#pcb manufacturer in delhi

Explore tagged Tumblr posts

Text

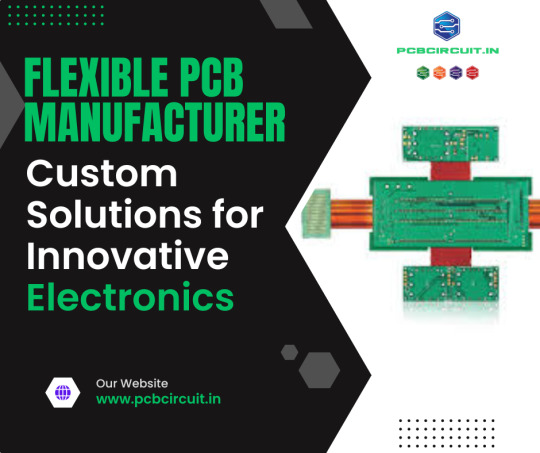

Flexible PCB Manufacturer - Custom Solutions for Innovative Electronics

We specialize in designing and manufacturing high-quality flexible pcb manufacture (PCBs) tailored to meet the demands of diverse industries. Our expertise in flexible circuit technology enables us to produce durable, reliable, and compact PCBs for applications ranging from consumer electronics to medical devices, automotive, and more. With precision engineering, fast turnaround times, and advanced manufacturing processes, we provide customized solutions that drive innovation in your electronic products.

#best pcb manufacturer#flex pcb manufacturer#multilayer pcb manufacturer#pcb manufacturer in haryana#low-cost pcb manufacturer#pcb manufacturer#pcb manufacturer in delhi#quick turn pcb fabrication#pcb manufacturer in maharashtra#pcb manufacturer near me

0 notes

Text

Factors to Consider When Selecting A Low-Cost PCB Manufacturer

Choosing the right low-cost PCB manufacturer can be challenging, especially with many available options. To help you make an informed decision, we've outlined five key factors to consider when selecting a low-cost PCB manufacturer.

#custom pcb manufacturing#pcb fabrication#pcb manufacturer in india#prototype pcb manufacturing#pcb manufacturer#two layer pcb stencil#pcbcircuit#best pcb stencil maker in hyderabad#pcb manufacturer in delhi#pcb manufacturer in maharashtra

0 notes

Text

#circuit board manufacturing#circuit board manufacturing companies#electronics manufacturing company#electronics manufacturing company in delhi#pcb assembly#pcb assembly services#pcb board assembly#pcb board manufacturer#pcb board manufacturers in India#pcb manufacturer in delhi ncr#pcb suppliers in india#printed circuit board manufacturers in India

0 notes

Text

High-Performance Metal Core PCB Manufacturing in Delhi NCR, India

Printed Circuit Boards (PCBs) play a vital role in the modern electronics industry. They form the foundation of countless devices, from smartphones to advanced medical equipment. Among the various types of PCBs, Metal Core PCBs (MCPCBs) stand out due to their superior thermal management properties and durability. In the bustling hub of Delhi NCR, several manufacturers are leading the charge in delivering high-performance MCPCBs that cater to the growing demands of diverse industries.

What Are Metal Core PCBs?

Metal Core PCBs are a specialized type of PCB that incorporate a metal base material, typically aluminum, copper, or a combination thereof. This metal core enhances the board’s thermal conductivity and helps dissipate heat away from critical components. As a result, MCPCBs are widely used in applications that generate significant heat, such as LED lighting, power converters, automotive electronics, and industrial machinery.

The primary benefits of Metal Core PCBs include:

Improved Thermal Management: The metal core allows efficient heat dissipation, reducing the risk of overheating.

Enhanced Durability: Metal Core PCBs are more robust and resistant to environmental factors.

Compact Design: By managing heat effectively, MCPCBs allow for more compact and high-density designs.

Energy Efficiency: These PCBs reduce energy loss, improving the overall performance of the device.

The Importance of High-Performance MCPCBs in Modern Applications

In today's rapidly evolving technological landscape, industries require components that are reliable, efficient, and capable of withstanding high stress. MCPCBs have become the preferred choice for manufacturers aiming to achieve these objectives. Their unique properties make them ideal for:

LED Lighting: High-power LEDs generate considerable heat. Metal Core PCBs ensure effective heat dissipation, enhancing the longevity and performance of LED lighting systems.

