#piston check valve

Explore tagged Tumblr posts

Text

EWOM is a Chinese Top Valves manufacturer in 2009, exported to 84 countries worldwide They are committed to providing high-quality products Best Stainless Steel ,Metal Seated Ball Valve or Api 600 Gate Valve provider technical support and deliver the best results for our clients through our Quality remarkable valve is designed to provide optimal performance and efficiency for a wide range of Management System.

#gate valve manufacturers china#wafer check valve#cast steel gate valve#check valve china#swing check valve china#gate valve china#api 600 gate valve#forged steel gate valve#cast steel globe valve#forged steel globe valve#piston check valve#Double block and bleed valve#ball valve china#floating ball valve#fully welded ball valve#stainless steel ball valve#metal seated ball valve#flanged ball valve#top entry ball valve#trunnion mounted ball valve

0 notes

Text

Piston Check Valves

A Piston Check Valve is a crucial component in many industrial systems where maintaining one-directional flow of fluids is essential. Unlike traditional swing or lift check valves, This valves utilize a piston mechanism to ensure that fluid flows in only one direction. This valve’s design not only ensures safety but also enhances the performance and efficiency of various processes in industries like oil and gas, petrochemical, power plants, and water treatment.

The Working Principle

The working principle behind the this valve is simple yet effective. It uses a piston that moves in response to the pressure differential between the upstream and downstream sides of the valve. When fluid flows in the desired direction, the piston is pushed open, allowing the fluid to pass. However, if the fluid begins to reverse flow, the piston automatically moves to block the flow, creating a tight seal and preventing any backflow.

This mechanism ensures that there is no leakage and no flow in the reverse direction, which could otherwise cause damage to equipment, contamination, or even dangerous system failures. The valve’s ability to respond quickly to changes in pressure ensures a continuous and controlled flow of fluid, protecting upstream systems and equipment.

Key Components of a Piston Check Valve

Piston: The core component of the valve, responsible for creating the seal when reverse flow is detected. It is typically made of durable materials like stainless steel, ensuring resistance to wear and tear.

Valve Body: The housing that contains the piston mechanism and provides structural integrity to the valve. It is usually made from high-strength materials like carbon steel or alloy steel, which are ideal for withstanding high-pressure conditions.

Seat: The surface against which the piston seals to prevent backflow. It is carefully designed to create a tight, leak-proof seal during reverse flow.

Spring (Optional): They are equipped with a spring that assists in pushing the piston back to its closed position when the flow pressure drops.

Benefits

Prevention of Backflow: The most important function of this valve is preventing backflow, which can lead to system damage, contamination, or even operational shutdowns. This valve ensures fluid flows in one direction only, providing peace of mind in critical applications.

Improved Performance: By preventing reverse flow, this valves maintain the efficiency of your system. They reduce the risk of contamination, corrosion, or damage to the piping and downstream equipment, ensuring the system runs smoothly.

Durability and Reliability: Due to their robust construction and advanced sealing capabilities, this valves offer superior reliability in high-pressure and high-temperature environments. This durability translates to longer service life and less frequent maintenance.

Minimal Leakage: They offers minimal leakage compared to other types of check valves. With an effective sealing mechanism, it ensures that the fluid stays within the intended path and prevents costly and harmful leaks.

Compact Design: Despite their superior functionality, they are typically compact, making them ideal for installations where space is limited. Their size allows for easier integration into various systems, without compromising their performance.

Applications

They are widely used in industries that require the prevention of backflow and the maintenance of efficient fluid flow. Some of the common applications include:

Oil and Gas: They protect pipeline systems from reverse flow and prevent contamination, ensuring the safe transportation of oil and gas.

Power Plants: These valves help maintain the integrity of steam and water lines, preventing the reverse flow of high-pressure steam or water.

Water Treatment: In water and wastewater treatment plants, they prevent the backflow of treated water or chemicals, ensuring proper water quality.

Pharmaceuticals: In clean systems, such as those used for water for injection (WFI), they prevent contamination by keeping the flow in one direction.

Conclusion

It is an essential component for many industries where the control of fluid flow is critical. Its simple yet effective design, combined with its durability and efficiency, ensures that it performs reliably in even the most demanding conditions. Whether it’s preventing backflow in pipeline systems, protecting equipment, or maintaining system integrity, they proves to be an indispensable tool in maintaining the safety and efficiency of industrial operations.

By choosing high-quality Piston Check valves from reliable manufacturers like Freture Techno Pvt. Ltd., industries can be assured of optimum performance and long-term reliability, making them an ideal solution for various industrial fluid control needs.

#check valves#piston check valves#forge piston check valves#stainless steeel piston check valves#freture techno

0 notes

Text

Engines and Affections

Pairing: Poly 141 x Assistant!reader

AU: Mechanic 141

Warning: fluff, the boys are a bit touchy

Authors note: I hope yall enjoy, it’s not poly until about half way through. I had to change a lot of this because it was similar to someone’s post that they posted so this is the newer one

Word Count: 2.2k

Masterlist

MDNI18+MDNI18+MDNI18+MDNI18+MDNI18+

The air at Price’s Auto Garage buzzed with the sound of engines and tools, the usual symphony of work that set the place alive each day. Price, Soap, Gaz, and Ghost moved around the garage with quiet confidence, focused on their tasks. They were the best at what they did, hands skilled and practiced, but the front desk? It was a mess. Calls went unanswered, invoices piled up, and the schedule was a puzzle no one had time to piece together. Price finally decided they needed help at the front.

The moment you walked in for the interview, they noticed.

You stood in the doorway, posture relaxed, radiating a confident smile as you scanned the space. Even though garages weren't exactly familiar territory, you weren’t about to let that show. Price gave you a welcoming nod, gesturing you inside, while Soap looked you over with a smirk, already leaning against a toolbox. Gaz offered a warm smile, while Ghost stood off to the side, arms crossed, as unreadable as ever.

Price glanced through your resume with a quick nod, but it was clear they’d made up their minds as soon as you walked in. A few questions later, and the job was yours.

It wasn’t long before you found yourself in the midst of the garage’s organized chaos. The phone rang constantly, schedules made only partial sense, and sometimes, the invoices looked like a language of their own. You tried your best to keep up, but this was a whole new world.

“Ah, I think… these are for you?” You handed Price a stack of papers one morning, hesitating when his eyebrows lifted in surprise.

“Love, these are last week’s invoices.” Price held back a chuckle, his eyes kind even as he gently corrected you. “I’ll show you how we sort ’em out, alright?”

His large hands guided yours through the stacks, showing you the little tricks they used to keep things organized. He took his time, explaining everything patiently, his voice low and calm as he brushed your shoulder every now and then. By the end of it, you had a better grasp—sort of.

Soap, however, took a different approach. Every few hours, he’d call you over, pulling you away from your desk to check out whatever project he was working on.

“Oi, lass, come look at this,” he called out one afternoon, grinning as he waved you over to the car he was working on.

You tried to seem interested, leaning in as he explained the engine in detail, even though the terms were lost on you. Your confidence started slipping as he talked about pistons, valves, and all kinds of parts you’d never heard of, but you nodded along, pretending to understand.

“See this part here?” He pointed, smirking as you leaned in closer, glancing from him to the engine.

“Oh, yeah! The… thing,” you managed, biting back a laugh when he rolled his eyes, grinning even wider.

“You’ve no idea what I’m on about, do ya?” He chuckled, nudging you playfully with his elbow. “Don’t worry, lass, I’ll teach ya everything I know. Might just take a bit.”

Despite your confusion, his excitement was infectious, and you found yourself laughing along, even if you still didn’t understand a word.

Gaz was the one who always made sure you felt comfortable, sensing when you were a bit overwhelmed. Every morning, he’d bring you a coffee, setting it on your desk with a small smile.

“To keep you sharp,” he said with a wink, and you’d thank him, feeling a little less lost in the unfamiliar world of auto repairs.

One afternoon, as you struggled with the printer again, Gaz appeared by your side. He’d noticed your mounting frustration and stepped in without a word, reaching over to press a few buttons with expert ease.

“Here, let me show you.” His hand rested on yours as he guided you through the steps, his voice soft and patient. You felt his presence close beside you, his attention entirely on helping you, and your nerves calmed as you finally figured out the tricky machine.

