#multilayer PCB manufacturing in India

Explore tagged Tumblr posts

Text

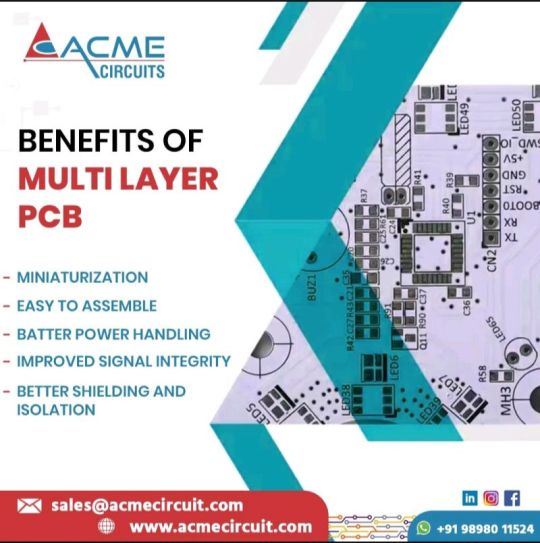

Multilayer PCBs (Printed Circuit Boards) offer numerous advantages over their single-layer or double-layer counterparts. These benefits arise from their enhanced design capabilities, improved performance, and greater flexibility. Here are some key advantages of multilayer PCBs:

#PCB#printed circuit board manufacturers#electronic cable assembly#pcb manufacturing#pcb assembly manufacturer#pcb assembly services#pcb board manufacturer#printed circuit board manufacturer in india#circuit board manufacturing#pcb exporters#pcba#pcb manufacturer#pcb design#pcbassembly#multilayer pcb

2 notes

·

View notes

Text

Essential Tools and Techniques in Prototype PCB Manufacturing

Prototype PCB manufacturing by PCB Circuit is a specialized process focused on quickly and efficiently bringing electronic designs from concept to functional boards. Whether testing new circuit designs or refining existing ones, PCB Circuit ensures precise fabrication, quality control, and quick turnaround times to help clients accelerate their product development cycles.

#PCB manufacturer#PCB fabrication In india#custom PCB manufacturing in india#prototype PCB manufacturing#low-cost PCB manufacturer#high-quality PCB manufacturing#quick turn PCB fabrication#flex PCB manufacturer#multilayer PCB manufacturer#Best pcb manufacturer#Top 10 pcb manufacturer#Pcb manufacturer near me#Pcb manufacturer in Maharashtra#Pcb manufacturer in haryana#Pcb manufacturer in delhi#Pcb manufacturer in india#Pcb manufacturer in Bombay#Pcb manufacturer in jaipur

0 notes

Text

Transforming Connectivity: The Evolving Landscape of PCB Manufacturers

With the technological advancement that is going on these, the PCB industry is playing a very important role such that the proper functioning of electronic devices takes place.

If we talk about modern electronics, then PCBs are indeed the backbone of it. Through this, components interconnection takes place while providing important electrical pathways.

Off lately, PCB manufacturers are coming up with new manufacturing materials and techniques such that reliability and performance are improved.

PCBs having a very high speed are capable to handle the boosted data rates using advanced materials. All of these are done using improved signal integrity properties.

Lastly, innovative techniques are used such that complex PCB structures can be created having functionality that is enhanced.

So, in this article, we would discuss the evolving landscape of PCB Manufacturers.

What are the recent trends that PCB Manufacturers should be aware of?

Increase in Miniaturization demand

Electronic devices these days have become very compact and small. Hence, there is an increase in the demand for PCBs having miniaturized components and high circular density.

Hence, PCB manufacturers in India need to keep up with the trend to meet the needs of electronic product designers. Thus, proper investment should be made in advanced manufacturing materials and techniques.

Increase in Multilayer designs

Electronic devices these days are equipped with a lot more functionalities and features. Consequently, the designs of PCB have become a lot more complex.

