#PET bottle recycling process explained

Explore tagged Tumblr posts

Text

Best Manufacturer & Exporter of Self Tapping Screws in India: Dasset Engineering

Self-tapping screws are essential components in various industries, known for their ability to create their own threads as they are driven into materials. In India, one company stands out for its excellence in manufacturing and exporting these vital fasteners—Dasset Engineering. Renowned for its commitment to quality, innovation, and customer satisfaction, Dasset Engineering has established itself as a leader in the self-tapping screw industry.

Why Self-Tapping Screws?

Before delving into Dasset Engineering’s contributions, it is crucial to understand why self-tapping screws are so valuable. Unlike traditional screws that require pre-drilled holes, self-tapping screws can create threads as they are driven into materials. This feature makes them incredibly versatile and efficient, reducing the need for additional tools and saving time during assembly. They are widely used in automotive, construction, electronics, and woodworking industries due to their convenience and reliability.

Dasset Engineering: A Legacy of Excellence

Dasset Engineering has built a strong reputation over the years as a top manufacturer and exporter of self-tapping screws. Their success can be attributed to several key factors:

Quality Assurance

Quality is the cornerstone of Dasset Engineering’s operations. The company employs stringent quality control measures at every stage of production, from raw material selection to the final inspection. Their self-tapping screws are made from high-grade materials, ensuring durability, strength, and corrosion resistance. This commitment to quality ensures that their products meet and exceed industry standards, providing customers with reliable and long-lasting solutions.

Advanced Manufacturing Facilities

Dasset Engineering boasts state-of-the-art manufacturing facilities equipped with the latest machinery and technology. These advanced facilities enable the company to produce a wide range of self-tapping screws in various sizes, designs, and specifications. Their manufacturing process is streamlined and efficient, allowing for high-volume production without compromising on quality.

Innovative Designs

Innovation is at the heart of Dasset Engineering’s product development strategy. The company continually invests in research and development to create innovative screw designs that cater to the evolving needs of different industries. Their self-tapping screws are designed for optimal performance, with features such as sharp cutting edges, precise threading, and superior holding power. This dedication to innovation ensures that Dasset Engineering remains at the forefront of the industry.

Customization Options

Understanding that different projects have unique requirements, Dasset Engineering offers customization options for their self-tapping screws. Customers can specify dimensions, materials, coatings, and other parameters to meet their specific needs. This flexibility makes Dasset Engineering a preferred choice for businesses looking for tailored solutions.

Global Reach

As a leading exporter, Dasset Engineering has a strong presence in international markets. Their self-tapping screws are in high demand worldwide, thanks to their reputation for quality and reliability. The company has a robust logistics network that ensures timely delivery to customers across the globe, making them a trusted partner for businesses in various industries.

Customer-Centric Approach

Dasset Engineering’s success is also driven by its customer-centric approach. The company prioritizes customer satisfaction by offering excellent after-sales support, technical assistance, and responsive service. Their team of experts is always ready to assist customers with their queries and provide guidance on the best solutions for their projects.

Conclusion

Dasset Engineering stands out as the best manufacturer and exporter of self-tapping screws in India, thanks to its unwavering commitment to quality, innovation, and customer satisfaction. Their advanced manufacturing facilities, innovative designs, and customer-centric approach make them a trusted partner for businesses across various industries. Whether you are in the automotive, construction, electronics, or woodworking sector, Dasset Engineering offers reliable and high-performance self-tapping screws that meet your needs and exceed your expectations.

#PET bottle recycling process explained#Plastic bottle lifecycle analysis#Importance of PET bottle recycling#Steps in PET bottle recycling#Environmental impact of PET recycling#Sustainable PET bottle management#PET bottle disposal and recycling#Recycling journey of plastic bottles#PET bottle recycling technology#Benefits of PET bottle recycling#Circular economy and PET recycling#Innovations in PET bottle recycling#PET recycling best practices#PET bottle recycling facilities#Role of Lyka Global Plast in PET recycling#Impact of PET recycling on the environment#Challenges in PET bottle recycling#Consumer awareness of PET recycling#Future of PET bottle recycling#PET recycling trends and insights#PET bottle recycling process steps#Sustainable solutions for plastic bottle disposal#PET bottle recycling initiatives worldwide#Environmental benefits of PET bottle recycling#PET bottle recycling impact on climate change#Effective PET bottle waste management strategies#PET bottle recycling rates and statistics#Innovations in PET bottle recycling technology#Circular economy principles in PET recycling#Best practices for PET bottle collection and sorting

0 notes

Photo

Visualizing PET's degradation by bacterial enzymes

The rigidity, transparency and hardness of PET (Polyethylene Terephthalate) make it one of the most valuable plastics for the manufacture of plastic bottles, packaging and other single-use products. However, these characteristics make it highly persistent in the environment, to the point that a plastic PET bottle may take several hundred years to degrade in the ocean.

At the molecular level, PET, and all plastics, have a polymeric structure made up of tens of thousands of repetitions of small subunits called monomers. In the last decades, the degradation of PET by a kind of bacterial enzymes called polyester hydrolases (or PETases) has been regarded with much hope, as it is considered as a potential eco-friendly method for recycling plastic waste and recover the original monomers, thus enabling an effective circular-material economy loop.

Now, a new study led by the Institut de Ciències del Mar (ICM-CSIC) and the University of Leipzig (Germany) has revealed the details, at the molecular level, of the PET degradation process by these enzymes.

"The results of our work can be very useful for the industry, as this is the first time we can 'see' the motion picture of the process. Also, they pave the way to design new enzymes capable of breaking down the plastic into its original soluble components with high efficiency," explains Francesco Colizzi, a leading author of the study.

Read more.

17 notes

·

View notes

Text

Egy Stitch & Tex Expo 2025: Oerlikon Manmade Fibers Solutions sets the tone in the Egyptian market

With a clear focus on the needs of the Egyptian market, Oerlikon Manmade Fibers Solutions will be presenting itself at the Egy Stitch & Tex Expo 2025 in Cairo from February 20 to 23, 2025. At the booth of Oerlikon agent ATAG Ltd. Trading Export & Import in Hall 1, Booth 1A12, experts from Oerlikon Barmag and from BB Engineering (BBE) will be explaining the comprehensive product and service portfolio.

The comprehensive DTY solutions from Oerlikon Manmade Fibers Solutions are the focus of the trade show appearance:

DTY yarns – uncompromising quality and maximum flexibility

Clothing, home textiles, automotive – there are countless applications for textured yarns. For the efficient and sustainable production of high-quality textured yarns made of different polymers, from polyester and polyamide to polypropylene, PLA and PTT, Oerlikon Barmag provides a wide range of different DTY machine configurations. With sophisticated components, expertise and proven technology, the modular DTY machines – whether manual or automatic – produce textured yarns for excellent downstream processing, while keeping OPEX costs to a minimum.

Increasing demand for fancy yarns

“But the demand for textiles with special properties, irregularities and a special look and feel is also becoming more and more important,” explains Jilali Lakraa, Regional Sales Director at Oerlikon Barmag. ”For such fabrics, so-called fancy yarns are required that deviate from the standard, e.g. cotton-like DTY, linen-like DTY or wool-like DTY. Effect yarns include a very wide range of yarn types that are manufactured using a variety of methods and additional components,” he continues. With its high-quality and flexible technology, detailed knowledge of the yarn path and the necessary parameter settings, Oerlikon Barmag is the ideal partner for the successful and flexible production and continuous development of these specialty yarns.

Extended product range for the manufacture of carpet yarns

The knowledge of all relevant technologies in manmade fiber spinning allows Oerlikon Barmag, as the only manufacturer worldwide, to extend its range of services for the production of carpet yarns. The system concept based on a POY and texturizing process is designed for a carpet and home textile product area that requires particularly soft and bulky polyester threads with BCF-like properties. The aim here is to produce yarns with a titer of up to 1300dtex and typically over 1000 filaments. Typical products include, for example, 1300dtex f1152 or 660dtex f1152 and 990dtex f768. The machine concept consists of the familiar WINGS HD POY winder and the eAFK Big-V texturing machine.

