#industry filtration

Explore tagged Tumblr posts

Text

day 9 - filtration system

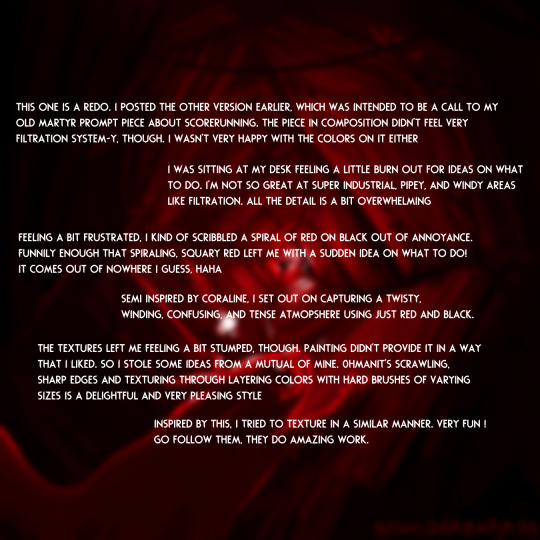

the final stretch. shoutout to @0hmanit for inspiring the :fish out of this piece (go follow them ) more insight below the cut

#rwartmonth#rwartmonth 2024#rain world art month#rain world#rain world art#rain world fanart#filtration system#black lizard#slugcat#pipes#industrial#wild draws#wild draws rain world

80 notes

·

View notes

Text

The global Industrial Filtration Market is expected to reach USD 47.1billion by 2029 from USD 37.1 billion in 2024 at a CAGR of 4.9% during the forecast period according to a new report by MarketsandMarkets™. The rigorous environmental regulations imposed by governments worldwide require industries to adopt filtration solutions to mitigate pollution and ensure compliance. This regulatory pressure creates a universal demand for filtration technologies across various sectors.

#industrial#industrialization#energy industry#chemical industry#industrial filtration#industrial wastewater treatment#industrial filtration market#filtration#bag filter#filter press#energy#energia#power generation#water treatment plant#wastewatertreatment#wastewater treatment#waste management#zero waste

2 notes

·

View notes

Text

Water Purifier in Dubai-Aqua Best Water Treatment

Aqua Best Water Treatment is one of the best-known companies providing water purifier services in Deira, Dubai at the best prices. We manufacture high-quality water treatment equipment designed to meet rigorous standards, and our products include advanced filtration systems, disinfection units, and chemical treatment solutions, ensuring clean and safe water for various applications.

#water filter in dubai#water filter in uae#water purifier in dubai#water purifier in uae#water treatment specialist#commercial water filtration system#industrial water softner#aqua best water treatment specialist#best water filter company in uae

2 notes

·

View notes

Text

Ok before i finish the game does anyone want to tell me if i missed any pearls so i don't have to go back and forth AGAIN

#rain world#rainworld#i have the two farm arrays ones one from filtration one from the start of subterranean one from industrial one from outskirts#one? from garbage wastes two from shoreline#one(?) from shaded two from sky islands#and i think one from chimney. that's it (the one on top of pebbles is lost to the void so dont count that one)#oh and the one from moon#wait is that the second shoreline one... i dont remember#edit yeah i have thirteen pearls so i either miscounted bc there WERE two in shoreline and one in moon#or some witchcraft is going on#edit number two yeah something fishy is going on#where is the fourteenth pearl. i dont have it.#wait.#i'm a fucking moron#it was in slugcat's stomach...#...this is a sign that i need to go to sleep#anyway yeah can you. tell me if i missed any pearls except the pebbles one. thank you#(i do not have downpour enabled by the way so dont worry about downpour exclusive pearls)

9 notes

·

View notes

Text

slightly different route:

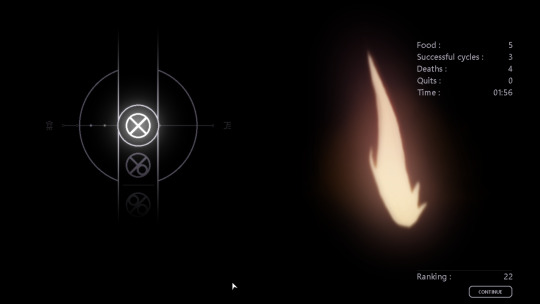

the legendary one cycle sprint to ascension! route suggested by @sevenrs which i decided to try. the route is honestly pretty similar to what i was doing before, with a few minor tweaks that ended up making it faster than my original route.

as you can see from the score screen though, it's not actually 'one' cycle; i starved twice to bring my karma up so i could go to pebbles. but the game doesn't know any better :) tbh this was pretty fun, particularly because i'm more familiar with the route now. if you're okay with navigating drainage system and filtration system in the dark, you can give it a whirl!

