#hydrocarbon waste cleaning robots

Explore tagged Tumblr posts

Text

Revolutionize Maintenance with Robotic Tank Cleaning

Maintaining tanks—especially industrial ones—has always posed challenges in terms of safety, efficiency, and thoroughness. Traditional tank cleaning requires extended downtimes, risks to personnel, and often doesn’t achieve a full clean. Fortunately, robotic tank cleaning now offers a cutting-edge solution that solves these challenges while optimizing results.

Arham Oil brings innovation to the forefront with robotic tank cleaning technology, offering a safe, efficient, and eco-friendly way to keep tanks spotless. Unlike conventional methods, robotic cleaning technology eliminates the need for human entry into tanks, thereby reducing health and safety risks significantly. Through precision automation, robotic cleaners are designed to handle the most challenging contaminants, achieving a deeper clean than manual methods.

Why Choose Robotic Tank Cleaning?

Enhanced Safety: With robotic technology, there’s no need for personnel to enter hazardous tanks, drastically lowering accident risks.

Reduced Downtime: Robotic cleaning minimizes the time tanks are out of service, meaning your operations can get back up and running faster.

Eco-Friendly Solution: Robotic tank cleaning uses optimized cleaning techniques, which are more environmentally responsible and waste-efficient.

Cost-Efficiency: By reducing labor needs and minimizing downtime, robotic cleaning helps in cutting overall maintenance costs.

How Does Robotic Tank Cleaning Work?

The robotic cleaning process is simple but powerful. High-tech robots equipped with state-of-the-art sensors are deployed to reach every nook and cranny of the tank. The precision-guided system effectively removes contaminants, from sludge to hard mineral deposits. With their advanced cameras, operators can monitor the cleaning process in real-time, ensuring no residue is left behind.

Why Arham Oil?

At Arham Oil, our commitment to quality and innovation drives us to offer only the best for our clients. Our Robotic Tank Cleaning services are designed to meet industrial-grade demands, whether in oil, gas, or chemical storage sectors. Interested in transforming your tank maintenance? Reach out to Arham Oil at +91 74860 42707 for a safe, efficient, and hassle-free solution.

Make the switch to robotic tank cleaning and experience a superior, smarter way to maintain your tanks!

#Robotic Tank Cleaning#Arham oil#hydrocarbon waste cleaning robots#oil industry#Mechanized tank cleaning

0 notes

Text

I'm not going to argue with a bird enthusiast about their compassion for birds. I believe them. I am grateful they exist. What I will argue against is these massive energy construction projects. Just like the craze for building hydroelectric dams, this newest iteration has proven to be the same story as that was. Dams have proven to be harmful to the water table, the river ecologies, local communities, floodplains, and even geology in terms of seismic effects and deformation of bedrock. They've nearly all built up silt to the point of costing more than they are worth without reasonable down-time to clean out planned because they demand being brought back online to the powergrid so quickly. And that silt builds up quickly! Massive construction projects tend to displace responsibility, abdicate it. They don't make people aware of the reality of modern infrastructure or the dynamics of their lifestyle in the role of culture. It brushes the problems under the rug, out of sight, out of mind, no personal changes or accountability needed. "There's an app for that!" mentality. Below are some points that basically make themselves. Just like the deluded mass-industry mentality behind the logistics of massive lithium-ion powerbanks for houses, or for cars, or for the electrical grid itself-- the use of iron for these wind turbines and mass energy projects is distorted and wasteful-- unsustainable. The amount of lithium used for an EV car battery could equal hundreds of electronic devices such as medical or even mere personal use devices like cellphones and laptops. Instead, the model of planned/engineered obsolescence that is perpetuated by capitalist consumerism not only makes those electronics wasteful in design, but also in resource logistics-- so nobody would ever even see how they deserve to be the way that the lithium is allocated to begin with instead. With the amount of iron and fossil fuels expended in constructing these wind turbines, a whole global system of nickel-iron (ferro-nickel) batteries could be built that would last hundreds of years. People have no cognitive intuition to what these metals and energy can do in the forms they can take. Instead? ...

The paragraph from the book in full reads: “The concept of net energy must also be applied to renewable sources of energy, such as windmills and photovoltaics. A two-megawatt windmill contains 260 tonnes of steel requiring 170 tonnes of coking coal and 300 tonnes of iron ore, all mined, transported and produced by hydrocarbons. The question is: how long must a windmill generate energy before it creates more energy than it took to build it? At a good wind site, the energy payback day could be in three years or less; in a poor location, energy payback may be never. That is, a windmill could spin until it falls apart and never generate as much energy as was invested in building it.” Hughes told Reuters that his comments had been taken out of context and that the passage relates to capacity factory, which is the “amount of electricity a wind mill actually generates compared to the amount it would generate if it was running at 100% of its rated Generating Capacity”.

