#lycoming engine

Explore tagged Tumblr posts

Text

Took the 540 out for runs this morning. Since it was a prop strike inspection and we didn’t have to replace any piston rings or cylinder components, I didn’t have to do a full break in run, which is 90 minutes at varying power intervals. This run up was more focused on getting her up to temperature and making sure she made full power with no leaks, so I got away with less than an hour on the stand. Post run checks were positive with no abnormal metal contamination or other indications of issues. Another successful build, and she’s off to her owner in the next couple days.

10 notes

·

View notes

Text

Are you in search of an aircraft engine for sale? Look no further! At Pinnacle Aircraft Engines, we offer a curated selection of top-quality aircraft engines. Concerned about engine rebuild cost? Our transparent pricing ensures you receive cost-effective solutions without compromising quality. We specialize in Continental engine parts, using genuine components for rebuilds and overhauls. Trust us to provide reliable, competitively priced engines and expert services tailored to your needs. Whether you're a discerning buyer, considering a rebuild, or in need of Continental engine parts, Pinnacle Aircraft Engines is your go-to destination. Contact us today for unparalleled service and the assurance of quality in every aspect of your aircraft engine needs.

0 notes

Text

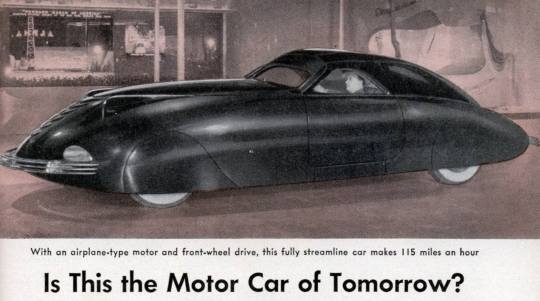

The Phantom Corsair is a prototype automobile built in 1938. It is a six-passenger 2-door sedan that was designed by Rust Heinz of the H. J. Heinz family and Maurice Schwartz of the Bohman & Schwartz coachbuilding company in Pasadena, California.

Although sometimes dismissed as a failure because it never entered production, the Corsair is regarded as ahead of its time because of its futuristic features, and styling cues such as faired-in fenders and a low profile.

The Corsair’s body was mated to the “most advanced chassis available in the United States” at that time, the Cord 810.

The Lycoming 80 V-8 engine-powered Cord chassis also featured front-wheel drive and an electrically operated four-speed pre-selector gearbox, as well as fully independent suspension and adjustable shock absorbers.

Though weighing a hefty 4,600 lb (2,100 kg), the Phantom Corsair could achieve speeds of up to 115 mph (185 km/h) because of its modified, naturally aspirated 125 bhp Lycoming engine as well as its aerodynamic shape.

60 notes

·

View notes

Text

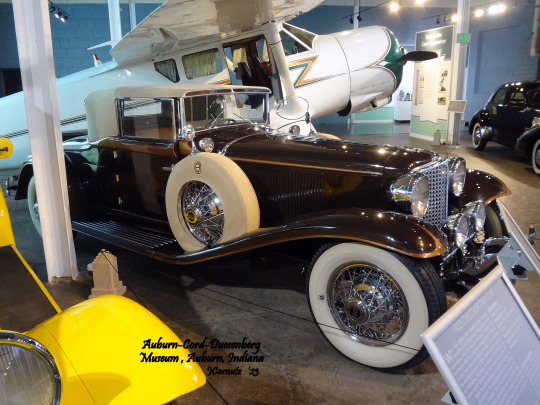

1930 Cord L-29 Cabriolet - ACD Museum, August 2023

The Cord L-29 was the first successful mass-produced front-wheel-drive American automobile. But it was much more than that. Look at the styling of this automotive masterpiece. It was styled by Alan Leamy and was conceived as a single unit with the symmetry of the interior reflecting the external lines. Automotive styling had come into its own with this design. No longer was it an afterthought. Leamy incorporated the mechanical features of the front drive unit into the subtle style of the Cord. Cloaking the most technologically advanced automobile of its day in beauty, Leamy ensured the L-29 was superior both mechanically and aesthetically.