#sky i am so sorry for the three tags now but i cannot in good conscience not tell you about this#or credit your (and your friend's) route planning#speeeeed#yes game i totally have only 1 minute and 56 seconds of playtime ✨#rain world#for anyone legitimately interested in trying this out:#skip the tutorial by not entering any of the tutorial food rooms#and get food elsewhere. exactly 5 is enough so don't bother hunting bats for too long#save in the outskirts shelter near the industrial complex gate#upon cycle 1's start: starve#do NOT touch the karma flower before you starve. i had to restart because i realized i fucked up#once you enter your starve cycle eat the karma flower in the room below the den#then die. quitting out might be faster but i need to check if it works; it should but just to be safe yknow#repeat with industrial complex flower and den#once you hit karma 4 reroll your rain timer until it's long enough to run all the way to pebbles in one cycle#yes it's doable. it's fun and scary and you will feel so cool#and then die or quit out once he gives you karma 10#so you'll be back in the outskirts den after that. just book it to filtration system through drainage system#you will have to deal with dark rooms but it's like. fuckinnnnnnn uhhh four or five rooms that are pitch black#and then you're in depths! and nothing matters anymore :) except fall damage i guess#don't die in depths to fall damage#i'm excited to see if anyone can beat my time. most of my speed comes from running away from enemies and chaining roll pounces#nothing fancy movement wise. so anyone better at movement than i am could probably beat that time easily

14 notes

·

View notes

Text

Mycorrhizae — The Great Filtration (Big Bovine Industrial Wastes)

youtube

Given its associations with fungi, Mycorrhizae might seem like a name better suited to a death metal band, and the damper and danker, the better. But Travis Minnick’s Mycorrhizae is a black metal project, and when you listen to The Great Filtration, the moniker begins to make some sense. The speed with which fungal lifeforms grow, the flying clouds of tiny spores, the rhizomic proliferation of underground shoots and channels — all that stuff gets registered in Mycorrhizae’s rapidly whirring, buzzing, sinuous sound. It’s simultaneously raw and unexpectedly canorous, rich and fetid and weirdly brittle. Like the taste of a dried candy cap mushroom, Mycorrhizae’s music is layered and complex.

The more complicated question is how seriously we’re supposed to take this stuff. The video Minnick has created for “Strength in Space” is appealingly bananas, and tonally inscrutable. Two dudes in camo and Ghillie suits, one of them snow white, run through dense forest and lovingly shred on their guitars. Are they collecting some shrooms? Stocking up for the apocalypse? Just generally taking the piss? This reviewer sort of loves the way the video plays it straight and, through its sheer, unblinking enthusiasm, seems to undercut its own gravid weightiness.

The music has the same force. It moves at an unflagging top gear, full of riffage and wide-eyed ideas; but it all flies by so quickly that it can be hard to track, and by the sixth song on The Great Filtration (a terrific tune called “Unwielding”), it’s a bit exhausting. That may be part of the band’s symbolic gambit. The deep microbial, organic processes of mycorrhizae are also relentless, remarkable for their energies, essential to life even as their fungoid nature signals dark, cold, underground properties that make us think of death. In that way, Mycorrhizae captures some of the most provoking ambiguities of black metal: it wants to be subterranean, shadowy and dead, but its very essentials render the music vigorous, and very much alive.

Jonathan Shaw

#Mycorrhizae#the great filtration#big bovine industrial wastes#jonathan shaw#albumreview#dusted magazine#black metal

3 notes

·

View notes

Text

Benefits of having an onsite Oil Condition Monitoring Equipment

Contamination is the major cause of failure for any lubricated mechanical element. Wear can easily be identified by monitoring the shape and composition of contaminants. To identify and monitor the source of contaminants, Particle Analyzer plays a very crucial role. It analyzes the solid contamination in a lubricant by counting the number of particles and categorising the degree of contamination according to the particle size.

The particle analyzer is considered to be one of the most important tests in oil analysis, as it determines a wide variety of problems easily. It monitors the amount and size of the particles in an oil sample. There are many uses of particle analyzer including testing filter leaks, checking real-time cleanliness and filter efficiency, creating testing routines, etc.