Where are ideal locations for energy to be harvested with these massive projects and how are they built? Are they always the most patient in doing things ethically, or do you think they seek a bottom-line of money?

youtube

youtube

as a huge lover of birds, 90% of the concern against wind turbines being used for energy is literally just pro fossil fuel propaganda. birds ARE at a risk however there is a lot of strategies even as simple as painting one of the blades that reduces a lot of accidental deaths. additionally renewable energy sources will do more in favor of the environment that would positively impact birds (and all of us). one study found over one million bird deaths from wind turbines. while that is a shockingly high number and we should work to drastically shrink it, at least 1.3 billion birds die to outdoor cats on a yearly basis. it was never about caring about birds

103K notes

·

View notes

Text

Understanding How Nanorobotics is Revolutionizing Our Future

Nanorobotics refers to the specialized branch of nanotechnology that deals with designing and building nanorobots; tiny robots or machines that have components measuring from 1 to 100 nanometers and can be programmed to perform specific tasks at the microscopic level. Nanorobots have the potential to revolutionize various industries by allowing tasks to be performed at the molecular level with unprecedented precision and control. Some of the key areas where nanorobotics is having a transformative impact include biomedical sciences, manufacturing, environmental remediation and more. Biomedical Applications One of the most promising applications of nanorobots is in the field of biomedical sciences and healthcare. Biomedical nanorobots could be miniaturized surgical machines that can be injected into the human body to repair damage at the cellular level, destroy cancer cells or target other injuries and diseases. They may even be able to augment cell and tissue regeneration. Researchers are working on developing blood nanobots that are smaller than red blood cells and can circulate through the body detecting problems and releasing medications only where needed. This would make treatments more targeted and reduce side effects. Another exciting possibility is assembling nanoscale medical devices inside the body from smaller components using nanorobots to perform complex surgeries or even augment certain body functions without invasive procedures. Targeted Drug Delivery By precisely delivering drugs, nutrients or other therapeutics only to diseased cells and tissues, nanorobots could revolutionize drug formulation and delivery. They could improve current treatments by encasing medicines in nanoparticles which are then guided by Nanorobotics to only affected areas via navigation techniques like magnetotaxis. This would maximize therapeutic benefits while minimizing unwanted side effects. For conditions like cancer, nanorobots may one day be used to transport cytotoxic drugs directly into tumors, killing them more effectively while sparing healthy cells. Chronic diseases requiring lifelong medication like diabetes may also benefit from nanorobots programmed to automatically release insulin only when blood sugar levels rise beyond a set point. Environmental Remediation Environmental pollution poses a serious threat and cleaning up toxic waste sites or oil spills manually is a complex challenge. Nanorobots have the potential to selectively identify and remove toxins from the environment autonomously. They could be deployed to absorb or break down pollutants like heavy metals or hydrocarbons at a molecular level. Teams of coordinated nanorobots may remediate sites more efficiently one day by sensing hazards, communicating data and self-assembling into larger structures as needed for pollution digestion or containment. Some researchers are even developing photoactive nanorobot catalysts that could help break down plastic waste using sunlight. Such applications may transform current waste management and decontamination methods.

Get more insights on Nanorobotics

Discover the Report for More Insights, Tailored to Your Language.

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#Nanorobotics#Nanobots#Medical Nanorobotics#Molecular Machines#Nanoscale Robots#Nanomedicine#Targeted Drug Delivery#Nanotechnology Applications#Cancer Treatment#Nanomaterials

0 notes

Text

DRIVING PRODUCTIVITY IN THE AUTOMOTIVE INDUSTRY Holistic solutions from Messung Group

Messung Group has been closely associated with India’s automobile and automotive industries for four decades. Messung has partnered with two wheeler and four wheeler manufacturers in their journey towards smart manufacturing, developing solutions for every stage of the vehicle manufacturing process.

Today, Messung’s capabilities stretch beyond factory automation to a complete package of technology solutions - under one roof! With innovative products & solutions, forty years of industry experience, and proven expertise in the auto sector, Messung delivers customised, high-performance solutions for practically every need in Automobile/Ancillaries manufacturing.

40 YEARS OF INNOVATION

INDUSTRIAL AUTOMATION & CONTROL

REQUIREMENT: The auto industry globally and in India, has been one of the first industries to embrace automation and to continuously drive the need for such technologies. New, additional technologies such as 3D printing, robots and collaborative robots, or co-bots are speeding up operations and ensuring high outputs and minimal downtime. As the industry shifts from combustion vehicles to electric ones, robotic automation will play an even more critical role as robots can be programmed to meet higher demands and perform new roles while meeting production criteria.

SOLUTION: To help automobile manufacturers and suppliers handle rising costs as well as constantly increasing productivity and quality demands, Messung provides process controllers for optimizing all production processes. The range ofindustrial automation applications covers the Press shop, Body shop, Assembly shop and Paint shop, as well as the intricate network of conveyors running through the factory.

Messung offers a complete range of Programmable Logic Controllers in India, from the large modular Nx-era Premium to the Nx-era Xpress, the leading micro PLC in India. Messung also manufactures Remote I/O modules under the XM-PRO Series – for Modbus, CANopen and their own ‘Mesbus’. They also provide servo& motion control solutions and VFD drives in collaboration with their partners, Sigmatek, Austria and Fuji Electric, Japan. In fact, Messung not only provides IoT-enabled automotive automation and control for machines and linked plants, they optimise every process stage and ensure greater reliability.

A PLC FOR EVERY APPLICATION

Messung solutions also facilitate the “Andon” system, the “Poka Yoke” system and the “Pica Pica” system that help automobile manufacturers to create an error free assembly process for the Engine assembly line and the Chassis assembly line. These systems help prevent errors, eliminate waste and streamline processes.

