#manufacturing green products

Explore tagged Tumblr posts

Text

How to Start a Biodegradable Plastic Bags Manufacturing Business

Want to turn your passion for sustainability into a thriving business? 🌍💼 Learn how to launch a biodegradable plastic bags manufacturing business and make a positive impact on the planet! #BiodegradableBags #sustainablebusiness #ecofriendlybusiness

The biodegradable plastic bag industry aims to create eco-friendly substitutes for conventional plastic bags. Biodegradable plastic bags are made to degrade more quickly in natural environments than ordinary plastics, which can take hundreds of years to break down. Usually composed of plant-based materials like sugarcane or cornstarch, these bags have a smaller environmental impact because they…

#biodegradable plastic bags#biodegradable plastic bags business#biodegradable products#biodegradable products industry#eco-conscious entrepreneurship#eco-friendly business opportunities#eco-friendly manufacturing#environmental business opportunities#green business ideas#green technology business#how to start a biodegradable plastic bags business#manufacturing green products#new business ideas 2024#plastic alternatives#profitable green business#profitable manufacturing business#profitable small business ideas#start a business#sustainable entrepreneurship#sustainable packaging#sustainable packaging solutions#sustainable startup

0 notes

Text

What Percentage of Cars Sold in 2023 Were Electric?

The automotive industry has been rapidly shifting towards electric vehicles (EVs), driven by increasing environmental concerns, technological advancements, and government incentives. The year 2023 marked a significant milestone in this transition. This transition has raised the question: What Percentage of Cars Sold in 2023 Were Electric? Let’s dive into the data to understand the impact and…

View On WordPress

#automotive industry#automotive trends#battery production#battery technology#car manufacturing#car market trends#car sales 2023#charging infrastructure#charging networks#China EV market#Clean Energy#cobalt#consumer acceptance#electric cars#electric mobility#electric vehicles#environmental awareness#Environmental Impact#Europe EV market#EV adoption#EV incentives#EV maintenance#EV technology#EVs#Ford#future of cars#General Motors#global sales#Government Incentives#green alternatives

2 notes

·

View notes

Text

Link to the court document here

From the Guardian article:

Houston-based Inhance manufactures an estimated 200m containers annually with a process that creates, among other chemicals, PFOA, a toxic PFAS compound. The Environmental Protection Agency (EPA) in December prohibited Inhance from using the manufacturing process.

But the conservative fifth circuit court of appeals court overturned the ban. The judges did not deny the containers’ health risks, but said the EPA could not regulate the buckets under the statute it used. The rule requires companies to alert the EPA if a new industrial process creates hazardous chemicals. Inhance has produced the containers for decades and argued that its process is not new, so it is not subject to the regulations. The EPA argued that it only became aware that Inhance’s process created PFOA in 2020, so it could be regulated as a new use, but the court disagreed.

Inhance said in a statement its “technologies … keep thousands of tons of harmful chemicals and fuels out of the environment, preserve product quality, and ensure compliance with many global regulations”. However, the company in 2021 admitted the creation of PFAS is “an unavoidable aspect” of its process [...]

#horrible#all the more reasons to grow your own food reduce consumerist demand for products in plastic packaging and plastic products in gen#and to blow up company numbers to complain that theyre fucking over everyone#also ur local and state reps. stop doing business w these fucks!!!#my greens#epa#environmental justice#pollution#plastic pollution#plastic#toxic waste#manufacturing#green link

1 note

·

View note

Text

"Taking a shower longer than 5mins is such a huge waste of water" in this country there are literal acres of fresh green grass being watered in the desert, draining our lakes and rivers for a luxury sport

also "ough life-saving essential medical equipment uses so much plastic" in this country you can purchase an artificial ballsack for your pickup truck

#its almost like the problem lies with the mega corps and not the individual#its almost like no matter how green all of us peons live we are still at the mercy of the coke brothers#maybe perhaps its on the part of the manufacturers how much plastic waste is produced by how they design their packaging#its kinda as if the choice of the products we're given and the way our society is run is skewed by luxury and privilege

136K notes

·

View notes

Text

Audi începe producția de mașini electrice la noua uzină din China: modele PPE pentru piața locală

Constructorul german Audi a demarat producția de vehicule electrice la noua sa uzină din Changchun, China, prin intermediul joint-venture-ului Audi FAW NEV Company, format în parteneriat cu FAW. Construcția uzinei a început la mijlocul anului 2022, iar acum este complet operațională, având capacitatea de a produce peste 150.000 de unități anual. Fabrica Audi din Changchun: un exemplu de…

#A6 e-tron#Audi#bam#carbon neutrality#China factory#diagnosis#diagnoza#Electric Vehicles#FAW#german#Green Technology#manufacturing robots#neamt#neutralitate carbon#PPE#producție sustenabilă#Q6L e-tron#roboți fabricație#roman#sustainable production#tehnologie verde#uzină China#vehicule electrice

0 notes

Text

What Innovations Make GreenH Electrolysis a Key Player in India's Hydrogen Revolution?

