#kaolin clay manufacturers

Explore tagged Tumblr posts

Text

How to Source Pharmaceutical-Grade Kaolin Powder for Medicinal Use

Discover the key steps to sourcing high-quality pharmaceutical-grade kaolin powder for safe and effective medicinal applications. for more info visit: https://justpaste.it/cxhhe

0 notes

Text

Leading Kaolin Clay Manufacturers: Quality Solutions for Multiple Industries

Discover top kaolin clay manufacturers offering high-grade products for various industries such as ceramics, paper, rubber, and paints. Our kaolin clay is known for its fine particle size, brightness, and excellent dispersion properties, making it ideal for enhancing product quality and performance. Whether you need kaolin for industrial applications or specialized formulations, our manufacturers provide reliable and consistent solutions tailored to meet your needs. Trust the best in the industry for superior kaolin clay products.

0 notes

Text

HD Microns Limited: Leading Kaolin Exporters for Superior Industrial Solutions

Kaolin, a versatile clay mineral, plays a crucial role in a wide array of industries, from paper to paints, rubber, and cement. Among the top-tier kaolin exporters, HD Microns Limited stands out as a leader, delivering unparalleled quality and innovation since its establishment in 1997. With a legacy of excellence and a commitment to customer satisfaction, HD Microns has solidified its reputation as a trusted supplier of high-grade kaolin products.

The HD Microns Advantage

Comprehensive Product Range

HD Microns Limited offers an extensive range of kaolin products tailored to meet diverse industrial needs:

Levigated China Clay

Hydrous China Clay

Spray Dried China Clay

Calcined China Clay

Meta Kaolin

Each product undergoes rigorous quality checks to ensure it meets international standards, making them ideal for applications in paper, paint, adhesives, cables, and more.

State-of-the-Art Facilities

HD Microns Limited utilizes cutting-edge technology and advanced machinery to produce top-quality kaolin products. The company’s calcined kaolin plant exemplifies this commitment, enabling precise control over the calcination process to produce kaolin with exceptional pozzolanic properties.

Meta Kaolin: A Game-Changer

One of HD Microns’ standout products is Meta Kaolin, a dehydroxylated form of kaolinite created through a controlled calcination process. This high-performance material offers numerous benefits for the construction industry, particularly in cement and concrete applications:

Enhanced Strength: Meta Kaolin reacts with calcium hydroxide to form additional calcium silicate hydrates (C-S-H), increasing the strength of concrete.

Reduced Permeability: The pozzolanic reaction densifies the concrete matrix, reducing water and chloride penetration.

Improved Durability: Concrete mixed with Meta Kaolin exhibits superior resistance to reinforcement corrosion, sulfate attacks, and alkali-silica reactions.

Aesthetic Appeal: Its light color makes it ideal for architectural concrete and white cement applications.

Typical dosages of Meta Kaolin range from 8-20% replacement of Portland cement by weight, making it a cost-effective solution for enhancing concrete performance.

Commitment to Excellence

Under the visionary leadership of Mr. Hansraj D. Patel, HD Microns Limited has continually evolved to meet the dynamic needs of the market. The company’s team of experienced professionals ensures that every product delivers maximum value to customers worldwide.

Why Choose HD Microns Limited?

As a leading name among kaolin exporters, HD Microns Limited stands out for its:

High-quality products that meet international standards.

Advanced manufacturing processes and facilities.

Dedicated customer support and tailored solutions.

Competitive pricing and reliable delivery.

Contact HD Microns Limited Today

Ready to elevate your industrial processes with superior kaolin products? Get in touch with HD Microns Limited

0 notes

Text

0 notes

Text

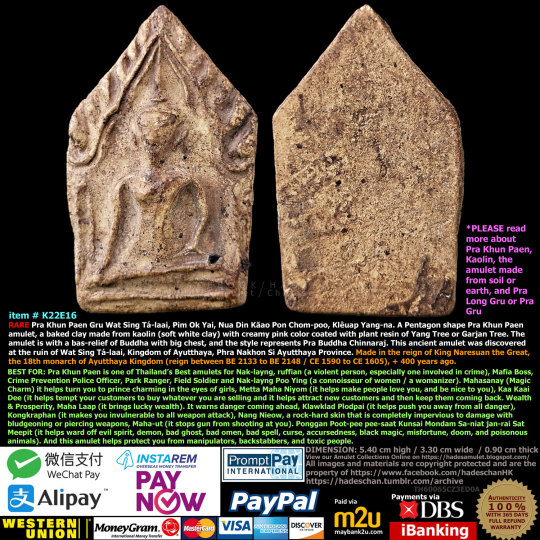

item # K22E16

RARE Pra Khun Paen Gru Wat Sing Tá-laai, Pim Ok Yai, Nua Din Kăao Pon Chom-poo, Klêuap Yang-na.A Pentagon shape Pra Khun Paen amulet, a baked clay made from kaolin (soft white clay) with creamy pink color coated with plant resin of Yang Tree or Garjan Tree. The amulet is with a bas-relief of Buddha with big chest, and the style represents Pra Buddha Chinnaraj. This ancient amulet was discovered at the ruin of Wat Sing Tá-laai, Kingdom of Ayutthaya, Phra Nakhon Si Ayutthaya Province. Made in the reign of King Naresuan the Great, the 18th monarch of Ayutthaya Kingdom (reign between BE 2133 to BE 2148 / CE 1590 to CE 1605), + 400 years ago.

……………………………………………….

