#low-cost pcb manufacturer

Explore tagged Tumblr posts

Text

Trusted PCB Manufacturing Companies in India

Pcbcircuit is well-known fast-growing Pcb manufacturer in india. We are committed to excellence, sustainability, and customer satisfaction”. We strive to provide our customers with the highest quality and most reliable PCBs that can withstand rigorous applications.

#pcb fabrication#low-cost pcb manufacturer#flex pcb manufacturer#pcb manufacturer in haryana#quick turn pcb fabrication

2 notes

·

View notes

Text

PCB Assembly Precision and Performance For Every Project

A PCB assembly company in Hyderabad specializes in manufacturing and assembling printed circuit boards (PCBs) for various industries such as electronics, automotive, and telecommunications. These companies offer services including PCB design, prototyping, component sourcing, assembly, and testing, serving both small-scale and large-volume production needs.

#top 10 pcb manufacturer#pcb fabrication#quick turn pcb fabrication#pcb stencil#pcbcircuit#low-cost pcb manufacturer

0 notes

Text

Top PCB Manufacturer in India

PCBcircuit is a leading PCB manufacturer in India, offering high-quality printed circuit boards tailored to diverse industries. With advanced technology, precision engineering, and reliable customer support, we ensure efficient and cost-effective PCB solutions to power your innovations. Trust PCBcircuit for quality and excellence in PCB manufacturing.

#flex pcb manufacturer#prototype pcb manufacturing#pcb manufacturer#custom pcb manufacturing#low-cost pcb manufacturer#pcb fabrication#quick turn pcb fabrication#high-quality pcb manufacturing#multilayer pcb manufacturer

0 notes

Text

Hyderabad's Best Low Cost PCB Assembly

Can you search Low cost pcb assembled in Hyderabad, We offer high-quality, affordable PCB manufacturing and assembly solutions tailored to meet your needs. We ensures precision, reliability, and quick turnaround times, making us the top choice for PCB services in Hyderabad. Contact us today to get a quote and start your project!

#low-cost PCB manufacturer#custom pcb manufacturing#pcb manufacturer in india#two layer pcb stencil#prototype pcb manufacturing#pcb fabrication#Pcb manufacturer in haryana#Pcb manufacturer in jaipur#Pcb manufacturer in Maharashtra

1 note

·

View note

Video

youtube

blog 2023 04 12 pcb fly probe test pcbsino

#youtube#blog.2023.04.12.pcb.fly.probe.test.pcbsino.mp4 pcb prototype manufacturer shenzhen chinafree samplecurrent supprising low cost mass producti

0 notes

Text

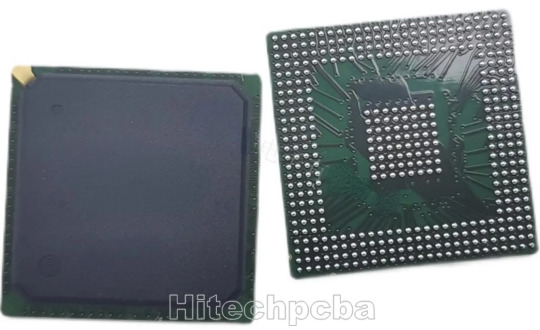

BGA PCB Assembly

What’s BGA PCB?

BGA PCB is Printed Circuit Boards with Ball Grid Array. We use various sophisticated techniques for making BGA PCBs. Such PCBs have a small size, low cost, and high packaging density. Hence, they are reliable for high-performance applications.

What’s BGA PCB Assembly?

Ball Grid Array (BGA) assembly technology is a surface mount packaging technology applied to integrated circuits, which is often used to permanently fix devices such as microprocessors. BGA assembly can accommodate more pins than other packages such as Dual in-line packages or Quad Flat Packages, and the entire bottom surface of the device can be used as pins , instead of only peripherals available, and also have a shorter average wire length than peripheral-limited package types for better high-speed performance.

Our BGA assembly services cover a wide range, including BGA prototype development, BGA PCB assembly, BGA component removal, BGA replacement, BGA rework and reballing, BGA PCB assembly inspection, and so on. Leveraging our full-coverage services, we can help customers streamline the supply network and accelerate product development time.

Benefits of BGA PCB Assembly

Efficient Use of Space – BGA PCB layout allows us to efficiently use the available space, so we can mount more components and manufacture lighter devices.

Better Thermal Performance – For BGA, the heat generated by the components is transferred directly through the ball. In addition, the large contact area improves heat dissipation, which prevents overheating of components and ensures long life.

Higher Electrical Conductivity – The path between the die and the circuit board is short, which results in better electrical conductivity. Moreover, there is no through-hole on the board, the whole circuit board is covered with solder balls and other components, so vacant spaces are reduced.

Easy to Assemble And Manage – Compared to other PCB assembly techniques, BGA is easier to assemble and manage as the solder balls are used directly to solder the package to the board.

Less Damage to Leads – We use solid solder balls for manufacturing BGA leads. Hence, there is a lesser risk that they will get damaged during the operation.

In a word, BGA PCB assembly, have these advantages, high density, better electrical conductivity, lower thermal resistance, easy to assembly & manage are some of the advantages of BGA PCB.

Stringent BGA PCB Assembly Testing Process

To achieve the highest quality standards for BGA assembly, we use a variety of inspection methods throughout the process including optical inspection, mechanical inspection, and X-ray inspection. Among them, the inspection of BGA solder joints must use X-rays. X-rays can pass through the components to inspect the solder joints below them, so as to check the solder joint position, solder joint radius, and solder joint thickness.

