#kaolin china clay

Explore tagged Tumblr posts

Text

How is Silica Sand Mined and Processed?

Discover the mining and processing of silica sand, from extraction to purification, and its essential role in industries like glassmaking and construction. for more info visit: https://thesharadgroup.com/how-is-silica-sand-mined-and-processed/

0 notes

Text

China Clay by 20 Nano: A Versatile Solution for Industries

China clay, also known as kaolin, is a naturally occurring, fine-grained mineral that has become an essential raw material across various industries. Composed primarily of hydrated aluminum silicate, this mineral is prized for its unique physical and chemical properties, including high brightness, fine particle size, and excellent plasticity. With its wide range of applications, china clay has cemented its position as a key component in industries like ceramics, paper, paints, rubber, and more.

Key Applications of China Clay

Ceramics Industry: The ceramics industry is one of the largest consumers of china clay. Its plasticity and fine particle size make it ideal for producing porcelain, tiles, and sanitaryware.

Paper Industry: China clay is widely used as a filler and coating material in the paper industry. It enhances the brightness, smoothness, and opacity of paper.

Paints & Coatings: In the paints and coatings industry, china clay is used as an extender and a pigment. Its excellent dispersion properties and opacity improve the durability and finish of paints.

Rubber & Plastics: China clay acts as a reinforcing filler in rubber and plastic products, improving their strength, flexibility, and durability.

Cosmetics: In the cosmetics industry, china clay is used for its absorbent and smooth-texture properties, making it a key ingredient in facial masks, powders, and other skincare products.

Why 20 Nano?

20 Nano offers high-quality, sustainable china clay solutions with consistent purity and performance. Their advanced processing ensures reliable products tailored to various industries.

Conclusion

China clay is an indispensable mineral, enhancing product quality and performance across industries. Explore premium china clay solutions with 20 Nano today!

1 note

·

View note

Text

April 20, Beijing, China, National Museum of China/中国国家博物馆 (Part 2 - Dehua white porcelain exhibition/德化白瓷展 continued):

This was actually the very first piece I encountered at the entrance to the exhibition, a gigantic basket of flowers (probably over 1 meter tall and over 1 meter wide?), the entire thing made of porcelain.

And to reiterate, every part of every piece is porcelain. Though I will say that despite the ultra-realistic shape of the flower petals and leaves, the only detail that hinted at these flowers being made out of porcelain was that the painted colors weren't as vibrant as real flowers. That's it. If you don't examine it up close you really can't tell that it's all porcelain.

This is a good place to roughly introduce the technical side of Dehua white porcelain. The color of Dehua white porcelain mainly comes from the clay it uses, which is a special kaolin clay (gaolingtu/高岭土 in Chinese) found in Dehua. The clay mineral used naturally contains sericite and quartz, both of which are silica minerals and may have contibuted to the almost translucent look of the finished pieces; it also contains comparatively high amounts of potassium oxides, while the amount of iron oxides present is low. Due to the intricate designs of the pieces, the firing success rate may be very low. All those pieces involving super thin parts representing fabric or paper or flower petals? They may bring the success rate down to about 5%. Which means many of these pieces may be the 15th-20th try that finally survived firing. For people who are more interested in the chemistry of Dehua white porcelain, this paper goes into depth about it. There's also a great book in Chinese that goes into depth all about Dehua porcelain. (link goes to the first chapter only)

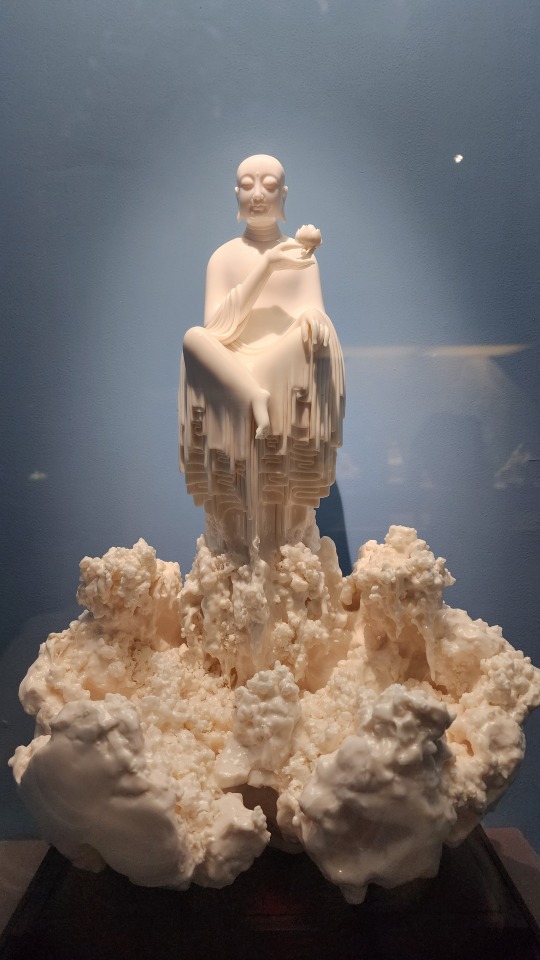

Continuing on, this is one of many Guanyin/观音 (Avalokiteśvara) statues at the exhibition, again with light clothing made out of porcelain:

More Guanyin statues in various classic depictions/forms, of which there are 33 total. This particular form is called Yulan Guanyin/鱼篮观音 (鱼篮 means fish basket), and comes from a legend where Guanyin transformed into a beautiful female fish vendor in order to guide mortals.

I believe the text here reads 持经观音 (Guanyin holding scripture)? The Guanyin here is holding a vase instead of a scroll though.

This is a classic depiction of Guanyin with a little bit of a modern-ish twist? Guanyin is often depicted with a vase of divine water, but here it forms a circle.