So, this is the reason Multilayer PCBs are gaining a lot of popularity as they can provide best-in-class performance. Other than this, they can manage several components as well.

Thus, as a PCB manufacturer, your focus must be on coming up with multilayer boards.

Using High-frequency applications

With the boost of communication technologies such as 5G networks and IoT, there has been an increase in the demand for high-frequency PCBs. Manufacturers need to use special materials and manufacturing processes such that signal integrity is ensured. Other than this, they need to make sure that signal loss by using such applications is minimized.

Sustainability in Environmental Practices

There has been a significant increase in consumer demands and environmental regulations when it comes to sustainable products. All of these are forcing the PCB industry to make use of greener practices.

Hence, PCB manufacturers need to follow certain environmental standards. Other than this, proper investment should be made in eco-friendly manufacturing processes such that environmental impact and waste are reduced.

Disruptions in the supply chain

Just like other industries, the PCB industry faces several challenges when it comes to shortages of components and supply chain disruptions.

So, manufacturers should come up with proper strategies related to supply chain management. Other than this, the supplier base needs to be diversified and monitor the market dynamics as well. In this way, risks can be mitigated and proper supply of components can happen.

Automation

Several industry 4.0 technologies such as machine learning, artificial intelligence, and automation are boosting the PCB manufacturing landscape.

Hence, it becomes very important for manufacturers to make use of smart manufacturing processes and data analytics such that quality control, productivity, and production efficiency can be optimized.

0 notes

Text

Prototype Multilayer PCB Manufacturer India

Looking for a reliable prototype multilayer PCB manufacturer in India? We specialize in high-quality, correct multilayer PCB prototyping to meet your design needs. With state-of-the-art technology and fast turnaround times, we ensure efficient solutions for complex PCB requirements. Trust us for quality, innovation, and timely delivery across India for your PCB manufacturing projects.

#custom pcb manufacturing#pcb fabrication#pcb manufacturer in india#prototype pcb manufacturing#pcb manufacturer#best pcb stencil maker in hyderabad#pcbcircuit#two layer pcb stencil#pcb manufacturer in delhi#pcb manufacturer in maharashtra

0 notes

Text

Leading Multilayer PCB Manufacturer in India

Pcbcircuit is a leading multilayer PCB manufacturer in India, specializing in high-quality, reliable, and precision-engineered printed circuit boards. With advanced technology and a commitment to excellence, we offer customized PCB solutions for diverse industries, ensuring superior performance and cost-effectiveness.

#custom pcb manufacturing#pcb manufacturer#flex pcb manufacturer#quick turn pcb fabrication#multilayer pcb manufacturer#low-cost pcb manufacturer#pcb fabrication#prototype pcb manufacturing#high-quality pcb manufacturing#3d printing

0 notes

Text

Multilayer PCB Manufacturer : Definition, Process & Benefits

A PCB is called Multilayer PCB, if it has 3 or more layers(sheets) of copper foil, insulated from each other(by lamination or coating) and joined together to form a single piece. Pcbcircuit is the best multilayer PCB manufacturer In India. Multilayer PCBs are extremely high-density assemblies, incorporating multiple layers into one PCB.

#top 10 pcb manufacturer#pcbcircuit#quick turn pcb fabrication#pcb stencil#pcb manufacturer in india#flex pcb manufacturer#low-cost pcb manufacturer

0 notes

Text

The Essence of Innovation – China’s Premier Flexible Circuit Manufacturer | Gekun

In the dynamic landscape of advanced electronics, precision and reliability are not just desired; they are essential. Gekun, China’s premier Flexible Circuit Manufacturer, understands this necessity and has dedicated itself to delivering unmatched quality and innovation in every product we create. Our factory’s flexible circuits are indispensable across a multitude of advanced electronic sectors, including telecommunications, computers, and consumer electronics. They also play a vital role in the automotive, medical, and industrial control industries, underscoring their versatility and importance.