Inspection of BGA PCB

We mostly use X-ray inspection for analyzing the features of BGA PCBs. This technique is known as XRD in the industry and relies on X-rays for unveiling the hidden features of this PCB. This kind of inspection reveals.

* Solder Joint Position

* Solder Joint Radius

* Change in Circular shape

* Solder Joint Thickness

The Hitechpcba advantage lies in a whole range of aspects, beginning from the fact that we have the proven technology available at our disposal. With over 15 years of experience in a wide range of PCB Fabrication and Assembly techniques, what we also have is trained manpower and importantly, robust industry experience and best practices that you can benefit from.

Our unstinting devotion to quality and customer satisfaction means that once you partner with us, you can rest assured that you will get nothing but the best. The customer-oriented approach also shows up in your commitment to delivery times. With quick turnaround times, you can reap the benefit of quick time-to-market, which, in turn, can be a major source of competitive advantage.

Whether your requirement is BGA PCB design, BGA PCB, BGA PCB layout, BGA PCB Assembly or BGA rework, you can rest assured that you will get superior quality and performance, that will in turn, positively impact the performance of your final product.

With our efficient network of component suppliers and the many economies of scale that we enjoy, that you will get optimal costs, is a given.

Please feel free to contact us ([email protected]) if you have any other special request on the BGA pcb assembly.

3 notes

·

View notes

Text

What is PCB Assembly ?

PCB Assembly manufacturer - Hitech Circuits Co., Limited

It’s the step in the manufacturing process in which you populate a blank board with the electronic components needed to make it into a functional printed circuit board. It’s these components that make a board into the circuit that enables an electronic product to function. PCB assembly typically takes place via one of two processes:

1. Surface-mount technology

SMT: SMT stands for “Surface Mount Technology“. The SMT components are very small sizes and comes in various packages like 0201, 0402, 0603, 1608 packages for resistors and capacitors. Similarly for Integrated circuits ICs we have SOIC, TSSOP, QFP and BGA.

The SMT components assembly is very difficult for human hands and can be time taking process so it is mostly done by automated pick and place machine.

2. Through-hole manufacturing

THT: THT stands for “Through hole Technology”. The components with leads and wires, like resistors, capacitors, inductors, PDIP ICs, transformers, transistors, IGBTs, MOSFETS are example.

The component has to be inserted on one side of PCB and pulled by leg on other side and cut the leg and solder it. The THT components assembly is usually done by hand soldering and is relatively easy.

Printed Circuit Board Assembly Techniques

There are only two common PCBA techniques available for use by a PCB designer. The methods are:

1. Automated PCB Assembly Techniques

Generally, this technique employs the use of state of the art machines, which are fully automatic. For example, the surface mount components are worth positioning with the aid of an automated pick and place machine.

Again, reflow soldering is commonly for surface mount components usually done in a reflow oven. An automated solder stencil is also used to apply the solder paste on the PCB.

Finally, high tech inspection machines are used to confirm and check the quality of the PCBA. Some of which include: Automated optical inspection machine (AOI), X-ray inspection machines, etc.

Above all, due to the precise monitoring, control of soldering, no human input and versatile machines.

This technique ensures utmost efficiency, output consistencies, and limits defects.

2. Manual PCB Assembly Techniques

This method is favorite for use with through-hole parts, which needs manual placement on the board. Besides, with these through-hole parts, it’s advisable you use wave soldering. Note that in the through- hole assembly process, you need to place the components and electronics on the PCB.

After that, you use wave soldering to solder the leads. Typically, you will need an individual to insert a component into a marked PTH. Once done, transfer the PCB to the next station where the next person will be on standby tasked with fixing another part.

What are the Benefits of SMT PCB Assembly?

SMT assembly provides many benefits and some of them are as follows:

It can be used to incorporate small components.

In SMT, the components can be placed on both sides of the board.

It assures high component densities.

Fewer holes need to be drilled for surface mounting than through-hole.

It require low initial costs and time for setting up the mass production.

SMT is the simpler and faster-automated assembly when compared to through-hole.

Errors regarding the component placement can be easily rectified.

Surface mount PCBs feature strong joints, which can easily withstand vibrations.

What are the techniques used in Surface Mount Technology?

There are several techniques for the reflow process. After applying the solder paste or a flux mixture on the board and after placing the components, the boards are conveyed to a reflow soldering oven. The techniques used for reflowing soldering include infrared lamps, hot gas convection, fluorocarbon liquids with a high boiling point, and so on.

What are the different testing methods used in SMT PCB Assembly?

Hitech Circuits as the PCB assembly manufacturer, we perform the following testing and inspection to ensure the quality of surface mount PCBs.

Automated Optical Inspection (AOI): This is performed before and after the soldering to identify the component placement, presence, and solder quality.

X-ray Testing: In this type of testing, the operator relies on the X-ray images of the PCB to check the solder joints and lead-less components such as Quad Flat Packs and ball grid arrays, which are generally not visible to naked eyes.

In-Circuit Testing (ICT): This method is used to detect manufacturing defects by testing the electrical properties in the SMT Assembly.

What type of files or documents should I send for SMT PCB Assembly?

Gerber Files: The file contains all details of physical board layers including solder masks, copper layers, drill data, legends, and so on.

Bill of Materials (BOM): This contains information on the list of items needed for the PCB manufacturing and the instructions of manufacturing.

Pick and Place File: This file contains information on all components to be used in the PCB design and their rotation and X-Y coordinates.

The whole process of PCB Assembly

1. Bare board loader machine

The first step in the PCB assembly is to arrange the bare boards on the rack, and the machine will automatically send the boards one by one into the SMT assembly line.