Despite some of the Guanyin statues having the amazing ceramic "clothing", this one remains my favorite, just because of the sense of space and serenity that this simple "frame" design creates:

And this very literal take on "thousand arm Guanyin" (千手观音). It's giving me that "biblically accurate angels" vibe:

Buddha floating atop.......idk what that is but the texture is amazing:

A fully painted statue of Guanyu/关羽. The gradient and detailed patterns on his robes is amazing:

Two identical (I think?) statues of the daomadan/刀马旦 (female commander archetype) character Mu Guiying/穆桂英 as she would appear in Chinese traditional opera, one painted and one unpainted. The word 巾帼英雄 in the title means "hero in women's headscarf", which is a term used exclusively in reference to female heroes. There's also the phrase "巾帼不让须眉", which roughly means "those in women's headscarves aren't inferior to those with beards and thick brows"

Porcelain depiction of Dunhuang's famous feitian/飞天 figures, in the classic pose of playing pipa in reverse (called 反弹琵琶). The clothing on this figure is made of porcelain, but this time also painted:

A porcelain statue of a couple in traditional Lhoba/Luoba/珞巴 clothing. The Lhoba/Luoba people are one of China's 55 少数民族 who mainly live in the south-eastern region of Tibet Autonomous Region, and as of 2019, it is the 少数民族 with the smallest population

A porcelain statue of a woman in traditional Miao/苗 clothing. I love how the artist recreated the traditional Miao silver crown in porcelain.

Painted porcelain bust of a woman wearing the Xunbu/蟳埔 "flower crown", named a zanhuawei/簪花围. The town of Xunbu in Fujian province is known for its tradition of zanhua/簪花, or wearing flowers in one’s hair.

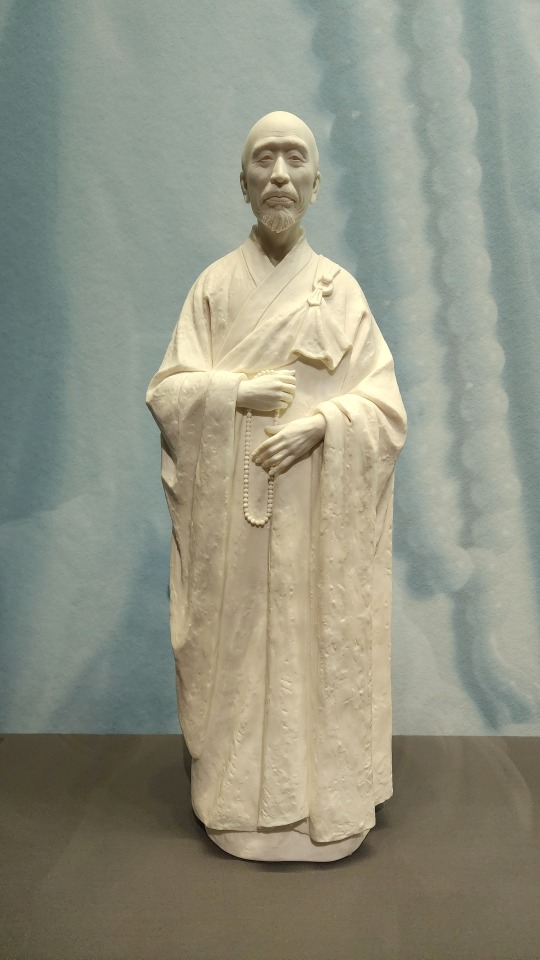

Porcelain statue of a Buddhist monk wearing a zhiduo/直裰 (the robes on the inside) and a jiasha/袈裟 (काषाय/kasaya; the garment on the outside that drapes over the left shoulder). From its looks, one can tell that zhiduo originated from hanfu, but with some minor changes (sidenote, this is not the same as the zhiduo of Ming-era hanfu). Jiasha evolved from the clothing of Indian Buddhist monks, but there appears to be a lot of influence from Central Asia and ancient Greece as well (link goes to pdf; this article is in Chinese).

Some modern-themed pieces. Look at those dresses omg

A porcelain statue of Hua Mulan/花木兰, the character from traditional Chinese literature and opera that inspired the Disney character. I will say though this pose reminds me of someone else.......

#2024 china#beijing#china#national museum of china#dehua porcelain#blanc de chine#porcelain#chinese art#chinese culture#art#culture#buddhism#guanyin

696 notes

·

View notes

Text

The Timeless Beauty of Hangzhou Porcelain: A Legacy of Art and Craftsmanship

The Timeless Beauty of Hangzhou Porcelain: A Legacy of Art and Craftsmanship

Hangzhou, a city renowned for its picturesque landscapes and rich cultural heritage, is also a hub for exquisite porcelain craftsmanship. Hangzhou porcelain, with its delicate designs and high-quality craftsmanship, has enchanted collectors and enthusiasts for centuries. Let's explore the fascinating history, unique features, and enduring allure of Hangzhou porcelain.To get more news about hangzhou porcelain, you can visit shine news official website.

A Glimpse into History: The Origins of Hangzhou Porcelain The history of porcelain production in Hangzhou dates back to the Tang Dynasty (618-907 AD). The region's abundant natural resources, including high-quality kaolin clay, provided the perfect materials for creating fine porcelain. During the Song Dynasty (960-1279 AD), Hangzhou emerged as a significant center for porcelain production, with artisans perfecting their techniques and creating pieces that were highly valued by the imperial court and elite.

Distinctive Features of Hangzhou Porcelain Hangzhou porcelain is celebrated for its unique characteristics, which set it apart from other porcelain styles. Key features include:

Exquisite Glazes: Hangzhou porcelain is known for its beautiful glazes, often featuring vibrant colors and intricate patterns. The use of celadon glaze, in particular, is a hallmark of Hangzhou's porcelain, creating a smooth and lustrous finish.

Delicate Designs: Artisans in Hangzhou excel in creating delicate and detailed designs. Traditional motifs often include nature-inspired elements such as lotus flowers, bamboo, and mythical creatures, reflecting the region's cultural and artistic influences.

High-Quality Craftsmanship: The meticulous craftsmanship involved in producing Hangzhou porcelain ensures that each piece is of the highest quality. From the careful selection of clay to the precise firing process, every step is executed with skill and dedication.