Power Electronics: Devices like inverters, power supplies, and converters rely on MCPCBs for stability under high power loads.

Automotive Electronics: From headlight systems to power management modules, MCPCBs play a crucial role in the automotive sector.

Industrial Equipment: Heavy-duty machinery and automation systems benefit from the durability and efficiency of MCPCBs.

Metal Core PCB Manufacturers in Delhi NCR

The Delhi NCR region has emerged as a significant hub for PCB manufacturing in India. This area is home to several innovative and technologically advanced companies specializing in Metal Core PCBs. These manufacturers leverage state-of-the-art equipment, cutting-edge technology, and skilled expertise to produce MCPCBs that meet international standards.

Key Features Offered by PCB Manufacturers in Delhi NCR:

Advanced Design Capabilities: Companies in the region provide custom solutions tailored to specific requirements, ensuring optimal performance for each application.

Quality Assurance: Strict quality control processes are followed to deliver reliable and durable PCBs.

Sustainability: Many manufacturers are adopting eco-friendly practices, reducing waste and environmental impact.

Competitive Pricing: Delhi NCR manufacturers offer high-quality products at competitive rates, making them an attractive option for businesses.

Saasin Electro Private Limited: A Trusted Name in MCPCB Manufacturing

One of the standout names in the Metal Core PCB manufacturing landscape is Saasin Electro Private Limited. This company has earned a reputation for its commitment to quality, innovation, and customer satisfaction. Based in Delhi NCR, Saasin Electro Private Limited offers a comprehensive range of MCPCBs tailored to meet the unique needs of various industries.

Why Choose Saasin Electro Private Limited?

State-of-the-Art Infrastructure: Equipped with modern machinery and advanced tools, the company ensures precision and efficiency in manufacturing.

Expert Team: Saasin Electro Private Limited boasts a team of skilled professionals dedicated to delivering top-notch solutions.

Customizable Solutions: The company provides bespoke designs, ensuring that every client’s specific requirements are met.

Quality Commitment: Adhering to stringent quality standards, Saasin Electro Private Limited ensures that its products meet international benchmarks.

Customer Support: Exceptional after-sales service and technical support make the company a reliable partner for businesses.

Conclusion

As industries continue to evolve, the demand for high-performance PCBs, particularly Metal Core PCBs, is on the rise. Delhi NCR has established itself as a prominent region for PCB manufacturing, with companies like Saasin Electro Private Limited leading the way. Whether you’re in the automotive, lighting, or industrial sector, choosing a trusted manufacturer ensures superior quality, reliability, and efficiency. If you’re looking for Metal Core PCB Manufacturers or PCB Manufacturers in Delhi, Saasin Electro Private Limited is your go-to partner. With their unwavering commitment to excellence, they are well-equipped to meet the dynamic demands of the electronics industry, driving innovation and growth in India and beyond. Reference: https://medium.com/@saasinelectro24/high-performance-metal-core-pcb-manufacturing-in-delhi-ncr-india-f56dc569cf05

#metalcorepcbmanufacturer#Metal Core PCB Manufacturers#pcbmanufacturers#saasin electro#bestpcbmanufacturer#PCB Manufacturer in Noida#PCB Manufacturers in Delhi#PCB Manufacturers in India

0 notes

Text

PCB Manufacturing Companies in Delhi by Shree Ram Electronics

We stand as one of the prominent PCB manufacturing companies in Delhi, embodying the spirit of Make in India. Founded under the visionary leadership of a women entrepreneur, our company excels in producing high-quality printed circuit boards tailored to meet diverse industrial needs. With a commitment to innovation and precision engineering, Shree Ram Electronics combines state-of-the-art technology with rigorous quality control to deliver reliable PCB solutions. Whether you require prototypes or full-scale production, our team ensures superior craftsmanship and timely delivery, making us a trusted partner in the electronics manufacturing sector.