2. Printing solder paste

When PCB on the SMT production line, firstly, we have to print solder paste on it, and the solder paste will be printed on the pads of the PCB. These solder pastes will be melt and solder the electronic parts to the circuit board when it passes through the high-temperature reflow oven.

In addition, when testing new products, some people will use film board/adhesive cardboard instead of solder paste, which can increase the efficiency for adjusting the SMT machines.

3. Solder paste inspection machine(SPI)

Since the quality of solder paste printing is related to the quality of welding of subsequent parts, some SMT factories will use optical machine to check the quality of solder paste after printed the solder paste in order to ensure stable quality. If there any poorly printed solder paste board, we will wash off the solder paste on it and reprint, or remove the excess solder paste if there is redundant solder paste on it.

4. High speed SMT machine

Usually, we will put some small electronic parts (such as small resistors, capacitors, and inductors) to be printed on the circuit board first, and these parts will be slightly stuck by the solder paste just printed on the circuit board, so even if the speed of printing is very fast and the parts on the board will not fall away. But large parts are not suitable for use in such high speed SMT machines, which will slow down the speed of small parts assembly. And the parts will be shifted from the original position due to the rapid movement of the board.

5. Universal SMT machine

Universal SMT machine is also known as "slow machine", it will be assembled some large electronic components, such as BGA IC, connectors, etc., these parts need more accurate positions, so the alignment is very important. Use a camera to take a picture to confirm the position of the parts, so the speed is much slower than High speed SMT machine we taked before. Due to the size of the components here, not all of them are packed in tape and reel, and some may be packed in trays or tubes. But if you want the SMT machine to recognize the trays or tube-shaped packaging materials, you must configure an additional machine.

Generally, traditional SMT machines are using the principle of suction to move electronic parts, and in order to place the parts successfully, and there must be the flat surface on these electronic components for the suction nozzle of the SMT machine to absorb. However, for some electronic parts don’t have a flat surface for these machines, and it is necessary to order special nozzles for these special-shaped parts, or add a flat tape on the parts, or wear a flat cap for thees electronic parts.

6. Manual parts or visual inspection

After assembled all parts by the high speed SMT machine or Universal SMT machine and before going through the high-temperature reflow oven, and we will set up a visual inspection station here and to pick out the deviation parts or missing components boards etc., because we have to use a soldering iron to repair if there are still defectives boards after passing the high-temperature oven, which will affect the quality of the product and will also increase the cost. in addition, for some larger electronic parts or traditional DIP parts or some special reasons cannot be processed by the SMT machine before, they will be manually placed on pcb here.

7. Reflow oven

The purpose of reflow oven is to melt the solder paste and form a non-metallic compound on the component feet and the circuit board, that means to solder electronic components on the circuit board. The temperature rise and fall curves often affect the soldering quality of the entire circuit board. According to the characteristics of the solder materials, usually the reflow oven will set the preheating zone, soaking zone, reflow zone, and cooling zone to achieve the best soldering effect.

For example, the melting point for SAC305 solder paste with lead-free is about 217°C, which means that the temperature of the reflow oven must be higher than the melting points to remelt the solder paste. What's more, the maximum temperature in the reflow furnace should not exceed 250°C, otherwise many parts will be deformed or melted because they cannot withstand such a high temperature.

Basically, after the pcb passed through the reflow oven, the assembly for the entire circuit board is almost complete. If there are hand-soldered parts, we need to transfer to DIP process, and then we have to check the quality after reflow oven by QC department.

8. Automatic optical inspection(AOI)

The main purpose of setting up AOI is because some high density boards can’t be process the following ICT test, so we used AOI inspection to replace it. But even using AOI inspections, there still have the blind spots for such checking, for example, the solder pads under the components cannot be checked by AOI. At present, it can only check whether the parts have side standing issue, missing parts, displacement, polarity direction, solder bridges, lack of soldering etc., but cannot checking the BGA solderability, resistance value, capacitance value, inductance value and other components quality, so far AOI inspection can’t completely replace ICT test.

Therefore, there is still some risk if only AOI inspection is used to replace ICT testing, but ICT test is also not 100% make sure the good quality, we suggest these two ways can be combined with together to make sure the good quality.

9. PCB unloader machine

After the board is fully assembled, it will be retracted to the unloder machine, which has been designed to allow the SMT machine to automatically pick and place the board without damaging the quality for PCB.

10. Visual inspection for finished products

Normally there will be a visual inspection area in our SMT production line whether there is an AOI station or not, and it will help to check if there are any defectives after completed assembled the pcbs. If there is an AOI station, it can reduce the visual inspection worker on our SMT line, and to reduce the potential cost, and because it is still necessary to check some places that cannot be judged by AOI, many SMT factories will provide the mainly visual inspection templates at this station, which is convenient for visual inspection worker to inspect some key parts and polarity for components.

11. DIP process

DIP process is a very important process in the whole PCBA processing, and the processing quality will directly affect the functional for PCBA boards, so it is necessary to pay more attention to the DIP process. There are many preliminary preparations for DIP process. The basic process is to re-process the electronic components first, like to cut the extra pins for some DIP components, our staff received the components according to the BOM list, and will check whether the material part numbers and specifications are correct or not, and performs pre-production pre-processing according to the PCBA samples. The steps are: Use various related equipment (automatic capacitor pins cutting machine, jumper bending machine, diode and triode automatic forming machine, automatic belt forming machine and other machines) for processing.