“You’re getting it,” he said with an approving nod, his fingers brushing yours for a moment longer before he stepped back, a quiet sense of pride in his smile.

Ghost, meanwhile, kept his distance—until you made a mistake too big for him to ignore. One evening, you’d accidentally given the wrong keys to a customer, causing a brief mix-up in the garage. Ghost’s expression was steely as he came over to you, clearly unimpressed.

“These keys belong to the truck in the back,” he said, his tone gruff but calm as he held them out to you.

“Oh, I’m sorry, I just—” You stammered, caught off guard by the intensity in his gaze.

He took a slow breath, running a hand over his face before meeting your eyes again. “Just double-check before you hand ’em out next time, alright?”

You nodded, cheeks flushed, but Ghost’s expression softened almost imperceptibly when he noticed your nervousness. Later, he quietly came over, placing the keys in their correct spots while you watched, making sure you’d gotten it right.

“Just remember,” he said, his voice low, “no rush. Take your time.” And with a small nod, he returned to his work, his rare show of patience lingering with you.

---

One rainy evening, as you prepared to leave, you stood by the door, staring at the downpour. You’d forgotten your jacket, and with the way the rain was coming down, you’d be soaked in minutes.

Ghost was passing by, his eyes flicking between you and the rain outside. He let out a sigh, already pulling out his keys. “Come on. I’ll drive you.”

Surprised, you followed him to his truck, slipping into the passenger seat as he climbed in. The ride was quiet but comfortable, the steady rhythm of the rain filling the silence. His presence was somehow reassuring, and you found yourself relaxing, even sneaking a few glances at him as he drove.

“Thanks for this,” you murmured as he pulled up to your place, his gaze still fixed forward.

He gave a small nod, his voice barely above a whisper. “Just get yourself a jacket next time.” But the corners of his mouth turned up slightly, and you knew he didn’t mind.

After that night, you’d started to find your rhythm in the garage. The guys were quick to help when you needed it, and slowly, you felt like part of the team. The way they each looked out for you in their own way brought you a quiet sense of belonging that you hadn’t expected, making the unfamiliar chaos of the garage feel like somewhere you could finally call home.

——

Over the next few months, the garage became more than just a workplace—it became a second home. The guys were always there, whether to lend a hand, share a laugh, or tease you about some new mistake. You noticed how each of them had their own way of making sure you were taken care of. And somewhere along the way, your small, shared moments with each of them started to feel… different.

Price became more attentive, stopping by your desk to chat with you about your day, his warm gaze lingering a moment too long. Soap’s teasing got softer, almost affectionate, his laughs filled with genuine happiness when he saw you smile. Gaz made a habit of bringing you coffee every morning, but now he’d stay a little longer, brushing your hand as he passed the cup, his gaze lingering on your lips. Even Ghost, usually distant, had become gentler, staying around the garage a little longer just to make sure you got home safe.

The four men started to notice each other’s shifts in behavior too. What was once harmless camaraderie and teamwork started to feel like an unspoken rivalry, each of them vying for more of your attention. Eventually, it reached a tipping point, and one late night at the garage, they decided to address it head-on.

“Alright, lads,” Price began, crossing his arms as he looked at the others. “It’s about her, isn’t it?”

Soap scoffed, trying to brush it off. “You mean the way you get all soft whenever she’s around?” he said, though there was no real bite to his tone.

Gaz chuckled, running a hand over the back of his neck. “We all know it’s not just Price. Let’s be honest with ourselves here.”

Ghost, silent as ever, watched the others, his gaze thoughtful. “You’re not wrong,” he admitted, his voice low but steady. “Guess we’ve all got feelings for her. Question is, what’re we gonna do about it?”

They sat in silence for a moment, each processing the quiet admission that their feelings ran deeper than simple friendship. Price broke the silence, his voice firm yet understanding.

“We’re not just co-workers; we’re a team,” he said. “So, if we’re all on the same page about her, then maybe it’s time we tell her.”

A few days later, the four of them gathered the courage to bring up the subject with you. It was the end of a long workday, and you were about to head home when Price called you over, his tone uncharacteristically serious.

As you walked into the main garage, the four of them stood there, exchanging glances as if silently confirming that this was the right moment. You felt your heart race, sensing that whatever was about to happen was important.

Price cleared his throat, his usual steady demeanor softening as he looked at you. “We, uh… have something we need to talk to you about. All of us.”

Confused, you looked between them, giving a small nod. “Okay, I’m listening.”

They each took turns explaining, their words stumbling a little at first but then gaining confidence as they shared their feelings. Price told you how much he admired your kindness and resilience, how you made the garage feel like home. Soap shared how much he loved making you laugh, how your presence was the highlight of his day. Gaz spoke of his protective instincts, how he felt compelled to make you happy. Even Ghost, usually guarded, admitted in his own quiet way that he’d come to care about you deeply.

It was overwhelming but touching, hearing each of them express feelings that you hadn’t dared to think might be mutual. Finally, Price looked at you, his eyes searching yours with a question that didn’t need words.

“Would you be open to… to something with all of us?” he asked gently.

It took a moment for you to process what they were asking, but as you looked at each of them, you realized that the idea didn’t scare you—in fact, it felt right.

“I… I would be,” you admitted, smiling as their tense expressions melted into ones of relief and happiness.

From that point on, your relationships with them grew deeper and more intimate. You shared quiet mornings with Gaz, who’d bring you coffee and pull you close, his arm around you as you eased into the day together. Soap’s playful teasing turned more flirtatious, his laughter warm as he’d brush your hair back, stealing little kisses when no one was looking. Price had a way of grounding you, his strong arms always there to wrap around you at the end of a long day, pressing soft, lingering kisses to your forehead that made you feel safe. And Ghost, though still reserved, became more open, offering a gentle touch here and there, his presence comforting in a way that words couldn’t quite describe.

One evening, after closing up shop, you found yourself nestled between them on the worn leather couch in the break room. Gaz leaned close, his hand tracing gentle patterns on your back, while Soap’s arm draped across your shoulders, pulling you close as he whispered jokes in your ear, his voice warm and soft. Price sat at your side, his hand resting on your knee, thumb drawing small circles as he met your gaze with a soft smile, his eyes filled with a quiet understanding.

And Ghost, ever the silent observer, brushed a gentle hand over your shoulder, his fingers lingering at your neck. You felt their affection surrounding you, each of them bringing their own unique warmth and comfort, and you knew that this—this closeness, this shared connection—was something rare, something to be cherished.

Over time, your moments together grew more intimate. The nights you spent with them were full of whispered words and gentle touches, each one of them showing their love in their own way. Soap’s playful nature softened, his teasing replaced with gentle affection as he held you close, his laughter quiet as he stroked your hair. Gaz would pull you into his lap, his hands warm against your back as he kissed you deeply, his eyes filled with warmth as he traced his thumb over your cheek. Price, always steady, would hold you close, his presence reassuring as he kissed you with a softness that made you feel cherished, his voice low as he murmured words of love.

And Ghost, though still quieter than the others, would sit beside you, his fingers brushing over yours, his touch reverent as he watched you with a gaze that spoke volumes. When he held you, it was gentle, almost hesitant, as if he couldn’t believe you were there with him.

In these shared moments, you found a kind of love and connection that you’d never known. Together, you formed a bond stronger than any you’d ever imagined, a family bound by love and trust. And in their arms, surrounded by their warmth, you knew you’d found a home, one where you were loved wholly and completely by each of them.

Hope you enjoyed! Please follow, like and Reblog💜 -Midnight’s Cafe

#x reader#141 x reader#tf 141#task force 141#tf 141 x reader#soap x reader#captain john price x reader#gaz x reader#ghost x reader#simon ghost riley x reader#simon ghost riley#simon riley x reader#simon riley x you#simon ghost x reader#john soap mctavish x reader#john price x reader#john soap mactavish#john price#kyle gaz x reader#kyle gaz garrick x reader#kyle gaz garrick#kyle garrick#task force 141 fanfic#tf 141 x you#poly 141 x reader#poly 141#mw2 141#cod 141#soap cod#ghost cod

537 notes

·

View notes

Text

Zora Arkus Duntov saw a huge problem for GM, due to their lack of participation in the Hot Rodding community in the early 50's.