VarioFil – flexible compact spinning system for countless applications and specialties

Whether carpets or upholstery fabrics, fashion or sportswear, or seat belts or airbags – a wide range of products is no challenge for the VarioFil system from BBE. This compact turnkey spinning system is also ideal for producers who manufacture small batch sizes or specialized products. It is similarly flexible when processing various polymers, regardless of whether it is PET, PP, PA 6 and PA 6.6 or PBT. Customized conversion packages enable quick adaptation of the system to constantly changing market demands. In combination with Oerlikon Barmag texturing machines, a wide range of end products can be covered. This ranges from standard textile yarns to textured yarns with properties similar to BCF.

Furthermore, with the VarioFil R+ it is possible to recycle and process PET bottle granulate and PET waste, which is produced during start-up, directly back into POY. The sustainable machine concept allows for high product flexibility, including the manufacturing of spun-dyed yarn.

JeTex air texturing enables a broad and flexible product portfolio

And for BB Engineering, it does not stop with yarn spinning: the Oerlikon Barmag subsidiary also offers a solution for texturing – with a flexibility similar to VarioFil. The JeTex air texturing system perfectly complements the Oerlikon Barmag DTY system, thus enabling the customer to expand its product portfolio to include high-quality ATY based on POY and FDY for a wide range of textile and industrial applications. The core element of the system is the texturing box developed by BB Engineering, which, in addition to many other state-of-the-art components from Oerlikon Barmag, ensures both gentle yarn treatment with reliable texturing effects and production efficiency in terms of

OPEX, handling and speed.

Particularly smart: JeTex is not only available as a closed system, but also as a conversion variant for existing Oerlikon Barmag DTY systems. This allows customers to expand or convert their product portfolio to ATY in a cost-saving and comparatively short time.

Versatile PET recycling solutions with VacuFil and Visco+

“From waste to value” – that's what BBE's VacuFil PET recycling system does. It is specially designed for high-quality processing of textile waste. The technology is unique and based on decades of experience in extrusion, filtration and spinning: it combines gentle large-area filtration with targeted IV regulation for consistently excellent rPET melt quality, comparable to virgin material. A wide range of input materials can be processed: in addition to the usual bottle flakes, VacuFil is particularly suitable for production waste from spinning mills, from start-up lumps to yarn and fabrics, and can also handle post-consumer waste. The patented key component Visco+, a liquid-state polycondensation, quickly and reliably removes volatile impurities and automatically regulates the IV. There are also various options for further processing the recycled melt. The melt can be added to the main melt flow, processed into chips via a pelletizing process or fed directly back into the spinning mill. The VacuFil recycling system can thus be flexibly and modularly customized to the customer's requirements.

Customer Services – Partnering for Performance

With Oerlikon Barmag's Lifecycle Management, chemical fiber producers can maintain and improve the future viability of their machines and systems. Pragmatic solutions for increasing and safeguarding productivity, including opening up new markets, enable profitable business over the entire service life of the machines. As a partner, Oerlikon Barmag offers leading technologies and services for long-term competitiveness – from upgrades and modernizations to preventive maintenance and repairs with original parts. The original part packages are explicitly designed for the demanding use of the systems for which they are intended. Due to their high-quality standards, they have a significantly longer service life than other spare parts. This avoids unplanned production downtimes and saves money in the end.

Upgrade solutions are based on the existing machine platforms, regardless of whether they are

technology upgrades to expand the product range and increase competitiveness,

process upgrades to improve throughput and yarn properties,

component upgrades to improve life expectancy, ease of use and cost savings, or

software upgrades.

0 notes

Text

Conversation with Takeda Pharma's head of packaging Sriman Banerjee

Sriman Banerjee is head of diagnostics, Software Devices & Packaging, and R&D Pharma Science, at the R&D-driven global biopharmaceutical major Takeda. With roots in Japan, the US$ 30 billion company is present across 80 countries with a major presence in the US, Europe, Canada, Japan, and other emerging markets. Based in the United States, Banerjee is the son of the late pioneer in plastic rigid packaging in India, Onkar Banerjee.

Banerjee is actively involved in Takeda’s environmental sustainability goals – partnering with suppliers to develop new materials, new printing and manufacturing processes, as well as recycling materials in packaging. He was recently in Bangkok to accept a WorldStar award in the medical and pharmaceutical category for Takeda Pharma and Aptar’s Instanyl DoseGuard Nasal Spray Devices.

According to Banerjee, there are two environmental sustainability aspects to packaging – carbon footprint and waste management and/or recycling. “The industry is balancing both aspects and moving more towards a circular economy by using a mix of materials, formats, manufacturing, and end-of-life solutions.”

Apart from reducing plastic use, how can the industry reduce its overall carbon footprint, such as the sensible use of water, power, inks, and chemicals? Banerjee says sustainability is not limited to material, format, or processing but is holistic. “However, we need to understand and find the right balance. The supply chain also plays an important role, including sourcing and manufacturing. Most companies are leveraging sustainable energy sources, water harvesting, and recycling to the extent possible and limiting the use of inks and chemicals. An example would be digital printing, the CMYK color palette, and so forth.”

As biodegradable and compostable packaging, renewable materials, and biopolymers have become buzzwords with many companies claiming such solutions, we ask about their feasibility in the long term as well as their cost-effectiveness. Banerjee explains that multiple aspects of feasibility, availability, manufacturing, costs, and sustainability are involved. For instance, most novel solutions currently have limited availability, which restricts their application. When availability increases, the industry will adopt these solutions.

The discussion shifts to packaging recycling and the circular economy, especially in the pharma and food industries. Banerjee sees an urgent need to overcome the thought process of downcycling. “Moreover, many packaging materials and formats used today are recycled laterally and used for the same application. Recycled PET is a good example where it is used for beverage bottles. There are similar examples of using recycled paper for secondary and tertiary packaging,” he said.

Speaking about the pharma industry confronting the sustainability challenge, he says while pharma companies are evaluating several alternatives, in Japan an interesting approach is biopolyethelene blisters. A consortium of four companies – Takeda, Astellas Pharma, Daiichi Sankyo and Eisai is collaboratively working on this development.

Takeda's recent WorldStar award was for a nasal spray device – the innovation of an electromechanical device and packaging for a drug product in a specific therapeutic area. Banerjee, who was present in Bangkok to receive the award, says it addresses the safety requirements for patients using a drug in that therapy. He says packaging design in the pharma industry is directed towards providing patient-centricity, dosage adherence, safety, and regulatory considerations. The new-age drugs of cell, gene and similar therapies have specific needs that are being addressed with a mix of design and technology, leveraging science.

We ask how he envisages the future of the packaging industry in a country like India where there is a surging demand for hygienically packed products after the global Covid pandemic but where the per capita consumption of packaging seems low. According to Banerjee, for the part of the population with a similar range of per capita income as the West, the packaging consumption is similar. “However, emerging economies have a substantial population that has a low per capita income and that skews the consumption numbers. As more sections of the population increase their per capita, the lifestyle evolves and so does the use of packaged products.”

0 notes

Text

https://spoder.mn.co/posts/61413067

Plastic Water Bottle Recycling in India

How India Recycles Plastic Water Bottles

Plastic Bottle Recycling Process Explained

Discover the steps of plastic water bottle recycling in India, from collection to manufacturing new products.

Learn about the detailed process and benefits of plastic water bottle recycling in India, promoting sustainability.

Explore how India recycles plastic water bottles, turning waste into valuable resources for various industries.

Introduction

Plastic water bottle recycling is crucial to combat environmental pollution and promote sustainability. This article explores the comprehensive recycling process in India, from collection and sorting to transforming plastic into reusable materials.

Importance of Plastic Water Bottle Recycling

Environmental Impact: Reduces plastic waste in landfills and oceans, protecting wildlife and ecosystems.

Economic Benefits: Generates jobs and supports economic growth.

Resource Conservation: Saves petroleum and energy required for new plastic production.