At Gekun, we believe that the backbone of modern technology lies in flexible circuits. These intricate, durable components are critical in ensuring seamless connectivity and optimal performance in various applications. Our commitment to excellence is reflected in our rigorous manufacturing processes, which include 28 stages of testing, guaranteeing that each flexible circuit meets the highest standards of quality and reliability.

Our influence extends well beyond China’s borders. Gekun exports to Europe, Vietnam, India, and America, making us a global leader in flexible circuit manufacturing. This widespread reach is a testament to the trust and confidence that our clients have in our products and services. We are not just a manufacturer; we are a partner in technological progress, committed to advancing industries and enhancing lives worldwide.

Continuous improvement and innovation are at the heart of Gekun’s philosophy. As a leading Flexible Circuit Manufacturer, we are constantly evolving to meet the ever-changing demands of the market. Our state-of-the-art manufacturing facilities are equipped with the latest technologies, enabling us to produce flexible circuits that are not only of the highest quality but also at the cutting edge of technological advancement. This commitment to innovation ensures that our products remain relevant and effective in an increasingly competitive landscape.

Our product range is designed to cater to a diverse array of needs. As a professional flex PCB manufacturer, Gekun offers a comprehensive selection of flexible circuits, rigid flex PCBs, multilayer flex PCBs, and PCB assemblies. Each product is crafted with meticulous attention to detail, ensuring that our clients receive solutions that perfectly align with their specific requirements. Whether it’s the complex demands of the telecommunications sector or the precise needs of medical equipment, Gekun’s flexible circuits deliver unparalleled performance and reliability.

Quality is a cornerstone of our operations. Gekun’s flexible circuits undergo a stringent 28-stage testing process to ensure they meet the highest standards. This meticulous approach not only guarantees product excellence but also ensures long-term durability, providing our clients with a continuous return on investment over three years. Our dedication to quality has earned us high praise from over 100 global software clients, reinforcing our reputation as a trusted Flexible Circuit Manufacturer.

Customer satisfaction is paramount at Gekun. We understand that providing high-quality products is only part of the equation. Equally important is offering exceptional service that builds lasting relationships. Our team is committed to delivering not only top-notch products but also comprehensive support, ensuring that our clients feel valued and supported at every step. We offer lifetime technical support for our software, adding an extra layer of assurance for our clients.

Imagine a world where every connection is flawless, every device operates seamlessly, and every innovation is realized with precision. This is the world Gekun aims to create. By pushing the boundaries of what’s possible in flexible circuit manufacturing, we empower our clients to bring their visions to life, transforming ideas into reality with unparalleled efficiency and reliability.

Join us on this journey of innovation and excellence. Experience the Gekun difference – where quality meets ingenuity, and every product is crafted with the utmost care and expertise. Let us be the catalyst that propels your projects to new heights, ensuring that you stay ahead in a world driven by technological advancements.

Discover the power of precision. Discover Gekun. Your trusted partner in flexible circuit manufacturing.

With Gekun, you’re not just choosing a Flexible Circuit Manufacturer; you’re choosing a future of limitless possibilities. Let our expertise and dedication to innovation drive your success. Embrace the future with Gekun, where every flexible circuit is a testament to our unwavering commitment to quality and excellence.

If you insteresting, plz check here

1 note

·

View note

Text

Powering Innovation: Professional PCB Designing and Manufacturing Companies in India

India's electronics industry is witnessing an exhilarating boom, driven by rising domestic demand and a burgeoning export market. At the heart of this growth lies the Printed Circuit Board (PCB), the unsung hero that connects and powers various electronic devices. Finding the right professional PCB designing and manufacturing company in India is crucial for businesses seeking reliable and high-quality solutions.