In addition to turnkey system solutions, Messung supplies standard Automation products, which allow machine manufacturers to configure controllers that are individually tailored to their applications. The control platform is based on industry and IT standards, and supports the implementation of Industry 4.0 concepts for machine-to-machine communication and for data processing and analysis in the cloud (OPC-UA and MQTT).

ENERGY MANAGEMENT

REQUIREMENT: While demand for vehicles is increasing worldwide, automotive OEMs are simultaneously coming under growing pressure to reduce their energy consumption. Worldwide pressure to cut carbon emissions and increase sustainability has led the automotive industry to evolve its production processes.

Given that the automotive industry is the most highly automated manufacturing industry, its energy management requirements are also important. Truly effective energy management depends on manufacturers being able to control and utilise this precious resource right across their production facilities. Energy management means managing Power Quality, including reducing Transients, Sag-Swell, Utilising Reactive power effectively and monitoring RCM (Residual Current monitoring) across the whole plant.

Cutting back on the energy consumed relies on detailed process insights that are at the heart of what Industry 4.0 and smart factory concepts are now delivering with tangible benefits.

SOLUTION:Messung, in partnership with Janitza, delivers customised energy management systems as per IEC 61000-4-30, EN 50160 and IEC 61000-2-4 standards to enable power conservation, optimise power consumption and improve quality of power. Using Janitza’s advanced power quality analysers and digital energy meters for energy management, power quality monitoring and residual current monitoring,and by leveraging the power of IoT, Messung ensures connectivity and real-time data analyses for prompt, informed decision making. Using ISO 50001 based supervisory softwares for supervision and monitoring of the entire Energy management systems, uniquely designed Device Home pages with innovative Apps downloaded on the Power quality meters greatly enhances user experience and utilisation.

Messung is also Master Distributor for Wöhner busbar systems, and designs advanced power distribution & control panels using their own PLCs, and Busbar products from Wöhner, international grade HMIs, energy meters and cloud interfaces. All control panel designs made by Messung are as per the latest technologies and as per IEC 61439 standards. Using high-end design software,

Messung is able to provide good quality documentation for easy and accurate maintenance and servicing.

EMS AS PER IEC 61000-4-30, EN 50160, IEC 61000-2-4

ENVIRONMENT/CLIMATE CONTROL

REQUIREMENT: Similar to warehouses and distribution centres, manufacturing facilities are high-bay buildings and require heating and ventilation systems as well as tempered cooling at times. Different parts of the automotive plant have different HVAC requirements and thus need a different mix of products to achieve the desired indoor air quality and thermal comfort levels.

HVAC systems consume a large amount of Energy and when used in areas of manufacturing where a lot of heat is generated, very careful algorithms need to be implemented to see that the usage of Energy is at its most efficient.

SOLUTION: Messung's HVAC solutions are designed and customised to meet all system requirements and provide optimal energy- and cost-efficiency.

Messung building management systems (BMS) can monitor the HVAC of manufacturing plants, assembly units and warehouses to ensure proper temperature and airflow, plus control of humidity and gas concentrations where management of these parameters is required.

Messung's innovative integrated building management systems enable you to connect and integrate HVAC and other different systems on a single, unified platform so you gain maximum functionality and operational efficiency while reducing costs and providing a safer, more comfortable indoor environment for your employees.

For factories and offices, Messung also provides a complete solution for “Lighting Management System” (LMS) based on advanced technology, service and support – to control lighting systems and their energy usage in a cost-efficient way.

The product range consists of a web-based, reliable software platform with redundancy option, shading control systems, visualisations, energy reporting systems and hardware components like occupancy sensors, photocell sensors, centralised and distributed routers, fixture-integrated sensors. All products are based on open standards like KNX, DALI, BACnet, Modbus, SNMP, TCP/IP, etc., and support the latest IoT technologies like MQTT and OPC UA.

IoT-enabled HVAC, BMS & LMS

WATER & WASTEWATER TREATMENT

REQUIREMENT: Automotive manufacturing facilities use a large amount of water in various manufacturing processes e.g. for surface treatment, coating, engine block cleaning, rinsing, paint spray booths, hosing, coolants used in machines, all producing large amounts of wastewater.This results in oily waste water with hydrocarbons and metal content.

From large plants to smaller mechanical workshops, all have to follow stringent trade waste regulations and therefore wastewater treatment plants are compulsory.

SOLUTION: Messung’s extensive knowledge and innovative technologies combine to deliver automated water purification systems and process controllers that reduce cost and down time while maximizing productivity. They build sustainability and expandability into their integrated automation solutions for plant engineering and plant lifecycle management while ensuring you meet regulatory compliance with efficiency.

The advanced technology embedded in Messung products provides extremely accurate data collection, secure communication and integrated control to make operations more agile and productive.

WORKPLACE ERGONOMICS

REQUIREMENT: Even though the automotive industry is highly automated, manpower is still an important asset, working closely with machines for better productivity. Industry needs to provide ergonomic working conditions for its people. In areas where electronics testing or R&D is done, ESD-safe furniture is essential for Health andSafetycompliances.

SOLUTION: For R&D labs, testing labs, calibration stations, manufacturing departments, assembly stations and training centres spread across the automotive industry, Messung offers an innovative range of ESD and general furniture that is designed to improve efficiency, safety and comfort.

