#lined valves

Text

Advancements in Smart Lined Valves: Integrating IoT for Enhanced Monitoring and Control

The integration of the Internet of Things (IoT) into industrial equipment is revolutionizing various sectors, including valve technology. Smart lined valves, equipped with sensors and connectivity features, represent a significant advancement in the field. These valves offer real-time monitoring, predictive maintenance, and remote control capabilities, enhancing efficiency and reliability in industrial processes. In this article, we will delve into the benefits of smart lined valves, their applications in different industries, and the future of this technology.

Benefits of Smart Lined Valves

Real-Time Monitoring: Smart lined valves come equipped with sensors that monitor various parameters such as pressure, temperature, and flow rate in real-time. This data is transmitted to a central monitoring system, allowing operators to have instant visibility into the performance of the valves. Real-time monitoring helps in early detection of anomalies, preventing potential failures and minimizing downtime.

Predictive Maintenance: Traditional maintenance strategies are often reactive, addressing issues only after they occur. Smart lined valves enable predictive maintenance by analyzing data trends and predicting when a valve might fail or require maintenance. This proactive approach reduces unplanned downtime, extends the lifespan of the valves, and optimizes maintenance schedules, thereby saving costs.

Remote Control and Automation: The ability to remotely control valves is a significant advantage, especially in industries with hazardous environments or difficult-to-access locations. Smart lined valves can be integrated into automated systems, allowing for remote adjustments and control. This feature enhances safety and operational efficiency by reducing the need for manual intervention.

Enhanced Data Analytics: The data collected from smart lined valves can be used for detailed analytics, providing insights into the overall system performance. These insights can help in optimizing processes, improving product quality, and reducing operational costs. Advanced analytics can also aid in compliance reporting, ensuring that all regulatory requirements are met.

Applications in Different Industries

Chemical Processing: In the chemical processing industry, the handling of corrosive and hazardous substances is common. Smart lined valves provide the necessary resistance to these chemicals while offering real-time monitoring and control. For instance, in a chemical plant dealing with highly corrosive acids, smart PTFE-lined valves can ensure safe and efficient handling of the substances, while predictive maintenance helps in avoiding unexpected downtimes.

Water Treatment: Water treatment facilities require precise control over the flow and composition of water. Smart lined valves, especially those lined with PVDF, are used to handle various chemicals involved in the treatment process. The real-time monitoring capabilities ensure that the water quality is consistently maintained, and any deviations can be promptly addressed.

Oil and Gas: The oil and gas industry operates in some of the harshest environments, where equipment reliability is crucial. Smart lined valves offer corrosion resistance essential for handling aggressive fluids and gases. Additionally, the integration of IoT allows for remote monitoring of offshore platforms, enhancing safety and reducing the need for on-site personnel.

Food and Beverage: In the food and beverage industry, maintaining hygiene and preventing contamination are critical. Smart lined valves help in achieving these goals by providing corrosion resistance and enabling real-time monitoring of the processes. For example, in a beverage production line, smart PFA-lined valves can ensure that the flow of ingredients is precisely controlled and monitored, maintaining product quality.

Future of Smart Lined Valves

The future of smart lined valves looks promising, with continuous advancements in IoT and sensor technology. Developments in artificial intelligence (AI) and machine learning (ML) are expected to further enhance the predictive maintenance capabilities, making these valves even more efficient and reliable.

Moreover, the integration of blockchain technology could provide secure and transparent data logging, ensuring compliance and traceability in industries with stringent regulatory requirements. This could be particularly beneficial in pharmaceuticals and food and beverage sectors, where product safety and traceability are paramount.

In addition, advancements in material science could lead to the development of new lining materials with even better performance characteristics. These materials could provide improved resistance to a wider range of chemicals and higher temperatures, expanding the applicability of lined valves in more demanding environments.