Collection and Transportation

Collection Methods: Curbside collection, drop-off centers, and buy-back programs.

Transportation Logistics: Efficient transport to recycling facilities ensures timely processing.

Sorting and Cleaning

Sorting Process: Manual and automated sorting based on type and color.

Cleaning Procedures: Pre-washing, label removal, and thorough washing to remove contaminants.

Shredding and Flaking

Shredding: Bottles are shredded into small pieces, creating plastic flakes.

Flaking: Flakes are processed to be uniform and ready for further processing.

Separation and Extrusion

Separation Techniques: Density and electrostatic separation.

Extrusion Process: Melting, filtering, and pelletizing the plastic flakes into pellets for new product manufacturing.

Manufacturing New Products

Recycled Plastic Applications: Used for bottles, textiles, construction materials, and consumer goods.

Quality Control: Ensuring recycled plastic meets industry standards.

Challenges and Solutions in India

Challenges: Lack of awareness, infrastructure gaps, and reliance on the informal sector.

Solutions: Education campaigns, infrastructure development, and formalizing the informal sector.

Government Policies and Initiatives

Policy Framework: Plastic Waste Management Rules (2016) and Extended Producer Responsibility (EPR).

Government Initiatives: Swachh Bharat Abhiyan and plastic waste management campaigns.

Case Study: Pashupati India

Pashupati India is a leading recycler, known for its sustainable practices and advanced technology, contributing to reducing plastic waste and promoting a circular economy.

Frequently Asked Questions (FAQs)

What types of plastic bottles can be recycled? PET and HDPE bottles.

How can individuals contribute? By segregating plastic waste, participating in recycling programs, and spreading awareness.

What happens to recycled plastic? Transformed into pellets for new product manufacturing.

Is recycled plastic safe for food containers? Yes, when it meets safety standards.

How does recycling help the environment? Reduces waste, conserves resources, saves energy, and cuts greenhouse gas emissions.

Conclusion

Plastic water bottle recycling in India is essential for environmental sustainability and economic growth. By supporting recycling initiatives and adopting sustainable practices, we can address the plastic waste challenge and work towards a cleaner, greener future.

0 notes

Text

From Bottles to Brilliance: Unveiling the R-PET Recycling Revolution in the Polymer World!

Did you ever think about what happens to a plastic bottle of water after you tossed it? Regrettably, an amount of plastic that is enough to fill a football field two times per day ends up in landfills and oceans, creating major environmental issues. However, the good news is that this! Recycled PET (polyethylene terephthalate) stands as an eco-friendly alternative to this.

This blog takes a deeper look into a particular plastic, recycled PET (r-PET), and explains how it can change the way we perceive plastic. We'll show why old plastic bottles are given a reprieve and made into soft fleece jackets, or sturdy car parts.

Are you prepared to discover the reasons behind the amazingness of recycled PET? We'll touch on the environmental advantages of plastic recycling, from cutting down the volume of trash that ends up in landfills to saving valuable resources. And to top it off, we'll cover the latest advancements in the recycled PET field, showing how it's being employed to make first-rate goods for numerous industries. Regardless of whether you are a concerned consumer or just curious about eco-living, this blog is for you. It's time we examine what recycled PET can do and how it can make a better tomorrow!

Introduction

PET, or polyethylene terephthalate, stands as a ubiquitous and favored material for plastic packaging across the globe, enjoying widespread usage. Unfortunately, its prevalence extends to oceanic waste, marking it as a dominant contributor to marine pollution. Despite this, the disposal of used PET bottles shouldn't be perceived as waste due to their complete recyclability. Through a straightforward process involving heating and molding, PET can be transformed into a myriad of shapes, rendering it a versatile and environmentally friendly packaging solution. Unlike its counterparts like glass and aluminum, PET boasts a notably low melting point, facilitating its conversion into a closed-loop or circular economy model. This circularity underscores its potential for sustainable reuse, offering a pathway towards mitigating plastic pollution and promoting responsible resource management. Consequently, PET emerges not only as a popular choice for packaging but also as a beacon of hope for transitioning towards more sustainable consumption and production practices, fostering a harmonious relationship between human activity and the natural environment. By recycling PET bottles, we effectively diminish landfill waste, curtail the consumption of non-renewable resources, and minimize water usage compared to the production of new plastic pellets. Additionally, the recycling process demands fewer chemicals to enhance the properties of recycled plastic items. Even when plastic becomes non-recyclable, it retains its calorific value, rendering it a viable fuel source. The surge in environmentally conscious consumers amplifies the demand for recycled goods, coinciding with a burgeoning global population that intensifies the need for resources. Through recycling, we mitigate reliance on Earth's finite raw materials, maximizing the utility of already extracted resources and fostering sustainability.

Manufacturing Process

The standard procedure for recycling PETinvolves a water-based washing method to eliminate contaminants such as dirt, labels, and adhesive residues from post-consumer PET materials. Illustrated in Figure, the conventional PET recycling process begins with resizing post-consumer PET bottles into flakes. Common cleaning agents used include caustic soda, typically constituting 2–3% of the solution, along with detergents. Subsequently, the mechanical reprocessing stage involves converting PET waste into granules through conventional extrusion after the removal of contaminants. Following this, a series of processes including collection/segregation, cleaning and drying, chipping/sizing, coloring/agglomeration, and palletization/extrusion precede the manufacturing of the final product. Tertiary recycling, a critical phase, entails the depolymerization of PET to yield monomers or other valuable low molecular weight compounds. Repolymerization can then utilize these monomers to regenerate the initial polymer, representing a significant opportunity for enhanced profitability and sustainability.

Step 1: Remove the contaminants

• The initial phase of the super clean process involves thorough removal of all contaminants adhered to PET surfaces, followed by re-extrusion to form pellets. Solid-state polycondensation (SSP) technology is subsequently employed to achieve deeper purification of PET. SSP operations can be conducted via batch or continuous processes, with key parameters including residence time, temperature, vacuum, and inert gas stream. • Typically, solid-state reactions require a residence time of 6–20 hours within a temperature range of 180–220°C, depending on the desired viscosity of the PET material. Through the re-extrusion process, recycling PET offers advantages such as uniform pellet size akin to virgin PET and homogeneous distribution of contaminants in post-consumer PET.

Step 2: Mechanical Recycling

• Mechanical recycling offers a solution for repurposing various forms of PET waste, including packaging, films, containers, sheets, and fibers used for insulation and floor coverings. The current technology predominantly employs dry processes for the initial stages, eliminating the need for washing water. • The recycling process encompasses several steps, including classification, sorting, washing, drying, size reduction, melt filtration, reforming, and compacting, tailored to accommodate the diverse nature of source plastic materials. • Pretreatment begins with sorting, optimizing conditions to screen waste based on particle size, fines, and material weight, as well as separating waste plastics by shape, distinguishing between 2D and 3D particles. • Subsequently, the material undergoes separation into two streams: one for large particle streams, including light, ferrous, aluminum, and plastic particles, and the other for smaller particle streams, primarily targeting ferrous and aluminum particles. Rotary screening is employed in this stage to refine the separation process further.

Step 3: Crushing

• Following sorting, the subsequent stage involves crushing the PET bottles, a process that categorizes them based on their properties while simultaneously reducing their particle size. • However, this method generates a significant quantity of fine particles and non-sortable materials, potentially impacting product quality. An effective example of this process utilizes slicing machines such as the Valley beater and the disc refiner, where PET waste undergoes intermittent sliding contact with multiple knife edges. • This process typically lasts up to 10 minutes, with an average residence mixing time of one minute or less for continuous operation of a disc refiner. • Counter comb shredders are frequently employed for the crushing of raw materials, particularly in sectors dealing with bedrocks or waste and recycling. These machines feature a primary rotatably driven comminution roller, equipped with comminution apparatus such as teeth, cutting edges, and movable hammers mounted on its cylindrical shell or roller body. The comminution process initiates with the counter apparatus of the comb, typically designed resembling a comb beam, spanning at least the entire width of the comminution roller to securely hold the device in place.