India is on the cusp of a green energy revolution, with hydrogen emerging as a critical pillar for achieving the nation’s ambitious climate goals. Green hydrogen, produced through electrolysis powered by renewable energy, is paving the way for decarbonizing industries, transportation, and power generation. Among the key players driving this transformation is GreenH Electrolysis. This article delves into the groundbreaking innovations that position GreenH Electrolysis at the forefront of India’s hydrogen revolution.

The Significance of Hydrogen in India’s Energy Transition

Green hydrogen is a versatile and sustainable energy carrier that holds immense potential for addressing climate challenges. As part of its National Hydrogen Mission, India aims to become a global leader in green hydrogen production, leveraging domestic manufacturing, renewable resources, and advanced technologies. Electrolysers, which split water into hydrogen and oxygen, are central to this vision, making innovation in this field a priority.

GreenH Electrolysis: A Beacon of Innovation

GreenH Electrolysis is revolutionizing the electrolyser market with its cutting-edge solutions tailored to the unique needs of the Indian ecosystem. Here are the key innovations that set the company apart:

1. Advanced Alkaline and PEM Technology

GreenH Electrolysis has developed next-generation alkaline and proton exchange membrane (PEM) electrolysers that offer superior efficiency and scalability. These systems are optimized to operate under varying conditions, ensuring high performance and durability. By addressing the challenges of energy efficiency and operational reliability, GreenH Electrolysis enables cost-effective green hydrogen production.

2. Energy Integration for Sustainability

A standout innovation by GreenH Electrolysis is its seamless integration of renewable energy sources into electrolyser operations. The company’s systems are designed to synchronize with solar and wind power, maximizing the use of clean energy for hydrogen production. This not only enhances sustainability but also reduces the carbon footprint of the entire process.

3. Modular and Scalable Designs

To cater to diverse market requirements, GreenH Electrolysis has introduced modular electrolysers that can be scaled up as needed. This flexibility is particularly beneficial for small and medium enterprises (SMEs) looking to adopt green hydrogen solutions without substantial initial investments. The modular approach also facilitates easy maintenance and upgrades, ensuring long-term value.

4. Digital Twin Technology

GreenH Electrolysis leverages digital twin technology to enhance the performance and reliability of its electrolysers. By creating a virtual replica of the physical system, the company enables real-time monitoring, predictive maintenance, and data-driven decision-making. This innovation minimizes downtime and optimizes efficiency, delivering significant cost savings.

5. Localized Manufacturing and Supply Chains

In alignment with India’s Make in India initiative, GreenH Electrolysis has established domestic manufacturing facilities that produce high-quality electrolysers at competitive costs. The company’s focus on local supply chains not only reduces dependency on imports but also supports the growth of the Indian manufacturing sector.

Addressing Industry Challenges

While the hydrogen revolution holds great promise, it also comes with challenges. High costs, infrastructure gaps, and policy uncertainties are significant barriers to widespread adoption. GreenH Electrolysis addresses these challenges through:

Cost Optimization: By innovating manufacturing processes and leveraging economies of scale, the company ensures affordability without compromising quality.

Collaborative Ecosystems: Partnerships with renewable energy providers, research institutions, and policymakers help create a robust ecosystem for green hydrogen adoption.

Advocacy for Supportive Policies: GreenH Electrolysis actively engages with stakeholders to promote regulatory frameworks that accelerate the deployment of hydrogen technologies.

Real-World Impact and Success Stories

The innovative solutions by GreenH Electrolysis have already made a tangible impact across various sectors. From renewable energy startups to large-scale industrial operations, the company’s electrolysers are enabling businesses to achieve their sustainability goals. Success stories include:

Decarbonizing Heavy Industries: GreenH Electrolysis has deployed systems that replace fossil fuels with green hydrogen in steel and cement production, significantly reducing emissions.

Green Mobility Projects: The company’s technology powers hydrogen fuel cell vehicles, promoting cleaner transportation options.

Energy Storage Solutions: By integrating with renewable energy projects, GreenH Electrolysis facilitates efficient energy storage and grid stability.

The Future of GreenH Electrolysis in India’s Hydrogen Revolution

As India intensifies its focus on green hydrogen, GreenH Electrolysis is poised to lead the charge with continued innovation and strategic growth. The company plans to:

Expand its manufacturing capacity to meet growing demand.

Develop next-generation electrolysers with even higher efficiency and lower costs.

Strengthen its presence in international markets, showcasing India’s capabilities in green hydrogen technology.

Foster talent and innovation through collaborations with academic and research institutions.

Conclusion

GreenH Electrolysis is not just a participant but a key driver of India’s hydrogen revolution. Its groundbreaking innovations in technology, sustainability, and cost optimization make it a preferred choice for electrolyser solutions. As the nation transitions towards a cleaner energy future, GreenH Electrolysis stands out as a beacon of progress, empowering industries to embrace green hydrogen and contribute to a sustainable tomorrow.