Benefits of Particle Analysis

There are enormous benefits; some of them are as follows:

It allows “real-time” analysis of oil

It confirms the corrective maintenance, needs for ferrography, and system flushing

It identifies poor repairs of machinery, any abnormal gear wear, abrasive wear, atmospheric pollutants, and defects in a filter

It verifies the operation of the pump, bearings, and suitability of the filter

It detects high corrosive wear, the condition of the by-pass filter, the time of use, and when to change the filter.

Six Common errors/mistakes during Particle Analysis:

It is important that the sample collected should correspond to the actual condition of the oil, but various conditions make it challenging to get it right during the collection process.

Poor sample division could be one of the reasons for errors in particle analysis, particularly for contaminants with broad size distributions. Also, the incorrect sample amount can be a concern and impact the measuring result negatively.

The separation of particles for measurement is called Dispersion. There are possibilities that particles may cling to one another and destroy the structures for measurement. As we know, every measuring instrument has certain uncertainties and tolerances which must be taken care of while interpreting the results. Underestimating and overestimating can be an issue.

The measurement method plays a decisive role. Identifying oversize particles can be a common issue in particle analysis.

In particle analysis, a fundamental and necessary requirement is to follow a standardized procedure to get meaningful and consistent results. Working without these procedures may lead to pointless results.

Generally, Particle analysis results are given as percentages which can vary in meaning. It may cause significant differences in interpretation as mass/mass, volume/volume, number, etc.

The Solution

The advent of IoT in the energy sector has resulted in smart solutions. Smart devices monitor and interpret information from their surroundings in real-time. This enables meaningful data gathering and system optimisation. Data analytics use historical data to provide actionable insights to utilize the data collected. Insights help in predicting future events that may take place. Apart from ensuring data privacy, IoT enables reaching technology maturity and reliability.

Online Particle Analysis technology enables sampling on low/high pressure hydraulic and lubrication systems. The product suppresses the air bubbles so that they are no longer counted as particles. This can be installed in most low to very high-pressure hydraulic and lubrication systems. It is easy to install because of its versatility. This technology has the potential to increase the flexibility and responsiveness of the smart assets connected to the grid and the visibility of these assets for the system operator. For more details, contact- [email protected]

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#lube oil flushing#lubeoil#oil filtration machine#oil testing#oil industry#oil and gas#oil#oil dehyration#frf machine#frf condition systems#electrostatics lube cleaner#transformation oil purification#transformer oil#coalescer separator#chemcal cleaning#minimac accepted challenges#chemical cleaning#oil filtration systems#oil filters

0 notes

Text

Exploring the Hollow Fiber Ultrafiltration Market: Trends, Forecasts, and Future Opportunities

In today’s water-conscious world, the Hollow Fiber Ultrafiltration (UF) market is rapidly expanding as industries and municipalities seek effective methods to purify water and treat wastewater. This article explores the latest market dynamics, including growth projections, emerging trends, and the global outlook for hollow fiber UF systems.

Understanding Hollow Fiber Ultrafiltration

Hollow Fiber Ultrafiltration technology relies on membranes designed with narrow, tubular fibers to filter out impurities from water and other liquids. These ultrafiltration systems excel at capturing fine particles, bacteria, and pathogens, making them essential for industries requiring high-quality water. UF technology is recognized for its efficiency and cost-effectiveness, particularly in sectors where water purity is critical. With tightening global regulations around water treatment and sustainability, the demand for UF solutions is accelerating worldwide.

Market Forecast: Significant Growth on the Horizon

Hollow Fiber Ultrafiltration (UF) market size is projected to grow from USD 2.08 billion in 2024 to USD 4.21 billion by 2029, registering a CAGR of 15.2% during the forecast period. The primary factors propelling this growth include:

Rising awareness around sustainable water use.

Increased government regulations regarding wastewater management.

Industrial growth in developing regions, especially in Asia-Pacific.

With these dynamics in place, North America, Europe, and Asia-Pacific will likely see strong market contributions. The Asia-Pacific region, in particular, is expected to register the highest growth, driven by rapid urbanization, water infrastructure investment, and stringent government regulations. North America and Europe will continue to see steady growth, primarily supported by established water infrastructure and advanced industrial activities.

Key Trends Influencing the Hollow Fiber UF Market

Growing Emphasis on Water Conservation and ReuseWater scarcity issues and increasing environmental awareness are pushing industries to adopt sustainable water management practices. Hollow fiber UF systems play a crucial role in recycling wastewater, reducing reliance on freshwater resources. Governments across the globe are introducing strict environmental standards, particularly in regions like the EU and Asia, which are known for implementing rigorous wastewater policies.