Step 4: Washing and Decontamination

• The PET flakes undergo a washing process to eliminate ground-up lids, rings, and labels, as well as other contaminants like glue. Following washing, they enter a high-temperature decontamination phase where migrated post-consumer substances and flavors are extracted. These substances can migrate into the material due to improper use of PET bottles for non-food liquids. • Additionally, during this step, the mechanical properties are restored to levels comparable to virgin material. Depending on the recycling technology, the material may be melted either before or after this stage, with solid contaminants being separated by a melt filter.

Step 5: Pelletizing

• Following washing and grinding, PET flakes undergo drying before being melted into long strands of PET plastic, which are subsequently cut into small pellets. • Part of the recycling process is also converting the melt into spherical, crystalline-PET-pellets for the production of new PET bottles.

Step 6: Reforming

• The recycled PET pellets are then transported to manufacturers within the packaging industry, where they are prepared for the production of new bottles. Once heated, the pellets are molded into the desired size and shape, rendering them ready for reuse, thereby completing the bottle-to-bottle recycling loop. • While the bottle-to-bottle loop represents the optimal recycling method for PET bottles, it is not always feasible. In cases where the collected plastic does not meet the required quality standards, the recycled PET undergoes a different process. It is ground into flakes, washed, and then subjected to heat, resulting in stretched fibers utilized in recycled polyester. These fibers find application in various products such as seat belts, bags, carpets, shoes, and clothing.

Applications of R-PET

1. Beverage Bottles: Plastic bottles produced from R-PET are usually used to make new beverage bottles such as water bottles and soda bottles. This in turn enables PET plastic to be recycled and used again, thereby limiting the need for the use of virgin plastics. R-PET bottles can have the advantage of being just as good in terms of strength and durability as virgin PET bottles, making them a good choice for both consumers and manufacturers.

2. Food Packaging: R-PET is usually preferred for food packaging because it is sturdy, light, and can be converted into trays, tubs, or clamshells. It not only acts as a shield to protect the food from contamination but also it is a parcel to transport the food. R-PET food packaging can be used for the packaging of a wide assortment of food products including fruits, vegetables, salads and prepared meals.

3. Textiles: R-PET is a material that can be shredded and spun into fibers, which are used to make clothes, fleece and carpets. Therefore, it is a sustainable means of clothing production which in turn helps to eliminate textile waste. R-PET clothing is becoming a fairly widespread trend as people strive to pick more sustainable options. It can serve as a material for different garment types, for example, t-shirts and jackets, sweaters and pants.

4. 3D Printing Filament: R-PET can be used as raw material for filament used in 3D printers. With this option, manufacturers can design products that are environmentally friendly and reduce plastic waste from 3D printing. R-PET filament is a fantastic option for companies who want to print prototypes or manufacture using 3D printing. It is cost-effective and environmentally friendly, and it helps to create the best products.

Market Outlook

R-PET market is supported by the fact that environmental consciousness, regulatory obligations, and the corporate sustainability agendas are converging. Awareness of plastic pollution and climate change is on the rise, which means that consumers, governments, and businesses are compelled to act in a sustainable manner, and the demand for R-PET is soaring. Strict regulations, along with the EPR laws and plastic bags, are the factors that in turn increase the demand for recycled materials. On the other hand, growing consumer taste for ecological products also plays a role in the growing popularity of R-PET in the different industries. The continuous technological advances in the recycling processes contribute to the quality and viability of R-PET, which in turn stimulates market growth. These factors, all together, are the key to the circular economy and, therefore, the future of sustainability.

R-PET Significant Global Players

Major players in the Global R-PET market are Clear Path Recycling LLC, Verdeco Recycling, Inc., Indorama Ventures Public Ltd., Placon, Zhejiang Anshun Pettechs Fibre Co., Ltd., PolyQuest, Evergreen Plastics, Inc., Biffa, Phoenix Technologies, Libolon, and Others.

Conclusion:

Recycled- Polyethylene Terephthalate (R-PET) is a game-changer for sustainability in the world of plastics. It keeps plastic out of landfills and oceans by giving it a second life. This not only conserves resources but also reduces the environmental burden of many products and industries. The growing demand for sustainable packaging is a major driver of the R-PET market. Consumers are more environmentally conscious, and companies are striving for circular economies. R-PET's ability to slash carbon footprint and reliance on virgin plastic makes it a star in the packaging world. Government regulations that encourage recycling and consumer preference for eco-friendly options further fuel market growth. Beyond packaging, industries like food and beverage, personal care, and household products are using more R-PET as sustainable packaging becomes a key selling point. The rise of R-PET reflects a broader shift towards eco-friendly practices and highlights the importance of recycled materials in creating a more responsible and sustainable future.

0 notes

Text

Toxicity of solid plastics is a popular but false image based on the human need to resist science so that we can believe in the impossible, which goes back to the comforts of infancy when nothing can be explained.

The article mixes up PET and PE and includes a drawing (above) that includes a water/soda bottle, which is made from PET, chemically very different from polyolefins and already valuably recycled. Not irrelevant, as it appeals to people who see lots of plastic bottles and think all plastics are harmful.

The drawing is also misleading as it shows the feed of a complex hydrocarbon which may derive from PE/PP but isn’t our familiar view of long chains. Also, the product is propylene, not propane. Propylene may be worth more than propane and doesn't need added hydrogens. The drawing also shows production of methane, a greenhouse gas that isn't wanted, especially in the air.

The article states that the economics to make propane and sell it are promising, but the authors give neither investment nor operating nor sales/price data. And there’s nothing on energy needs in kilowatt-hours, which may make the process less attractive to many environmental-minded people. You need to break a lot of those strong C-C bonds to break the polymer chain, a basic flaw in much advanced/chemical recycling except some pyrolysis.

Lastly, the article invokes the popular image of plastics in our bodies, ignoring the impossibility of digestion or circulation. Micro-plastic particles are far too big to penetrate the gut wall and then circulate through our network of capillaries. And how much matters, as I often say. Discarded fishnets may be harmful to aquatic creatures, but so is catching fish and eating them.

Yet, many people still want to believe that micro-plastics are inside us to support their need to resist science, which deprives them of the comfort of miracles. They are quick to label plastic as toxic because it is:

unnatural (but earthquakes, rattlesnakes, and viruses are natural);

chemical (but everything is chemical, including water, air, and us);

changeable (but so is weather and our bodies);

synthetic (but so are many medicines and foods);

corporate (but corporations can be creative, and volume and efficiency can keep prices down when responsibly regulated).

What we really fear is ourselves — humanipulation.

It isn't only the unscientific masses who think this way. Our own industry is doing what the public — our customers — wants when it talks about sustainability and circularity, and the politicians correctly see such myth-understanding as doing what the voters want.

Waste is a separate and opposite problem from pollution. Waste is losing good stuff, but pollution is the presence of bad stuff. Our plastics industry can and should reduce its waste. But don’t single out plastics as more wasteful than other materials, and remember that they reduce other waste — food, energy, water — and keep us healthy, as they don’t support bacteria (as wet paper does) and, thus, prevent sickness and help in the cures.

Plastics are relatively harmless but people want them to be bad? Yes, and now maybe you see why.

0 notes

Link

I read the words, “mutant enzyme” in this story and shuddered. Just what we need, another mutant whatever to learn to eat us because we have plastic in us.

Excerpt from this EcoWatch story:

Scientists have engineered a mutant enzyme that converts 90 percent of plastic bottles back to pristine starting materials that can then be used to produce new high-quality bottles in just hours. The discovery could revolutionize the recycling industry, which currently saves about 30 percent of PET plastics from landfills, reported Science Magazine.

Poly(ethylene terephthalate) (PET) is the plastic used in soda bottles, textiles and packaging. With almost 70 million tons manufactured annually worldwide, it is also the most abundant polyester plastic because it is strong and lightweight, explains the study's abstract, which was published in Nature.