Cultural Significance and Collectibility Hangzhou porcelain holds immense cultural significance in China. It is not only appreciated for its aesthetic beauty but also for its historical and artistic value. Collectors around the world seek Hangzhou porcelain for its rarity and craftsmanship, making it a prized addition to any collection. Museums and galleries often feature Hangzhou porcelain as part of their exhibits, showcasing its enduring legacy.

Modern Innovations and Trends While traditional techniques continue to be revered, modern innovations in porcelain production have also emerged in Hangzhou. Contemporary artists and designers are experimenting with new forms, glazes, and designs, blending traditional craftsmanship with modern aesthetics. This fusion of old and new has resulted in innovative pieces that appeal to a broader audience while preserving the essence of Hangzhou porcelain.

Visiting Hangzhou: Exploring Porcelain Artistry For those visiting Hangzhou, exploring the city’s porcelain heritage is a must. Several workshops and studios offer insights into the intricate process of porcelain making. Visitors can witness artisans at work, learn about the history and techniques, and even try their hand at creating their own porcelain pieces. Additionally, local markets and galleries provide opportunities to purchase authentic Hangzhou porcelain as a souvenir or collectible.

Conclusion Hangzhou porcelain embodies the timeless beauty and meticulous craftsmanship that have defined Chinese porcelain for centuries. Its rich history, distinctive features, and cultural significance continue to captivate collectors and art enthusiasts worldwide. As Hangzhou porcelain evolves with modern innovations, it remains a testament to the enduring legacy of art and craftsmanship that this historic city proudly upholds.

2 notes

·

View notes

Text

Chinese artist Bian Xiaodong’s glossy ceramics resemble falling droplets, however their inverted forms drip upwards rather than down. The artist crafts his gravity-defying artworks from kaolin clay derived from Jingdezhen — a part of east China’s Jiangxi Province known for its history of crafting porcelain.

After adding the clay to silicone moulds, Bian turns the pieces upside down and lets the natural flow of the clay create a unique shape. In the high-temperature firing process, this ultra-thin clay body further morphs into different forms. Once his ceramics are formed, the artist paints them, using an array of colourful pigments including metallic grey and sunflower yellow. (From the Colossal).

22 notes

·

View notes

Text

Porcelain Chinese Tea Set

Porcelain Chinese Tea Set: A Timeless Tradition

The porcelain Chinese tea set is not just a collection of drinking vessels; it's a symbol of centuries-old tradition, craftsmanship, and culture. From its delicate texture to artistic designs, a porcelain tea set offers aesthetic beauty and functional excellence, making it a treasured piece in Chinese households and among tea enthusiasts worldwide.

The Origins of Porcelain in China

Porcelain, known as “china” in the West, has its roots in China, where it was first developed during the Tang Dynasty (618–907 AD). The techniques evolved further in the Song and Ming Dynasties, eventually giving rise to the sophisticated porcelain we recognize today. Porcelain tea sets were initially crafted for royalty and the elite, who valued the material’s fine, translucent quality. Over time, as the methods of production became more refined, porcelain tea sets spread throughout Chinese society, becoming a staple in daily tea rituals.

The Craftsmanship Behind Porcelain Tea Sets

The process of creating porcelain tea sets involves a meticulous series of steps. Made primarily from kaolin, a fine white clay, porcelain undergoes high-temperature firing (around 1200-1400°C), which gives it its signature hardness, smooth surface, and translucent appearance. The process also allows for intricate hand-painted designs, which are often glazed to preserve the artwork.

Famous styles like Blue and White Porcelain (青花瓷) originated in the Ming Dynasty and remain popular today. The distinctive blue patterns against the white backdrop make these tea sets particularly iconic. Additionally, tea sets may feature landscapes, flora, fauna, and calligraphy, each telling a story about the culture and artistry of the time.

The Importance of Porcelain Tea Sets in Chinese Tea Culture

In China, tea drinking is more than just a simple refreshment; it's a practice steeped in history, etiquette, and philosophy. The porcelain tea set plays a crucial role in enhancing the tea-drinking experience. Its delicate and smooth texture feels pleasant in the hands, while the thinness of the cup allows the drinker to appreciate the aroma and flavor of the tea fully.

Porcelain is especially well-suited for green tea, white tea, and lighter oolong teas, as its non-porous surface preserves the pure flavor of the tea. Unlike clay tea sets, porcelain does not absorb the essence of previous brews, making it ideal for those who like to switch between different types of tea.

Design and Symbolism in Porcelain Tea Sets

Porcelain tea sets often feature symbolic patterns that reflect Chinese beliefs and values. Common motifs include:

Lotus flowers: Symbolizing purity and spiritual enlightenment.

Dragons and phoenixes: Representing power and prosperity.

Peonies: A symbol of wealth and honor.

These designs not only add to the beauty of the tea set but also create a deeper connection with Chinese culture, turning every tea session into a meaningful ritual.

Modern-Day Popularity of Porcelain Tea Sets

Today, porcelain Chinese tea sets are admired globally for their elegance and durability. While they continue to be used in traditional tea ceremonies, they have also found a place in modern homes as decorative pieces or thoughtful gifts. Collectors and tea enthusiasts alike value porcelain tea sets for their historical significance, artistic value, and functionality.

A porcelain Chinese tea set is more than just a functional item for brewing tea; it is a bridge to China’s rich cultural heritage. Whether for casual tea drinking or formal tea ceremonies, porcelain tea sets embody the essence of Chinese artistry, tradition, and respect for the art of tea. Owning one means embracing a tradition that has been perfected over centuries, blending beauty, history, and craftsmanship in every sip.