Technological Advancements in Filtration MembranesResearch into new materials and nanotechnology has led to notable improvements in filtration membranes. Modern hollow fiber UF membranes are more resistant to fouling and provide higher filtration precision. Innovations in membrane composition not only extend the product lifespan but also enhance system efficiency, especially beneficial for industrial applications with complex contaminants.

Industrial and Municipal DemandUF systems are gaining traction across several industries, notably pharmaceuticals, food and beverage, and petrochemicals. The ability of hollow fiber UF technology to handle high-contaminant loads makes it ideal for industrial wastewater treatment. Meanwhile, municipal governments are increasingly turning to UF systems for large-scale purification of drinking water.

Combination Filtration TechnologiesMany manufacturers are integrating UF systems with technologies like reverse osmosis (RO) and nanofiltration (NF) for comprehensive water treatment solutions. These hybrid systems enhance purification capabilities while minimizing energy and maintenance costs. The trend toward multi-stage filtration aligns with the demands of high-precision applications, such as in healthcare and advanced manufacturing sectors.

Market Landscape and Leading Companies

The Hollow Fiber Ultrafiltration market includes numerous players, both global and regional, that are competing to capture market share. Key players in this space include:

Pentair

DuPont

Asahi Kasei Corporation

SUEZ

Toray Industries, Inc.

These companies are heavily invested in innovation, with significant efforts devoted to developing high-performance, low-maintenance ultrafiltration systems. Their focus on expanding UF system portfolios reflects an understanding of the growing need for cost-effective, reliable water treatment solutions.

Insights from Industry Experts

Experts highlight that as environmental concerns escalate, demand for UF technology will only continue to rise. Hollow fiber ultrafiltration systems, known for their efficiency and cost savings, are gaining traction as industries worldwide focus on minimizing their ecological footprint. As per industry leaders, the heightened global emphasis on water quality is expected to drive the market forward, especially in regions facing severe water scarcity. Additionally, the increased adoption of hollow fiber UF for applications such as desalination and medical water purification reflects the market’s growing versatility.

Global Outlook for Hollow Fiber UF

The global market outlook for Hollow Fiber Ultrafiltration remains optimistic, with robust growth anticipated across various sectors. North America and Europe will likely retain their market position, given their well-developed infrastructure and consistent focus on industrial sustainability. The Asia-Pacific region, however, stands out as a high-growth area due to rapid industrialization and significant government investments in clean water initiatives.

Emerging markets in Latin America and Africa are also set to contribute to market expansion, driven by improving infrastructure and a heightened need for water management. Water-stressed areas, in particular, are exploring hollow fiber UF technology as a sustainable option to address water scarcity and ensure access to clean water.

Download PDF Brochure :

The Hollow Fiber Ultrafiltration market is entering a period of significant expansion as demand for water treatment solutions increases. Trends like environmental sustainability, membrane technology advancements, and hybrid filtration systems point to a promising future for UF technology. As more industries and municipalities prioritize water conservation, hollow fiber UF systems are set to play a critical role in achieving these sustainability goals.

The growing global need for clean, accessible water highlights the essential role of ultrafiltration in modern water treatment. By staying innovative and responsive to environmental needs, companies in the Hollow Fiber UF market can expect substantial growth and a long-term place in global water management.

#Hollow Fiber Ultrafiltration#Water Treatment Technology#UF Market Trends#Industrial Water Filtration#Ultrafiltration Membranes#Global Water Sustainability#Wastewater Management Solutions

0 notes

Text

#Turbine Oil Cleaning System#Oil Cleaning Machines#Turbine Oil Cleaning Systems#Oil Filtration Plant#Gear Oil Filtration Systems#Industrial Oil Filter Machine#Oil Filtration Systems#Double Stage Oil Transformer Machine#Oil Filtration Elements#Oil Filtration Machine#Oil Filtration & Cleaning Systems#Thermic Oil Filtration Systems#On Site Oil Testing#Online Oil Cleaning Systems#Hydraulic Oil Online Filters#Mobile Oil Filtration Plant#Portable Oil Filtration Plant#Portable Oil Filtration System#Turbine Oil Filtration Plant#Turbine Oil Filtration Machine#Transformer Oil Filtration System#Transformer Oil Cleaning Systems#Evacuation System for Transformers#Transformer Oil Filtration Plant#Two Stage Transformer Oil Filtration Plant#Transformer Evacuation System#Transformer Oil Filtration Machine#Transformer Oil Filter Machine#Turbine Oil Flushing System#Centrifugal Oil Cleaner