SPECIFICATIONS Model: Cabriolet Wheelbase: 137.5 inches Engine: Lycoming in-line eight-cylinder Transmission: Three speed manual Displacement: 299 cubic inches Horsepower: 125 at 3,400 rpm Weight: 4,500 lbs. Price When New: $3,195

44 notes

·

View notes

Text

i started overhauling a piston engine today! the model we're using is a lycoming 235. we're disassembling, measuring and inspecting various parts, and then reassembling on an engine test stand so it can be tested ! im learning a lot :)

8 notes

·

View notes

Text

Day 2 (bonus!)

Hello! This is the weekend bonus for today, the segment where we look at vehicles that aren't automobiles!

Today, the Piper Archer II PA-28-181 aircraft.

I'll be honest I don't know much about aircraft but I wanted this series to be a bit more varied and interesting for everyone!

Find more info on the Piper Archer II PA-28-181 below.

Date launched: May 22, 1972

Empty Weight: 1416 Lb

Company: Piper Aircraft

Exterior Height: 7 ft 3 in

Wing Span: 35 ft 5 in

Length: 24 ft 0 in

Max T/O Weight: 2550 Lb

Max Landing Weight: 2550 Lb

Payload Useful: 1134 Lb

Fuel Capacity: 48 gallons

Galph burned: 10 galph

Payload W/Full Fuel: 637 Lb

Engines: 1

Engine Mfg: Lycoming

Rate of Climb: 667 fpm

Max Speed: 125 kts

Normal Cruise: 116 kts

Economy Cruise: 110 kts

Occupancy: 1 crew, 4 passenger

Price: $119,000 USD

20 notes

·

View notes

Text

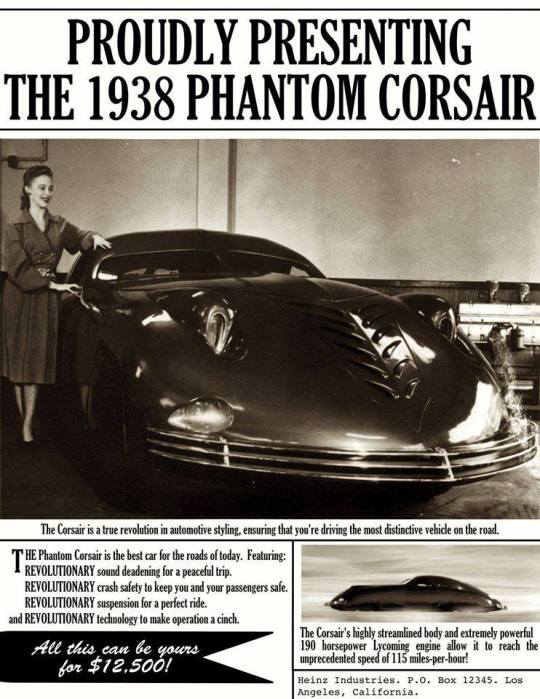

The Phantom Corsair

The Phantom Corsair was a marvel of futuristic design when it was shown publicly for the first time in 1938. The uniquely laid out body gave it seating for 6 but only 2 doors and 2 windows either side, giving it a beautiful, clean profile and leaving it still looking futuristic, even 70+ years later.

The Phantom was designed by Rust Heinz (of the H. J. Heinz family) and Maurice Schwartz of the California based Bohman & Schwartz coach building company. Heinz and Schwartz based the concept car on the Cord 810, possibly the most advanced chassis of the era, the Cord’s engine was a Lycoming 4.7L 8-cylinder unit, supercharged to produce 190 hp and was capable of propelling the Phantom Corsair to a top speed of 115mph.

The design of the car was revolutionary in the late 1930’s, the overall height of the car is just 58″ and there are no running boards, fenders or door handles. Interestingly, the lower part of the Phantom’s frame was welded chromoly steel and the upper frame was constructed of electrically welded aviation steel tubing, this helped keep the enormous car’s weight down to just 4500 lbs (2000 kg), that may not be feather weight but it would have been far higher with the more common all steel construction.