12. ICT test

Printed Circuit board open/short circuit test (ICT, In-Circuit Test), The purpose of ICT test is mainly to test whether the components and circuits on the printed circuit board are open or short issues. It can also measure the basic characteristics of most components, such as resistance, capacitance, and inductance values to judge whether the functions of these parts are damaged, wrong parts or missing parts etc. after passing through the high-temperature reflow oven.

ICT test machines are divided into advanced and basic machines. The basic ICT test machines are generally called MDA (Manufacturing Defect Analyzer). It’s just to measure the basic characteristics of electronic components and judge open and short circuits issue we talked above.

In addition to all the functions of the basic ICT test machines, for advanced ICT test machine can also test the whole PCBA by using power, start to testing the PCBA boards by setting the program in the test machine. The advantage is that it can simulate the function of the printed circuit board under the actual power-on condition, this test can partly replace the following functional test machine (Function Test). But the cost for the test fixture of this advanced ICT test can probably buy a car, it’s too expensive and we suggest it can be used in mass production products.

13. PCBA function test

Functional testing is to make up for the ICT test, because ICT only tests the open and short circuits on the the PCBA board, and other functions such as BGA and other fuctions are not tested, so it is necessary to use a functional testing machine to test all functions on the whole PCBA board.

14. Cutting board (assembly board de-panel)

Normally, printed circuit boards will be produced in panel, and it will be assembled to increase the efficiency of SMT production. It means several single boards in one panel, such as two-in-one, four-in-one etc. After finished all the pcb assembly process, it needs to be cut into single boards, and for some printed circuit boards with only single boards also need to cut off some redundant board edges.

There are several ways to cut the printed circuit board. You can design the V-cut using the blade cutting machine (Scoring) or directly manually break off the board (not recommended). For more high density circuit boards, it will be used the professional splitting machine or the router to split the board without any damage the electronic components and printed circuit boards, but the cost and working hours will be a little longer.

Why Choose Hitech Circuits PCB Assembly Manufacturer for Your PCB Assembly Projects?

There are several PCB manufacturers specializing in PCB assemblyservices. However, Hitech Circuits PCB Assembly stands out owing to the following:

Assistance in Material Procurement:

Technically, in PCB assembly services, the quality of parts is the responsibility of the OEM; however, we ease your job by assisting you to make the right selection. We can help you procure all your parts of the same type own a single part number, thanks to our supply chain and vendor network as well as experience. This saves time and cost that goes in ordering single parts as you plan.

Testing procedures:

We are very focused on quality and thus implement stringent testing procedures at each stage of the assembly and after completion.

Fast Turnaround Times:

Our well-equipped facility and the right tools enable us to complete your requirements well before time, and without compromising on the quality or functioning of the PCBs. For simple designs we revert in 24 to 48 hours.

Cost Effectiveness:

While PCB assembly is a cost-effective alternative, we go a step further and assure that the parts you list are of a good quality and suitable for your requirement. Also, you can control the part flow and replenish them as needed. This eliminates the need to buy extra stock and store it.

Quick Quote:

We offer a quick quote based on your BOM. All you need is a detailed BOM, Gerber files, your application requirement sheet, and quantity.

We’re not one to stand still, which is why we use the latest equipment and the finest minds to create your PCB projects. We’re constantly keeping our finger on the pulse of the latest trends. And as a result, we know how to deliver the highest standards of PCB assembly to meet all your requirements.

Our dedicated, friendly customer service team also means that we support you every step of the way. Offering our expert guidance to ensure a complete PCB project that you’re happy with.

Contact us today

No matter what your printed circuit board assemblyneeds are, we always aim to deliver efficient, dependable solutions. For more information about our services, do not hesitate to get in touch with us today for a no-obligation quote

2 notes

·

View notes

Text

PSA Nitrogen Generator Plants for Various Industry

Nitrogen gas plays a critical role in numerous industries, from food packaging to semiconductor manufacturing. Traditionally, businesses relied on nitrogen cylinders or bulk liquid nitrogen deliveries. However, PSA nitrogen plant technology has revolutionized the industry by enabling on-site nitrogen generation, offering cost-effective, efficient, and reliable gas supply.

In this article, we will explore the working principles of PSA nitrogen generators, their advantages, and how various industries, including the food, chemical, glass, and semiconductor sectors, benefit from them.

How Does a PSA Nitrogen Plant Work?

A Pressure Swing Adsorption (PSA) nitrogen plant operates by separating nitrogen from atmospheric air using carbon molecular sieves (CMS). The process involves two adsorption towers filled with CMS, which selectively adsorb oxygen and other impurities, allowing pure nitrogen to pass through.

Key Benefits of PSA Nitrogen Generation:

On-Demand Supply – Eliminates dependency on external nitrogen deliveries.

Cost Savings – Reduces operational costs associated with liquid or bottled nitrogen.

High Purity – Provides nitrogen with purity levels up to 99.999%, depending on the application.

Eco-Friendly – Reduces carbon footprint by eliminating transportation-related emissions.

Minimal Maintenance – Requires low operational oversight compared to other nitrogen sources.

With these advantages, PSA nitrogen generators have become a preferred choice across various industries.

Industries Benefiting from PSA Nitrogen Generators

1. Nitrogen Generator for Food Industry

In the food industry, nitrogen is widely used for food packaging, storage, and preservation. Oxygen exposure can cause food spoilage and bacterial growth. A Nitrogen Generator for food packaging ensures an inert atmosphere, extending shelf life and maintaining product freshness.

Applications include:

Modified Atmosphere Packaging (MAP) – Used in chips, coffee, and bakery products.

Food Storage & Transportation – Prevents oxidation and moisture damage.

Wine & Beverage Preservation – Prevents spoilage and retains flavor.