#PCB manufacturing companies in Delhi#pcb design and fabrication in Delhi#Pcb designing in delhi ncr

0 notes

Text

868MHz LoRa 9dBi Spring Magnetic Antenna with RG174 Cable ( L - 3Mtr) + SMA (M) Connector

A 868MHz LoRa (Long Range) 9dBi Spring Magnetic Antenna is a specific type of antenna designed for use with LoRa devices that operate at a frequency of 868MHz. Let's break down the key components of this description:

868MHz: This refers to the operating frequency of the LoRa devices. LoRa is a wireless communication technology designed for long-range and low-power applications, and 868MHz is one of the common frequency bands used for LoRa communication in Europe.

LoRa: LoRa (Long Range) is a type of low-power, wide-area networking (LPWAN) technology used for IoT (Internet of Things) and M2M (Machine-to-Machine) communication. It allows devices to transmit data over long distances with minimal power consumption.

9dBi: This is a measure of antenna gain, which quantifies the ability of the antenna to focus or concentrate the radiated energy in a particular direction. A 9dBi gain indicates that the antenna has relatively high gain, which can extend the range and improve signal strength for LoRa devices.

Spring Magnetic Antenna: This refers to the physical design of the antenna. A spring magnetic antenna typically has a spring-like or coiled structure, and it's equipped with a magnet at its base, which allows it to be easily attached to a metal surface. This magnetic mounting makes it convenient to install on vehicles or other metallic objects.

In summary, a 868MHz LoRa 9dBi Spring Magnetic Antenna is a specialized antenna designed to enhance the performance of LoRa devices operating at 868MHz by increasing signal gain and making it easy to attach to metal surfaces for better reception. It's commonly used in applications such as IoT, telemetry, and remote monitoring where long-range communication is essential. Read More

#IoT Lora LPWAN Antenna#IoT Lora LPWAN antenna in india#IoT Lora LPWAN antenna manufactures#IoT Lora LPWAN antenna manufactures in india#IoT Lora LPWAN antenna suppliers in india#IoT Lora LPWAN antenna wholesalers in india#manufactures 5G Internal in pune#suppliers of PCB Antenna#wholesalers of Screw mount Antenna#Spring Magnetic Antenna in Ahmedabad#IoT Lora LPWAN antenna in delhi#Rubber Magnetic Antenna in mumbai#IoT Lora LPWAN antenna in chennai#IoT Lora LPWAN antenna in bangalore#IoT Lora LPWAN antenna in bangaluru#IoT Lora LPWAN antenna in Hyderabad#IoT Lora LPWAN antenna in Kolkata#IoT Lora LPWAN antenna in Pune#Wi-Fi 5dBi Screwable Puck Antenna Suppliers In Ahmedabad#IoT Lora LPWAN antenna in ahmedabad price#best manufactures Combo Screw Mount Antenna in ahmedabad#IoT Lora LPWAN ahmedabad#IoT Lora LPWAN antenna price#IoT Lora LPWAN Antenna at Best Price in India#IoT Lora LPWAN antenna manufacturers in delhi#IoT Lora LPWAN antenna manufacturers in mumbai#IoT Lora LPWAN antenna manufacturers in chennai#IoT Lora LPWAN antenna manufacturers in bangalore#IoT Lora LPWAN antenna manufacturers in hyderabad#IoT Lora LPWAN antenna manufactures in kolkata

0 notes

Text

Singhania Group flow for sustainability‼️

As the Delhi assembly elections of 2020 drew near, Chief Minister Arvind Kejriwal made a resolute promise to the public: to restore the Yamuna River to a state where it would be safe for swimming by the year 2025. Yet, as the deadline approaches, the grim reality of the river's pollution persists. Recent data from environmental agencies paints a stark picture - pollution levels in the Yamuna River have surged by a troubling 25% over the past year alone. The untreated effluents discharged by industries emerge as a significant contributor to this alarming trend. Furthermore, public awareness and concern regarding environmental issues have surged, with a notable 78% of individuals expressing a preference for supporting environmentally responsible companies.

In the midst of these environmental challenges, the Pollution Control Board (PCB) intervened, delivering a damning public notice against the Singhania Group. The accusation was severe - the group was accused of discharging an alarming 62% of untreated effluent into the already beleaguered Yamuna. This revelation cast a shadow over the reputation of the Singhania Group, a textile manufacturer with a distinguished three-decade legacy. The timing of this accusation couldn't have been more detrimental as the promising future suddenly seems uncertain for the company as share prices take a dramatic plunge in the wake of recent accusations. This unfortunate timing, just as optimism reigned, casts a long shadow over their previously rosy outlook.