A Spectrum of Expertise:

India boasts a diverse range of PCB companies, each specializing in different aspects of the design and manufacturing process. Some cater to specific industries like medical, aerospace, or automotive, while others offer broader services. Key capabilities include:

Multilayer PCB design: Companies adept at handling complex, high-density boards with numerous layers.

High-frequency PCB design: Expertise in managing signal integrity and minimizing interference for RF and microwave applications.

Flexible PCB design: Design and fabrication of flexible and rigid-flex PCBs for applications requiring space constraints or movement. Prototype development: Rapid prototyping services to validate designs and iterate quickly.

Turnkey PCB assembly: One-stop solution for PCB design, fabrication, and assembly, including component sourcing and testing.

Advantages of Choosing Indian PCB Companies:

Cost-effectiveness: Compared to their international counterparts, Indian companies offer competitive rates while maintaining high quality standards.

Proximity and Time Zone Benefits: Working with domestic companies simplifies communication, facilitates site visits, and aligns time zones for efficient collaboration.

Skilled Workforce: India has a vast pool of talented engineers and technicians well-versed in PCB design and manufacturing processes. Government Initiatives: Supportive government policies and initiatives aim to boost the electronics manufacturing sector, fostering innovation and growth.

Choosing the Right Partner:

Selecting the ideal PCB company requires careful consideration. Here are some essential factors to evaluate:

Experience and track record: Opt for companies with a proven history of successful projects in your industry or application area. Certification and compliance: Ensure they adhere to international quality standards like IPC and UL.

Capabilities and technology: Verify if their expertise aligns with your specific PCB requirements, including layer count, materials, and finishes.

Communication and customer service: Assess their responsiveness, transparency, and willingness to collaborate throughout the project. Pricing and turnaround time: Compare quotes and ensure they align with your budget and project timeline.

The Future of PCB Design and Manufacturing in India:

With its skilled workforce, growing infrastructure, and supportive government policies, India is poised to become a global leader in PCB design and manufacturing. By leveraging the expertise of professional companies, businesses can access high-quality, cost-effective solutions to power their electronic innovations.

0 notes

Text

Electrical Cad Engineer Job Vacancy in Valeo | B.E, M.E. Electrical Engineers Can Apply | Chennai

Electrical Cad Engineer Job Vacancy in Valeo | B.E, M.E. Electrical Engineers Can Apply | Chennai

Company Name : Valeo

Valeo is a global tech company, designing breakthrough solutions to reinvent the mobility industry. We are leader on our businesses, and recognized as one of the largest innovative companies. We offer a large number of job opportunities that are as diverse as they are rewarding. Whether you are a student seeking an internship, a recent graduate, or an experienced professional, you will find an interesting opportunity at Valeo for you!