1 note

·

View note

Text

#Organic fabric wholesalers#Eco-friendly garment manufacturers#Wholesale sustainable textiles#Ethical fashion suppliers#B2B sustainable apparel#Global eco-fashion distributors#Low MOQ sustainable fashion#Green clothing wholesale#Organic cotton fabric bulk#Ethical fashion sourcing#Worldwide eco-textile suppliers#Hemp fabric manufacturers#Sustainable clothing materials#Responsible fashion wholesalers#Eco-conscious garment production#Sustainable fashion sourcing#Environmentally friendly textiles#Fair trade clothing suppliers

0 notes

Text

How to Design a Solar Panel Factory: 7 Expert Tips (2024)

Why This Matters: A Simple Introduction

Imagine a factory that makes solar panels while using very little energy itself - that's what we're talking about today! Just like a chef needs a well-designed kitchen to cook great meals, solar panel makers need smart factories to create high-quality panels. In this guide, we'll explore how to build the perfect solar panel factory that's both efficient and environmentally friendly.

"The solar industry isn't just about making panels cheaper anymore -- it's about making them better and smarter." - Solar Energy World, 2024

Why Factory Design is More Important Than Ever

Think about this: when you're baking cookies, having a modern oven with good temperature control helps you make better cookies, right? The same goes for solar panels! Recent studies show that well-designed factories can work up to 95% more efficiently than older ones. That means they can make more panels while using less energy and creating less waste.

How Smart Factories are Changing the Game

Let's break down the numbers in a way that's easy to understand:

7 Smart Ways to Build the Perfect Factory

1. Robots and Smart Machines (Advanced Automation)

Think of this like having a super-smart kitchen where:

Robots handle materials carefully (like having an extra set of careful hands)

Computers check everything is perfect (like having a master chef watching every step)

Machines fix problems before they happen (like knowing your oven needs fixing before it breaks)

Everything works together smoothly (like a well-rehearsed dance)

2. Smart Building Design

Imagine a building that:

Uses its own solar panels for power (like growing your own vegetables)

Makes the most of natural light (like having big windows in your house)

Keeps temperature just right (like a smart thermostat)

Reuses heat instead of wasting it (like using bath water to water plants)

3. Modern Production Lines

Recent breakthroughs have made solar panels much better. For example, new materials called "perovskites" help panels convert almost 30% of sunlight into electricity - that's huge! Our production lines use:

Smart material handling (like having a conveyor belt in a restaurant kitchen)

Precise cutting tools (like having a perfect bread slicer)

Automatic assembly (like a machine that decorates cakes perfectly)

Smart testing systems (like having a food taster check every dish)

4. Better Quality Checking

We use:

Computer vision (like having eyes that can spot tiny problems)

Real-time testing (like tasting food while cooking)

Heat cameras (like seeing where heat escapes from your house)

Automatic problem spotting (like spell-check for solar panels)

5. Waste Reduction

Just like reducing food waste in a kitchen:

Recycling materials (like composting vegetable scraps)

Reusing water (like collecting rainwater for plants)

Saving silicon (like saving leftover ingredients)

Smart packaging (like using just the right amount of wrapping)

6. Smart Resource Management

Think of this like managing a restaurant's supplies:

Smart tracking of materials (like knowing what's in your fridge)

Ordering just what's needed (like buying fresh ingredients daily)

Perfect timing of production (like preparing dishes just before serving)

Using energy wisely (like turning off appliances when not in use)

7. Earth-Friendly Operations

We care about our planet:

No harmful emissions (like using electric cars instead of gas ones)

Using clean energy (like powering your home with solar panels)

Recycling everything possible (like sorting household waste)

Working with green suppliers (like buying from local organic farms)

Using Next-Generation Technology

At Sunpal Solar, we're proud to make state-of-the-art solar panels. Our PERC 550W solar panel is a great example of combining smart manufacturing with high performance. Here's how we make them:

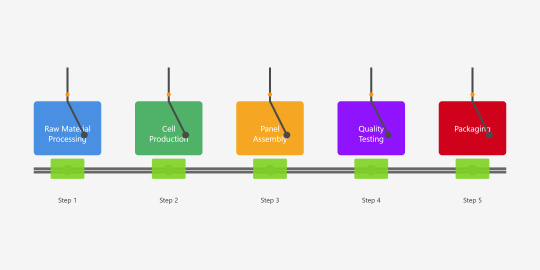

Step-by-Step Production Process

Preparing Raw Materials

Cleaning silicon (like washing vegetables)

Making thin wafers (like slicing bread)

Creating special surfaces (like adding texture to cookie dough)

Making Solar Cells

Adding PERC technology (like adding a special ingredient)

Adding anti-reflection coating (like glazing a cake)

Creating electrical contacts (like adding wiring to a lamp)

Putting Panels Together

Connecting cells (like building a puzzle)