Unfortunately, current PET recycling is inefficient. When plastics of different colors are melted down during the recycling process, a gray or black plastic starting material results that few companies want to purchase to package their products, explained Science Magazine. The process results in low-grade plastic fibers only good enough for clothing and carpets, reported The Guardian. These eventually end up in a landfill or incinerated, added Science Magazine.

"It's not really recycling at all," explained professor John McGeehan, the director of the Centre for Enzyme Innovation at the University of Portsmouth, to Science Magazine.

McGeehan, who was not involved in the research, called the new enzyme "a huge step forward," reported Science Magazine. He also noted that Carbios, the French sustainable plastics company behind the breakthrough, is the industry leader in engineering enzymes to break down PET at large scale, reported The Guardian.

The mutant enzyme broke down 90% of 200 grams of PET in a small reactor in just 10 hours. Different colors didn't matter because the enzyme can ignore dyes and other plastics in the molten mix. The researchers were able to use the resultant chemical building blocks to produce new PET and food-grade plastic bottles that were just as strong as those made from virgin plastics, reported Science Magazine.

4K notes

·

View notes

Text

While many of us are eager to recycle the plastic products in our homes, the recycling process in the United States is often confusing and opaque.

New Jersey-based TerraCycle is a recycling company that has partnered with consumer goods brands to make this process easier. But a recent lawsuit—and a settlement this week—shows how many problems exist in the plastic recycling system, and how much work companies still need to do to clean up their practices.In the suit, filed in March, a California-based nonprofit called the Last Beach Cleanup argued that eight consumer goods companies led customers to believe that they could send back plastic packaging and/or single-use products for free to be recycled by TerraCycle. The LBC said this encouraged customers to shop from these brands and use plastic products without worrying about their environmental impact. In reality, however, only a certain number of customers could actually recycle those products for free. Then, customers would either have to pay to recycle the product or throw it away.According to the terms of the settlement announced Monday, the eight companies (Coca-Cola, Procter & Gamble, Late July Snacks, Gerber, L’Oreal, Tom’s of Maine, Clorox, and Materne) will now make it clear on their labels when participation is limited. TerraCycle has also agreed to pay the LBC’s legal fees and implement a supply chain certification program to give customers more confidence about how their products are recycled.

MISLEADING CLAIMS Tom Szaky founded TerraCycle two decades ago as a way to fill the gaps in the U.S.’s broken recycling system. Municipal curbside recycling programs accept only some forms of plastic, like PET bottles and takeout containers. They aren’t equipped to handle more complex plastic products, like makeup packaging or baby food packets, which are often made from several different materials.TerraCycle partners with dozens of companies—including the eight in the lawsuit—that pay TerraCycle to collect packaging from consumers and then recycle it. These sponsored recycled programs are by far TerraCycle’s largest source of revenue, generating $10.5 million for the company in 2020. However, these brands set aside a limited amount of money to pay for the recycling, which means that in some cases, when demand is high, they run out of money to continue operating the program.

“In some cases, the programs are so popular that the budget hits a limit,” Szaky explains. “So we limit the number of participating locations that can take part.” Fast Company reached out to all eight consumer companies for comment, but none responded by the time of publication. Szaky declined to provide specifics on what these companies’ budgets were.

Jan Dell, founder of the Last Beach Cleanup, ran into these limits. She started collecting her plastic waste—like toothpaste tubes, makeup containers, and plastic cleaning bottles. But when it came time to send them in to TerraCycle, she discovered that the recycling program was closed to new participants. When she went online, she found people on Reddit in the same situation. She would either have to throw out all the plastic she’d accumulated or pay for one of TerraCycle’s “Zero Waste” boxes—which can cost consumers anywhere from $42 to more than $100—to collect and send in her recyclables. (These boxes are TerraCycle’s second-largest source of revenue, generating $7.5 million in 2020.)

To Dell, this was a big problem because she believed consumers like her were being misled. Consumers might choose a particular product believing that it would be properly recycled for free; if they had known the program was so limited, they may not have made the purchase. It also seemed problematic that brands were able to have the sheen of sustainability by advertising their recycling program, when in fact only a portion of their packaging would be recycled. “Brands were telling the world that all these products could be sent back to be recycled for free, but there were actually limits,” she says. “It was clear to me that this could not be legal.” (Neither the LBC nor TerraCycle specified how many customers were turned away from these programs.)The LBC worked with Lexington Law Group to file the suit against TerraCycle, asking for its labels to be corrected to make it clear that participation is limited. Per the terms of the settlement, brands must say on their packaging that there may be some limits to the TerraCycle recycling program. Szaky points out that there are many companies that have never hit their budget limit. Out of the 15 companies that offer pet food recycling programs, for instance, only two have limits.

When it comes to the required supply chain certification program, Szaky says TerraCycle was already working on an audit of its third-party recyclers. He says the company will share it publicly as soon as the audit is completed next year. “I want to be clear that we began doing this audit before the lawsuit even came up,” he says. “This was something we were already working on.”THE BROADER RECYCLING PROBLEM While TerraCycle and these eight companies are the latest to come under fire for deceptive practices, they are far from the only companies accused of misleading customers about recycling.In December 2020, Greenpeace sued Walmart for falsely labeling items as recyclable. It claimed that several plastic products, like applesauce and yogurt cups, can be recycled only in certain areas. The court dismissed the suit, saying that Walmart was not deliberately misleading in its labeling practices, and the judge has given Greenpeace the opportunity to file a new, amended complaint. In 2018, Keurig faced a class-action lawsuit for making false claims about its coffee pods’ recyclability. While the pods are made from recyclable plastic, most municipal recycling facilities aren’t able to process such small pieces of plastic, meaning they��re actually not recyclable to many consumers. The case is still in court.

Meanwhile, there’s increasing evidence that a lot of plastic that people put in their curbside recycling bins ends up in landfills. For years, the U.S. sent enormous quantities of plastic to China to be recycled, but in 2018, the country said it would no longer accept the plastic. Extensive reporting from NPR and PBS has found that in many parts of the U.S., municipalities end up dumping this plastic into landfills. Since plastic doesn’t biodegrade, it will break into smaller and smaller fragments that may eventually end up in the food chain, potentially poisoning animals and humans.Dell believes this sets up a situation in which consumers think they can continue using and recycling plastic with abandon, when it fact their plastic consumption is actively harming the planet. She advocates for companies to redesign packaging to use biodegradable, nonplastic materials or to use packaging that can easily be recycled in municipal recycling facilities.Szaky also believes that the recycling system is broken. He says this is why TerraCycle is currently directing its profits toward Loop, a new division of the company founded in 2019, which helps companies move away from single-use plastic to reusable bottles. It has created durable containers for dozens of brands, including Clorox, Häagen-Dazs, and Seventh Generation, which consumers can send back to the retailers to be refilled. The program is already up and running in the U.K., France, and Japan, and it’s planned to roll out in the U.S. in the coming months.

In other words, even though TerraCycle’s business model now depends on recycling, Szaky believes reuse is the way forward. “Recycling—whether through TerraCycle or through municipal recycling—is only a Band-Aid,” he says. “We believe reuse is the right answer and we’re continuing to pour all our profits into making Loop work. And frankly, if Loop really takes off, it will actually cannibalize our other business, kind of like Netflix’s streaming killed off their DVD business. That will be a good thing.”