Conclusion

Lined valves play a crucial role in ensuring the safety, reliability, and efficiency of industrial processes across various sectors. In the pharmaceutical industry, they are indispensable for maintaining sterility and preventing contamination. The advent of smart lined valves, integrating IoT technology, marks a significant leap forward, offering enhanced monitoring, predictive maintenance, and remote control capabilities.

As industries continue to evolve, the adoption of advanced lined valve technologies will be essential for meeting the increasing demands for safety, efficiency, and regulatory compliance. Companies like Freture Techno Pvt. Ltd., a leading manufacturer of lined valves in Mumbai, India, are at the forefront of this technological revolution, providing high-quality solutions to meet the diverse needs of their clients.

0 notes

Text

THEY'D BE BEST FRIENDS,,,

mute protagonists.... UNITE! :3c

#tsp#the stanley parable#portal#portal fanart#portal 2#valve#fanart#tsp stanley#tsp fanart#tspud#krita#digital art#digital illustration#my stuff#weighted companion cube#companion cube#adventure line

1K notes

·

View notes

Text

some saxwell and unfinished saxtooons

#honestly that line from saxton rent free in my head#valve made him bisexual for real#tf2#tf2 saxton hale#tf2 bidwell#saxwell

1K notes

·

View notes

Text

He sure knows how to pull people

#dynamo#abrams#wraith#lady geist#pocket#infernus#haze#lash#paradox#art#spending days on big artwork abt a game that doesnt exist [clown shoes sqeauking]#inspired by a friend's message#““I’m polyamorous” - dynamo line while in lane at random”#also inspired by that bisexual meme of anne hathaway that people keep redrawing#hottest orb known to man#does valve know what they did

306 notes

·

View notes

Text

I think Deadlock might blow up on here once people learn about Ivy. Do you guys still like monster gremlin girlthings?

91 notes

·

View notes

Text

I'm cooking so hard

#noctiwaft#tf2#team fortress 2#tf2 spy#spy tf2#sniper tf2#tf2 sniper#valve#this is not as suggestive as it looks i promise.#im never gonna stop drawing spy's silly tan lines giggles