2 notes

·

View notes

Text

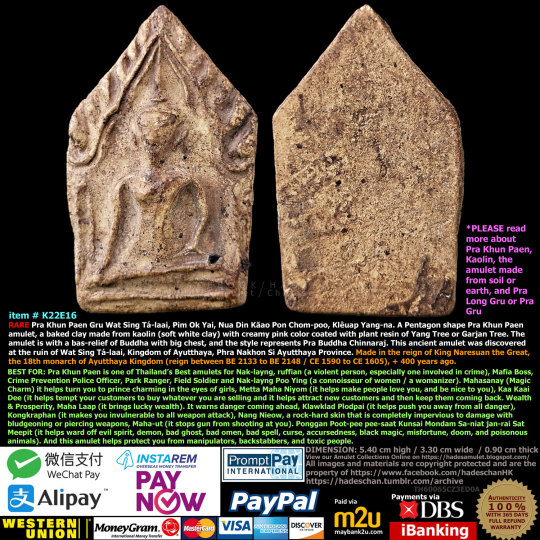

item # K22E16

RARE Pra Khun Paen Gru Wat Sing Tá-laai, Pim Ok Yai, Nua Din Kăao Pon Chom-poo, Klêuap Yang-na.A Pentagon shape Pra Khun Paen amulet, a baked clay made from kaolin (soft white clay) with creamy pink color coated with plant resin of Yang Tree or Garjan Tree. The amulet is with a bas-relief of Buddha with big chest, and the style represents Pra Buddha Chinnaraj. This ancient amulet was discovered at the ruin of Wat Sing Tá-laai, Kingdom of Ayutthaya, Phra Nakhon Si Ayutthaya Province. Made in the reign of King Naresuan the Great, the 18th monarch of Ayutthaya Kingdom (reign between BE 2133 to BE 2148 / CE 1590 to CE 1605), + 400 years ago.

……………………………………………….

BEST FOR: Pra Khun Paen is one of Thailand’s Best amulets for Nak-layng, ruffian (a violent person, especially one involved in crime), Mafia Boss, Crime Prevention Police Officer, Park Ranger, Field Soldier and Nak-layng Poo Ying (a connoisseur of women / a womanizer). Mahasanay (Magic Charm) it helps turn you to prince charming in the eyes of girls, Metta Maha Niyom (it helps make people love you, and be nice to you), Kaa Kaai Dee (it helps tempt your customers to buy whatever you are selling and it helps attract new customers and then keep them coming back. Wealth & Prosperity, Maha Laap (it brings lucky wealth). It warns danger coming ahead, Klawklad Plodpai (it helps push you away from all danger), Kongkraphan (it makes you invulnerable to all weapon attack), Nang Nieow, a rock-hard skin that is completely impervious to damage with bludgeoning or piercing weapons, Maha-ut (it stops gun from shooting at you). Ponggan Poot-pee pee-saat Kunsai Mondam Sa-niat jan-rai Sat Meepit (it helps ward off evil spirit, demon, bad ghost, bad omen, bad spell, curse, accursedness, black magic, misfortune, doom, and poisonous animals). And this amulet helps protect you from manipulators, backstabbers, and toxic people.

……………………………………………….

Pra Khun Paen

The Pra Khun Paen is a type of amulet with figure of Pra Buddha Chinnaraj of Wat Phra Si Rattana Mahathat Woramahawihan (Wat Yai or Wat Pra Buddha Chinnaraj) seating inside an elaborate arch. This type of amulet was first discovered at Wat Pra Roop Archaeology Site, Suphan Buri Province. And such type of ancient baked clay amulet with figure of Pra Buddha Chinnaraj is called “Pra Khun Paen” ever since. It was called Pra Khun Paen to honor the Thai famous Warrior General Khun Paen, the Governor of Suphan Buri Province in the Kingdom of Ayutthaya.

……………………………………………….

Kaolin

Kaolin, soft white clay that is an essential ingredient in the manufacture of china and porcelain. Kaolin is named after the hill in China (Kao-ling) from which it was mined for centuries. Kaolin is found in Lampang , and Ranong Province of Thailand.

……………………………………………….

The amulet made from soil or earth

The soil or earth is the oldest minerals on Earth, it accumulates all power of good deeds of all Arhats (or Luohan), Bodhisattva and Buddha as long as you and your enemies are standing/living on the earth, the Pra Mae Thoranee (the Earth Goddess) will witness good deeds and bad deeds, if you have made good deeds, then your good deeds have already witnessed by Pra Mae Thoranee, Pra Mae Thoranee will help you, and your enemies could not do any harm to you. And the difficulties of your life, Pra Mae Thoranee also witnesses, and Pra Mae Thoranee will ease all of your difficulties.

……………………………………………….

Pra Long Gru or Pra Gru

Pra ���Long Gru” or “Pra Gru” means amulet that was stored in the chamber of a chedi/stupa or in a container buried under the ground for many of years, and later found by someone.

According to the prophecy in Pali Canon that Buddha’s Dispensation (Buddhism), and Dharma (Buddha’s teaching) would exist and follow 5,000 years after the Buddha passed away or entered nirvana. The “Long Gru” is a Thai traditional practice to preserve Buddha amulets with figure of Buddha in them in the case that after the decline of indigenous religious practices of Buddhism, the future generations would learn that Buddhism ever to have existed on earth.

The Pra Long Gru, Thais believe that after long period of time that the Buddha amulets were kept, the power that was accumulated in each and every amulet would break apart the chamber (in Thai called Gru Takk) that amulets were hidden.

……………………………………………….

DIMENSION: 5.40 cm high / 3.30 cm wide / 0.90 cm thick

……………………………………………….

item # K22E16

Price: price upon request, pls PM and/or email us [email protected]

100% GENUINE WITH 365 DAYS FULL REFUND WARRANTY

Item location: Hong Kong, SAR

Ships to: Worldwide

Delivery: Estimated 7 days handling time after receipt of cleared payment. Please allow additional time if international delivery is subject to customs processing.

Shipping: FREE Thailandpost International registered mail. International items may be subject to customs processing and additional charges.