Messung manufactures a world-class range of ESD chairs & stools, ESD workstations, ESD racks, etc. as per IEC 6134-5-1 and ANSI ESD S20.20.2014. Messung’s industrial work tables, lab tables with drawers and other workplace solutions enable users to optimise their work environment for enhanced productivity.

Messung's range of ergonomic workstation chairs and stools, andlaboratory chairs are proven in tough industrial conditions, and trusted for enhancing comfort, boosting productivity.

ESD TABLES & CHAIRS AS PER IEC 6134-5-1

CONCLUSION

Contact Messung Group for any requirements in your automobile manufacturing or automotive ancillary industry. Messung is a leading Top 10 PLC manufacturer in India with decades of experience in the automotive sector, so you can expect efficient and cost-effective solutions – to enhance productivity and help you achieve global quality and sustainability standards.

0 notes

Photo

Illustration Photo: Shore-side LNG storage tanks (credits: JAXPORT / Flickr Creative Commons Attribution-NonCommercial 2.0 Generic (CC BY-NC 2.0))

Energy Open Innovation Challenge - Robotics

Robotics

7. How can we check for corrosion of the storage tank plate without having to take the tank out of service? BACKGROUND/CONTEXT The integrity of a hydrocarbon storage tank is of utmost importance as the stored substances can be highly volatile. Therefore, it is critical for companies to regularly inspect the tanks to check for any signs of corrosion. Current solutions require the tanks to be taken off the running process plant for prolonged periods of time before using equipment to scan the bottom plate of the tank. If the plate is thinner than the specified standard, that would mean corrosion has occurred and replacement/repairs need to be done. However, this is a very time-intensively and cost-ineffective procedure.

REQUIREMENTS We are looking for a robotic/mechanical solution that can achieve the following:

Measure the thickness of the storage tank’s bottom plate or identify corrosion on the bottom place while the tank is in operation Able to fully maneuver in a tank with >300mm of sludge DESIRED SOLUTION A robot/machine that can reliably check for corrosion in the hydrocarbon storage tank while the tank is in operation.

8. How can we remove highly fused agglomerated catalyst in an inert and confined environment? BACKGROUND/CONTEXT Catalyst used in hydro-finer reactors build up over time. As part of the "cleaning" process, the reactors will have to be taken out of service, before they are filled with inert gases to ensure the safety of the worker entering the confined space. Then, the worker will manually break apart the fused catalyst particles using jackhammers, before manually removing the loosened waste. The entire process is extremely time-consuming and cost-ineffective as revenue is forgone when the equipment is taken out of service. Potential solutions - e.g., high pressure water jetting and carbodumping, have proven ineffective as they did not decrease the time needed to carry out the removal of the agglomerated catalyst.

REQUIREMENTS We seek a solution (ideally robotic/mechanical) that can accomplish the following:

Reduce human exposure in the agglomerated catalyst removal process Able to exert enough force to loosen the agglomerated catalyst for removal Can achieve the above as or more efficiently than human workers DESIRED SOLUTION A robot that can efficiently remove agglomerated catalysts in inert, confined environments with little to no human involvement.

9. How to create a fast and seamless re-fueling experience at petrol stations? BACKGROUND/CONTEXT When it comes to refuelling for customers' vehicles at petrol stations, there is huge potential to rely on robotics to boost operation efficiency and safety levels, while enhancing the levels of service. By developing an automated robotic refueling system, customers can enjoy a safe, swift and convenient refueling experience at the stations. Also, an automated refueling system can offer safe, reliable and consistent services to customers by reducing human intervention and accurately calibrated refueling.

REQUIREMENTS We are looking for an automated solution to refueling that can substantially enhance the refueling experiences at petrol stations and efficiency for users while also decreasing on-site costs. Speed, safety and convenience are key.

The robot shall be able to conduct simple engagement with customer such as identifying loyalty customer, communicating promotion events, collecting customer feedback etc.

DESIRED SOLUTION An automated refueling technology that is easy to implement and has the flexibility to enable future growth and development at operating stations.

10. How to inspect tanks while keeping them operational? BACKGROUND/CONTEXT As the materials stored in tanks are often volatile substance, a leak or any corrosive damage on the tank can have serious consequences. Careful inspections are needed to ensure the tank’s integrity. However, this currently requires the tank to be taken out of service which results in an inefficient use of company resources. Additional tank units would be required to fill the void of those being inspected. Therefore, there is a need for a technology that can meticulously inspect running live tanks remotely or autonomously. The inspections must, at the very least, include Ultrasonic Testing (UT) and Magnetic Flux Leakage (MFL).

REQUIREMENTS The proposed solution should be able to sufficiently inspect running live hydrocarbon tanks without needing to take the tanks out of service. The solutions chosen to progress to the final rounds will be put under the following tests: > Inspect a running live water tank at ambient temperatures > If Successful, inspect live hydrocarbon tanks without taking tanks out of service

DESIRED SOLUTION A technology that is able to non-disruptively inspect running live tanks.

11. How to remotely / autonomously paint confined spaces? BACKGROUND/CONTEXT It is critical that storage tanks maintain their integrity over the course of their use. As the stored materials are often volatile substances, a leak or any corrosive damage to the tank can have serious consequences. Coating the tanks with protective paint to prevent corrosion may seem like a simple task, but it presents unique challenges.

- Firstly, there is a real possibility of toxic fumes gathering at the bottom of the tank. These toxic vapors can be harmful or even fatal to the painting crew that enters the confined space.