Sadly, the Phantom Corsair never made it into production, Heinz had planned a limited production run at an estimated selling price of $12,500 (1938 dollars), however he passed away shortly after the car was completed . It now lives in the National Automobile Museum (The Harrah Collection) in Reno, Nevada

48 notes

·

View notes

Text

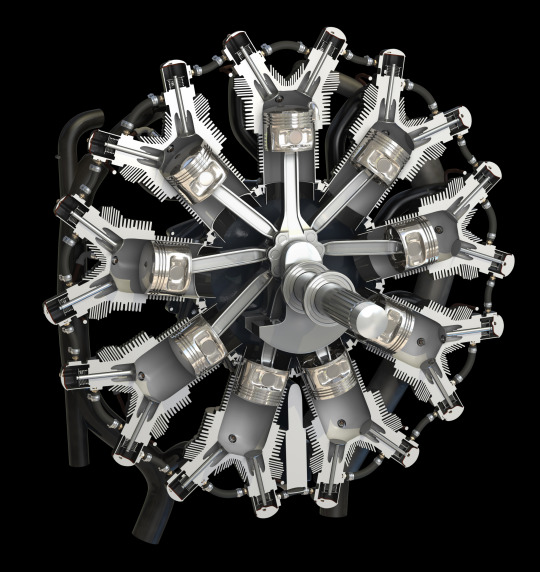

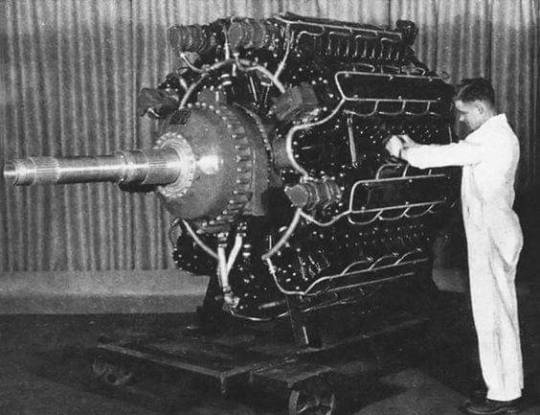

Look at the size of that engine! The massive 5,000 hp Lycoming XR-7755 first ran in 1946, and at 127 litres (7,750 cu in) is the largest piston aircraft engine ever built in the US. designed to power the next generation of large aircraft. However, it was never installed in an aircraft and was cancelled the same year.

4 notes

·

View notes

Text

1929 Duesenberg Model J Convertible Victoria Coachwork by Rollston

Duesenberg Model J and Model SJ

Fred Duesenberg was a master of creating engines and was a creative designer. He had a talent for conceiving new ideas and ways of doing things. The engines he constructed were beautiful, mechanically sound, and advanced. E.L. Cord gave him one task: 'Create the best car in the world.' This was a very tall order and came at a very difficult time in history. The onset of the Great Depression and the Stock Market crash was just around the corner. Competition in the luxury car segment was fierce and involved all facets of the automobile. The cylinder wars that began in the 1920s and continued into the 1930s had marque's trying to outdo each other on the bases of its engine output, the number of cylinders, and the speed of their ultra-luxury automobiles. Styling continued to be very important and often outsourced to the greatest designers and coachbuilders of the time. Maruqee's such as Cadillac, Packard, Rolls-Royce, Hispano-Suiza, Isotta Fraschini, Bugatti, and others were all trying to out-do each other and continue in business during this difficult point in history.