Sealing everything together (like wrapping a present)

Adding frames and protection (like putting food in containers)

Checking Everything

Testing how well it works (like taste-testing food)

Looking for any problems (like checking for burned spots)

Making sure it will last (like checking food expiration dates)

How Computers Make Everything Smarter

Modern factories use artificial intelligence (AI) to:

Schedule work better (like planning your week)

Fix problems early (like maintaining your car)

Check quality automatically (like spell-checking your writing)

Save energy (like having a smart home)

Being Kind to the Environment

Our factories care about nature:

Zero waste goals (like using every part of ingredients)

No carbon pollution (like riding a bike instead of driving)

Smart water use (like taking shorter showers)

Clean energy use (like using wind and solar power)

Planning for the Future

To stay successful, we think about:

Room to grow (like having an expandable house)

Flexible equipment (like having multi-use kitchen tools)

Easy updates (like being able to update your phone)

Using resources wisely (like saving for the future)

Money Matters

When building a smart factory, consider:

Starting costs (like buying kitchen equipment)

When you'll earn money back (like saving on energy bills)

Lower running costs (like efficient appliances saving money)

Environmental benefits (like solar panels paying for themselves)

Looking Ahead

The future of solar panel making is exciting! Smart factories will:

Spend less money to run

Make more panels faster

Help protect nature

Make better quality panels

Learning from Others

Recent research from industry experts shows amazing progress. For example, new perovskite-silicon panels can convert almost 30% of sunlight into electricity - much better than older panels! This shows how important good factory design is for making the best products.

Making It All Work Together

Think of a solar panel factory like a symphony orchestra:

Every part must work perfectly (like musicians playing together)

Timing is crucial (like keeping the beat in music)

Quality must be consistent (like hitting the right notes)

Everything must work as one (like different instruments making beautiful music)

Final Thoughts

Building an energy-efficient solar panel factory is like creating a perfect recipe - it takes the right ingredients, proper tools, and careful attention to detail. By following these strategies, we can make better solar panels while protecting our environment.

Want to learn more about our advanced manufacturing and our PERC 550W solar panels? Visit us at Sunpal Solar.

#solar panel#sunpal#sunpal power#sunpal solar#solar energy#Best practices for solar panel manufacturing#PERC 550W solar panel production process explained#Sustainable solar factory design guide#Green manufacturing technology trends 2024

0 notes

Text

Green Agrow | Home Grocery | Online Purchase - Organic Toor Dal | Ph. 9566188518 | JB Enterprises Group, No.358, Avvai Shanmugam Salai, GJ Plaza, II Floor, Gopalapuram, Chennai-600086

Toor Dal, also called pigeon peas, are used to prepare the most common dishes in homes on a daily basis. This legume is very nutritive and rich in proteins. These pigeon peas may be sprouted briefly, then cooked, for a flavour different from green or dried peas.

#Green Agrow#Online Organic Grocery Shop#Chennai#Online Organic Grocery Store#Green Agrow Manufacturing Company#Gopalapuram#Green Agrow Organic Products#Organic Rices#Organic Ponni Boiled Rice#Organic Idly Rice#Cold Pressed Oil#Pressed Coconut Oil#Deepam Oil#Cold Pressed Premium Ground Nut Oil#Cold Pressed Premium Gingelly Oil#Wheat Flour#Organic Vendhayam#Cardamon#Cinnamon#Organic Chilli Powder#Clove#Organic Cumin#Organic Black Pepper#Organic Sun Dried Red Chilli#Traditional Sambar Powder#Traditional Rasam Powder#Tamarind Deseeded#Organic Turmeric Powder#Desi Cow Ghee#Desi A2 Cow Ghee Organic Channa Dal

0 notes

Text

Top Carpet Manufacturers in India: Weaving Tradition and Innovation

Rug manufacturing is surely one of the esteemed arts from the country.Today, India is among the world's largest exporters of handmade rugs, its manufacturers marrying centuries-old craftsmanship with contemporary design to feed a global market.

Conventionally, rug-making has been associated with centers like Bhadohi, Mirzapur, Jaipur, and Kashmir. Each region has its typical style and weaving technique. For example, Kashmir is famous for its silk rugs of high quality, usually with flowing floral motifs, while Bhadohi is characterized by geometrical patterns in woolen rugs. These skills have been passed on from generation to generation, maintaining the heritage and authenticity of Indian rugs.

Blending in New Ideas in Rug Manufacturing

Even though Indian manufacturers give maximum importance to traditional ways of manufacturing rugs, innovation is found in order to be aligned with modern taste and global trends. This fusion of old and new is something that makes Indian rugs different in the international market. There is a rise in experiments with new materials, designs, and technologies for making rugs that are not only pleasing aesthetically but eco-friendly and durable.

Another significant innovation hitting the Indian rug industry is eco-friendly materials.handmade rugs india With people starting to become more aware of the deteriorating environment, most manufacturers have started going green either in natural dyes, organic wool, or recyclable materials for their production. This does not only reduce the environmental impact but also appeals to those consumers who want home decor that is sustainable.