Electrical Cad Engineer Job Vacancy in Valeo Our Latest YOUTUBE Videos Link : https://www.youtube.com/channel/UCZYt-jtPk975fMuI6tLpUEg Our Telegram Channel Link: https://t.me/employmentjobs Related Jobs : - Sharda Motors Company Jobs - Hyundai Supplier Company Jobs - Nissan Company Jobs In Chennai Job Interview in Pegatron Company – Diploma & B. E. Engineers | Mahindra World City | Chengalpattu Designation: Engineer & Sr.Engineer Educational Qualifications: B.E. Engineer & Diploma Role: Permanent Year of Experience: Min Experience Job Location: Mahindra World City – Chengalpattu Apply link - Click Here BEL Recruitment 2023 | BEL நிறுவனத்தில் Apprenticeship Training அறிவிப்பு Designation: Apprenticeship Training Educational Qualifications: B.E, B.Tech Engineers Role: Trainee Year of Experience: Fresher Job Location: Bangalore Salary Details: 17,500 /- Per month Apply link - Click Here Latest Jobs By : Chennai JobsClick HereCoimbatore JobsClick HereBangalore JobsClick HereHyderabad JobsClick HereAndra Pradesh JobsClick HereSalem JobsClick HereMadurai JobsClick HereTrichy JobsClick HerePondicherry JobsClick HereAcross India JobsClick HereOther Cities JobsClick HereElectrical Cad Engineer Job Vacancy in Valeo Designation: ECAD Engineer Educational Qualifications: B.E , M.E. Electrical Engineer Role: Permanent Year of Experience: Fresher / Experience Job Location: Chennai / Tamilnadu Salary Details: As per the Company Standard Mechanical JobsClick HereELE / ECE JobsClick HereCivil JobsClick HereIT / Software JobsClick HereBPO / Call Centre JobsClick HereH/W & Networking JobsClick HereHuman Resource Jobs Click HereAcc/Fins JobsClick HereArts & Science JobsClick HereElectrical Cad Engineer Job Vacancy in Valeo Electrical Cad Engineer Job Vacancy in Valeo Job Description : 1. PCB Design layout : • Layout of complex multilayer printed circuit boards containing analog, digital and high voltage power components • Placement and routing per Valeo Design Layout Specifications and Guidelines • Schematic Capture using Valeo Global component library • Create and manage PCB documentation including fabrication and assembly drawings, Gerber files, etc • Work with PCB fabricators to resolve DFM or other manufacturing related issues. • Create, manage and maintain the E-CAD libraries (schematic symbols, PCB footprints, etc.) • Central ECAD library database management 2. Ensure Quality of the deliverable : • Checks that the final design complies with the ECAD Layout Specifications • Checks the DFM,DFT, DFA constraints and Ensure zero error. • Ensure EMI/EMC in the design • Ensures trouble free designs using the Ecad checklist template documents • Reports any issues or suggestions to improve the designs. How to Apply for this Job? Details & Apply link : Click Here Titan Company Jobs | Hosur Location Designation: Mechanical Engineer Educational Qualifications: B.E.Mechanical Engineer Role: Permanent Year of Experience: Min 2 Years Job Location: Hosur , Tamilnadu Apply link - https://myemploymentjobs.com/titan-company-jobs-hosur-location-b-e-mechanical-engineer/ Foxconn Company Off Campus Drive 2023 Designation: Trainee Educational Qualifications: Mechanical , EEE , ECE & Arts and Science Role: Permanent Year of Experience: Fresher Job Location: Sriperumbudur , Chennai Apply link : https://myemploymentjobs.com/foxconn-company-off-campus-drive-2023/ TATA Auto Jobs | டாடா நிறுவன நிரந்தர வேலை வாய்ப்புகள் Designation: Engineers Educational Qualifications: B.E , B.Tech , M.E, M. Tech Role: Permanent Year of Experience: 1 – 8 Years Experience Job Location: Chennai , Bangalore & Pune Apply link : https://myemploymentjobs.com/tata-auto-jobs-permanent-job-openings-2023/ For more Job info, subscribe to our website & and check our website daily. Join Our youtube ChannelClick HereJoin Our Telegram ChannelClick HereOur linkedin PageClick HereOur Quora PageClick Here Read the full article

#eeebasicinterviewquestions#eeeengineeringjobs#eeejobs#ElectricalCadEngineerJobVacancyinValeo#ElectricalCadEngineerJobVacancyinValeochennai#ElectricalCadEngineerJobVacancyinValeoupdates#electricaldesignengineer#electricalengineeringcompanies#electricalengineeringjobsforfreshers#electricalmaintenanceengineerinterview#electricalmaintenancejobs#electronicdesignengineerjobs#electronicsandtelecommunicationengineeringjobs

0 notes

Link

#Multilayer PCB manufacturers in India#Fine-Line Circuits Limited#multilayer printed circuit board manufacturers in India#multilayer PCB manufacturing in India#multi layer circuit board#multilayer PCB fabrication India