Payments: PayPal / Western Union / MoneyGram /maybank2u.com / DBS iBanking / Wechat Pay / Alipay / INSTAREM / PromptPay International / Remitly / PAYNOW

*************************************************

2 notes

·

View notes

Text

Best Supplier of kaolin powder

As the best supplier of kaolin powder, Pratibha Refractory Minerals offers ultra-fine, high-purity kaolin tailored to meet diverse industrial requirements. Our kaolin features excellent brightness, low abrasiveness, and superior dispersibility, making it the preferred choice in ceramics, paper coating, rubber, paints, and plastics industries.

0 notes

Text

Premium Kaolin Clay Suppliers for the Ceramic Industry in Gujarat, India

Asteroid Microns Pvt Ltd offers high-quality kaolin clay tailored for the ceramic industry in Gujarat, India. Our kaolin enhances the strength, finish, and optical properties of ceramic products, making it ideal for applications in white tableware, tiles, sanitary ware, insulators, and refractories.

0 notes

Text

This charming and detailed illustration, published in 1953 by the Tokyo Ceramic Cooperative Association, offers a step-by-step glimpse into the making of Setomono (せともの)—a term broadly used for Japanese ceramics, particularly those from the Seto region, one of Japan’s oldest pottery centers. The flowchart-like image, drawn in a simple and accessible style, captures the essence of postwar industrial craft—balancing tradition with modern production techniques.

Starting from the raw materials—kaolin, feldspar, and clay—the process begins with crushing and grinding, where stones are broken down and ground into fine particles. These are then mixed with water and processed in a slurry tank before being filtered and kneaded. The material is carefully refined and shaped, often using a potter’s wheel or a molding press, depending on the design.

Once shaped, the ceramics undergo drying and initial bisque firing (素焼き). At this stage, the surface is prepared for underglaze decoration (下絵付け), where artisans apply motifs or patterns before the application of transparent or colored glazes. After glazing, the pieces are fired again—often in a climbing kiln (のぼり窯)—to achieve durability and aesthetic richness.

The final stage involves inspection and quality control, where flawed pieces are discarded or reprocessed. Once approved, the ceramics are carefully packed and transported, often by rail or truck, to shops and markets, eventually finding their way to family dining tables. The illustration ends with a cozy image of a family enjoying tea, emphasizing that these humble yet beautiful objects become an integral part of daily life.

This postwar pamphlet not only documents the technological advancements in ceramic production but also serves as a reminder of the resilience of Japanese craft traditions. Even amid rapid modernization, the fundamental steps remain rooted in careful craftsmanship and communal effort. Setomono, whether simple tableware or ornate pieces, carries within it the legacy of artisanship, blending old methods with the spirit of a new era.

#ceramic#ceramics#handmade ceramics#decor#coffee#tea#home#japan#japanese pottery#japanese culture#japanese history#japanese art#japanese print#art and crafts#crafts#nippon#japanese#kyoto#tokyo#zen#zen art

1 note

·

View note

Text

Ceramic vs Porcelain: The 5 Differences You Should Know

When it comes to tableware and decorative items, the debate between ceramic and porcelain has long captivated both casual consumers and connoisseurs alike. Whether you are a restaurant owner seeking dinner plates wholesale or simply searching for the best housewarming gifts, understanding the key differences between these two materials can significantly impact your purchasing decisions. This comprehensive guide will delve into the five crucial distinctions that set ceramic and porcelain apart, helping you make informed choices for your home or business.

The Historical Journey

The story of ceramics and porcelain is deeply intertwined with human civilization. While ceramic production dates back to ancient civilizations across the globe, porcelain's discovery in China during the Tang Dynasty (618-907 CE) marked a revolutionary advancement in pottery-making. This "white gold," as it became known in Europe, was so valuable that it sparked international trade routes and influenced global commerce for centuries.

Understanding the Fundamental Differences

Composition and Manufacturing Process

At their core, both ceramic and porcelain are clay-based materials, but their composition and manufacturing processes differ significantly. Traditional ceramics are typically made from earthen clays, often combined with various minerals and water. The resulting mixture is shaped and fired at temperatures between 1,000°C and 1,200°C.

Porcelain, however, is crafted from a specific type of clay called kaolin, mixed with feldspar and quartz. This refined composition undergoes firing at much higher temperatures, usually between 1,200°C and 1,400°C. The intense heat causes the materials to vitrify, creating that characteristic translucent quality that makes porcelain particularly appealing as a gift for a wedding couple in Sri Lanka or other special occasions.

Density and Durability

The higher firing temperature of porcelain results in a denser, more durable material compared to traditional ceramics. This increased density makes porcelain more resistant to chipping and scratching, which explains why it is often chosen for employee gifts and other professional presentations where durability matters.

The molecular structure of porcelain is more tightly packed, creating fewer pores and air pockets within the material. This structural difference not only contributes to its strength but also affects its water absorption rate, which is typically less than 0.5% for porcelain compared to ceramics' 3% or higher.

Appearance and Aesthetic Quality

Perhaps the most immediately noticeable difference between ceramic and porcelain lies in their appearance. Ceramics generally have a more rustic, earthy appearance with varying degrees of translucency. The colour can range from deep terracotta to pure white, depending on the clay composition and glazing techniques used.

Porcelain, conversely, is known for its clean, bright white appearance and characteristic translucency when held up to light. This refined look comes from the kaolin clay and the high-temperature firing process, which creates a glass-like finish. While both materials can be glazed and decorated, porcelain typically achieves more delicate, precise patterns due to its smoother surface.

Versatility and Applications

Both materials offer unique advantages in different applications. Ceramics excel in situations where a more casual, rustic aesthetic is desired. They are often used in:

Everyday tableware.

Decorative pottery.

Garden planters.

Architectural elements.

Porcelain's superior strength and refined appearance make it ideal for:

Fine dining establishments.

Medical and laboratory equipment.

High-end bathroom fixtures.

Electrical insulators.

The versatility of both materials extends beyond their traditional uses, with modern manufacturing techniques expanding their potential applications continuously.

Cost and Value Considerations

The price difference between ceramic and porcelain items can be substantial, primarily due to their manufacturing processes and raw material costs. Ceramic products are generally more affordable, making them accessible for everyday use and casual settings. The simpler manufacturing process and more readily available materials contribute to their lower cost.