Check out this letter he wrote on the subject:

TO: Mr Maurice Olly, ADDRESS: Research & Development Section

FROM: Mr Z Arkus-Duntov, ADDRESS: Research & Development Section

DATE: December 16, 1953

SUBJECT: Thoughts Pertaining to Youth, Hot Rodders, and Chevrolet

The Hot Rod movement and interest in things connected with hop-up and speed is still growing. As an indication: the publications devoted to hot rodding and hop-upping, of which some half-dozen have a very large circulation and are distributed nationally, did not exist some six years ago.

From cover to cover, they are full of Fords. This is not surprising that the majority of hot rodders are eating, sleeping, and dreaming modified Fords. They know Ford parts from stern to stern better than Ford people themselves.

A young man buying a magazine for the first time immediately becomes introduced to Ford. It is reasonable to assume that when hot rodders or hot rod-influenced persons buy transportation, they buy Fords. As they progress in age and income, they graduate from jalopies to second-hand Fords, then to new Fords.

Should we consider that it would be desirable to make these youths Chevrolet-minded? I think that we are in a position to carry out a successful attempt. However, there are many factors against us:

Loyalty and experience with Ford.

Hop-up industry is geared with Ford.

Law of numbers: thousands are and will be working on Fords for active competition.

Appearance of Ford’s overhead V-8, now one year ahead of us.

When a superior line of GM V-8s appeared, there where remarkably few attempts to develop these, and none too successful. Also, the appearance of the V-8 Chrysler was met with reluctance even though the success of Ardun-Fords conditioned them to the acceptance of Firepower.

This year is the first one in which isolated Chrysler development met with successes. The Bonneville records are divided between Ardun-Fords and Chryslers.

Like all people, hot rodders are attracted by novelty. However, bitter experience has taught them that new development is costly and long, and therefore they are extremely conservative. From my observation, it takes an advanced hot rodder some three years to stumble toward the successful development of a new design. Overhead Fords will be in this stable between 1956 and 1957.

The slide rule potential of our RPO V-8 engine is extremely high, but to let things run their natural course will put us one year behind – and then not too many hot rodders will pick Chevrolet for development. One factor which can largely overcome this handicap would be the availability of ready-engineered parts for higher output.

If the use of the Chevrolet engine would be made easy and the very first attempts would be crowned with success, the appeal of the new RPO V-8 engine will take hold and not have the stigma of expensiveness like the Cadillac or Chrysler, and a swing to Chevrolet may be anticipated. This means the development of a range of special parts – camshafts, valves, springs, manifolds, pistons, and such – should be made available to the public.

To make good in this field, the RPO parts must pertain not only to the engine but to the chassis components as well. In fact, the use of light alloys and brake development, such as composite drums and discs, are already on the agenda of the Research and Development group.

These thoughts are offered for what they are worth: one man’s thinking aloud on the subject.

Signed,

Zora Arkus-Duntov

December 16, 1953

27 notes

·

View notes

Note

OMG I'm such a dumbass I knew you did one on the GR Yaris before too, and I love her ALSO, but I actually meant the GR Supra 😳🫣 (slip of the tongue)

Gotcha.

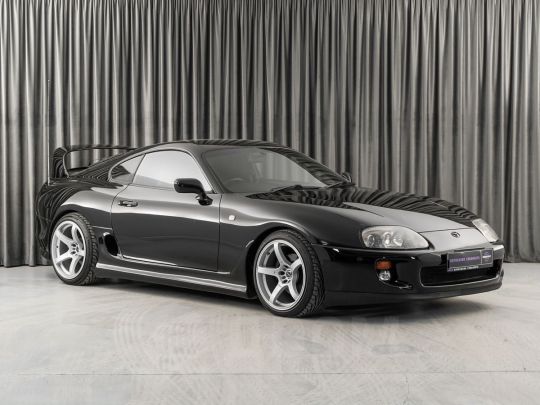

Since I managed to take some two weeks to answer this (got distracted both by real life obligations and other posts that were meant to be very quick to make. Meant to.) y'all may have forgotten, but our dear friend of the blog had asked for opinions on the GR Yaris, hinting to its controversial status. Turns out the GR Supra is what that request, and thus that hint, was actually about - so let's talk about the car and the controversy that engulfs it.

In 1993, Toyota launched the fourth generation of its rear wheel drive sportscar (well, arguably a bit of a Grand Tourer, i.e. something more oriented to cruising than a sportscar) the Supra - which was born a quarter century earlier as a more upmarket, six cylinder version of the Celica, graduating from Celica Supra to its own dignified name with the third generation I talked about that one time I forgot to check what blog I was reblogging with.

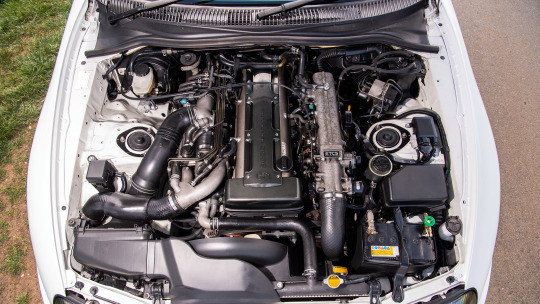

But this time, things would be different. Most notably because the inline six the Mk4 Supra came out with was an absolute MONSTER.

Remember how I talked about the GT-R's RB26 engine being one of the greatest, most coveted production engines to ever come out of Japan? Well, the 2JZ-GTE is the other.

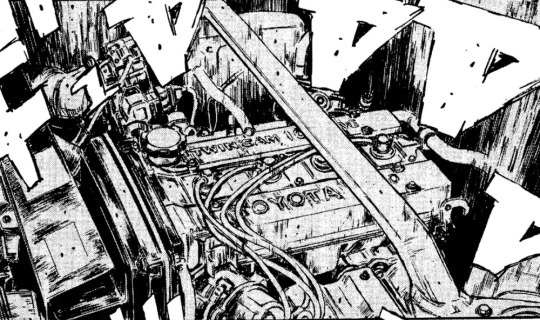

It was larger at 3 liters, no less powerful, and to reduce turbocharger lag it used two of them sequentially: first air goes in the smaller, more responsive turbo, then gradually some of it gets sent to the bigger turbo to make it start spinning, then when it gets going the two are finally used in conjunction. (Imagine the big turbo as a hung husband that takes a while to get it up and the small turbo as an eager stepson ready to take over until the hung one can join in for a spitroast. Or something. I don't watch porn with real people, but from what I gather the plots seem to resemble how sequential turbos work.) It even at one point got Variable Valve Timing, i.e. the ability to vary the time in which the valves open depending on engine speed, which allows to optimize tuning for performance and efficiency! (Cool thing to go over in detail if y'all want me to.) And also, the kind of things that engine is able to take make me wish I hadn't used up my porn analogy quota.

See, to chop off eons of nuance, an engine is just a big block of metal with a lot of bits attached, and the two main measures of an engine's potential are the slope of the line in the Bits Fiddled With / Power Output graph and how far up (It's up, right? The second axis you specify is the vertical one, right?) you can take it before the block becomes the weakest link - with another important point being when you need to start messing with internals, i.e. the components inside the engine, e.g. pistons (the things the boom pushes down), camshaft (the thing the pistons spin) and connecting rods (you can guess).

So for instance, just to make the point that an engine can be beloved without having much overall tuning potential, in one of Toyota's most beloved engines, the 4A-GE four cylinder illustrated above (yes, the one from that white and black car in all the eurobeat videos), some pin the block's limit as low as 250hp. The 2JZ, tho? It can take 800hp without even messing with the internals, and once you get your grubby hands on those you can keep pushing the line to some 2000hp. That is two Bugattis. That is 40 times my car. That is well above the power level where "tires that will at any point grip" and "tires that are in any way road legal" stop intersecting.

I am not in the slightest exaggerating when I say that this and the Skyline GT-R are widely regarded as the top of Japan's 20th century automotive production. The Messi & Ronaldo of the Japanese Domestic Market. It is absolutely no coincidence this was the hero car in The Fast And The Furious.

And then in 2002, as all things, its production ended, and given the abysmal sales and catastrophic recession, Toyota decided that would be that.

And then, years later, The Teasening began.

I want to stress, almost half of my conscious life (I choose to believe the stretch from birth to kindergarten is just run-up) the world was in some state of getting teased with talk of a new Supra. The trademark on the name was renewed in 2010. In 2014 they dropped the FT-1 concept, and of course that became speculation about what the production version would look like.