0 notes

Link

Multilayer PCB Manufacturer in India, Multilayer PCB Manufacturer Delhi, Multilayer PCB, Multilayer PCB Circuit Board Delhi, Multilayer PTH PCBs Delhi. Double Sided PCB Manufacturers in India, PCB Manufacturer in Delhi

1 note

·

View note

Text

Benefits of Multi-Color PCBs in Circuit Design

Multi-color printed circuit boards (PCBs) are transforming the landscape of electronic design by blending functionality with aesthetics. One of the primary benefits of multi-color PCBs is that different colors can indicate specific circuit functions or components, helping engineers and technicians quickly identify issues during manufacturing and testing. , the use of multi-color PCBs can improve thermal management and signal integrity

#PCB manufacturer#PCB fabrication In india#custom PCB manufacturing in india#prototype PCB manufacturing#low-cost PCB manufacturer#high-quality PCB manufacturing#quick turn PCB fabrication#flex PCB manufacturer#multilayer PCB manufacturer#Best pcb manufacturer#Top 10 pcb manufacturer#Pcb manufacturer near me#Pcb manufacturer in Maharashtra#Pcb manufacturer in haryana#Pcb manufacturer in delhi#Pcb manufacturer in india#Pcb manufacturer in Bombay#Pcb manufacturer in jaipur#Best pcb assemble in hyderabad#Low cost pcb assembled in hyderabad#Good pcb assemble in hyderabad#Free sample pcb assemble in India#pcb stencils#Two layer pcb stencil

0 notes

Text

The Rise of Sustainable Circuitry: Exploring Eco-Friendly Practices in PCB Manufacturing

In recent years, there has been a growing global concern regarding the environmental impact of various industries. One sector that has gained significant attention is the electronics industry, particularly in the manufacturing of printed circuit boards (PCBs). PCBs are integral components of electronic devices, ranging from smartphones and laptops to industrial machinery and medical equipment. As the demand for electronics continues to rise, it becomes crucial to explore eco-friendly practices in PCB manufacturing. This article delves into the emerging trend of sustainable circuitry and highlights the importance of adopting environmentally conscious approaches in the production of PCBs.

I. The Environmental Impact of Traditional PCB Manufacturing:

The conventional methods of PCB manufacturing have significant environmental consequences. The production processes involve the use of hazardous chemicals, such as lead, mercury, and brominated flame retardants (BFRs), which pose risks to human health and the ecosystem. Additionally, the energy consumption and carbon emissions associated with PCB manufacturing contribute to climate change. These factors have spurred the need for alternative practices that prioritize sustainability.

II. The Principles of Sustainable Circuitry:

Sustainable circuitry aims to minimize the environmental impact of PCB manufacturing through various principles:

a) Material Selection: One of the fundamental aspects of sustainable circuitry is choosing eco-friendly materials for PCB production. Opting for lead-free solder, recyclable substrates, and non-toxic coatings reduces the ecological footprint of the manufacturing process.

b) Waste Reduction: Sustainable circuitry emphasizes the reduction of waste generated during PCB manufacturing. Implementing efficient production techniques, recycling solder and unused materials, and proper disposal of hazardous waste are crucial steps in achieving this objective.

c) Energy Efficiency: Energy consumption plays a significant role in the environmental impact of PCB manufacturing. Sustainable practices focus on optimizing energy efficiency through process improvements, equipment upgrades, and the utilization of renewable energy sources.

d) Lifecycle Considerations: Sustainable circuitry takes into account the entire lifecycle of PCBs, including their disposal. Designing for disassembly and recyclability ensures that the materials used in PCBs can be recovered and reused, reducing the need for virgin resources.