69 notes

·

View notes

Text

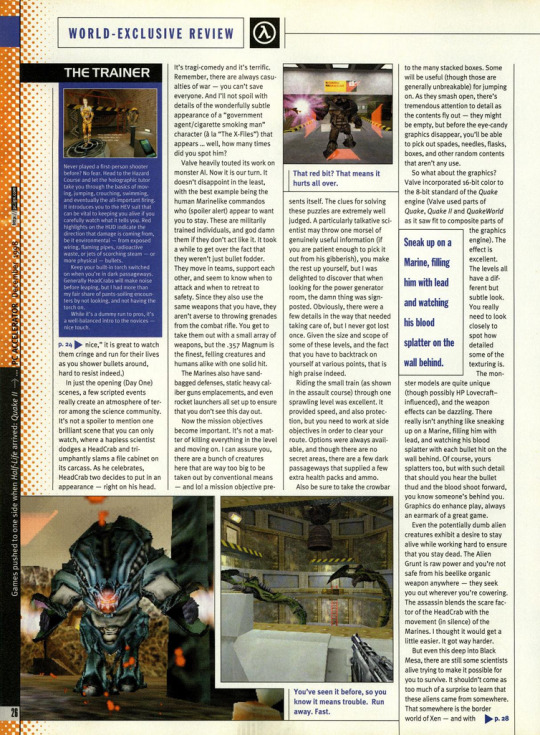

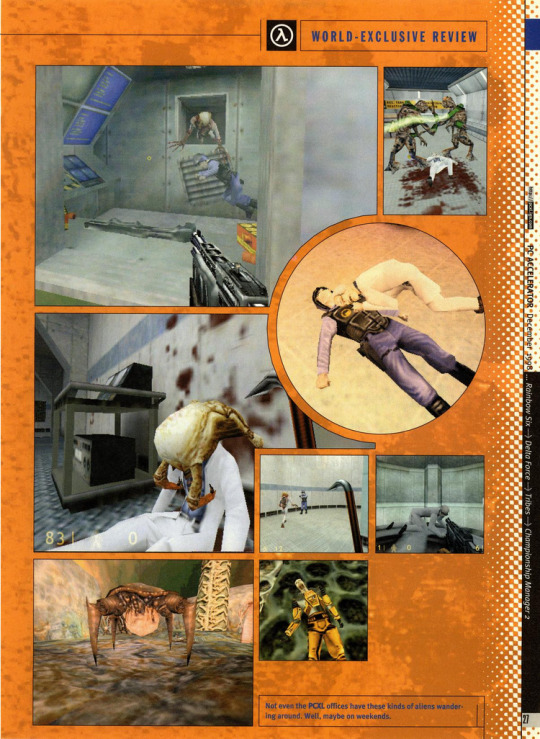

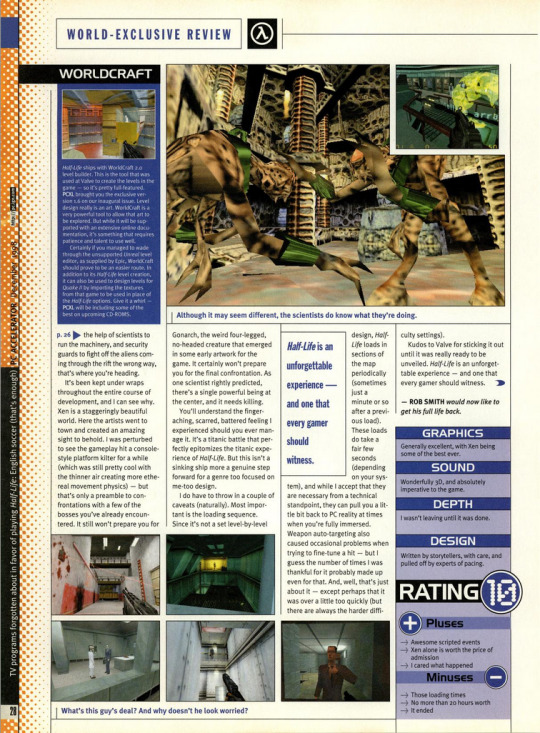

" Half-Life is an unforgettable experience, and one that every gamer should witness! "

PC Accelerator Magazine n04 - December, 1998.

#PC#PC Games#GoldSrc#GoldSrc Engine#VALVe#VALVe Software#Sierra#Sierra Studios#Sierra On line[#Half Life#HL#Gordon Freeman

126 notes

·

View notes

Text

#at last I can sleep#don't zoom in too far#there are some wobbly lines because it was drawn on a steam-hauled train lmao#flying scotsman#flying scotsman centenery#gresley a3#preserved british steam locos#british steam#copic markers#actually cheap knockoff copics but who's keeping track#my art owo#going to have nightmares about valve gears for months#flying scotsman ttte#wagahai wa train de aru

213 notes

·

View notes

Text

I have so much brainrot about Medic's wife, specifically the design from the comic doodles that Makani drew, I'm so ready to draw a whole comic about her, man I love hallucinating.

#60 seconds till mission begins rambles#But also I have so many things to do I could cry#I don't like engaging in fights about which ships are valid in the eyes of canon etc#I've seen many people try to ignore medic's wife's potential existence because it would invalidate the possibility of him being gay#insisting the doodles were drawn before Makani joined Valve; and Demo's domination line just being gibberish etc etc#That's sad to me because I think she's a REALLY cool character and I cry about her never ever coming to the official material#So listen to me; headcanon; what about#He's bisexual (and discovers he has a preference for men)#boom#we win🏳🌈#also the doodles where his wife appears are the same doodles where he's smooching heavy so why are you only reading half of the scriptures?#I'm just foaming at the mouth about the idea of Medic having a female best friend who he married and who understands him in a different way#I just like the idea of both of them being opportunistic and marrying for the societal benefits a marriage gave you back in the days#and like being the only other person to have enough blackmail material on the other#Ok no I cant talk more about this I'll give away the entire story I have in my head