Because come the fuck on, it's not gonna look like that.

Or was it?

Only five entire years and much more teasing later would we officially get an answer, when after seventeen years, the Toyota GR Supra (and for those wondering what GR means, y'all should've clicked the Yaris link >:C) hit the streets.

You know what, good enough.

Good enough to earn itself a sea of words of praise, Jason Cammisa's "The most punch-above-its-weight sportscar ever made" just some among them.

It did have its share of problems at the start, like its power being 335hp and not 382, a lack of manual transmission, and the inability to spec it with a less powerful 4 cylinder engine - well, I don't know who considered that last one a problem, but Toyota's updates solved that one too.

The Supra has a much bigger problem than those though, one no little update can solve. That red car in the background.

See, the new Supra is actually a joint venture with BMW, who made a new model of its Z4 roadster out of the platform. And unlike with the other joint-venture sportscar Toyota sells, people are big mad about that. Why?

See, the interior is engulfed in BMW switchgear and the drivetrain is all BMW (the manual gearbox took until this year to come out because BMW did not have one for that engine so Toyota had to modify another BMW transmission to fit), giving people the impression that this was less of a joint venture and more of a BMW project that Toyota tacked its design on top of, which is a problem whether true or not.

See, a range-topping sportscar is supposed to represent what the brand is capable of - having it done by someone else (or so the criticism goes) is a bit like performing Hallelujah in playback.

Actually, a better musical analogy: You know "I'm back bitch" singles? When a humongous artist drops a new record with a humongous lead single about absolutely nothing but reaffirming they're the biggest fucking deal in the universe? Without Me, Bad, Gimme More, so on. Well, think of SexyBack - one of the most monumental phenomenons of its decade, most incontrovertibly proving Justin Timberlake sat atop the goddamn world. Now, imagine if, after all the years that went by between that record and the next, when he finally came out with Suit And Tie all the verses were Jay-Z. Going from a humongous statement about having the power to reach the top of the game and stay there to having to get absolutely carried by what in this logic is essentially a competitor. Basically, that's the critics' complaint: the supra went from 2JZ to too much Jay-Z.

And therein lies the other problem of the Supra: the Supra.

See, any time you evaluate something, you do so relative to its context - and when you give it a nameplate, you make that context include where else that nameplate has been. An undeserved name may not just be stupid, but even outright kill the car in some's eyes, see the case of the Dodge Dart, or get me to talk about the Ford Capri prototype recently spotted if you want to find out what I'm like when I lose my cool. (I'd liken this phenomenon to undeserved Grammies but I already used my music analogy quota too.) So the Toyota Supra does not just need to be good, it needs to deserve the name. And some argue it doesn't. But why? This thing is no less powerful, no slower, hell it's not even any bigger or heavier and we've gone over how rare that is these days! So is it the lack of backseats and a targa version? No, no one gives a crap about those. It's something deeper.

Sometimes, the problem with a revival is people base their expectation not on what the original was like in the context of its time but what it's like in the context of today (for example, I've heard people call the latest GT-R "too computerized, too assisted, far from the pure driving experience of its predecessors", when its predecessors had some of the most technologically advanced driving assists of their time and could only be called "pure" and "analog" by comparison with cars decades newer). But of course, that'll only be some people - so if what the original car looks like to modern eyes and what the original car represented at its time are two different enough concepts, any revival will receive some criticism for not being one of the two.

But for the Supra, this compounds with another problem: the original Supra (as in the previous generation, since no one gives a crap about the first three), to modern eyes, looks like a thousand-horsepower flame-spitting beast, because that's what all Supras have been turned into, and that's why you know of Supras in the first place (it sure isn't because people bought it!), and that, consciously or not, exacerbates the problem of misplaced expectations to a level akin to hearing an NBA player is about to have a brother and expecting the baby to be a 6'4" three-shooter.

But I wasn't asked about the controversies, I was asked about my take. And my take is: no realistic expectation of what a Supra would look like today was disappointed - at least not by where the car stands today. Well, unless the expectation involved backseats.

"But it was made by BMW" and so? This is a new Supra, and a good one - what does it matter how it got here? Especially when this is an upgrade over the Z4 in every way - looks way better, drives better, and now has a manual that the Z4 doesn't.

Okay, almost every way: the Supra's roof won't get out of the way. If only though, if only. Could you imagine a Toyota product that looks this good, sounds this good, goes this fast, and has a drop top? ...and maybe backseats?

Well, I can.

Yes, the badge and core concept may have some people consider it from midlife crisis mobile to old man's car. (though we know it's not a car bought by old men because if that was the case someone would be buying these). But just try to imagine sitting in this thing.

Take a couple of seconds to take in that picture and truly immerse yourself. You're in a Lexus LC500 Convertible, with a V8 at your right foot's command, its spectacular sound ready to battle the perfect sound system serenading you with your fanciest CD, because of course Lexuses still come with CD players.

Are you immersed? Okay: Someone just called your Lexus a midlife crisis car. See? You don't give a shit either, do ya.

Automatic only though. The pain. Oh, and it kind of costs as much as two Supras. But, you know, neither of those Supras will be convertibles!

Links in blue are posts of mine about the topic in question - if you liked this post, you might like those!

52 notes

·

View notes

Note

As a Guy who Fixes Machines for a living, but unfortunately doesn't have Much experience with engines, *but* has read a Ton about them: please tell me about steam engines and/or their Repair Quirks and Logistics. Infodump Away :chinhands:

I'm going to be honest with you - this is one of the most flattering asks I've ever received in my 14+ years on this website.

Steam locomotives seem pretty overwhelming at first because, as you'd expect, there's a lot of moving parts, and they're actually huge. Like many large animals, people often don't realize how big they can actually get until they're in the presence of one. The one I drove, Strasburg #90, weighs in at 212,000 lbs - and she's smaller than a lot of the active steam locomotives operating today. 106 tons is nothing to sneeze at, and she's still considered smaller.

You probably don't need this in layman's terms, but I'm going to try to keep the explanations easy to understand in case anyone who doesn't work with machines reads this.

How do the beasts run?

Continuing the metaphor of these things basically being really large animals, you have to feed and water them. Early steam locomotives ran on wood, but as time went on the most common fuels became coal and oil, and today some can even run clean on vegetable oil or torrefied biomass. The fact that they need to be fed and watered fairly regularly is why there's always at least two people in the locomotive cab - you've got an engineer driving and a fireman keeping the beast fed and monitoring the water levels in the boiler.

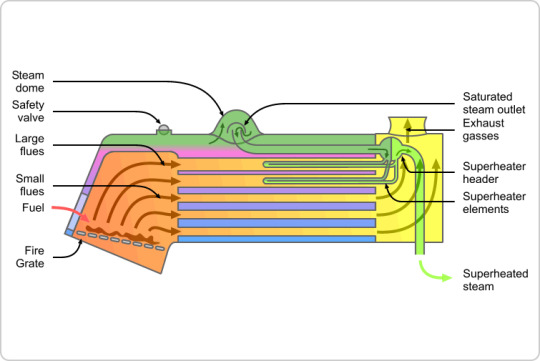

This is a diagram of a fire tube boiler from Wikipedia. Steam locomotives generally use this type of boiler, which gives them their familiar shape. The fuel is thrown into the firebox on the left of the diagram, and the heat from the fire flows up to the tubes in the boiler. The water in the boiler becomes steam (specifically what's called "wet steam" because it's saturated). The steam rises to the highest point in the boiler, the steam dome at the top. From here, the steam is sent down into a superheater, which dries it out and produces superheated steam, and that's what's directed down to the cylinders to get everything moving. The smokestack on the right of the diagram is where the exhaust gasses are released, giving off that plume of smoke everyone expects to see.

Now that the steam is at the cylinders, the pistons can start pumping and moving the driving rods on the driving wheels (the big ones). Here's an animated gif of that process, again from Wikipedia.

At this point, it's basically like any other engine with pistons - the pistons get pumping and the machine starts operating. This whole section of the locomotive is referred to as the running gear, and includes the valve gear, connecting rods, brake gear, wheelsets, axleboxes, and springing.

Essentially, it's a steam engine with wheels that is capable of pulling incredible amounts of weight if everything is done correctly. Your average steam locomotive is still stronger than your average diesel or electric locomotive is. Depending on what you needed your steam locomotive to do, the size of the driving wheels would differ - locomotives built for high speed tend to have really large drive wheels, whilst locomotives designed to go slower but pull more weight have smaller drivers for better adhesion and traction.