The Duesenberg Model J was first unveiled to the public at the New York Car Show on December 1st of 1928. Only the chassis and engine were shown and it still impressed enough to make front-page news. The wheelbase was 142-inches making it nearly 12 feet. The chassis had a six cross-members made it very sturdy and able to accommodate the heaviest of bodies. The engine had dual overhead camshafts and eight-cylinders with four valves per cylinder. It displaced 420 cubic-inches and produced an impressive 265 horsepower in un-supercharged form. The engine had been designed by Fred Duesenberg and constructed by the Lycoming Company, which had been recently acquired by E.L. Cord. There was a brilliant lubrication system which automatically lubricated various mechanical components after sixty to eighty miles. Two lights mounted on the dashboard indicated when the lubrication process was transpiring. After 750 miles, lights mounted on the dashboard would light-up indicating the oil required changing. After 1500 miles, the lights would illuminate indicating the battery should be inspected. The top speed was 119 mph and 94 mph in second gear. With the use of a supercharger, the top speed increased even further, to nearly 140 mph. Zero-to-sixty took around eight seconds with 100 mph being achieved in seventeen seconds.

2 notes

·

View notes

Photo

(via XM1 Abrams Main Battle Tank by DarkWizard83 on DeviantArt)

The original prototype vehicle that led to one of - if not the - most powerful tank in the world, and current backbone of Us armored forces, the M1 Abrams MBT. Born out of the failed German-American MBT-70 project, the XM1 was developed by the Chrysler Motor Corporation, and in 1978 Chrysler delivered to the Army a sleek, low-silhouette heavy tank that incorporated every major technological feature of the day, including computerized controls and a laser rangefinder. But the most significant design feature of the new tank was its use of Chobham composite armor on the hull and turret. While the exact nature and composition of Chobham armor remains a closely guarded secret, the evidence suggests that it utilizes a matrix of ceramic armor tiles, layered between the vehicle's internal steel and external armored plating. When a high-velocity projectile - such as a round fired from a tank or an anti-tank missile - hits the armor, the explosion produces a high-velocity jet of gas that shears through the armor plating. In normal armor, this jet of gas - once it had passed through the outer armor - would blast into the hull of the tank, causing irreprible damage and often killing the crewmen inside. However, with Chobham armor's interweaved layers of ceramic composite, the forces that would normally tear into a tank's hull are forced to spread out and dissipate over a much wider area, leaving the inner hull intact. This not to say that Chobham armor renders a tank invincible - any hit will still cause exterior damage, and a powerfiul direct hit could still damage or disable the tracks or sensitive electronic equipment. But it would keep the crew alive, and often protect the tank itself enough to keep fighting. Another key crew safety feature is the vault-like armored compartment that houses the Abrams' primary ammunition. One of the primary causes of a tank's destruction has not been the direct result of armor-pierecing hits, but the inderict results of those hits ignigting and detonating the tank's munitions. To protect this, a kevlar and steel armored plate seperates the crew from the ammunition store. Same with the tank's fuel supply. Even if the compartments were pierced, and the ammunition or fuel ignited, the protective plates would insulate the crew from explosion and fire. In combat, the Abrams has proven to be second to none. During Operation Desert Storm in 1991, M1s were able to take out Iraqi tanks at distances as long as 4km. Of the nearly 2,000 Abrams to see combat in the conflict, only 18 were ever taken out of service due to combat damage, and none resulted in any crew casulties. In 2003 and onwards during Operation Iraqi Freedom, the Abrams again demonstrated a mastery of the battlefield, driving to Baghdad virtually unopposed. However, the Abrams clearly showed its vulnerability to ambush attacks, with a number of M1s severly damaged and disabled from RPGs, and far more frequently by roadside IED bomb traps. However, even when caught in some of the largest IED explosions, crew casualties have so far been astoundingly low, a testament to the M1s protection and survivability. While no future M1's are planned for production, a number of older models are currently slated for upgrade to current standards over the next few years, and the Abrams will continue to serve with the Us Army and Marine Corps. for mcuh of the century to come. M1 Abrams Vehicle Stats: Type: Main battle tank Manufacturer: General Dynamics Land Systems First deployed: 1980 Crew: 4 Length: 9.76 m Width: 3.65 m Height: 2.88 m Weight: 61.4 tons Armor: Classified Armament, primary: 1 x 105mm M68 rifled tank gun; later models equipped with 120mm M256 smoothbore tank gun Armament, secondary: 2 x 7.62mm FN-Browning M240 machineguns, 1 x .50-cal Browning M2 BMG machinegun Ammo stowage, primary: 55 rounds Ammo stowage, secondary: 11,000 rounds 7.62mm, 1,000 rounds .50-cal Powerplant: Textron Lycoming AGT1500 1,500hp gas-turbine engine Max speed: 72 km/h Max range: 498km Operators: Australia, Egypt, Kuwait, Saudi Arabia, USA