2. Nitrogen Generator for Beverage Industry

In the beverage industry, nitrogen is essential for carbonated drinks, beer production, and bottling processes. A Nitrogen Generator for the beverage industry helps maintain product consistency, prevent oxidation, and improve foaming characteristics in beverages like beer and soda.

Common uses include:

Purging oxygen from beverage containers.

Pressurizing kegs and beer tanks.

Nitrogen-infused beverages, such as nitro coffee and beer.

3. Nitrogen Generator for Chemical Blanketing

Many chemicals react with oxygen, leading to degradation or even hazardous situations. A Nitrogen Generator for chemical blanketing creates an inert environment, preventing oxidation, combustion, and contamination.

Industries that rely on nitrogen blanketing include:

Pharmaceuticals – Protects sensitive drug compounds.

Petrochemicals & Refineries – Prevents vapor combustion.

Paint & Coatings – Reduces spoilage and maintains viscosity.

Using a PSA nitrogen plant ensures a consistent nitrogen supply, improving process safety and efficiency.

4. Nitrogen Generator for Semiconductors

The semiconductor industry demands ultra-pure nitrogen for wafer processing, component testing, and circuit board assembly. A Nitrogen Generator for semiconductors ensures a stable and contamination-free production environment.

Applications in semiconductor manufacturing:

Wafer Fabrication & Etching – Prevents oxidation.

PCB Assembly & Soldering – Reduces defects in electronic components.

Laser Cutting & Cooling – Enhances precision in manufacturing.

By using a PSA nitrogen generator, semiconductor manufacturers can achieve higher yields and improve product reliability.

How to Choose the Right PSA Nitrogen Plant for Your Industry

When selecting a PSA nitrogen plant, several factors must be considered:

1. Nitrogen Purity Requirements

Food & Beverage: 99-99.5% purity.

Semiconductors & Electronics: Up to 99.999% purity.

Chemical & Petrochemical: Typically 98-99.9% purity.

2. Nitrogen Flow Rate & Pressure

Determine the required flow rate (Nm³/hr) and pressure (bar/psi) based on industry needs.

Higher flow rates are necessary for large-scale production facilities.

3. Space & Installation Considerations

On-site nitrogen generation requires minimal space compared to liquid nitrogen storage.

Ensure proper ventilation and safety measures for installation.

4. Operational Costs & Energy Efficiency

A PSA nitrogen plant has lower running costs compared to traditional nitrogen supply methods.

Look for energy-efficient models to reduce electricity consumption.

Installation & Maintenance of PSA Nitrogen Generators

Installation Process:

Site Assessment – Evaluate space, power requirements, and safety needs.

Equipment Setup – Connect the generator to the existing gas supply network.

Testing & Calibration – Ensure nitrogen purity and flow rates meet requirements.

Maintenance Tips:

Regular Filter Changes – Keeps the system running efficiently.

Monitor Pressure & Purity Levels – Prevents contamination.

Annual System Inspection – Ensures long-term performance and reliability.

Conclusion

A PSA nitrogen plant provides industries with a cost-effective, reliable, and sustainable solution for nitrogen generation. Whether it's a Nitrogen Generator for food industry, chemical blanketing, semiconductors, or beverage production, businesses can achieve greater efficiency, safety, and quality control with on-site nitrogen generation.

By switching to PSA nitrogen generators, companies reduce operational costs, improve productivity, and enhance product quality while minimizing environmental impact. If you're considering on-site nitrogen generation, now is the time to invest in a PSA nitrogen plant tailored to your industry’s needs.

Would you like a consultation on choosing the right nitrogen generator for your business? Get in touch today!

0 notes

Text

Flexible PCB Manufacturer - Custom Solutions for Innovative Electronics

We specialize in designing and manufacturing high-quality flexible pcb manufacture (PCBs) tailored to meet the demands of diverse industries. Our expertise in flexible circuit technology enables us to produce durable, reliable, and compact PCBs for applications ranging from consumer electronics to medical devices, automotive, and more. With precision engineering, fast turnaround times, and advanced manufacturing processes, we provide customized solutions that drive innovation in your electronic products.

#best pcb manufacturer#flex pcb manufacturer#multilayer pcb manufacturer#pcb manufacturer in haryana#low-cost pcb manufacturer#pcb manufacturer#pcb manufacturer in delhi#quick turn pcb fabrication#pcb manufacturer in maharashtra#pcb manufacturer near me

0 notes

Text

India's Best Custom PCB Manufacturer - Pcbcircuit

We specialize in delivering high-quality, precision-engineered PCBs tailored to your exact specifications. From concept to final product, our team ensures top-notch reliability and innovation at every stage. Trust us to power up your electronics with industry-leading PCB solutions! Best PCB manufacturers are known for their experience, customer support, and ability to scale production based on project requirements.

#top 10 pcb manufacturer#pcb fabrication#quick turn pcb fabrication#pcb stencil#pcbcircuit#low-cost pcb manufacturer

0 notes

Text

Choosing The High-quality PCB Manufacturing in India

Pcbcircuit is a High-quality PCB manufacturing service in India. We offer precision-engineered printed circuit boards tailored to meet diverse industry needs. Ensure reliability, durability, and efficiency in your electronic projects by choosing our high-quality PCBs, designed to exceed global standards. Perfect for innovation-driven businesses.