BEST FOR: Pra Khun Paen is one of Thailand’s Best amulets for Nak-layng, ruffian (a violent person, especially one involved in crime), Mafia Boss, Crime Prevention Police Officer, Park Ranger, Field Soldier and Nak-layng Poo Ying (a connoisseur of women / a womanizer). Mahasanay (Magic Charm) it helps turn you to prince charming in the eyes of girls, Metta Maha Niyom (it helps make people love you, and be nice to you), Kaa Kaai Dee (it helps tempt your customers to buy whatever you are selling and it helps attract new customers and then keep them coming back. Wealth & Prosperity, Maha Laap (it brings lucky wealth). It warns danger coming ahead, Klawklad Plodpai (it helps push you away from all danger), Kongkraphan (it makes you invulnerable to all weapon attack), Nang Nieow, a rock-hard skin that is completely impervious to damage with bludgeoning or piercing weapons, Maha-ut (it stops gun from shooting at you). Ponggan Poot-pee pee-saat Kunsai Mondam Sa-niat jan-rai Sat Meepit (it helps ward off evil spirit, demon, bad ghost, bad omen, bad spell, curse, accursedness, black magic, misfortune, doom, and poisonous animals). And this amulet helps protect you from manipulators, backstabbers, and toxic people.

……………………………………………….

Pra Khun Paen

The Pra Khun Paen is a type of amulet with figure of Pra Buddha Chinnaraj of Wat Phra Si Rattana Mahathat Woramahawihan (Wat Yai or Wat Pra Buddha Chinnaraj) seating inside an elaborate arch. This type of amulet was first discovered at Wat Pra Roop Archaeology Site, Suphan Buri Province. And such type of ancient baked clay amulet with figure of Pra Buddha Chinnaraj is called “Pra Khun Paen” ever since. It was called Pra Khun Paen to honor the Thai famous Warrior General Khun Paen, the Governor of Suphan Buri Province in the Kingdom of Ayutthaya.

……………………………………………….

Kaolin

Kaolin, soft white clay that is an essential ingredient in the manufacture of china and porcelain. Kaolin is named after the hill in China (Kao-ling) from which it was mined for centuries. Kaolin is found in Lampang , and Ranong Province of Thailand.

……………………………………………….

The amulet made from soil or earth

The soil or earth is the oldest minerals on Earth, it accumulates all power of good deeds of all Arhats (or Luohan), Bodhisattva and Buddha as long as you and your enemies are standing/living on the earth, the Pra Mae Thoranee (the Earth Goddess) will witness good deeds and bad deeds, if you have made good deeds, then your good deeds have already witnessed by Pra Mae Thoranee, Pra Mae Thoranee will help you, and your enemies could not do any harm to you. And the difficulties of your life, Pra Mae Thoranee also witnesses, and Pra Mae Thoranee will ease all of your difficulties.

……………………………………………….

Pra Long Gru or Pra Gru

Pra “Long Gru” or “Pra Gru” means amulet that was stored in the chamber of a chedi/stupa or in a container buried under the ground for many of years, and later found by someone.

According to the prophecy in Pali Canon that Buddha’s Dispensation (Buddhism), and Dharma (Buddha’s teaching) would exist and follow 5,000 years after the Buddha passed away or entered nirvana. The “Long Gru” is a Thai traditional practice to preserve Buddha amulets with figure of Buddha in them in the case that after the decline of indigenous religious practices of Buddhism, the future generations would learn that Buddhism ever to have existed on earth.

The Pra Long Gru, Thais believe that after long period of time that the Buddha amulets were kept, the power that was accumulated in each and every amulet would break apart the chamber (in Thai called Gru Takk) that amulets were hidden.

……………………………………………….

DIMENSION: 5.40 cm high / 3.30 cm wide / 0.90 cm thick

……………………………………………….

item # K22E16

Price: price upon request, pls PM and/or email us [email protected]

100% GENUINE WITH 365 DAYS FULL REFUND WARRANTY

Item location: Hong Kong, SAR

Ships to: Worldwide

Delivery: Estimated 7 days handling time after receipt of cleared payment. Please allow additional time if international delivery is subject to customs processing.

Shipping: FREE Thailandpost International registered mail. International items may be subject to customs processing and additional charges.

Payments: PayPal / Western Union / MoneyGram /maybank2u.com / DBS iBanking / Wechat Pay / Alipay / INSTAREM / PromptPay International / Remitly / PAYNOW

*************************************************

2 notes

·

View notes

Text

Tile Manufacturing Industry in India

The Indian ceramic tiles manufacturing industry has grown significantly over the last few decades and has emerged as one of the major sectors within the country's building and construction materials industry. Tiles are widely used in residential, commercial, and industrial applications and are made from materials such as ceramic, porcelain, vitrified, and natural stone. Rapid urbanization, increased demand for housing, and infrastructure development have played a major role in the growth of tile manufacturing in India.

1. Market Overview

India is the second-largest and largest tile consumer and producer in the world. With a significant domestic market, India has also established itself as one of the key countries exporting tiles, primarily to destinations like the Middle East, Europe, and Africa. The increasing demand for both decorative and highly durable flooring and wall applications in the residential and commercial sectors has been propelling the market.

2. Types of Tiles Manufactured in India

Indian tiles industry manufactures various tiles to cater to different consumer preferences and market requirements. Some of the common types include the following:

Ceramic Tiles: These are the most common type of tiles, made from clay and fired at high temperatures. They are affordable, durable, and come in a wide range of designs. Porcelain tiles are relatively stiffer, stronger, and relatively tougher and water-resistant when comparing ceramic. They are utilized as an item to form both flooring &wall purposes. Vitrified strong and less in pores which makes them better than some options from the other product which were there in the building markets. They are processed using an assortment of ingredients at elevated temperatures by subjecting a heated mixture of clays/silica/fender. Glass Tiles: These tiles are mainly used for aesthetic purposes in bathrooms, kitchens, and other decorative areas. They are made from glass. Natural Stone Tiles: Those tiles are made from natural stones like marble, granite, and slate. They are used for luxury applications.