[ source- https://www.fastcompany.com/90697087/recycling-in-the-u-s-is-an-absolute-mess-this-lawsuit-shows-just-how-hard-it-is?partner=feedburner&utm_source=feedburner&utm_medium=feed&utm_campaign=feedburner+fastcompany&utm_content=feedburner&cid=eem524:524:s00:11/16/2021_fc&utm_source=newsletter&utm_medium=Compass&utm_campaign=eem524:524:s00:11/16/2021_fc

5 notes

·

View notes

Text

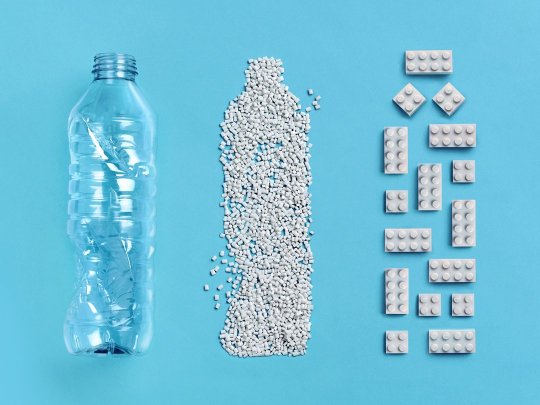

The obstacle course to 'green' Lego blocks

Lego has made a block out of recycled PET for the first time. A new step in the complex search for more sustainable variants of his iconic plastic toys, involving universities and companies such as Avantium[1], Indaver[2] and Ineos[3]. PET (Polyethylene terephthalate) is a type of plastic that is typically used to make soft drink bottles. “Through recycling, we can now make about eight classic Lego blocks from one such discarded bottle,” says Tim Brooks, sustainability director at the Danish company, as he shows a gray prototype. “It is the first time that we use PET as a raw material.”

Founded in 1916, Lego switched from wood to plastic to make toys in 1947. In 1958 it patented its typical building block: round studs at the top and hollow at the bottom. It conquered the world. The formula for success? Nearly indestructible blocks, with dimensions accurate to the hundredth of a millimeter so that all pieces from each set, from the 1970s to the present, click perfectly together and can be taken apart again. Time after time.

The essence

Lego makes 3,500 types of building elements, all of which it sells nearly 100 billion units a year. It uses 20 types of plastic for this, but 80 percent is made from the ultra-strong petroleum derivative ABS[4]. By 2030, Lego wants to switch completely to sustainable materials: recycled plastic or bioplastic. Lego is the largest toy manufacturer in Europe. In 2020, the company posted a turnover of 5.9 billion euros (+13 percent) and a net profit of 1.3 billion euros (+19 percent).

Half a billion

Technically ideal, but in times of growing environmental awareness and the pursuit of CO2 neutrality, this is by no means the way forward. It takes 2 kilograms of petroleum to make 1 kilogram of ABS. Not ideal for the reputation of a company that focuses on future generations. In interviews, CEO Niels Christiansen repeatedly said that he receives letters from young Lego fans who are concerned about the climate. So Lego announced a strategic shift in 2015: by 2030, the company only wants to use 'sustainable' raw materials for its toys. Do not read: no more plastic, but read: greener plastic. “There are two ways to do that,” Brooks says. “Or with more sustainable raw materials. So no plastics based on petroleum derivatives, but based on biological materials, such as plants, algae or even coffee residue. Or by recycling plastic. I estimate that will be the most important part.”

To make the change, Lego set up a Sustainable Materials Center in its Danish home base Billund, which now employs about 150 people. Since 2015, nearly half a billion euros in investments in research and development have been announced. “We do a lot ourselves. For the recycled PET, we ourselves looked for additional ingredients in the process. But of course we also work together with universities and a few dozen companies.”

Antwerp

There is ABSolutely Circular[5], for example, a European research project of chemical company Ineos - an important supplier of Lego anyway - and the Flemish environmental technology company Indaver for recycled ABS. In mid-July 2021 the first 10 kilograms of this were made at Ineos in Cologne. In a next step, there will be a small production in Antwerp, with a Lego block as a pilot product. Another example: Lego, together with the detergent manufacturer Henkel and the beer brewer Carlsberg, joined PEFerence[6], a project led by the Brussels-listed green chemical company Avantium to develop biological plastics. Partnerships are also underway with consumer goods groups Danone, L'Oréal and Bic and tire manufacturer Michelin. This is gradually producing the first results. In 2018, Lego presented a first small collection made of polyethylene based on sugar cane. It was a set of trees, plants and dragon wings. “These are more flexible elements,” explains Brooks, 'because it is a softer material that is not suitable for the hard blocks.'

The sugar cane cubes were an important milestone, but hardly the major turnaround. The material is suitable for barely 2 percent of the supply. But now there is a prototype made from recycled PET, which could possibly be used on a larger scale. Brooks doesn't want to put a number on that. “As much as possible, of course. But we still need to take steps to increase production. We hope to have the material effectively on the market in 18 to 24 months.”

Sweat

“The cover is very complex,” he explains. “Whoever makes children's toys cannot compromise on quality or safety. We go far into that. We test whether our blocks are resistant to sweat or saliva.” Lego simulates in tests the effect of biting with a force of 22.5 kilograms on a block. And whether nothing breaks off the block if it is crushed under a metal disc. "It shouldn't scratch or change shape or color if left in the sun for a long time." The challenge is then that the 'green' blocks have the same color and shine, even make the same sound. And above all: with the perfect coupling. “Our company is literally built on blocks that stick together and at the same time are easy to disassemble. That requires material with extreme precision. We have been perfecting ABS for fifty years. We are not there yet with the alternatives.” All kinds of problems arise in the experiments: the blocks shrink during production.

Source

STEPHANIE DE SMEDT, De Tijd, 23 juni 2021 https://www.tijd.be/de-tijd-vooruit/innovatie/het-hindernissenparcours-naar-groene-lego-blokjes/10315509.html

[1] https://www.brightlands.com/brightlands-chemelot-campus/companies-institutes/companies/company/avantium Avantium is a pioneer in the emerging industry of renewable and sustainable chemistry. [2] https://www.indaver.com/be-en/home/ Indaver – a European player with facilities and operations in Belgium, the Netherlands, Germany and Ireland – manages and treats industrial and household waste in specialist facilities for businesses, waste collectors and governments. It recovers valuable raw materials from this waste that can replace primary raw materials. [3] https://www.ineos.com/ INEOS is a global chemical company. Its products touch every aspect of modern day life. It comprises 36 businesses with 194 sites in 29 countries throughout the world. [4] Acrylonitrile butadiene styrene (ABS) is a common thermoplastic polymer. ABS provides favorable mechanical properties such as impact resistance, toughness, and rigidity when compared with other common polymers. [5] https://absolutely-circular.com/ The project, called LIFE ABSolutely Circular aims at demonstrating the environmental and economic benefits of using advanced recycling technologies to close the loop of plastic recycling. An initial key objective of the project is to demonstrate for the first time the production of ABS based on recycled feedstock taking advantage of advanced recycling technologies. [6] https://peference.eu/ PEFerence will establish a unique, industrial scale, cost-effective biorefinery flagship plant producing FDCA (furan dicarboxylic acid), a bio-based building block to produce high value products. Bio-based FDCA can be used to make a wide range of chemicals and polymers such as polyesters, polyamides, coating resins and plasticizers and, crucially, can also be used to make PEF (polyethylene furanoate), a 100 % bio-based polyester used to make bottles, films and fibres.

2 notes

·

View notes

Text

Self Tober Prompt 25

Bowtie

Grillby/Reader

Who else could I have written about?

You would be lying if you said you didn’t like a well-dressed man. There was just something about well-tailored outfits that just made you swoon a bit when you saw them. Even better? When those well-dressed men got comfortable, pushing their sleeves to their elbow, loosening their tie, unbuttoning their shirt? Perfection.

But, you were totally not undressing your boss with your eyes. You were not imagining slowly loosening his bowtie and slipping it from his neck.

Not at all.

You were cleaning tables, taking orders, joking and laughing with the mix of monster and human patrons, and stoutly avoiding Sans. The little skeleton gremlin would be able to instantly know what you were thinking if he hadn’t already figured it out. Sans was very perspective.

A series of excited howls drew your attention away from the table you were cleaning up to see the wolf pack piling into the bar for their nightly game of poker. You smiled and greeted them all with pets and praise and instantly reciting their order, constantly moving so that Doggo could see you. With a slight deviation to their normal order, you picked up your tray full of dirty dishes and headed over to the bar.

“…normal order?” Grillby asked, placing a freshly cleaned glass down in its spot and shifting it so it perfectly lined up with the others.