- Furthermore, the coating material itself may emanate toxic fumes during the painting process which can quickly accumulate within the tank.

- Lastly, as some tanks are quite large, there must be fall protection systems in place to prevent accidents.

While there are solutions currently in place to address these issues, they significantly increase the amount of time it takes to complete the job hence increasing the amount of time the tanks are not in use. These challenges would no longer be a factor if there was a way to remotely or autonomously paint the confined spaces without the need of human entry into the tank.

REQUIREMENTS The proposed solution should address the following: > Be able to remotely/autonomously paint the confined tank spaces (all directions) > Does not require human entry in the tank > Just as or more efficient (less time spent) as using a human crew

DESIRED SOLUTION A technology that is able to remotely/autonomously paint confined spaces without human entry.

12. How to remove hydrocarbon sludge from tanks and pipes without having to take the system out of service at all or for extended periods of time? BACKGROUND/CONTEXT Fuel storage tanks accumulate large amounts of hydrocarbon sludge, sediments, and scales that can reduce the working capacity of the tanks by taking up valuable storage space and clogging pipes. Current methods to remove hydrocarbon sludge require taking the entire system out of service and can potentially expose workers to hazardous substances. This results in a huge loss in potential revenue and increases the risk of accidents. While mechanized methods utilizing big pumps with cleaning nozzles, and tank cleaning robots have been proposed, none of these solutions are capable of cleaning the pipes and tanks without having to take the system out of service at all or for extended periods of time.

REQUIREMENTS We seek a solution that can achieve the following:

Robotically or mechanically removes hydrocarbon sludge from tanks and pipes Achieves the above without taking the system (tank/pipes) out of service Eliminates direct human exposure to the hazardous substances DESIRED SOLUTION A robotic or mechanical solution that can remove hydrocarbon sludge from tanks and pipes while they are in operation.

Application Deadline: 6 Nov 2020, 12:00 PM GMT+8

Check more https://adalidda.com/posts/JS5HMAHuLABySz2Fj/energy-open-innovation-challenge-robotics

0 notes

Photo

Remediation As a Catalyst

Following the shifting industrial technology, Industrial estates have undergone a patchy recovery. Even with the decontamination methods, experts question the long-term resilience of Amata Nakorn which has been contaminated with nature. Tackling the issue of pollutants, the scheme is a speculative master plan that challenges the current approaches towards toxicity prevention and landscape in Chonburi, by using bio-remediation as a catalyst.

The proposal aims to facilitate the regeneration of Industrial estate and the adjacent community areas. By tapping on the industrial land’s potential economic, societal and ecological benefits. The scheme both attracts, mobilizes and retains a demographic that matures with restoration efforts.

After a decade, the scheme stretches outwards, blurring the threshold that once delineated human and nature.

The project is divided in five chapters of detecting clues and solutions

Chapter 01 : Evidences and Traces.

Industrial Ecology is an integrated system where attempts to induce balance and cooperation between industrial processes and environmental sustainability, such that neither violates the other.

In Chonburi province where many industrial estates or IE are growing too fast and too many. The whole system is unbalanced.

Amata Nakorn is one of the biggest IE in Chonburi. It is an estate which includes many types of heavy industry such as automotive, electronics and so on.

Industrial ecology would involve the optimization of the whole material life cycle from the raw material extraction to the final product including components and the wastes that result from each stage of the material production and process.

Water and other raw materials such as metals and plastics are converted in the manufacturing process and resulted in finished products and waste.Then It is treated in certain types of treatment. Some wastes cannot be treated, so it leads to global and environmental impacts.

Chapter 02 : Suspected

Who is the suspect? , this question is raised in this process.

The answer comes to Amata Nakorn where pollutants are produced which affect in different dimensions such as economy, ecological environment and humans.

Chapter 03 : Investigation

As a result of the rapid industrialization in Chonburi, urbanization started to be developed. More people start coming to Chonburi to work and live. Population growth is rising up. The more people, the more problems it causes. People start to exploit the land and transform it into different kinds of uses. Natural resources are extracted

Regarding the changes in population rate over decades, from the agricultural landscape with low population to the rapid growth of population in the industrialization stages of Chonburi, to constant rates nowadays, future trends regarding our population tend to still rise up, but the roles of humans are changing.

Shifting from heavy industry in 2020 to biotech and automotion in the next 30 years, jobs and lifestyles are going to be different as well as the industrial landscapes. Some will be abandoned because of the unused factories. It will be left as “Scars”, both environmental and social impacts. The advanced technology starts to evolve. The abandoned industrial landscapes are resilient

Post industrial landscapes are often associated with extremes of disturbance and fluctuations in a wide range of environmental factors such as soil structure and nutrient, drainage and contamination. The sites are derived from ongoing processes such as metal forming and chemical processes. Bare substrates will continue to be exposed and natural weathering and re-vegetation will produce a variety of wildlife habitats. The particular industrial process could be creating unique and non-recreatable biological communities.

To accelerate the process of changing landscape, / boost metabolism ,Bio interventions are invented to accelerate the transforming landscape process and decontaminating the land.

Bioremediation is widely used to clean up the land pollutants. Microorganisms are combined with technology to introduce an organization providing microrobotics for industrial factories to rent. Different types of robots are presented.