3. Production Process

The manufacturing process of tiles generally involves the following steps:

Preparation of Raw Materials: Raw materials like clay, kaolin, silica, feldspar, and other minerals are sourced and prepared. Forming: The raw materials are mixed into a slurry, which is then formed into the desired tile shape using different methods, such as pressing or extrusion. Firing: The formed tiles are fired at temperatures ranging from 1000°C to 1400°C in kilns, which harden and give the tiles their desired characteristics. Glazing: Many tiles undergo a glazing process where a ceramic coating is applied to create smooth, glossy surfaces. Packaging and Distribution: Once the tiles are cooled, inspected, and tested for quality, they are packed and distributed to retailers, wholesalers, and customers.

4. Growth Drivers

The tiles manufacturing industry in India has been spurred by several factors:

Urbanization and Infrastructure Development: With rapid urban growth and increasing demand for residential, commercial, and industrial spaces, there has been a surge in the demand for tiles. Growing Disposable Incomes: With the increase in the purchasing power of the Indian middle class, there is an increase in demand for tiles that are aesthetically pleasing and durable. Government Policies: Schemes such as Housing for All, Smart Cities, and Atal Mission for Rejuvenation and Urban Transformation (AMRUT) are really providing a boost to the construction and building materials industries, such as tiles manufacturing. Export Possibilities: Indian tiles companies have gained an aggressive stand on the international markets; with growth opportunities in Europe, Africa, and the Middle East, higher overseas demand for quality tile supplies triggers demand to generate further.

5. Obstacles

Though the industry in India is developing a robust stance in manufacturing Indian tiles, it faces quite some obstructions in its way;

Raw Material Dependence- several producers rely on the input from foreign lands making its cost fluctuation probable while disturbing the supply line occasionally. Environmental Issues: Tile manufacturing is an energy-intensive and environmentally polluting activity. Tighter rules on carbon emission and waste handling might affect the manufacturing processes. Competition: The Indian tiles industry is very competitive. International as well as local companies compete to gain market share. Technology Advancements: Consumers' preferences and tastes keep changing, so manufacturers must keep investing in new technologies, designs, and environmentally friendly techniques to remain in the game.

6. Future Outlook

The Indian tiles manufacturing industry is expected to continue its growth. The demand for good quality and innovative tiles coupled with technological advancements will drive the sector's expansion. With a push towards sustainable production and an increasing export market, Indian manufacturers are well-positioned to capture a significant share of the global market.

#tiles#tilesmanufacturer#floortiles#walltiles#bathroomtiles#kitchentiles#outdoortiles#ceramictiles#porcelaintiles

1 note

·

View note

Text

Exploring Key Industrial Minerals in India

India has a geologically diverse and richer composition, thanks to which it is among the most mineral-resource-endowed nations. Such commodities are needed in industries like manufacturing, construction, energy, chemicals, and agriculture. Among those, Indian minerals used for industries are of great importance in influencing the nation's economic and industrial growth. In contrast to metallic minerals, industrial minerals in India are employed directly in their unprocessed form or after slight processing and form a major part in the manufacture of omnipresent materials.

What Are Industrial Minerals?

Industrial minerals are naturally occurring, inorganic, and non-metallic minerals, which are developed based on their commercial utility and utilized in all kinds of industries. They can be limestone, talc, quartz, barite, gypsum, feldspar, kaolin, and bentonite, just to mention a few among thousands. Industrial minerals are employed from building and ceramics to cosmetics, plastics, and paper.

Indian consumption of industrial minerals has matched quick growth in urbanization, increased infrastructure development, and an aggressive manufacturing base. Increased demand has also opened doors for mining organizations and exporters to increase their operation both within and outside the country.

Major Industrial Minerals of India

India possesses extremely huge numbers of industrial minerals, which are exceedingly crucial to various industries. The major ones are:

1. Limestone

India is the world's second largest producer of limestone. It is used in cement, steel, and building construction manufacturing. The main producing states are Rajasthan, Madhya Pradesh, Andhra Pradesh, and Chhattisgarh.

2. Talc

Talc is a soft mineral used in paper, paint, ceramic, and personal care products. India has heavy deposits of talc in Maharashtra and Rajasthan. Indian talc is so white and brilliant that it is export-oriented to foreign markets.

3. Feldspar and Quartz

Both are raw materials for the glass and ceramics industry. Rajasthan, Andhra Pradesh, and Tamil Nadu produce them mainly.

4. Bentonite

A clay mineral that has extensive application in drilling mud, foundry, and construction. Big-scale Indian production of bentonite takes place in Gujarat.

5. Kaolin

Kaolin or china clay finds application in the ceramic, rubber, paint, and paper industries. West Bengal and Kerala are major sources of the mineral.

6. Gypsum

Gypsum, with extensive application in the cement and plaster industries, is mined largely from Rajasthan and Jammu & Kashmir.

These are just some of the very vast array of industrial minerals found in India. All of them have a unique purpose and contribute to adding value to millions of products that people consume every day.

Chanda Minerals – A Leading Talc and Industrial Mineral Supplier

Among the numerous players in the process and mining sector, Chanda Minerals stands out as a reliable and quality firm. From Maharashtra, Chanda Minerals deals in the export and manufacturing of high-grade talc powder, besides other industrial minerals. Chanda Minerals supplies its products to industries like ceramics, plastics, rubber, paper, and paints.

How Chanda Minerals has remained successful in satisfying their customers is that they have a history of consistent quality, timely delivery, and specialized solutions. Their talc is higher in whiteness, natural fine particle size, and chemical purity. The firm has state-of-the-art grinding facilities and processing equipment that enables them to deliver precise specifications demanded in various industries. Chanda Minerals is thus significant in filling the demand for high-grade industrial minerals in India and overseas.

