer#plastic pelletizer business#plastic pelletizer machine#plastic pelletizing line#plastic pelletizing machine#plastic pelletizing recycling machine#plastic Pellets business plan#plastic Pellets making machine#plastic Pellets manufacturing business#plastic Pelletsbusiness#plastic recycling business#plastic recycling machine#plastic recycling process#production of plastic Pelletsbusiness

0 notes