Maintenance?

As expected, since they have a lot of moving parts, steam locomotives need a lot of active maintenance. They're checked frequently, have mandated annual inspections, and are required by the Federal Railroad Administration in the United States to have a more thorough inspection every 1,472 days of active service - so it's basically 15 years or 1,472 days of operation, whichever comes first. 90, the locomotive I drove at Strasburg, is currently undergoing her 1,472-day inspection as I write this post and she'll hopefully be back in operation for her 100th birthday next year.

One of the things that's unique about steam locomotive maintenance is that the boiler regularly has to be cleaned out, which is why the boilerplate on the front has hinges - that thing's a door! This job was more dangerous historically because boilers were often insulated with asbestos, but pretty much anything operating today has had any asbestos removed or wasn't built with it in the first place. This website has a really good explanation of the process of cleaning out and fixing up a locomotive boiler for a 1,472 day inspection, complete with photos!

In terms of steam locomotive shops, I'm biased towards Strasburg because I grew up going there all the time, but they really do perform incredible work. Late last year, one of their locomotives, #475, had a run-in with a crane left on the track due to a misthrown switch, and her smokebox took some damage. Fortunately, the damage was minor, and they were able to get her repaired in a mere 96 hours.

She now looks like this:

They opted to braze weld her and didn't smooth it out as a reminder to crews to stay vigilant, so she now has some really cool battle scars.

I'm not as well-versed in repair since I don't have hands-on experience with it (yet), but once I can start volunteering I'll hopefully have some more stuff to talk about since I'm hoping to learn to work with these machines more closely! (And drive. Drive all the time. Drive forever.)

40 notes

·

View notes

Text

Engine Repair Instruction Full Guide

Engines are the heart of any vehicle, powering everything from your daily commute to long road trips. Knowing how to repair an engine can be a game-changer, whether you're an enthusiast who loves getting your hands dirty or someone looking to save money on mechanic bills. This guide will walk you through the entire process of engine repair, from diagnosing problems to reassembling your engine and ensuring it runs smoothly.

Understanding the Basics of an Engine

Before diving into the repair process, it’s crucial to understand how an engine works. Most vehicles use an internal combustion engine, which combines fuel and air, ignites it, and transforms that explosion into mechanical energy.

Components of an Internal Combustion Engine

The main components include:

Cylinder Block: The engine's core where combustion occurs.

Cylinder Head: Houses the valves and spark plugs.

Pistons: Move up and down to create the force needed to turn the crankshaft.

Crankshaft: Converts the pistons' up-and-down movement into rotational motion.

Camshaft: Controls the opening and closing of the valves.

Valves: Regulate the flow of fuel and air into the engine and exhaust gases out.

How an Engine Works: A Simple Explanation

An engine works by pulling in a mixture of air and fuel, compressing it, igniting it with a spark (in gasoline engines), and then expelling the exhaust gases. This cycle—intake, compression, power, and exhaust—happens in each cylinder and repeats hundreds of times per minute.

Tools and Equipment Needed for Engine Repair

Whether you're performing a basic repair or diving into more complex work, having the right tools is essential.

Essential Tools for Basic Repairs

Socket Set: For removing and tightening bolts.

Wrenches: Different sizes for various engine parts.

Screwdrivers: Flathead and Phillips for screws and clips.

Pliers: For handling wires and small parts.

Torque Wrench: Ensures bolts are tightened to the correct specifications.

Specialized Equipment for Advanced Engine Work

Engine Hoist: For removing the engine from the vehicle.

Cylinder Hone: Prepares cylinders for new piston rings.

Compression Tester: Checks the health of each cylinder.

OBD-II Scanner: Diagnoses engine codes and issues.

Safety Gear and Precautions

Gloves: Protect your hands from cuts and chemicals.

Safety Glasses: Shield your eyes from debris.

Work Boots: Offer protection against heavy parts or tools.

Diagnosing Engine Problems

Accurately diagnosing engine problems is the first step in any repair process. Understanding the symptoms can save time and prevent unnecessary work.

Common Symptoms of Engine Issues

Check Engine Light: Indicates a problem detected by the car's computer.

Strange Noises: Knocking, tapping, or grinding sounds can signal internal damage.

Excessive Smoke: Blue smoke might mean burning oil, while white could suggest a coolant leak.

Loss of Power: Often linked to fuel or air delivery issues.

Step-by-Step Diagnostic Process

Listen and Observe: Note any unusual sounds, smells, or behaviors.

Check Engine Light Codes: Use an OBD-II scanner to retrieve error codes.

Perform Compression Test: Assesses the health of your engine’s cylinders.

Inspect Fluids: Look for contamination or leaks in oil, coolant, and other fluids.

Step-by-Step Guide to Reassembly

Prepare Your Workspace: Ensure that your workspace is clean, organized, and well-lit. Lay out all the parts and tools you'll need in the order of reassembly. Keep the engine manual handy for specific torque specs and sequences.

Install the Crankshaft: Place the crankshaft back into the engine block, ensuring it is seated correctly. Use assembly lube on the main bearings to prevent damage during the initial startup. Torque the main caps to the manufacturer's specifications.

Insert the Pistons: Install the pistons and connecting rods. Be sure to align the piston rings correctly and use a ring compressor to insert the pistons into the cylinder bore. Attach the connecting rods to the crankshaft and torque the rod bolts to spec.

Install the Camshaft and Timing Components: If your engine uses a timing chain or belt, install it according to the timing marks on the camshaft and crankshaft gears. This step is crucial for ensuring the engine's valves open and close at the correct times.

Attach the Cylinder Head: Place the cylinder head gasket on the engine block, followed by the cylinder head. Torque the head bolts in the correct sequence and to the proper specifications. This ensures a good seal and prevents head gasket failure.

Install Valves, Lifters, and Pushrods: If applicable, install the engine's valves, lifters, and pushrods. Make sure they are properly aligned and that the lifters are seated correctly in their bores.

Reassemble the Valve Train: Install the rocker arms and adjust the valve lash according to the engine manual. Proper valve lash is critical for engine performance and longevity.

Reattach External Components: Begin reattaching external components like the water pump, oil pump, timing cover, oil pan, and intake manifold. Replace any gaskets and seals during this process to prevent leaks.

Reconnect the Fuel and Ignition Systems: Reinstall the fuel injectors, spark plugs, and ignition wires. Ensure all electrical connections are secure and properly routed to avoid short circuits or malfunctions.

Final Checks: Before moving on, double-check all connections, bolts, and components. Make sure nothing is left loose or unconnected.

Applying Proper Torques and Specifications

Every engine has specific torque settings for each bolt. Over-tightening can strip threads or warp components, while under-tightening can lead to leaks or parts coming loose. Use a torque wrench and follow the manufacturer's specifications closely.

Double-Checking Work for Mistakes

It's easy to miss a step or make a mistake during reassembly. Double-check your work:

Ensure all components are installed in the correct order.

Verify all bolts are torqued to spec.

Check for any leftover parts or tools in the engine bay.

Testing the Repaired Engine

With the engine reassembled, the next step is testing it to ensure everything is functioning properly.

Preparing for Initial Startup

Before starting the engine, perform a few preparatory checks:

Prime the oil system: This can be done by cranking the engine with the fuel system disabled until oil pressure is achieved.

Fill the engine with fresh oil and coolant.

Double-check all electrical connections and fuel lines.

Checking for Leaks and Unusual Noises

Once you start the engine, pay close attention to any unusual noises or leaks:

Oil Leaks: Check around the oil pan, valve covers, and front and rear seals.

Coolant Leaks: Inspect the radiator, hoses, and water pump area.

Unusual Noises: Listen for knocking, tapping, or whining sounds, which could indicate an issue with the timing components or internal parts.

Fine-Tuning and Adjusting the Engine

After the initial startup, the engine may require some adjustments:

Timing Adjustments: Use a timing light to set the ignition timing.

Idle Speed: Adjust the idle speed according to the manufacturer’s specifications.

Fuel Mixture: On carbureted engines, you may need to adjust the air-fuel mixture for optimal performance.