Significance of Indian Economy to Industrial Minerals

Industrial mineral sector contributes an impressive percentage to the GDP of India and functions as a driver for upstream industries to develop. Construction sector, alone, depends extensively on sand, gypsum, and limestone, and production sectors need minerals such as talc, kaolin, and quartz.

India's position as one of the top producers of most industrial minerals places it on a competitive edge in the global market. Indian production of industrial minerals has increased in recent decades with countries in Asia, the Middle East, and Europe importing construction, manufacturing, and consumer goods raw materials from Indian producers.

Besides this, the government has also been promoting exploration, sustainable mining, and the private sector so that the maximum potential of India's mineral resources can be reached. This creates ample opportunities for domestic companies, investors, and foreign partners wishing to partner in India's industrial minerals industry.

Challenge and Opportunities within the Industry

Even though India has gigantic potential, the industrial minerals industry faces numerous challenges:

Environmental Issues: Mining will exert a negative effect on the environment unless done in a responsible manner. Proper mining operations are necessary to avoid environmental damage.

Regulatory Issues: Reforms of mining laws and lengthy clearance procedures sometimes hinder implementation of projects.

Infrastructure Deficiencies: Poor infrastructure in remote areas of mining can restrict mobility and raise operating costs.

Despite these challenges, the future is bright. Improvements in mining technology, governmental-initiated reforms, and increasing global demand for minerals are opening new avenues for growth in the Indian industrial minerals industry.

Final Thoughts

India's industrial and economic growth is inextricably linked with the mining and application of industrial minerals. From bentonite and feldspar to limestone and talc, the minerals are enabling millions of applications in industries. With industry giants like Chanda Minerals when it comes to quality and innovation, India will be a global supplier of industrial minerals in no time.

For producers, investors, and traders, alike, this industry has not only present economic value, but future worth. As the production continues to expand and infrastructure matures, so will the demand for India's rich and varied industrial mineral wealth.

0 notes

Text

High-Quality Calcined China Clay Supplier in Gujarat – Asteroid Microns

Looking for premium-grade calcined china clay? Asteroid Microns is a trusted manufacturer and supplier in Gujarat, offering high-whiteness, low-moisture calcined clay ideal for paint, paper, rubber, and plastic industries. Backed by advanced processing and strict quality control, we deliver consistent and reliable solutions for industrial applications.

0 notes

Text

Best Supplier of kaolin powder

As the best supplier of kaolin powder, Pratibha Refractory Minerals offers ultra-fine, high-purity kaolin tailored to meet diverse industrial requirements. Our kaolin features excellent brightness, low abrasiveness, and superior dispersibility, making it the preferred choice in ceramics, paper coating, rubber, paints, and plastics industries.

0 notes

Text

How to Evaluate Quality Standards When Choosing a China Clay Manufacturer in India

When sourcing raw materials like china clay for industrial or commercial use, quality assurance is paramount. With a multitude of china clay manufacturers in India, it becomes critical for buyers to understand how to differentiate between vendors who merely supply and those who uphold world-class standards. This article outlines a comprehensive framework for evaluating quality standards when choosing the right manufacturer, while also shedding light on china clay properties and the role of a reliable mineral mining company in consistent supply chains.

Understanding China Clay and Its Industrial Significance

China clay, also known as kaolin, is a soft white clay rich in kaolinite. It’s prized for its physical and chemical characteristics that make it suitable for industries such as ceramics, paper, rubber, paints, plastics, and pharmaceuticals. The china clay properties that most influence its quality include:

Brightness and whiteness

Particle size and distribution

Plasticity and viscosity

Moisture content

Impurity levels (e.g., iron, titanium)

These properties must be consistent across batches to ensure quality end-products, making the choice of a manufacturing partner crucial.

Why Quality Standards Matter in China Clay Procurement

In industries like paper and ceramics, even slight deviations in china clay properties can result in defective products, cost overruns, and brand damage. Here’s why adherence to quality standards is non-negotiable:

Operational Consistency: Uniformity in clay composition helps streamline downstream processes.

Regulatory Compliance: Especially in pharma and food packaging, materials must meet safety benchmarks.

Cost Efficiency: Low-grade clay may require additional processing or result in high rejection rates.

Customer Satisfaction: High-quality raw materials result in better product finish and customer experience.

Step-by-Step Guide to Evaluating Quality Standards

1. Verify the Manufacturer’s Certifications

When assessing china clay manufacturers in India, start with their certifications. The most reputable players hold:

ISO 9001 (Quality Management System)

ISO 14001 (Environmental Management System)

OHSAS 18001 (Occupational Health and Safety)

REACH Compliance for export to European markets

These certifications reflect a commitment to quality control, traceability, and environmental responsibility.

2. Review the Source of Raw Material

A trustworthy mineral mining company will either directly own or have long-term access to kaolin deposits. Ask the manufacturer:

Where is your clay sourced from?

Are your mines audited for environmental and labor compliance?

How do you maintain geological consistency?

A direct link between the china clay manufacturers in India and a reputed mineral mining company ensures better oversight and accountability.

3. Inspect Laboratory Testing Facilities

State-of-the-art labs are a strong indicator of quality commitment. Look for capabilities in:

XRF and XRD Analysis: For elemental composition

Sedimentation Tests: To check particle size

Brightness Meter Testing

Moisture Analysis

Microscopic Examination

Reputable manufacturers will not only have these facilities but will also provide Certificate of Analysis (COA) for every batch.

4. Examine Batch-to-Batch Consistency

Batch uniformity is one of the most overlooked aspects. Inquire about:

Process Control Measures during milling, sieving, and drying

Storage Conditions that prevent contamination or degradation

Internal Quality Audits before dispatch

A premium mineral mining company often implements traceability from pit to product, ensuring higher batch consistency.

5. Request for Technical Data Sheets and Samples

Any competent china clay manufacturer in India should provide:

Detailed TDS (Technical Data Sheets)

MSDS (Material Safety Data Sheets)

Free Samples with full lab analysis

These documents allow you to perform your own validations or third-party testing.