#custom pcb manufacturing#pcb manufacturer#flex pcb manufacturer#low-cost pcb manufacturer#quick turn pcb fabrication#high-quality pcb manufacturing#pcb fabrication#prototype pcb manufacturing#multilayer pcb manufacturer

0 notes

Text

Comprehensive Guide on Printed Circuit Boards (PCBs)

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices, providing the necessary electrical connections and mechanical support for components. From smartphones to industrial machinery, PCBs play a critical role in ensuring seamless functionality. This guide will walk you through everything you need to know about PCBs, including their types, design process, manufacturing, and applications.

What is a Printed Circuit Board?

A Printed Circuit Board (PCB) is a flat, laminated board made of non-conductive material with conductive pathways etched onto its surface. These pathways, also called traces, allow electricity to flow between various components, facilitating efficient communication within electronic devices. PCBs can be single-layered, double-layered, or multi-layered, depending on the complexity of the circuit.

Types of PCBs

1. Single-Layer PCBs

Single-layer PCBs have a single conductive layer, making them simple and cost-effective. They are commonly used in low-cost consumer electronics and basic circuit applications.

2. Double-Layer PCBs

These PCBs have conductive layers on both sides of the board, allowing for more complex circuit designs. They are widely used in automotive electronics, power supply circuits, and industrial control systems.

3. Multi-Layer PCBs

Multi-layer PCBs consist of multiple conductive layers stacked together, separated by insulating layers. They are essential for high-performance electronic devices like computers, medical equipment, and aerospace applications.

4. Rigid PCBs

Rigid PCBs are made from solid substrates, which prevent them from bending or flexing. They are commonly found in computers, televisions, and industrial control systems.

5. Flexible PCBs

Flexible PCBs use flexible materials like polyimide, allowing them to bend and fold. They are used in wearable technology, medical devices, and compact electronic products.

6. Rigid-Flex PCBs

These PCBs combine both rigid and flexible board technology, offering greater design versatility and durability. They are widely used in military, aerospace, and medical applications.

PCB Design Process

The design of a PCB involves several key steps to ensure optimal performance and functionality. Here’s a step-by-step breakdown:

1. Concept and Schematic Design

Engineers begin by creating a schematic diagram, which serves as a blueprint for the circuit. This diagram includes all components and their interconnections.

2. PCB Layout Design

Using specialized software like Altium Designer, Eagle, or KiCad, designers create a PCB layout based on the schematic. This step involves placing components and routing traces.

3. Design Rule Check (DRC)

A Design Rule Check ensures that the PCB layout adheres to manufacturing constraints, such as trace width, spacing, and hole sizes.

4. Generating Gerber Files

Gerber files are industry-standard files used by PCB manufacturers. These files contain detailed information about each layer of the PCB design.

5. Prototype Development

Before mass production, a prototype PCB is manufactured and tested to ensure the design functions correctly.

Applications of PCBs

PCBs are used in a vast range of industries, including:

1. Consumer Electronics

Smartphones, laptops, televisions, and gaming consoles all rely on PCBs for operation.

2. Automotive Industry

Modern vehicles use PCBs in engine control units, navigation systems, and safety features like airbags and ABS.

3. Medical Devices

PCBs are critical in medical equipment such as MRI machines, pacemakers, and diagnostic tools.

4. Aerospace and Defense

Aircraft, satellites, and military systems use high-reliability PCBs designed to withstand extreme conditions.

5. Industrial Automation

PCBs power robotics, control panels, and automation systems in manufacturing and logistics.

Conclusion

PCBs are an essential part of modern electronics, offering reliability, efficiency, and scalability. Understanding their types, design, manufacturing, and applications can help businesses and engineers make informed decisions in electronic development. As technology advances, PCBs will continue to play a crucial role in shaping the future of electronics. For high-quality PCB repairs and services, IER Industrial Electronic Repairs LTD is your trusted partner, providing expert solutions for all your industrial electronic needs.

1 note

·

View note

Text

RF & Microwave PCBs: Key Considerations for Fabrication and Performance

In high-frequency applications like radar systems, satellite communications, and wireless networks, RF & microwave PCBs play a crucial role in ensuring seamless signal transmission. These specialized circuit boards require precision engineering, advanced materials, and expert fabrication techniques. Choosing the right RF microwave PCB manufacturer is essential for optimal performance and reliability.

Key Considerations in RF & Microwave PCB Fabrication

1. Material Selection

The foundation of any RF microwave PCB lies in the materials used. Standard FR4 substrates are unsuitable for high-frequency applications due to high dielectric loss. Instead, manufacturers rely on advanced materials such as:

Rogers Laminates – Low-loss, high-frequency stability

PTFE (Teflon) Substrates – Excellent signal integrity at GHz frequencies

Taconic and Arlon Materials – Enhanced thermal and electrical performance

A high-quality RF microwave PCB manufacturer will provide a range of materials tailored to your specific frequency and application needs.

2. Controlled Impedance & Precision Etching

Maintaining controlled impedance is critical in RF and microwave applications. Any variation in trace width, dielectric thickness, or copper weight can affect signal integrity. Advanced manufacturing techniques like laser direct imaging (LDI) and precision etching ensure accurate impedance matching and minimal signal loss.

3. Thermal Management Solutions

RF and microwave circuits generate significant heat, which can impact performance and longevity. Effective thermal management solutions, including thermal vias, heat sinks, and advanced copper plating techniques, help dissipate excess heat and maintain operational stability.

4. Surface Finishes for RF Performance

The choice of surface finish affects signal integrity and board longevity. Common finishes for RF microwave PCBs include:

ENIG (Electroless Nickel Immersion Gold) – Corrosion-resistant and highly conductive

Silver Plating – Low insertion loss for improved high-frequency performance

OSP (Organic Solderability Preservative) – Cost-effective and environmentally friendly

Why Choose ASC for RF & Microwave PCBs?