Chapter 04 : Bio-SYSTEM

In the Biggest picture of Chonburi Region, By using the bioremediation bacteria, the bacterias community can grow like a city system-like to form their own systems. Three Different types of Bacterias are used to refer contaminants differently. Ones are heavy metals, hydrocarbons and the other is organic compounds.

Three Strategies of Remediation are introduced.

1. Creating Biotopes

Phytoremediation as ecological energy network providing habitat for plants and animals, also toxic removal

2. The use of By product of energy extraction

Dismantling and separation of unused vacant building (automotives and some of others)

Dismantle > Separate> reuse/storage

3. Recycling and Repurposing the existing building

Repurposing the existing into new development of biotechnology facilities where it requires less space

Building and Growing on the existing infrastructure

All three strategies combine into one whole piece of new Amata Nakorn, where the green belt of phytoremediation field is placed across the entire land in order to connect 2 adjacent natural resources on the side.

Zooming in to the existing warehouses of Amata Nakorn, Phytoremediation is now used to remediate and clean up in order to be able to reuse it as another as purposes.

Industrial Transformation

New activities and functions are introduced.

- Experiment storage

- Bacteria / fungi laboratory

- Plants specimen room

Reverse material flow

How the material flow is reversed. Like changing the way materials move through the site; from a place of raw resource consumption, with waste as an end product, to a place where waste is the raw resource that is consumed and the support and production of natural systems and biotech facilities is the product.

Chapter 05: Archives of Toxins

In this chapter, toxins and pollutants are archives and stored in order to be examined how each one affect humans’ body.

For full resolution Atlas can be founded here in this link

https://issuu.com/siwakarnsabpaisarn6781/docs/atlas-new-minimized

0 notes

Text

Revolutionising Oil and Gas Maintenance with Robotic Tank Cleaning

The Challenges of Traditional Crude Oil Tank Cleaning

Crude oil tanks accumulate sludge and residue over time, which reduces storage capacity and affects operational efficiency. Regular maintenance is crucial to prevent contamination and ensure compliance with industry regulations. However, traditional crude oil tank cleaning procedures come with several challenges:

Health and Safety Risks — Manual cleaning exposes workers to harmful chemicals, toxic fumes, and dangerous sludge.

Extended Downtime — Conventional methods require tanks to be emptied and ventilated, leading to operational delays.

High Costs — Labour-intensive cleaning results in higher costs for workforce management, waste disposal, and safety compliance.

Environmental Impact — Improper sludge handling can lead to pollution and regulatory fines.

To address these challenges, the industry is increasingly adopting robotic tank cleaning equipment, which minimises human exposure, reduces downtime, and ensures better efficiency.

How Robotic Tank Cleaning Works

Arham Oil offers state-of-the-art robotic tank cleaning in the oil and gas industry, designed to handle the toughest sludge removal tasks. These robotic systems are remotely operated, eliminating the need for human entry into confined spaces. The process typically includes:

Automated Inspection — Robots equipped with high-resolution cameras and sensors assess the tank’s interior condition, identifying sludge build-up and corrosion.

High-Pressure Cleaning — Using powerful water jets and rotating nozzles, robots break down sludge and deposits from tank walls and floors.

Sludge Extraction — Specialised suction systems remove the loosened sludge, ensuring efficient and complete cleaning.

Hydrocarbon Recovery — Valuable hydrocarbons trapped in the sludge are recovered, maximising resource efficiency and reducing waste.

Benefits of Robotic Tank Cleaning

Switching to robotic crude oil tank cleaning offers numerous advantages over conventional methods. Some of the key benefits include:

1. Improved Safety

By eliminating the need for human entry into hazardous environments, robotic tank cleaning significantly reduces the risk of accidents, exposure to toxic fumes, and confined space incidents.

2. Reduced Downtime

Robotic systems clean tanks more efficiently, allowing companies to resume operations faster. This translates to increased productivity and minimal disruption to refining and storage activities.

3. Cost-Effective Solution

Although robotic tank cleaning involves advanced technology, it reduces overall costs by lowering labour expenses, minimising waste disposal fees, and optimising operational efficiency.

4. Enhanced Cleaning Precision

Advanced robotic cleaning systems ensure thorough sludge removal, preventing residue build-up and prolonging tank lifespan. Their ability to operate in challenging conditions makes them ideal for crude oil tank cleaning equipment applications.

5. Environmentally Friendly

By recovering valuable hydrocarbons and reducing sludge waste, robotic cleaning methods promote sustainability and help companies comply with environmental regulations.

Why Choose Arham Oil’s Robotic Tank Cleaning Services?

Arham Oil is a leader in providing cutting-edge robotic tank cleaning in the oil and gas industry. Their expertise and innovative technology help businesses maintain optimal efficiency while ensuring safety and regulatory compliance. Key reasons to choose Arham Oil include:

Proven Expertise — Years of experience in crude oil tank maintenance and sludge removal.

Advanced Technology — High-performance robotic cleaning systems for superior results.

End-to-End Solutions — From inspection to sludge disposal, Arham Oil offers comprehensive services.

Commitment to Safety & Environment — Ensuring safe operations while promoting sustainable practices.

Get in Touch

If you are looking for reliable robotic crude oil tank cleaning equipment to optimise your maintenance operations, Arham Oil is your go-to solution. Learn more about their advanced robotic tank cleaning services. For inquiries, visit their contact us and get expert assistance today!