Common Engine Repair Mistakes to Avoid

Engine repair is complex, and mistakes can be costly. Here are some common errors to watch out for:

Misalignments and Incorrect Torques

Misaligned timing components can lead to poor engine performance or damage.

Incorrectly torqued bolts can cause leaks, parts failure, or engine damage.

Overlooking Small Parts and Connections

Small parts like washers, clips, or gaskets are easy to overlook but crucial for preventing leaks and ensuring proper function.

Electrical connections: Double-check that all sensors and connectors are properly seated.

Skipping Diagnostic Steps

Skipping steps in the diagnostic process can lead to unnecessary repairs or missed issues. Always perform thorough diagnostics before and after repairs.

Maintaining Your Engine After Repair

Proper maintenance is key to ensuring the longevity of your newly repaired engine.

Importance of Regular Maintenance

Regular maintenance, such as oil changes, air filter replacements, and coolant checks, is essential to keep your engine running smoothly and prevent future problems.

Tips for Extending Engine Life

Use high-quality oil and filters.

Avoid hard driving until the engine is fully warmed up.

Regularly check and maintain fluid levels.

When to Seek Professional Help

While DIY repairs can save money, some issues are best left to professionals, especially if you encounter complex problems or lack the necessary tools and expertise.

Dealing with Advanced Engine Repairs

Some engine repairs are too complex for the average DIYer. Here's when to consider professional help:

Understanding When It’s Beyond DIY

Extensive internal damage: Cracked blocks or severely worn bearings usually require professional expertise.

Advanced electrical issues: Problems with engine management systems often need specialized diagnostic tools and knowledge.

Overview of Complex Repairs: Timing Belt, Engine Rebuilds

Timing Belt Replacement: Involves precise alignment of engine components and is critical for preventing engine damage.

Engine Rebuilds: This is a time-consuming and complex task that often requires professional machining and specialized tools.

Working with a Professional Mechanic

When the repair is beyond your capabilities, working with a professional mechanic ensures that the job is done correctly and safely. They have the tools, experience, and resources to handle complex engine repairs.

Cost Considerations in Engine Repair

Engine repair costs can vary widely depending on the scope of work, parts required, and whether you do it yourself or hire a professional.

Estimating Costs for DIY vs Professional Repair

DIY Repairs: Typically cost less but require an investment in tools and time.

Professional Repairs: Can be expensive but come with the assurance of experience and often a warranty.

Budgeting for Tools, Parts, and Time

Consider the cost of any special tools or equipment you might need, as well as the cost of replacement parts. Factor in the time required, especially if the vehicle is your daily driver.

Understanding the Cost of Mistakes

Mistakes can be costly. Stripping a bolt, breaking a part, or incorrect assembly can lead to additional expenses. Always weigh the risks before starting a major repair.

Conclusion

Recap of Key Points

Engine repair is a rewarding but challenging task that requires careful planning, the right tools, and attention to detail. Whether you’re fixing a minor issue or performing a complete rebuild, following the correct procedures is crucial for success.

Encouragement for DIY Enthusiasts

For those who love working on their vehicles, engine repair can be a satisfying and cost-effective way to maintain your car. With patience and persistence, even complex repairs can be tackled with confidence.

Final Thoughts on Engine Repair

Always approach engine repair with a clear plan and the right resources. Don’t hesitate to seek professional help when needed, and remember that regular maintenance is the best way to avoid major repairs.

FAQs

How do I know if my engine needs repair?

Common signs include unusual noises, excessive smoke, loss of power, and a check engine light. Regular diagnostics can help catch issues early.

Can I repair my engine without professional help?

Basic repairs like replacing gaskets or sensors can often be done at home with the right tools. However, more complex tasks like engine rebuilds may require professional expertise.

What are the signs of a failing engine?

Signs include knocking noises, excessive oil consumption, smoke from the exhaust, and persistent overheating.

How long does it take to repair an engine?

The time required varies greatly depending on the complexity of the repair. Simple repairs might take a few hours, while a full rebuild could take several days or longer.

2 notes

·

View notes

Text

From Engine to Electronics: Proper Diagnostic Techniques for Resolving Maserati Problems

Maserati, the epitome of Italian luxury and performance, is renowned for its stylish design and high-performance capabilities. However, like any high-end vehicle, Maserati can encounter a range of issues, from engine troubles to electronic malfunctions. Proper diagnostics is crucial in maintaining the health and performance of these sophisticated machines. This article will guide you through the common problems Maserati face and the proper diagnostic techniques to resolve them.

Common Maserati Problems

1. Engine Issues

Maserati engines are marvels of engineering, but they can develop problems over time. Common engine issues include:

Misfires and Rough Idling: This can be caused by faulty spark plugs, ignition coils, or fuel injectors.

Overheating: Often due to a malfunctioning cooling system, such as a failed water pump or a clogged radiator.

Oil Leaks: These can originate from various seals and gaskets, leading to low oil levels and potential engine damage.

2. Transmission Problems

Maserati transmissions are designed for performance but can experience:

Slipping Gears: This could indicate worn-out clutch plates or issues with the transmission fluid.

Delayed Shifts: Often due to problems with the transmission control module or low fluid levels.

3. Electrical and Electronic Failures

Modern Maseratis are equipped with advanced electronics that can sometimes fail, including:

Dashboard Warning Lights: These can indicate issues ranging from simple sensor failures to serious engine problems.

Infotainment System Glitches: Problems with the touch screen, navigation, or audio system are not uncommon.

Diagnostic Techniques

1. OBD-II Scanner

The On-Board Diagnostics II (OBD-II) scanner is an essential tool for diagnosing Maserati problems. It can read error codes from the car's computer, providing insight into various issues.

How to Use: Connect the OBD-II scanner to the port located under the dashboard. Turn on the ignition and follow the scanner’s instructions to retrieve the error codes.

Interpreting Codes: Each code corresponds to a specific problem. For example, P0300 indicates a random/multiple cylinder misfire, while P0128 points to a coolant thermostat issue.

2. Visual Inspection

A thorough visual inspection can reveal obvious issues such as leaks, damaged components, or worn-out parts.

Engine Bay: Check for oil leaks, loose connections, and the condition of belts and hoses.

Undercarriage: Inspect for fluid leaks and damage to the exhaust system.

Electrical Connections: Look for corroded or loose battery terminals and wiring issues.

3. Multimeter Testing

A multimeter is useful for diagnosing electrical issues in a Maserati.

Battery Voltage: Measure the voltage across the battery terminals. A healthy battery should read around 12.6 volts when the car is off and around 14 volts when running.

Sensor Checks: Test various sensors, such as the oxygen sensor or mass airflow sensor, to ensure they are functioning correctly.

4. Compression Test

A compression test helps diagnose internal engine problems such as worn piston rings or valves.

Procedure: Remove the spark plugs and insert a compression gauge into each cylinder. Crank the engine and note the pressure readings. Low or uneven readings indicate internal engine issues.

5. Professional Diagnostic Tools

Maserati dealerships and specialized repair shops use advanced diagnostic tools that can access proprietary systems and provide more detailed information.

SD2/SD3 Diagnostic Systems: These are specialized tools used by Maserati technicians to diagnose and program vehicle systems accurately.

Diagnostic Software: Tools like Xentry or PIWIS can interface with Maserati's electronic systems for comprehensive diagnostics.

Addressing Common Issues

1. Engine Repairs

Misfires and Rough Idling: Replace faulty spark plugs, ignition coils, or fuel injectors. Regular maintenance and using high-quality fuel can prevent these issues.

Overheating: Ensure the cooling system is functioning correctly by checking the water pump, radiator, and thermostat. Flushing the coolant system periodically is also recommended.

Oil Leaks: Identify the source of the leak and replace the necessary seals or gaskets. Regularly check oil levels and change the oil according to the manufacturer's recommendations.

2. Transmission Solutions

Slipping Gears: Inspect and replace worn clutch plates and ensure the transmission fluid is at the correct level. Consider a fluid change if necessary.

Delayed Shifts: Diagnose and repair issues with the transmission control module or solenoids. Regular transmission servicing can prevent many of these problems.

3. Electrical Fixes

Dashboard Warning Lights: Use an OBD-II scanner to identify and address the underlying issue. Reset the warning lights after repairs are completed.

Infotainment System Glitches: Perform software updates and check for any loose connections or faulty components. In some cases, a complete system reset may be required.