For high-performance RF microwave PCB manufacturing, Advanced Circuits (ASC) is a trusted industry leader.

Why Work with ASC?

✅ Expertise in RF & microwave PCB fabrication

✅ High-quality materials for superior signal performance

✅ Precision manufacturing with controlled impedance

✅ Fast prototyping and large-scale production capabilities

For reliable RF microwave PCB solutions, choose ASC. Contact them today to get started on your next high-frequency project!

0 notes

Text

Low Cost PCB Circuit Board manufacturing

We provide printed circuit board fabrication with competitive prices for thousands of electronic design engineers, PCB assemblers, hobbyists and students from all over the world.

Three differences between us and other low-cost PCB manufacturers are as followed:

1. We provide higher quality boards with low cost which are made in China.

2. Faster lead time (24 hours for 2 layers PCBs prototypes and small batch production).

3. Superior customer service (Dedicated account rep, personal to personal).

As experts in the manufacture and assembly of printed circuit boards, we work to make our blog a helpful resource on PCB topics and the industries that we work with, including automotive, consumer electronics, aerospace and many more. Here you'll find insights into PCB design, tech trends, assembly issues, and trending topics in the general news media as they relate to printed circuit board technology.

Higher quality PCBs at a Lower Price

We can provide you with high quality domestic printed circuit boards that are not only at a low price, but also meet our stringent testing and quality standards. Every piece of printed circuit board will be tested before shipping. If you are ever unsatisfied with our low-cost PCB manufacturing services, we can quickly resolve any issues with our local in-house manufacturing capabilities and try our best to meet all your requirements. We aren't just providing you with "cheap PCBs", we are providing you with inexpensive PCBs that are of the highest quality! Don't be tricked by other discounted PCB factory, make sure you are still getting the board quality that your PCB prototyping efforts demand.

Are you looking for Cheap PCB Prototyping manufacturer in China?

Hitech Circuits manufactures printed circuit boards for the simplest 2 layer hobbyist projects to the most complex PCB to meet the rigorous requirements for military, medical, aerospace, etc. To satisfy the needs of our wide range of customers, we have created 3 different ways to order printed circuit boards: Standard Spec, Custom Spec, and our 2 & 4 Layer Prototyping Specials. The different categories help our customers stay on budget while making it easy to meet their project requirements

There is no shortage of PCB manufacturers that produce boards “on the cheap”. But how does their cheap PCB fabrication compare with our low cost prototyping options? Hitech Circuits’ experienced CAM engineers fully inspect your PCB design files before manufacturing, contacting you if there are any issues found. Unlike the “no-touch” alternatives, you are not left on your own with design issues after manufacturing with boards that you are not able to use. We also offers you:

Industry’s best on-time shipping record

Quick turn as fast as Same Day

100% China Based Manufacturing

Industry’s largest support team

24 Hr. tech support

Latest state-of-the-art equipment

High Quality Standards

Detailed CAM Review

Generally, PCB buyers choose a targeted PCB manufacturer based on the overall needs of the factory when choosing a PCB manufacturer. Professional PCB manufacturers produce PCBs with more quality assurance and low cost. Therefore, PCB buyers will choose PCB manufacturers with solid production and service capabilities to reduce the overall PCB procurement risk. However, it is not easy for PCB buyers to find a suitable PCB manufacturer, so how to choose a PCB manufacturer?

Let us understand how to choose the best China pcb manufacturer?

A: As a PCB manufacturer for hobbyist, PCB manufacturers near me is an important consideration

For example, PCB manufacturing USA, PCB manufacturing UKand PCB manufacturing Australia. China has more cheap PCB manufacturers. It is also a good idea to choose China PCB manufacturer.

B: Pay attention to the range of process capability and services.

PCB manufacturing process is complex and tedious; when choosing a PCB manufacturer, try to choose a PCB manufacturer with a wide range of functions and rich process capabilities so as not to delay the process involved beyond the ability of the PCB manufacturer, which will affect the PCB delivery time, so first when choosing a PCB manufacturer There must be a detailed reference to the PCB process requirements to prevent electrical functions from being affected due to the lack of PCB manufacturer's process.

C: Pay attention to whether the PCB manufacturer's production equipment can meet the requirements. Due to the different types of PCBs, the PCB production requirements are pretty additional, and the equipment levels used by PCB manufacturers are also different. Therefore, PCB manufacturers must make sample comparisons before considering batch cooperation.

D: Pay attention to whether there is a pegging fork clause. Due to the particularity of PCB custom processing, all PCBs that need to be assembled and shipped have a single probability of being scrapped. Generally, the customer accepts the pegging fork clause by default. If you do not buy it, you need to contact the PCB. The manufacturer communicates, usually, the PCB manufacturer will charge a certain fee, and you need to choose whether to accept the flat cross according to your situation.

E: Pay attention to whether the PCB manufacturer's quality assurance products. Regarding quality assurance, when choosing the best china pcb manufacturer, you must first judge the quality of the PCB manufacturer, such as whether the PCB has tested the PCB product before shipment to avoid the impact of quality problems. The later use of PCB prevents subsequent safety issues.

The main factors to calculate a pcb prototype price:

1. Board size: the larger dimension, the much expensive.

2. Materials: Some substrate and laminate PCB materials cost more than others. If high performance is essential, then your materials may be more expensive.

3. Complexity: Having a large number of components, complex wiring, or a very dense board can increase the overall cost.

3. Copper thickness: the heavier copper thickness, the much expensive price

4. Surface finished: usually HASL and OSP is the cheapeat, then silver, Tin, ENIG, ENEPIG is expensive

What is the Difference between Standard PCB and PCB Prototype?