By adopting robotic tank cleaning, companies can achieve safer, cleaner, and more cost-effective operations. Upgrade your maintenance process with Arham Oil and experience the future of oil and gas industry cleaning solutions.

#robotic tank cleaning#arham oil#crude oil storage tank cleaning services#mechanized tank cleaning#online mechanical desludging#crude oil tank cleaning

0 notes

Text

How Robotic Tank Cleaning Works

In the oil and gas industry, maintaining storage tanks is a critical aspect of operations. Crude oil tanks accumulate sludge, hydrocarbons, and sediments over time, which can reduce storage capacity and affect operational efficiency. Traditionally, tank cleaning was performed manually, exposing workers to hazardous conditions. However, advancements in automation have introduced robotic tank cleaning, revolutionising the process by improving safety, efficiency, and environmental compliance.

The Process of Robotic Tank Cleaning

Robotic tank cleaning involves deploying remotely controlled robots equipped with advanced sensors and cleaning mechanisms inside crude oil tanks. These robotic systems follow a well-defined procedure to ensure effective sludge removal without human entry.

1. Initial Inspection and Setup

Before starting the cleaning process, a thorough inspection of the tank is conducted. Robotic cleaning companies use advanced inspection tools such as ultrasonic sensors and cameras to assess sludge accumulation, internal conditions, and possible obstructions.

The robotic system is then introduced into the tank through a designated entry point. Operators control the robot remotely using a specialised control unit, ensuring precision and safety.

2. Sludge Loosening and Mobilisation

Once inside, the robot utilises high-pressure water jets and chemical agents (if required) to loosen and break down hardened sludge deposits. The robotic arm, equipped with rotating nozzles, ensures thorough sludge mobilisation across the tank’s interior.

Some robotic tank cleaning systems are designed with suction units that continuously extract loosened sludge, preventing re-deposition and reducing cleaning time.

3. Sludge Extraction and Separation

The mobilised sludge is removed from the tank using vacuum pumps or integrated suction units. This extracted material is then processed using crude oil tank cleaning equipment, such as centrifuges or decanters, to separate recoverable hydrocarbons from waste sludge. This step not only maximises oil recovery but also minimises environmental impact.

4. Final Cleaning and Inspection

After sludge removal, the robot performs a final wash using high-pressure water jets to ensure no residues remain. Advanced robotic systems also feature onboard cameras and sensors that help operators verify the cleanliness of the tank.

A post-cleaning inspection is conducted to confirm compliance with industry standards, ensuring the tank is ready for use without any operational risks.

Advantages of Robotic Tank Cleaning

Enhanced Safety — The biggest advantage of robotic tank cleaning is the elimination of human entry into confined spaces filled with toxic gases and hazardous sludge.

Improved Efficiency — Robots clean tanks faster than manual methods, reducing downtime and improving operational efficiency.

Better Oil Recovery — The process effectively separates recoverable crude oil from sludge, increasing overall resource utilisation.

Eco-Friendly Approach — Robotic cleaning reduces waste generation and ensures compliance with environmental regulations.

Cost-Effective — Though initial investment in robotic cleaning may be high, it significantly reduces long-term maintenance and labour costs.

Conclusion

Robotic tank cleaning is transforming the crude oil tank cleaning procedure by making it safer, more efficient, and environmentally sustainable. As the oil and gas industry continues to embrace automation, robotic cleaning technology is becoming the preferred choice for crude oil tank cleaning worldwide.

For advanced robotic tank cleaning solutions, visit Arham Oil. For inquiries, contact us at +917486042707 or +917486042709.

Read More:

Magnetic Robotic Crawler for Tank Cleaning | Arham Oil

Oil Recovery from Tank Sludge | Arham Oil

#robotic tank cleaning#arham oil#oily sludge tank cleaning#mechanized tank cleaning#crude oil tank cleaning

0 notes

Text

Leading the Way in Oil Sludge Recovery: Arham Oil's Modern Techniques

In the world of oil and gas, oil sludge recovery is a crucial process. It involves processing residual waste from the storage, transportation, and refining of crude oil to recover valuable hydrocarbons. Arham Oil provides cutting-edge solutions that not only recover oil but also ensure environmental protection.

Why Sludge Oil Recovery Is Useful

Oil sludge, composed of hydrocarbons, water, and solid particles, is considered hazardous waste. Effective recovery from sludge oil is guided by several reasons:

Environmental Protection: Proper handling prevents contamination of soil and water, protecting ecosystems and human health.

Resource Optimization: Recovering hydrocarbons from sludge reduces spillages and optimizes resource use.

Economic Benefits: Recovered oil can be reprocessed for sale, providing a significant financial return.

Advanced Techniques by Arham Oil

Robotic Tank Cleaning

Traditional manual tank cleaning methods are labor-intensive, time-consuming, and risky. Arham Oil introduces robotic tank cleaning technology to replace these conventional methods. Our robotic systems clean tanks efficiently and safely, ensuring minimal downtime and maximum sludge removal. Advanced sensors enable the cleaning mechanisms to adjust to varying conditions in the tank, ensuring a thorough cleaning job.

Mechanized Tank Cleaning

Our mechanized tank cleaning services utilize state-of-the-art equipment to clean large storage tanks effectively and rapidly. This method reduces manual intervention, enhancing safety and efficiency. Even the most difficult sludge deposits are effectively removed, resulting in clean tanks ready for use or further maintenance.