Porcelain's higher price point reflects its more complex production process, requiring specific raw materials and higher energy consumption during firing. However, its durability often makes it a more cost-effective choice in the long run, particularly for items that see frequent use.

Making the Right Choice

When deciding between ceramic and porcelain, consider these key factors:

Intended Use: Consider how the item will be used. For everyday casual dining, ceramics might be perfectly suitable. However, for special occasions or professional settings, porcelain's elegance and durability might justify the higher investment.

Maintenance Requirements: Both materials require careful handling, but porcelain's density makes it more resistant to staining and easier to clean. Ceramics might require more attention to prevent water absorption and staining, particularly in unglazed areas.

Environmental Conditions: If the items will be exposed to outdoor conditions or extreme temperature changes, porcelain's superior durability and lower water absorption rate make it the better choice. Ceramics are more susceptible to damage from freezing temperatures and moisture.

Final Thoughts

Understanding the differences between ceramic and porcelain empowers consumers to make informed decisions based on their specific needs and circumstances. While ceramics offer charm and affordability suitable for casual settings, porcelain's durability and refinement make it ideal for more formal or professional applications.

As manufacturing techniques continue to evolve, the line between these materials may become increasingly blurred. However, their distinct characteristics ensure that both ceramic and porcelain will maintain their unique places in our homes and workplaces. Whether you are selecting items for personal use or choosing corporate gifts, considering these five key differences will guide you toward the perfect choice for your specific needs.

Remember that quality varies significantly within both categories, and reputable manufacturers often provide detailed specifications about their products' composition and performance characteristics. By carefully considering your needs against these five fundamental differences, you can make choices that will serve you well for years to come.

#dinner plates wholesale#Best housewarming gifts#Employee Gifts#gift for wedding couple in sri lanka

0 notes

Text

Best kaolinite blends for lightweight concrete—what do experts recommend?

When it comes to lightweight concrete, kaolinite plays a crucial role in enhancing its strength, durability, and workability. Experts recommend various kaolinite blends to optimize performance, and the right selection depends on specific project requirements. In this article, we will discuss the best kaolinite blends for lightweight concrete, their advantages, and expert insights.

Why Use Kaolinite in Lightweight Concrete?

Kaolinite, commonly known as kaolin, is a fine, white clay mineral that is extensively used in construction materials. It improves the rheological properties of concrete, making it more workable while enhancing its strength and thermal insulation properties. Some of the major benefits of using kaolinite in lightweight concrete include:

Improved durability: Enhances resistance to weathering and chemical attack.

Higher compressive strength: Optimized kaolinite blends provide superior structural integrity.

Thermal insulation: Reduces heat conductivity, making it ideal for energy-efficient buildings.

Reduced shrinkage: Helps prevent cracking and improves longevity.

Expert-Recommended Kaolinite Blends for Lightweight Concrete

1. Metakaolin-Based Blends

Metakaolin is a calcined form of kaolinite and is widely recognized for its pozzolanic properties. When blended with lightweight aggregates, metakaolin significantly enhances the compressive strength and durability of concrete. China clay manufacturers in India produce high-quality metakaolin, which is used in a variety of industrial applications for kaolin such as cement replacement and high-performance concrete.

Recommended Blend:

50% Metakaolin + 50% Lightweight Aggregate (e.g., expanded perlite or vermiculite)

Cement Replacement: Up to 15% by weight

Water-to-Binder Ratio: 0.35 to 0.45

This blend provides excellent compressive strength, reduced permeability, and enhanced resistance to sulfate attack.

2. Kaolin and Silica Fume Hybrid Blends

Silica fume is another high-performance additive that, when blended with kaolin, significantly improves the mechanical properties of lightweight concrete. This blend is particularly useful for precast elements and ultra-lightweight panels.

Recommended Blend:

30% Kaolin + 20% Silica Fume + 50% Lightweight Aggregate

Cement Replacement: 10-20%

Water-to-Binder Ratio: 0.4

This combination enhances the pozzolanic reaction, leading to denser concrete with better mechanical properties.

3. Kaolin with Fly Ash and Pumice-Based Aggregates

Fly ash is an industrial byproduct that, when combined with kaolin, can improve the sustainability and workability of lightweight concrete. Experts often recommend this blend for large-scale commercial construction projects where cost efficiency and environmental benefits are priorities.

Recommended Blend:

25% Kaolin + 25% Fly Ash + 50% Pumice Aggregate

Cement Replacement: Up to 30%

Water-to-Binder Ratio: 0.42

This blend is ideal for reducing the carbon footprint while maintaining excellent workability and strength.

The Role of China Clay Manufacturers in India

India is one of the largest producers of kaolin, with several kaolin producers supplying high-quality raw materials to the construction industry. Many china clay manufacturers in India provide specialized kaolinite products tailored for concrete applications. These manufacturers ensure:

High Purity Kaolin: Suitable for high-performance concrete.

Customizable Blends: Adapted for specific project needs.

Sustainable Sourcing: Environmentally friendly extraction and processing.

Key Industrial Applications for Kaolin in Concrete

Apart from lightweight concrete, kaolin is extensively used in other industrial applications for kaolin, including:

Self-compacting concrete (SCC): Improves flowability and reduces segregation.

High-strength concrete: Enhances compressive and flexural strength.

Refractory concrete: Provides high heat resistance in industrial structures.

Geopolymer concrete: Acts as a key ingredient in eco-friendly construction materials.

Choosing the Right Kaolin Producer for Your Concrete Projects

Selecting a reliable kaolin producer is essential for obtaining consistent and high-quality materials. The best kaolin producers offer:

Tested and certified products

Technical support and guidance

Customization based on project specifications

Some of the top china clay manufacturers in India provide laboratory-tested metakaolin, ensuring compliance with international construction standards.