46 notes

·

View notes

Note

Im soooooo hungry i neeed.... gaming trivia. tO live 😺

i mostly just have TF2 trivia, as its history has always been something ive always been fascinated with, so i hope these suffice:

The Pyro's Beta Head: While 8 of the 9 classes had their heads redone throughout development (to better show off Valve's new facial flex system), only the Pyro was left untouched, leaving them as the only class to still have their beta head.

Reference Posing Medics: In "Trailer 2", there are two Medics who are in their reference pose, during the first-person sequence of the Scout running through RED's base. While their role isn't clear, one likely theory is that they were meant to be camera positions for shots that were ultimately removed, in favour of the Scouts perspective, and Valve just forgot to remove or hide them. The second Medic even turns to look at the Scout as he runs by, maybe further proving their original purpose.

The Teaser Corkboard: While we don't have a clear idea as to what Valve had been planning with the "Teaser Corkboard", one likely theory is that it was created for the proposed update that would've included both Asteroid and Cactus Canyon, due to the few mentions of "Future", the blueprint of the rocket engine from Half Life 2 Episode 2, and Poopy Joe. Also worth noting, the two posters that were added with the corkboard share similar styles Asteroid and Cactus Canyon.

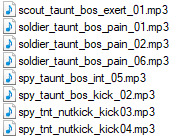

The Balls of Steel Taunt: Originally, The Love & War update was meant to include a lot more taunts than what ultimately shipped. One of the few to get scrapped is a taunt called "Balls of Steel", where the initiator would dare other players to kick them in the groin. While we don't have footage of this taunt, we do have voiceline files that reference the taunt's intention, as well as the name. The few files that remain were reused for other contexts, such as the Soldiers Conga taunt, where his "Ooh!" and "Ahh!" lines were originally his pain sounds for the taunt.

#ask#anon#im a little late to respond to this. so i hope you didnt starve anon#if you did. whoopsies. uh oh. oh well anyway#i didnt want this to be too long so i left it to just 4 trivia pieces#was gonna answer this earlier but my phone died of low battery. so instead i took the time to get images for all the bulletpoints#i'm still kinda sad thinking about Asteroid and Cactus Canyon#also ik the blue poster isnt as clear to Asteroid. but to me it lines up more with the maps original idea of being a moonbase#and said poster has the moon.... i know. grasping for straws.#also for those interested. the corkboard deciphers to ''be sure to drink your jarute/jarbate''#its unclear if the mispelling is intentional or accidental. given how the spellbook pages translate weirdly#theres also the red herring on the corkboard itself. maybe as a way for valve to have a way out if development doesnt go as planned#thats just my interpretation of it atleast. the corkboard was added in december of 2013 iirc.#while Asteroid was teased in April. and later released as a beta map a few months later with Cactus Canyon#anyway thats all my brain could muster for trivia#i havent thought about this kind of stuff in a long time. so searching through the file cabinet in my brain is a little tough#i hope these were interesting. or were new information to people#thank you for your ask anon!

31 notes

·

View notes

Text

LIKE I DUNNO IM TOYING WITH MICROSOFT SAMS PITCH AND SPEED BUT IM REALLY STARTING TO THINK HL1 VOX IS JUST A HEAVILY EDITED SAM

#dectalk speaking#my friend found a reddit post where several interviews stated valve used microsofts SAPI 4 to make the vox#which came with sam. mike. and mary. and 2 more but they were of a separate company or something#sam has the deepest voice of the group which is already a telltale#and another telltale is that i played one of vox's unused lines#where he says ''mesa'' in a peculiar way. more like ''meser''#which. sam does about the same

7 notes

·

View notes

Text

Lined Valves: Where Innovation Meets Fluid Control Excellence

In the intricate world of fluid handling, where safety, corrosion resistance, and precision are paramount, lined valves emerge as a groundbreaking solution. These remarkable engineering marvels combine the robustness of traditional valves with advanced lining materials, resulting in a seamless fusion of durability, versatility, and efficiency. In this article, we embark on a comprehensive exploration of lined valves, delving into their construction, advantages, applications, and the transformative impact they bring to industries worldwide.