From the design point of view, this has broken the mold of traditional patterns as Indian rug manufacturers include contemporary styles. Most modern Indian rugs boast an abstract design, minimalistic patterns, or a vivid color palette that appeals to the taste of a young, more design-conscious consumer. Meanwhile, there is an interesting trend that looks toward timelessness whereby traditional motifs are mixed with modern tastes. The result is timeless yet trendy rugs.

Top Indian Rug Manufacturers

A few Indian rug manufacturers have carved a niche for themselves among the top-rated names of the global market in terms of both quality and innovation. Companies such as Obeetee, Jaipur Rugs, and The Rug Republic are only a few to name that exude the blend of tradition with modernity.

Obeetee is amongst India's oldest and most reputed rug manufacturers, with its base in Mirzapur.Handmade Rugs Manufacturer Founded as early as 1920, it has had ample time to establish itself in the high-quality art of manufacturing rugs by hand. Very well known, Obeetee goes for traditional craftsmanship in weavings apart from including modern elements in its designing. The company is also at the vanguard in terms of sustainability, using eco-friendly materials and practices in production.

Innovation in Jaipur has become coupled with Jaipur Rugs, an Indian enterprise based out of Jaipur. Directly working with artisans in rural India, the company provides resources and support to skilled artisans who can create this art of beauty in handmade rugs. In addition, Jaipur Rugs is known for its contemporary designs and social impact initiatives that are undertaken to uplift and empower local communities.

Then there is the Panipat-based enterprise known as The Rug Republic, which is another major player in this field.Rugs manufacturers in india It specializes in modern, eco-friendly rugs manufactured from recycled materials. Innovative approaches to design and sustainability make The Rug Republic the favorite of consumers in search of stylish and environmentally conscious home décor options.

Conclusion

The success of rug manufacturing in India comes from the perfect balancing of tradition with innovation. While preserving ancient techniques, Indian rug manufacturers also use new materials, designs, and technologies to create products finding their place in the hearts of every consumer all over the world. As these manufacturers keep evolving, they are not only keeping the rich rug-making heritage of India alive but setting new standards for quality and creativity in the global market.

#Rug manufacturing is surely one of the esteemed arts from the country.Today#India is among the world's largest exporters of handmade rugs#its manufacturers marrying centuries-old craftsmanship with contemporary design to feed a global market.#Conventionally#rug-making has been associated with centers like Bhadohi#Mirzapur#Jaipur#and Kashmir. Each region has its typical style and weaving technique. For example#Kashmir is famous for its silk rugs of high quality#usually with flowing floral motifs#while Bhadohi is characterized by geometrical patterns in woolen rugs. These skills have been passed on from generation to generation#maintaining the heritage and authenticity of Indian rugs.#Blending in New Ideas in Rug Manufacturing#Even though Indian manufacturers give maximum importance to traditional ways of manufacturing rugs#innovation is found in order to be aligned with modern taste and global trends. This fusion of old and new is something that makes Indian r#designs#and technologies for making rugs that are not only pleasing aesthetically but eco-friendly and durable.#Another significant innovation hitting the Indian rug industry is eco-friendly materials.handmade rugs india With people starting to become#most manufacturers have started going green either in natural dyes#organic wool#or recyclable materials for their production. This does not only reduce the environmental impact but also appeals to those consumers who wa#From the design point of view#this has broken the mold of traditional patterns as Indian rug manufacturers include contemporary styles. Most modern Indian rugs boast an#minimalistic patterns#or a vivid color palette that appeals to the taste of a young#more design-conscious consumer. Meanwhile#there is an interesting trend that looks toward timelessness whereby traditional motifs are mixed with modern tastes. The result is timeles#Top Indian Rug Manufacturers#A few Indian rug manufacturers have carved a niche for themselves among the top-rated names of the global market in terms of both quality a#Jaipur Rugs

0 notes

Text

Green Tea Manufacturers & Suppliers in India: JRP Impex

Green tea, known for its numerous health benefits and rich antioxidant content, has become increasingly popular worldwide. India, with its diverse climate and rich soil, is a significant player in the global tea industry. Among the top manufacturers and suppliers of green tea in India is JRP Impex, a renowned name in the tea market. This blog explores the world of green tea, its benefits, and why JRP Impex stands out as a leading manufacturer and supplier in India.

The Rising Popularity of Green Tea

Green tea has gained immense popularity due to its potential health benefits, including weight loss, improved brain function, and a reduced risk of cancer. Unlike black tea, green tea is made from unoxidized leaves, retaining more antioxidants and beneficial polyphenols. The subtle and refreshing flavor of green tea, combined with its health benefits, makes it a preferred choice for health-conscious consumers.

The Benefits of Green Tea

Rich in Antioxidants: Green tea contains a high concentration of catechins, powerful antioxidants that help protect cells from damage. These antioxidants can reduce the formation of free radicals in the body, which are known to cause aging and various diseases.