Why suggest the PCB before choosing design Prototype PCB?

And what circumstances is PCB prototyping suggestion?

What are the advantages of PCB prototyping? You will find the answer below.

1. Quantity

The number of Prototypes PCB designs is far less than standard design products. Basically less than 10 or between 100 and 500.

2. Production Lead Time

Unless the delivery time of a single component is longer, the production lead time of the PCB prototype design will within 10 days.

3. Unit Cost and Total Cost

The total cost is much lower. PCB prototype design has many advantages beyond standard design.

Hitech Circuits is China PCB manufacturer. If you need PCB manufacturer with low price, please get in touch with us.

0 notes

Text

High-frequency board materials

High-frequency PCBs require specific materials to ensure reliable performance in signal transmission at elevated frequencies. These materials must have stable electrical properties, low loss, and good signal integrity. Here’s an overview of the most commonly used materials for high-frequency PCBs:

1. PTFE (Polytetrafluoroethylene)

Common Brand Names: Teflon, Rogers 4000 series

Properties: PTFE-based materials have a low dielectric constant (Dk) and low loss tangent (Df), which reduces signal loss, making them ideal for high-frequency applications.

Applications: Microwave and RF (Radio Frequency) circuits, satellite communication, automotive, aerospace, and wireless applications.

Challenges: PTFE materials can be difficult to work with due to their high processing temperatures and the need for special equipment.

2. Ceramic PCBs

Common Types: Alumina, Aluminum Nitride, Beryllium Oxide

Properties: Ceramic materials offer very low dielectric loss and high thermal conductivity, which is essential for high-frequency and high-power applications. These materials also have excellent thermal stability.

Applications: Used in high-power RF applications, radar systems, medical devices, and automotive electronics.

Challenges: Ceramics are brittle, so they can be difficult to handle during manufacturing, and their cost is usually higher compared to standard PCB materials.

3. Rogers Laminates

Common Products: Rogers 4003C, 4350B, 5880

Properties: Rogers materials are widely used for high-frequency PCB applications due to their consistent electrical performance, low loss, and high reliability. The Dk values for Rogers laminates can be tailored to meet specific design requirements.

Applications: Aerospace, RF amplifiers, GPS, and telecommunications.

Challenges: They are typically more expensive than standard FR4 and may require specialized fabrication techniques.

4. FR-4 with Epoxy Resin and Glass Fiber

Properties: FR-4 is the most common material for standard PCBs, but there are variations specifically designed for high-frequency applications. These FR-4 versions are modified to have better performance in the GHz frequency range by using higher-quality epoxy resins and specialized glass fibers.

Applications: FR-4 high-frequency versions are used in lower-cost RF applications, consumer electronics, and embedded systems.

Challenges: While cheaper than PTFE or ceramics, FR-4 is not ideal for the highest frequencies and can experience higher signal loss at very high frequencies.

5. Polyimide

Properties: Polyimide materials offer good mechanical properties, high-temperature resistance, and stable electrical performance at higher frequencies. It is often used for flexible PCBs, which can be crucial in high-frequency applications where space is tight.

Applications: Used in applications where flexibility is required, such as mobile phones, wearable electronics, and aerospace systems.

Challenges: Polyimide materials can be more expensive and may require specialized manufacturing techniques, especially for flexible high-frequency applications.

6. PTFE and Glass Fabrics (Hybrid Materials)

Properties: Hybrid materials that combine PTFE with glass fibers or ceramics can further enhance the performance characteristics of a PCB. The glass fibers help improve the mechanical strength of PTFE, which is otherwise relatively weak.

Applications: Used in applications where both electrical performance and mechanical strength are important, such as RF circuits and high-frequency communication systems.

Key Factors in Choosing High-Frequency PCB Materials:

Dielectric Constant (Dk): A material's Dk affects signal propagation speed and impedance. For high-frequency applications, you need materials with stable Dk values.

Loss Tangent (Df): This measures the material's ability to dissipate energy. Low-loss materials are critical to minimizing signal degradation.

Thermal Stability: High-frequency PCBs can generate heat, so thermal conductivity and stability are vital in material selection.

Mechanical Strength: For high-frequency applications, materials must withstand mechanical stresses during manufacturing and operation.

Conclusion:

When selecting materials for high-frequency PCB design, it's important to consider not only the electrical properties but also factors like thermal performance, mechanical stability, and cost. PTFE and Rogers laminates are popular for high-end applications, while ceramics and polyimide materials are used in specialized high-performance environments.

If you need further details or have any specific application questions, feel free to ask!

0 notes

Text

📡 High-Frequency PCB Manufacturing Techniques 🔧

High-frequency PCBs are crucial for advanced communication and RF applications. Here's a breakdown of their manufacturing techniques:

🔍 Key Highlights: ✔️ Material Selection: Use specialized substrates like PTFE, Rogers, or ceramic for minimal signal loss and high stability. ✔️ Precision Etching: Ensures accurate trace dimensions to maintain impedance control. ✔️ Multilayer Design: Essential for complex circuits to support high-speed signal integrity. ✔️ Plating Techniques: Employ advanced methods like ENIG (Electroless Nickel Immersion Gold) for reliable connections. ✔️ Testing Protocols: Rigorous testing for dielectric constant (Dk) and dissipation factor (Df) to ensure performance.

Pro Tip: Focus on low-loss materials and precise manufacturing to enhance signal quality and reduce interference. 🚀

👉 Learn more: https://www.viasion.com/blog/low-cost-pcb-manufacturing/

0 notes