“Almost, Doggo would like a double order of fries instead of the burg, and Dogamy and Dogressa are starting them off early with their usual rounds of drinks,” you said, slipping behind the counter with the tray of dirty dishes. Grillby took the tray from you easily, and gestured towards the wall of alcohol before disappearing into the fire exit. It was a pun, mainly, because you had entered behind there a lot of times and it was just the back room for cooking and storage. Nothing fancy.

When you had asked about it, Grillby told you in the Underground they had less rules about what was required in having a business. That back room literally couldn’t be accessed by anyone other than him because it was on fire. Magical fire that didn’t spread, but fire nonetheless.

You were glad there were codes against that, or you probably wouldn’t have gotten a job.

You didn’t linger long staring after him, moving to do your job. It had once been incredibly hard for you to remember the different drink mixtures, but now it was like second nature. Especially the drinks you made day in and day out. Sans watched you, sipping on his ketchup, without comment. You didn’t offer any commentary either as you placed the four drinks on the tray and headed back over to the dog monsters.

The rest of the night passed by with no incidents and, as always, Ugly Fish and Red Bird were the final monsters to stumble their way out of the bar. Red Bird throwing compliments and flirts at Grillby the entire way out. You weren’t sure whether or not Grillby appreciated them, as he wasn’t very expressive. Or…maybe he was? You only saw him at work, after all.

You locked the door behind them, switching the sign to off, closed the blinds, and turned around to smile at Grillby. He returned it with what you assumed was his smile before the two of you quietly finished cleaning the bar up.

As you moped, Grillby counted the till, slipping what needed to go to the bank into an envelope and into his pocket before working on splitting up the tips. At your previous waitressing gig, you had a feeling that your boss had been siphoning some of the tips into his own pocket, but with Grillby? Some nights you had to fight with him because you swore he gave you some of his tips as well.

You tucked away the mop and headed over to the jukebox in the corner to turn it off, pausing beside it as it switched to a song you recognized. Just for a moment before you hit the power button and the lights blinked off.

Grillby had already headed into the back so you made sure everything was away properly before following him.

It was the end of the week, which meant bank night. Normally, you were the first to leave so you never saw Grillby in anything besides his work outfit. It was a slow night tonight, so everything had gotten finished early so he hadn’t sent you home early.

He had taken off his apron and hung it up on the peg next to the door, which was normal, but what wasn’t normal? He pulled on a leather jacket over top of his work uniform, and was currently in the process of untying his bow tie.

Oh no.

Your weakness.

You had to firmly remind yourself that he was your boss and therefore those thoughts were off limits! You turned your gaze away immediately as you headed over to stand beside him. You hung your apron up, and slipped your own jacket over your shoulders and then pulled on your toque.

Grillby wasn’t a vocal monster, so you weren’t surprised when he simply gestured towards the door after opening it. You nodded your head and slipped out into the chilly air. It was just after Halloween and there was already snow falling. That wasn’t unusual to this part of the world, but you still glared up at the sky as the puffy white flakes drifted down. You’d hoped that the snow would have stayed behind the clouds until you got back to your apartment.

“…see you tomorrow,” Grillby said, interrupting your glaring. You turned to face him, watching the snow melt and evaporate well before it touched his flames.

“I’m off tomorrow, remember,” you said, stepping a bit closer to him and his warmth when a blast of icy wind managed to worm it’s way up your jacket. You should’ve worn your winter jacket but you weren’t ready to give up on fall yet! “My parents are coming to town to visit.”

“…right,” he said with a faint nod. Another gust of wind, and he gestured towards the street, “…would you like me to walk you to your car?”

That surprised you. A break from the script?

“I…uh, don’t drive,” you said giving him a smile, “Thanks for the offer though.”

“…you don’t drive?” he said slowly, some sparks flying from the top of his head.

“Don’t have car, it’s more expensive to drive than to walk,” you explained, stuffing your hands into your pockets, “I’ll see you in a couple days.”

You turned, but his hand gently touched your elbow, “…I can walk you home.”

“What?” you blurted out in surprise, twisting to look at him. There was a shift of his flames and you swore that they shifted to blue for a moment.

“…it’s cold,” he gestured to the air, “…and it’s three in the morning.”

“Exactly, so you should drop the money off at the bank and get back to your place,” you said waving your hands in a dismissive way, “Does the cold not bother you?”

He shook his head, “…my flames just get warmer in response…which way is your apartment?”

You gestured down the street, “four blocks or so that way.”

“…that’s on the way to the bank,” he said, there was a hesitation in his voice. “…I can walk you…if you’d like.”

A pause.

“Sure,” you relented, it was just a friendly suggestion. Besides, you’d much prefer walking with someone this early in the morning. Especially if said someone let off a wonderful heat that chased away a majority of your chill.

Walking you home became a daily thing after that, and soon he stopped asking if you’d like to be walked home. It was just expected. As the nights got colder, you bundled up more, and on the coldest of nights he traded the leather jacket for a black pea coat.

You got comfortable enough with him to compliment the pea coat and told him that he had impeccable fashion sense.

“…really?” he said, glancing down at himself, “…Sans says I look old fashioned.”

You blushed lightly, tugging your scarf up slightly, “I mean, you do…but that’s not a bad thing? I like that style. Especially the bow tie. It…really suits you.”

After that conversation, you noticed subtle changes to Grillby’s wardrobe. If you thought he was trying before to look good, you were wrong. This was him trying. You were impressed.

Still, you just thought that your compliment merely spurred him into accepting his sense of style more. It was Sans who set you straight on that aspect.

Grillby went into the back to prepare some orders and you were manning the bar. You handed Sans a fresh bottle of ketchup and tucked the other aside to be cleaned up and recycled.

“grillbz has been changing up his look lately, know anything about that?” Sans asked, leaning against the counter top and inclining the bottle of ketchup towards you.

“Not really, I told him that the old fashion look suits him. Might’ve been a little boost to his confidence?” you shrugged a shoulder, “He hasn’t mentioned anything to me about it, though.”

“so him wearing a bowtie that happens to match the colour of your shirt has nothing to do with you?” Sans asked, a shit eating grin on his face.

You frowned slightly, “What? He’s not-“

The fire exit door opened and Grillby swept past the bar to deliver the cooked food to some of the regulars. You glanced down at your button up, it was a deep purple and when you looked back up at Grillby, so was his tie. You blushed, and quickly spun around to organize some of the bottles on the wall.

“That’s just a coincidence,” you hissed to Sans after your face had calmed down, peeking over at Grillby as he spoke quietly with the dogs at the poker table.

“was he wearing a tie when you started?” he asked, his grin twitching upward again. You paused and then shook your head. “hehe…and I thought I was a numbskull.”

“He wouldn’t have time to do that, and I wasn’t paying attention to his-“

“ya can’t lie to me kid,” Sans pointed out, turning around and leaning back against the bar to look at Grillby. “plus, grillbz’ lives above the bar in the studio.”

That made you freeze slightly, watching Grillby as he left the dogs to check up on the other patrons and then started making his way back to the bar. You glared at the back of Sans’ skull lightly. You didn’t need to be thinking that way about your boss, you would’ve been much more content in your ignorance.

Actually, you wouldn’t have.

You had a huge crush on Grillby and had for a while. The fact that he was matching his bow tie to your shirt colour was adorable. But…you didn’t really trust Sans. It could’ve totally been a coincidence! So, the next day you made sure to note if Grillby was wearing a bowtie, he was, and you relaxed when you noticed it wasn’t the same colour as your shirt. But then you felt bad. You had been happy at the thought that…well, it didn’t matter anymore.

Yet, at the end of the day you noticed the subtle shift of colour to his bowtie. It matched your shirt.

When you had started, he simply told you that the work uniform was dress pants, shoes, shirt and a black vest. The button up shirt could be any colour that you wanted.

The next day, just to make sure that it hadn’t been a fluke, you set up a stupid little test. You brought an extra button up shirt of a different colour and during your break you changed it. Explaining to Sans when he asked that you had spilt some sauce on your sleeve. A few minutes after that Grillby had come back into the room with a different coloured bowtie.

Sans snickered, and you blushed.