14 notes

·

View notes

Text

From dry fit for bearing measurements yesterday to fully closed and assembled today. I’m switching tracks this week from TCM engines back to a IO-540 Lycoming that had a prop strike. The work involved in the inspection and repair following a prop strike is usually as much as an overhaul. Everything must still be disassembled, inspected, and major components sent for NDT. The list of parts required might not be as long, depending on the situation, because the mandatory parts replacement of an overhaul isn’t normally applicable. Sometimes the damage is significant enough to warrant an overhaul for the sake of costs, but luckily for this customer that wasn’t the case.

9 notes

·

View notes

Text

This is the Lycoming AGT 1500, the engine used in the M1 Abrams tank

I think I'll name it "Thomas"

2 notes

·

View notes

Text

1946 Stinson V-77 Gullwing - ACD Museum, August 2023

The Stinson Aircraft Company was founded in Dayton, Ohio in 1920 by Edward Stinson. By 1927, Northwest Airlines (now known as Delta Airlines) utilized Stinson aircraft in their fleet. E.L. Cord acquired 60% of Stinson stock in September 1929 through the Cord Corporation, which allowed Stinson to offer six aircraft models in 1930 and gave Cord his first foray into the world of air transportation. This Stinson V-77 was built for military use in WWII as a utility aircraft. Under the At-19 designation, it was used by the United States Army for training. Following the end of WWII, the surplus Stinson aircraft were sold on the civilian market as the V-77 Gullwing. This Stinson was completely restored with a wood instrument panel, leather seats and lace curtains.

SPECIFICATIONS Model: V-77 Gullwing Engine: Lycoming R-680-E3B 9-cylinder radial Horsepower: 300 at 2,200 rpm Wingspan: 41 feet, 3 inches Length: 28 feet, 3 inches – Height: 8 feet, 7 inches Maximum Speed: 145 mph Ceiling: 14,000 feet – Range: 575 miles Crew: Up to five – Armament: None Weight: 4,150 lbs.

MOVING A PLANE INSIDE Moving a plane inside a building is no easy feat. It took planning, scale drawings, and figuring out just the right angles to move the plane inside. The wings needed to be removed prior to installation inside the museum, while the horizontal stabilizers stayed on. Once the plane was inside, the wings were carefully installed using a forklift, soft moving cloths and a team of knowledgeable volunteers.

10 notes

·

View notes

Text

If all goes well with the engine shop post school, I think I might be able to get the Ultra Pup done by the end of the year >w>

With VW engine installed tho. I would love to slap a Rotax on there but likely not until I can determine if the engine shop's going to be stable/legit. I might play with the VW in ground effect for funsies/getting a feel for the plane, I'm just not so sure about flying with it.. yet. It barfed its oil all over the runway on the guy who built it, so it has to win my trust a little. I mean, I'll trust it as far as I can throw it, but still. :'3

Plus I kinda want a Rotax even more now as one of my teachers recently acquired a Rans RV homebuilt with one installed and he said it's better than any Continental or Lycoming he's flown on. Cheaper & tons more efficient too.

4 notes

·

View notes

Text

The Legacy of Lycoming: Innovating on the Road and in the Sky

Founded in 1845 in Williamsport, Pennsylvania, Lycoming began its journey in manufacturing with sewing machines and later bicycles. However, its foray into internal combustion engines for automobiles and aircraft would establish its name as a significant contributor to American engineering and transportation history. Automotive History Lycoming entered the automotive market in 1910, producing…

0 notes