The fallout triggered a domino effect, eroding investor trust and confidence. With scepticism about the company's leadership and practices rising, investors are pulling back, sending share prices spiralling downwards. Heightened media attention and public speculation further amplify the negative sentiment, compounding the downward trend.

This situation underscores profound questions about environmental responsibility, corporate ethics, and the integrity of political promises. While the actions of the PCB may appear justifiable in their mission to safeguard the Yamuna, the timing raises legitimate concerns about potential political motivations. Conversely, the Singhania Group finds itself grappling with the consequences of potential negligence in effluent treatment, underscoring the critical importance of responsible industrial practices.

In response to these challenges, the Singhania Group must embark on a concerted outreach campaign aimed at showcasing their ongoing efforts to address environmental concerns. Transparency, coupled with robust community engagement initiatives and tangible sustainability measures, will be key in demonstrating the group's unwavering commitment to environmental stewardship. By aligning their corporate interests with the broader goals of societal and environmental well-being, the Singhania Group can chart a course towards a more sustainable and socially responsible future, thereby regaining the trust and confidence of the public.

TASK AT HAND

As the Singhania Group's CSR head,

1) develop a CSR campaign to restore the company's reputation

2) an investment portfolio that prioritises sustainable solutions.

3) Make a website to promote the company's CSR actions and increase transparency.

DELIVERABLES

PPT of not more than 7 slides

A website

3 notes

·

View notes

Text

Customs Advance Ruling New Delhi Bench- on LCD Panels & PCB used by Audio system manufacturer for Motor vehicles

Customs Advance Ruling New Delhi Bench- on LCD Panels & PCB used by Audio system manufacturer for Motor vehicles

“Indirect Tax I Indirect Tax Litigation I Customs & FTP I Central Licensing I Arbitration I Advisory” Dated: 22.02.2025 Customs Advance Ruling New Delhi Bench- on LCD Panels & PCB used by Audio system manufacturer for Motor vehicles Background of the Case: M/s Clarion India Private Limited, a manufacturer and supplier of audio systems for motor vehicles, sought an Advance Ruling regarding the…

#BIS#BISAct#BISExempted#BISRegistration#BISStandard#CAAR#CBIC#Customs#CustomsAct#CustomsAct1962#CustomsAdvanceRuling#CustomsBoard#CustomsClearance#CustomsCompliance#CustomsDepartment#CustomsLitigations#Customstariff#DGFT#DPIIT#Exports#Facebook#GovtofIndia#Imports#IndirectTax#Indirecttaxes#IndirectTaxIndia#IndirectTaxLaw#IndirectTaxLitigations#Indirecttaxmatters#Instagram

1 note

·

View note

Text

Enhance PCB Performance with High-Quality Cleaning Solutions

Enhance PCB Performance with High-Quality Cleaning Solutions

Printed Circuit Boards (PCBs) are the backbone of modern electronics. To ensure their optimal performance and longevity, effective cleaning and coating solutions are essential. At Mectronics, we offer industry-leading solutions for PCB Cleaning Machines, PCB cleaning chemicals, and Acrylic Conformal Coating, making us a trusted name in the industry.

The Role of PCB Cleaning Machines

PCB cleaning machines are indispensable for removing contaminants like flux residues, soldering debris, and other impurities that can compromise circuit functionality. These machines ensure thorough cleaning, offering:

Enhanced conductivity.

Better adhesion for conformal coatings.

Prolonged lifespan of PCBs.

Mectronics provides advanced PCB cleaning machines designed to meet stringent industry standards, catering to diverse industrial requirements.

PCB Cleaning Chemicals for Comprehensive Solutions

Using the right chemicals is crucial to achieving spotless and contamination-free PCBs. Our PCB cleaning chemicals are formulated for:

Flux residue removal.

Oxidation prevention.

Gentle yet effective cleaning without damaging delicate components.

We partner with top brands like Zestron to ensure that our cleaning chemicals deliver precision and efficiency for all your PCB maintenance needs.