Weight Loss and Metabolism Boost: The caffeine and catechins in green tea can help boost metabolism and increase fat burning. Regular consumption of green tea has been associated with a reduction in body fat, especially in the abdominal area.

Improved Brain Function: Green tea contains caffeine and the amino acid L-theanine, which can improve brain function. The combination of these two ingredients can have synergistic effects, enhancing cognitive function and increasing the production of neurotransmitters.

Lower Risk of Cancer: The antioxidants in green tea, particularly catechins, have been shown to have protective effects against various types of cancer. Studies suggest that green tea drinkers have a lower risk of breast, prostate, and colorectal cancers.

Heart Health: Regular consumption of green tea can improve heart health by lowering LDL cholesterol levels and increasing the antioxidant capacity of the blood, which protects the LDL particles from oxidation. This can reduce the risk of cardiovascular diseases.

Why Choose JRP Impex for Green Tea?

JRP Impex is a leading manufacturer and supplier of high-quality green tea in India. The company is committed to providing premium green tea products that meet international standards. Here are a few reasons why JRP Impex is a preferred choice for green tea:

Quality Assurance: JRP Impex ensures that its green tea products are sourced from the finest tea gardens in India. The company follows strict quality control measures to ensure that every batch of tea is of the highest quality.

Wide Range of Products: JRP Impex offers a diverse range of green tea products, including loose leaf tea, tea bags, and flavored green tea. The company's product range caters to the varying tastes and preferences of consumers.

Sustainable Practices: JRP Impex is committed to sustainable and ethical practices. The company works closely with tea growers to ensure that their operations are environmentally friendly and socially responsible.

Innovation and Customization: JRP Impex is known for its innovative approach to tea production. The company offers customized blends and packaging solutions to meet the specific needs of its customers.

Global Reach: With a strong presence in the global market, JRP Impex exports its green tea products to various countries, ensuring that the world enjoys the best green tea India has to offer.

Conclusion

Green tea is more than just a refreshing beverage; it's a source of numerous health benefits. JRP Impex, a top manufacturer and supplier of green tea in India, offers high-quality products that cater to the needs of health-conscious consumers worldwide. With its commitment to quality, sustainability, and innovation, JRP Impex is a trusted name in the green tea industry. Whether you're a green tea enthusiast or a business looking to source premium green tea, JRP Impex is your go-to partner for the best green tea from India.

#Best green tea manufacturers in India#Organic green tea suppliers in India#Green tea wholesale suppliers in India#Top green tea brands in India#Green tea leaves suppliers in India#Bulk green tea exporters from India#Premium green tea suppliers India#Green tea manufacturers for private label in India#Certified organic green tea producers in India#Best green tea company in India for export#Indian green tea suppliers for health benefits#Green tea production companies in India#Custom green tea blends manufacturers India#Quality green tea wholesalers in India#Indian green tea exporters to the world

0 notes

Text

Top 10 Eco Friendly Business Ideas to Start a Sustainable Future

🌿 Go green and grow profits! Discover the Top 10 Biodegradable Product Manufacturing Business Ideas that are shaping a sustainable future. 🌎💡 Start your eco-friendly journey today! 💰♻️ #BiodegradableBusiness #EcoFriendlyIdeas #SustainableLiving #Green

Today, as you all know, environmental protection is one of the biggest challenges. The solution to this challenge is biodegradable products, which do not harm the environment. The global market for biodegradable products has expanded significantly over the past few years as individuals and businesses adopt more sustainable practices. The government of India is also promoting this sector and…

#biodegradable business ideas#biodegradable manufacturing business#biodegradable product ideas for business#biodegradable product manufacturing business ideas#business ideas#eco friendly business#eco friendly small business ideas#Eco-Friendly Business#eco-friendly business ideas#ecofriendly business#green business#green business ideas#manufacturing business ideas#new business ideas#small business ideas#sustainable business ideas

0 notes

Text

#Marble Paper#marble wrapping paper#suminagashi ink#marble paper price#marmorpaperie#green marble paper#red marble paper#black marble paper#marble cardstock#suminagashi paper#hand marbled paper#marble tissue paper#blue marble paper#yellow marble paper#white marble paper#Marble patterned crafts#Global marble paper trends#Traditional paper marbling#Eco-friendly handmade paper#Creative paper projects#Artistic stationery supplies#DIY marble print ideas#Handmade paper decor#Specialty paper products#Marbled paper artistry#Sustainable paper crafting#Handmade paper innovations#handmade Marble print paper manufacturer