6. Evaluate Customization Capabilities

Every industry may require specific grades of china clay with tailored china clay properties. For example:

High plasticity and low shrink-swell ratio for ceramics

Ultra-fine particle size for paint and coatings

Low iron content for paper and pharma

Reliable china clay manufacturers in India should offer product customization based on end-use requirements.

7. Assess Manufacturing Infrastructure

A visit or virtual audit of the manufacturing facility will reveal:

Kiln Types (rotary, flash dryers, etc.)

Automated Handling Systems

Real-time Quality Monitoring Sensors

Dust and Effluent Control Units

These indicators reflect whether the manufacturer is truly committed to producing high-quality china clay.

8. Ask About Supply Chain Reliability

Even the best product is of no use if it doesn’t arrive on time. Check:

Inventory Management Systems

Logistics Partnerships (domestic and export)

Backup Mines or Plants for supply assurance

Some top-tier china clay manufacturers in India function as vertically integrated operations with their own mineral mining company, processing units, and export capabilities.

9. Review Case Studies or Client Testimonials

Look for real-world case studies showcasing:

Industries Served (paint, rubber, pharma, etc.)

Problem Solving Examples (e.g., color consistency issues, impurities, etc.)

Global Reach or OEM partnerships

Social proof goes a long way in narrowing down reliable china clay manufacturers in India.

10. Prioritize Long-Term Partnership Potential

Finally, the relationship should be more than transactional. Ask:

Do you offer volume discounts or annual contracts?

Is there a technical support team available?

Can you co-develop product grades based on feedback?

A manufacturer that values long-term relationships will also consistently uphold their quality standards.

Red Flags to Watch Out For

Here are some warning signs that a manufacturer might not meet the quality standards expected:

Lack of certifications or out-of-date documents

Inability to provide third-party lab reports

Unclear sourcing of raw material

Limited documentation or vague specifications

Refusal to provide samples or references

Steering clear of such suppliers helps mitigate the risk of receiving sub-par material.

Conclusion: Make Quality Your Core Selection Metric

Choosing among the many china clay manufacturers in India is not just about cost—it’s about quality, consistency, and long-term reliability. Whether you’re sourcing for ceramics, pharmaceuticals, or rubber manufacturing, prioritizing high china clay properties ensures your end products perform as intended.

By focusing on technical documentation, certifications, sourcing transparency, and lab testing capabilities, buyers can confidently select a mineral mining company or manufacturing partner that aligns with their operational needs and quality benchmarks.

If your business relies on high-purity, customizable china clay, it pays to do the due diligence upfront—because quality clay is not a commodity, it’s a competitive advantage.

0 notes

Text

Ceramic vs Porcelain: The 5 Differences You Should Know

When it comes to tableware and decorative items, the debate between ceramic and porcelain has long captivated both casual consumers and connoisseurs alike. Whether you are a restaurant owner seeking dinner plates wholesale or simply searching for the best housewarming gifts, understanding the key differences between these two materials can significantly impact your purchasing decisions. This comprehensive guide will delve into the five crucial distinctions that set ceramic and porcelain apart, helping you make informed choices for your home or business.

The Historical Journey

The story of ceramics and porcelain is deeply intertwined with human civilization. While ceramic production dates back to ancient civilizations across the globe, porcelain's discovery in China during the Tang Dynasty (618-907 CE) marked a revolutionary advancement in pottery-making. This "white gold," as it became known in Europe, was so valuable that it sparked international trade routes and influenced global commerce for centuries.

Understanding the Fundamental Differences

Composition and Manufacturing Process

At their core, both ceramic and porcelain are clay-based materials, but their composition and manufacturing processes differ significantly. Traditional ceramics are typically made from earthen clays, often combined with various minerals and water. The resulting mixture is shaped and fired at temperatures between 1,000°C and 1,200°C.

Porcelain, however, is crafted from a specific type of clay called kaolin, mixed with feldspar and quartz. This refined composition undergoes firing at much higher temperatures, usually between 1,200°C and 1,400°C. The intense heat causes the materials to vitrify, creating that characteristic translucent quality that makes porcelain particularly appealing as a gift for a wedding couple in Sri Lanka or other special occasions.

Density and Durability

The higher firing temperature of porcelain results in a denser, more durable material compared to traditional ceramics. This increased density makes porcelain more resistant to chipping and scratching, which explains why it is often chosen for employee gifts and other professional presentations where durability matters.

The molecular structure of porcelain is more tightly packed, creating fewer pores and air pockets within the material. This structural difference not only contributes to its strength but also affects its water absorption rate, which is typically less than 0.5% for porcelain compared to ceramics' 3% or higher.

Appearance and Aesthetic Quality

Perhaps the most immediately noticeable difference between ceramic and porcelain lies in their appearance. Ceramics generally have a more rustic, earthy appearance with varying degrees of translucency. The colour can range from deep terracotta to pure white, depending on the clay composition and glazing techniques used.

Porcelain, conversely, is known for its clean, bright white appearance and characteristic translucency when held up to light. This refined look comes from the kaolin clay and the high-temperature firing process, which creates a glass-like finish. While both materials can be glazed and decorated, porcelain typically achieves more delicate, precise patterns due to its smoother surface.

Versatility and Applications

Both materials offer unique advantages in different applications. Ceramics excel in situations where a more casual, rustic aesthetic is desired. They are often used in:

Everyday tableware.

Decorative pottery.

Garden planters.

Architectural elements.

Porcelain's superior strength and refined appearance make it ideal for:

Fine dining establishments.

Medical and laboratory equipment.

High-end bathroom fixtures.

Electrical insulators.

The versatility of both materials extends beyond their traditional uses, with modern manufacturing techniques expanding their potential applications continuously.