PCB Cleaners in Delhi: Trusted Local Solutions

For those in need of top-notch PCB cleaners in Delhi, Mectronics is your one-stop destination. With a strong local presence, we supply high-quality cleaning products that meet the specific needs of industries and electronics manufacturers in the region.

Our PCB cleaners stand out for:

Compatibility with automated and manual cleaning processes.

Compliance with international safety and quality standards.

Exceptional cleaning results for various PCB applications.

Acrylic Conformal Coating: Shielding PCBs from Environmental Damage

To further protect PCBs from harsh environmental factors, Acrylic Conformal Coating is the solution. This protective layer ensures:

Resistance to moisture, dust, and chemicals.

Improved insulation.

Enhanced durability against mechanical stress.

At Mectronics, we offer premium-grade acrylic conformal coatings that are easy to apply and provide long-lasting protection, ensuring your PCBs remain reliable under challenging conditions.

Why Choose Mectronics for PCB Cleaning and Coating?

Comprehensive Solutions: From cleaning machines to chemicals and coatings, we cover all your PCB maintenance needs.

Trusted Expertise: Decades of experience in delivering cutting-edge products to the electronics industry.

Customer-Centric Approach: Personalized guidance to help you choose the best solutions for your specific requirements.

Elevate your PCB maintenance game with our top-quality products. Visit Mectronics to explore our range of PCB cleaners, machines, and coatings tailored for excellence.

0 notes

Text

How to Find the Best PCB Manufacturer in Delhi for Your Needs

PCB manufacturers in Delhi are key players in the production of high-quality printed circuit boards. They offer a wide range of services, including custom PCB design, fabrication, assembly, and testing, using advanced technology and high-quality materials. Delhi, being a major hub for electronics manufacturing in India, boasts several PCB manufacturers who provide cost-effective and efficient solutions.

#top 10 pcb manufacturer#pcb fabrication#quick turn pcb fabrication#pcb stencil#pcbcircuit#low-cost pcb manufacturer#pcb manufacturer in india#flex pcb manufacturer

0 notes

Text

Top Printed Circuit Board Manufacturers in Delhi

Pcbcircuit is the top Pcb manufacturer in Delhi. We deliver high-quality PCB solutions tailored to your needs, ensuring precision and reliability. Our experts provide efficient and cost-effective services for various industries from design to assembly.

#custom pcb manufacturing#pcb manufacturer#prototype pcb manufacturing#flex pcb manufacturer#low-cost pcb manufacturer#high-quality pcb manufacturing#pcb fabrication#multilayer pcb manufacturer#quick turn pcb fabrication

0 notes

Text

Trusted PCB Manufacturer of Superior Circuit Boards

At pcb circuit, we are a trusted PCB manufacturer, specializing in producing high-quality circuit boards designed to meet the needs of industries worldwide. Our commitment to precision, reliability, and advanced technology ensures that every board we make is built to the highest performance and durability standards. Whether you need prototypes, low-volume, or mass production, we deliver superior PCB solutions that power innovation and drive success in your projects.

#best pcb manufacturer#flex pcb manufacturer#multilayer pcb manufacturer#pcb manufacturer in haryana#low-cost pcb manufacturer#pcb manufacturer#pcb manufacturer in delhi#quick turn pcb fabrication#pcb manufacturer in maharashtra#pcb manufacturer near me

0 notes

Text

India's Trusted PCB Stencil Suppliers for Electronics Manufacturing

Explore precision and reliability with India’s trusted PCB stencil suppliers. Our stencils ensure accurate solder paste application, enhancing the efficiency and quality of your electronics manufacturing. Designed for various PCB types, we provide solutions tailored to your needs. Partner with us for exceptional stencils that deliver flawless results every time.