0 notes

Text

Hydrogen Revolution: Electrolyzers Leading the Charge Towards Zero Emissions

Are you ready to delve into the future of energy? Buckle up as we explore the groundbreaking technology of electrolyzers and their pivotal role in reshaping the energy landscape. Understanding Electrolyzers: Unlocking the Power of Hydrogen In our quest for sustainable energy solutions, electrolyzers stand out as game-changers. These devices utilize an electrochemical process to split water into hydrogen and oxygen, offering a clean and efficient way to produce hydrogen gas. The Green Promise: Environmental Benefits of Electrolyzers One of the most compelling aspects of electrolyzers is their environmental friendliness. By harnessing renewable energy sources such as solar or wind power, electrolyzers can generate hydrogen with zero carbon emissions, paving the way for a greener future. Empowering Industries: Applications of Electrolyzers From transportation to manufacturing, electrolyzers have a wide range of applications across various industries. In the automotive sector, hydrogen fuel cells powered by electrolyzer-produced hydrogen offer a clean alternative to traditional fossil fuels, reducing greenhouse gas emissions and mitigating air pollution. Moreover, electrolyzers play a crucial role in industrial processes such as ammonia production and metal refining, where hydrogen serves as a key ingredient. Overcoming Challenges: Advancements in Electrolyzer Technology While electrolyzers hold immense potential, technological advancements are essential to overcome existing challenges. Improving efficiency, reducing costs, and enhancing durability are among the primary focus areas for researchers and engineers working on electrolyzer development. By addressing these challenges, we can accelerate the adoption of electrolyzer technology on a global scale. Looking Ahead: The Future of Electrolyzers As we look to the future, electrolyzers are poised to play a central role in the transition to a sustainable energy economy. With ongoing research and innovation, we can expect electrolyzer technology to become more accessible, affordable, and efficient, driving widespread adoption and facilitating the shift towards clean energy solutions. Supporting Innovation: Join the Movement Are you passionate about shaping the future of energy? Join us on this journey towards sustainability by supporting initiatives that promote innovation and development in electrolyzer technology. Together, we can create a brighter, cleaner tomorrow for generations to come. In conclusion, electrolyzers represent a paradigm shift in energy production, offering a clean, efficient, and versatile solution to meet the growing demand for sustainable energy. By harnessing the power of electrolyzers, we can pave the way towards a brighter and greener future for our planet.

#Electrolyzers#Energy Production#Hydrogen#Sustainable Energy#Environmental Benefits#Industry Applications#Technological Advancements#Clean Energy#Renewable Energy#Green Technology#Transportation#Manufacturing#Innovation#Climate Action#Zero Emissions#Energy Efficiency#Renewable Resources#Sustainability#Clean Technology#Future of Energy

0 notes

Text

NASA Expanding Lunar Exploration with Upgraded SLS Mega Rocket Design - Technology Org

New Post has been published on https://thedigitalinsider.com/nasa-expanding-lunar-exploration-with-upgraded-sls-mega-rocket-design-technology-org/

NASA Expanding Lunar Exploration with Upgraded SLS Mega Rocket Design - Technology Org

As NASA prepares for its first crewed Artemis missions, the agency is preparing to build, test, and assemble the next evolution of its SLS (Space Launch System) rocket. The larger and more powerful version of SLS, known as Block 1B, can send a crew and large pieces of hardware to the Moon in a single launch and is set to debut for the Artemis IV mission.

A final round of certification testing for production of new RS-25 engines to power the SLS (Space Launch System) rocket, beginning with Artemis V, is underway at NASA’s Stennis Space Center near Bay St. Louis, Mississippi. Block 1B will also be built to house new-production RS-25 core stage engines that will operate routinely at 111% of their rated power versus the Block 1 RS-25 engines that operate at 109%, providing almost 2,000 more pounds of payload to the Moon. Image credit: NASA

“From the beginning, NASA’s Space Launch System was designed to evolve into more powerful crew and cargo configurations to provide a flexible platform as we seek to explore more of our solar system,” said John Honeycutt, SLS Program manager. “Each of the evolutionary changes made to the SLS engines, boosters, and upper stage of the SLS rocket are built on the successes of the Block 1 design that flew first with Artemis I in November 2022 and will, again, for the first crewed missions for Artemis II and III.”

Early manufacturing is underway at NASA’s Michoud Assembly Facility in New Orleans, while preparations for the green run test series for its upgraded upper stage are underway at nearby Stennis Space Center in Bay St. Louis, Mississippi.

While using the same basic core stage, solid rocket booster design, and related components as Block 1, Block 1B features two big evolutionary changes that will make NASA’s workhorse rocket even more capable of future missions to the Moon and beyond. A more powerful second stage and an adapter for large cargos will expand the possibilities for future Artemis missions.

“The Space Launch System Block 1B rocket will be the primary transportation for astronauts to the Moon for years to come,” said James Burnum, deputy manager of the NASA Block 1B Development Office. “We are building on the SLS Block 1 design, testing, and flight experience to develop safe, reliable transportation that will send bigger and heavier hardware to the Moon in a single launch than existing rockets.”

You can offer your link to a page which is relevant to the topic of this post.