III. Innovations in Sustainable Circuitry:

The pursuit of sustainable circuitry has driven innovations in PCB manufacturing. These advancements not only reduce environmental impact but also enhance the performance and longevity of electronic devices.

a) Green Chemistry: Green chemistry principles are being applied to develop eco-friendly alternatives to traditional PCB manufacturing chemicals. This includes the use of water-based fluxes and solder masks, as well as the development of halogen-free flame retardants.

b) Renewable Materials: Researchers are exploring the use of renewable materials, such as bioplastics and bio-based resins, as substitutes for conventional PCB substrates. These materials offer reduced environmental impact and can be derived from renewable resources.

c) Closed-Loop Manufacturing: Closed-loop manufacturing systems aim to minimize waste and resource consumption by recycling materials within the production process. This approach reduces the reliance on virgin materials and contributes to a more circular economy.

d) Life Cycle Assessment (LCA): LCA is a methodology used to evaluate the environmental impact of a product throughout its entire lifecycle. Applying LCA to PCB manufacturing allows for the identification of areas with the highest environmental impact, enabling targeted improvements and informed decision-making.

IV. The Role of Vishal International in Sustainable Circuitry:

Vishal International is at the forefront of promoting sustainable circuitry in PCB manufacturing. The company recognizes the importance of minimizing environmental impact and has implemented several eco-friendly practices.

a) Lead-Free Manufacturing: Vishal International utilizes lead-free solder in its PCB manufacturing processes. This eliminates the use of toxic materials and reduces the potential harm to both human health and the environment.

b) Energy Efficiency Measures: The company has invested in energy-efficient machinery and production techniques, reducing energy consumption and greenhouse gas emissions.

c) Waste Management: Vishal International emphasizes proper waste management, ensuring that hazardous materials are disposed of in compliance with environmental regulations. Additionally, the company actively promotes recycling and reuse of materials whenever possible.

d) Sustainable Material Choices: Vishal International prioritizes the use of eco-friendly materials in PCB manufacturing, such as recyclable substrates and non-toxic coatings. These choices contribute to the overall sustainability of their products.

Conclusion

As the demand for eco-friendly electronics grows, Vishal International's dedication to sustainable practices positions it as largest multilayer pcb manufcturers in India. By supporting companies like Vishal International, we can drive the transition toward a more sustainable and greener future in the electronics industry.

#multilayer pcb manufacturers in India#double sided pcb manufacturers in india#pcb suppliers in India

0 notes

Text

PCB Fabrication Services in India

PCB Fabrication in India offer top-notch design, manufacturing, and assembly solutions for a variety of industries. From single to multilayer PCBs, these services ensure accuracy and quality at every stage. With advanced technology and timely delivery, Indian PCB fabrication is reliable and cost-effective for both prototyping and large-scale production.

#custom pcb manufacturing#prototype pcb manufacturing#pcb manufacturer in india#pcb fabrication#two layer pcb stencil#pcbcircuit#pcb manufacturer in delhi#pcb manufacturer#PCB fabrication In india

0 notes

Text

Top Multilayer PCB Manufacturer in India

PCBCircuit is a leading multilayer PCB manufacturer in India, specializing in high-quality, customized printed circuit boards. With advanced technology and a commitment to excellence, we deliver innovative solutions for various industries, ensuring reliability and efficiency in every product.

#custom pcb manufacturing#pcb manufacturer#flex pcb manufacturer#prototype pcb manufacturing#low-cost pcb manufacturer#high-quality pcb manufacturing#quick turn pcb fabrication#multilayer pcb manufacturer#pcb fabrication#3d printing

0 notes

Text

Automotive PCB Market Research Provides an In-Depth Analysis on the Future Growth Prospects and Industry Trends Adopted by the Competitors | (2021-2027)