#custom pcb manufacturing#pcb fabrication#pcb manufacturer in india#prototype pcb manufacturing#pcb manufacturer#two layer pcb stencil#pcbcircuit#best pcb stencil maker in hyderabad#pcb manufacturer in delhi#pcb manufacturer in maharashtra

0 notes

Text

#circuit board manufacturing#circuit board manufacturing companies#electronics manufacturing company#electronics manufacturing company in delhi#pcb assembly#pcb assembly services#pcb board assembly#pcb board manufacturer#pcb board manufacturers in India#pcb manufacturer in delhi ncr#pcb suppliers in india#printed circuit board manufacturers in India

0 notes

Text

Top PCB Manufacturers in Delhi: Delivering Precision, Innovation, and Quality in Custom Printed Circuit Boards for Diverse Industries

In the fast-paced world of electronics, the demand for high-quality, reliable Printed Circuit Boards (PCBs) is ever-growing. PCBs are the backbone of most modern electronic devices, from consumer electronics like smartphones and laptops to complex systems used in the automotive, medical, and telecommunications industries. With India’s expanding electronics industry, Delhi has emerged as a major hub for PCB manufacturing. Among the key players in the capital’s PCB sector, Sassin Electro has established itself as one of the top PCB manufacturers in Delhi, offering precision, innovation, and exceptional quality across a range of industries.

In this article, we’ll explore the landscape of PCB manufacturing in Delhi, highlight the role of companies like Sassin Electro, and discuss why they are a trusted name when it comes to custom PCBs for various industries.

The Growing Role of PCB Manufacturers in Delhi

Delhi, being the capital of India, has always been at the center of economic and technological advancements. The city’s electronics manufacturing ecosystem has grown rapidly over the years, with a thriving network of suppliers, manufacturers, and innovators in the PCB sector. As the demand for sophisticated electronics increases, especially in industries like automotive, healthcare, consumer electronics, telecommunications, and the rapidly growing Internet of Things (IoT) space, the need for high-quality, custom-designed PCBs has never been greater.

PCB manufacturers in Delhi are tasked with meeting the growing demand for more compact, efficient, and durable circuit boards that can handle increasingly complex and power-hungry devices. The key to their success lies in their ability to provide cost-effective, high-performance solutions with fast turnaround times. This is where Sassin Electro has earned its reputation as one of the top PCB manufacturers in Delhi, offering cutting-edge technologies and expert solutions to cater to a diverse range of industries.

Why Sassin Electro is Leading the Way in PCB Manufacturing

Sassin Electro is one of the premier PCB manufacturers in Delhi, known for its commitment to delivering precision, quality, and innovation in custom PCB solutions. The company has built a reputation for providing reliable and high-performance PCBs for a variety of industries. Below are some key reasons why Sassin Electro stands out in a competitive market:

1. Expertise in Custom PCB Solutions

One of the primary reasons businesses choose Sassin Electro is their specialization in providing custom PCB solutions. Unlike other manufacturers that focus on mass production, Sassin Electro works closely with clients to design and develop PCBs that are tailored to their specific requirements. Whether it's a single-layer PCB, a multi-layer PCB, or a flexible PCB, the company has the expertise to deliver the right solution for diverse applications.

The company's team of skilled engineers ensures that each custom PCB is designed to meet the technical specifications of the project. This attention to detail helps Sassin Electro deliver PCBs that work seamlessly in complex environments, from wearable devices and medical gadgets to advanced automotive systems and industrial machinery.

2. State-of-the-Art Manufacturing Facilities

To meet the growing demands of the PCB industry, Sassin Electro has invested heavily in state-of-the-art manufacturing facilities. The company’s production lines are equipped with the latest machinery, allowing them to offer high precision, fast turnaround times, and exceptional consistency. Sassin Electro uses automated processes, such as pick-and-place machines, soldering machines, and advanced testing equipment, to manufacture PCBs with superior quality and reliability.

Advanced equipment also allows for the production of high-density interconnect (HDI) PCBs, multi-layer boards, and flexible PCBs—products that are often required in industries like telecommunications, aerospace, and consumer electronics.

3. Quality Assurance and Rigorous Testing

For any electronic device to perform reliably, the PCB that powers it must meet stringent quality standards. Sassin Electro places a strong emphasis on quality control, ensuring that every PCB leaving their factory adheres to both national and international standards. The company follows a rigorous testing process that includes:

Electrical testing: Ensures that the circuit board functions correctly and the components are properly connected.

Thermal cycling: Tests the PCB’s durability under temperature fluctuations to ensure it performs well in harsh environments.

Environmental testing: Verifies the PCB’s ability to withstand moisture, corrosion, and other environmental factors.