Conclusion

Proper diagnostics are essential for maintaining the performance and reliability of your Maserati. By using the right tools and techniques, you can identify and resolve issues promptly, ensuring your luxury car continues to deliver the driving experience it was designed for. Regular maintenance and timely repairs are key to keeping your Maserati in top condition, from the engine to the sophisticated electronics.

#maserati car#maserati car diagnosis#maserati service center#maserati car maintenance#maserati car mechanic

2 notes

·

View notes

Photo

Mitsubishi Lancer Evolution IX GT-A Wagon

I don't know about you, but when I think of a wagon, I normally think of a car that's had the thrill factor turned down a notch or two. Not here. The Lancer Evolution Wagon is a fully-blown Evo in every detail. Dropped onto the same four-wheel- drive platform as the Evo IX, this luggage-lugger is about as extreme as they come.

Outside, it's no raving beauty with its Volvo-esque rear end grafted onto the chunky, sharp-edged Evo front. Inside the story's much the same. Except for the leather-wrapped gear-shifter and three-spoke steering wheel, and the supportive Recaro seats, bland grey plastic is the order of the day. Fortunately, when you fire up that 2-litre turbo it all starts to get rather more interesting.

The Wagon gets the same turbocharged 2-litre engine that debuted in the Evo IX saloon, complete with its sophisticated MIVEC variable valve timing system, but uniquely has the option of an automatic transmission to supplement the standard and excellent six-speed manual.

Bottom-end torque response is beefy and comes on hot and strong from 2500rpm, while at the top-end you can enjoy a deluge of free-flowing revs. That's the beauty of the MIVEC system, in that it allows you ready access to the considerable all that the engine has to give, but if you're stuck in slow-moving city traffic it gives you the luxury of shunt-free progress. The six-speed manual has deliciously short throws and is ideally matched to the engine's torque curve. So how fast is the Evo Wagon? Around Japan's most popular race track, the 2.1km-long Tsukuba Circuit near Tokyo, it clocked an impressive 1min 7sec, a mere one second off the pace of its booted brother. Just like the saloon, the Evo Wagon employs MacPherson struts on the front and a multi-link on the rear with the same rally-bred body rigidity and Bilstein dampers added for good measure. And just like the saloon, the Wagon feels rock-solid in the corners with minimum body-roll, while the ride quality is noticeably better and more compliant than that of the Evo currently on sale in Europe.

But while the Wagon inherits the four-door's Active Centre Differential (ACD) with the three-way Tarmac/Gravel/Snow control, it doesn't get the Evo IX's highly-rated Super Active Yaw Control (AYC). One Mitsubishi engineer suggested that price was the probable reason for its omission, but this car doesn't really need it. With its squared-off and heightened rear bodywork the wagon hauls an extra 70kg over the rear wheels, which works to improve the car's front to rear weight distribution.

Throw it into a corner and the Wagon turns in fast as the extra kilos at the rear get the tail moving and the nose turned-in, while the front-mounted helical LSD and ACD keep the nose in check. At the limits of adhesion, either understeer or oversteer is there for the taking. With no AYC to get in the way of a good slide, and the extra rear weight making it easier to provoke rear-end breakaway, the Wagon can be chucked into prolonged power-slides all day long. And unlike the four-door, which 'floats' its rear inside tyre in tight, fast corners, you can actually feel all four tyres (Yokohama Advan AO46s) in contact with the road, even through the quick corners.

Throw it into a corner and the Wagon turns in fast as the extra kilos at the rear get the tail moving and the nose turned-in, while the front-mounted helical LSD and ACD keep the nose in check. At the limits of adhesion, either understeer or oversteer is there for the taking. With no AYC to get in the way of a good slide, and the extra rear weight making it easier to provoke rear-end breakaway, the Wagon can be chucked into prolonged power-slides all day long. And unlike the four-door, which 'floats' its rear inside tyre in tight, fast corners, you can actually feel all four tyres (Yokohama Advan AO46s) in contact with the road, even through the quick corners.With four-piston Brembo callipers up front, sports pads and large rotors, the brakes wipe speed off instantly and feel perfectly balanced under-foot.

The Evo IX Wagon was without doubt the fastest- cornering wagon on the planet (at least until new versions of the Audi RS6 and RS4 Avants arrived to challenge its supremacy). But as Mitsubishi maked only 2500 Wagons, none officially destined for export.

26 notes

·

View notes

Text

Check Valves: The Key to Preventing Backflow

Check valves are a crucial component in any plumbing system, as they play a vital role in preventing backflow. Backflow occurs when water or other liquids flow in the opposite direction than intended, potentially contaminating clean water sources and posing a health hazard. Check valves are designed to allow flow in one direction only, effectively preventing backflow and protecting the integrity of the plumbing system.

Check valves are commonly used in a variety of applications, including residential, commercial, and industrial settings. They are installed in water supply lines, sewage systems, irrigation systems, and more to ensure that water and other liquids flow in the correct direction and do not contaminate clean water sources.

There are several types of check valves available, including swing check valves, lift check valves, and inline check valves. Each type has its own unique design and functionality, but they all serve the same basic purpose of preventing backflow. Swing check valves have a disc or flap that swings open to allow forward flow and closes to prevent backflow. Lift check valves use a piston or ball to lift and allow flow in one direction only. Inline check valves have a spring-loaded disc that opens and closes based on flow direction.

Proper maintenance and installation of check valves are essential to ensure they function effectively and prevent backflow. Check valves should be inspected regularly for any signs of wear or damage and replaced if necessary. It is also important to install check valves in the correct orientation to ensure they operate properly and prevent backflow.

In conclusion, check valves are the key to preventing backflow in plumbing systems. By installing and maintaining check valves properly, you can protect clean water sources and ensure the safety and integrity of your plumbing system. If you are experiencing issues with backflow in your plumbing system, consider installing check valves to prevent future problems.

2 notes

·

View notes

Text

5 Problems that Can Make Your BMW Engine Misfire at Idle

Misfiring in engine have become a major problem in many cars including BMW. Mostly while idling, it is found that the cars get misfires. During a misfire, the cars be have abnormally which takes the attention of the user because it has such symptoms that are quite noticeable. Misfiring occurs while the engine is running at any time while the car is idling or running, etc. Misfiring is generally an issue in the power production. If you own a car, and notice the misfires in your car, then you should know about some problems that cause the engine to misfire. Here I’m gonna tell you about the causes of misfiring in engine of BMW while idling.

Misfires during idle

Misfire is a problem in the engine cylinders that lead to stumbling, jerking and shaking of the car. Misfiring leads to a very rough running or idling of the car. Along with jerking, the cars also produce some unusual noises. Misfires are disturbing and can make the passengers uncomfortable. So during idle, the engine revs, but the car is not in a motion.

The RPM (revolution per minute) of the engine during idle is not of a high magnitude to accelerate the car. The RPM while idling is of a specific value for a car, but if the RPM of the engine becomes too low or doesn’t remain constant, then the idling becomes rough. The car would shake more while idling. The problem with the RPM is caused due to power loss, misfire in the engine. When the engine detects a very low output, it takes certain actions that make the engine to shake. The engine gets such a low RPM due to problems in the ignition, fuel and air ratios in the fuel mixture in the combustion chamber.

Here are some common signs of misfiring

Rough idling

A very slow acceleration when after gas pedal is pressed

Check engine light glows

Engine would produce a different sound than usual, like popping, banging, chuffing, etc.

Jerking

What causes the misfiring while idling of the car?

Here are some problems in some components would cause the misfires in engine.

Faulty spark plugs and its wires

The spark plugs fire in the combustion chamber to burn the mixture of fuel and air. It gets electricity through its wires. So if there is no proper and consistent firing, then both spark plug and its wires can be the culprit. Spark plugs can themselves be the defective and unable to produce sparks. It can even malfunction if the wires connected to it is damaged, disconnected, etc. If the sparks produced by the spark plugs cannot be able to burn the fuel and air mixture properly, then it would result into misfire.

Worn Ignition coils

Ignition coils have great role in burning the fuel and producing the power. These coils supply power to the spark plugs. If these coils are worn, then the functioning of the whole ignition system would be badly affected.

Clogged fuel and air intake system

The fuel and the air intake systems supply fuel and air to the engine in a specific quantity. But many times, the lines in these systems get some obstruction like damage of parts like gaskets and hoses or some dirt make the filters clogged. If these systems are clogged, then the flow of two necessary things, that is the fuel and the air would be obstructed and cannot reach the engine in proper amount.