Cost and Value Considerations

The price difference between ceramic and porcelain items can be substantial, primarily due to their manufacturing processes and raw material costs. Ceramic products are generally more affordable, making them accessible for everyday use and casual settings. The simpler manufacturing process and more readily available materials contribute to their lower cost.

Porcelain's higher price point reflects its more complex production process, requiring specific raw materials and higher energy consumption during firing. However, its durability often makes it a more cost-effective choice in the long run, particularly for items that see frequent use.

Making the Right Choice

When deciding between ceramic and porcelain, consider these key factors:

Intended Use: Consider how the item will be used. For everyday casual dining, ceramics might be perfectly suitable. However, for special occasions or professional settings, porcelain's elegance and durability might justify the higher investment.

Maintenance Requirements: Both materials require careful handling, but porcelain's density makes it more resistant to staining and easier to clean. Ceramics might require more attention to prevent water absorption and staining, particularly in unglazed areas.

Environmental Conditions: If the items will be exposed to outdoor conditions or extreme temperature changes, porcelain's superior durability and lower water absorption rate make it the better choice. Ceramics are more susceptible to damage from freezing temperatures and moisture.

Final Thoughts

Understanding the differences between ceramic and porcelain empowers consumers to make informed decisions based on their specific needs and circumstances. While ceramics offer charm and affordability suitable for casual settings, porcelain's durability and refinement make it ideal for more formal or professional applications.

As manufacturing techniques continue to evolve, the line between these materials may become increasingly blurred. However, their distinct characteristics ensure that both ceramic and porcelain will maintain their unique places in our homes and workplaces. Whether you are selecting items for personal use or choosing corporate gifts, considering these five key differences will guide you toward the perfect choice for your specific needs.

Remember that quality varies significantly within both categories, and reputable manufacturers often provide detailed specifications about their products' composition and performance characteristics. By carefully considering your needs against these five fundamental differences, you can make choices that will serve you well for years to come.

#dinner plates wholesale#Best housewarming gifts#Employee Gifts#gift for wedding couple in sri lanka

1 note

·

View note

Text

U.S. Aluminosilicate Prices 2025, News, Trend, Graph, Chart and Forecast

Aluminosilicate prices have been a focal point for industries relying on this crucial mineral compound, which plays a significant role in applications such as ceramics, glass manufacturing, catalysts, and refractories. The market for aluminosilicates is influenced by several factors, including raw material costs, production capacities, supply chain dynamics, and global economic conditions. As industrial demand continues to grow, price fluctuations remain a key concern for manufacturers and buyers alike. Understanding the pricing trends in the aluminosilicate market requires a closer look at various economic and industrial variables shaping the supply and demand balance.

One of the major drivers of aluminosilicate prices is the availability and cost of raw materials. Aluminosilicates are derived from natural sources such as clay minerals, feldspar, and kaolin, making mining and extraction costs a primary factor in determining price movements. The costs associated with mining, refining, and processing these minerals vary depending on geographical location, labor expenses, and technological advancements in extraction methods. In regions where mining regulations are stringent, production costs tend to be higher, leading to an increase in overall aluminosilicate prices. On the other hand, countries with abundant raw material reserves and efficient mining infrastructure can offer aluminosilicates at relatively lower prices.

Get Real time Prices for Aluminosilicate: https://www.chemanalyst.com/Pricing-data/aluminosilicate-1518

Another crucial factor impacting aluminosilicate prices is the demand from key end-use industries. The ceramics and glass manufacturing sectors are among the largest consumers of aluminosilicates, utilizing them for their high-temperature resistance and structural stability. A surge in construction activities, especially in emerging economies, has led to increased demand for ceramic tiles, glass panels, and insulation materials, consequently driving aluminosilicate prices higher. Additionally, the chemical industry extensively employs aluminosilicates as catalysts in petroleum refining and wastewater treatment, further influencing their market value. Any fluctuations in these industries, such as production slowdowns or expansions, have a direct impact on aluminosilicate price trends.

The role of supply chain dynamics in shaping aluminosilicate prices cannot be overlooked. Transportation and logistics costs significantly affect final pricing, particularly when raw materials or finished products need to be transported over long distances. Rising fuel costs, disruptions in global shipping routes, and geopolitical tensions can lead to supply chain bottlenecks, ultimately pushing up prices. The COVID-19 pandemic highlighted these vulnerabilities, with lockdowns and restrictions causing supply shortages and price hikes across multiple industrial sectors, including aluminosilicates. Companies have since been exploring ways to enhance supply chain resilience, such as establishing regional production hubs and reducing dependency on single-source suppliers.

Technological advancements in aluminosilicate processing have also played a role in shaping pricing trends. Innovations in refining techniques and material engineering have enabled manufacturers to enhance product quality and optimize production efficiency. While these advancements initially require significant investment, they often lead to cost reductions in the long run, benefiting both producers and consumers. Companies that adopt cutting-edge technologies for aluminosilicate synthesis and refinement tend to gain a competitive edge in the market, offering products at competitive prices without compromising quality.

Environmental regulations and sustainability initiatives are becoming increasingly important in determining aluminosilicate pricing. Governments worldwide are enforcing stricter environmental norms to reduce carbon footprints and minimize mining-related ecological damage. Compliance with these regulations often requires additional investments in sustainable mining practices, waste management, and pollution control, which can add to production costs. As sustainability concerns grow, industries are gradually shifting towards eco-friendly alternatives, which may impact aluminosilicate demand and, consequently, its market pricing.

Fluctuations in currency exchange rates and global trade policies also play a role in determining aluminosilicate prices. Since the mineral is traded internationally, exchange rate variations influence import and export costs. A strong local currency can make imports cheaper, thereby affecting domestic market prices, whereas a weaker currency can increase import expenses. Moreover, trade restrictions, tariffs, and geopolitical conflicts can lead to supply chain disruptions, affecting the cost structure of aluminosilicates in different regions.