#000#2022#ARTEMIS Mission#astronauts#Astronomy news#Building#certification#Design#development#earth's moon#engines#Evolution#Features#flight#Fundamental physics news#Future#green#Hardware#Link#Manufacturing#mega#Moon#NASA#Pieces#platform#power#Production#program manager#Rocket#rockets

1 note

·

View note

Text

youtube

manufacturer information pho sweaters,what is unif clothing,sweaters Enterprise

sweater maker https://sweaterchina.net

Email: [email protected]

manufacturer information pho sweaters,what is unif clothing,sweaters Enterprise button sweater vest manufacturer,button sweater vest men Manufacturing plant,button up cardigan sweater xxl women,button up oversize sweater women,button up sweater vest men,button v neck unisex wool cotton cardigan sweater,buttoned sweaters for men,buttonless sweater Maker,buy fleece sweaters petites,buy men's cardigan sweater,buy online sweater hoodies,buy women knitting cardigan,buy wool cardigan for women,buzos cuello tortuga mujer,byk beden triko kolsuz yelek bayan,bzb women s devil oversized sweater batwing long s,c and c california sweatshirt,c by bloomingdales cashmere sweater,c channel manufacturing process,manufacturer information pho sweaters,what is unif clothing,sweaters Enterprise cashmere sweater coat Maker https://sweaterchina.net/cashmere-sweater-coat-maker/ manufacturer information pho sweaters,what is unif clothing,sweaters Enterprise c men cardigan sweater xl,c und a kaschmir pullover damen,cable crewneck pullover sweater with pompoms,cable jumper female manufacturer,cable jumper manufacture company,cable knit 100% cashmere blanket baby,cable knit batwing sweater,cable knit cardigan for men,cable knit cardigan sweater for men,cable knit cardigan sweater men's,cable knit cardigan sweater women,cable knit cardigan womens,cable knit cardigans women's,cable knit cashmere factories chinese,cable knit cashmere oem Factory complex,cable knit designers turtle neck womens sweaters,cable knit dual pocket cardigan,cable knit dual pocket long cardigan,manufacturer information pho sweaters,what is unif clothing,sweaters Enterprise woollen hombre pullover Maker https://sweaterchina.net/woollen-hombre-pullover-maker/ manufacturer information pho sweaters,what is unif clothing,sweaters Enterprise cable knit factories in chinese,cable knit hooded cardigan,cable knit jacquard sweater,cable knit jumper dress Producer in chinese,cable knit jumper men stripe,cable knit long hooded cardigan,cable knit manufacturer,cable knit midi sweater dress,cable knit nylon fabric jumper,cable knit open front pocket,cable knit Producer chinese,cable knit pullover pattern cashmere sweater,cable knit quarter zip sweater,cable knit sweater cooficial style,cable knit sweater custome logo,cable knit sweater dress clothing maxi,cable knit sweater dress women,cable knit sweater manufacturers,cable knit sweater men bespoke companies,cable knit sweater men Maker chinese,cable knit sweater men Manufacturing enterprise,cable knit sweater outfit,cable knit sweater oversized,cable knit sweater oversized mens,manufacturer information pho sweaters,what is unif clothing,sweaters Enterprise cachemire ladies cardigan summer private label https://sweaterchina.net/cachemire-ladies-cardigan-summer-private-label/ manufacturer information pho sweaters,what is unif clothing,sweaters Enterprise cable knit sweater plus size womens sweaters,cable knit sweater pullover,cable knit sweater v neck,cable knit sweater v neck men,cable knit sweater v neck preppy,cable knit sweater vest manufacturer,cable knit sweater women cardigan,cable knit teddy bear cardigan,cable knit women cute Maker,cable knit women cute Manufacturing enterprise,cable knit women cute oem company,cable knit women's cardigan,cable knitted,cable knitted button down mini dress,cable knitted company chinese,cable knitted customization upon request,cable knitted Factory floor,cable knitted odm Production ,cable knitted oem,cable knitted Producer,cable knitted roll neck pullover,cable knitted sweaters Firm,cable knitted sweaters oem Processing factory,cable knitwear Production,cable knitwear women Processing factory,cable knot sweater skirt set,cable pullover Firm,cable pullover sweater companies,cable ruched fashion knit skirt,cable super flexi jumper 04130697 huawei,cable sweater dress companies,cable sweater dress companies china,cable sweater dress private label in china,cable sweater dress Processing plant,cable sweater Firm,cable sweater oem in chinese

#woollen size sweaters Maker#100 cashmere girls sweater Producer#fleeces baby flower cardigan manufacturer#cashmere infant sweater blank Producer#merino wool mens full zip sweaters Maker#cashmere arbeitspullover Factory floor#merino wool green knit Factory complex#cashmere silk ?cat sweater factories#en laine mens autumn sweaters factory#en laine bunny sweater for baby Production#fleeces sweater dresses Factory floor#cashmere silk cardigan christmas Manufacturing facility#merino wool jumper men Factory floor#woollen fabrica de sweaters Manufacturing plant#Youtube

0 notes