Timing problems

If the timing in the engine has the problem, then the whole process would be affected more. The movement of the camshaft, the opening and the closing of the valves are all controlled through timing. But if the timing gets some problems, then the intake valves would not operate properly with time. And lead to a wrong ratio of the air and fuel in the mixture and even the exhaust gasses would not be properly removed out of the combustion chamber. So a timing problem would definitely lead to misfiring.

Some mechanical issues

Due to the mechanical components, the engine is able to produce torque. The components like cylinder walls, piston rings, valves also have a very important role in the combustion process. Misfires would happen if any of these components get issues.

Conclusion

If you get the signs of engine misfiring, then get your car inspected as soon as possible so that there would be no further problems in the engine to arise. Get your BMW well maintained regularly.

5 notes

·

View notes

Text

Pioneering Excellence in Industrial Valve Manufacturing Since 1977

Introduction

Prime Industrial Valves Mfg. Co., established in 1977, is a premier manufacturer of industrial valves, headquartered in Ahmedabad, India. Over the years, the company has emerged as a leader in the industrial valve sector, known for its commitment to quality, innovation, and customer satisfaction. With a robust infrastructure, dedicated R&D capabilities, and a highly skilled workforce, Prime Industrial Valves Mfg. Co. continues to set benchmarks in the industry.

Vision and Mission

Vision: To be a globally recognized leader in the industrial valve manufacturing industry, delivering innovative solutions tailored to the evolving needs of our clients.

Mission: To provide high-quality, cost-effective, and timely solutions while ensuring superior customer satisfaction and environmental sustainability.

Infrastructure and Certifications

Prime Industrial Valves Mfg. Co. operates a state-of-the-art manufacturing facility in Ahmedabad, equipped with cutting-edge technology. The facility boasts an in-house casting unit renowned for its precision and excellence. A dedicated R&D unit drives innovation and continuous improvement, enabling the company to stay ahead in the competitive market.

The company’s commitment to quality and efficiency is validated by prestigious certifications, including:

ISO 9001: For adhering to international quality management standards.

NSIC Certification: Demonstrating our capabilities as a trusted MSME partner.

IBR Certification: Ensuring compliance with the Indian Boiler Regulations.

Product Portfolio

Prime Industrial Valves Mfg. Co. offers a comprehensive range of valves and related products, tailored to meet the diverse needs of industries worldwide. Each product is manufactured from high-quality materials such as Forged Steel, Alloy Steel, Stainless Steel Valve, and Duplex Steel. Here’s an overview of the product range:

1. Gate Valves

Used in water and sewage systems, oil and gas industries, and various industrial processes, gate valves ensure reliable flow control.

2. Globe Valves

Ideal for water and wastewater systems, chemical processing, oil and gas applications, and power plants. Globe valves are designed to regulate flow effectively and withstand challenging environments.

3. Ball Valves

Widely used in water and wastewater treatment, HVAC systems, oil and gas industries, and chemical processing, Ball valves offer durability and precise control. With advanced sealing technologies, they ensure leak-proof operation.

4. Butterfly Valves

Designed for water and wastewater treatment, industrial processes, and pipelines, Butterfly Valves provide efficient flow regulation and are available in various configurations to meet specific needs.

5. Check Valves

Preventing backflow, Check valves are essential for water distribution systems, pumping stations, and fire protection systems. Their robust design ensures long-term reliability.

6. Strainers

Used in water systems, HVAC systems, industrial processes, marine applications, and petrochemicals, strainers ensure the removal of debris and particles, protecting downstream equipment.

7. Needle Valves

Perfect for laboratories, hydraulic systems, fuel systems, and aerospace industries, needle valves provide precise flow control, ensuring accuracy in critical operations.

8. Piston Valves

Used in hydraulic and pneumatic systems, chemical processing, and water treatment, Piston valves are known for their reliability and ability to handle high-pressure environments.

9. Pressure Reducing Valves

Designed for water, gas, steam, and hydraulic systems, Pressure Reducing valves regulate pressure effectively, enhancing system efficiency and safety.

10. Knife Edge Gate Valves

Ideal for wastewater treatment, mining, pulp and paper, and chemical processing, Knife Edge Gate Valves are built for rugged environments and can handle slurry and viscous media efficiently.

11. Specialized Products

Moisture Separators: For steam systems and compressed air applications, ensuring dryness and efficiency.

Blow Down Valves: For boilers and pressure vessels, helping in the effective removal of impurities.

Flush Bottom Valves: Facilitating cleaning and maintenance in industrial processes, ideal for reactors and tanks.

Steam Traps: Enhancing efficiency in heating systems, steam boilers, and autoclaves.

2-3 Way Motorized, Cylinder & Pneumatic Control Valves: Offering precision control in automation systems, designed for advanced industrial needs.

Industries Served

Prime Industrial Valves Mfg. Co. caters to a wide array of industries, ensuring customized solutions for each sector’s unique requirements. Key industries include:

Oil and Gas: Valves designed to handle high pressure and corrosive environments.

Chemical Processing: Specialized valves for handling aggressive chemicals and high temperatures.

Water and Wastewater: Solutions for efficient water management and distribution systems.

Power Generation: High-performance valves for power plants and energy systems.

HVAC Systems: Components ensuring optimal flow and temperature control.

Food and Beverage: Hygienic and durable valves for stringent industry standards.

Marine and Petrochemicals: Robust valves designed for challenging environments.

Operational Philosophy

Prime Industrial Valves Mfg. Co. operates on the philosophy of "QUALITY, COST, and DELIVERY." This ensures that every product not only meets stringent quality standards but is also cost-efficient and delivered on time to exceed customer expectations. The focus on maintaining high standards across all operations has solidified the company’s reputation for excellence.

Research and Development

Innovation is the cornerstone of Prime Industrial Valves Mfg. Co. The R&D unit is equipped with the latest technology and software tools, enabling the design and development of advanced valve solutions. Recent innovations include high-efficiency sealing systems, corrosion-resistant materials, and automation-compatible valves. Continuous research helps the company introduce new products and improve existing ones, ensuring alignment with global industry trends.

Commitment to Sustainability

As a socially responsible organization, Prime Industrial Valves Mfg. Co. is committed to environmental sustainability. The company employs eco-friendly manufacturing practices and materials, minimizing its environmental footprint while maximizing operational efficiency. Initiatives such as energy-efficient production processes and recycling programs reflect the company’s dedication to a greener future.

Global Reach and Export Capabilities

Prime Industrial Valves Mfg. Co. has established a strong presence in both domestic and international markets. Key export regions include the Middle East, Southeast Asia, Africa, and Europe. By maintaining high-quality standards and offering competitive pricing, the company has successfully built lasting relationships with clients worldwide. Customized solutions and efficient logistics ensure timely delivery, enhancing customer satisfaction.

Conclusion

Prime Industrial Valves Mfg. Co. stands as a testament to excellence in the industrial valve manufacturing industry. With a legacy of over four decades, the company has consistently demonstrated its expertise in delivering high-quality, innovative, and cost-effective solutions. Guided by its core values of quality, efficiency, and customer focus, Prime Industrial Valves Mfg. Co. is poised to continue its journey of excellence and innovation in the years to come.

youtube

0 notes

Text

What is the most common problem on Volkswagen?

Volkswagen (VW) vehicles are renowned for their reliability, performance, and innovative engineering. However, like any automotive brand, they are not immune to issues. Among the various concerns reported by owners, one of the most common problems with Volkswagen vehicles involves the engine and its related components.

Understanding Volkswagen Engine Issues

Volkswagen engines are sophisticated, but their complexity can sometimes lead to recurring problems. Commonly reported issues include:

Oil Leaks

Oil leaks are a frequent complaint, particularly in older Volkswagen models or those with higher mileage. Leaks often originate from the valve cover gasket, oil pan, or rear main seal. If left unaddressed, they can cause severe engine damage or lead to a drop in oil levels, affecting overall performance.

Timing Chain Tensioner Failure

Some Volkswagen models are prone to timing chain tensioner issues. A failing tensioner can cause the chain to skip, leading to engine misfires or, in extreme cases, complete engine failure. This is particularly common in models equipped with turbocharged engines.