The Art of Construction: The Fusion of Strength and Protection

At the heart of lined valves lies a meticulous craftsmanship that involves bonding a specialized lining material to the internal surfaces of the valve body and components. This lining acts as a protective barrier, shielding the valve from the corrosive effects of aggressive fluids, chemicals, and abrasive media. The choice of lining material is crucial, with options ranging from PTFE (polytetrafluoroethylene) to PFA (perfluoroalkoxy) and other fluoropolymers, each tailored to specific applications.

Advantages Beyond Compare: Redefining Fluid Handling

Lined valves offer a plethora of advantages that elevate them above conventional valves. Their robust lining provides exceptional resistance to corrosion, erosion, and chemical attack, ensuring prolonged service life and reduced maintenance costs. Moreover, the non-stick properties of the lining facilitate smooth flow, preventing clogging and minimizing pressure drop. This translates to improved efficiency, reduced energy consumption, and enhanced system performance.

Applications Across Industries: From Pharmaceuticals to Petrochemicals

The versatility of lined valves finds its canvas across a wide spectrum of industries. In pharmaceutical manufacturing, these valves ensure the purity and integrity of sensitive processes. In the petrochemical sector, they withstand aggressive chemicals and demanding conditions. From food and beverage production to water treatment plants, lined valves stand as a reliable guardian against contamination and degradation.

A Greener Footprint: Sustainability and Safety

In an era emphasizing sustainability, lined valves shine as eco-friendly champions. By preventing leaks, reducing maintenance, and prolonging equipment life, these valves contribute to resource conservation and minimize environmental impact. Furthermore, their ability to prevent fluid contact with metal components ensures product purity and safety, safeguarding both processes and personnel.

Charting the Future: Innovations and Beyond

As industries evolve, so do lined valves. Emerging technologies are paving the way for smart lined valves equipped with sensors and monitoring systems, enabling real-time data collection and predictive maintenance. These advancements not only enhance operational efficiency but also underline the adaptability and transformative potential of lined valve technology.

Conclusion: The Seamlessness of Efficiency and Protection

Lined valves stand as a testament to human ingenuity in addressing the challenges of fluid handling in the most demanding environments. Their seamless integration of strength, protection, and efficiency redefines fluid control possibilities. As industries continue their quest for uncompromising performance and safety, lined valves emerge as a beacon of innovation, reshaping the landscape of fluid handling with unparalleled excellence.

#lined valves#lined valve manufacturer#lined valved suppliers#Lined Valved exporters#manufacturers#valve muanufacturers#freture techno

0 notes

Text

God I fucking CALLED IT the other day I woke up and realized “oh I think I dreamed about M last night, her parents must be thinking of having a date night and asking me to babysit” and then this evening I got the text asking if I could watch her Saturday evening

#this is a consistent series of events I have never dreamed of her and not heard from her parents soon after#but then this is also the child who had just learned how to speak and asked me if I remembered when I used to be her mommy so there’s that#again I’m not saying I’m psychic#but sometimes I be knowin stuff#and my dreams have a tendency to be slightly prophetic though in uninteresting ways#which is why I’m so earnestly trying to figure out what that stray kitten dream might portend because I don’t usually dream about animals#except for the time I dreamt about two dogs that looked like the two dogs we ended up adopting#so if I had a dream about a stray kitten showing up and our cat loving it and taking care of it….#I’m kind of expecting to see a teeny tiny fluffy grey kitten in the near future#I figured out the car trouble dream where I was worried about a sewing machine from a couple weeks ago…#I drove across state lines to buy an antique sewing machine and then that night my thermo control valve shit the bed#you see what I mean by vaguely prophetic in uninteresting ways#and useless at that#except in the case of clearing my schedule for babysitting#they’re good for that#psychic stuff