Lagoon Cleaning

Industrial lagoons often accumulate significant amounts of sludge, which can pose environmental hazards if not properly managed. Arham Oil's lagoon cleaning services employ advanced techniques to de-sludge and clean these large water bodies. Our approach ensures minimal disruption to the surrounding environment while maximizing sludge recovery.

Extensive Oil Recovery Services

Arham Oil offers comprehensive oil recovery services, covering every aspect of sludge treatment and reclamation. Our expertise extends to:

Sludge Oil Recovery: State-of-the-art technology in separating hydrocarbons from the sludge to recover valuable oil and reduce waste.

Environmental Compliance: Our processes adhere to stringent environmental regulations, ensuring safe and eco-friendly operations.

Custom Solutions: We tailor our services to meet the specific needs of our clients, providing customized solutions for diverse sludge recovery challenges.

The Future of Oil Sludge Recovery

As the demand for sustainable and efficient oil recovery methods grows, Arham Oil remains committed to innovation and excellence. Our dedication to research and development ensures that we stay ahead of industry trends, continuously improving our techniques and expanding our service offerings.

By choosing Arham Oil, clients benefit from advanced sludge recovery solutions, contributing to a cleaner and more sustainable environment. Our comprehensive approach ensures that valuable resources are reclaimed, waste is minimized, and the impact on our planet is reduced.

Learn more about our innovative solutions for the recovery of sludge oil. View our services for robot tank cleaning and mechanized tank cleaning to see how we can meet your oil recovery needs effectively.

0 notes

Text

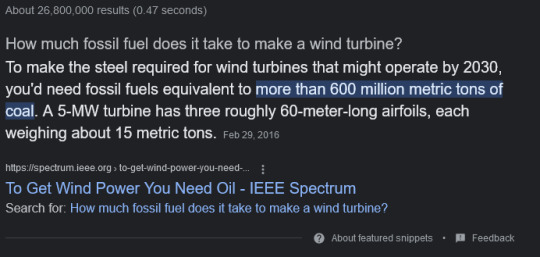

I'm not going to argue with a bird enthusiast about their compassion for birds. I believe them. I am grateful they exist. What I will argue against is these massive energy construction projects. Just like the craze for building hydroelectric dams, this newest iteration has proven to be the same story as that was. Dams have proven to be harmful to the water table, the river ecologies, local communities, floodplains, and even geology in terms of seismic effects and deformation of bedrock. They've nearly all built up silt to the point of costing more than they are worth without reasonable down-time to clean out planned because they demand being brought back online to the powergrid so quickly. And that silt builds up quickly! Massive construction projects tend to displace responsibility, abdicate it. They don't make people aware of the reality of modern infrastructure or the dynamics of their lifestyle in the role of culture. It brushes the problems under the rug, out of sight, out of mind, no personal changes or accountability needed. "There's an app for that!" mentality. Below are some points that basically make themselves. Just like the deluded mass-industry mentality behind the logistics of massive lithium-ion powerbanks for houses, or for cars, or for the electrical grid itself-- the use of iron for these wind turbines and mass energy projects is distorted and wasteful-- unsustainable. The amount of lithium used for an EV car battery could equal hundreds of electronic devices such as medical or even mere personal use devices like cellphones and laptops. Instead, the model of planned/engineered obsolescence that is perpetuated by capitalist consumerism not only makes those electronics wasteful in design, but also in resource logistics-- so nobody would ever even see how they deserve to be the way that the lithium is allocated to begin with instead. With the amount of iron and fossil fuels expended in constructing these wind turbines, a whole global system of nickel-iron (ferro-nickel) batteries could be built that would last hundreds of years. People have no cognitive intuition to what these metals and energy can do in the forms they can take. Instead? ...

The paragraph from the book in full reads: “The concept of net energy must also be applied to renewable sources of energy, such as windmills and photovoltaics. A two-megawatt windmill contains 260 tonnes of steel requiring 170 tonnes of coking coal and 300 tonnes of iron ore, all mined, transported and produced by hydrocarbons. The question is: how long must a windmill generate energy before it creates more energy than it took to build it? At a good wind site, the energy payback day could be in three years or less; in a poor location, energy payback may be never. That is, a windmill could spin until it falls apart and never generate as much energy as was invested in building it.” Hughes told Reuters that his comments had been taken out of context and that the passage relates to capacity factory, which is the “amount of electricity a wind mill actually generates compared to the amount it would generate if it was running at 100% of its rated Generating Capacity”.

Where are ideal locations for energy to be harvested with these massive projects and how are they built? Are they always the most patient in doing things ethically, or do you think they seek a bottom-line of money?

youtube

youtube

as a huge lover of birds, 90% of the concern against wind turbines being used for energy is literally just pro fossil fuel propaganda. birds ARE at a risk however there is a lot of strategies even as simple as painting one of the blades that reduces a lot of accidental deaths. additionally renewable energy sources will do more in favor of the environment that would positively impact birds (and all of us). one study found over one million bird deaths from wind turbines. while that is a shockingly high number and we should work to drastically shrink it, at least 1.3 billion birds die to outdoor cats on a yearly basis. it was never about caring about birds

#energy#renewable energy#peak oil#capitalism#ecology#environmentalism#conservation#environment#wildlife conservation#Youtube

103K notes

·

View notes