By incorporating these quality checks into every stage of production, Sassin Electro ensures that their PCBs are of the highest quality and can meet the rigorous demands of various industries.

4. Industry-Specific Expertise

Each industry has unique requirements when it comes to PCBs, and Sassin Electro is adept at creating custom PCBs to meet these specialized needs. The company’s ability to design and manufacture PCBs for a wide range of applications has made it a preferred partner for businesses across various sectors:

Automotive industry: With the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), automotive companies require high-performance PCBs that are durable, reliable, and capable of handling high-speed data transmission. Sassin Electro manufactures PCBs that meet the stringent demands of automotive electronics.

Telecommunications: The telecommunications industry requires PCBs that can handle high-frequency signals, such as those used in 5G technology. Sassin Electro provides high-quality PCBs designed for fast data transfer and signal integrity.

Medical devices: Medical equipment such as pacemakers, ECG monitors, and diagnostic tools require precision-engineered PCBs that are both reliable and biocompatible. Sassin Electro manufactures medical-grade PCBs that comply with international quality and safety standards.

Consumer electronics: Whether it’s a smartphone, tablet, or wearable device, Sassin Electro provides custom PCBs that meet the compact size, durability, and performance demands of modern consumer electronics.

By working closely with clients in these sectors, Sassin Electro ensures that their products are designed to meet the specific needs of each industry, ensuring better performance and reliability.

5. Faster Turnaround Times and Cost Efficiency

In the electronics industry, speed to market is crucial, and Sassin Electro understands the need for quick turnarounds without compromising on quality. The company’s streamlined manufacturing processes and highly efficient production lines ensure that clients receive their custom PCBs in a timely manner, even for complex projects that require multiple iterations.

Additionally, Sassin Electro offers competitive pricing, making it an attractive option for businesses looking for high-quality PCBs at affordable rates. By optimizing their production process and using advanced technologies, the company can reduce costs, providing cost-effective solutions for both small and large-scale projects.

6. Commitment to Sustainability

As the global focus on sustainability increases, Sassin Electro is committed to adopting environmentally friendly practices. The company uses eco-friendly materials and follows sustainable manufacturing practices to minimize waste and reduce energy consumption. By adhering to global environmental standards and regulations, Sassin Electro is contributing to a greener and more sustainable PCB manufacturing industry.

The Future of PCB Manufacturing in Delhi

The future of PCB manufacturing in Delhi looks promising, with continued growth expected in industries like consumer electronics, telecommunications, automotive, and healthcare. As technology continues to advance, the demand for more complex and high-performance PCBs will increase. Companies like Sassin Electro are well-positioned to take advantage of these trends by continually innovating and providing cutting-edge solutions to meet the evolving needs of their clients.

With advancements in IoT, artificial intelligence (AI), and 5G, there will be a growing need for custom-designed, high-density, and flexible PCBs. As a leading PCB manufacturer in Delhi, Sassin Electro is ready to meet these challenges by continuing to offer precision, reliability, and innovation in every product they create.

Conclusion

As one of the top PCB manufacturers in Delhi, Sassin Electro has proven its ability to deliver high-quality, custom-designed PCBs for a variety of industries. By combining state-of-the-art manufacturing technology, a highly skilled workforce, and a commitment to quality, they continue to lead the way in PCB innovation. Whether for automotive, medical, telecommunications, or consumer electronics, Sassin Electro remains a trusted partner for businesses in need of precision-engineered PCBs that meet the most demanding industry standards.

For companies looking to stay ahead of the curve in the ever-evolving world of electronics, Sassin Electro provides the expertise, technology, and dedication to deliver superior PCB solutions that power the next generation of electronic devices.

0 notes

Text

We stand out as the leading PCB manufacturer in Delhi, embodying the Make in India ideology. Founded by a visionary woman entrepreneur, this organization has grown to be a pioneer in the field. Our commitment to quality and innovation has made us a trusted name in the industry. Shree Ram Electronics takes pride in its ability to deliver high-quality PCBs that meet the diverse needs of its clients. With a focus on customer satisfaction and technological excellence, we continue to lead the way in the PCB manufacturing sector in Delhi.

#leading PCB manufacturer in Delhi#pcb manufacturing companies in Delhi#pcb design and fabrication in Delhi

0 notes