2 notes

·

View notes

Text

i should have my home taken from me because i am such a hapless putrid idiot and anyone thats ever helped me with it should be able to kick me in the stomach until i throw up my heart and entrails

#i stripped the valve screw on my furnace while trying to bleed the line#and now i have to pay a guy $300 for like 10 minutes of work to replace it#i could order the valve screw but i just.#i just want heat in my house man

7 notes

·

View notes

Text

y'all my rice cooker just broke. please bring flowers to my funeral

#that thing fed me for 15 years dude#the plastic lining around the safety valve crumbled when i tried to clean it#it's a discontinued model and the new ones don't have the plastic valve (prob. bc the manufacturers realized the plastic parts fail first)#so i can't just replace the lid#which sucks since everything else still works great after all these years and it's literally just the housing for one part#but i am Not fucking using a pressure cooker without a functional safety valve nuh uh#that's not 'not getting your security deposit back'; that's just 'not having an apartment anymore'#muse please sing a magical song about the miracles of 3d printing that manifests a new perfect part in my kitchen#i post

3 notes

·

View notes

Text

Why you need to keep main line shut off valve in working condition ?

To prevent plumbing disasters and ensure your home is protected while you’re away, it’s crucial to keep your main water line valve in good working condition.

Before you leave, consider the story of the Johnson family, who learned this lesson the hard way. They were excited for their two-week cruise, dreaming of sunsets and relaxation. However, they didn’t close their main shut-off valve before they left. During their vacation, a small leak in their water heater turned into a burst pipe, which ultimately led to a significant flood in their basement. When they returned, they faced extensive water damage and costly repairs. By closing the main shut-off valve before your departure, you can avoid such plumbing disasters.

Shutting off the main valve stops the flow of water into your home, effectively preventing leaks, bursts, or floods from causing damage. This simple action ensures that if any part of your plumbing system were to fail, there would be no water supply to fuel it.

Additionally, for long vacations, draining the water from your water heater can add another layer of protection. This step prevents potential issues related to freezing temperatures or slow leaks, further reducing the risk of water damage. So, as you finalize your vacation plans, take a moment to safeguard your home. Close the main shut-off valve to protect against leaks and bursts. This small precaution will help ensure you return to a home that's as carefree as your time away.

Phone

224-754-1984

#Why you need to keep main line shut off valve in working condition ?#To prevent plumbing disasters and ensure your home is protected while you’re away#it’s crucial to keep your main water line valve in good working condition.#Before you leave#consider the story of the Johnson family#who learned this lesson the hard way. They were excited for their two-week cruise#dreaming of sunsets and relaxation. However#they didn’t close their main shut-off valve before they left. During their vacation#a small leak in their water heater turned into a burst pipe#which ultimately led to a significant flood in their basement. When they returned#they faced extensive water damage and costly repairs. By closing the main shut-off valve before your departure#you can avoid such plumbing disasters.#Shutting off the main valve stops the flow of water into your home#effectively preventing leaks#bursts#or floods from causing damage. This simple action ensures that if any part of your plumbing system were to fail#there would be no water supply to fuel it.#Additionally#for long vacations#draining the water from your water heater can add another layer of protection. This step prevents potential issues related to freezing temp#further reducing the risk of water damage. So#as you finalize your vacation plans#take a moment to safeguard your home. Close the main shut-off valve to protect against leaks and bursts. This small precaution will help en#Phone#224-754-1984

2 notes

·

View notes