The outlook for aluminosilicate prices remains dependent on a combination of macroeconomic trends, industry-specific developments, and technological progress. As demand continues to rise in key sectors such as construction, chemicals, and automotive, price fluctuations are expected to persist. Market participants must closely monitor shifts in supply chain logistics, energy costs, and regulatory landscapes to navigate pricing challenges effectively. Companies investing in sustainable production methods, advanced processing technologies, and diversified supply chains are likely to achieve long-term stability in aluminosilicate pricing.

Overall, the aluminosilicate market remains dynamic, with multiple factors influencing price trends. While supply chain constraints, raw material availability, and environmental regulations play a significant role in driving price variations, ongoing technological advancements and strategic industry initiatives could help stabilize costs in the future. Buyers and suppliers must stay informed about market developments to make well-informed decisions, ensuring that they can adapt to changing price dynamics while maintaining operational efficiency.

Get Real time Prices for Aluminosilicate: https://www.chemanalyst.com/Pricing-data/aluminosilicate-1518

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Aluminosilicate Pricing#Aluminosilicate News#Aluminosilicate Price Monitor#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Kaolin Clay Supplier in India , Kaolin Manufacturer | ZSM

The Kaolin Supplier in India is a ZSM that specializes in the sale of Kaolin Clay and Diatomaceous Earth. Zillion Sawa Minerals Pvt. Ltd. provides a wide range of products for customers in India as well as around the world. ZSM was founded by a man who started out with a few sacks of Kaolin Clay that he found on the side of the road and has grown into a large enterprise with more than 3,000 products and 100,000 customers.

1 note

·

View note

Text

Pharmaceutical & Cosmetic Raw Material Manufacturer in India – Delivering Quality for Superior Formulations

The pharmaceutical and cosmetic industries require premium-quality raw materials to create safe, effective, and high-performance products. A trusted supplier ensures consistency, purity, and regulatory compliance, which are crucial for manufacturers. Among the leading names in India, Caltron Clays & Chemicals Pvt Ltd has earned a strong reputation for offering top-grade pharmaceutical and cosmetic raw materials.

From Algae Calcium Powder to Kaolin Powder, Caltron Clays supplies a wide range of ingredients that support the development of nutraceuticals, skincare products, and pharmaceutical formulations. This blog explores why sourcing high-quality raw materials matters and how Caltron Clays meets industry demands.

Why Choosing High-Quality Raw Materials is Essential?

In pharmaceuticals and cosmetics, the effectiveness, safety, and success of a product depend largely on the quality of raw materials used. Selecting a reliable supplier ensures:

Consistent Purity & Quality – Helps maintain formulation standards.

Regulatory Compliance – Adheres to industry certifications such as GMP, ISO, and FSSAI.

Enhanced Product Performance – Improves stability, absorption, and overall effectiveness.

Sustainable & Ethical Sourcing – Supports eco-friendly and responsible ingredient procurement.

By prioritizing purity, safety, and industry regulations, Caltron Clays ensures its raw materials meet the highest quality benchmarks.

Caltron Clays – Providing Reliable Raw Materials for Pharmaceuticals & Cosmetics

Caltron Clays specializes in manufacturing and supplying pharmaceutical and cosmetic ingredients that are widely used in nutraceuticals, personal care, and pharmaceutical formulations. The company’s expertise ensures safe, effective, and industry-approved materials for diverse applications.

Product Line at Caltron Clays

1. Algae Calcium Powder

A highly bioavailable calcium source, Algae Calcium Powder is rich in minerals and trace elements, making it ideal for bone health supplements and nutraceuticals.

🔗 Explore more: Algae Calcium Powder Manufacturer

2. Coral Calcium Powder

This marine-derived calcium is widely used in dietary supplements for its superior absorption and support for bone health.

🔗 More details: Coral Calcium Powder

3. Oyster Shell Calcium Carbonate

Known for its natural purity, this calcium source is used in pharmaceutical tablets, capsules, and fortified foods, ensuring optimal nutrient absorption.

🔗 Explore more: Oyster Shell Calcium Carbonate Supplier

4. MCHC Powder (Microcrystalline Hydroxyapatite Complex)

An excellent bone health supplement ingredient, MCHC Powder is a natural source of calcium, phosphorus, and collagen, promoting joint and skeletal health.

🔗 More details: MCHC Powder

Why Partner with Caltron Clays?

A dependable raw material manufacturer plays a crucial role in helping businesses create products that meet industry standards and customer expectations. Caltron Clays is a preferred choice for many brands due to its commitment to quality and sustainability.

What Makes Caltron Clays Stand Out?

Strict Quality Control Every batch undergoes thorough testing to maintain purity, consistency, and performance.

Sustainable & Ethical Sourcing Ingredients are sourced through eco-friendly and responsible procurement methods, ensuring minimal environmental impact.

Industry-Certified Manufacturing The company complies with GMP, ISO, and FSSAI standards, making its raw materials suitable for pharmaceutical and cosmetic applications.

Global Supply Network Caltron Clays is trusted by leading brands worldwide, providing high-quality ingredients for international markets.

Applications of Caltron Clays’ Raw Materials

Pharmaceutical Industry

Used in dietary supplements to support bone and joint health.

Essential for pharmaceutical tablets, capsules, and syrups.

Formulated in nutritional powders and oral suspensions.

Cosmetic Industry

Kaolin Powder helps control excess oil in face masks and cleansers.

Diatom Scrubbing Salt is used in natural exfoliators and body scrubs.

Plays a role in personal care products, including creams and lotions.

Emerging Trends in Pharmaceutical & Cosmetic Raw Materials

The demand for natural and sustainable ingredients is transforming both pharmaceutical and cosmetic industries.