0 notes

Text

Pranjali Water Solution Technology: Delivering Advanced Water Treatment Solutions

Pranjali Water Solution Technology has become a key player in providing cutting-edge water treatment systems, catering to the growing need for clean, purified water in various sectors. Known for its precision-engineered solutions, the company stands as a trusted manufacturer in the industry, offering an extensive range of water purification systems, from residential units to large-scale industrial plants. Whether it's reverse osmosis systems, ultrafiltration technology, or water softeners, We delivers quality and innovation to ensure efficient and sustainable water management.

Leading the Way in Reverse Osmosis Systems

Pranjali Water Solution Technology is a renowned name among Reverse Osmosis System Manufacturers. The company's reverse osmosis (RO) systems are designed to remove impurities, contaminants, and dissolved solids from water, ensuring high-quality drinking water for residential, commercial, and industrial applications. With their advanced filtration technology, Pranjali’s RO systems are not only efficient but also energy-saving, making them a go-to solution for clients seeking reliable water purification.

For businesses and institutions, Pranjali stands out as one of the top Commercial RO Plant Manufacturers. These plants are built to handle larger volumes of water, delivering high-capacity filtration with minimal maintenance. Designed for commercial establishments like hotels, hospitals, and schools, Pranjali’s commercial RO plants ensure access to safe, clean water for daily use.

Industrial RO Plants for Large-Scale Water Purification

In addition to commercial RO systems, We has earned a reputation as one of the leading Industrial RO Plant Manufacturers. These systems are tailored to meet the rigorous demands of industrial applications, where large-scale water purification is essential. Industries like pharmaceuticals, food and beverage, and manufacturing rely on Pranjali’s industrial RO plants to achieve the highest levels of water purity, ensuring both safety and compliance with regulatory standards. These industrial RO plants are designed to handle heavy-duty operations, providing robust, long-term solutions for large-scale water treatment needs.

Advanced Ultrafiltration Systems

Apart from RO systems, We counted also a trusted name among Ultra Filtration System Manufacturers. Ultrafiltration (UF) is a highly effective method for removing bacteria, viruses, and suspended particles from water. Unlike reverse osmosis, UF allows essential minerals to remain in the water, making it a perfect solution for industries that require purified water without complete mineral removal. Pranjali’s UF systems are widely used in applications such as wastewater treatment, drinking water purification, and pre-treatment for reverse osmosis systems, offering superior filtration performance and cost-efficiency.

Water Softener Treatment Plants for Hard Water Solutions

Hard water is a common issue faced by industries and households alike. We addresses this problem as one of the leading Water Softener Treatment Plant Manufacturers. Their water softener systems effectively remove hardness-causing minerals like calcium and magnesium, preventing scale buildup in pipes, appliances, and industrial equipment. By offering reliable and efficient water softening solutions, Pranjali helps improve water quality, extend the lifespan of machinery, and reduce energy consumption for both domestic and industrial clients.

Hence

We continues to lead the water treatment industry with its commitment to providing top-tier solutions for diverse applications. As a trusted manufacturer of Reverse Osmosis Systems, Ultra Filtration Systems, and Water Softener Treatment Plants, the company offers products that are not only technologically advanced but also tailored to meet the specific needs of each client. Whether it's for residential use, commercial businesses, or large-scale industrial operations, We ensures clean, safe, and efficient water treatment solutions that help create a sustainable future.

#Reverse Osmosis System Manufacturers#Commercial RO Plant Manufacturers#Industrial RO Plant Manufacturers#Ultra Filtration System Manufacturers#Water Softener Treatment Plant Manufacturers

0 notes

Text

Effluent treatment plant in Dubai-Alkhabeerwt Reverse osmosis in the UAE is vital for water purification, while sewage treatment plants and effluent treatment in Dubai help manage wastewater. Filtration system suppliers in Dubai offer solutions for industrial wastewater treatment across the UAE, ensuring efficient water management. https://www.alkhabeerwt.com/effluent-treatment-plant.html

#Reverse Osmosis in UAE#Sewage Treatment Plant in UAE#Effluent treatment plant in Dubai#Filtration system supplier in Dubai#Industrial Wastewater Treatment in UAE

0 notes

Text

Bulk Filtration Market Growth Analysis with Investment Opportunities For 2024-2030