Conclusion

Experts agree that the choice of kaolinite blends in lightweight concrete significantly influences performance and durability. Whether using metakaolin-based blends, kaolin with silica fume, or kaolin with fly ash, careful selection of materials is key. Collaborating with leading china clay manufacturers in India and trusted kaolin producers ensures high-quality, efficient, and sustainable concrete solutions. For construction professionals looking to enhance their concrete mix designs, incorporating kaolin into lightweight concrete is a game-changer in modern building practices.

0 notes

Text

Superior China Clay for Ceramics & Industrial Uses | 20 Nano

Superior China Clay from 20 Nano, designed for ceramics and diverse industrial applications. Our China Clay enhances product quality, durability, and finish because of its excellent whiteness, plasticity, and smooth texture. It delivers reliable, consistent results across industries and is ideal for use in ceramics, paper, paints, and coatings. 20 Nano’s China Clay meets the performance needs of demanding applications.

For more information: https://20nano.com/china-clay-kaolin/

0 notes

Text

U.S. Metakaolin Prices 2025, News, Trend, Graph, Chart and Forecast

Metakaolin prices in the global market are influenced by several factors, including raw material availability, production costs, demand-supply dynamics, and regional economic conditions. As a high-reactivity pozzolan widely used in the construction and ceramics industries, metakaolin's price trends are closely linked to infrastructure growth, cement and concrete production, and technological advancements in materials science. Over the past few years, the market has witnessed fluctuations driven by energy prices, logistics disruptions, and raw material shortages. These factors have impacted overall production costs, leading to periodic price hikes or stabilization depending on regional supply chain efficiencies.

The demand for metakaolin has seen a steady rise, primarily due to its role in enhancing the strength and durability of concrete structures. As the construction industry continues to expand, particularly in emerging economies where urbanization is rapid, the need for supplementary cementitious materials like metakaolin remains high. Countries such as China, India, and Brazil have shown significant growth in infrastructure projects, driving up the consumption of metakaolin and influencing its pricing trends. Additionally, stringent environmental regulations pushing for sustainable and low-carbon alternatives in construction have fueled the adoption of metakaolin, as it helps reduce carbon emissions associated with cement production.

Get Real time Prices for Metakaolin : https://www.chemanalyst.com/Pricing-data/metakaolin-1121

Raw material availability plays a crucial role in determining the price trends of metakaolin. Since it is derived from kaolin clay, fluctuations in kaolin mining operations, regulatory policies, and geopolitical issues affecting major mining regions can lead to supply constraints. When supply is tight, manufacturers often face increased costs, which are passed on to consumers. On the other hand, advancements in extraction and processing technologies have helped stabilize prices in some regions by improving production efficiency and reducing waste. However, energy costs remain a major component of metakaolin pricing, as the calcination process requires significant amounts of heat, and fluctuations in fuel prices can directly impact production costs.

The market is also affected by logistics and transportation costs, which have become particularly volatile in recent years due to global supply chain disruptions. Shipping rates, fuel prices, and port congestions have all played a role in altering metakaolin prices across different regions. For instance, higher freight costs can make imported metakaolin less competitive in certain markets, leading to increased reliance on domestic production where available. This localization of supply chains can sometimes stabilize prices, but it may also result in regional price disparities depending on availability.

Another significant factor influencing metakaolin prices is technological innovation and advancements in production processes. Many companies are investing in research and development to optimize production techniques, enhance quality, and reduce costs. The introduction of more energy-efficient kilns, automation in processing plants, and better quality control measures have contributed to improved supply conditions, helping stabilize prices over time. Moreover, ongoing developments in high-performance concrete and specialty ceramics continue to drive demand for metakaolin, adding upward pressure on prices when supply struggles to keep pace.

Environmental and sustainability trends are also shaping the pricing landscape of metakaolin. As industries shift towards greener construction materials, the demand for metakaolin as a substitute for traditional cementitious materials has surged. This shift is driven by global initiatives to reduce carbon footprints in building materials and construction projects. Governments and regulatory bodies in various regions are promoting the use of eco-friendly pozzolans, further strengthening market demand. Consequently, suppliers focusing on sustainable production methods and low-emission processing technologies have been able to command premium prices in some markets.

Regional variations in metakaolin prices are evident due to differences in production capacities, demand patterns, and regulatory landscapes. In North America and Europe, where there is a growing emphasis on sustainable construction practices, metakaolin prices have remained relatively high due to strong demand and strict environmental policies. In contrast, Asia-Pacific, being a major hub for kaolin mining and metakaolin production, has seen more competitive pricing due to the presence of numerous manufacturers and abundant raw material supply. However, fluctuating energy costs and regulatory challenges in key production countries such as China and India continue to introduce uncertainty in price stability.

Market players, including manufacturers, suppliers, and end-users, are constantly adapting to these price fluctuations through strategic procurement practices, long-term contracts, and investments in local production facilities. Many companies are looking to secure stable supply chains by diversifying their sourcing regions and adopting cost-effective processing technologies. In some cases, partnerships between construction firms and metakaolin suppliers have been established to ensure consistent supply and price stability.

Overall, the global metakaolin market remains dynamic, with pricing trends being shaped by a mix of economic, technological, environmental, and logistical factors. While demand continues to grow due to expanding construction activities and sustainability initiatives, challenges related to raw material availability, energy costs, and supply chain constraints persist. Industry stakeholders are focusing on innovations, efficiency improvements, and strategic supply chain management to mitigate price volatility and ensure steady market growth. As the market evolves, future price trends will likely depend on a balance between supply-side efficiencies and increasing demand for high-performance, eco-friendly materials in construction and industrial applications.

Get Real time Prices for Metakaolin : https://www.chemanalyst.com/Pricing-data/metakaolin-1121

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Metakaolin Pricing#Metakaolin News#Metakaolin Database#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

What Does A Clay Mask Do? What Are Clay Masks Good For?

What Does A Clay Mask Do? What Are Clay Masks Good For?

Clay masks have been used for centuries as a beauty staple for improving skin and hair health. These masks are revered for their ability to cleanse, brighten, and balance the skin. Whether you are tackling acne, excess oil, or dullness, clay masks offer various benefits for different skin types.