Current Market Trends

Growing Preference for Plant-Based & Marine-Derived Ingredients More manufacturers are opting for Algae Calcium and Coral Calcium due to their bioavailability and sustainability.

Eco-Conscious Beauty & Skincare Brands are increasingly using natural exfoliants like Diatom Scrubbing Salt instead of synthetic microbeads.

Advancements in Nutraceuticals Ingredients like MCHC Powder provide high-absorption calcium, making them ideal for bone health supplements.

As Caltron Clays continues to innovate, it remains a leading supplier of natural and functional raw materials that meet evolving market demands.

Conclusion – Trusted Supplier for High-Quality Raw Materials

Manufacturers in the pharmaceutical, nutraceutical, and cosmetic industries require raw materials that are safe, effective, and sustainable. Caltron Clays & Chemicals Pvt Ltd delivers high-quality ingredients, ensuring businesses can create top-tier formulations.

0 notes

Text

Is porcelain dinnerware durable?

Porcelain has long been considered one of the most coveted materials for dinnerware, particularly when searching for the best drinkware sets. Its delicate appearance might suggest fragility, but porcelain is surprisingly robust and has been a staple in households worldwide for centuries.

The Composition of Durability

Porcelain is created through a remarkable manufacturing process that involves firing clay at extremely high temperatures, typically between 1,200 and 1,400 degrees Celsius. This intense heat transforms the raw materials into a dense, glass-like ceramic with extraordinary strength. The key to porcelain's durability lies in its unique composition of kaolin clay, feldspar, and quartz, which create a remarkably resilient material.

Resistance to Wear and Tear

Unlike other ceramic materials, high-quality porcelain demonstrates impressive resistance to chipping, scratching, and cracking. Its non-porous surface makes it highly hygienic and easy to clean, which is why it remains a popular choice for employee gifts and formal dining settings. In regions like Sri Lanka, where porcelain products in Sri Lanka have a rich cultural significance, the material is valued not just for its beauty but also for its longevity.

Practical Considerations for Porcelain Care

While porcelain is inherently strong, proper care can significantly extend its lifespan. Avoid sudden temperature changes, which can cause thermal shock and potential cracking. Hand washing with mild detergents and storing pieces carefully will help maintain their pristine condition. Modern manufacturing techniques have further enhanced porcelain's durability, making it an excellent gift for a wedding couple in Sri Lanka or anywhere else in the world.

The Verdict on Durability

Porcelain strikes an exceptional balance between elegance and strength. Its ability to withstand regular use while maintaining a sophisticated appearance makes it a superior choice for dinnerware. With proper care, a quality porcelain set can last generations, transforming from a simple dining tool to a cherished family heirloom.

#best drinkware sets#gift for wedding couple in sri lanka#Employee Gifts#porcelain products sri lanka

0 notes

Text

China Clay Powder Manufacturers in India - Sudarshan Group

China clay, also known as kaolin, is an essential mineral with a wide range of industrial applications. From ceramics to paper production, paints, rubber, and cosmetics, the demand for high-quality china clay powder is ever-growing. If you’re searching for reliable China clay powder manufacturers, look no further than Sudarshan Group, a trusted name in the industry.

What is China Clay?

China clay is a soft, white clay composed primarily of kaolinite, a naturally occurring mineral. Its unique properties, such as high purity, excellent plasticity, and chemical inertness, make it indispensable in various sectors. Whether it’s for enhancing the brightness of paper, improving the strength of rubber, or serving as a key ingredient in ceramic production, china clay plays a vital role.

A Pioneer in China Clay Manufacturing

Established with a vision to deliver top-quality industrial minerals, We has earned a reputation as one of the leading China clay powder manufacturers in the industry. With decades of experience, advanced technology, and an unwavering commitment to quality, We ensures that their products meet and exceed client expectations.

Why Choose us?

Premium Quality Our sources china clay from the finest deposits, ensuring high purity and uniform particle size. Their strict quality control measures guarantee that every batch meets the specific requirements of different industries.

State-of-the-Art Infrastructure The company employs cutting-edge machinery and advanced processing techniques to manufacture china clay powder. Their facilities are equipped to produce consistent, high-quality material that adheres to global standards.

Environmentally Responsible Practices Sudarshan Group is committed to sustainability. Their eco-friendly mining and manufacturing processes minimize environmental impact, ensuring a greener future.

Tailored Solutions Understanding that every industry has unique needs, Sudarshan Group offers customized china clay solutions. From fine particle size to specific chemical properties, they provide tailored products to meet diverse client demands.

Global Reach As a leading exporter, Sudarshan Group caters to a global clientele, delivering products to industries in various countries. Their reliable supply chain and efficient logistics ensure on-time delivery, no matter the destination.

Applications of China Clay Powder

Sudarshan Group’s high-grade china clay powder finds application across several industries:

Ceramics: Ideal for manufacturing porcelain, tiles, and sanitary ware due to its high plasticity and ability to withstand high temperatures.

Paper: Enhances paper brightness and smoothness, making it a critical component in the paper industry.

Paints and Coatings: Improves paint texture, adhesion, and durability.

Rubber: Acts as a filler to enhance the strength and elasticity of rubber products.

Cosmetics: Used in beauty products for its skin-soothing and oil-absorbing properties.

Commitment to Customer Satisfaction

At Sudarshan Group, customer satisfaction is a top priority. They work closely with clients to understand their requirements and deliver solutions that drive efficiency and innovation in their operations.

Partner with us:

When it comes to China clay powder manufacturers, we stands out for its quality, expertise, and dedication. By choosing Sudarshan Group, you’re not just getting a product; you’re gaining a partner committed to your success.

Whether you need china clay powder for ceramics, paper, paints, or any other application, trust Sudarshan Group to deliver excellence.

0 notes