That night, as you were pulling on your jacket. Grillby moved to hand you your ‘soiled’ button up and paused, looking at the sleeve. You noticed him subtly check the other sleeve before you zipped up your jacket and turned to him.

“...” he stared at you for a moment before his flames shifted colour, sparking a bit with blue.

“Yes?” you asked, tilting your head slightly, and taking your shirt from him and tucking it away in your bag.

“…I thought you said it was…dirtied?” he asked quietly.

“I may have lied?” you said, peering up at him shyly, “Because I wanted to test a theory.”

“……..oh?”

He shifted slightly, almost as if he was trying to hide his bowtie that he hadn’t taken off yet.

You hesitated before reaching up and adjusting his jacket lapels so that the bowtie was more visible. His flames brightened slightly, and you dropped your hands. “…I can explain…”

You paused, did…he think you were mad? You tilted your head and waited quietly.

“…”

He sighed, a few sparks escaping his mouth, “…I…was…flattered by your compliment.”

“Which one?”

“…about the bowtie…”

“Oh.”

“…I am realizing that it might be weird as your boss,” he said, flushing even bluer. “I apologize. I’ll stop.”

“It’s fine,” you blurted out, and then added without thinking, “I think it’s cute.” You flushed and covered your face, “that was inappropriate! I’m so sorry-“

“Cute?” Grillby said, flames growing larger.

“Uh…yeah…cute,” you mumbled, “ANYWAYS! Time to go home!”

“…I find you cute as well,” he said quickly making you blush even more. If that was even possible.

“What?” you blurted out, “How?”

“Why…wouldn’t I?” he said, hesitantly placing his hands on his hips, “…it is…inappropriate as your boss…”

“Can we…walk?” you suggested quietly, gesturing towards the door. He opened the door and the two of you stepped out into the snow. “I’m attracted to you, I’ll admit,” you said, burying your face into your scarf, “and it won’t affect my work ethic because I’ve been attracted to you since I started.”

His flames grew a bit more wild, “…I am attracted to you as well…”

“But you are my boss,” you reminded him gently, and he nodded.

The two of you were silent as you walked, you stopped by the entrance to your apartment complex.

“So…do we just continue on like…nothing happened?” you asked quietly.

“…do you wish to?”

You stared up at him. Did you? Not at all.

“No…”

The two of you stared at each other for a moment, before he slowly reached up and brushed his fingers against your cheek. “…then would you care to come early to work tomorrow?”

“Why?” you said, leaning into his touch.

“…for a date.”

You blushed, “Only if you wear your red bowtie.”

He blinked his golden eyes at you, before his mouth split open in a grin. “…for you, yes.”

#grillby#grillby x reader#grillby/reader#fanfiction#fanfic#myfanfics#my fanfics#undertale fanfiction#selftober#self insert#reader insert

31 notes

·

View notes

Photo

(via The case of the vanishing gecko | The Daniel Island News)

“On Sept. 10, Bill’s big adventure began, as he escaped while sequestered during a cage cleaning. The students were heartbroken and Ms. White desperately searched every nook and cranny in the classroom, cleaning out cabinets and closets. Students monitored three hours of the hallway security camera footage to catch a glimpse of his escape…no Bill to be seen.

“I decided to use it as a teachable moment,” White said. “We have been learning about the engineering design process in class, so I decided to make this a real world problem solving activity.”

By activating the STEAM (science, technology, engineering, art, mathematics) principles that the school infuses into it’s curriculum, she challenged the students to design and create prototypes of “gecko traps” using materials like Styrofoam trays, cardboard boxes, straws, tape, plastic containers and bottles, different-sized lids, and anything else in the classroom recycled collection.

The students worked in small groups and began creating their traps using STEAM skills. They thought about ways to design a container that would allow Bill to enter in without escaping again. They also considered his personality and wanted to create an environment with areas where he could hide and feel comfortable.

Student Jaydon Camp explained his group’s design process: “We were using STEM skills like engineers, so we drew a sketch, built the trap, tested it, and then put it in a place where we thought we could catch the gecko.”

“A couple of days before he escaped, we learned about the engineering design process, where you talk about your ideas, make a sketch, use provided materials, and then you make it,” added teammate Jasper Seig.

Reagan Williams, another student in the class, said that creating an inviting space was a key factor.

“We had to make sure the environment was right for him and the trap didn’t have openings where he could crawl back out.”

The traps were constructed and put into place on Thursday afternoon.

“I put mealworms in every single trap and went home thinking, it would be really cool if this works, but he is gone,” said White. “At least we tried, and every student helped.

”When Friday morning arrived, Ms. White checked the traps…and Bill was back! Ava Wolf, Olivia Cole, and Nevaeh Newingham designed the winning trap -- dark, cave-like, and stocked with food, all of which Bill found irresistible. The trap was made from a shallow pizza box with a cardboard ramp leading in, Styrofoam walls to prevent an escape, and a juice lid chute on the top that allowed the girls to drop mealworms into a feeding dish. The team sketched their design but made revisions based on research about geckos and their ability to jump. They secured the pizza box so it would remain closed and narrow to prevent a second escape. The class was ecstatic that they devised a successful solution as a team and kept their pet out of harm’s way.“

15 notes

·

View notes

Text

Gideros change color of sprite

She’s also on a mission to combat harmful stereotypes that plague the massage industry. In response, Fleming launched the ethics course, “Safety & Solicitation: Gaslighting and Power Dynamics” to help other therapists recognize threatening behavior from clients. I wasn't sure if it was worth it, but I stuck it out, “ says Fleming. So I really contemplated just leaving the industry all together between the vulgar messages and then trying to navigate that. “At that point I now had to process this traumatic experience while also navigating a brand new industry that put me alone in a dark room with strangers. What she didn’t expect was sexual harassment, which she says began almost instantly. Priscilla Fleming became a licensed massage therapist in 2019 to help people. Why 'Late Night with Seth Meyers' Is Canceled for Rest of the WeekĬandace Cameron Bure Explains What Happened Between Her and Jojo Siwa While the appearance of Sprite is getting a revamp, rest assured that the drink itself will maintain the same crisp flavor everybody knows and loves-with the added value of (one small step towards) saving the planet.Ĭhris Rock Finally Responds To Infamous Will Smith Oscars Slap But don't worry, the recognizable shade of green will still be incorporated. Sprite's wrap and logo will also receive a makeover, as the company aims to make the design more uniform worldwide to create a more cohesive branding moment. Coke projects that these changes will reduce roughly 20 million pounds of new plastic waste. While Sprite is the first to get a makeover, Fresca, Seagram's, and Mello Yello will follow suit in the coming months. Notably, Sprite is not the only green bottle in the brand's lineup. According to Julian Ochoa, CEO of R3CYCLE, which is assisting Coca-Cola with its recycling initiatives, "When recycled, clear PET Sprite bottles can be remade into bottles, helping drive a circular economy for plastic," as reported by CNN.

0 notes

Text

Sustainability in the Fashion Industry

Sustainability: focuses on meeting the needs of the present without compromising the ability of future generations to meet their needs.

Sustainability is one of the key topics which is being faced in the fashion industry, as fast fashion is at an all time high, as well as the consumers needs to keep up to date with the latest trends in this throw away society. The fashion industry is the 2nd largest polluter in the world, the first being the oil industry.

Sustainability is something that should be thought about at every stage of the production process, from where the materials are sourced (are they organic?) to the transportation of them to the shops (air pollution from lorries/planes etc.) A way that with could be done is by having transparency within the brand/ supply chain. By having transparency and showing where all elements are made/ bought it means that there is more trust between the company and the consumer. Another way of gaining trust is if the brand has official certification that shows the status of the quality of the material, e.g. to prove that a garment is made of 100% organic cotton.

There are many reasons why some brands are finding it hard to make sustainable changes/ doing more;

- trying to find a solution to the issue is far too complex and there is no single solution.

- some solutions just create more issues, e.g. people thought that faux fur was a better alternative than real fur, however, faux fur is made out of acrylic, a plastic that does not decompose naturally unlike real fur. This makes it worse for the environment.