What is Clay Mask?

A clay mask is a skincare product made from various types of natural clays like kaolin, bentonite, or rhassoul. These clays are mineral-rich, and each has unique properties that benefit the skin.

Clay masks are known for their ability to draw out impurities, absorb excess oil, and cleanse clogged pores. They are a popular part of skincare routines for those with oily, acne-prone, or combination skin.

What Are the Benefits of Clay Mask?

Clay masks offer a range of benefits, especially for those with oily or acne-prone skin. Here are the primary advantages:

Pore Cleansing: Clay masks help remove dirt, oil, and dead skin cells that can clog pores.

Oil Control: They absorb excess sebum, helping balance skin for a matte finish.

Exfoliation: Some clay masks gently exfoliate, removing dead skin and revealing a smoother complexion.

Detoxification: Many clays have a negative charge that binds to positively charged toxins, helping to remove impurities from the skin.

Acne Treatment: By absorbing oil and unclogging pores, clay masks can help prevent breakouts.

Skin Brightening: Regular use may enhance skin’s radiance and even out skin tone.

Skin Tightening: As the mask dries, it creates a temporary tightening effect, making skin feel firmer.

Clay Mask for Face

Clay masks are commonly used on the face to treat various skin concerns:

Clay Mask for Oily Skin

For those with oily skin, clay masks are a game-changer. They help absorb excess oil and control shine, preventing breakouts. Bentonite and French green clay are especially effective at soaking up oil and leaving skin feeling balanced.

Clay Mask for Pores

Clogged pores can lead to blackheads and acne. Clay masks help cleanse and minimize the appearance of pores by drawing out impurities. Regular use can result in clearer, smoother skin.

Clay Mask for Dry Skin

Although clay masks are known for their oil-absorbing properties, certain types like red clay and kaolin are suitable for dry skin. These clays are gentle and help lock in moisture while removing impurities. To avoid over-drying, limit use to once a week.

Clay Mask for Acne-Prone Skin

Clay masks can help manage mild acne by removing oil and bacteria that clog pores. Green clay and bentonite are commonly used to treat acne-prone skin due to their strong oil-absorbing and antibacterial properties.

Clay Mask for Hair

Clay masks are also beneficial for hair, particularly for those with oily scalps or dandruff. They help cleanse the scalp, absorb excess oil, and remove product buildup. Rhassoul clay is often recommended for hair due to its mineral-rich composition and gentle exfoliating properties.

To use a clay hair mask, apply it evenly to the scalp and hair. Leave it on for 5–10 minutes before rinsing thoroughly. Avoid using clay masks if you have a sensitive or dry scalp to prevent further irritation.

Types of Clay Mask

There are various types of clay masks, each with distinct benefits:

Kaolin Clay: Also known as china clay, kaolin is gentle and ideal for sensitive or dry skin. It absorbs oil without stripping moisture and may also improve circulation.

Bentonite Clay: Derived from volcanic ash, bentonite is highly absorbent and effective for oily skin. It helps tighten skin and reduce breakouts.

French Green Clay: Known for its exfoliating properties, this clay is ideal for drawing out impurities and improving blood circulation.

Fuller’s Earth Clay: A powerful absorbing clay, Fuller’s earth is best for oily skin. It can also help lighten blemishes.

Rhassoul Clay Mask: Rich in minerals like magnesium and potassium, rhassoul clay is excellent for detoxifying and balancing both skin and hair.

How to Apply and Remove a Clay Mask

Applying a clay mask correctly is key to reaping its benefits:

Cleanse: Start with a gentle cleanser to remove dirt and makeup.

Apply: Scoop out a small amount of clay and spread a thin, even layer over your face, avoiding the eyes and mouth.

Set Time: Leave the mask on for about 15 minutes or until it hardens.

Remove: Rinse with lukewarm water or use a damp cloth to gently wipe off the mask. Pat your skin dry.

Moisturize: Follow up with a moisturizer to replenish hydration.

Clay Mask at Home

Making a DIY clay mask at home is easy and customizable. Simply mix clay powder with water or ingredients like aloe vera, honey, or tea tree oil for added benefits. This allows you to create a mask tailored to your skin type and concerns.

Frequency and Side Effects

To avoid over-drying, it’s best to use clay masks no more than twice a week. Common side effects include dryness, redness, and irritation, especially if the mask is left on too long. Always patch-test new products to ensure they’re suitable for your skin.

For detailed information, read this informative article on clay masks — What Is Clay Mask? What Are The Benefits Of Clay Mask?

Conclusion

Clay masks are a versatile skincare product that can address various concerns, from oily skin to acne and dullness. Whether you choose kaolin for sensitive skin or rhassoul clay for detoxification, there’s a clay mask for every skin type.

Incorporating a clay mask into your skincare routine can help you achieve clearer, healthier, and more radiant skin. If you’re looking to try a clay mask at home, ensure proper application and limit usage to maintain balanced skin health.

#skincare tips#skincare routine#skincare#dry skin#clay mask#beauty products#beauty tips#skincare products#glowingskin#korean skincare#k skin

0 notes

Text

Chinese artist Bian Xiaodong’s glossy ceramics resemble falling droplets, however their inverted forms drip upwards rather than down. The artist crafts his gravity-defying artworks from kaolin clay derived from Jingdezhen — a part of east China’s Jiangxi Province known for its history of crafting porcelain.

After adding the clay to silicone moulds, Bian turns the pieces upside down and lets the natural flow of the clay create a unique shape. In the high-temperature firing process, this ultra-thin clay body further morphs into different forms. Once his ceramics are formed, the artist paints them, using an array of colourful pigments including metallic grey and sunflower yellow. (From the Colossal).

Bian Xiaodong studied BA in Environmental Art Design at Wuchang Institute of Technology, BIAN Xiaodong established the Raindrop Ceramic Design Studio in Jingdezhen in February 2012.

16 notes

·

View notes