According to a research report “Bulk Filtration Market by Filtration System (Cartridge, Bag, Filter press, Coalescer), End Use (Heavy Equipment, Machinery & Equipment, Commercial Marine, Power Generation), Mounting Type, Fluid Type, Application, Region – Global Forecast to 2030″ , the Bulk filtration market is anticipated to grow from estimated USD 13.63 billion in 2024 to USD 18.76 billion by…

#Bulk Filtration#Bulk Filtration Industry#Bulk Filtration Market#Bulk Filtration Market Share#Bulk Filtration Market Size#Bulk Filtration Market sizing#Bulk Filtration Market Trends#Bulk Filtration Solutions#Filtration Equipment#Filtration Industry#Filtration Systems#Filtration Technology#Industrial Filters#Industrial Filtration#Market Analysis#Market Forecast

0 notes

Text

/PRNewswire/ -- Refinery and Petrochemical Filtration Market is projected to reach USD 6.1 billion in 2028 from USD 4.6 billion in 2023 at a CAGR of 6.0% according to a new report by MarketsandMarkets™. Refinery and petrochemical filtration are essential processes in downstream oil and gas production. Refinery filtration purifies crude oil and feedstocks, creating high-quality fuels and lubricants. Petrochemical filtration eliminates contaminants from chemicals and gases used in plastics and industrial goods. Filters are crucial to guarantee the quality and purity of final products while minimizing environmental impact and reducing operational costs.

#refinery#refineries#petrochemicals#petrochenical#petroleum#energy#energia#oil industry#oil rig#oil and gas companies#oil and gas#filtration#refinery and petrochemical filtration

0 notes

Text

Are you trying to make your oil look better than it is?

However, a wrong sampling technique might not reveal the true condition of the machine and thus, leads to the wrong representation and pre-mature breakdown. Thus, MINIMAC SYSTEMS is starting this #knowyouroil series under which we will make you aware of:

How to collect a sample

Type of contaminants and how they are harmful for your machines

Oil analysis and how to decode it

Oil changes are mostly done under two conditions:

On the basis of time or operating hours

On the basis of oil condition

Most of the time, changing oil based on time or operating hours is expensive and hence, changing based on oil condition is more viable. At this juncture, an Oil Analysis Report is key to decision making. For accurate oil analysis, correct sampling is the pre-requisite. For queries related to Oil Testing: https://www.linkedin.com/company/minimacsystemsprivatetlimited

3 points to be considered while taking sample:

TURBULENCE: The best sampling point is the place like sharp elbows or bends where the oil turns a lot and thus, carries a lot of impurities. The point which are located where the flow is laminar tends to have lesser particle carrying tendency and as a result, makes the oil appear cleaner than what it is.

INGRESSION POINTS: Oil samples should be taken downstream of parts that have a lot of wear and tear and before the oil gets into the inlet to the main oil tank. As once the oil gets mixed with the rest of the oil, the contamination gets diluted and results in poor sample.

FILTRATION: Inline filters ensure that they provide cleaner oil to the machinery downstream of them. If a sample is taken downstream to the filters it will be a lot cleaner than what the actual sample is until unless the filter is not working and is in the by-passed condition. Hence, the sample at all times should be taken upstream to the filters.

When a true representative sample goes for oil analysis it can give answer to the following questions: (Call +91 8975150700 to book an appointment)

Whether the oil is suitable for further use or requires filtration, dehydration/flushing?

What are the types of contaminants in the oil? Are they in the limit as per ISO standards?

What is the condition of the rotating part? Is there excessive wear and tear?

Are there problems like Sludge/Varnish developing which requires flushing of the entire system.

Get your machine's oil check today with our technical expert by clicking on https://www.linkedin.com/company/minimacsystemsprivatetlimited or call +91 8975150700.

Like, Comment, Share this article to spread awareness in achieving Zero Mechanical Breakdown.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#oil dehydration systems#oil contamination#oil filter systems#transformer oil filter#oil filteration#oil filters#oil filter machine#hydraulic oil flushing#lube oil flushing#chemical cleaning#electrostatics lube cleaner#coalescer separator#diesel oil purification#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#power generation#power industry#transformer oil filtration

0 notes

Text

Many jmcc industrial water filtration reviews are available from a large base of happy and satisfied customers to testify to the credibility, reputation, and efficacy of JMCC Water Filters. Hence, it is high time to say goodbye to misleading jmcc water filters complaints and invest in state-of-the-art JMCC Water Filters.

0 notes