Stats and Research in its recent publication, provides thorough analysis of the global Automotive PCB Market, wherein, historical and current trends have been assessed to determine the future prospects of the Automotive PCB market. The study brings to fore credible insights on multiple factors of the Automotive PCB market, which can arm vendors with vital information to take critical decisions with clarity and confidence. The report includes key indicator assessment to unfold the growth behaviour of the Automotive PCB market for the period between 2021 and 2027. SNR analyses a range of drivers, restraints, trends, opportunities, and challenges in the Automotive PCB market, and offers forecast statistics in terms of value (US$ million/billion) and volume (thousand units). The Automotive PCB market report covers a detailed taxonomy along with a comprehensive analysis of the competitive landscape. The study profiles a number of trending companies as well as new entrants in the Automotive PCB markets, wherein, the product portfolios, and innovations, and business development strategies of these market players have been provided. Impact Analysis of Market: The population around the globe had restricted themselves going out of their home and edge towards confining themselves to their homes which is impacting all the market negatively or positively. According to the current market situation, the report further assesses the present and future effects of the COVID-19 pandemic on the overall market, giving more reliable and authentic projections. The spread of coronavirus has crippled the entire world. Our latest research, perspectives, and insights on the management issues that matter most to the companies and organization about the market, which is leading through the COVID-19 crisis to managing risk and digitizing operations to deliver trusted information and experiences to the decision makers. Get a Free Sample Copy of the Report @:www.statsandresearch.com/request-sample/33280-global-automotive-pcb-market Key players operating in the global Automotive PCB market are: Jingpeng, TTM, CMK, Meiko, KCE, Jiantao, Jianding, AT&S, Qisheng, Yidun, WUSPRINTED CIRCUIT CO., LTD, KINWANG, Schweizer, Sheng Hong, BPMIN ELECTRONIC, Aoshikang, others. Automotive PCB Market, By Product Type:Single Layer Rigid PCB, Double and Multilayer Rigid PCB, Flexible PCB Automotive PCB Market, By Application:Safety System, Power System, Vehicle Electronic Investigator Observers Strong Growth in Specific Regions: -Europe Market (Germany, UK, France, Russia, Italy) -Center East and Africa Market (Saudi Arabia, UAE, Egypt, Nigeria, South Africa) -South America Market (Brazil, Argentina, Colombia) -North America Market (United States, Canada, Mexico) -Asia Pacific Market (China, Japan, Korea, India, Southeast Asia). Click to Check Discount@: (Exclusive Offer Flat 20% discount):-www.statsandresearch.com/check-discount/33280-global-automotive-pcb-market Market Forecast Related Considerations - Impact on each country and various region - Change in supply chain related operation - Positive and negative scenarios of the market during the ongoing pandemic - Impact on various sectors facing the greatest drawbacks are manufacturing, transportation and logistics, Healthcare, Chemical and retail and consumer goods. Objectives of the Study - To define, describe, and forecast the global Automotive PCB market by products and services and region - To analyze micro markets with respect to individual growth trends, prospects, and contributions to the overall Automotive PCB market - To analyze market opportunities for stakeholders and provide details of the competitive landscape for key players - To forecast the size of the Automotive PCB market in five major regions along with their respective key countries (Europe, North America, Asia-Pacific, Latin America, and Middle East and Africa) - To profile the key players in the global Automotive PCB market and comprehensively analyze their core competencies and market shares - To track and analyze competitive developments such as product launches, expansions, and Research and Development activities of the leading players in the Automotive PCB market. Buy this Report @:www.statsandresearch.com/placeorder?report=33280-global-automotive-pcb-market&type=su About Us Stats and Research is a global market research and consulting service provider specialized in offering wide range of business solutions to their clients including market research reports, primary and secondary research, demand forecasting services, focus group analysis and other services. We understand that how data is important in today's competitive environment and thus, we have collaborated with industry's leading research providers who works continuously to meet the ever-growing demand for market research reports throughout the year. Contact: Stats and Research Mangalam Chamber, Office No-16, Paud Road Sankalp Society, Kothrud, Pune, Maharashtra 411038 Phone: +1 650-646-3808 Email: [email protected] Web: https://www.statsandresearch.com/ Email: [email protected] Web: https://www.statsandresearch.com/ Follow Us on: LinkedIN| Twitter| Facebook | Instagram

0 notes